Page 1

LM9011

Electronic Ignition Interface

General Description

The LM9011 is an interface circuit which integrates the timing detection and logic control functions required for an automotive electronic ignition system into one device.

A VRS interface is provided for crankshaft position information via a toothed-wheel.

Four voltage comparators are provided for hardware diagnostics.

An electronic timing interface with output fault diagnostics is

provided to enable a micro-processor to drive an external

four channel ignition spark circuit.

The LM9011 is fully specified over the automotive temperature range of -40˚C to +125˚C, and is available in a 28 pin

Small Outline surface mount package.

Key Specifications

Features

n Single 5V supply operation

n VR Sensor Interface with dynamic hysteresis

n Four Channel Electronic Timing spark driver with output

diagnostics

n Electronic Timing Interface spark driver output voltage

from 5V to 16V

n One Non-Inverting voltage comparator with hysteresis

n Three Inverting voltage comparators with hysteresis

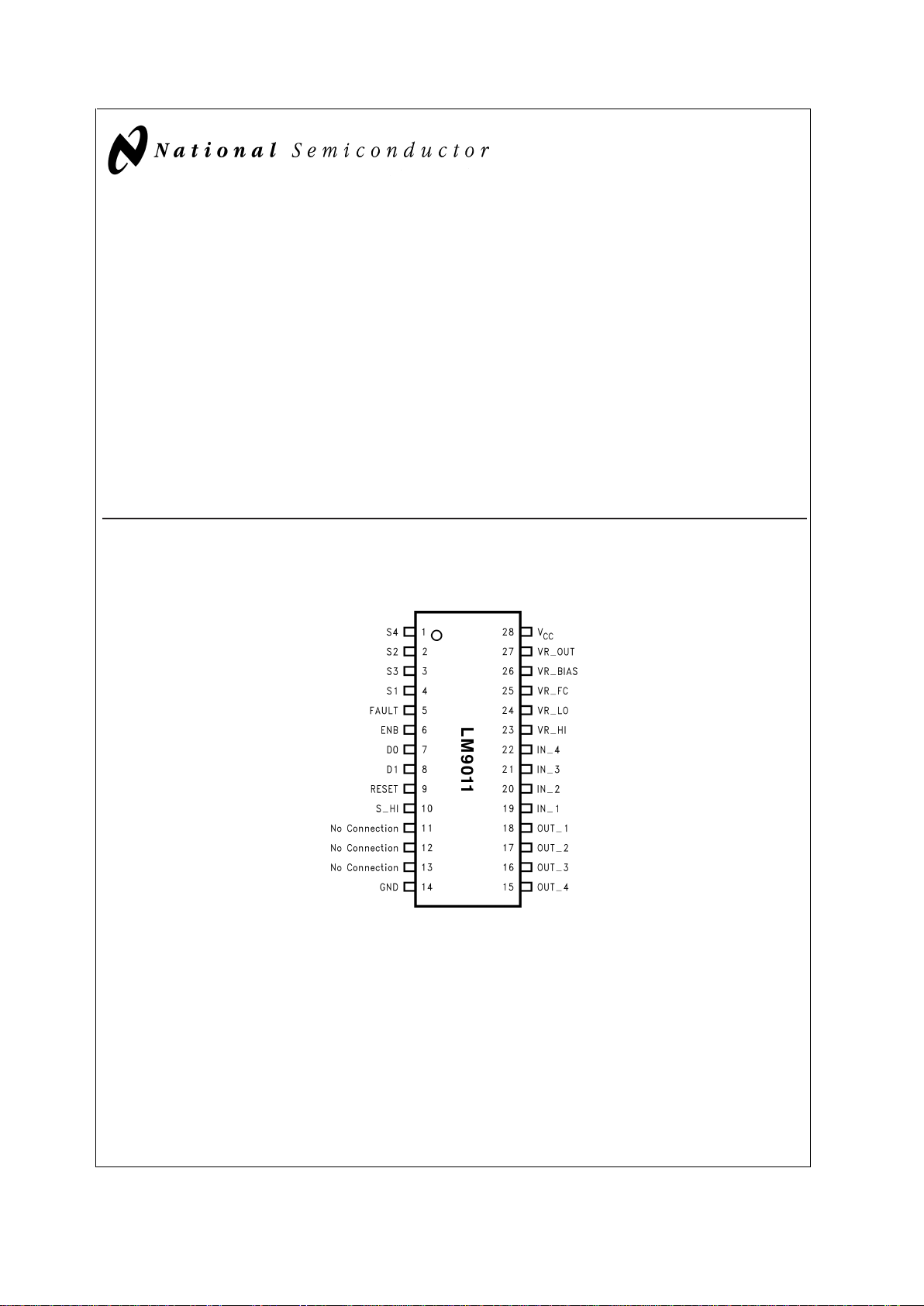

Connection Diagram

Top View

DS101264-1

Ordering Information LM9011M

See NS Package M28B

February 2000

LM9011 Electronic Ignition Interface

© 2000 National Semiconductor Corporation DS101264 www.national.com

Page 2

Absolute Maximum Ratings (Note 1)

Voltage -0.3V to +7.0V

S_HI Voltage -0.3V to 26.5V

VR_HI and VR_LO Inputs +/-3mA

Comparator Inputs -0.3V to +7.0V

Timing Interface Inputs -0.3V to +7.0V

ESD Susceptibility (Note 3) +/-2000V

Maximum Junction Temperature 150˚C

Storage Temperature Range -65˚C to +150˚C

Lead Soldering Information:

Vapor Phase (60 Seconds) 215˚C

Infrared (15 Seconds) 220˚C

Operating Ratings (Note 3)

V

CC

Voltage 4.75V to 5.25V

S_HI Voltage V

CC

to 26V

Sx Outputs -0.3V to S_HI +0.3V

Comparator Inputs

VR_HI and VR_LO Inputs

-0.3V to V

CC

+0.3V

+/-2.75mA

Timing Interface Inputs -0.3V to V

CC

+0.3V

Thermal Resistances (M28B):

Junction to Case (θJ-C) 15˚C/W

Junction to Ambient (θJ-C) 69˚C/W

DC Electrical Characteristics The following specifications apply for V

CC

= 5V, V

RESET=VCC,VS_HI

=

V

CC

, -40˚C ≤ TA≤ +125˚C, Application Circuit Figure 16, unless otherwise specified.

Symbol Parameter Conditions Minimum Maximum Units

I

CC

Supply Current

RESET, IN_4 = V

CC

25 mA

ENB, D0, D1, IN_1, IN_2, IN_3 =

0V

VR_HI = +12.5µA

VR_LO = -12.5µA

Comparators

V

TH

1 Input Threshold VIN_1 Decreasing from VCCto 0V

until V

OUT

_1>VCC/2

V

CC

X 0.435 VCCX 0.485 V

V

TH

2 Input Threshold VIN_2 Decreasing from VCCto 0V

until V

OUT

_2>VCC/2

V

CC

X 0.435 VCCX 0.485 V

V

TH

3 Input Threshold VIN_3 Decreasing from VCCto 0V

until V

OUT

_3>VCC/2

V

CC

X 0.40 VCCX 0.45 V

V

TH

4 Input Threshold VIN_4 Decreasing from VCCto 0V

until V

OUT

_4<VCC/2

V

CC

X 0.45 VCCX 0.50 V

V

HYST

Input Hysteresis All Comparators 150 400 mV

I

BIAS

Input Bias Current IN_1, IN_2, IN_3 = 0V ≤ VIN≤V

CC

IN_4 = 0V ≤ VIN_4 ≤ VCC-1V

750 µA

V

OH

Output High Voltage I

LOAD

= -100µAV VCC-1 V

V

OL

Output Low Voltage I

LOAD

= +100µAV 750 mV

VR Sensor Interface

V

OH

Output High Voltage I

LOAD

= -15µA

VR_HI= -1mA, VR_LO = +1mA

VCC-1 V

V

OL

Output Low Voltage Load = +15µA

VR_HI=+1mA, VR_LO = -1mA

750 mV

I

DIFF(MIN)

Minimum Detect Differential Input

Current (Note 4)

-40˚C ≤ TA≤ +25˚C

T

A

= +85˚C (Note 7)

T

A

= +125˚C

0.5

0.6

1.0

3.0

3.5

5.0

uA Pk-Pk

uA Pk-Pk

uA Pk-Pk

I

HYS

1 Input Hysteresis (Note 4) I

DIFF

= 1mA pk-pk 75 250 uA Pk

I

HYS

2 Input Hysteresis (Note 4) I

DIFF

= 2.5mA pk-pk 185 625 uA Pk

Electronic Timing Interface

V

IH

Input Logic 1 D0, D1, ENB,

RESET

VCCX 0.7 V

V

IL

Input Logic 0 D0, D1, ENB,

RESET

VCCX 0.3 V

I

IH

Input High Current Inputs D0, D1,

RESET

VIN=V

CC

10 µA

I

IH

Input High Current Input ENB VIN=V

CC

125 µA

LM9011

www.national.com 2

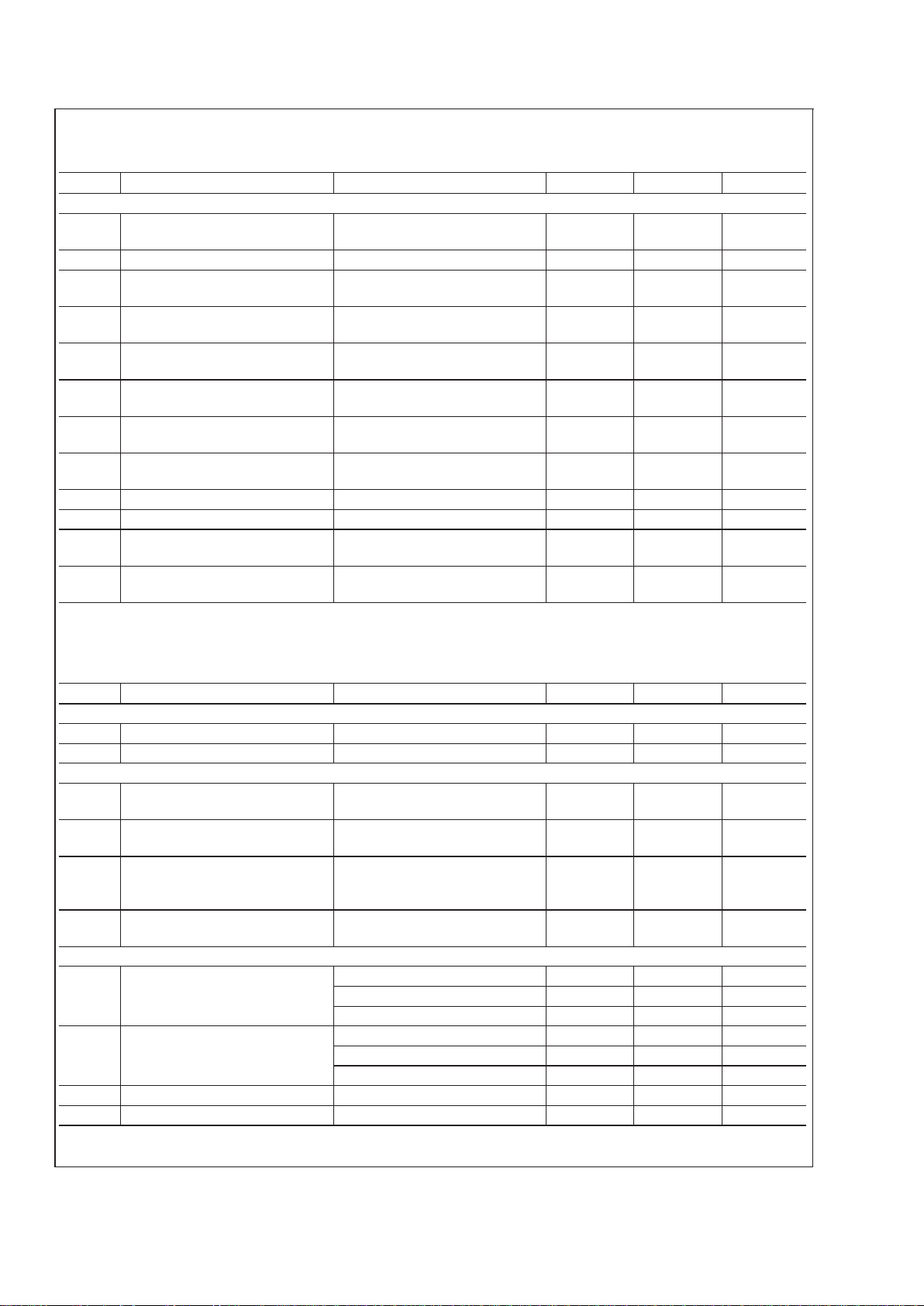

Page 3

DC Electrical Characteristics The following specifications apply for V

CC

= 5V, V

RESET

=VCC,V

S_HI=VCC

,

-40˚C ≤ T

A

≤ +125˚C, Application Circuit Figure 16, unless otherwise specified. (Continued)

Symbol Parameter Conditions Minimum Maximum Units

Electronic Timing Interface

I

IL

Input Low Current Inputs D0, D1,

ENB

VIN= 0V -10 µA

I

IL

Input Low Current Input RESET VIN= 0V -125 µA

V

OH

Output High Voltage Outputs S1,

S2, S3, S4

I

LOAD

= -10mA, V

S_HI

= 5V 3.75 V

V

OL

Output Low Voltage Outputs S1,

S2, S3, S4

I

LOAD

= 1mA, V

S_ HI

= 5V 300 mV

V

OH

Output High Voltage Outputs S1,

S2, S3, S4

I

LOAD

= -10mA, V

S_HI

= 16V 14 V

V

OL

Output Low Voltage Outputs S1,

S2, S3, S4

I

LOAD

= 1mA, V

S_HI

=16V 450 mV

V

OH

Output High Voltage Outputs S1,

S2, S3, S4

I

LOAD

= -10mA, V

S_HI

=26V 22 V

V

OL

Output Low Voltage Outputs S1,

S2, S3, S4

I

LOAD

= 1mA, V

S_HI

=26V 600 mV

V

OH

FAULT Pin Output High Voltage I

FAULT

= -100µA, no fault VCC-1 V

V

OL

FAULT Pin Output Low Voltage I

FAULT

= 100µA, any fault 750 mV

V

FAULT

Fault Treshold Voltage Outputs

S1, S2, S3, S4

Sx Output Short Fault VCCX 0.2 VCCX 0.5 V

I

FOL

TRI-STATE Output Current

Outputs S1, S2, S3, S4

V

RESET

= 0V, V

S _HI

=5V

R

LOAD

= 10KΩ

-12 -50 µA

AC Electrical Characteristics

The following specifications apply for VCC= 5V, V

S_HI=VCC,VRESET=VCC

, -40˚C≤TA≤+125˚C. The AC Timing Characteristics

are not production tested. Minimum and Maximum limits are guaranteed by device characterization.

Symbol Parameter Conditions Minimum Maximum Units

Comparators

T

RISE

Output Rise Time 10%to 90%,C

LOAD

= 25pF 5 µs

T

FALL

Output Fall Time 90%to10%,C

LOAD

= 25pF 5 µs

VR Sensor Interface (Note 4)

T

RISE

Output Rise Time 10%to 90%,C

LOAD

= 100pF,

R

LOAD

= 100KΩ

10 µs

T

FALL

Output Fall Time 90%to10%,C

LOAD

= 100pF,

R

LOAD

= 100kΩ

5ms

T

DELAY

Zero Crossing Delay Time (Note6)I

DIFF

= 5µA pk-pk, F

VRS

= 200Hz

I

DIFF

= 50µA pk-pk, F

VRS

=

2.5KHz

1

10

ms

ms

F

MAX

Maximum VRS Frequency C

LOAD

= 100pF, R

LOAD

= 100KΩ

I

DIFF

= 5µA pk-pk

50 KHz

Electronic Timing Interface

T

RISE

1 Sx Output Rise Time Sx Rises10%to 90

%

C

LOAD

= 6.8nF, R

LOAD

= 10KΩ 5µs

C

LOAD

= 12.7nF, R

LOAD

= 10KΩ 8µs

T

FALL

1 Sx Output Fall Time Sx Falls 90%to 10

%

C

LOAD

= 6.8nF, R

LOAD

= 10KΩ 15 µs

C

LOAD

= 12.7nF, R

LOAD

= 10KΩ 25 µs

T

SETUP

SetupTime (Notes 7, 8 and 9) 1 µs

T

HOLD

Hold Time 0.5 µs

LM9011

www.national.com3

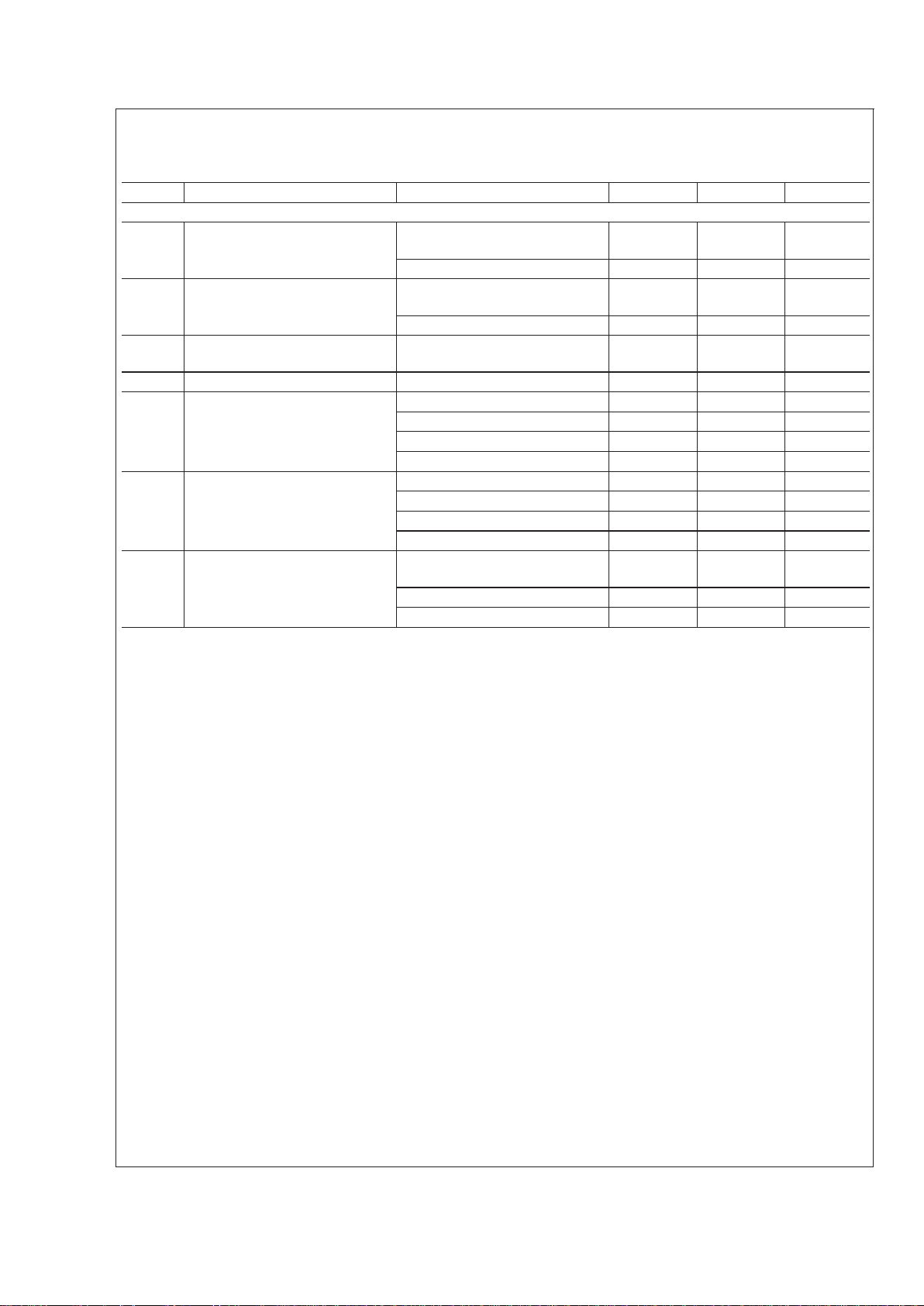

Page 4

AC Electrical Characteristics (Continued)

The following specifications apply for VCC= 5V, V

S_HI=VCC,VRESET=VCC

, -40˚C≤TA≤+125˚C. The AC Timing Characteristics

are not production tested. Minimum and Maximum limits are guaranteed by device characterization.

Symbol Parameter Conditions Minimum Maximum Units

Electronic Timing Interface

T

DF

1 Fault Delay Time Sx Output Short to Ground Fault

From ENB=1toFAULT ≤ 10

%

C

FAULT

= 25pF 2 µs

T

DF

2 Fault Delay Time Sx Output Short to Battery Fault

From ENB=0toFAULT ≤ 10

%

C

FAULT

= 25pF 2 µs

T

TRI

TRI-STATE Delay Time From RESET=0toAllSx

Outputs Off

2µs

T

RISE

2 Fault Pin Rise Time 10%to 90%,C

FAULT

= 25pF 5 µs

T

FF(OFF)

False Fault Time From ENB=0toFAULT ≥ 90

%

C

FAULT

= 25pF

C

LOAD

= 6.8nF, R

LOAD

= 10KΩ 25 µs

C

LOAD

= 12.7nF, R

LOAD

= 10KΩ 30 µs

T

FF(ON)

False Fault Time From ENB=1toFAULT ≥ 90

%

C

FAULT

= 25pF

C

LOAD

= 6.8nF, R

LOAD

= 10KΩ 8µs

C

LOAD

= 12.7, R

LOAD

= 10KΩ 10 µs

T

UDF

Undefined Fault Time From ENB = 0 for 8uSec, to Valid

FAULT

C

LOAD

= 6.8nF, R

LOAD

= 10KΩ 20 µs

C

LOAD

= 12.7nF, R

LOAD

= 10KΩ 25 µs

Note 1: Absolute Maximum Ratings indicate the limits beyond which damage may occur.

Note 2: ESD Ratings is with Human Body Model: 100pF discharged through a 1500Ω resistor.

Note 3: Operating ratings indicateconditions for which the device is intended to be functional, but may not meet the guaranteed specificperformance limits. For guar-

anteed specifications and conditions, see the Electrical Characteristics.

Note 4: Tested per VR Sensor Interface test circuit. See figures 8 and 9.

Note 5: Minimum Detect Current is not production tested at +85C. Specifications is guaranteed through device characterization and Test Limits at 25˚C and 125˚C.

Note 6: VR Sensor Interface Tdelay, measured from VR input sine wave zero-crossing to VR_OUT going high. See figure 9.

Note 7: Electronic Timing Interface Tsetup, minimum time between Vcc

>

4.75V and RESET = 1.

Note 8: Electronic Timing Interface Tsetup, minimum time between RESET = 1 and D0 = 1.

Note 9: Electronic Timing Interface Tsetup, minimum time between D0 / D1 = valid and ENB = 1.

LM9011

www.national.com 4

Page 5

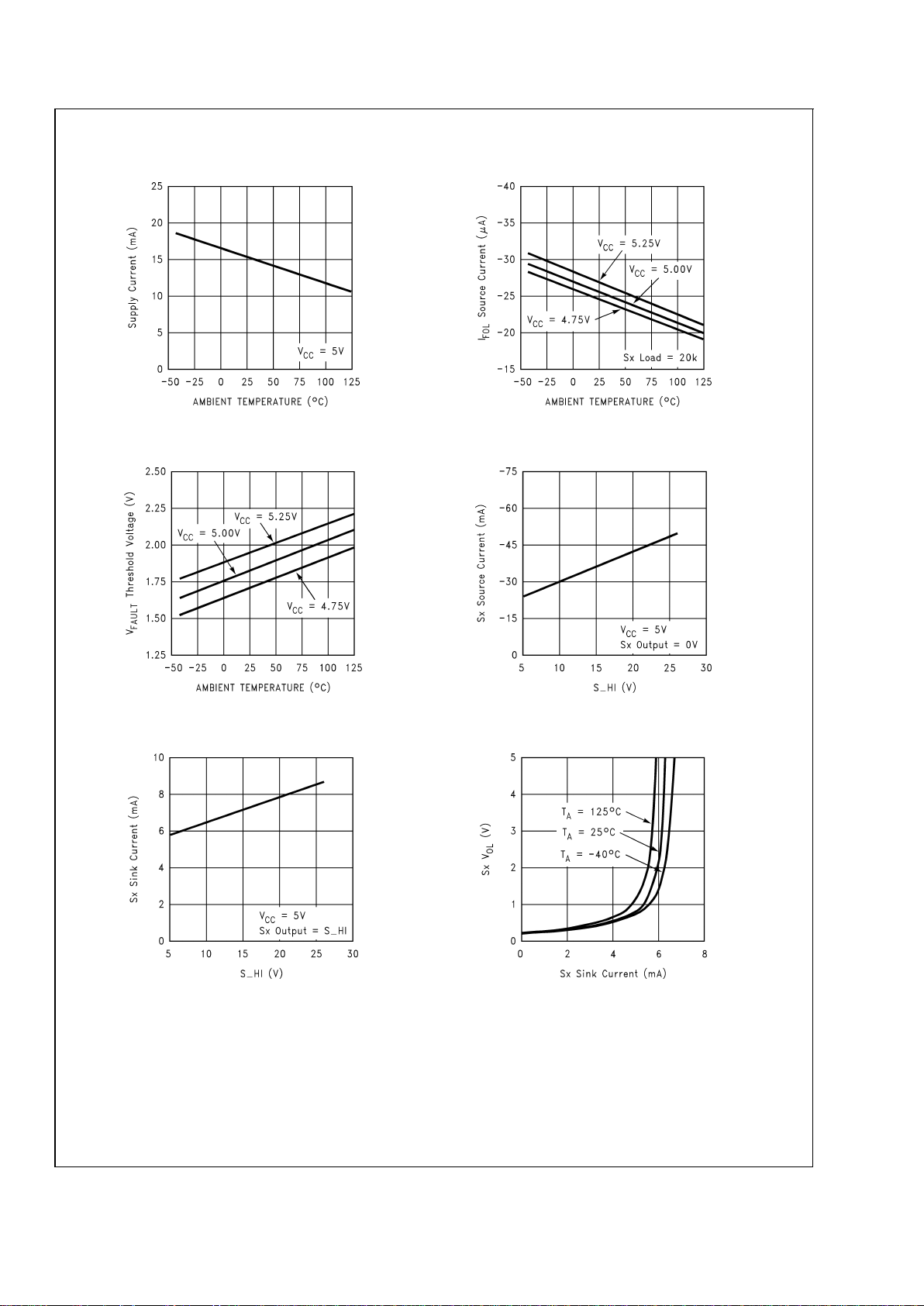

Typical Performance Characteristics

Supply Current vs Temperature

DS101264-3

Ifol Source Current vs Temperature

DS101264-4

VFault Threshold vs Temperature

DS101264-5

Sx Source Current vs S_HI Voltage

DS101264-6

Sx Sink Current vs S_HI Voltage

DS101264-7

Sx Vol vs Sx Sink Current

DS101264-8

LM9011

www.national.com5

Page 6

Typical Performance Characteristics (Continued)

Sx Voh vs Sx Source Current

DS101264-9

VRS Interface Minimum Detect

vs Temperature

DS101264-10

VRS Interface Minimum Detect

vs VR_BIAS

DS101264-11

LM9011

www.national.com 6

Page 7

Timing Diagrams

DS101264-12

FIGURE 1. Electronic Timing Interface Timing Diagram

DS101264-13

FIGURE 2. Fault Pin Timing During Sx Shorted to Ground

DS101264-14

FIGURE 3. Fault Pin Timing During Sx Shorted to Battery

LM9011

www.national.com7

Page 8

Timing Diagrams (Continued)

DS101264-15

FIGURE 4. False FAULT Time for Disabled Sx Output

DS101264-16

FIGURE 5. False FAULT Time for Enabled Sx Output

LM9011

www.national.com 8

Page 9

Timing Diagrams (Continued)

DS101264-17

FIGURE 6. Time for Valid Fault Detection

DS101264-18

FIGURE 7. Electronic Timing Interface Typical Waveforms

LM9011

www.national.com9

Page 10

Timing Diagrams (Continued)

DS101264-19

FIGURE 8. VR Interface Test Circuit

DS101264-20

FIGURE 9. VR Interface Timing Diagram

LM9011

www.national.com 10

Page 11

Circuit Description

VR Sensor Interface

The differential inputs, VR_HI and VR_LO are low impedance inputs with a DC voltage bias of one half of Vcc, Both

inputs require equal value series resistance on their respective pins to convert the VR sensor voltage to a differential input current. The differential input current range is typically

2.5µA peak-to-peak to 2.5mA peak-to-peak. Each input has

active current limiting that will clamp the current at typically

+/-5mA. This is intended for short circuit protection and not

for input signal limiting.

Differential voltages of 500mV peak-to-peak to 500V peakto-peak can be processed with the specified 100KΩ series

resistor on each input. Numerous variables will determine

the output voltage signal from a VR sensor across a frequency range. The input resistors can be scaled from typically 50KΩ to 200KΩ to keep the differential input current

with-in the recommended range for a given VR Sensor output voltage. Bypass capacitors can be added to form a low

pass filter to limit the differential inputsignalatthehigher frequencies.

The VR Sensor interface utilizes a dynamic hysteresis which

will increase the hysteresis level as the input signal from the

VR Sensor increases. The circuit requires two external components to fully implement the hysteresis function: a capacitor on VR_FC to filter and store the peak detector signals;

and a 150KΩ resistor on VR_BIAS to set a reference current

for the hysteresis circuit.Thetypical value range for the peak

detector storage capacitor is 0.1µF to 0.47µF.

The peak detector has an internal 3KΩ (typical) current limiting resistor to Vcc forchargingthe storage capacitor.An external resistor in parallel with the peak detector storage capacitor is used to set the RC discharge rate of the peak

detector capacitor.

For input levels greater than typically 10µA peak-to-peak the

voltage on thepeakdetector output pin VR_FC is used to ac-

tively derive the hysteresis level. The active hysteresis will

typically be 30%of the peak input signal. As the input level

falls below typically 10µA peak-to-peak the hysteresis level

will begin to rise as the static hysteresis level takes effect.

The static hysteresis level is set by the current out of the VR_BIAS pin and is a constant level of typically 1µA peak with

a VR_BIAS resistor of 150KΩ. This static hysteresis level

acts as the minimum detect threshold as there will be no output if the input signal is not greater than the static hysteresis

level.

The VR_BIAS resistor can be scaled from typically 50KΩ to

500KΩ, but the practical range is typically 75KΩ to 300KΩ.

Increasing the resistance (i.e.reducingthe current) will lower

the minimum hysteresis level. Conversely, reducing the resistance will raise the minimum hysteresis level. Since the

VR_BIAS current is modified by the same square root circuit

used for the input signal, the relationship between the VR_BIAS resistor value and the minimum detect level is not linear. For VR_BIAS values greater than 500KΩ, the minimum

detect level is typically determined more by the internal device offsets, and thermal effects.

Voltage Comparators

The circuit includes four general purpose voltage comparators that use an internal reference voltage to set their voltage

thresholds. Three of the comparators have their noninverting inputs tied to the internal reference voltage, and

their inverting-inputs are brought out. The remaining one

comparator has its inverting input tied to the internal voltage

reference, and its non-inverting input is brought out. All four

comparators include hysteresis to improve noise immunity.

The comparator outputs are internally pulled up to V

CC

. Any

un-used comparator should have its input connected to device ground.

DS101264-21

FIGURE 10. VR Sensor Interface Block Diagram

DS101264-22

FIGURE 11. Voltage Comparator Block Diagram

LM9011

www.national.com11

Page 12

Circuit Description (Continued)

DS101264-23

FIGURE 12. Electronic Timing Interface Block Diagram

DS101264-24

FIGURE 13. Output Fault Detection Block Diagram

LM9011

www.national.com 12

Page 13

Circuit Description (Continued)

The Electronic Timing Interface provide signals to the spark

module from themicro-processor. The interfacerequiresfour

input data signals, and provides four output control channels.

The interface also provides one output channel for diagnostic information for any open or shorted loads on S1 to S4.

The RESETpin has an internal pull-up resistor to V

CC

of typically 100KΩ, and the ENB pin has an internal pull-down resistor to ground of typically 100KΩ.

To put the outputs into the TRI-STATE mode at power-on,

the RESET pin should be held low until V

CC

is above 4.75V.

This can be accomplished by micro-processor control, or by

adding a capacitor from the RESET pin to ground.

The RESET pinisused to disable the spark driver outputs by

putting them in a TRI-STATE mode. While in the TRI-STATE

mode the Open Output Fault detection circuitry is active. An

open Output is detected by forcing a small current (I

FOL

)

through the outputs to the loads, and monitoring the voltage

on the output pins rises above the Output Fault Threshold

Voltage(V

FAULT

) the FAULT pin will be forced low. The intent

is to detect an open wire condition, and not necessarily to

detect a local resistance threshold.

Note that if any output has a Short to battery fault, the fault

pin will go low during this TRI-STATE mode. The internal

comparator is unable to discern why an output pin may be

above the Fault Threshold Voltage, only that it is. In any

case, a fault is reported, even if it is not the anticipated fault.

The TRI-STATE mode is a latched condition. For the outputs

to come outofthe TRI-STATE mode, theRESETpin must be

high, and then the data input pin D0 must toggle from a low

state to a high state. The state of the outputs will now be set

by the data inputs D0 and D1, and the ENB input. If ENB is

low when the TRI-STATE mode is cleared, all of the outputs

will go low.

Pins D0 and D1 are used select an output, and ENB will enable the selected output. The outputs have have active pull

up to S_HI, and the active pull down to Ground. The default

not enabled output conditions is low, and the enabled output

condition is high. Only one output can be enabled (high) at a

time. The outputs are not latched in any state and will follow

the input selected with D0 and D1 as long as ENB is high.

The detection of an output shorted to ground, or battery, is

dependent on the status of ENB. While ENB is logical 0, all

of the outputs are forced low and the Short to Battery fault

detection circuitry is active. A Short to Battery is detected by

monitoring the voltage on the output pins. If the voltage on

any output pin is above the Fault Threshold Voltage (V

FAULT

)

the FAULT pin will go low. The output current sink is limited

to typically 8mA. The short to battery condition must be able

to provide enough current to overcome the current limit and

raise the output pin voltage above the V

FAULT

threshold.

When ENB is logical 1, the selected output will be high and

the Short to Ground detection circuitry is active. A Short to

Ground is detected by monitoring the voltage on the output

pins. If the voltage on the selected output pin is below the

Fault Threshold Voltage (V

FAULT

) the FAULT pin will go low.

The output current source is from S_HI limited to typically

25mA to 50mA across the S_HI voltage range. The short to

ground condition must be allow enough resistance to allow

the output pin voltage to fall below the V

FAULT

threshold with

the output sourcing short circuit current. Typically, a short to

ground which has 100 Ohms of resistance, or more, can not

be reliably detected. Typically, a short to ground of 20 Ohms,

or less, can be reliably detected across the entire S_HI voltage range and device operating temperature range. Note

that if any output has a Short to Battery fault, a Short to

Electronic Timing Interface

Inputs Output

RESET ENB D0 D1 S1 S2 S3 S4

0 X X X Tri Tri Tri Tri

10XXLLLL

1100HLLL

1110LHLL

1101LLHL

1111LLLH

FIGURE 14. Truth Table for Electronic Timing Interface

LM9011

www.national.com13

Page 14

Circuit Description (Continued)

Ground cannot be detected. The internal logic is unable to

discern which output pin is above the Fault Threshold Voltage, only that a pin is. Thus, the logical requirement of an Sx

pin voltage above the Fault Threshold voltage is met and no

fault is reported.

The output rise and fall times are basically a function of the

output current drive (source and sink) and the output load

characteristics. Due to the scaling of the output stages, and

variations in the value of S_HI, the fall time will typically be

two to ten times longer than the rise time for a given capacitive load.

Since the output fault detection mode changes immediately

with the status of the ENB pin, and the voltage on the output

pin cannot change instantly,the FAULTpin will go low during

the output transition times. The FAULT pin will stay low until

the output voltage rises above, or falls below, the active fault

threshold. See Figure 15.

When switching the outputs from the active mode to the TRISTATE mode the ENB should be taken low first. This will

take all of the outputs low.Then the RESET pin can be taken

low. This will eliminate false ’open’ faults that will be generated while waiting for the one output that was high, to discharge any capacitance below the V

FAULT

threshold.

DS101264-25

Figure 15. FAULT Pin Output During Normal Operation

LM9011

www.national.com 14

Page 15

Circuit Description (Continued)

DS101264-26

Figure 16. Typical Application

LM9011

www.national.com15

Page 16

Physical Dimensions inches (millimeters) unless otherwise noted

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

labeling, can be reasonably expected to result in a

significant injury to the user.

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

National Semiconductor

Europe

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: ap.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

www.national.com

Note: Unless otherwise specified.

1. STANDARDLEAD FINISH TO BE 200 MICROINCHES / 5.08 MICROMETERS MINIMUM LEAD / TIN (SOLDER) ON COPPER.

2. DIMENSION DOES NOT INCLUDE MOLD FLASH.

3. REFERENCE JEDEC REGISTRATION MS-013, VARIATION AE, DATED MAY 1990.

28-LEAD MOLDED PLASTIC SMALL OUTLINE PACKAGE

NS Package Number M28B

LM9011 Electronic Ignition Interface

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...