Page 1

TL/H/12372

LM9040 Dual Lambda Sensor Interface Amplifier

August 1995

LM9040

Dual Lambda Sensor Interface Amplifier

General Description

The LM9040 is a dual sensor interface circuit consisting of

two independent sampled input differential amplifiers designed for use with conventional Lambda Oxygen Sensors.

The Lambda Sensor is used for monitoring the oxygen concentration in the exhaust of gasoline engines using catalytic

after treatment and will deliver a voltage signal which is dependent on the air-fuel mixture. The gain of the amplifiers

are internally set and can directly convert the Lambda sensor output voltage to a level suitable for A/D conversion in a

system using a 5V reference.

The input common mode voltage range of each amplifier is

g

2V with respect to the IC ground pin. This will allow the IC

to connect to sensors which are remotely grounded at the

engine exhaust manifold or exhaust pipe.

Each amplifier is capable of independent default operation

should either, or both, of the leads to a sensor become

open circuited.

Noise filtering is provided by an internal switched capacitor

low pass filter as part of each amplifier, and by external

components.

The LM9040 is fully specified over the automotive temperature range of

b

40§Ctoa125§C and is provided in a 14-pin

Small Outline surface mount package.

Features

Y

Single 5V supply operation

Y

Common mode input voltage range ofg2V

Y

Differential input voltage range of 50 mV to 950 mV

Y

Sampled differential input

Y

Switched capacitor low pass filter

Y

Internal oscillator and VBBgenerator

Y

Open input default operation

Y

Cold sensor default operation

Y

Low power consumption (42 mW max)

Y

Gain set by design and guaranteed over the operating

temperature range

Applications

Y

Closed loop emissions control

Y

Catalytic converter monitoring

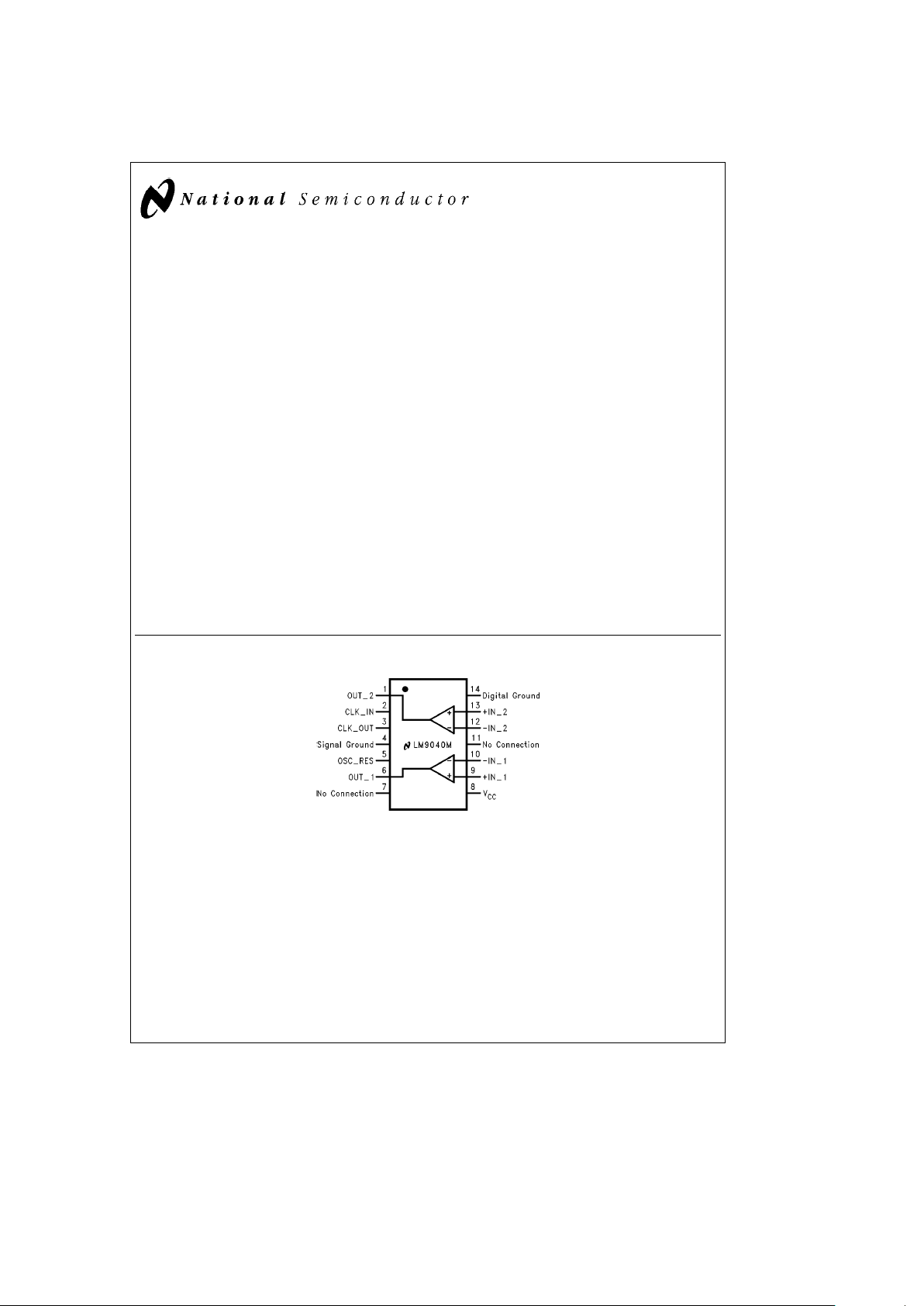

Connection Diagram

TL/H/12372– 1

Top View

Ordering Information

LM9040M

See NS Package Number M14B

C

1995 National Semiconductor Corporation RRD-B30M115/Printed in U. S. A.

Page 2

Absolute Maximum Ratings

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales

Office/Distributors for availability and specifications.

Supply Voltage

b

0.3V toa6.0V

Input Voltage Continuous (Note 1)

g

14V

Input Voltage Transient t

s

1 ms (Note 1)

g

60V

ESD Susceptibility (Note 2)

g

2000V

Maximum Junction Temperature 150§C

Storage Temperature Range

b

65§Ctoa150§C

Lead Soldering Information

Vapor Phase (60 Seconds) 215

§

C

Infrared (15 Seconds) 220

§

C

Operating Ratings

Supply Voltage 4.75V to 5.25V

Differential Input Voltage 0V toa1V

Common Mode Voltage

g

2V

Power Dissipation 42 mW

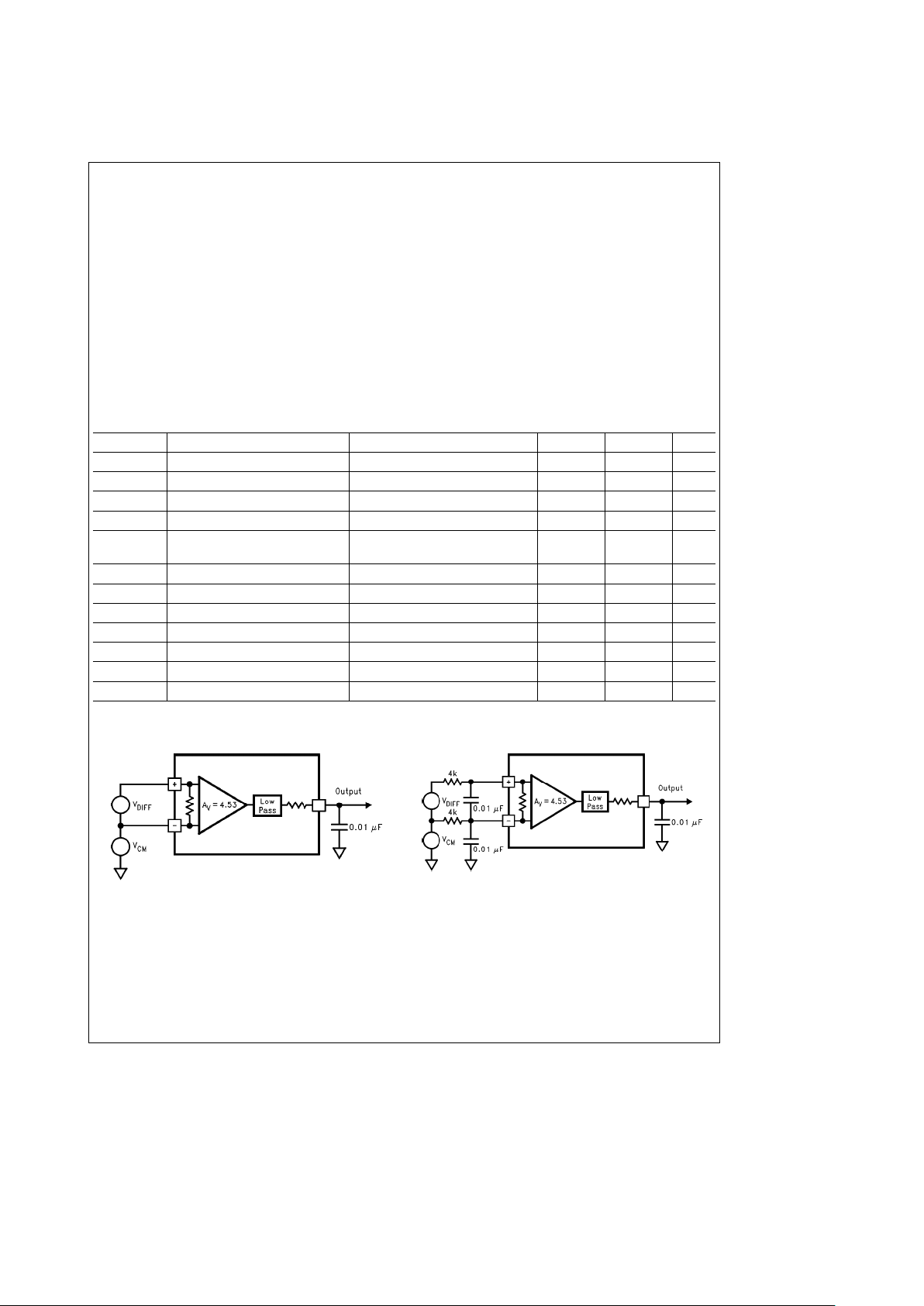

DC Electrical Characteristics

The following specifications apply for V

CC

e

5.0V, V

DIFF

e

500 mV, V

CM

e

0V, R

OSC

e

178 kX,b40§CsT

A

s

a

125§C, DC

Test Circuit

Figure 1

, unless otherwise specified.

Symbol Parameter Conditions Min Max Units

I

CC

Supply Current 4.75VsV

CC

s

5.25V 8.0 mA

Z

DIFF

Differential Input Impedance 4.75VsV

CC

s

5.25V 1.05 1.60 Meg X

Z

IO

Inverting Input to Ground Impedance Non-Inverting Inputs Open 10.00 Meg X

V

OL

Output Low Voltage V

DIFF

e

0V, I

LOAD

e

2.0 mA 100 mV

V

OC

V

OUT

Center One, or Both, Input(s) Open V

CC

#

0.380 V

CC

#

0.425 V

4.75V

s

V

CC

s

5.25V

V

OUT(ERROR)(VOUT

)–(V

DIFF

#

4.53) 50 mVsV

DIFF

s

950 mV, V

CM

e

0V

g

65 mV

V

OH

Output High Voltage V

DIFF

e

5V, I

LOAD

eb

2mAV

CC

b

0.1V V

R

OUT

Output Resistance 1500 3500 X

CMRR

(DC)

DC Common Mode Error

b

2VsV

CM

s

a

2V

g

4.5 mV/V

T

RISE

Output Rise Time C

OUT

e

0.01 mF 1.2 ms

T

FALL

Output Fall Time C

OUT

e

0.01 mF 1.2 ms

F

C

Low Pass Filterb3dB C

OUT

e

0.01 mF 400 700 Hz

Note 1: The input voltage must be applied through external 4 kX input resistors. See

Figure 2

, AC Test Circuit. Amplifier operation will be disrupted, but will not be

destructive.

Note 2: ESD rating is with Human Body Model: 100 pF discharged through a 1500X resistor.

TL/H/12372– 2

FIGURE 1. DC Test Circuit

TL/H/12372– 3

FIGURE 2. AC Test Circuit

2

Page 3

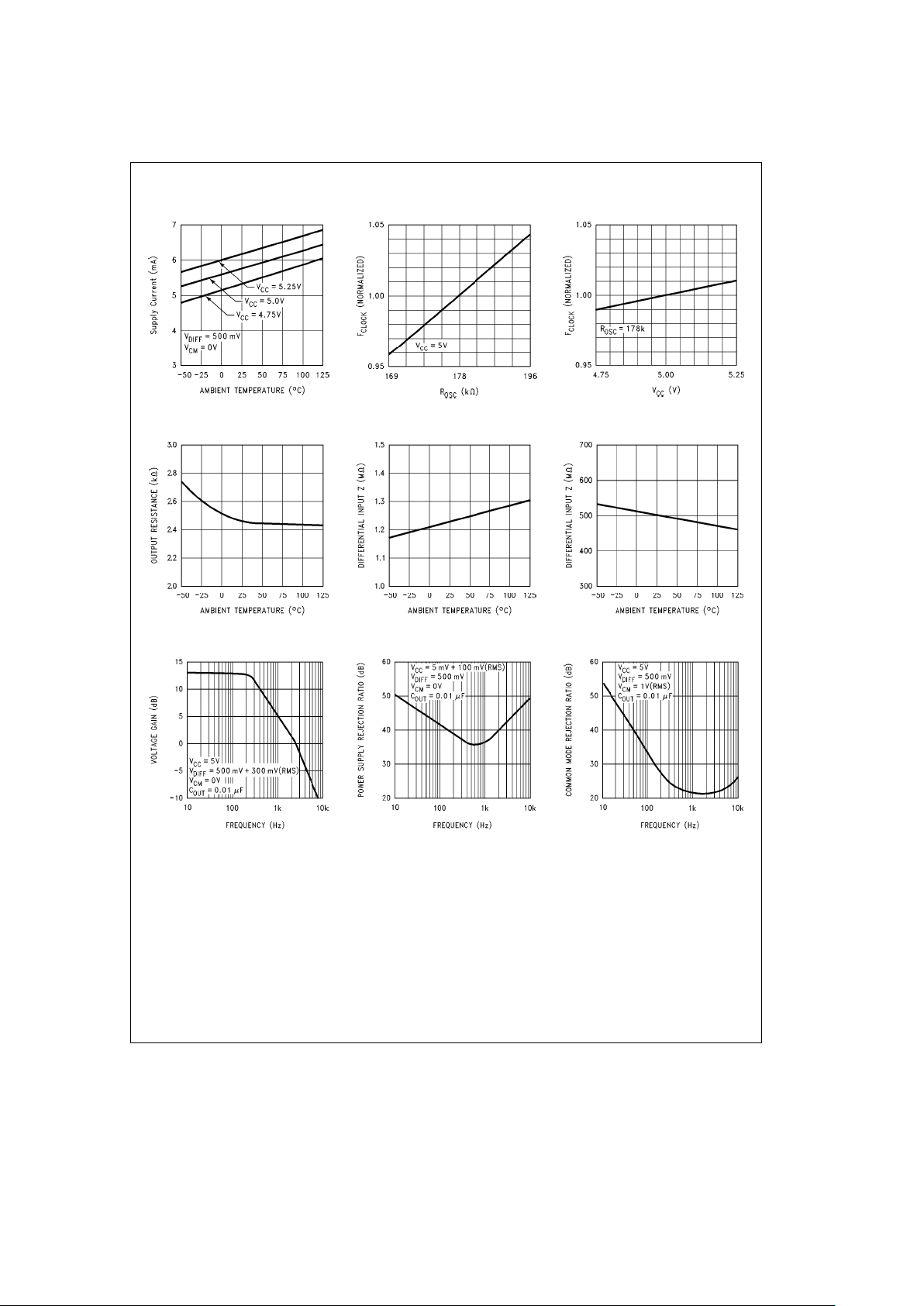

Typical Performance Characteristics

Supply Current vs Temperature

TL/H/12372– 4

F

CLOCK

(Normalized) vs R

OSC

TL/H/12372– 5

F

CLOCK

(Normalized) vs V

CC

TL/H/12372– 6

Output R vs Temperature

TL/H/12372– 7

Z

DIFF

vs Temperature

TL/H/12372– 8

FCvs Temperature

TL/H/12372– 9

Voltage Gain vs Frequency

TL/H/12372– 10

PSRR vs Frequency

TL/H/12372– 11

CMRR vs Frequency

TL/H/12372– 12

3

Page 4

Circuit Description

The LM9040 is fabricated in CMOS technology and is designed to operate from a single, well regulated, 5V supply.

The IC consists of two independent differential amplifiers

which are designed using two-phased switched capacitor

networks (SCN). The differential inputs have a common

mode operating range of 2V above and below ground. The

SCN includes the input sampling, the lowpass filter, cold

sensor bias voltage, and the gain circuitry. Each amplifier

has an independent voltage comparator to detect an open

inverting input pin. Additional support circuitry includes the

oscillator, clock generator, and V

BB

bias generator.

TL/H/12372– 13

FIGURE 3. Simplified Circuit

Oscillator

The device contains an internal oscillator which is used to

drive the internal two-phase clock generator. The oscillator

requires an external resistor value of 178 kX from the

‘‘OSCÐRES’’ pin to device V

CC

. This resistor value determines the charge rate of the internal capacitor, and thus

sets the oscillator frequency. The internal oscillator capacitor is matched to the switched capacitor networks, so that

the absolute capacitance values are not as important as is

the absolute ratios of the capacitors. The oscillator frequency is approximately 200 kHz.

The oscillator resistor should be located as close to the

OSCÐRES pin as possible. Any variation of the oscillator

resistor value, any stray capacitance on the OSCÐRES pin,

or any changes in the supply voltage, will result in a change

in the oscillator frequency. This will directly affect the device

Differential Input Impedance, and Low Pass filter response.

Additional circuitry takes the oscillator signal and generates

two non-overlapping clock signals, and a CLKÐOUT signal.

The clock signals operate at one half the oscillator frequency, or typically 100 kHz. This results in a Nyquist frequency

of typically 50 kHz.

Clock Out/Clock In

For the input stage to work with common mode voltages

below Ground potential, a negative bias voltage (V

BB

)is

needed. The CLKÐOUT pin is used to provide the AC signal needed to drive the internal V

BB

bias generator through

an external coupling capacitor. A minimum coupling capacitor value of 100 pF to a maximum value of 0.1 mF is recommended. The CLKÐIN pin is the input to the V

BB

bias gen-

erator circuitry.

Differential Input Circuit

The input stage can be best described as a switched Sample and Difference circuit (see

Figure 4

). When the input

capacitor C

IN

is switched to the non-inverting input, the in-

put voltage plus the common mode voltage is stored on C

IN

.

When C

IN

is switched to the inverting input, CINwill be discharged by an amount equal to the common mode voltage.

The remaining charge across C

IN

will be equal to the differential input voltage, and a proportional charge will be transferred through the virtual ground via the gain stage.

TL/H/12372– 14

FIGURE 4. Simplified Switched Capacitor Input Circuit

4

Page 5

Differential Input Circuit (Continued)

The differential input impedance is a function of the value of

the input capacitor array and the sampling frequency. The

capacitor C

BIAS

is used to generate a bias voltage across

the Differential Input impedance (Z

DIFF

). This bias voltage is

similar to the Lambda Sensor output voltage at the stoichiometric air-fuel mixture (l

e

1). The bias voltage is set by the

ratio of C

IN

and C

BIAS

, and the value of VCC.

The resulting bias voltage across the Differential Input is

defined as:

V

BIAS

e

V

CC

#

C

BIAS

(C

IN

a

C

BIAS

)

With C

BIAS

e

0.7286 pF, C

IN

e

7.421 pF, F

CLOCK

e

100 kHz, and V

CC

e

5V:

V

BIAS

e

5#7.286E-13

(7.4213E-12a7.286E-13)

V

BIAS

e

447 mV

In effect, the result is the same as forcing a bias current

through the Differential Input impedance.

The bias current is defined as:

I

BIAS

e

V

CC

#

C

BIAS

#

F

CLOCK

I

BIAS

e

364.3 nA

The Differential Input impedance is defined as:

Z

DIFF

e

1

(C

IN

a

C

BIAS

)#F

CLOCK

Z

DIFF

e

1.227 MX

This bias voltage will be developed across the Differential

Input impedance (Z

DIFF

) if there is no other path available

from the non-inverting input pin for I

BIAS

, and the inverting

input has a current path to ground. See

Figure 5

. During

normal operating conditions I

BIAS

will have a negligible ef-

fect on accuracy

TL/H/12372– 15

FIGURE 5. Equivalent Input Bias Circuit

Differential Input Filtering

Since each input is sampled independently, an anti-aliasing

filter is required at the amplifier inputs to ensure that the

input signal does not exceed the Nyquist frequency.

This external low-pass filter is implemented by adding a capacitor (C

DIFF

) across the differential input. See

Figure 6

.

This forms an RC network across the differential inputs in

conjunction with the required external 4 kX resistors and

the differential input impedance (Z

DIFF

). The capacitor selected should be small enough to have minimal effect on

gain accuracy in the application, yet large enough to filter

out unwanted noise. Given that the F

C

of the LM9040 is

typically 500 Hz, the use of a 0.01 mF capacitor will generally provide adequate filtering, with less than

b

0.4 dB of input

attenuation at 500 Hz and approximately

b

28 dB at 50 kHz.

A larger value capacitor can be used if needed, but a value

larger than typically 0.02 mF will begin to dominate the cutoff frequency of the application. This capacitor must be a

low leakage and low ESR type so that circuit performance is

not degraded.

TL/H/12372– 16

FIGURE 6. Differential and Common Mode Filtering

Common Mode Filtering

The differential input sampling of the LM9040 actually reduces the effects of common mode input noise at low frequencies. The time interval between the sampling of the

inverting input and the non-inverting input is one half of a

clock period. A change in the common mode voltage during

this short time interval can cause an error in the charge

stored on C

IN

. This will result in an error seen on the output

voltage. For a sine-wave common mode voltage the minimum common mode rejection is:

CMRR

e

2

#q#

F

CMR

#

(0.5/F

CLOCK

)#4.53

Where F

CMR

is the frequency of the common mode signal,

and F

CLOCK

is the clock frequency.

5

Page 6

Common Mode Filtering (Continued)

For a common mode sine wave signal having a frequency

100 Hz, and with a F

CLOCK

of 100 kHz, the minimum com-

mon mode rejection would be:

CMRR

e

2#3.14159#100#5E-6#4.53

CMRRe0.014eb37 dB

If the common mode sine wave has a peak to peak value of

2V, the maximum voltage error at the output would be:

V

OUT(CM)

e

2V#0.014e28 mV

As this formula shows, the value of V

OUT(CM)

is proportional

to the frequency of the CMR signal. If the frequency is doubled, the value of V

OUT(CM)

is also doubled. The addition of

a small bypass capacitor (C

CM

) from the non-inverting input

to ground will help counter this problem. See

Figure 6

. However, the use of this bypass capacitor creates a new problem in that the differential input is no longer balanced. While

the Lambda sensor is cold (i.e. R

SENSOR

l

10 MegX) there

is little difference in CMR performance. As the Lambda sensor heats to the operating temperature and the sensor resistance decreases, the common mode signal is no longer

applied to both inputs equally. This imbalance causes

V

OUT(CM)

to increase as R

SENSOR

decreases, as the noninverting input will see the full common mode signal, while

the non-inverting input will see an attenuated common

mode signal.

The selection of the value of the CMR bypass capacitor

needs to be balanced with the need for reasonable reduction, or elimination, of common mode signals with both cold

and hot sensors. Since normal operation will need to include consideration of the entire impedance range of the

sensor, a trade off in overall application performance may

be needed.

Generally, the value of the CMR bypass capacitor should be

kept as low as possible, and should not be larger than the

differential input filter capacitor. Values in the range of

0.001 mF to 0.01 mF will usually provide reasonable CMR

results, but optimum results will need to be determined empirically, as the source of common mode signals will be

unique to each application.

Gain and Filter Stage

The signal gain and filter stage is designed to have a DC

gain of 4.53 V/V, with a cut-off frequency of typically

500 Hz. The external 4 kX resistors on each input pin are in

series with the differential input impedance. Together they

form a voltage divider circuit across the input such that the

net DC gain of the application circuit is 4.50 V/V.

TL/H/12372– 17

FIGURE 7. Simplified Gain and Filter Circuit

The internal gain is set by the ratio of C

IN

and CFB:

GAIN

DC

e

C

IN

C

FB

GAIN

DC

e

7.4213 pF

1.6383 pF

e

4.53 V/V

The corner frequency (

b

3 dB) is set by the ratio of CFBand

C

INT

, and by F

CLOCK

:

F

C

e

F

CLOCK

#

C

FB

2

#q#

C

INT

F

C

e

1E5#1.6383E-12

2#3.14159#52.1E-12

e

500 Hz

TL/H/12372– 18

FIGURE 8. Equivalent Gain and Filter Circuit

6

Page 7

Cold Sensor

Typically, a Lambda sensor will have an impedance of less

than 10 kX when operating at temperatures between 300

§

C,

and 500

§

C. When a Lambda sensor is not at operating temperature, its impedance can be more than 10 MegX. Any

voltage signal that may be developed is seriously attenuated. During this high impedance condition the LM9040 will

provide a default output voltage.

TL/H/12372– 19

FIGURE 9. V

OUT

with Cold Lambda Sensor

Each amplifier input has a bias charge applied across the

Differential Input impedance (Z

DIFF

) by means of charge

redistribution through the switched capacitor network. This

bias charge is a ratio of V

CC

, and is typically 447 mV for a

V

CC

value of 5.00V. This will provide an output voltage of

typically 2.025V.

While the Lambda sensor is high impedance, the 447 mV

across Z

DIFF

will be the dominant input signal. As the Lambda sensor is heated, and the sensor impedance begins to

drop, the voltage signal from the sensor will become the

dominate signal.

Output Resistance

With normal operation, each output has typically 2.5 kX of

resistance. This resistance, along with an external capacitor, form a RC low pass filter to remove any clock noise

from the output signal. An external output filter capacitor

value of 0.01 mF is recommended. Additionally, the output

resistance will provide current limiting for the output stage

should it become shorted to Ground or V

CC

.

Any DC loading of the output will cause an error in the measured output voltage. This error will be equal to the I

#

R drop

across the output resistance:

V

ERROR

e

I

LOAD

#

2.5 kX

Open Input Pins Defaults

In any remote sensor application it is desirable to be able to

deal with the possibility of open connections between the

sensor and the control module. The LM9040 is capable of

providing an output voltage scaled to V

CC

should either, or

both, of the wires to the Lambda sensor open. The two

inputs handle the open circuit condition differently. The

LM9040 will provide a default V

OUT

that is typically 2.025V

when V

CC

is at 5V.

For the case of an open connection of the non-inverting

input, the device would react the same as for the Cold Sensor condition. The internal bias voltage across Z

IN

would

cause the output voltage to be at a value defined by V

CC

and the LM9040 DC gain. The inverting input would still be

connected to the Lambda sensor ground, so any common

mode signals would still need to be allowed for in this condition. See

Figure 9

.

For the case of an open connection of the inverting input,

the device output stage switches from the amplifier output

to a resistive voltage divider. In this case, the default V

OUT

is not dependent on the gain stage, and any signal on the

non-inverting input will have no effect on the output. Each

amplifier has a comparator to monitor the voltage on the

inverting input pin. When the voltage on an inverting pin

goes above typically 2.5V, the comparator will switch the

output from the amplifier output to the voltage divider stage.

To fully implement this function requires external pull-up resistors for each of the inverting inputs. To minimize signal

errors due to DC currents through the 4 kX resistors, the

pull-up resistors need to be added in the application circuit

between the 4 kX input resistor and the connection to the

Lambda sensor ground point. A typical pull-up value of

51 kX to V

CC

is recommended. During this condition, the

effective resistance of the output stage will be 3.5 kX typically. See

Figure 10

.

TL/H/12372– 20

FIGURE 10. V

OUT

with Open Inverting Input

7

Page 8

Open Input Pins Defaults (Continued)

In the cases where both the inverting and non-inverting pins

are open, the non-inverting condition (i.e.: voltage divider

across the output) will be the dominant condition.

Any common mode signal seen by inverting input pin should

not be allowed to exceed the Common Mode voltage range.

Exceeding the positive Common Mode voltage limit could

cause the inverting input pin voltage comparator to act as if

the inverting input pin is open. Since the comparator circuit

is not part of the switched capacitor network there is no

frequency limitation on the signal to the comparator. Any

transient on the inverting input pin which goes above the

comparator threshold will immediately cause the output to

switch to the open sensor mode. The output will return to

normal operation when the voltage on the inverting input

falls below the comparator threshold.

Supply Bypassing

For best performance the LM9040 requires a VCCsupply

which is stable and noise free. The same 5V V

REF

supply

used for the A/D converter is the recommended V

CC

supply. During operation the device will generate current spikes

coincident with the clock edges. Inadequate bypassing will

cause excessive clock noise on the outputs, as well as

noise on the V

CC

line. The LM9040 VCCpin should be bypassed with a minimum 0.1 mF capacitor to the Signal

Ground pin, and should be located as close to the device as

possible. Some applications may require an additional

4.7 mF tantalum capacitor, especially if there are several

other switched capacitor devices running off the same 5V

supply line. The Signal and Digital Ground pins should be

tied together as close to the device as possible.

TL/H/12372– 21

FIGURE 11. Typical Application

8

Page 9

9

Page 10

LM9040 Dual Lambda Sensor Interface Amplifier

Physical Dimensions inches (millimeters)

14-Lead (0.300×Wide) Molded Small Outline Package, JEDEC

Order Number LM9040M

NS Package Number M14B

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL

SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or 2. A critical component is any component of a life

systems which, (a) are intended for surgical implant support device or system whose failure to perform can

into the body, or (b) support or sustain life, and whose be reasonably expected to cause the failure of the life

failure to perform, when properly used in accordance support device or system, or to affect its safety or

with instructions for use provided in the labeling, can effectiveness.

be reasonably expected to result in a significant injury

to the user.

National Semiconductor National Semiconductor National Semiconductor National Semiconductor

Corporation Europe Hong Kong Ltd. Japan Ltd.

1111 West Bardin Road Fax: (

a

49) 0-180-530 85 86 13th Floor, Straight Block, Tel: 81-043-299-2309

Arlington, TX 76017 Email: cnjwge@tevm2.nsc.com Ocean Centre, 5 Canton Rd. Fax: 81-043-299-2408

Tel: 1(800) 272-9959 Deutsch Tel: (

a

49) 0-180-530 85 85 Tsimshatsui, Kowloon

Fax: 1(800) 737-7018 English Tel: (

a

49) 0-180-532 78 32 Hong Kong

Fran3ais Tel: (

a

49) 0-180-532 93 58 Tel: (852) 2737-1600

Italiano Tel: (

a

49) 0-180-534 16 80 Fax: (852) 2736-9960

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...