Page 1

APPROVED BY:

DATE

SHARP

LIQUlDCRYSTALDISPL4YGROUP

SHARPCORPORATlON

SPECIFICATION

DEVlCESPECIFICATIONfoor

Passive Matrix Color LCD Module

(640 X 480 dots)

SPECNo. LC98312

FILENo.

ISSU' MAR.30.1998

PAGE 28 Pages

REPREZENTATIVEDIVWON

ENGINEERINGDEPARTMENT

DUTYLCDDEVELOPMENT

CENTER

NARALIQUIDCRYSTAL

DISPLAYGROUP

.~

I

q CUSTOMER~APPROVAL

DATE

BY

Model No.

L

LMSV311

., ,.

,--.y _~ .,

1 ,, '. : :

_,’ :

. . . . . a

) ‘, “’

: ‘,C:

DIVISION~ENERALMANAGER

DUTYLCDDEVELOPMENTCENTER

NAR4LlQtilDCRYSTALDlSPLAYGROUP

SHARPCORPORATION

Page 2

SHARP

DRAWING No.

Page 3

SPEC x0.

.MODEL No. PAGE

SHARP

OPrecautions

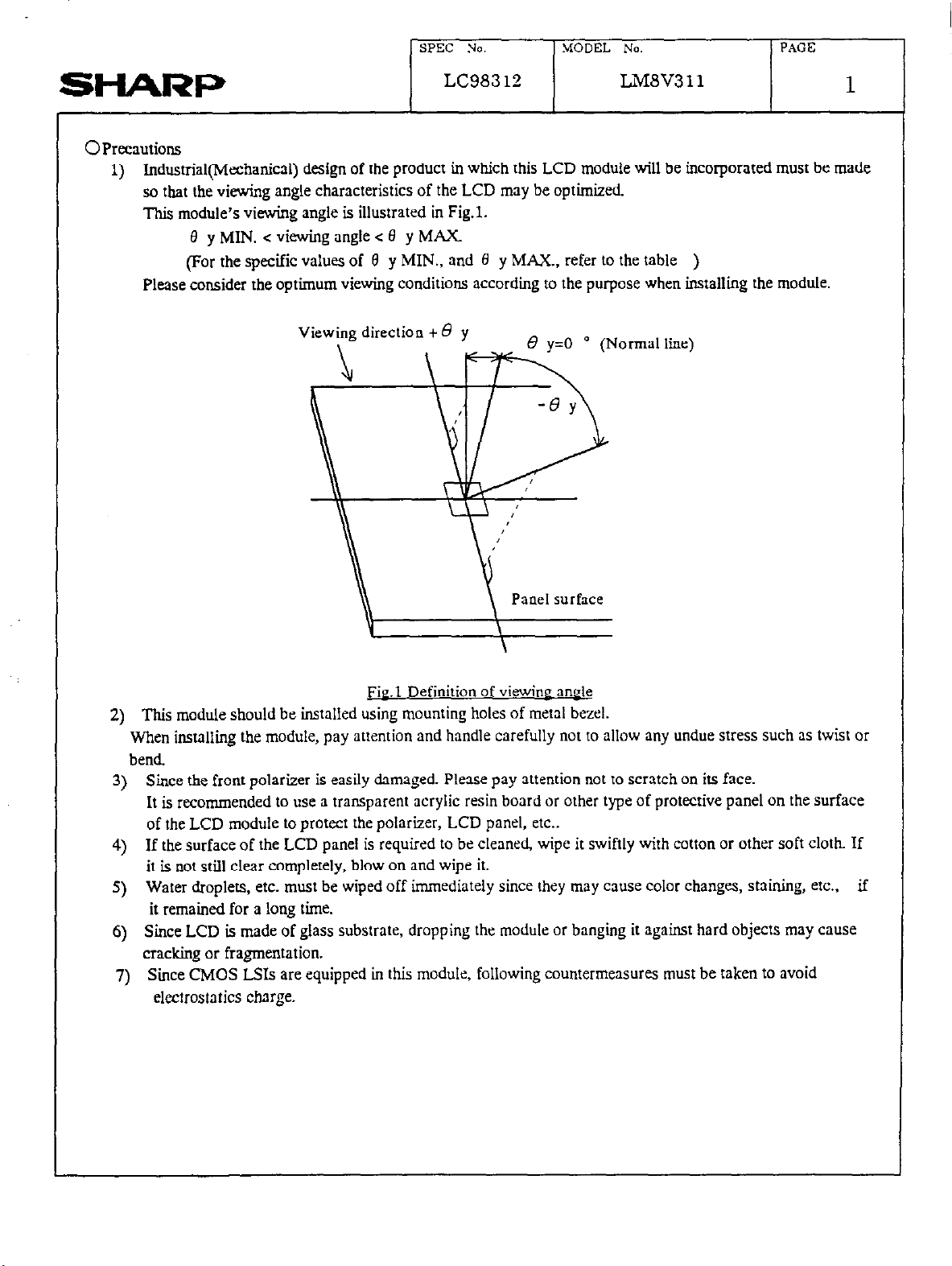

1) Indusuial(Mechanica1) design of the product in which this LCD module will be incorporated must be made

so that the viewing angle characteristics of the LCD may be optimized.

This module’s vieGig angle is illustrated in Fig.1.

Please consider the optimum viewing conditions according to the purpose when installing the module.

LC983 12

f3 y MIN. < viewing angle < 0 y MAX

(For the specific values of 0 y MIN., and B y MAX., refer to the table )

Viewin;

g direction + 6 y

63 y=O ’ (Normalline)

LYiM8V311

,’

,’

>’

1

Panel surface

a

Fie.1 Definition of viewine anele

2) This module should be installed using mounting holes of metal bezel.

When installing the module, pay attention and handle carefully not to allow any undue stress such as twist or

bend.

3) Since the front polarizer is easily damaged. Please pay attention not to scratch on its face.

It is recommended to use a transparent acrylic resin board or other type of protective panel on the surface

of the LCD module to protect the polarizer, LCD panel, etc..

4) If the surface of the LCD panel is required IO be cleaned, wipe it swiftly with cotton or other soft cloth. If

it is not still clear completely, blow on and wipe it.

5) Water droplets, etc. must be wiped off immediately since they may cause color changes, staining, etc., if

it remained for a long time.

6) Since LCD is made of glass substrate, dropping the module or banging it against hard objects may cause

cracking or fragmentation.

7) Since CMOS LSIs are equipped in this module, following countermeasures most be taken to avoid

electrostatics charge.

Page 4

I

SPEC 210~ MODEI. x0. PAGE

SHARP

1 I operator

Electrostatic shielding clothes shall be had because it is feared that the static electricity is electrified to

human body in case that operator have a insulating garment.

2. Equipment

There is a possibility that the static electricity is charged to equipment which have a function of peeling

or mechanism of friction(EX: Conveyer, soldering iron, working table), so the

countermeasure(electrostaticearth:l X 10’ Q) should be made.

3. Floor

Floor is a important part to leak static electricity which is generated from human body or equipment.

There is a possibility that the static electricity is charged to them without leakage in case of insulating

floor, so the countermeasure(electrostatic earth:1 X 10’ Q) should be made.

4Humidity

Humidity of working room may lower electrostatics generating material’s resistance and have something

to prevent electrifying. So, humidity should be kept over 50 % because humidity less than 50 % may

increase material’s electrostatic earth resistance and it become easy to electrify.

5.Transportationlstorage

The measure should be made for storage materials because there is a possibility that the static electricity,

which electrify to human body or storage materials like container by friction or perling, cause the

dielectric charge.

6. Others

The laminator is attached on the surface of LCD module to prwent from scratches, fouling and dust.

It should be peeled off unhurriedly with using static eliminator.

And also, static eliminator should be installed to prevent LCD module from electrifying at assembling

line.

8) Don’t use any materials which emit gas from epoxy rcsin(amines’ hardener) and silicon adhesive

agent(dealcohol or deoxym) to prevent change polarizer color owing to gas.

9) Since leakage current, which may be caused by routing of CCFT cables, etc., may affect the brightness of

display, the inverter has to be designed taking the leakage current into consideration. Thorough evaluation of

the LCD module/inverter built into its host equipment shall be conducted, therefore, to ensure the specified

brightness.

10) Avoid to expose the module to the direct sun-light, strong ultraviolet light, etc. for a long time.

11) If stored at temperatures under specified storage temperature, the LC may freeze and be deteriorated.

If storage temperature exceed the specified rating. the molecular orientation of the LC may change to that of

a liquid, and they may not revert to their original state. Therefore, the module should be always stored at norm;

room temperature.

12) Disassembling the LCD module can cause permanent damage and should be strictly avoided.

LC98312

LM8V311

countemxasure

2

Page 5

SPEC No. MODEL No. PAGE

1

SHARP

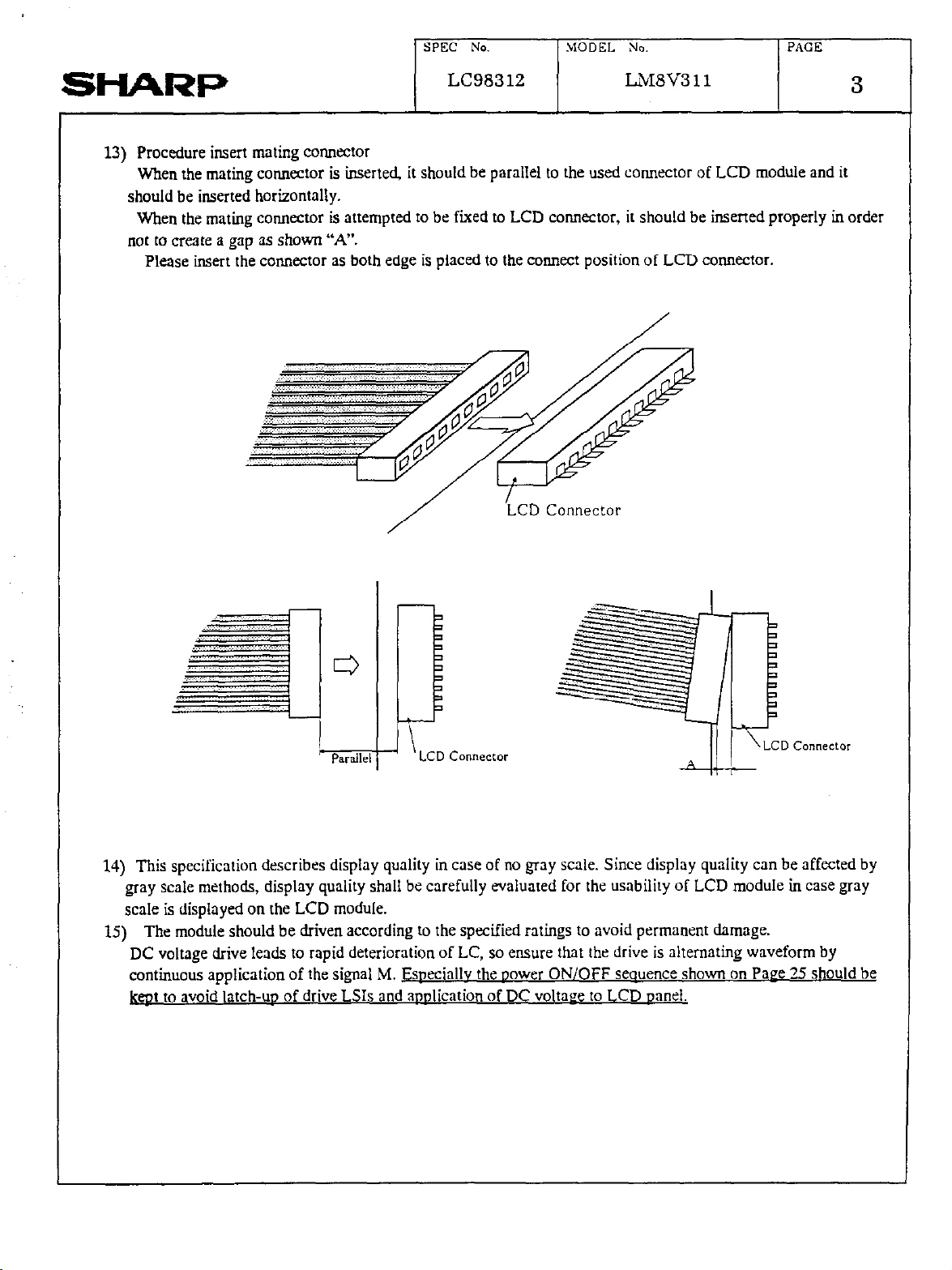

13) Procedure insert mating connector

When the mating connector is inserted it should be parallel to the used connector of LCD module and it

should be inserted horizontally.

when the mating connector is attempted to be fiied to LCD comxctor, it should be inserted properly io order

not to create a gap as shown “A”.

Please insert the coooector as both edge is placed to the connect position of LCD comxctor.

LC98312 LhI8V3 11

3

14) This specification describes display quality in case of no gray scale. Since display quality can be affected by

gray scale methods, display quality shall be carefully evaluated for the usability of LCD module in case gmy

scale is displayed on the LCD module.

15) The module should be driven according to the specified ratings to avoid permamnt damage.

DC voltage drive leads to rapid deteriomtion of LC, so ensure that the drive is alternating waveform by

continuous application of the signal M. ~sneciallv the Dower ON/OFF seauence shown on Page 25 should be

kept to avoid latch-w of drive LSIs and aonlication of DC voltaee to LCD onnel.

Page 6

SPEC No.

1

.MODEL No.

PAGE

SHARP

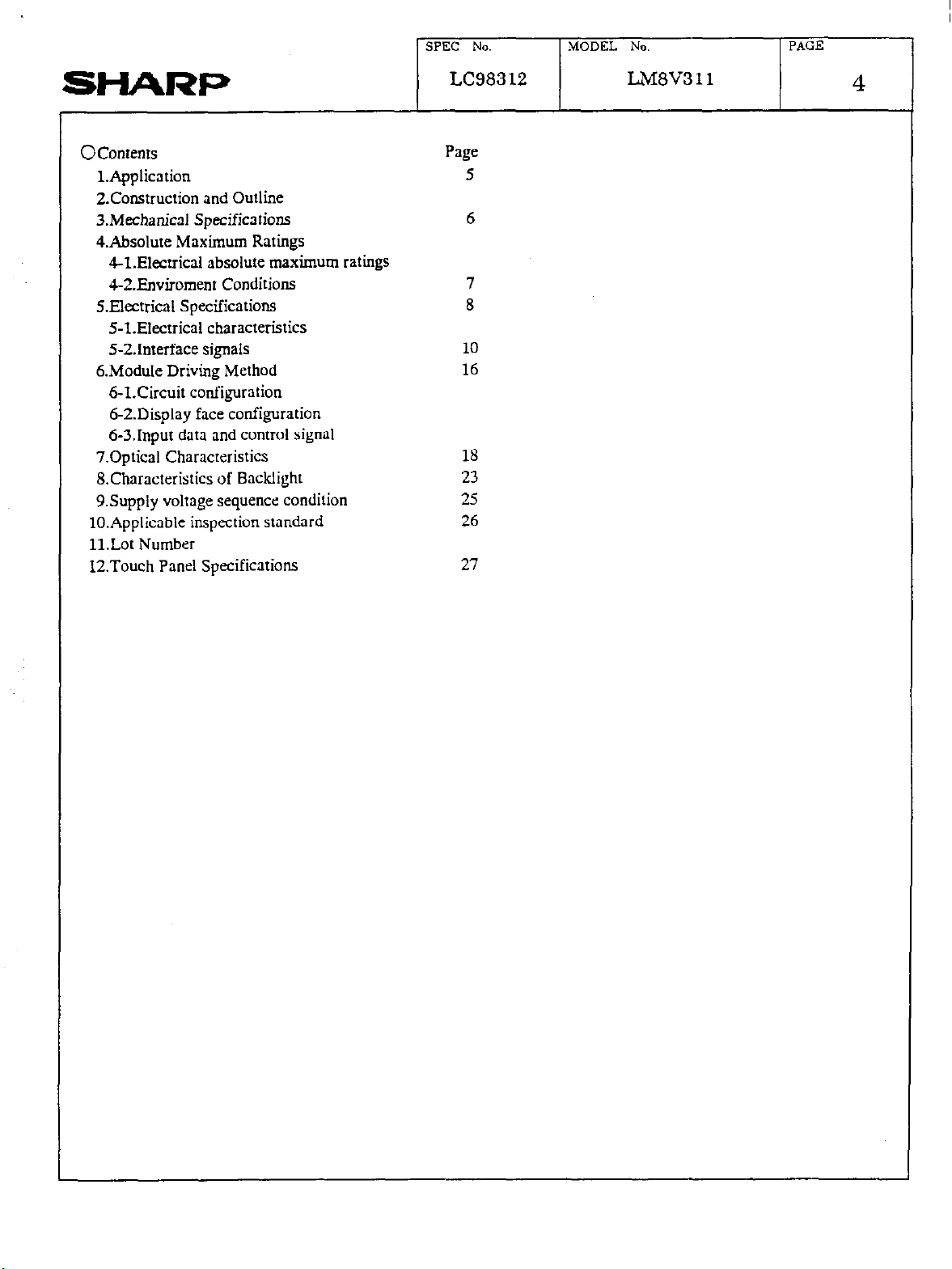

OConrenrs

l.Application

t.Coostruction and Outline

3.Mechanical Specifications

4Absolute Maximum Ratings

4-LElectrical absolute maximum ratings

4-Z.Enviroment Conditions

S.EIectricaI Specifications

.5-LEIectrical characteristics

.5-Z.Interface signals

6.Module Driving Method

6-LCircuit configuration

6-Z.Display face configuration

6-3.Input data and control signal

7.0ptical Characteristics

&Characteristics of Backlight

9.Suppiy voltage sequence condition

lO.Applicable inspection standard

ll.Lot Number

12.Touch Panel Specifications

LC98312

Page

5

6

7

8

10

16

18

23

25

26

27

LM8V3 11

4

Page 7

SPEC No. .MODEL No.

1

PAGE

SHARP

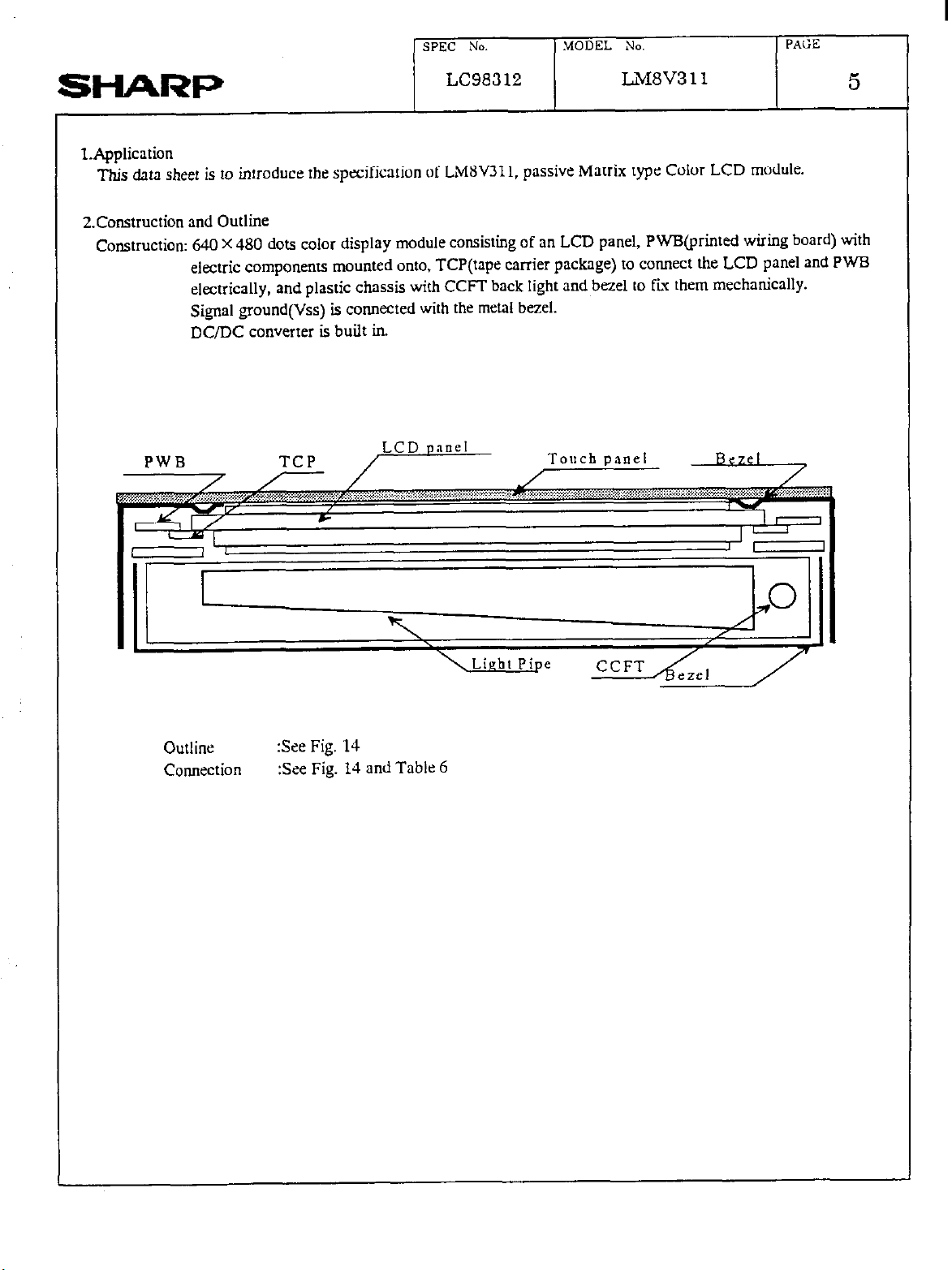

IApplication

This data sheet is to introduce the specification of L~M8V311. passive Matrix type Color LCD module.

2.Cortstruction and Outline

Construction: 640 X 480 dots color display module consisting of an LCD panel, PWB@rixtted wiring board) with

electric comuonems mounted onto, TCP(tapc carrier package) to connect the LCD panel and PWB

electrically. and plastic chassis with CCFT back light and bezel to fix them mechanically.

Signal ground(Vss) is connected with the metal bezel.

DC/DC converter is built in.

PWB

/ r-------

I-M,

, 1

LC98312 LiiSV311

I I

Touch panel

,

I-

5

I

Outline

Connection

:See Fig. 14

See Fig. 14 and Table 6

,

*O

/

Page 8

SPEC No. .M”“EL No.

PAGti

SHARP

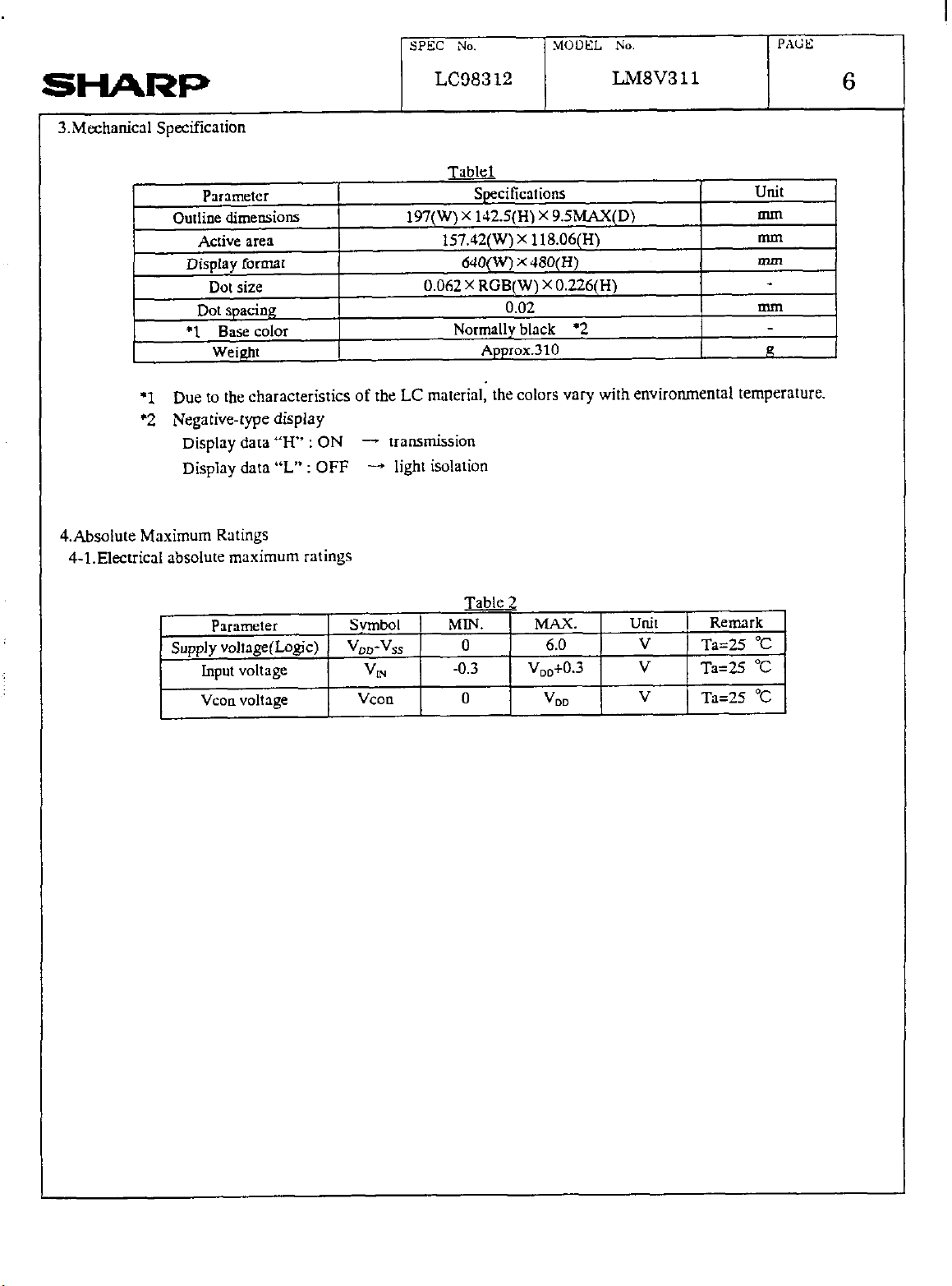

3Mechanical Specification

‘1 Due to the characteristics of the LC material; the colors vary with environmental temperature.

‘2 Negative-type display

Display data “H” : ON - transmission

Display data “L” : OFF -+ light isolation

4.Absolute Maximum Ratings

4-LElectrical absolute maximum ratings

LC983 12 Lh48V311

I I

6

I

PWam~t.X

Supply v0lt~ge(logic)

Input voltage

Vcon voltage

Table

Symbol MIN. MAX. unit

vm-vss

VU+

VCOO 0

0 6.0

-0.3 v,,+o.3

VDD

V

V

V

Remxk

Ta=25 “C

Ta=25 “C

Ta=25 “C

Page 9

SPEC No.

MODEL No.

PACE

SHARP

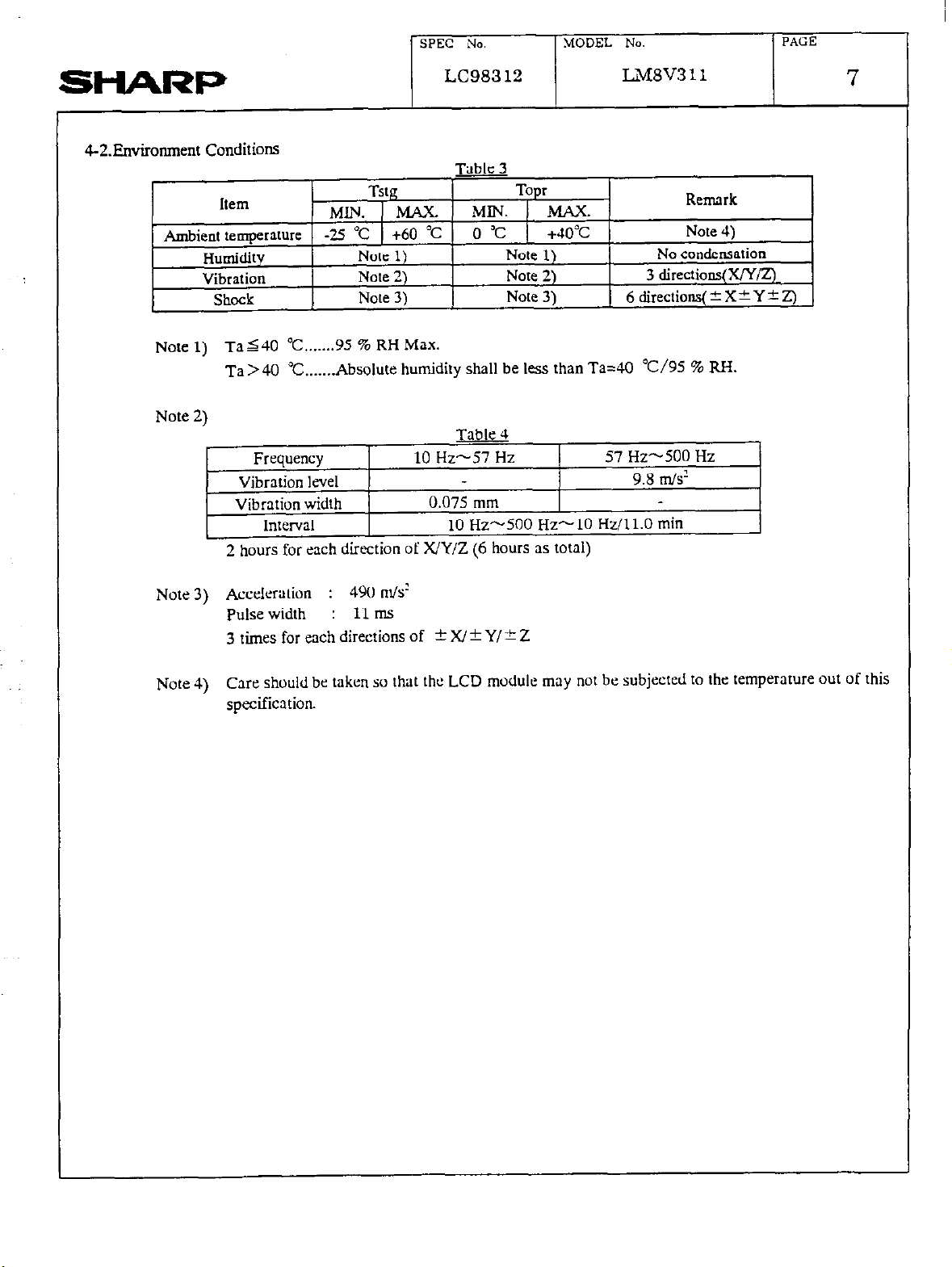

4-Z.Enviromnent Conditions

km

Ambient tempernture

Humiditv

Vibration

Shock Note 3)

Note 1) Ta540 “c . .._... 95 % RH Max.

Note 2)

LC983 12

I

Tsta

MIN. 1 MAX. MIN. ) MAX.

-2s “C 1 +60 “C

Note 1) Note 1)

Note 2) Note 2) 3 directions(XNlZ)

Ta>40 %.......Absolute humidity shall be less than Ta=40 “C/95 % RI%

Frequency 10 Hz-57 Hz 57 Hz-500 Hz

Vibration level 9.8 mls’

Vibralion width

Interval 10 Hz-500 Hz-10 Hz/ll.O min

2 hours for exh direction of WY/Z (6 hours as total)

0 % 1

Note 3)

w

0.075 mm

I

Topr

+JO%

LSfSV3 11

Remark

Note 4)

No condensation

6 directions( * X 2 Y + z)

T

I

7

Note 3) Acceleration : 490 m/s’

Pulse width : llms

3 times for each directions of +X/t Y/+ 2

Note 4) Care should be taken so that the LCD module may not be subjected to the temperature out of this

specification

Page 10

SPEC No. MODE!., No.

PAGE

SHARP

SXlectrical Specifications

5-l.Eiectrical characteristics

PWImtXeI

Supply voltage (Logic)

Contrast adjust voltage

Note 1) Under the following conditions.;

0 Immediately after the rise of V,,

@ Under the situation that DISP signal is on and kept steady : 0.15AX 100 u S

LC983 12 LiiSV3 11

-J-abJ&

Symbol

vm-vss

Vcon -v, Ta = 0 “C--JO%

Ta = O-40 “C (Note 1)

Ta=25 “C

Condilions Min.

VDD= 3.3 Vr. 10 %

PP.

3.0 3.3

0.8 1.95

: 0.6AX 1oms

8

l/tFRM=75 Hz

Max. unit

3.6

2.8

V

V

Note 2)

Note 3)

Frame frequency = 75 Hz, Vcon - Vss =max contrast voltage

Display pattern = all digits ON (DUO-7,DLO-7 = “H”)

q uoooooooonoonnoooo~

cl0000000n00000n0000G

COUOOCOOC!OOOOOOOO@@O

q

ClECIOOOUOOClOCiOUOOClO@

Frame frequency = 75 Hz. Vcon - Vss = max contrast voltage

Display pattern = black/white

00000000000000000000

stripe

pattern

n n n n n n n n n n n n n n n n n n n n

00G00000000000000000

n n n n n n n n n n n n n n n n n n n n

Page 11

SPEC No. ,XODEL No. PAGE

SHARP

Note 4) Contrast adjust voltage “Vcon-VW is transformed into the LCD driving voltage “V,” by following

circuit built in the LCD module.

LCD driving voltage “V,,

range by the temperature compensation circuit.

Temperature compensation circuit built in LCD module have been set obtain the optimum contrast under

following driving conditions.;

Take care that voltage for optimum contrast is changed under the different conditioa

Frame frequency : 75 Hz, Duty ratio : 11244 (an odd number frame), Ta = 25 “c

XThe above is the condition of the module settin?. not the electrical characteristics.

” is adjusted automatically according to the change of ambient temperature

LC98312 LiiSV3

,

I

11

VDD

Control signal

VLCD

vcm-

9

Page 12

SPEC ?Io.

MODEL No. P.GE

SHARP

5-2.lnterface signals

OCNl

LC983 12

Table 6-l

LMSV3 11

10

OCN2

13

I4

Table 6-2

I

NC

VCOD

I I

Contrast xljustment voltage

Page 13

SPEC No.

MODEL No.

PAGE

SHARP

OCCFr

5-3.CoMectors

OLCD

OCCFT

Except

I I

Table&3

Pin No

1

2

3 HV

Used

COM6!CtOr

Correspondable connector

Used coonector

Correspondable connector

above cotmector shall be out of guaranty.

Symbol Description

GND

NC

Ground line (from Invener)

High voltage line (from Inverter)

: CNl 53X1-1510(Molex)

: CNl 51021-lSOO(Molex)

:QZ-19~3FOl(Honda Tsushin kogyo)

:QZ-lY-A3MYL#OZ(Honda Tsushin kogyo)

LC98312

NC

LMSV311

Level

CN2 53261-1410(Molex)

CN2 51021-1400(Molex)

11

Page 14

SPEC No.

MODEL No.

PAGE

SHARP

LC98312

Lw3v3 11

640 x 3 (RGB)

x 480 dots

12

-I\

(480.1) (480,2)

(480,639) (480,640)

_.--_.-_..

m Upper SEG Drcvers . Upper d.ra(DUO-7)

- Lowvsr SEF Drivers .Lowucr data(DLO-7)

Page 15

SPEC No. .MclDEl. No.

P.GE

SHARP

LC98312 LkfSV311

13

1

DL5

E

k?t

DLO

I

-fuI--L---l-rL

l

Electric.4 and optical chnr~ckrislics are spccilied by above condition.

Fk. 3 Data innut riminecharr

Page 16

SPEC No.

.MODEt. No.

PAGE

SHARP

YD At-

LP /

<

t

"IS

i+--+

l-

LC98312

t

FR"

t

H""

3

t

LIE

N

Q&

LAmv3

11

t

L""

14

XCK

DUO-7

DLO-7

<

t

LS

J t

<

t,

-4-t-, ,

LH

V,H = 0.8 v,,,

VIL = 0.2 V,D

tr

Page 17

SPEC No.

,

1

.MODEL No.

PAGE

SHARP

LC98312

Table 7 interface timine rating

IA48V3

Ta=2.5 “c,VDD=3.3 ‘.‘*lO %

11

15

‘1 When LCD module is operated by high speed of XCK(ShiIt clock), (tcr - t,,, -twcKL) /2 is maximum,

‘2 According to our experiments, frame cycle of 8.33 ms Min. or frame frequency of 120 Hz Max. will

demonstrate optimum display quality in terms of Hicker and “shadowing”. But since judgment of display

quality is subjective and display quality such as “shadowing” is pattern dependent, it is recommended

that decision of frame frequency, to which power consumption of the LCD module is proportional, be made

based on your own through testing on the LCD module with every possible patterns displayed on it

:.

X Th

e imervnls

The intervals must be 70 in s Max.

of one LP fall and nrxt must he nlwnvs the sane, and LPs must he innut continuouslv.

Page 18

SPEC No. .MODEL No. PAGE

SHARP

6. Module Driving Method

6-l. Circuit configuration

Fig.10 shows the block diagram of the module’s circuitry.

6-2. Display face configuration

The display consists of 640 X 3(R,G,B) X 480 dots as

The interface is single panel with double drive to be driven at 1/244duty ratio.

6-3. Input data and control signal

The LCD driver is 240 bits LSI, consisting of shift regisrers, latch circuits and LCD driver circuits. Input data

for each row 640 X 3 (R,G,B) will be sequentially transferred in the form of 8 bit parallel data through

shift registers from top left of the display together with clock signal (XCK).

When input of one row 640 X 3 (R,G,B) is completed, the data will be latched in the form of parallel

data corresponding to the signal electrodes by the falling edge of latch signal (LP) then, the corresponding

drive signals will be transmitted to the 640 X 3 lines of column electrodes of the LCD panel by the LCD

drive circuits.

At this time, scan start-up signal (I’D) has been transferred from the scan signal driver to the 1st TOW of scan

electrodes, and the contents of the data signals are displayed on the 1st row of the display face according to

the combinations of voltages applied to the scan and signal electrodes of the LCD. While the data of 1st row

are being displayed, the data of 2nd row arc cntercd. When data for 640 X 3 dots have beon transferred, they

will be latched by the falling edge of LP, switching the display to the 2nd row.

LC98312 LiiSV311

shown

in Fig. 2..

16

Such data input will be repeated up to the 244th row of each display segment, from upper row to lower

rows. to complete one frame of display by time sharing method.

Simultaneously the same scanning sequence occur at the lower panel.

Then data input proceeds to the next display frame.

YD generates scan signal to drive horizontal electrodes.

Since DC voltage. if applied to LCD panel, causes chemical reaction in LC materials, causing deterioration of

the materials, drive wave-form shall be inverted at ewry display frame to prevent the generation of such DC

voltage.

Control signal ,M plays such a role.

Because of the characteristics of the CMOS driver LSI. the power consumption of the display module goes up

with the

To minimize data transfer speed of XCK clock the LSI has the system of transferring 8 bit parallel data

through the 8 lines of shift registers.

Thanks to this system the power consumption of the display module is minimized.

In this circuit configuration, 8 bit display data shall input to data input pins of DUO-7 and DLO-7.

Furthermore, the display module has bus linr system for data input to minimizc the power consumption with

data input terminals of each driver LSI being activated only when relevant data input is fed.

clock

frequency of XCK.

Page 19

SPEC No. MODEL. No. PAGE

SHARP

Data input for column electrodes and chip sekc~ of

The driver LSI at the left end of the display face is first selected, and the adjacent driver LSI right next side

is selected when data of 240 dot (3OXCK) is fed. Ths process is sequentially continued until data is fed to

the driver LSI at the right end of the display face. This process is followed simultaneously both at the top

bottom column

Thus data input will be made through 8 bit bus line sequentially from the left end of the display face.

Since this display module contains no refresh RAM, it requires the above data and timing pulse inputs even for

static display.

The timing chart of input signals are shown in fig. 4 and Table 7

drivers LSI’S.

LC98312 Li’dSV3 11

driver

LSI are made as follows:

17

and

Page 20

SPEC No.

.MOL)EL N”.

I’AC E

SHARP

LC98312 LMSV3 11

1 , ,

7.0ptical Characteristics

Followittg spec are based upon the electrical measuring condirions, on which the contrast of perpendicular

direction(B x= fl y=O ’ )willbeMAX..

Ta = 25 “C, V,,= 3.3V, Vcon-V, = Vma,

Note 1) The viewing angle range is defined as shown Fig.5

18

tex

Note 2)

Note 3)

tex

-BY

-BY

Fir.5 Definition of Viewine AnpIe

Contrast ratio is defied as follows:

Co Luminance(brightness) all pixes “White” at Vmax

= Luminance@tightness) all pixes “dark ” at V~ZLX

Vmax is defied in Fig.7.

The response characleristics of photo-detector output are measured as shown in Fig.9, assuming that input

signals are applied so as to select and deselect the dot to be measured, in the optical characteristics test

method shown in Fig.8.

Page 21

I

SPEC No.

PAGE

SHARP

LC98312

19

Measuring Spot Size : @ 10 mm

B x : Angle from “normal” to viewing surface rotated about the horizontal axis

0 y :

I I

Angle from “normal” to viewing surface rotated about the vertical axis.

Fi.z.6 Optical Characteristics Test Method I

' Vcon-vss (V)

Vmax .

Fie.7 Definition of Vmax

Page 22

SPEC 30.

MODEL No.

PAGE

SHARP

(Response Measurement)

Ta = 25 “C

In dark mom

LCD Module

~, Era

,-

,’

,‘1

%

LC983 12

,’

’ ,’

LTTSV3 11

TOPCON BM7 + quartz fiber

_’

\,? ,\

L

20

(Measuring spot size : ~3 10 mm, Measuring Field : 2 ’ )

Fig. 8 Optical Characteristics Test Method II

Page 23

SPEC No. .MODEL iNo.

PAOE

SHARP

T 1

[Drive waveform]

LC983 12 LM8V3 11

11244 Duty Ratio

21

1

-Non-select

wavefom

[Responce waveform]

2-r

,

Fie.9 Definition of Resmnse time

rd

\

r r: Risetitne

7 d: Decaytime

I

/\

Page 24

SPEC No.

MODEJ. No.

PAGE

SHARP

ILO-DL7

YCK

LP

I

I

I-

Bias generator

Protection circuit

1 DISP

&

LC983 12

LII8V3 11

22

-

,

-

jEG Drivers (Upper)

i b=-

(2,640)

i

R B

m

I

r

240,l)

)

241,t) (241,640)

640 X 480 DOTS LCD PANEL

(24~,fj4_0?

T

1(460,1)

(480,640) 1

I

VSS

VDD

‘:

Converter

Vcon

CCFT

Inverter

,1..--............-.............~-.........-.--..

Temperature

Compensation

ic. 0 Circuit block diwra

I

1

I ?T M

I 1

I

I

SEG Drivers (Lower)

T

I

I

Page 25

SHARP

8.Cbaracteristics of Backlight

The ratings are given on condition that the following conditions are satisfied.

1) Rating(Note)

Parameter

Brightness

2)

Measurement circuit : CXA-LOSOS-VJL(TDK)

3) Measurement equipment :

4) Measurement conditions

4-l. Measurement circuit voltage :

4-2. LCD: All digits WHITE, VDD= 3.3 V, Vcon-VSS = Vmax, DUO-7=“H”(Wbite),DL0-7=“H”(White)

Fmme Frequency 75 Hz

4-3. Ambient temperature : 25 %

Measurement shall he executed 30 minutes after turning on.

5) Used lamp : KCA1344SH(WEST ELECTRIC Co.)

Used cable : UL3579,AWG#26

(NISSEI ELECTRIC CO.,LTD “I- SUMITOMO ELECTRIC INDUSTRIES LTD.)

5-l.

MIN.

38

BM-7 (TOPCON Corporation)

DC = 12.0 V,

LC98312

Table9

TV. MAX.

55

(at IL = 3.0 InArms)

at primary side

LMSV3 11

23

Unit

cd/m’

~a=25 “C

( 1050 VrtIls

Within no conductor closed. (CCFf “my)

*1 It is recommended that IL be not mow than 4.0 mArms so that heat radiatic

may least affect the display quality.

‘2 Power consumption excluded invertrr loss.

‘3 The circuit voltage of the invertcr should be designed to have some margin. because VS may be

increased due to the leak current in use of the LCD module.

‘4 Average life time of CCFf will be decreased when LCD is operating at lower temperature.

. ~

Ta= 0 “C ‘3

h Ta=25 “C

Ta= 0 “C ‘4

h

m of CCm backlight

Page 26

SPEC No.

MODEL No. PAGE

SHARP

5-2. Operating life

(NOTE) Rating are defied as the average brightness inside the viewing area specified in Fig.11.

LC98312 LiiSV3 11

The operating life time is 25 000 hours or more at 3.0 tn.&.

(Operating life with CXA-LOSO5-VJL or equivalent.)

The inverter should meet the following conditions to keep the specified life time of used lamp;

-Since, symmetric waveform without spike in positive and negative

-Output frequency range: 30 kHz-70 kHz

Make sure the operating conditions by executing the bum-in enough time.

The operating life time is defied as having ended when any of the following conditions occur; 25 2 1°C

-when the voltage required for initial discharge has reached 110 % of the initials value.

-When the illuntinence quantity of light has decreased to 50 % of the initials value.

ACTIVE AREA

/

24

1

120

240

360

dots

a,-

_.....

:

320 480 dots

Fie.11 Mcasurine ooints 11-5)

Page 27

SPEC x0. MODEL No.

PACE

SHARP

9.Supply voltage sequence condition

<

&

VDD

YD

LP

YCK

DATA

DISP

VDD

‘VSS”

-

LC98312

I

1500 ms MIN. (NOTE 1)

I I

Interface ttmtttg acttve operation

LM8V311

I

>

e 1s MIN

1

25

(NOTE 1)

(NOTE 2) Before DISP rise up. the signals of YD,LP,XCK,DATA must be input, and the above condition of “a”

Symbol

a 0 ms MIN.

b

c

d

Power ON/OFF cycle time. All signals and power line shall be in accordance with above sequence in

case of power ON/OFF.

must be satisfied. The signals which comply with the interface timing in Fig.3,Fig.4, and table 6, must

be input.

POWER ON

Allowable value

1sMAX.

-

50 m MIN.

100 ns MAX.

10 ms MAX.

( 10 msMIN. )

g

-

Page 28

SPEC No. .MODEL No.

1

PAGE

SHARP

lO.Applicable inspection standard

The LCD module shall meet the following inspection standard : S-U-037

ll.Lot Number

Lot number is shown at the position mentioned in Fig.13 in accordance with the following numbering rule.

Serial number(Missing number exist)

Productloo month(A=Jan.,B=Feb:“.L=Dec.)

pamp’e) L Production year

LC98312 LMSV311

26

m

r

\Model and Serial number

Page 29

SPEC No.

.MODEL No.

PACE

SHARP

12.Touch Panel Specifications

12.1. Rating

12.1.1. Maximum voltage and current: 7V 24mA

X2.1.2. Operating temperature: -10°C

12.1.3. Storage temperature: -40”C270”C(Humidity from 20% to 90%. No dew condensation)

12.2. Electrical Performance

12.2.1. Resistance between terminals:

Direction “X”(Film side) : 350-900 Q(TYP. 480 Q)

Direction “Y’(Glass side): 450-1100 Q(TYP. 630 Q)

12.2.2 Linearity

Direction “x”: 1.5% or less

Direction “Y? 1.5% or less

12.2.3.

12.2.4. Chattering: 1Omsec or less

12.3. Mechanical Performance

12.3.1. Input: finger or special stylus pen

12.32. Activation Force:

Insulation

Input with finger: 80g or less (typ.lSg)

Input with stylus: 8Og or less (typl5g)

resistance: DC 25V and 201M 51 or more

--SO”C(Humidity from 20% to 90%, No dew condensation)

LC983 12 LX8V3

11

27

12.3.3. Surface hardness: Hardness of pencil 3H or more

12.4. Optical Performance

12.4.1. Optical clarity: 77%(MIN.) 79%(TyP.)

12.5. Correspondable connector

04FFS-SP-TF(JST: SMT,Non-ZIF type) or equivalent

Page 30

IC-Ol<O. 6

B :2.5to.l3

68: 1. 5to. 5

A :2.5*0.6

AA:1.5*0.5

3) OBLIQUITY OF DISPLAY AREA

21 TOLERANCE Y-DIRECTION

\TOUCH PANEL 11 TOlERANCE X-DIRECTION

159. 4x120. 1

IUCH PANEL ACTIVE AREA

100. 67fl ( I/F mvmm tenon

Toucti PANEL IIF CABLE

I NTERFAChCiNNECTOR

CN1:53261-1510(MOLEX)

<PIN LAYOUT>

(2) CN2:53261-1410(MOLEx)

I

Loading...

Loading...