Page 1

PRELIMINARY

LM8300/LM8400/LM8500

Four Wire Resistive Touchscreen Controller with

Brownout

General Description

The LM8300/8400/8500 is a 4-wire resistive touch screen

controller. The controller samples and drives the touch

screen without the need of any external hardware. The built

in 10-bit A/D provides a maximum of 500 coordinate pairs

per second (cpps). The data sampled from the touch screen

is sent out on the UART at a speed of 38400 bps.

The controller has a power-saving mode which causes the

controller to self-power down when no touch is detected on

the touch screen for a specified amount of time. In the

Devices included in this datasheet:

Device

LM8300 3, 5 V 2.7 to 2.9 V 3.27 MHz 18

LM8400 3, 5 V No Brownout 3.27 MHz 18

LM8500 5 V 4.17V to 4.5V 3.27, 10 MHz 18

Operating

Voltage

Brownout

Voltage

Operating

Frequency

self-power down mode, the current drawn is typically less

than 2 µA. The device resumes normal operation when a

touch is detected on the touch screen or communication is

detected on the UART. In addition to the self-power down

mode, the controller can be disabled by pulling the SHUTDOWN pin low. The controller resumes normal operation

when the SHUTDOWN pin is tristated or pulled high.

The controller has an internal non-volatile memory storage

element to store configuration data such as calibration points

or controller configurations.

I/O

Pins

Packages Temperature

44 LLP, 44 PLCC,

48 TSSOP

44 LLP, 44 PLCC,

48 TSSOP

44 LLP, 44 PLCC,

48 TSSOP

LM8300/LM8400/LM8500 Four Wire Resistive Touchscreen Controller with Brownout

October 2002

0˚C to +70˚C

0˚C to +70˚C

0˚C to +70˚C

Features

KEY FEATURES

n Supports 4 wire resistive touch panels

n Low power standby current typically less than 2 µA at

5.5V

n Maximum speed of 500 coordinate pairs per second

n Automatic wake up and return to standby

n 10 bit A/D

n On-chip touch screen current drivers - no external driver

required

n UART interface

n Controller configurations are stored in the internal

non-volatile storage element

n Touch pressure can be measured

APPLICATIONS

n Personal Digital Assistants

n Smart Hand-Held Devices

n Touch Screen Monitors

n Point-of-Sales Terminals

n KIOSK

n Pagers

n Cell Phones

COP8™is a trademark of National Semiconductor Corporation.

© 2002 National Semiconductor Corporation DS200372 www.national.com

Page 2

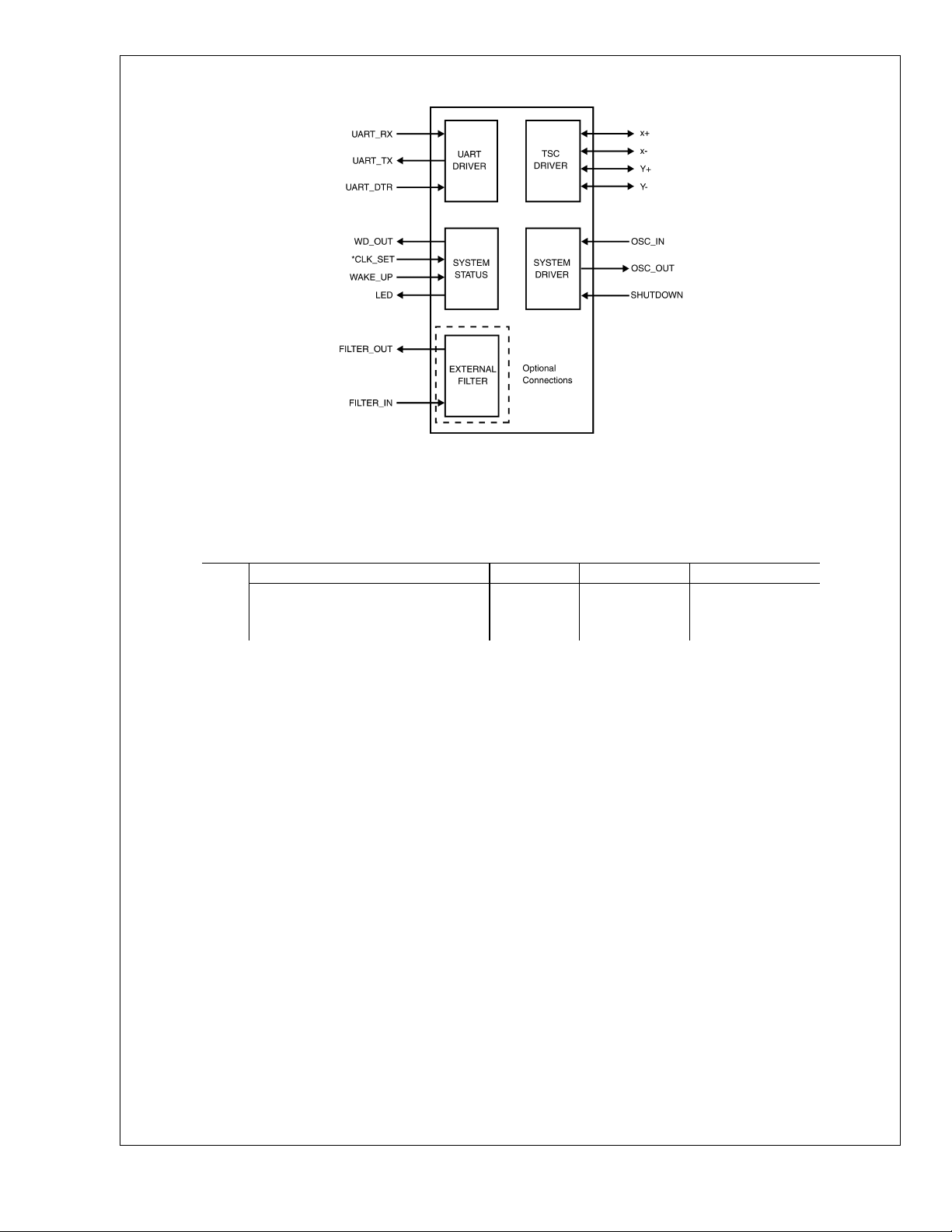

Block Diagram

LM8300/LM8400/LM8500

*

This pin is available in the LM8500. It is unused in the LM8300/LM8400.

Ordering Information

Part Numbering Scheme

LM 8300 H VA 9

Family and Feature Set Indicator No. Of Pins Package Type Temperature

8300 = Low Brownout Voltage

8400 = No Brownout

8500 = High Brownout Voltage

H=44Pin

I=48Pin

LQ = LLP

MT = TSSOP

VA = PLCC

20037201

9 = 0 to +70˚C

www.national.com 2

Page 3

Table of Contents

General Description ............................................................................................................................................ 1

Features ............................................................................................................................................................. 1

Block Diagram .................................................................................................................................................... 2

Ordering Information .......................................................................................................................................... 2

Connection Diagrams ......................................................................................................................................... 4

2.0 Pin Descriptions ........................................................................................................................................... 5

Absolute Maximum Ratings ............................................................................................................................... 7

3.0 Electrical Characteristics .............................................................................................................................. 7

4.0 Functional Description .................................................................................................................................. 8

4.1 General ...................................................................................................................................................... 8

4.2 Advanced Pin Descriptions ....................................................................................................................... 8

4.3 USART Framing Format ............................................................................................................................ 9

4.3.1. Data packet format table .................................................................................................................... 9

4.3.2 Command Bytes .................................................................................................................................. 9

4.3.3 Advanced Command Bytes Descriptions .......................................................................................... 10

5.0 Oscillator .................................................................................................................................................... 12

6.0 Power Save Mode (Low Power Stand-by) ................................................................................................ 13

7.0 Averaging Algorithm ................................................................................................................................... 13

7.1 Delta Algorithm ........................................................................................................................................ 13

7.2 Focus Algorithm ....................................................................................................................................... 13

7.3 Communication Modes ............................................................................................................................ 14

8.0 Brownout Reset .......................................................................................................................................... 14

9.0 Calibration .................................................................................................................................................. 15

9.1 General Calibration Procedures .............................................................................................................. 17

9.2 Calibration Procedures with Coordinates Checking Enabled ................................................................. 18

9.3 Calibration Procedures with Coordinates Checking Disabled ................................................................ 18

Physical Dimensions ........................................................................................................................................ 19

LM8300/LM8400/LM8500

www.national.com3

Page 4

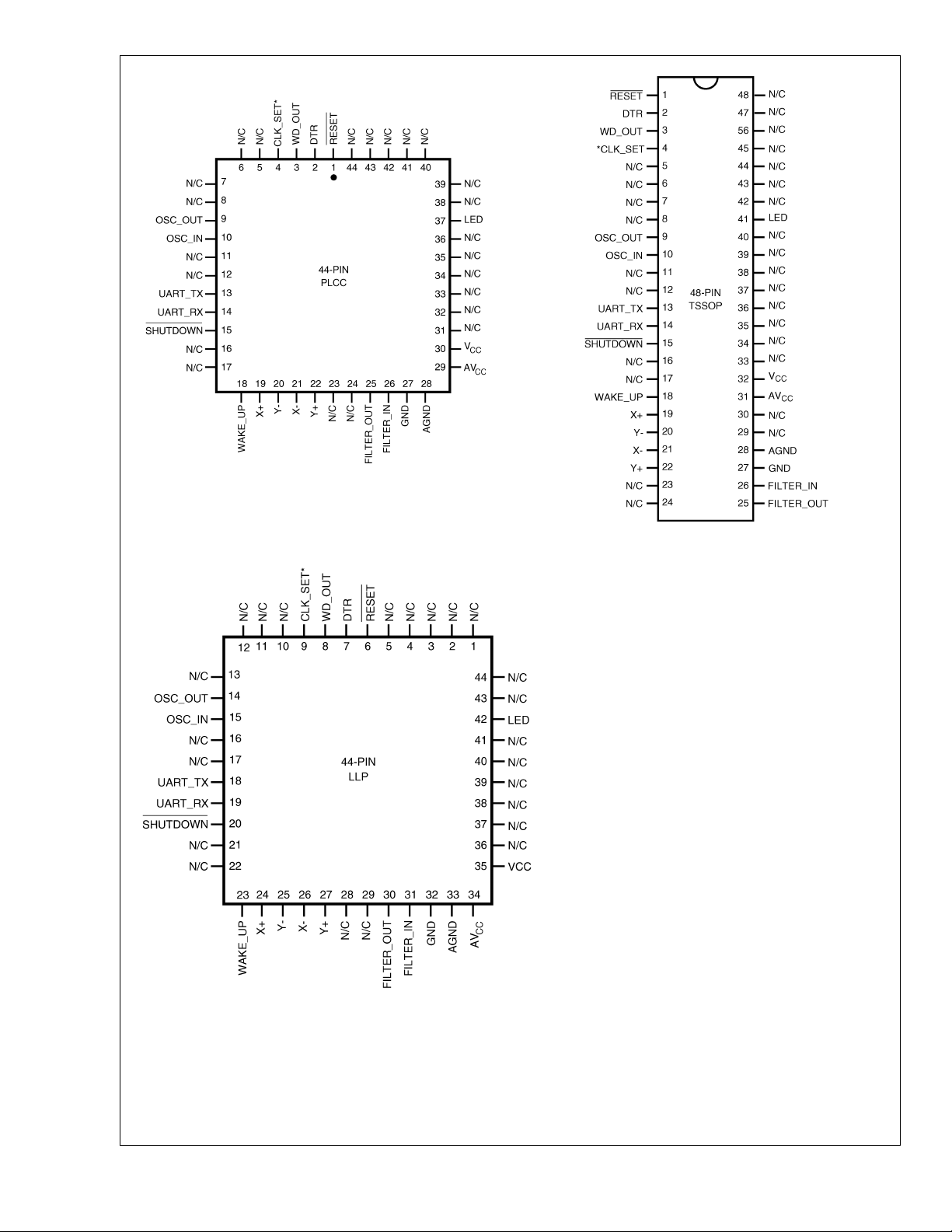

Connection Diagrams

LM8300/LM8400/LM8500

*

This pin is available in the LM8500. It is unused in the LM8300/LM8400.

20037202

Top View

Plastic Chip Package

See NS Package Number V44A

*

This pin is available in the LM8500. It is unused in the LM8300/LM8400.

20037204

Top View

TSSOP Package

See NS Package Number MTD48

*

This pin is available in the LM8500. It is unused in the LM8300/LM8400.

20037203

Top View

LLP Package

See NS Package Number LQA44A

www.national.com 4

Page 5

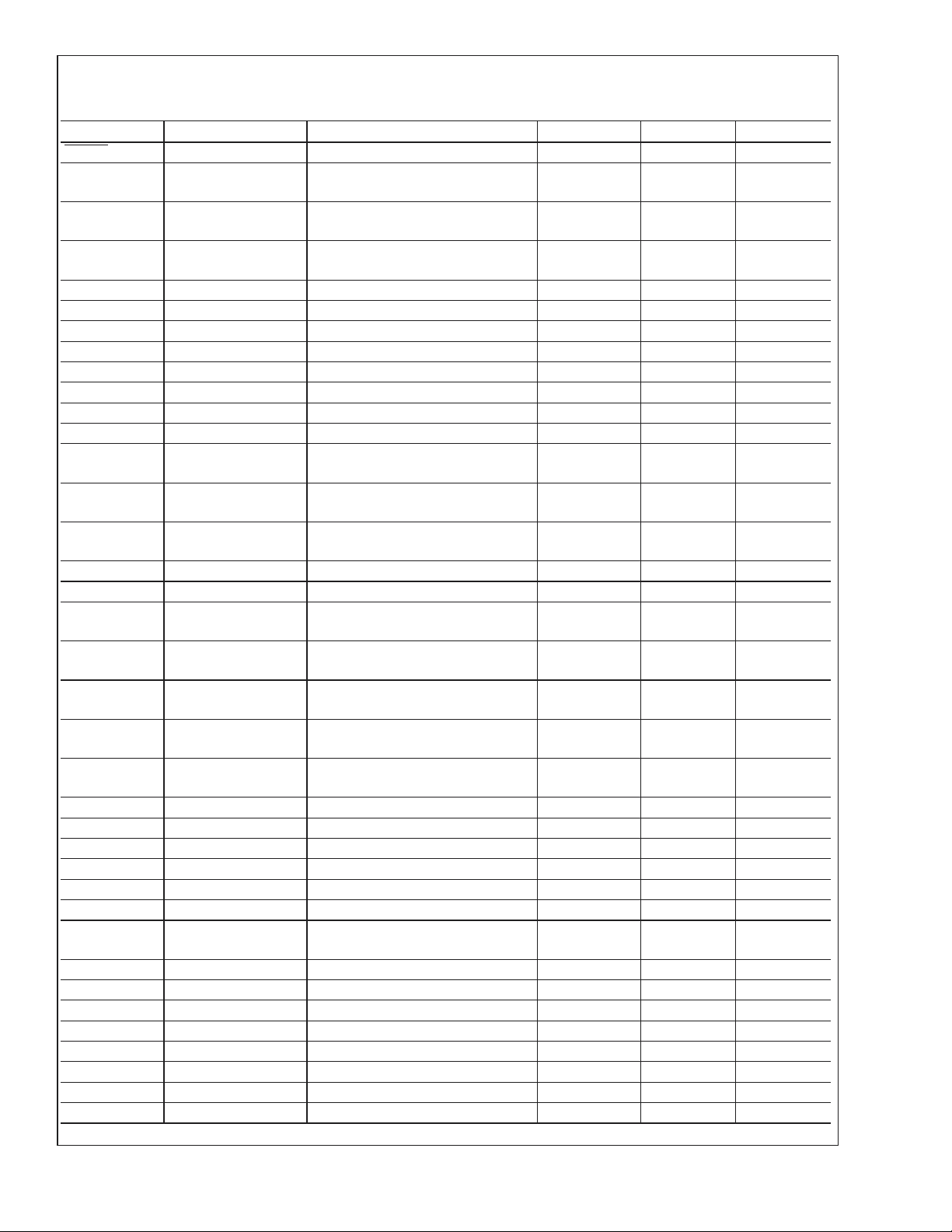

2.0 Pin Descriptions

Pinouts for 44- and 48-Pin Packages

Pin Name Direction Pin Description 44-Pin LLP 44-Pin PLCC 48-Pin TSSOP

RESET

DTR

WD_OUT

CLK_SET

Unused

Unused

Unused

Unused

1

2

2

2

2

OSC_OUT O Clock oscillator output 14 9 9

OSC_IN I Clock oscillator input 15 10 10

2

Unused

2

Unused

UART_TX O UART transmit pin (inverted for use

UART_RX I UART receive pin (inverted for use

SHUTDOWN I Shutdown pin, puts the device in halt

2

Unused

2

Unused

WAKE-UP I Used to wake up the processor from

X+ I/O Drives the X+ wire, also analog input

Y- I/O Drives the Y- wire, also analog input

X- I/O Drives the X- wire, also analog input

Y+ I/O Drives the Y+ wire, also analog input

2

Unused

2

Unused

FILTER_OUT O Analog output to the filter 30 25 25

FILTER_IN I Analog input from the filter 31 26 26

GND Digital ground 32 27 27

AGND Analog ground 33 28 28

AV

CC

V

CC

2

Unused

2

Unused

2

Unused

2

Unused

2

Unused

2

Unused

2

Unused

I Reset pin, pull low to reset 6 1 1

I

O

I

UART Data terminal ready signal, low

if not ready

Watchdog output, tie to RESET pin

for correct function

Used to set if crystal is 3.3 MHz (low)

or 10 MHz (floating or pulled high)

722

833

944

10 5 5

11 6 6

12 7 7

13 8 8

16 11 11

17 12 12

18 13 13

with standard RS-232 drivers)

19 14 14

with standard RS-232 drivers

20 15 15

mode if pulled low

21 16 16

22 17 17

23 18 18

halt mode with touch on touch screen

24 19 19

when sampling

25 20 20

when sampling

26 21 21

when sampling

27 22 22

when sampling

28 23 23

29 24 24

Analog power supply, connect to filter

34 29 31

for best performance

Digital power supply 35 30 32

XX33

XX34

36 31 35

37 32 36

38 33 37

39 34 38

40 35 39

LM8300/LM8400/LM8500

www.national.com5

Page 6

2.0 Pin Descriptions (Continued)

Pinouts for 44- and 48-Pin Packages (Continued)

Pin Name Direction Pin Description 44-Pin LLP 44-Pin PLCC 48-Pin TSSOP

2

Unused

LED Output Optional LED output, low when

running, high in halt-mode

2

Unused

2

Unused

LM8300/LM8400/LM8500

2

Unused

Note 1: This is available in the LM8500 only.

Note 2: These pins are for future functional expansions.

41 36 40

42 37 41

34246

44347

54448

www.national.com 6

Page 7

LM8300/LM8400/LM8500

Absolute Maximum Ratings (Note 3)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage (V

Voltage at Any Pin −0.3V to V

Total Current into V

)7V

CC

+0.3V

CC

Pin (Source) 200 mA

CC

Total Current out of GND Pin (Sink) 200 mA

Storage Temperature Range −65˚C to +140˚C

ESD Protection Level 2 kV (Human Body

Model)

Note 3: Absolute maximum ratings indicate limits beyond which damage to

the device may occur. DC and AC electrical specifications are not ensured

when operating the device at absolute maximum ratings.

3.0 Electrical Characteristics

TABLE 1. DC Electrical Characteristics (0˚C ≤ TA≤ +70˚C)

Datasheet min/max specification limits are guaranteed by design, test, or statistical analysis.

Parameter Conditions Min Typ Max Units

Operating Voltage 2.7 5.5 V

Power Supply Rise Time 10 50 x 10

Power Supply Ripple (Note 4) Peak-to-Peak 0.1 V

Supply Current (Note 5)

High Speed Mode

CKI = 10 MHz V

CKI = 3.33 MHz V

= 5.5V 11.5 mA

CC

= 4.5V 5 mA

CC

HALT Current with BOR Disabled (Note 6)

High Speed Mode V

Supply Current for BOR Feature V

= 5.5V, CKI=0MHz

CC

= 5.5V 45 µA

CC

<

210µA

High Brownout Trip Level (BOR Enabled) 4.17 4.28 4.5 V

Low Brownout Trip Level (BOR Enabled) 2.7 2.78 2.9 V

Input Levels (V

Logic High 0.8 V

IH,VIL

)

CC

Logic Low 0.16 V

Internal Bias Resistor for the CKI

Crystal/Resonator Oscillator

Hi-Z Input Leakage V

Input Pullup Current V

= 5.5V −0.5 +0.5 µA

CC

= 5.5V, VIN= 0V −50 −210 µA

CC

Port Input Hysteresis 0.25 V

0.3 1.0 2.5 MΩ

CC

Output Current Levels

Outputs X+, X-, Y+, Y-

Source (Note 7) V

Sink (Note 7) V

= 4.5V, VOH= 4.2V −10 mA

CC

V

= 2.7V, VOH= 2.4V −6 mA

CC

= 4.5V, VOL= 0.3V 10 mA

CC

V

= 2.7V, VOL= 0.3V 6 mA

CC

Allowable Sink and Source Current per Pin 20 mA

All Others

Source (Weak Pull-Up Mode) V

Source (Push-Pull Mode) V

Sink (Push-Pull Mode) (Note 7) V

= 4.5V, VOH= 3.8V −10 µA

CC

V

= 2.7V, VOH= 1.8V −5 µA

CC

= 4.5V, VOH= 3.8V −7 mA

CC

V

= 2.7V, VOH= 1.8V −4 mA

CC

= 4.5V, VOL= 1.0V 10 mA

CC

V

= 2.7V, VOL= 0.4V 3.5 mA

CC

Allowable Sink and Source Current per Pin 15 mA

TRI-STATE Leakage V

= 5.5V −0.5 +0.5 µA

CC

Maximum Input Current without Latchup

RAM Retention Voltage, V

(in HALT Mode) 2.0 V

R

Input Capacitance 7pF

6

CC

CC

±

200 mA

ns

V

V

V

V

www.national.com7

Page 8

Note 4: Maximum rate of voltage change must be<0.5 V/ms.

Note 5: Supply and IDLE currents are measured with CKI driven with a

square wave Oscillator, CKO driven 180˚ out of phase with CKI, inputs

connected to V

and outputs driven low but not connected to a load.

CC

Note 6: The HALT mode will stop CKI from oscillating. Measurement of I

HALT is done with device neither sourcing nor sinking current; all inputs tied

to V

; A/D converter and clock monitor and BOR disabled.

CC

Note 7: Absolute Maximum Ratings should not be exceeded.

DD

A/D Converter Electrical Characteristics (0˚C ≤ TA≤ +70˚C) (Single-ended mode only)

Datasheet min/max specification limits are guaranteed by design, test, or statistical analysis.

Parameter Conditions Min Typ Max Units

Resolution 10 Bits

DNL V

LM8300/LM8400/LM8500

DNL V

INL V

INL V

Offset Error V

Offset Error V

Gain Error V

Gain Error V

Input Voltage Range 2.7V ≤ V

CC

CC

CC

CC

CC

CC

CC

CC

=5V

=3V

=5V

=3V

=5V

=3V

=5V

=3V

<

5.5V 0 V

CC

±

1 LSB

±

1 LSB

±

2 LSB

±

4 LSB

±

1.5 LSB

±

2.5 LSB

±

1.5 LSB

±

2.5 LSB

CC

V

Analog Input Leakage Current 0.5 µA

Analog Input Resistance (Note 8) 6k Ω

Analog Input Capacitance 7pF

Operating Current on AV

Note 8: Resistance between the device input and the internal sample and hold capacitance.

CC

AVCC= 5.5V 0.2 0.6 mA

4.0 Functional Description

4.1 General

The LM8300/8400/8500 is a 4-wire resistive touch screen

controller. The primary communication is through the built in

UART operating at a baud rate of 38400. The LM8300/8400/

8500 has the ability to measure pressure on the Z-axis, in

addition to the X-Y coordinates.

The device has the capability to do a 2, 5, and 13 point

calibration. All calibration data is stored in the internal nonvolatile storage element. In addition, all settings pertaining to

the controller are stored internally. This feature negates the

need for external EEPROM.

The device has three built in averaging algorithms: oversampling, delta, and focus. These algorithms help to minimize

noise and A/D variation due to noise. Refer to the averaging

algorithm for a more detail explanation. These algorithms are

implemented on-chip, freeing the main processor from these

tasks. To further minimize noise in extremely noisy environments, the device has the ability to route the signal from the

touch panel to an external filtering stage before A/D conversions are performed.

To minimize power consumption, the device can be put into

power save mode. The device can be set to go into power

save mode automatically or manually by pulling the external

shutdown pin low.

4.2 Advanced Pin Descriptions CLK_SET — This pin is the selection pin used to determine

the operating frequency of the controller. On power up, the

controller polls this pin to determine if the operating frequency is set to 10 MHz or 3.3 MHz. If the pin is left floating

or tied high, then the operating frequency is 10 MHz. If the

pin is tied low, then the operating frequency is set to 3.3

MHz.

Note: This is available on the LM8500 only.

SHUTDOWN — This is the external shut down pin. When

pulled low, the controller goes into power saving mode. This

selection pin state has higher priority than the internal power

save mode settings.

WAKE_UP — This pin is used to wake the controller from

power save mode. When the device is in power save mode,

the pin must be tied to one of X-Y lines coming from the

touch screen panel.

X+ — Connect to X+ terminal of the resistive screen.

X- — Connect to X- terminal of the resistive screen.

Y+ — Connect to Y+ terminal of the resistive screen.

Y- — Connect to Y- terminal of the resistive screen.

Filter_out — Analog output to external filter. The use of the

external filter is controlled by sending a command byte of

$A0 on the UART to the controller.

Filter_in — Analog input from external filter. The use of the

external filter is controlled by sending a command byte of

$A0 on the UART to the controller.

LED — Optional LED output. When the controller is operating in normal (non power save) mode, a low is output to the

pin. When the controller is in power save mode, a high is

output to the pin.

RESET — Reset pin. When pulled low, a manual reset is

executed. For normal operation, this pin must be pulled high.

Under no circumstances should the pin be left floating.

Note: For the LM8400, an external reset must be used as outlined in the

Brownout Reset section.

TTL_TX — UART transmit pin. The signal is inverted for use

with standard RS-232 drivers.

TTL_RX — UART receive pin. The signal is inverted for use

with standard RS-232 drivers.

DTR — Data Terminal Ready signal for the UART. If a low

level is detected on the pin, this signals that the UART is not

ready. If a high level is detected on the pin, this signals that

the UART is ready.

www.national.com 8

Page 9

4.0 Functional Description (Continued)

WD_Out — Watch dog output. For correct operation, this

pin should be connected to the RESET pin.

OSC_OUT — Clock oscillator output pin.

OSC_IN — Clock oscillator input pin

GND — Digital Ground

AGND — Analog ground

— Digital power supply.

DV

CC

— Analog power supply. For best performance, this

AV

CC

pin should be connected to a filter.

Users of the LLP package are cautioned to be aware that the

central metal area and the pin 1 index mark on the bottom of

the package may be connected to GND. See figure below:

20037216

FIGURE 1. LLP Package Bottom View

4.3 USART Framing Format

The device communicates with the touch screen driver using

the UART set at a baud rate of 38400, 8, n, 1.

All communication from the host software and the controller

consists of a command byte and occasionally data byte(s). If

data byte(s) follow a command byte, it must be sent directly

after the command byte. If the device is in the power save

mode, a delay must be inserted between the wake up command and the command byte. Refer to the Power Save

mode section for more details. For every command byte sent

to the controller, an acknowledge byte is sent back and

sometimes data byte(s).

A command byte is distinguished by having the 7th bit of the

command byte set (1). If any data byte(s) is to follow, the 7th

bit of the data byte is reset (0).

Data packets sent to the host software can be either four or

five bytes in length. If the pressure measurement is enabled,

five bytes are sent. If the pressure measurement is not

enabled, four bytes are sent.

The first byte of each data packet is a header byte. This

header byte is used to synchronize and differentiate between

four or five byte packages. If a four byte data package is

sent, the 4th bit of the header byte is reset (0). If a five byte

data package is sent, the 4th bit of the header byte is set (1).

The 6th bit of the second byte of the data packet is used to

indicate the touch state. If the bit is set (1), then a touchdown

or continuous touch is detected. If the bit is reset (0), then a

liftoff is detected.

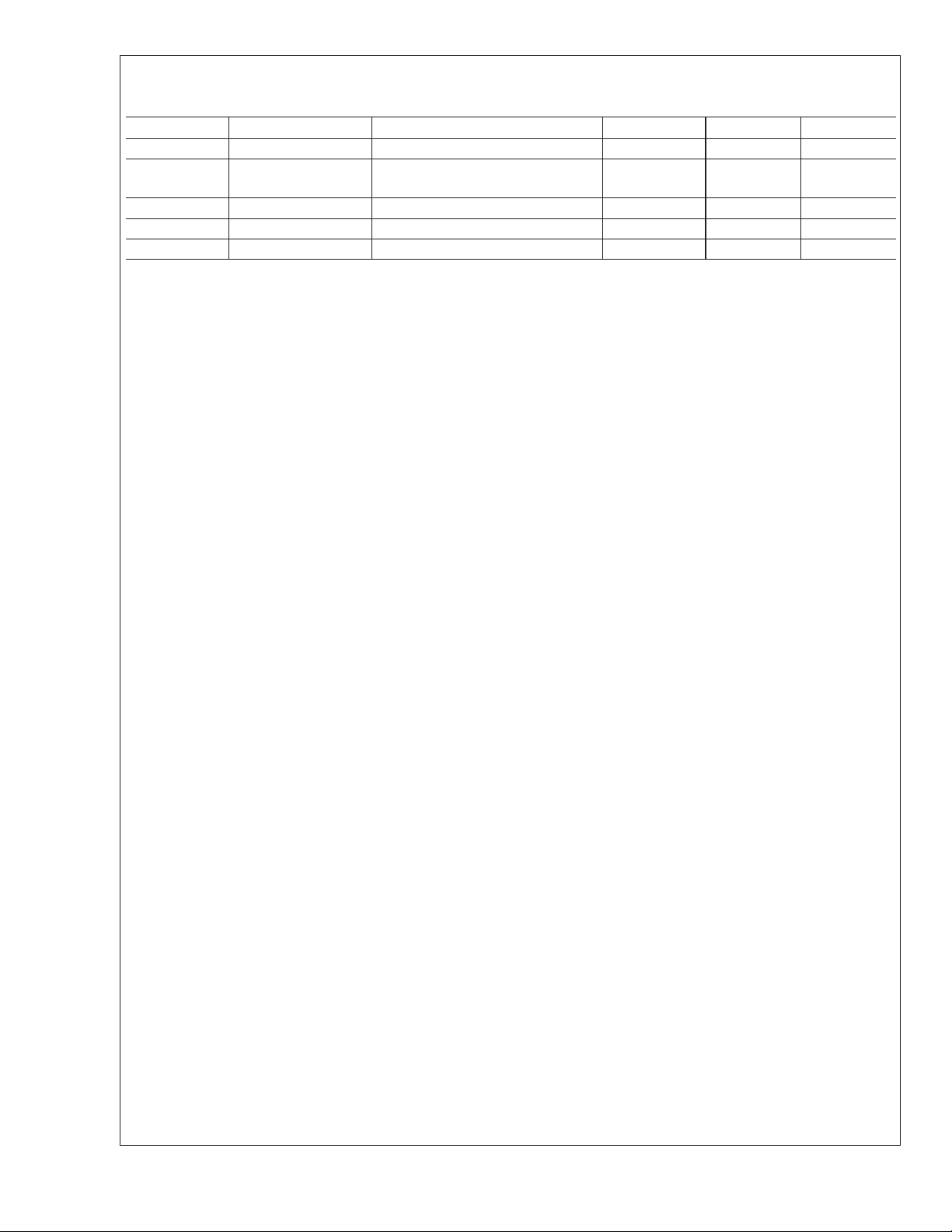

4.3.1. Data packet format table

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 1 1 0 0 L 0 0 0 0

Byte 2 0 S X

Byte 3 0 X9X8X7X6X5X4X

Byte 4 0 Y9Y8Y7Y6Y5Y4Y

Byte 5 0 Z6Z5Z4Z3Z2Z1Z

X1X0Y2Y1Y

2

0

3

3

0

L - Package length. (0 = 4 bytes,1=5bytes)

S - Touch state (0 = liftoff, 1 = touchdown or continuous

touch)

- X position (10 bit value)

X

X

- Y position (10 bit value)

Y

Y

- Z positon (7 bit value), this byte is only transmitted if the

Z

Z

pressure measurement is enabled

4.3.2 Command Bytes

PC

CommandPCByte 1PCByte 2

Read

$B0 $CA $00, $01

TSC

Byte 1

TSC

Byte 2

clock-speed

(3,33MHz,

10MHz)

Read

parameters

$B1 $CA 4.3.3

Advanced

Command

Bytes

Descriptions

Read

software

version

number

$B2 $C7 4.3.3

Advanced

Command

Bytes

Descriptions

Read # of

calibration

$B3 $CA $00, $02,

$05, $0D

points

Read stored

calibration

points

$B4 $CA 4.3.3

Advanced

Command

Bytes

Descriptions

$

Set focus

$B8 $0-$3F $CA

00-$3F

value (# of

pixels on

touch panel)

Set#of

samples per

coordinate (1,

$BA $01, $02,

$04, $08,

$10, $20

$CA $01, $02,

$04, $08,

$10, $20

2, 4, 8, 16,

32)

Set

communication

$BB $01, $02,

$04

$CA $01, $02,

$04

mode

(stream,

touchdown,

liftoff)

LM8300/LM8400/LM8500

www.national.com9

Page 10

4.0 Functional Description (Continued)

PC

CommandPCByte 1PCByte 2

Set max delta

(# of pixels

from

predicted

coordinate)

LM8300/LM8400/LM8500

Set calibration

points

Set minimum

pressure

Toggle

disable/enable

external filter

path

Toggle

disable/enable

self

power-down

Toggle

disable/enable

echo mode

Toggle

disable/enable

pressure

measurements

Toggle

disable/enable

calibration

coordinate

check

Wakeup $A7

Shutdown $A8 $CA

Soft reset $AF $CA $CB, $CC

TSC Replies

Timeout $CF

Re-send $CE

Self test failed $CC

Self test ok $CB

Acknowledge $CA

Calibration

coordinates

ok

Error / buffer

overrun

Software

version

Data transmit $80/$90 Payload

$BC $00-$3F $CA $00-$3F

$BD 4.3.3

Advanced

Command

Bytes

Descriptions

$BE $00-$7F $CA $00-$7F

$A0 $CA $00, $01

$A2 $CA $00, $01

$A3 $CA $00, $01

$A4 $CA $00, $01

$

A5 $CA $00, $01

TSC

Byte 1

$CA 4.3.3

$C4

$C8

$C7 $0-$7F

TSC

Byte 2

Advanced

Command

Bytes

Descriptions

(3/4 bytes)

4.3.3 Advanced Command Bytes Descriptions

Unless otherwise mentioned, all values are in hex.

$B0: Read clock-speed

Reply Byte #1: $CA (Acknowledge)

Byte #2: Clock readout (0 = 3.3MHz, 1 = 10MHz)

CLK_SEL pin tells the firmware which oscillator speed is

used. If the CLK_SEL input pin is floating or pulled high a

10.0MHz oscillator must be connected. If the pin is pulled

low a 3.3MHz oscillator must be connected. This command

enables the driver software to determine which oscillator

speed is used with the touch screen controller, as this determines the maximum coordinate pair per second data rates.

Note: This is available in the LM8500 only.

$B1: Read parameters

Reply Byte #1: $CA (Acknowledge)

Reply Byte #2: First byte in software version number,

year 20 (00-99)

Reply Byte #3: Communication mode (1 = stream, 2 =

touchdown, 4 = liftoff)

Byte #4: Wakeup on touch (0 = disabled, 1 = enabled)

Reply Byte #5: Number of samples (1,2, 4, 8, 16 or

32)

Byte #6: Clock readout (0 = 3.3MHz, 1 = 10MHz)

Byte #7: Second byte in software version number,

month (1-12)

Byte #8: Third byte in software version number, day

(1-31)

Byte #9: Focus value (0-63)

Byte #10: Max delta (0-63)

Byte #11: Number of calibration coordinates (0, 2, 5 or

13)

Byte #12: Toggle-flags:

Bit #5: calibration coordinates check (0=disabled,

1=enabled)

Bit #4: Pressure measurement (0=disabled,

1=enabled)

Bit #3: Echo mode (0=disabled, 1=enabled)

Bit #2: Self Power-Down mode (0=disabled,

1=enabled)

Bit #1: Unused

Bit #0: External filter path (0=disabled, 1=enabled)

Byte #13: Pressure threshold for valid touch

This command allows the user to read all the selected parameters. It is primary intended to aid in debugging. This

command can also be used if a configuration utility needs to

determine the current setting of controller.

www.national.com 10

Page 11

4.0 Functional Description (Continued)

$B2: Read software version number

Reply Byte #1: $C7 (Software version number)

Byte #2: First byte in version number, year 20 (00-99)

Byte #3: Second byte in version number, month (1-12)

Byte #4: Third byte in version number, day (1-31)

$B3: Read # of calibration points

Reply Byte #1: $CA (Acknowledge)

$

Byte #2: (

$

05 — 5 points or$0D — 13 points)

$B4: Read stored calibration points

Reply Byte #1: $CA (Acknowledge)

Byte #2: (

$

05 — 5 points or$0D — 13 points)

Byte #3: X-max (2 MSB for coordinate 1)

Byte #4: X-min (8 LSB for coordinate 1)

Byte #5: Y-max (2 MSB for coordinate 1)

Byte #6: Y-min (8 LSB for coordinate 1)

Continue until all coordinates have been sent. A zero is send

back if calibration has not been performed and there are no

data bytes.

$B8: Set focus value

Byte #2: Focus value (0-63)

Reply Byte #1: $CA (Acknowledge)

Byte #2: Focus value (0-63)

The set focus command allows the setting of different values

to improve touch screen focusing. Focusing is defined as the

ability of the touch screen controller to detect exactly identical coordinate values from measurement to measurement if

the pointer on the touch screen has not moved. The focus

values are equivalent to pixels of touch screen resolution. If

for example a value of 2 is selected, this means that every

coordinate value that is within two pixels of the previously

measured coordinate value is considered to be identical to

that previous value and that in this case the touch screen

controller transmits the previous coordinate information. This

keeps the mouse pointer steady at the point being touched,

rather than "jumping around" the point. A Focus value of zero

disables the focusing algorithm. The default setting is 4.

$BA: Set number of samples per coordinate

Byte #2: Number of samples per coordinate ($01 - 1

samples/coordinate, $02 - 2 samples/coordinate, $04

- 4 samples/coordinate, $08 - 8 samples/coordinate,

$10 - 16 samples/coordinate, $20 - 32

samples/coordinate)

Reply Byte #1: $CA (Acknowledge)

Byte #2: Number of samples per coordinate ($01 - 1

samples/coordinate, $02 - 2 samples/coordinate, $04

- 4 samples/coordinate, $08 - 8 samples/coordinate,

$10 - 16 samples/coordinate, $20 - 32

samples/coordinate)

This command allows the selection of different sample numbers per X, Y, and Z coordinates. The higher the number of

samples per X, Y, and Z coordinates, the better the accuracy,

but the lower the coordinates per second data rate. The

default setting is 8.

$BB: Set communication mode

Byte #2: Communication mode (

touchdown,

00 — no calibration done,$02 — 2 points,

$

00 — no calibration done,$02 — 2 points,

$

$

04 = liftoff)

01 = stream,$02 =

Reply Byte #1: $CA (Acknowledge)

Byte #2: Communication mode (

$

touchdown,

04 = liftoff)

$

01 = stream,$02 =

See the communication modes section for a description of

the stream, touchdown and liftoff modes. This command

selects the communication mode. The default setting is

stream mode.

$BC: Set max delta

Byte #2: Max delta value (0-63)

Reply Byte #1: $CA (Acknowledge)

Byte #2: Max delta value (0-63)

See the averaging algorithms section for a detailed description of this setting. Simply put, this command sets how much

the "coordinate velocity" can change from one coordinate to

the next. The default setting is 8.

$BD: Set calibration points

Byte #2: High nibble: Number of calibration points

$

01 = two,$02 = five,$04 = thirteen)

(

Low nibble: Active calibration cross (1-13 = cross #)

Reply Byte #1: $CA (Acknowledge)

Byte #2: High nibble: Number of calibration points

$

01=two,$02=five,$04=thirtheen)

(

Low nibble: Active calibration cross # (1-13)

Refer to the calibration section for details.

$BE: Set minimum pressure

Byte #2: Minimum pressure value (0-127)

Reply Byte #1: $CA (Acknowledge)

Byte #2: Minimum pressure value (0-127)

This setting controls how high the pressure (Z-axis) must be

in order for samples to be accepted. Setting this value too

low may result in having faulty coordinates accepted. This

value is internally multiplied by two in the controller (due to

the 7-bit limitation in the communication format, which can

not send 8-bit values larger than 127 in one byte). The

default setting is 40.

$A0: Toggle disable/enable external filter path

Reply Byte #1: $CA (Acknowledge)

Byte #2: (0 = now disabled, 1 = now enabled)

This command enable/disable external filter path. The external filter path enabled option will require the addition of a

single external low pass filter (either R/C or active OpAmp

based), which is then applied to the touch screen signal

lines. This option can be used in high noise environments to

significantly improve performance and accuracy of the touch

screen controller.

The default setting is filter path enabled.

$A2: Toggle disable/enable self-power down

Reply Byte #1: $CA (Acknowledge)

Byte #2: (0 = now disabled, 1 = now enabled)

This command can switch between self-power down mode

enable or disabled. Refer to the Power Save Mode section

for details. The default setting is Self-Power Down mode

enabled. If the echo mode is enabled, any command byte

send to the device will be echo back and executed.

$A3: Toggle disable/enable echo mode

Reply Byte #1: $CA (Acknowledge)

Byte #2: (0 = now disabled, 1 = now enabled)

The echo mode is available for debugging purposes. If enabled, the touch screen controller will echo back any data

that is received via the UART interface.

LM8300/LM8400/LM8500

www.national.com11

Page 12

4.0 Functional Description (Continued)

The default setting is Echo mode disabled.

$A4: Toggle disable/enable pressure measurement

Reply Byte #1: $CA (Acknowledge)

Byte #2: (0 = now disabled, 1 = now enabled)

The pressure measurement sets the touch screen to also

sample the Z-axis when reading the X and Y coordinates.

The default setting is pressure measurement enabled.

LM8300/LM8400/LM8500

$A7: Wakeup

There is no reply byte to this command.

When the self-power down mode of the device is enabled,

the touch screen driver must send a wakeup command prior

to any command byte(s). If the self-power down mode of the

TSC is enabled. The wakeup command must also to be sent

if the driver puts the TSC in power-down mode via the

shutdown command.

$A8: Shutdown

Reply Byte #1: $CA (Acknowledge)

When the TSC driver wants the controller to go into power

save mode it sends a shutdown command to the controller.

The driver needs to send a wakeup to the controller before

starting up the communication again.

With the TSC has the self-power-down mode enabled, then

a touchdown on the touch screen will wake-up the TSC from

shutdown mode in addition to sending the wake up command. If the self-power-down mode is disabled, then only the

wakeup command can wake-up the controller from shutdown mode (i.e. wake-up on touchdown is disabled).

$AF: Soft reset (restart the controller)

Reply Byte #1: $CA (Acknowledge)

Byte #2: $CB/$CC (Self test OK/Self test fail)

When the PC driver sends the soft reset command, the

touch screen controller executes a soft reset, which clears

and re-initializes all internal RAM configuration registers

from on-chip FLASH and performs a self-check of internal

RAM and program memory.

CONTROLLER REPLIES

$CF: Timeout.

Communication timeout has occurred, and current command

has been aborted.

$CE: Re-send

Request the TSC driver to resend the last command. This

command is used if the controller does not understand the

received command or a buffer overrun condition occurs.

$CC: Self test fail (done at startup, reset, and after

calibration)

$CB: Self test OK (done at startup, reset, and after

calibration)

$CA: Acknowledge

$C4: Calibration coordinates OK

This is sent if the coordinates are within the predefined

value.

$C8: Error / TX Buffer overrun

This is added to the last place in transmit buffer to signal that

a buffer overrun has occurred.

$C7: Software Version number

Byte #2: High part of version number (0-127)

Byte #3: Low part of version number (0-127)

$80: Format tablet for Z-axis disabled (see Format Table

section for more info.)

Byte #2: Status, low X and low Y

Byte #3: High X

Byte #4: High Y

$90: Format tablet for Z-axis enabled (see Format Table

section for more info.)

Byte #2: Status, low X and low Y

Byte #3: High X

Byte #4: High Y

Byte #5: Z-axis (0-127)

5.0 Oscillator

OSC_IN is the clock input while OSC_OUT is the clock

generator output to the crystal. Table 2 shows the compo-

nent values required for various standard crystal values.

Figure 2 shows the crystal oscillator connection diagram.

20037215

FIGURE 2. Crystal Oscillator

TABLE 2. Crystal Oscillator Configuration,

= 25˚C, VCC=5V

T

A

C1 (pF) C2 (pF)

18 18 10

18–36 18–36 3.27

The crystal and other oscillator components should be

placed in close proximity to the OSC_IN and OSC_OUT pins

to minimize printed circuit trace length.

The values for the external capacitors should be chosen to

obtain the manufacturer’s specified load capacitance for the

crystal when combined with the parasitic capacitance of the

trace, socket, and package (which can vary from 0 to 8 pF).

The guideline in choosing these capacitors is:

Manufacturer’s specified load cap = (C

C

parasitic

C2can be trimmed to obtain the desired frequency. C

should be less than or equal to C1.

CKI Freq.

(MHz)

1*C2

)/(C1+C2)+

2

www.national.com 12

Page 13

LM8300/LM8400/LM8500

6.0 Power Save Mode (Low Power Stand-by)

The power consumption of the controller can be minimized

by enabling the low power stand by mode. The power save

mode can be controlled internally by sending a command of

$A2 to the controller, externally by pulling the SHUTDOWN

pin low, or by issuing a driver shutdown command of $A8.

The self power down mode is enabled/disabled by sending a

command of $A2 to the controller. When enabled, the controller automatically goes into low power stand by if no more

touch activity is detected or if there is no UART communication. The controller automatically comes out of low power

stand by mode when a touch is detected on the touch panel

or if an incoming communication on the UART is detected. In

the low power stand by mode, all activity is disabled, including the oscillator. Also, the LED pin is driven high. To wake

up the controller on the UART, the wake up command byte

must be sent, followed by a minimum time delay of 1ms for

the LM8500 and 3ms for the LM8300/8400 before sending

any command byte. The delay time is needed to allow the

oscillator to restart and stabilize. Table 3 shows the average

startup time for a given operating frequency.

The SHUTDOWN pin will shut down the controller when

pulled low. When the SHUTDOWN pin is pulled low, the

controller will continue to be in the low power stand by mode

until the pin is pulled high or released. While the SHUTDOWN pin is pulled low, all activities are stopped and any

touch or communication will be ignored. Immediately following the SHUTDOWN pin being released or pulled high, the

controller clears the UART transmit and receive buffers and

resumes normal operation.

The controller can be put in the low power stand by mode by

sending a $A8 command to it. Upon receiving this command,

the controller goes into low power stand by mode. If the self

power down mode is enabled and the controller is put into

low power stand by mode, the controller will wake up if the

wake up command ($A7) is received or if a touch is detected

on the touch panel. If the self power down mode is disabled

and the controller is put into low power stand by mode, the

controller can only be woken up if it receives the wakeup

command. After the controller wakes up, the UART transmit

and receive buffers are cleared and resume normal operation.

Samples per coordinate vs. CPPS for LM8300/8400

Samples

per coordinate

1 250

2 220

4 190

8 150

16 100

32 65

Samples per coordinate vs. CPPS for LM8500

Samples

per coordinate

1 500

2 430

4 360

8 270

16 190

32 110

7.1 Delta Algorithm

The delta filter is used to remove large variations in sampled

values due to noise and glitches. The delta filter tries to

predict where the next coordinate could be. This is done by

taking the two previous coordinates and subtracting one

from the other, producing a delta value. This delta value is

then added or subtracted to the last coordinate. The resulting value is the predicted coordinate. If the new sampled

coordinate is close to this predicted value, then the new

value is accepted as valid and is passed to the focus algorithm, provided the focus algorithm is enabled. If the new

sampled coordinate is not close to the predicted coordinate,

then the value is discarded and is stored to be used in the

following delta calculations.

The number by which the new sampled coordinate can differ

from the predicted coordinate is controlled by setting the Set

Max Delta value. The Set Max Delta value can be from a

value of 0-63. The factory default is 8.

Coordinate pairs

per second (CPPS)

Coordinate pairs

per second (CPPS)

TABLE 3. Startup Times

CKI Frequency Startup Time

10 MHz 1–10 ms

3.33 MHz 3–10 ms

7.0 Averaging Algorithm

To achieve better accuracy and noise filtering, each X, Y, and

Z coordinate is oversampled by specific amount. The possible oversampling settings are 1, 2, 4, 8, 16, and 32. The

factory setting is 8. The greater the oversampling, the

greater the accuracy, but the lower the CPPS.

7.2 Focus Algorithm

The focus algorithm removes some inaccuracy and noise

that could cause the coordinate to differ only by a couple of

pixels. The focus algorithm is used to eliminate the "jittering"

effect of the pointer when the pointer is stationary.

The focus algorithm compares the value of the previous

stored value to the value passed from the delta algorithm

and determines if the difference is greater than or equal to

the Set Focus Value. If the difference is greater or equal to

the value in Set Focus Value then the new coordinate is sent

out through the UART and stored as the previous value. If

the difference is less than the Set Focus Value then the

value is discarded and the stored valued is set through the

UART.

The amount of difference between the new coordinate and

the old coordinate is set in the Set Focus Value. This value

can be from 0-63 with a value of 0 disabling the focus

algorithm. The factory default is 4.

www.national.com13

Page 14

7.0 Averaging Algorithm (Continued)

7.3 Communication Modes Liftoff

When set to the liftoff mode, the controller only sends data

through the UART on liftoff. The controller continuously

samples the touchscreen as long as there is a touch detected on the touchscreen but only the last coordinate is sent

out to the UART.

Touchdown

LM8300/LM8400/LM8500

When set to the touchdown mode, the controller only sends

data through the UART on touchdown. The controller continuously samples the touchscreen as long as there is a

touch detected on the touchscreen but only the first coordinate is sent out to the UART.

Streaming

When set to the streaming mode, the controller continuously

sends data through the UART as long as there is a touch

detected on the touchscreen.

8.0 Brownout Reset

The device is initialized when the RESET pin is pulled low or

the On-chip Brownout Reset is activated. The Brownout

Reset feature is not available on the LM8400.

The RESET input initializes the device when pulled low. The

RESET pin must be held low for a minimum of 0.5µs for the

LM8500 and a minimum of 1.5µs for the LM8300/8400 to

guarantee a valid reset. During Power-Up initialization, the

user must ensure that the RESET pin of a device without the

Brownout Reset feature is held low until the device is within

the specified V

with a delay 5 times (5x) greater than the power supply rise

time is recommended. Reset should also be wide enough to

ensure crystal start-up upon power-up. A recommended reset circuit for this device is shown in Figure 3.

voltage. An R/C circuit on the RESET pin

CC

20037205

FIGURE 3. Reset Circuit using External Reset

When enabled, the device generates an internal reset as

V

rises. While VCCis less than the specified brownout

CC

voltage (V

), the device is held in the reset condition for t

bor

= 120-128 µs for the LM8500 and tid= 360-384 µs for the

LM8300. Once the t

reaches zero, the internal reset is

id

released and the controller resume normal operation. This

internal reset will perform the same functions as external

reset. Once V

is above the V

CC

instruction execution begins. If, however, V

the selected V

, an internal reset is generated, and tidis set

bor

and tidreaches zero,

bor

drops below

CC

to 120-128 µs for the LM8500 and 360-384 µs for the

LM8300. The device now waits until V

is greater than V

CC

bor

at which time the countdown starts over. When enabled, the

functional operation of the device, at frequency, is guaranteed down to the V

level.

bor

One exception to the above is that the brownout circuit will

insert a delay of approximately 3 ms on power up or any time

the V

be held in Reset for the duration of this delay before t

count down. This delay starts as soon as the V

drops below a voltage of about 1.8V. The device will

CC

CC

id

starts

rises

above the trigger voltage (approximately 1.8V). This behavior is shown in Figure 4.

In Case 1, V

rises from 0V and the on-chip RESET is

CC

undefined until the supply is greater than approximately

1.0V. At this time the brownout circuit becomes active and

holds the device in RESET. As the supply passes a level of

about 1.8V, a delay of about 3 ms (td) is started and t

id

preset with 120-128 µs for the LM8500 or 360-384 µs for the

LM8300. Once V

starts to count down.

t

id

is greater than V

CC

and td has expired,

bor

Case 2 shows a subsequent dip in the supply voltage which

goes below the approximate 1.8V level. As V

, the internal RESET signal is asserted. When VCCrises

V

bor

drops below

CC

back above the 1.8V level, td is started. Since the power

supply rise time is longer for this case, td has expired before

rises above V

V

CC

greater than V

Case 3 shows a dip in the supply where V

, but not below 1.8V. On-chip RESET is asserted when

V

bor

goes below V

V

CC

goes back above V

and tidstarts immediately when VCCis

bor

.

bor

and tidstarts as soon as the supply

bor

.

bor

drops below

CC

id

,

is

www.national.com 14

Page 15

8.0 Brownout Reset (Continued)

LM8300/LM8400/LM8500

FIGURE 4. Brownout Reset Operation

If the Brownout Reset feature is enabled, the internal reset

will not be turned off until t

counts down to zero. The

id

internal reset will perform the same functions as external

reset. The device is guaranteed to operate at the specified

frequency down to the specified brownout voltage. After the

underflow, the logic is designed such that no additional

internal resets occur as long as V

remains above the

CC

brownout voltage.

The device is relatively immune to short duration negative

going V

transients (glitches). Proper filtering of the V

CC

CC

power supply voltage is essential for proper brownout functionality. Power supply decoupling is vital even in battery

powered systems.

There are two optional brownout voltages. The part numbers

for the three versions of this device are:

LM8500, V

LM8300, V

= high voltage range.

bor

= low voltage range.

bor

LM8400, BOR is disabled.

Refer to the device specifications for the actual V

volt-

bor

ages.

High brownout voltage devices are guaranteed to operate at

10MHz down to the high brownout voltage. Low brownout

voltage devices are guaranteed to operate at 3.33MHz down

to the low brownout voltage. Low brownout voltage devices

are not guaranteed to operate at 10MHz down to the low

brownout voltage.

Under no circumstances should the RESET pin be allowed

to float. If the on chip Brownout Reset feature is being used,

the RESET pin should be connected directly to V

CC

. The

20037206

RESET input may also be connected to an external pull-up

resistor or to other external circuitry. The output of the brownout reset detector will always preset t

to a value between

id

120-128µs for the LM8500 and 360-384µs for the LM8300.

At this time, the internal reset will be generated.

If the BOR feature is disabled, then no internal resets are

generated. In this case, the external RESET must be used.

When BOR is disabled, this on-chip circuitry is disabled and

draws no DC current.

9.0 Calibration

The device supports two, five, and thirteen point calibration.

If desired, the calibration points can be stored internally in

the non-volatile storage element. During calibration time, the

device has the unique ability to check if the calibration points

make sense. For instance, if the desired calibration point

was to be at the upper left hand corner, but by accident, the

actual point detected was at the lower right hand corner, the

device will reject this point. This ensures the calibration

process is not performed incorrectly.

The calibration checking, can be enabled or disabled. If the

calibration checking is enabled, the controller will always

check the current calibration point being done against the

theoretical point and determine if the value is within

the raw A/D values. If this option is desired, the touch screen

driver must perform the calibration according to the calibration mapping for the two, five, and thirteen points as shown

in Figure 5, Figure 6, and Figure 7, respectively. The theoretical values for the two, five, and thirteen points are shown

in Table 4, Table 5, and Table 6 respectively.

±

127 of

www.national.com15

Page 16

9.0 Calibration (Continued)

LM8300/LM8400/LM8500

TABLE 4. Two Points Calibration

Calibration point Theoretical X-value Theoretical Y-value

1 127 127

2 895 895

TABLE 5. Five Points Calibration

Calibration point Theoretical X-value Theoretical Y-value

1 127 127

2 895 895

3 127 895

4 511 511

5 895 127

FIGURE 5. Two Points Calibration Mapping

FIGURE 6. Five Points Calibration Mapping

20037207

20037208

TABLE 6. Thirteen Points Calibration

Calibration point Theoretical X-value Theoretical Y-value

1 127 127

2 895 895

3 127 895

4 511 511

5 895 127

6 895 511

7 511 895

8 127 511

9 511 127

10 623 319

11 623 623

12 319 623

13 319 319

20037209

FIGURE 7. Thirteen Points Calibration Mapping

www.national.com 16

Page 17

9.0 Calibration (Continued)

9.1 General Calibration Procedures

Calibration is invoked by sending a command byte of $BD

followed by a command byte to the device. The command

byte is broken into two parts: the high nibble states the

number of calibration points to performs and the lower nibble

states the active calibration point. For example, to do the first

calibration point for the two point calibration, the command

bytes of $BD and $11 are sent to the device. The device then

echos $BD and $11 back to the TS driver and waits for a

touch on the panel. When a touch is detected, the device

checks to see if the point is within the specified parameters

if the calibration point checking is enabled. If the calibration

point checking is disabled, the device will send a

byte to the TS driver regardless of where the touch was

detected. This calibration point checking can be enabled or

disabled by sending a command byte of $A5 to the device.

When all the calibration points are done, the device will do a

self-test and send a command of $CB for OK or a command

of $CC for failed. If a $CC is received, the TS driver should

issue a warning stating the calibration was not done properly

and redo the calibration procedures. The flowchart for the

calibration procedures is shown in Figure 8.

$

C8 for OK

LM8300/LM8400/LM8500

FIGURE 8. Calibration Procedures with Coordinates Checking Enabled

20037210

www.national.com17

Page 18

9.0 Calibration (Continued)

9.2 Calibration Procedures with Coordinates Checking Enabled

To do TS calibration with coordinates checking enabled, first

ensure the Calibration Coordinates Checking is enabled on

the device. This can be accomplished by sending a command byte of $B1 (Read Parameters command) and checking the 5th bit of the 12th reply byte is set. Alternatively, if the

device is set to Calibration Coordinates Checking enabled

LM8300/LM8400/LM8500

as default, this step can be skipped.

The TS driver sends the command byte to do calibration

($BD). The TS driver should wait for the reply bytes and

ensure it is the same command bytes it sent. The device

waits for a touch to be detected on the panel. Once a touch

is detected, the device checks it against the predetermined

calibration values as noted on Table 4, Table 5 , and Table 6.

If the detected touch is within the predefined value (

the raw A/D value), the device will send a command of $C4

to the TS driver and store the calibration point in the internal

flash. The TS driver can now send a command byte to do the

next calibration point. If the detected touch is not within the

predefined value, the device will send a reply byte of $C8 to

the TS driver. Upon receiving this reply byte, the TS driver

can resend the calibration command for the same calibration

point, go the next calibration point, or abort the calibration

process.

Once all the calibration points are done, the device does a

self-test. If the self-test was not successful, the device will

send a reply byte of $CC to the TS driver. At this point, the

TS driver should either notify the user to redo the calibration

±

127 of

point or automatically redo the calibration again. If the selftest was successful, the device will send a reply byte of $CB

to the TS driver.

9.3 Calibration Procedures with Coordinates Checking Disabled

To do TS calibration with coordinates checking disabled, first

ensure the Calibration Coordinates Checking is disabled on

the device. This can be accomplished by sending a command byte of $B1 (Read Parameters command) and checking the 5th bit of the 12th reply byte is not set. Alternatively,

if the device is set to Calibration Coordinates Checking

disabled as default, this step can be skipped.

The TS driver sends the command byte to do calibration

($BD). The TS driver should wait for the reply bytes and

ensure it is the same command bytes it sent. The device

waits for a touch to be detected on the panel. Once a touch

is detected, the device save the values into the internal flash

and send a reply byte of $C4 to the TS driver. The TS driver

can now send a command byte to do the next calibration

point. Since the Calibration Checking is disabled, the TS

driver should ensure the calibration point is within the range

of the calibration cross.

Once all the calibration points are done, the device does a

self-test. If the self-test was not successful, the device will

send a reply byte of $CC to the TS driver. At this point, the

TS driver should either notify the user to redo the calibration

point or automatically redo the calibration again. If the selftest was successful, the device will send a reply byte of $CB

to the TS driver.

www.national.com 18

Page 19

Physical Dimensions inches (millimeters) unless otherwise noted

LM8300/LM8400/LM8500

LLP Package (LQA)

Order Number LM8300HLQ9 or LM8400HLQ9 or LM8500HLQ9

NS Package Number LQA44A

TSSOP Package (MTD)

Order Number LM8300IMT9 or LM8400IMT9 or LM85009IMT9

NS Package Number MTD48

www.national.com19

Page 20

Physical Dimensions inches (millimeters) unless otherwise noted (Continued)

Plastic Leaded Chip Carrier (VA)

Order Number LM8300HVA9 or LM8400HVA9 or LM8500HVA9

NS Package Number V44A

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

LM8300/LM8400/LM8500 Four Wire Resistive Touchscreen Controller with Brownout

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Fax: 65-6250 4466

Email: ap.support@nsc.com

Tel: 65-6254 4466

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: nsj.crc@jksmtp.nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...