Page 1

August 2007

LM8333

Mobile I/O Companion Supporting Key-Scan, I/O

Expansion, PWM, and ACCESS.bus Host Interface

1.0 General Description

The LM8333 Mobile I/O Companion offloads the burden of

keyboard scanning from the host, while providing extremely

low power consumption in both operational and standby

modes. It supports keypad matrices up to 8 × 8 in size (plus

another 8 special-function keys), for portable applications

such as cellphones, PDAs, games, and other handheld applications.

Key press and release events are encoded into a byte format

and loaded into a FIFO buffer for retrieval by the host processor. An interrupt output (IRQ) is used to signal events such

as keypad activity, a state change on either of two interruptcapable general-purpose I/O pins, or an error condition. Interrupt and error codes are available to the host by reading

dedicated registers.

Four general-purpose I/O pins are available, two of which

have interrupt capability. A pulse-width modulated output

based on a host-programmable internal timer is also available, which can be used as a general-purpose output if the

PWM function is not required.

To minimize power, the LM8333 automatically enters a lowpower standby mode when there is no keypad, I/O, or host

activity.

The device is packaged in a 32–pin Leadless Leadframe

package (LLP) and a 49-pin MICRO-ARRAY . Both are chipscale packages.

2.0 Features

■

8 × 8 standard keys

■

8 special function keys (SF keys) providing a total of 72

keys for the maximum keyboard matrix

■

ACCESS.bus (I2C-compatible) communication interface

to the host

■

Four general purpose host programmable I/O pins with

two optional (slow) external Interrupts

■

16 byte FIFO buffer to store key pressed and key released

events

■

Error control with error reports on (FIFO overrun, Keypad

overrun, invalid command)

■

Host programmable PWM

■

Host programmable active time and debounce time

3.0 Applications

■

Mobile phones

■

Personal Digital Assistants (PDAs)

■

Smart handheld devices

■

Personal media players

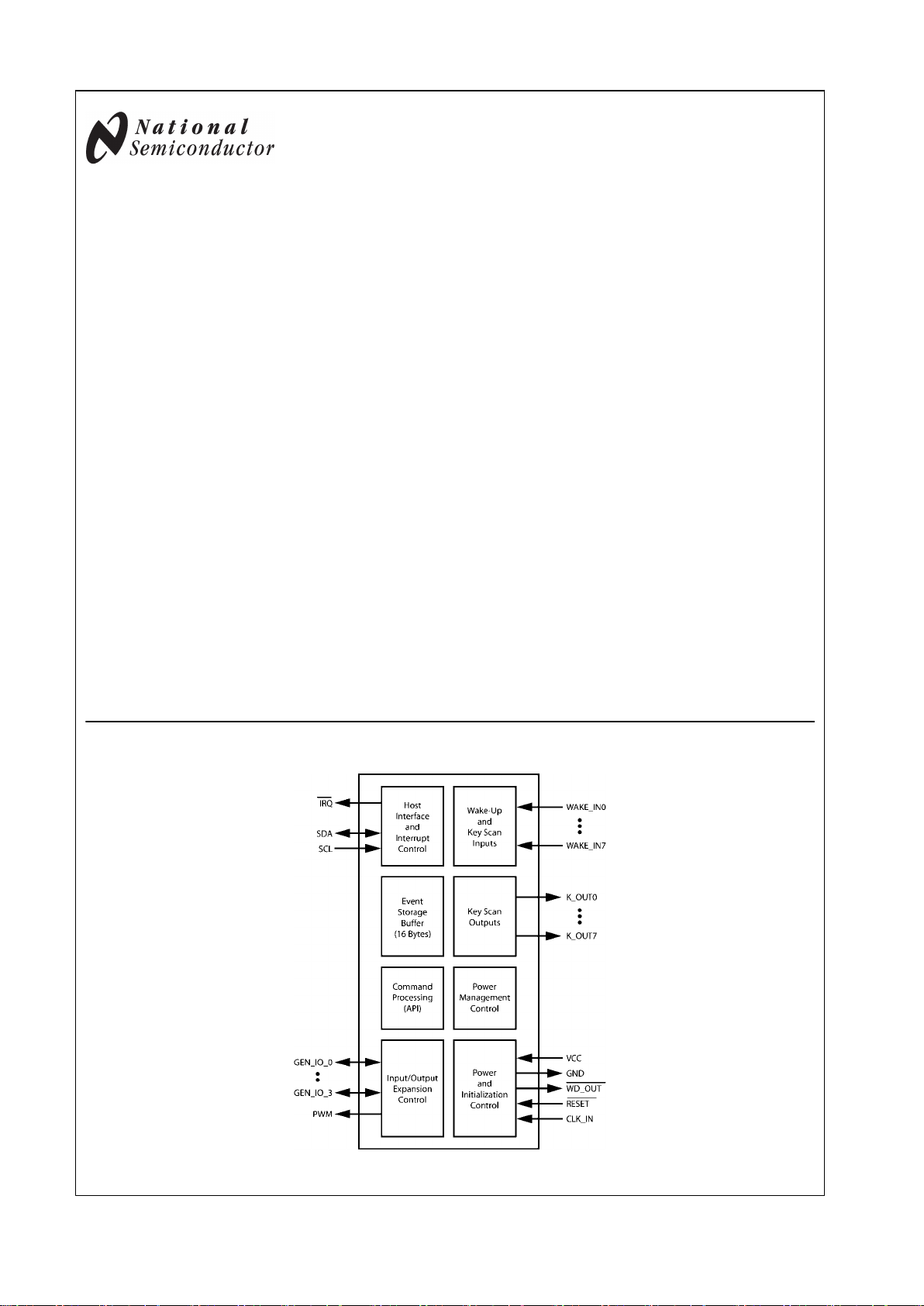

4.0 Block Diagram

20210601

I2C® is a registered trademark of Phillips Corporation.

© 2007 National Semiconductor Corporation 202106 www.national.com

LM8333 Mobile I/O Companion Supporting Key-Scan, I/O Expansion, PWM, and ACCESS.bus

Host Interface

Page 2

5.0 Ordering Information

NSID Spec. No. of Pins Package Type Temperature Package Method

LM8333FLQ8X NOPB 32 LLP −40 to + 85°C 2500 pcs Tape & Reel

LM8333FLQ8Y NOPB 32 LLP −40 to + 85°C 250 pcs Tape & Reel

LM8333GGR8 NOPB 49 Micro-array −40 to + 85°C 1000 pcs Tape & Reel

NOPB = No PB (No Lead)

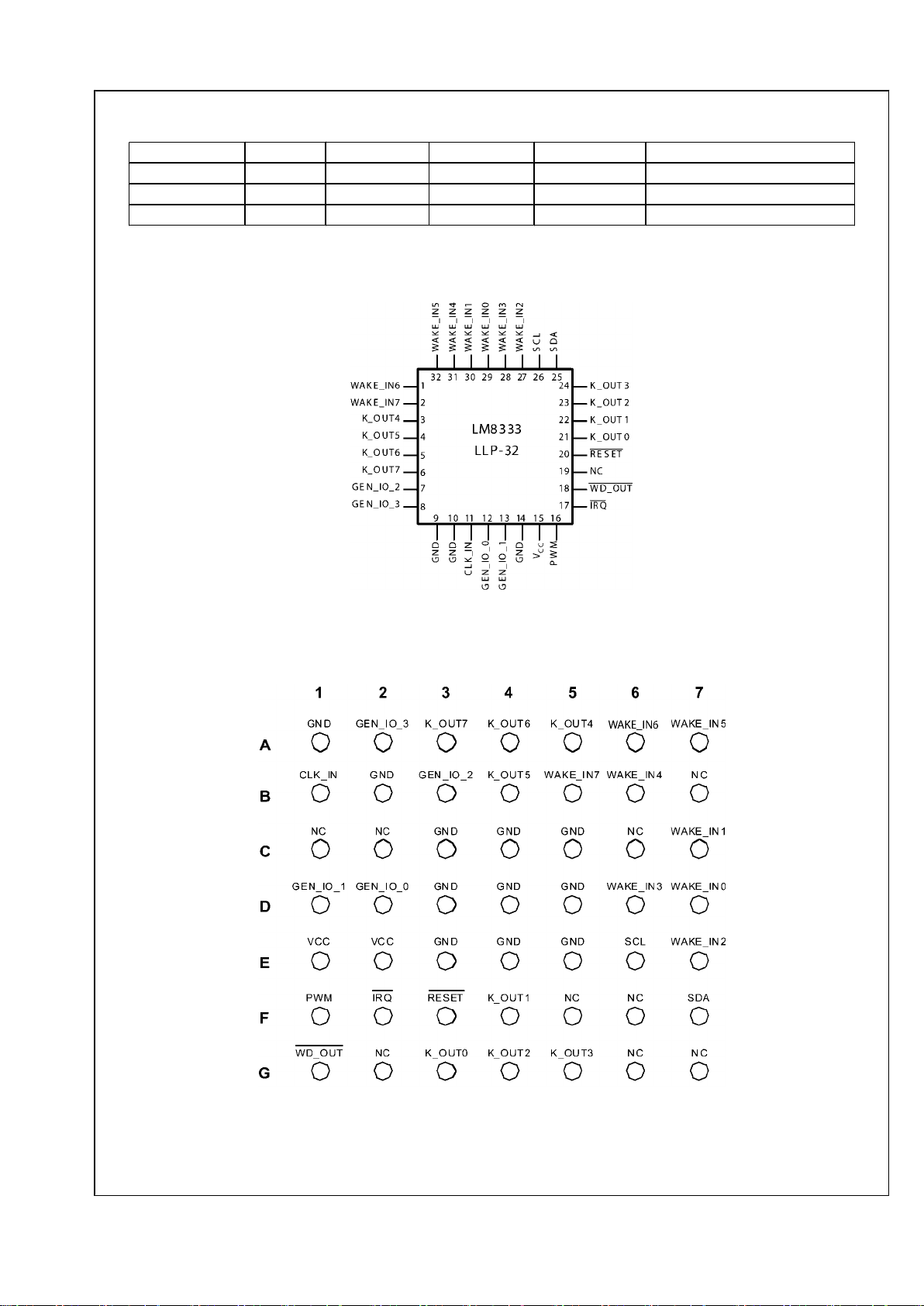

6.0 Pin Assignments

20210649

Top View

Leadless Leadframe Package

See NS Package Number LQA32A

20210602

Top View

MICRO-ARRAY Package

See NS Package Number GRA49A

www.national.com 2

LM8333

Page 3

Table of Contents

1.0 General Description ......................................................................................................................... 1

2.0 Features ........................................................................................................................................ 1

3.0 Applications .................................................................................................................................... 1

4.0 Block Diagram ................................................................................................................................ 1

5.0 Ordering Information ........................................................................................................................ 2

6.0 Pin Assignments ............................................................................................................................. 2

7.0 Signal Descriptions .......................................................................................................................... 4

8.0 Typical Application ........................................................................................................................... 5

8.1 FEATURES .................................................................................................................................. 5

8.2 I/O EXPANSION OPTIONS ............................................................................................................ 5

8.3 WATCHDOG TIMER ..................................................................................................................... 5

8.4 HALT MODE ................................................................................................................................ 5

8.4.1 ACCESS.bus Activity ................................................................................................................ 5

8.5 KEYPAD SCANNING ..................................................................................................................... 6

8.6 COMMUNICATION INTERFACE ..................................................................................................... 6

8.6.1 Interrupts Between the Host and LM8333 ..................................................................................... 6

8.6.2 Interrupt Sources ...................................................................................................................... 6

9.0 Device Operation ............................................................................................................................ 6

9.1 EVENT CODE ASSIGNMENT ......................................................................................................... 6

9.2 I/O EXPANSION ........................................................................................................................... 7

9.2.1 PWM Output with Programmable Duty Cycle ................................................................................ 7

9.2.2 General-Purpose I/O (GPIO) ...................................................................................................... 8

9.2.3 External Interrupts .................................................................................................................... 8

9.3 HOST COMMAND EXECUTION ..................................................................................................... 9

9.3.1 Command Structure .................................................................................................................. 9

9.4 HOST WRITE COMMANDS ......................................................................................................... 10

9.5 HOST READ COMMANDS ........................................................................................................... 10

9.6 WAKE-UP FROM HALT MODE ..................................................................................................... 11

10.0 Interrupts .................................................................................................................................... 11

10.1 INTERRUPT CODE ................................................................................................................... 11

10.2 ERROR CODE .......................................................................................................................... 11

10.3 STATUS CODES ....................................................................................................................... 12

10.4 INTERRUPT PROCESSING ....................................................................................................... 12

10.5 COMMAND EXECUTION SUMMARY .......................................................................................... 13

11.0 Absolute Maximum Ratings ........................................................................................................... 14

12.0 DC Electrical Characteristics ......................................................................................................... 14

13.0 AC Electrical Characteristics ......................................................................................................... 15

14.0 Physical Dimensions .................................................................................................................... 17

3 www.national.com

LM8333

Page 4

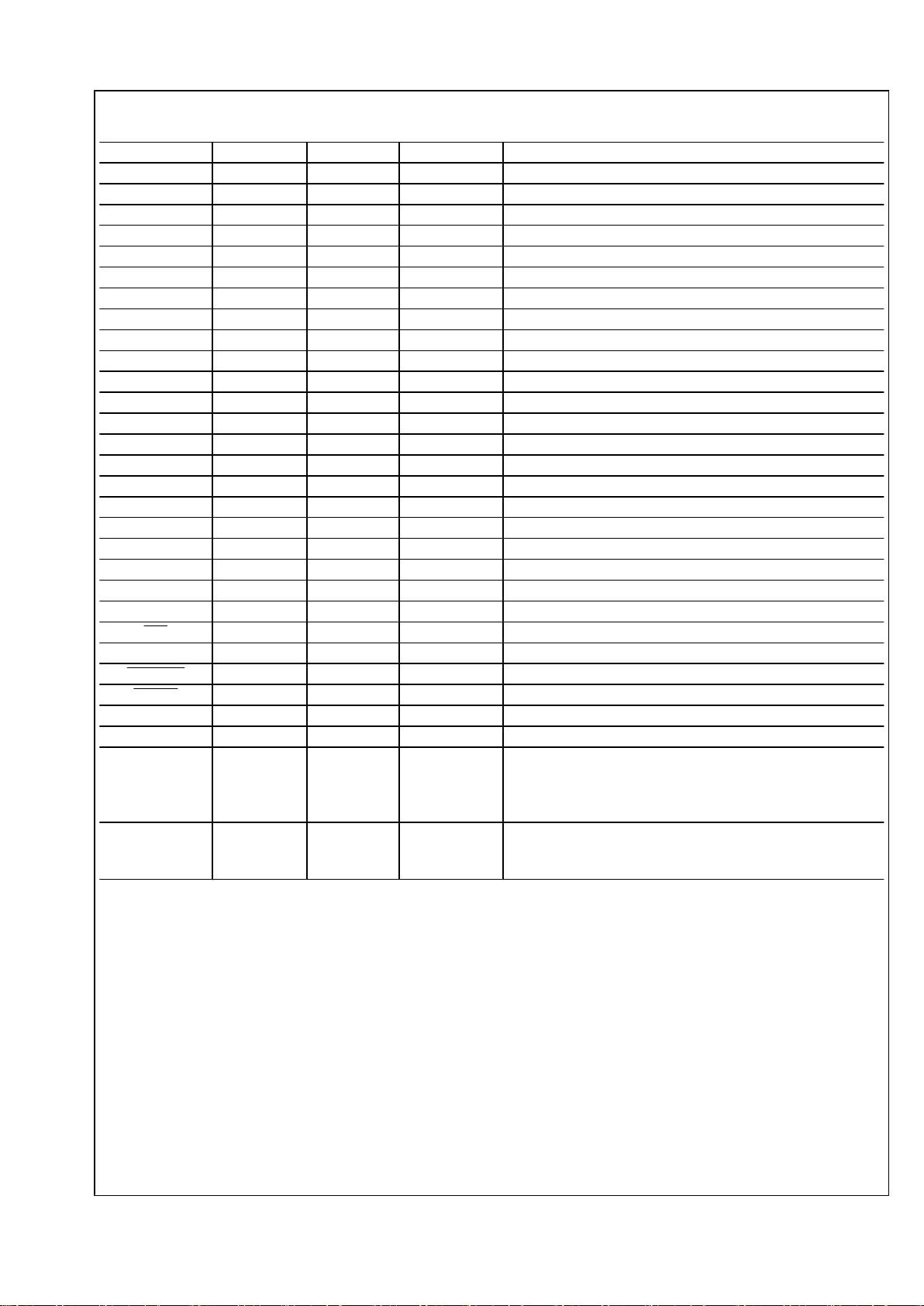

7.0 Signal Descriptions

Name 32 Pins 49 Pins I/O Description

WAKE_IN0 29 D7 Input Wake-up input/Keyboard scanning input 0

WAKE_IN1 30 C7 Input Wake-up input/Keyboard scanning input 1

WAKE_IN2 27 E7 Input Wake-up input/Keyboard scanning input 2

WAKE_IN3 28 D6 Input Wake-up input/Keyboard scanning input 3

WAKE_IN4 31 B6 Input Wake-up input/Keyboard scanning input 4

WAKE_IN5 32 A7 Input Wake-up input/Keyboard scanning input 5

WAKE_IN6 1 A6 Input Wake-up input/Keyboard scanning input 6

WAKE_IN7 2 B5 Input Wake-up input/Keyboard scanning input 7

K_OUT0 21 G3 Output Keyboard scanning output 0

K_OUT1 22 F4 Output Keyboard scanning output 1

K_OUT2 23 G4 Output Keyboard scanning output 2

K_OUT3 24 G5 Output Keyboard scanning output 3

K_OUT4 3 A5 Output Keyboard scanning output 4

K_OUT5 4 B4 Output Keyboard scanning output 5

K_OUT6 5 A4 Output Keyboard scanning output 6

K_OUT7 6 A3 Output Keyboard scanning output 7

GEN_IO_0 12 D2 I/O General-purpose I/O 0

GEN_IO_1 13 D1 I/O General-purpose I/O 1

GEN_IO_2 7 B3 I/O General-purpose I/O 2

GEN_IO_3 8 A2 I/O General-purpose I/O 3

SDA 25 F7 I/O ACCESS.bus data signal

SCL 26 E6 Input ACCESS.bus clock signal

IRQ 17 F2 Output Interrupt request output

PWM 16 F1 Output Pulse-width modulated output

WD_OUT 18 G1 Output Watchdog timer output (connect to RESET input)

RESET 20 F3 Input Reset input

CLK_IN 11 B1 Input Clock input (connect to ground through a 68k ohm resistor)

VCC 15 E1, E2 n.a. Vcc

GND 9, 10, 14 A1, B2, C3,

C4, C5, D3,

D4, D5, E3,

E4, E5

n.a. Ground

NC 19 B7, C1, C2,

C6, F5, F6,

G2, G6, G7

n.a. No connect

www.national.com 4

LM8333

Page 5

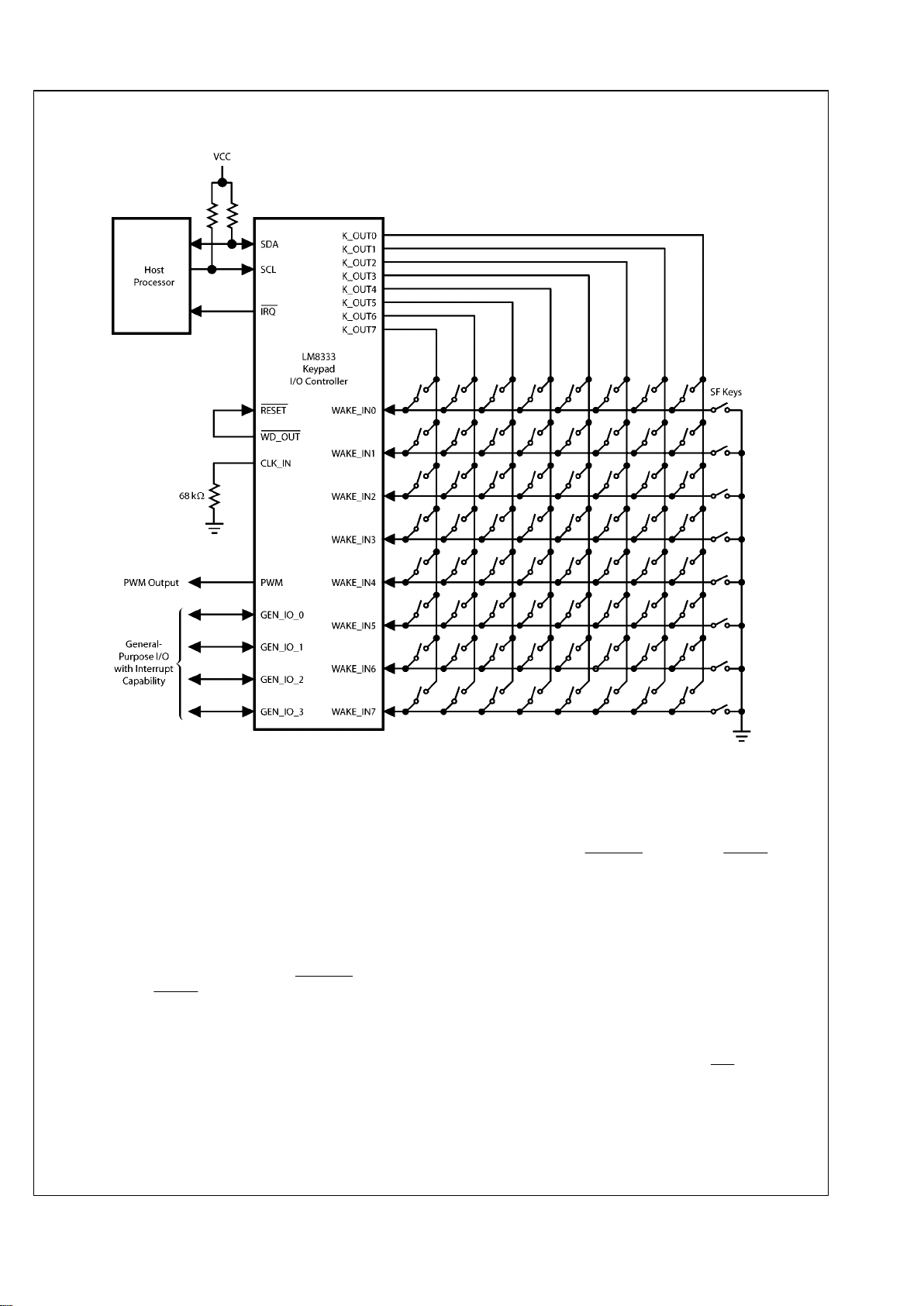

8.0 Typical Application

20210603

FIGURE 1. Typical Keypad Configuration

8.1 FEATURES

The following features are supported:

•

8 x 8 standard keys.

•

8 special function keys (SF keys) with wake-up capability

by forcing a WAKE_INx pin to ground. Pressing a SF key

overrides any other key in the same row.

•

A total of 72 keys can be scanned.

•

ACCESS.bus (I2C-compatible) interface for

communication with the host.

•

The watchdog timer is mandatory, so WD_OUT

must be

connected to RESET.

8.2 I/O EXPANSION OPTIONS

•

One host-programmable PWM output which also may be

used as a general-purpose output.

•

Four host-programmable general-purpose I/O pins,

GEN_IO_0, GEN_IO_1, GEN_IO_2, and GEN_IO_3.

GEN_IO_0 and GEN_IO_1 can also be configured for

“slow” interrupts, in which any transition will trigger a

hardware interrupt event to the host.

8.3 WATCHDOG TIMER

The watchdog timer is always enabled in hardware. To use

the timer, connect the WD_OUT

output to the RESET input.

8.4 HALT MODE

The fully static architecture of the LM8333 allows stopping the

internal RC clock in Halt mode, which reduces power consumption to the minimum level.

Halt mode is entered when no key-press, key-release, or

ACCESS.bus activity is detected for a certain period of time

(by default, 500 milliseconds). The mechanism for entering

Halt mode is always enabled in hardware, but the host can

program the period of inactivity which triggers entry into Halt

mode.

The LM8333 will remain in Active mode as long as a key

event, or any other event, which causes the IRQ output to be

asserted is not resolved.

8.4.1 ACCESS.bus Activity

When the LM8333 is in Halt mode, any activity on the

ACCESS.bus interface will cause the LM8333 to exit from

Halt mode. However, the LM8333 will not be able to acknowl-

5 www.national.com

LM8333

Page 6

edge the first bus cycle immediately following wake-up from

Halt mode. It will respond with a negative acknowledgement,

and the host should then repeat the cycle.

The LM8333 will be prevented from entering Halt mode if it

shares the bus with peripherals that are continuously active.

For lowest power consumption, the LM8333 should only

share the bus with peripherals that require little or no bus activity after system initialization.

8.5 KEYPAD SCANNING

The LM8333 starts new scanning cycles at fixed time intervals

of about 4 ms. If a change in the state of the keypad is detected, the keypad is rescanned after a debounce delay.

When the state change has been reliably captured, it is encoded and written to the FIFO buffer.

If more than two keys are pressed simultaneously, the pattern

of key closures may be ambiguous, so pressing more than

two keys asserts the Error Flag condition and the IRQ output

(if enabled). The host may attempt to interpret the events

stored in the FIFO or discard them.

The SF keys connect the WAKE_INx pins directly to ground.

There can be up to eight SF-keys. If any of these keys are

pressed, other key presses that use the same WAKE_INx pin

will be ignored.

8.6 COMMUNICATION INTERFACE

The two-wire ACCESS.bus interface is used to communicate

with a host. The ACCESS.bus interface is fully compliant with

the I2Cbus standard. The LM8333 operates as a bus slave at

speeds up to 400 kHz.

An ACCESS.bus transfer starts with a byte that includes a 7bit slave device address. The LM8333 responds to a fixed

device address. This address is 0xA2, when aligned to the

MSB (7-bit address mapped to bits 7:1, rather than bits 6:0).

Bit 0 is a direction bit (0 on write, 1 on read).

Because it is a slave, the LM8333 never initiates an

ACCESS.bus cycle, it only responds to bus cycles initiated by

the host. The LM8333 may signal events to the host by asserting the IRQ interrupt request.

8.6.1 Interrupts Between the Host and LM8333

The IRQ output is used to signal unresolved interrupts, errors,

and key-events to the host.

The host can use an available GEN_IO_0 or GEN_IO_1 pin

to interrupt (or wake-up) the LM8333, if it is not being used for

another function. The host can also wake-up the LM8333 by

sending a Start Condition on the ACCESS.bus interface.

Note:

The LM8333 it will not be able to acknowledge the first byte received

from the host after wake-up. In this case, the host will have to resend

the slave address.

8.6.2 Interrupt Sources

The IRQ

output is asserted on these conditions:

•

Any new key-event.

•

Any error condition, which is indicated by the error code.

•

Any enabled interrupt on either of the GEN_IO_0 or

GEN_IO_1 pins that can be configured as external

interrupt inputs. When enabled, any rising or falling edge

triggers an interrupt.

The IRQ output remains asserted until the interrupt code is

read.

9.0 Device Operation

9.1 EVENT CODE ASSIGNMENT

After power-on reset, the LM8333 starts scanning the keypad.

It stays active for a default time of about 500 ms after the last

key is released, after which it enters a standby mode to minimize power consumption (<2 µA standby current).

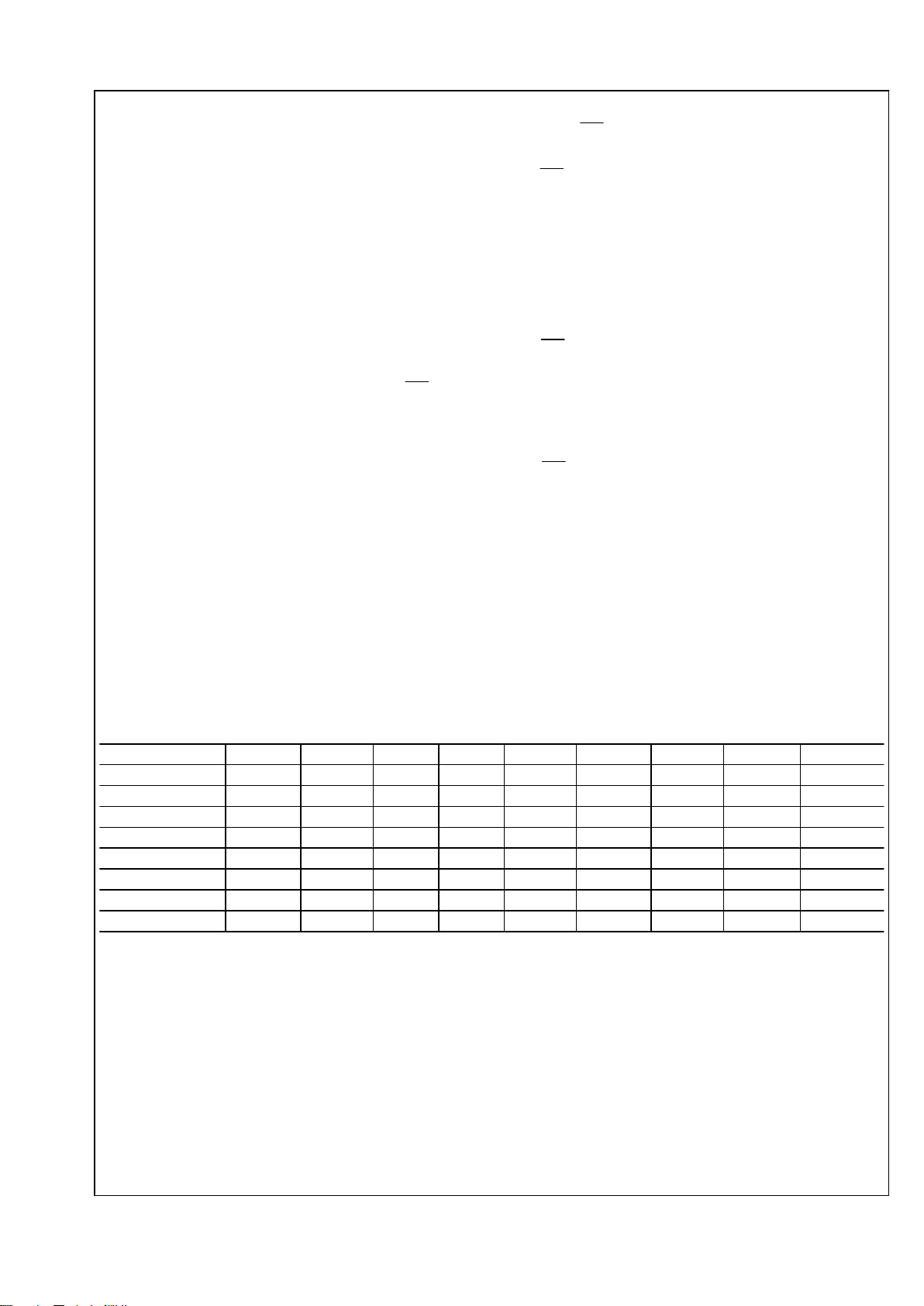

Table 1 lists the codes assigned to the matrix positions encoded by the hardware. Key-press events are assigned the

codes listed in Table 1, but with the MSB set. When a key is

released, the MSB of the code is clear.

TABLE 1. Keypad Matrix Code Assignments

K_OUT0 K_OUT1 K_OUT2 K_OUT3 K_OUT4 K_OUT5 K_OUT6 K_OUT7 SF Keys

WAKE_IN0 0x01 0x02 0x03 0x04 0x05 0x06 0x07 0x08 0x09

WAKE_IN1 0x11 0x12 0x13 0x14 0x15 0x16 0x17 0x18 0x19

WAKE_IN2 0x21 0x22 0x23 0x24 0x25 0x26 0x27 0x28 0x29

WAKE_IN3 0x31 0x32 0x33 0x34 0x35 0x36 0x37 0x38 0x39

WAKE_IN4 0x41 0x42 0x43 0x44 0x45 0x46 0x47 0x48 0x49

WAKE_IN5 0x51 0x52 0x53 0x54 0x55 0x56 0x57 0x58 0x59

WAKE_IN6 0x61 0x62 0x63 0x64 0x65 0x66 0x67 0x68 0x69

WAKE_IN7 0x71 0x72 0x73 0x74 0x75 0x76 0x77 0x78 0x79

The codes are loaded into the FIFO buffer in the order in

which they occurred. Table 2 shows an example sequence of

events, and Figure 2 shows the resulting sequence of event

codes loaded into the FIFO buffer.

www.national.com 6

LM8333

Page 7

TABLE 2. Example Sequence of Events

Event Number Event Code Event on Input Matrix Node Description

1 0xF1 Wake_INP7 K_OUT0 Key is pressed

2 0xB6 Wake_INP3 K_OUT5 Key is pressed

3 0x71 Wake_INP7 K_OUT0 Key is released

4 0x36 Wake_INP3 K_OUT5 Key is released

5 0xB4 Wake_INP3 K_OUT3 Key is pressed

6 0x34 Wake_INP3 K_OUT3 Key is released33

7 0x91 Wake_INP1 K_OUT0 Key is pressed

8 0x00 NA NA Indicates end of stored events

20210604

FIGURE 2. Example Event Codes Loaded in FIFO Buffer

9.2 I/O EXPANSION

In addition to keypad scanning, the LM8333 supports various

I/O expansion options.

9.2.1 PWM Output with Programmable Duty Cycle

The PWM pin may be used either as a pulse-width modulated

output driven by a 16-bit timer or as a general-purpose output

pin. In the PWM mode, the low time (TLO) and high time

(THI) are programmable between 1 × tC and 65K × tC cycles

in which tC is the cycle time (nominally 1 microsecond), as

shown in Figure 3. The period TPD is the sum of THI and TLO.

The PWM_LO command writes TLO, and the PWM_HI command writes THI. Operational modes of the PWM pin are

controlled by the PWM_CTL command. Before activating the

PWM output, the TLO and THI times must be initialized. Figure

4 shows the command formats.

20210605

FIGURE 3. Programmable PWM

20210606

FIGURE 4. PWM Control Commands for Arbitrary Duty Cycle

7 www.national.com

LM8333

Page 8

TABLE 3. Summary of PWM Control Bits

OUT_DIR Bit PWM_DIR Bit MOD BIT Description

0 1 0 Drive output low

1 1 0 Drive output high

0 0 0 TRI-STATE® mode

X X 1 PWM timer output

9.2.2 General-Purpose I/O (GPIO)

Figure 5 shows the commands to write, read and control the

general-purpose I/O port pins, GEN_IO_0, GEN_IO_1,

GEN_IO_2, and GEN_IO_3.

All general-purpose I/O pins can be programmed as inputs or

outputs as shown in Table 4. The GEN_IO_0 and GEN_IO_1

pins provide an additional capability for programmable wakeup.

20210607

FIGURE 5. General-Purpose I/O Control Commands

Table 4 shows the pin configuration for all four combinations

of control bit settings (data output and direction) for the general-purpose I/O pins. GEN_IO_3 cannot be put into the high

impedance (Hi-Z) input mode. When programmed as an input, it can only be configured as an input with a weak pullup.

TABLE 4. General Purpose I/O Pin Configuration

GEN_IO_DIR Bit GEN_IO_OUT Bit Direction State

0 0 Input Hi-Z

0 1 Input Weak Pullup

1 0 Output Drive Low

1 1 Output Drive High

9.2.3 External Interrupts

When the GEN_IO_0 or GEN_IO_1 pins are configured as

inputs, a SET_EXT_INT command (0xD1) can be used to

enable receiving external interrupts on either or both of these

pins. Setting the EX_0 or EX_1 bits in the data byte of the

SET_EXT_INT command (as shown in Figure 6) enables the

corresponding pin as an external interrupt input. When enabled as an interrupt input, any rising or falling edge causes

the IRQ

output to be asserted. If the LM8333 was in Halt

mode, it also wakes up into Active mode.

20210608

FIGURE 6. SET_EXT_INT Command Data Byte

When both GEN_IO_0 and GEN_IO_1 are configured as interrupt inputs, bits 1 and 2 of the interrupt code indicate which

input asserted the interrupt. However, if only one of

GEN_IO_0 or GEN_IO_1 is configured as an interrupt input,

both bits 1 and 2 of the interrupt code will be set when an

interrupt occurs.

www.national.com 8

LM8333

Page 9

TABLE 5. Interface Commands for Controlling the LM8333

Function Cmd Dir Data Bits Data Description

FIFO_READ 0x20 R 128

Event Codes from

FIFO

Read an event from the FIFO.

Maximum 14 event codes stored in the FIFO.

MSB = 1: key pressed.

MSB = 0: key released.

RPT_FIFO_READ 0x21 R 128

Event Codes from

FIFO

Repeats a FIFO read without advancing the FIFO pointer,

for example to retry a read after an error.

Maximum 14 event codes stored in the FIFO.

MSB = 1: key pressed.

MSB = 0: key released.

DEBOUNCE 0x22 W 8 nnnn nnnn

Default is 10 ms. Valid range 1–255.

Time ~ n × 3 ms

GEN_IO_IN 0x30 R 8 0000 nnnn Read port data.

GEN_IO_OUT 0x31 W 8 0000 nnnn

Specify port mode. (Drive 0 or 1 when the port is configured

as an output; select Hi-Z or pullup when the port is

configured as an input.)

GEN_IO_DIR 0x32 W 8 0000 nnnn Select port direction (input or output).

PWM_HI 0x40 W 16

(n+1) × t

C

Sets the low pulse time of the PWM signal.

PWM_LO 0x41 W 16

(n+1) × t

C

Sets the high pulse time of the PWM signal.

PWM_CTL 0x42 W 8 0000 0nnn Activate, reactivate, or stop PWM.

READ_INT 0xD0 R 8 0000 nnnn

Reads the interrupt code, acknowledges the interrupt,

deasserts the IRQ output, and clears the code.

SET_EXT_INT 0xD1 W 8 0000 00nn

Enables/disables external interrupts on GEN_IO_0 and

GEN_IO_1.

READ_STAT 0xE0 R 8 000n nnnn Status Information.

SCAN_REQ 0xE3 W 8

Requests rescanning the keypad (for example, after an

error was reported).

ACTIVE 0xE4 W 8 nnnn nnnn

Specifies the time after the last event during which the

LM8333 stays active before entering Halt mode. The active

time must be greater than the debounce time.

Default is 500 msec

Valid range for n is 1–255

Time ~ n × 3 msec.

READ_ERROR 0xF0 R 8 0nnn nnnn Reads and clears the error code.

9.3 HOST COMMAND EXECUTION

9.3.1 Command Structure

All communication with the LM8333 over the ACCESS.bus

interface is initiated by the host, usually in response to an in-

terrupt request (IRQ low) asserted by the LM8333. Figure 7

shows a sequence of Start conditions, slave addresses,

READ_INT command (0xD0), acknowledge cycles, data

bytes, and Stop condition for reading the interrupt code.

20210609

FIGURE 7. Typical Command Sequence from Host

9 www.national.com

LM8333

Page 10

Every transfer is preceded by a Start condition (S) or a Repeated Start condition (RS). The latter occurs when a command follows immediately upon another command without an

intervening Stop condition (P). A Stop condition indicates the

end of transmission. Every byte is acknowledged (A) by the

receiver.

The first byte in a write from the host to the LM8333 is 0xA2,

and the first byte in a read is 0xA3. This byte is composed of

a 7-bit slave address in bits 7:1 and a direction bit in bit 0. The

direction bit is 0 on writes from the host to the slave and 1 on

reads from the slave to the host.

The second byte sends the command. The commands are

listed in Table 5. In the example, the READ_INT command

(0xD0) reads the interrupt code.

The slave address is repeated in the third byte, with the direction bit set to 1. The Start (or Repeated Start) condition

must be repeated whenever the slave address or the direction

bit is changed. In this case, the direction bit is changed.

The data is sent from the slave to the host in the fourth byte.

When the master is the receiver, it sends a negative acknowledgement (NA) to indicate the end of the data.

9.4 HOST WRITE COMMANDS

Some host commands include one or more data bytes written

to the LM8333. Figure 8 shows a SET_EXT_INT command,

which consists of an address byte, a command byte, and one

data byte.

The first byte is composed of a 7-bit slave address in bits 7:1

and a direction bit in bit 0. The state of the direction bit is 0 on

writes from the host to the slave and 1 on reads from the slave

to the host.

The second byte sends the command. The commands are

listed in Figure 9. The SET_EXT_INT command is 0xD1.

The third byte send the data, in this case configuring

GEN_IO_0 as an external interrupt input.

20210610

FIGURE 8. Host Write Command

9.5 HOST READ COMMANDS

Some host commands include one or more data bytes read

from the LM8333. Figure 9 shows a READ_INT command

which consists of an address byte, a command byte, a second

address byte, and a data byte.

The first address byte is sent with the direction bit driven low

to indicate a write transaction of the command to the LM8333.

The second address byte is sent with the direction bit undriven

(pulled high) to indicate a read transaction of the data from

the LM8333.

The Start (or Repeated Start) condition must be repeated

whenever the slave address or the direction bit is changed. In

this case, the direction bit is changed.

The data is sent from the slave to the host in the fourth byte.

This byte ends with a negative acknowledgement (NACK) to

indicate the end of the data.

20210611

FIGURE 9. Host Read Command

www.national.com 10

LM8333

Page 11

9.6 WAKE-UP FROM HALT MODE

Any bus transaction initiated by the host may encounter the

LM8333 device in Halt mode or busy with processing data,

such as controlling the FIFO buffer or executing interrupt service routines.

Figure 10 shows the case in which the host sends a command

while the LM8333 is in Halt mode (CPU clock is stopped). Any

activity on the ACCESS.bus wakes up the LM8333, but it

cannot acknowledge the first bus cycle immediately after

wake-up.

The host drives a Start condition followed by seven address

bits and a R/W bit. The host then releases SDA for one clock

period, so that it can be driven by the LM8333.

If the LM8333 does not drive SDA low during the high phase

of the clock period immediately after the R/W bit, the bus cycle

terminates without being acknowledged (shown as NACK in

Figure 10). The host then aborts the transaction by sending

a Stop condition. After aborting the bus cycle, the host may

then retry the bus cycle. On the second attempt, the LM8333

will be able to acknowledge the slave address, because it will

be in Active mode.

Alternatively, the I2C specification allows sending a START

byte (00000001), which will not be acknowledged by any device. This byte can be used to wake up the LM8333 from Halt

mode.

The LM8333 may also stall the bus transaction by pulling the

SCL low, which is a valid behavior defined by the I2C specification.

20210612

FIGURE 10. LM8333 Responds with NACK, Host Retries Command

10.0 Interrupts

10.1 INTERRUPT CODE

The interrupt code is read and acknowledged with the

READ_INT command (0xD0). This command clears the code

and deasserts the IRQ

output. Table 6 shows the format of

the interrupt code.

Note that when only one of the interrupt-capable pins

GEN_IO_0 or GEN_IO_1 is configured as an interrupt input,

bits 1 and 2 are both set when an interrupt occurs. When both

GEN_IO_0 and GEN_IO_1 pins are configured as interrupt

inputs, only one bit corresponding to the interrupt source is

set when an interrupt occurs.

TABLE 6. Interrupt Code

7 6 5 4 3 2 1 0

0 0 0 0 ERROR EX_1 EX_0 KEYPAD

Bit Description

ERROR An error condition occurred.

EX_1 A rising or falling edge was detected on GEN_IO_1.

EX_0 A rising or falling edge was detected on GEN_IO_0.

KEYPAD A key-press or key-release event occurred.

10.2 ERROR CODE

If the LM8333 reports an error, the READ_ERROR command

(0xF0) is used to read and clear the error code. Table 7 shows

the format of the error code.

TABLE 7. Error Code

7 6 5 4 3 2 1 0

0 FIFOOVR 0 NOINT 0 KEYOVR CMDUNK CMDOVR

11 www.national.com

LM8333

Page 12

Bit Description

FIFOOVR Key event occurred while the FIFO was full.

NOINT Interrupt deasserted before it could be serviced.

KEYOVR More than two keys were pressed simultaneously.

CMDUNK Not a valid command.

CMDOVR Command received before it could be accepted, e.g. after wake-up.

10.3 STATUS CODES

The host can use the READ_STAT command (0xE0) to read

the status code, for example to synchronize after an error.

TABLE 8. Status Codes

Status Code Description

Reset 0000 0000 Default after reset.

Wake Up Interrupt 0000 0010 Wake-up caused by external interrupt.

Ack 0000 0110 Last host command was successful.

NoAck 0001 0101 Last host command was not successful.

10.4 INTERRUPT PROCESSING

Unexpected states encountered during run-time, for example

overrun of the FIFO buffer, are reported as errors. When the

host receives an interrupt from the LM8333, it uses a

READ_INT command to read the interrupt code. If the code

has a set ERROR bit, the host then uses a READ_ERROR

command to read the error code, as shown in Figure 11.

20210613

FIGURE 11. Interrupt Processing

www.national.com 12

LM8333

Page 13

10.5 COMMAND EXECUTION SUMMARY

•

With the interrupt, status, and error codes, the LM8333

provides the features needed to support a reliable keyscan functionality.

•

Up to 14 key-scan events can be stored in an internal FIFO

buffer. The end of buffer is indicated with the 00 (empty

character) code.

•

The host can repeatedly read the FIFO without modifying

the FIFO pointer using the RPT_FIFO_READ command

(0x21), for example if an error is encountered during a

read.

•

The LM8333 asserts the IRQ

output low when a new

character is pressed after the last interrupt acknowledge

from the host. The IRQ output will be deasserted after the

host has acknowledged the interrupt by reading the

interrupt code using the READ_INT command (0xD0).

•

The host can synchronize with the LM8333 by reading the

status code with the READ_STAT command (0xE0). The

status code verifies whether the last command was

successfully completed.

•

Two GPIO pins on the LM8333 may be configured as

external interrupt inputs. A rising or falling edge on an

enabled interrupt input triggers wake-up from Halt mode

and asserts an interrupt to the host by pulling the IRQ

output low.

•

The host can change the debounce time from the default

time of 10 ms. This can be used for reliable scanning of

keyboards with noisy contacts. The debounce time can be

set to about 1 second in steps of 4 milliseconds. The

debounce time is set with the DEBOUNCE command

(0x22).

•

The host can change the active time permitted before

entering Halt mode from the default period of 500 ms. The

active time is the time during which the keypad is scanned

after the last key is released, before entering Halt mode.

The active time must be longer than the debounce time.

•

The host can program the direction and output state of four

general-purpose I/O pins. The host can also read the

states on these pins.

•

The host can program a 16-bit timer for generating a PWM

output. If the PWM function is not used, the PWM pin can

be used as a general-purpose output.

13 www.national.com

LM8333

Page 14

11.0 Absolute Maximum Ratings (Note

1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage (VCC)

3.5V

Voltage at Any Pin -0.3V to VCC +0.3V

Maximum Input Current Without

Latchup ±100 mA

ESD Protection Level

Human Body Model 2 kV

Machine Model 200V

Total Current into VCC Pin

(Source) 80 mA

Total Current out of GND Pin (Sink) 60 mA

Storage Temperature Range −65°C to +140°C

12.0 DC Electrical Characteristics

(Temperature: -40°C ≤ TA ≤ +85°C)

Data sheet specification limits are guaranteed by design, test, or statistical analysis.

Symbol Parameter Conditions

Min

(Note 2)

Typ

Max

(Note 2)

Units

V

CC

Operating Voltage 2.25 2.9 V

Power Supply Rise Time from 0.0V 20 µs 10 ms

(On Chip Power-On Reset Selected)

I

DD

Supply Current (Note 3) RC Clock = 10 MHz, 6 mA

VCC = 2.75V, TC = 1 µs (Note

4)

I

HALT

Standby Mode Current (Note 5) VCC = 2.75V, TC = 0 µs, (Note

4), TA = 25°C

<2 15 µA

V

IL

Logical 0 Input Voltage 0.25 V

CC

V

V

IH

Logical 1 Input Voltage 0.8 V

CC

V

Hi-Z Input Leakage (TRI-STATE Output) VCC = 2.75V -0.1 0.1 µA

Input PullupCurrent VCC = 2.75V, VIN = 0V -15 -120 µA

Port Input Hysteresis (Note 6) 0.1 V

Output Current Source (Weak Pull-Up) VCC = 2.25V, VOH = 1.7V -10 -80 µA

Output Current Source (Push-Pull Mode) VCC = 2.25V, VOH = 1.7V -10 mA

Output CurrentSink (Push-Pull Mode) VCC = 2.25V, VOL = 0.4V 10 mA

Allowable Sink and Source Current per Pin 16 mA

C

PAD

Input Capacitance 8.5 pF

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

intended to be functional, but specific performance is not guaranteed. For guaranteed specifications and test conditions, see the Electrical Characteristics tables.

Note 2: Data sheet minimum and maximum limits are guaranteed by design, test, or statistical analysis.

Note 3: Supply current is measured with inputs connected to VCC and outputs driven low but not connected to a load.

Note 4: TC = instruction cycle time (min. 0.7 µs).

Note 5: In Halt mode, the internal clock is switched off. Supply current in Halt mode is measured with inputs connected to VCC and outputs driven low but not

connected to a load.

Note 6: Guaranteed by design, not tested.

www.national.com 14

LM8333

Page 15

13.0 AC Electrical Characteristics

(Temperature: -40°C ≤ TA ≤ +85°C)

Data sheet specification limits are guaranteed by design, test, or statistical analysis.

Symbol Parameter Conditions

Min

(Note 7)

Typ

Max

(Note 7)

Units

Internal Oscillator

External R from CLK_IN to Gnd (R

= 68 kohm)

0.75 µs

2.25V ≤ VCC ≤ 2.75V

System Oscillator (mclk)

External R from CLK_IN to Gnd (R

= 68 kohm)

2.25V ≤ VCC ≤ 2.75V

75 ns

System Oscillator and Internal

Frequency Variation

2.25V ≤ VCC ≤ 2.75V

±30 %

Input Pulse Width Low 0.7 µs

Input Pulse Width High 0.7 µs

ACCESS.bus Input Timing (Note 8)

t

BUFi

Bus free time between Stop and

Start Condition

t

SCLhigho

t

CSTOHsi

SCL setup time Before Stop Condition 8 mclk

t

CSTRHhi

SCL hold time After Start Condition 8 mclk

t

DHCsi

Data High setup time Before SCL Rising Edge (RE) 2 mclk

t

DLCsi

Data Low setup time Before SCL RE 2 mclk

t

SCLlowi

SCL low time After SCL Falling Edge (FE) 12 mclk

t

SCLhighi

SCL high time After SCL RE 12 mclk

t

SDAhi

SDA hold time After SCL FE 0 ns

t

SDAsi

SDA setup time Before SCL RE 2 mclk

ACCESS.bus Output Timing (Note 8)

t

BUFo

Bus free time between Stop and

Start Condition

t

SCLhigho

t

CSTOso

SCL setup time Before Stop Condition t

SCLhigho

t

CSTRho

SCL hold time After Start Condition t

SCLhigho

t

CSTRso

SCL setup time Before Start Condition t

SCLhigho

t

DHCso

Data High setup time Before SCL RE t

SCLhigho

t

DLCso

Data Low setup time Before SCL RE t

SCLhigho

t

SCLlowo

SCL low time After SCL FE 16 mclk

t

SCLhigho

SCL high time After SCL RE 16 mclk

t

SDAho

SDA hold time After SCL FE 7 mclk

t

SDAvo

SDA valid time Before SCL FE 7 mclk

Note 7: Data sheet minimum and maximum limits are guaranteed by design, test, or statistical analysis.

Note 8: The ACCESS.bus interface of the LM8333 device implements and meets the timing necessary for interface to the I2C bus and SMBus protocol at logic

levels. The bus drivers are designed with open-drain output as required for bidirectional operation. The LM8333 device will not meet the AC timing and current/

voltage requirements of the full bus specification.

15 www.national.com

LM8333

Page 16

20210614

FIGURE 12. ACCESS.bus Start and Stop Condition Timing

www.national.com 16

LM8333

Page 17

14.0 Physical Dimensions inches (millimeters) unless otherwise noted

Leadless Leadframe Package

Order Number LM8333FLQ8X or LM8333FLQ8Y

NS Package Number LQA32A

Micro Array Package

Order Number LM8333GGR8

NS Package Number GRA49A

17 www.national.com

LM8333

Page 18

Notes

LM8333 Mobile I/O Companion Supporting Key-Scan, I/O Expansion, PWM, and ACCESS.bus

Host Interface

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2007 National Semiconductor Corporation

For the most current product information visit us at www.national.com

National Semiconductor

Americas Customer

Support Center

Email:

new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Customer Support Center

Fax: +49 (0) 180-530-85-86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +49 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor Asia

Pacific Customer Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

www.national.com

Loading...

Loading...