Page 1

December 2003

LM64

±

1˚C Remote Diode Temperature Sensor with PWM Fan

Control and 5 GPIO’s

LM64

±

1˚C Remote Diode Temperature Sensor with PWM Fan Control and 5 GPIO’s

General Description

The LM64 is a remote diode temperature sensor with PWM

fan control. The LM64 accurately measures its own temperature and that of a remote diode. The LM64 remote temperature accuracy is factory trimmed for a MMBT3904 diodeconnected transistor with a 16˚C offset for high

temperatures. T

The LM64 features a PWM, open-drain, fan control output, 5

GPIO (General Purpose Input/Output) and 5 GPD (General

Purpose Default) pins. The 8-step Lookup Table allows for a

non-linear fan speed vs. temperature transfer function often

used to quiet acoustic fan noise.

ACTUAL DIODE JUNCTION

=T

LM64

+ 16˚C

Features

n Accurately senses remote and local diode temperatures

n Integrated PWM fan speed control output

n Programmable 8-step Lookup Table for quieting fans

n ALERT and T_Crit open-drain outputs

n Tachometer input for measuring fan RPM

n 10 bit plus sign remote diode temperature data format,

with 0.125˚C resolution

n SMBus 2.0 compatible interface, supports TIMEOUT

n 5 General Purpose Input/Output pins

n 5 General Purpose Default input pins

n 24-pin LLP package

Key Specifications

n Remote Diode Temperature Accuracy (includes

quantization error)

Ambient Temp Diode Temp Max Error

±

30˚C to 50˚C 120˚C to 140˚C

0˚C to 85˚C 25˚C to 140˚C

n Local Temp Accuracy (includes quantization error)

Ambient Temp Max Error

25˚C to 125˚C

n Power Supply Requirements

Supply DC Voltage 3.0 V to 3.6 V

Supply DC Current 1.1 mA (typ)

1.0˚C (max)

±

3.0˚C (max)

±

3.0˚C (max)

Applications

n Computer Processor Thermal Management

n Graphics Processor Thermal Management

n Voltage Regulator Modules

n Electronic Instrumentation

n Power Supplies

n Projectors

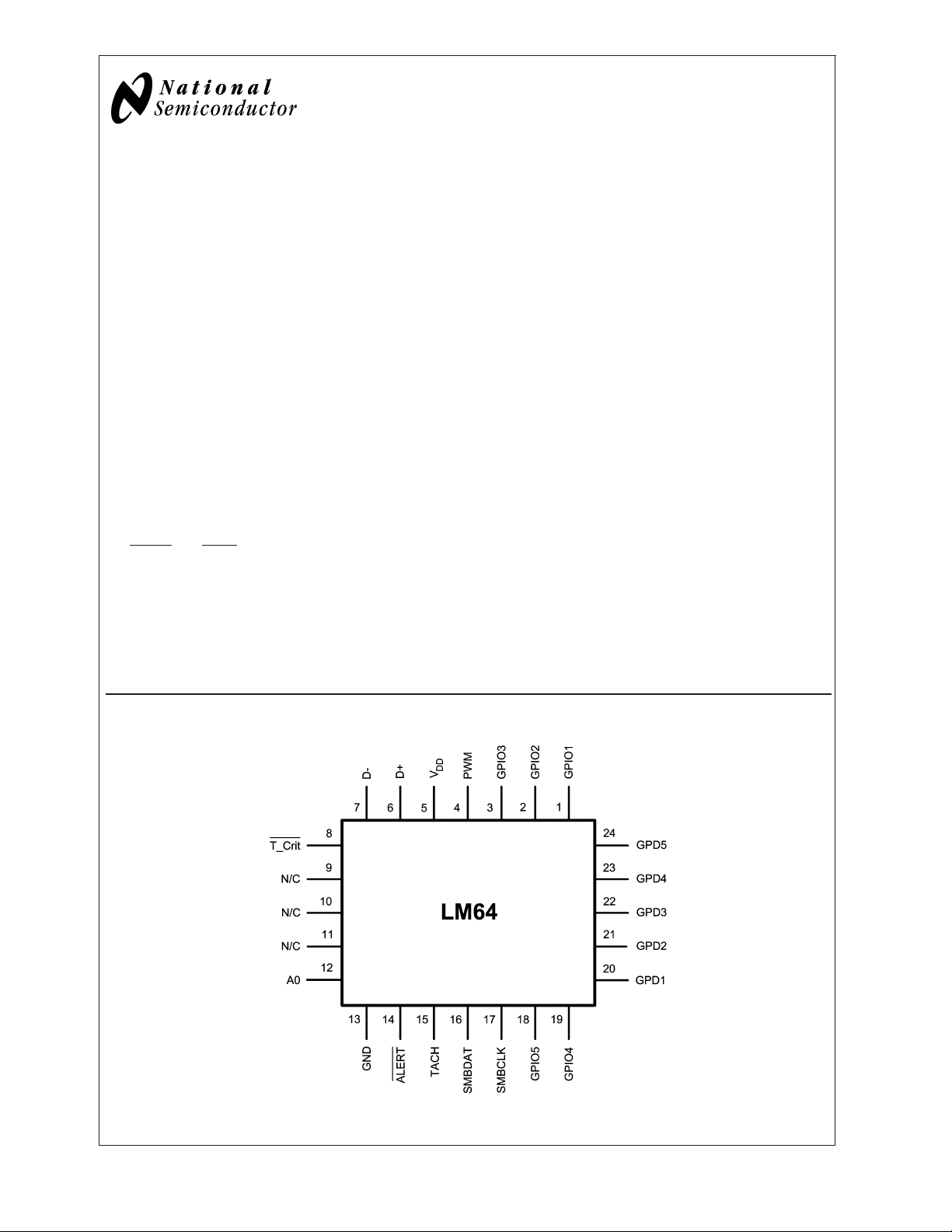

Connection Diagram

20065501

© 2003 National Semiconductor Corporation DS200655 www.national.com

Page 2

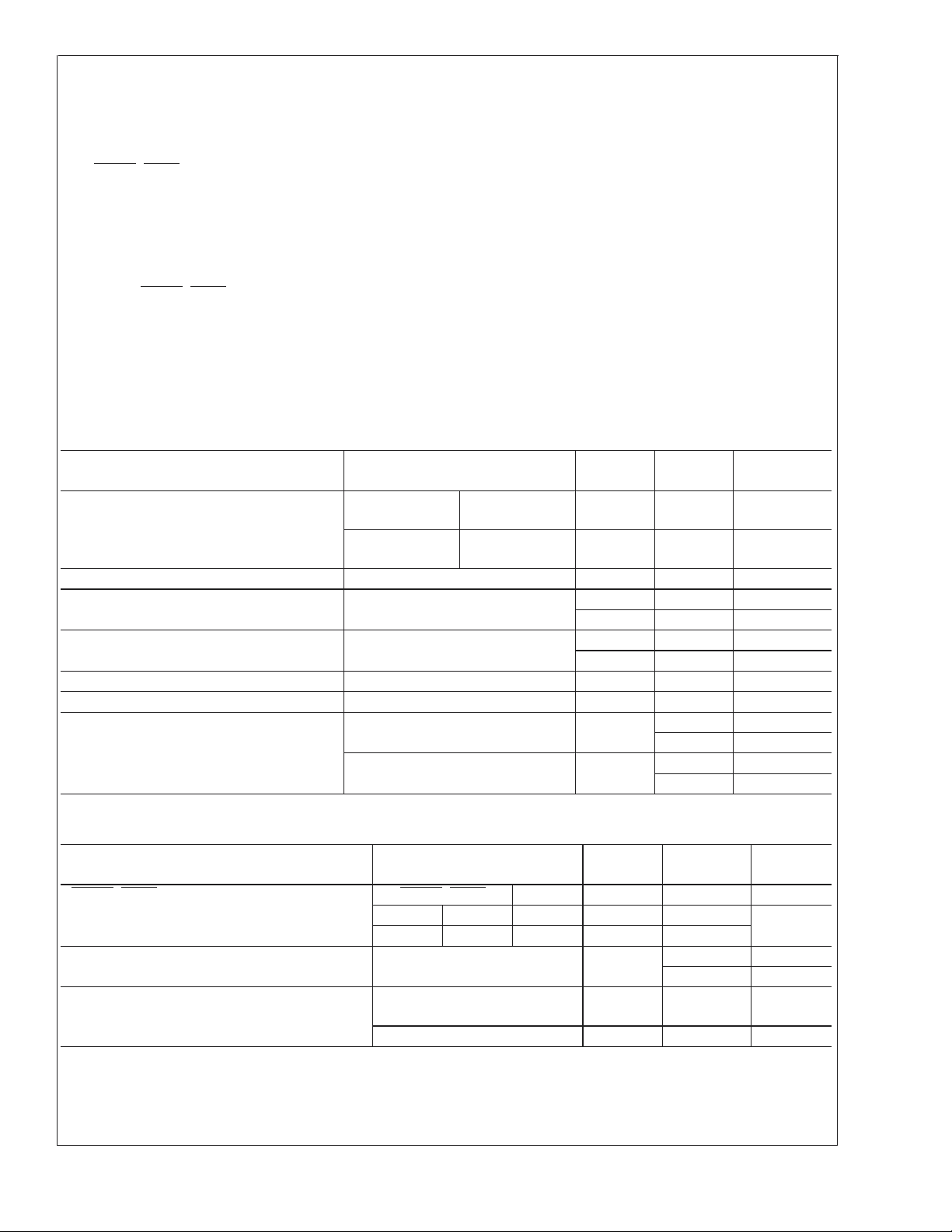

Pin Descriptions

LM64

Pin Name Input/Output Function and Connection

1 GPIO1

2 GPIO2

3 GPIO3

4 PWM

5V

DD

Digital Input/

Open-Drain Output

Digital Input/

Open-Drain Output

Digital Input/

Open-Drain Output

Open-Drain

Digital Output

Power Supply Input

General Purpose Open-Drain Digital Output or Digital Input. Typical pull-up

resistor is 10 kΩ to V

.

DD

General Purpose Open-Drain Digital Output or Digital Input. Typical pull-up

resistor is 10 kΩ to VDD.

General Purpose Open-Drain Digital Output or Digital Input. Typical pull-up

resistor is 10 kΩ to V

.

DD

Open-Drain Digital Output. Connect to fan drive circuitry. The power-on

default for this pin is low (pin 4 pulled to ground).

Connect to a low-noise +3.3

±

0.3 VDC power supply, and bypass to GND

with a 0.1 µF ceramic capacitor in parallel with a 100 pF ceramic capacitor.

A bulk capacitance of 10 µF needs to be in the vicinity of the LM64’s V

pin.

6 D+ Analog Input

7 D- Analog Input

8 T_Crit

Open-Drain

Digital Output

Connect to the anode (positive side) of the remote diode. A 2.2 nF ceramic

capacitor must be connected between pins 6 and 7.

Connect to the cathode (negative side) of the remote diode. A 2.2 nF

ceramic capacitor must be connected between pins 6 and 7.

Open-Drain Digital Output. Typical pull-up resistor is 3 kΩ to V

9 N/C N/A No Connection.

10 N/C N/A No Connection.

11 N/C N/A No Connection.

12 A0 Digital Input

SMBus Address Select pin. If High, the SMBus address is 0x4E or, if Low,

the SMBus address is 0x18. Typical pull-up resistor is 10 kΩ to V

13 GND Ground This is the analog and digital ground return.

14 ALERT

Open-Drain

Digital Output

15 TACH Digital Input

16 SMBDAT

Digital Input/

Open-Drain Output

This pin is an open-drain ALERT Output. Typical pull-up resistor is 3 kΩ to

.

V

DD

This pin is a digital tachometer input. Typical pull-up resistor is 3 kΩ to

.

V

DD

This is the bi-directional SMBus data line. Typical pull-up resistor is 1.5 kΩ

.

to V

DD

17 SMBCLK Digital Input This is the SMBus clock input. Typical pull-up resistor is 1.5 kΩ to V

18 GPIO5

19 GPIO4

Digital Input/

Open-Drain Output

Digital Input/

Open-Drain Output

20 GPD1 Digital Input

21 GPD2 Digital Input

22 GPD3 Digital Input

23 GPD4 Digital Input

24 GPD5 Digital Input

General Purpose Open-Drain Digital Output or Digital Input. Typical pull-up

resistor is 10 kΩ to V

.

DD

General Purpose Open-Drain Digital Output or Digital Input. Typical pull-up

resistor is 10 kΩ to V

.

DD

General Purpose Default Input Pin. Typical pull-up resistor is 10 kΩ to V

Always connect to a logical High or Low level.

General Purpose Default Input Pin. Typical pull-up resistor is 10 kΩ to VDD.

Always connect to a logical High or Low level.

General Purpose Default Input Pin. Typical pull-up resistor is 10 kΩ to V

Always connect to a logical High or Low level.

General Purpose Default Input Pin. Typical pull-up resistor is 10 kΩ to VDD.

Always connect to a logical High or Low level.

General Purpose Default Input Pin. Typical pull-up resistor is 10 kΩ to V

Always connect to a logical High or Low level.

DD

.

DD

.

DD

.

DD

.

DD

.

DD

.

DD

www.national.com 2

Page 3

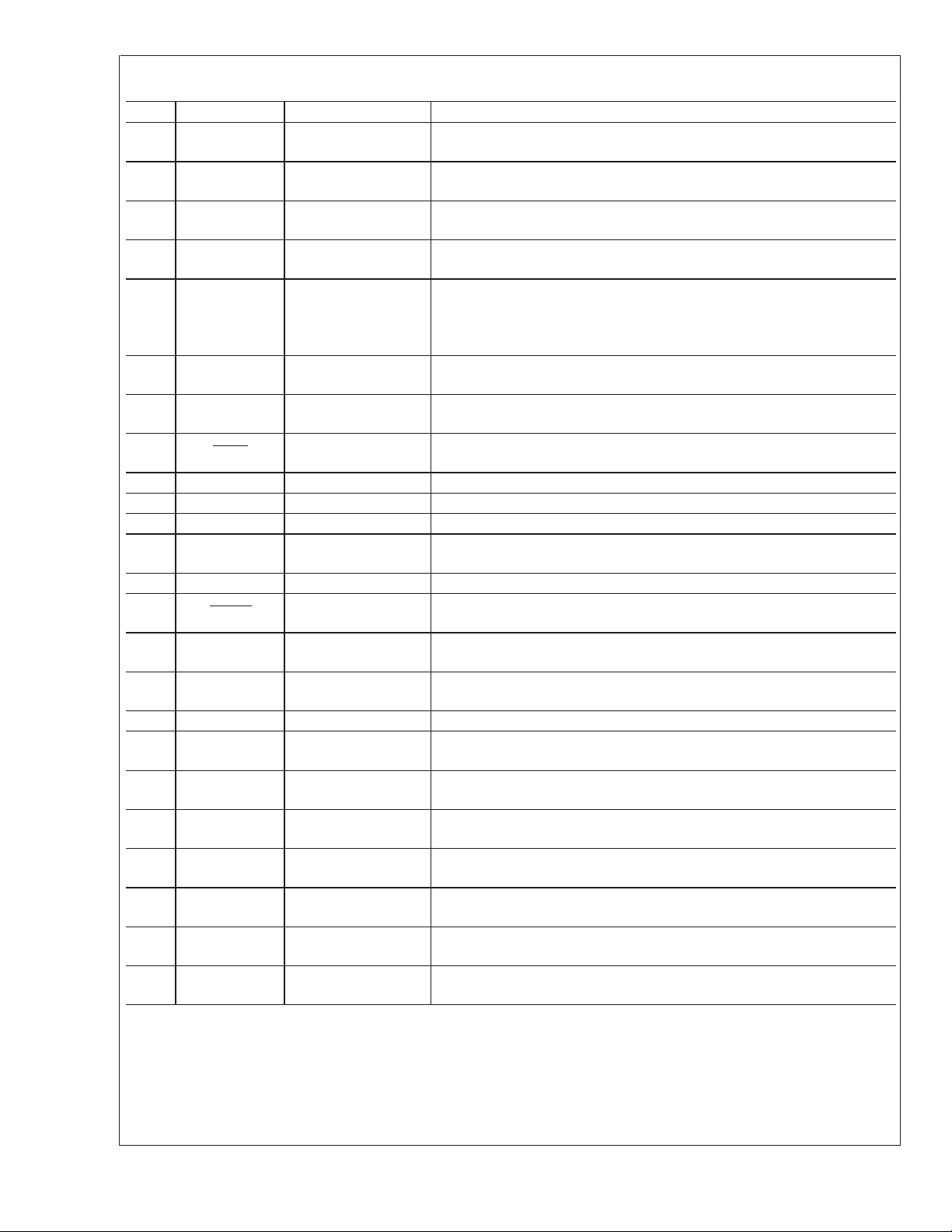

Simplified Block Diagram

LM64

Ordering Information

Part Description Order Number Top Mark Transport Media

LM64 24-pin LLP LM64CILQ-F 64CILQF 1000 Units in Tape and Reel

LM64 24-pin LLP LM64CILQX-F 64CILQF 4500 Units in Tape and Reel

LM64 Evaluation Board

With Software and Manual

20065502

LM64EVAL N/A Packaged

www.national.com3

Page 4

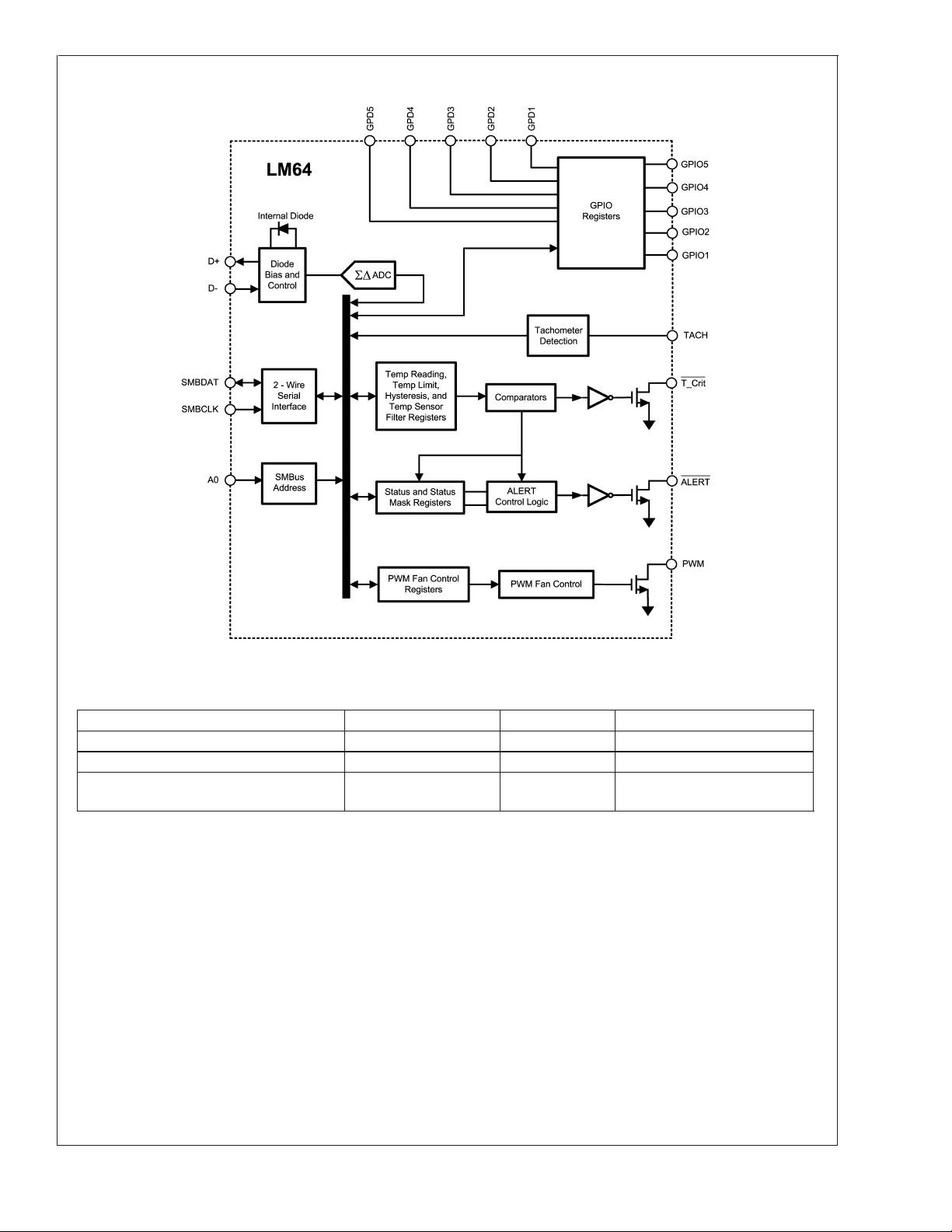

Typical Application

LM64

www.national.com 4

20065503

Page 5

LM64

Absolute Maximum Ratings (Notes 1,

2)

Supply Voltage, V

DD

Voltage on SMBDAT, SMBCLK,

ALERT, T_Crit, PWM Pins −0.5 V to 6.0 V

Voltage on Other Pins −0.3 V to (V

Input Current, D− Pin

−0.3 V to 6.0 V

+0.3V)

DD

±

1mA

ESD Susceptibility (Note 4)

Human Body Model 2000 V

Machine Model 200 V

SMT Soldering Information

See National Semiconductor Application Note AN-1187,

"Leadless Leadframe Package" for information on SMT

Assembly using LLP Packages. This is available at

http://www.national.com/an/AN/AN-1187.pdf.

Input Current at All Other Pins (Note 3) 5 mA

Package Input Current (Note 3) 30 mA

Package Power Dissipation (Note 5)

SMBDAT, ALERT, T_Crit, PWM pins

Output Sink Current 10 mA

Storage Temperature −65˚C to +150˚C

Operating Ratings (Notes 1, 2)

LM64 Operating Temperature Range 0˚C ≤ T

Remote Diode Temperature Range 25˚C ≤ T

Electrical Characteristics T

MIN

≤ +85˚C

A

≤ +140˚C

D

≤ TA≤ T

MAX

Supply Voltage Range (VDD) +3.0 V to +3.6 V

DC Electrical Characteristics

TEMPERATURE-TO-DIGITAL CONVERTER CHARACTERISTICS The following specifications apply for VDD= 3.0 VDC to

3.6 VDC, and all analog source impedance R

T

A=TMIN

to T

; all other limits TA= +25˚C.

MAX

Parameter Conditions

Temperature Error using a diode-connected

MMBT3904 transistor. T

is the Remote

D

Diode Junction Temperature.

T

D=TLM64

+ 16˚C

Temperature Error Using the Local Diode T

Remote Diode Resolution 11 Bits

Local Diode Resolution 8 Bits

Conversion Time of All Temperatures Fastest Setting 31.25 34.4 ms (max)

D− Source Voltage 0.7 V

Diode Source Current

=50Ω unless otherwise specified in the conditions. Boldface limits apply for

S

= +30˚C to

T

A

+50˚C

T

= +0˚C to

A

+85˚C

= +25˚C to +125˚C (Note 10)

A

TD= +120˚C to

+140˚C

TD= +25˚C to

+140˚C

Typical

(Note 7)

±

1

Limits

(Note 8)

±

1 ˚C (max)

±

3 ˚C (max)

±

3 ˚C (max)

Units

(Limits)

0.125 ˚C

1˚C

(V

D+−VD−

Current

) = +0.65 V; High

160

Low Current 13

315 µA (max)

110 µA (min)

20 µA (max)

7 µA (min)

Operating Electrical Characteristics

Parameter

ALERT, T_Crit and PWM Output Saturation

Voltage

Conditions

ALERT, T_Crit

I

I

OUT

OUT

4mA 6mA 0.4

6mA 0.55

PWM

Typ

(Note 7)

Power-On-Reset Threshold Voltage 2.4 V (max)

Supply Current (Note 9) SMBus Inactive, 16 Hz

Conversion Rate

1.1 2.0 mA (max)

STANDBY Mode 320 µA

Limits

(Note 8)

V (max)

1.8 V (min)

www.national.com5

Units

Page 6

AC Electrical Characteristics

LM64

The following specifications apply for VDD= 3.0 VDC to 3.6 VDC, and all analog source impedance RS=50Ω unless other-

wise specified in the conditions. Boldface limits apply for T

A=TMIN

Symbol Parameter Conditions

to T

; all other limits TA= +25˚C.

MAX

Typical

(Note 7)

Limits

(Note 8)

TACHOMETER ACCURACY

Fan Control Accuracy

±

10 % (max)

Fan Full-Scale Count 65535 (max)

Fan Counter Clock Frequency 90 kHz

Fan Count Update Frequency 1.0 Hz

FAN PWM OUTPUT

Frequency Accuracy

±

10 % (max)

Digital Electrical Characteristics

Symbol Parameter Conditions

V

V

I

IH

I

IL

C

Logical High Input Voltage 2.1 V (min)

IH

Logical Low Input Voltage 0.8 V (max)

IL

Logical High Input Current VIN=V

DD

Logical Low Input Current VIN= GND −0.005 −10 µA (max)

Digital Input Capacitance 20 pF

IN

Typical

(Note 7)

0.005 +10 µA (max)

Limits

(Note 8)

Units

(Limit)

Units

(Limit)

SMBus Logical Electrical Characteristics

The following specifications apply for VDD= 3.0 VDC to 3.6 VDC, and all analog source impedance RS=50Ω unless other-

wise specified in the conditions. Boldface limits apply for T

A=TMIN

to T

Symbol Parameter Conditions

SMBDAT OPEN-DRAIN OUTPUT

V

I

OH

Logic Low Level Output Voltage IOL=4mA 0.4 V (max)

OL

High Level Output Current V

OUT=VDD

SMBDAT, SMBCLK INPUTS

V

V

V

HYST

Logical High Input Voltage 2.1 V (min)

IH

Logical Low Input Voltage 0.8 V (max)

IL

Logic Input Hysteresis Voltage 400 mV

; all other limits TA= +25˚C.

MAX

Typical

(Note 7)

0.03 10 µA (max)

Limits

(Note 8)

Units

(Limit)

www.national.com 6

Page 7

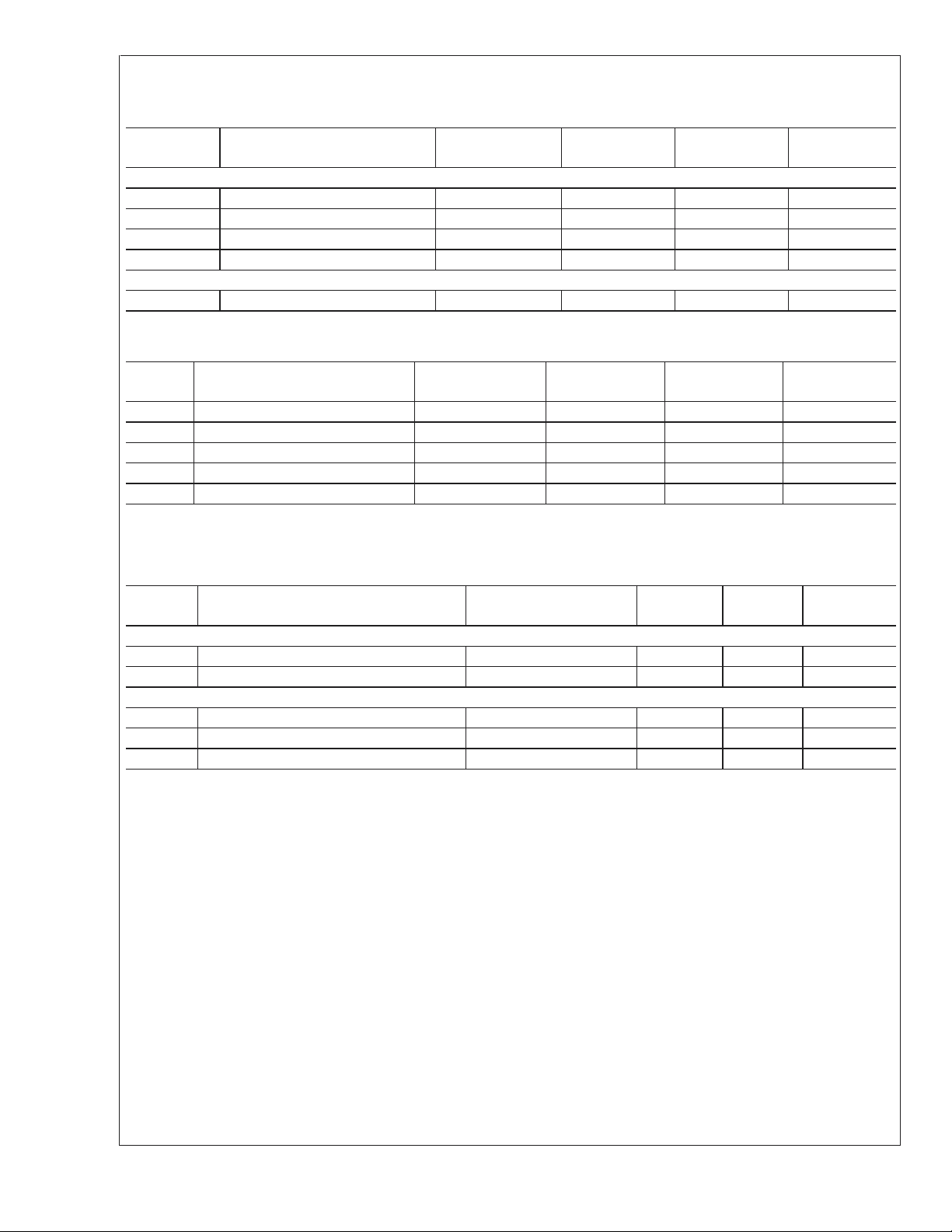

SMBus Digital Switching Characteristics

Unless otherwise noted, these specifications apply for VDD= +3.0 VDC to +3.6 VDC, CL(load capacitance) on output lines =

80 pF. Boldface limits apply for T

A=TJ;TMIN

≤ TA≤ T

switching characteristics of the LM64 fully meet or exceed the published specifications of the SMBus version 2.0. The following

parameters are the timing relationships between SMBCLK and SMBDAT signals related to the LM64. They adhere to but are

not necessarily the same as the SMBus bus specifications.

Symbol Parameter Conditions

f

SMB

t

LOW

t

HIGH

t

R

t

F

t

OF

t

TIMEOUT

SMBus Clock Frequency 10

SMBus Clock Low Time From V

SMBus Clock High Time From V

SMBus Rise Time (Note 11) 1 µs (max)

SMBus Fall Time (Note 12) 0.3 µs (max)

Output Fall Time CL= 400 pF, IO=3mA 250 ns (max)

SMBData and SMBCLK Time Low for Reset

of Serial Interface See (Note 13)

t

SU:DAT

t

HD:DAT

t

HD:STA

Data In Setup Time to SMBCLK High 250 ns (min)

Data Out Hold Time after SMBCLK Low 300

Hold Time after (Repeated) Start Condition.

After this period the first clock is generated.

t

SU:STO

Stop Condition SMBCLK High to SMBDAT

Low (Stop Condition Setup)

t

SU:STA

SMBus Repeated Start-Condition Setup Time,

SMBCLK High to SMBDAT Low

t

BUF

SMBus Free Time between Stop and Start

Conditions

; all other limits TA=TJ= +25˚C, unless otherwise noted. The

MAX

Limits

(Note 8)

100

IN(0) max

IN(1) min

to V

to V

IN(0) max

IN(1) min

4.7 µs (min)

4.0

50

25

35

930

4.0 µs (min)

100 ns (min)

4.7 µs (min)

4.7 µs (min)

Units

(Limit)

kHz (min)

kHz (max)

µs (min)

µs (max)

ms (min)

ms (max)

ns (min)

ns (max)

LM64

FIGURE 1. SMBus Timing Diagram for SMBCLK and SMBDAT Signals

20065504

www.national.com7

Page 8

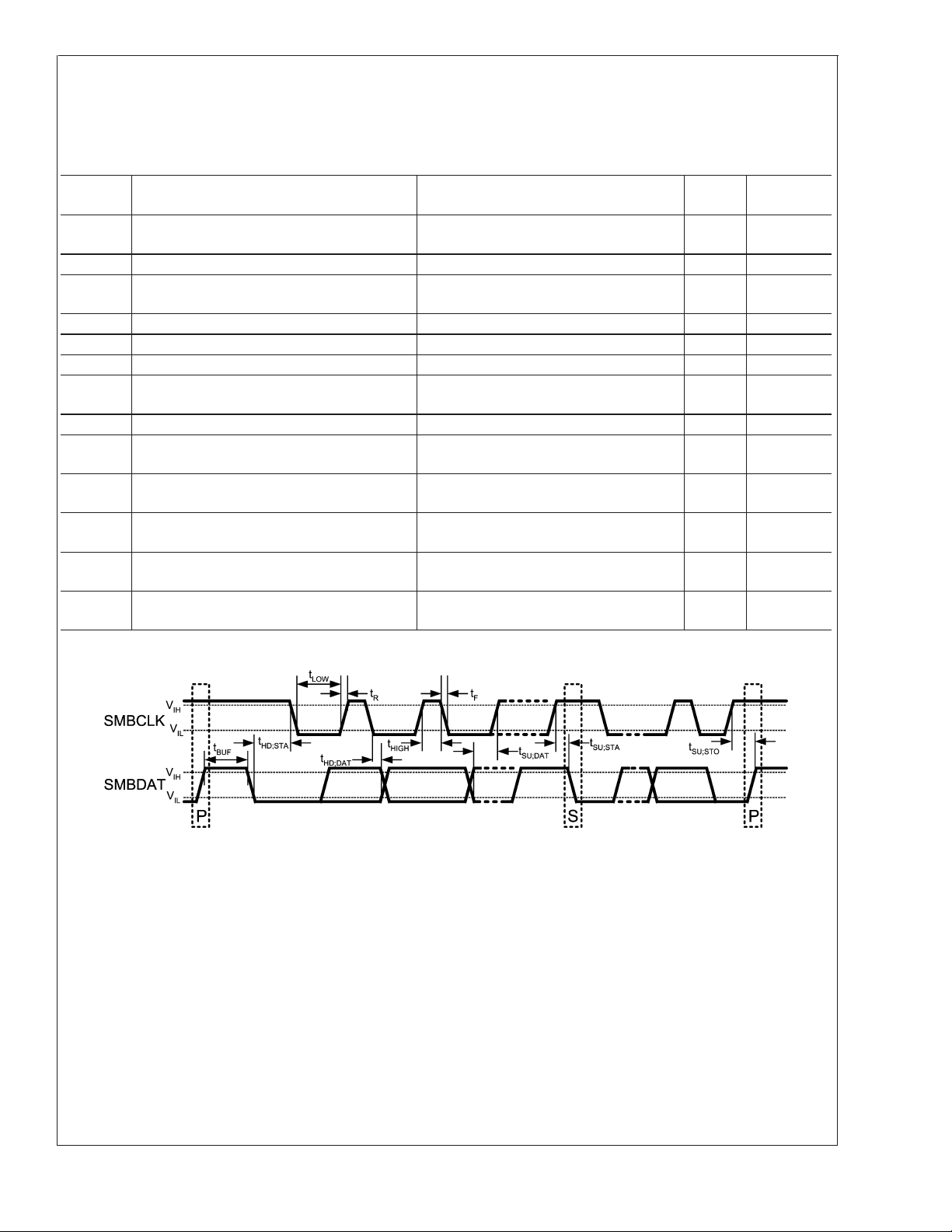

Notes

LM64

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

functional, but do not guarantee performance limits. For guaranteed specifications and test conditions, see the Electrical Characteristics. The guaranteed

specifications apply only for the test conditions listed. Some performance characteristics may degrade when the device is not operated under the listed test

conditions.

Note 2: All voltages are measured with respect to GND, unless otherwise noted.

Note 3: When the input voltage (V

components and/or ESD protection circuitry are shown in the table below, for the LM64’s pins, by an "X" when it exists. Care should be taken not to forward bias

the parasitic diode, D1, present on pins D+ and D−. Doing so by more than 50 mV may corrupt temperature measurements.

) at any pin exceeds the power supplies (V

IN

IN

<

GND or V

>

V+), the current at that pin should be limited to 5 mA. Parasitic

IN

Pin Name PIN

#

D1 D2 D3 D4 D5 D6 R1 SNP ESD CLAMP

GPIO1 1 X X X

GPIO2 2 X X X

GPIO3 3 X X X

PWM 4 X X X

V

DD

5 X

D+ 6 XX XXX X

D− 7 XX XXX X

T_Crit

8X XXX

A0 12 X

ALERT

14 X X X X

TACH 15 X X X

SMBDAT 16 X X X

SMBCLK 17 X

GPIO5 18 X X X

GPIO4 19 X X X

GPD1 20 X

GPD2 21 X

GPD3 22 X

GPD4 23 X

GPD5 24 X

20065505

FIGURE 2. ESD Protection Input Structure

Note 4: Human body model, 100 pF discharged through a 1.5 kΩ resistor. Machine model, 200 pF discharged directly into each pin. See Figure 2 above for the ESD

Protection Input Structure.

Note 5: See the National Semiconductor Application Note AN-1187 for Thermal Resistance Junction-to-Ambient Temperature.

Note 6: See the National Semiconductor Application Note AN-1187 for recommendations on SMT assembly using the LLP packages.

Note 7: “Typicals” are at T

Note 8: Limits are guaranteed to National’s AOQL (Average Outgoing Quality Level).

Note 9: The supply current will not increase substantially with an SMBus transaction.

Note 10: Local temperature accuracy does not include the effects of self-heating. The rise in temperature due to self-heating is the product of the internal power

dissipation of the LM64 and the thermal resistance. See (Note 5) for the thermal resistance to be used in the self-heating calculation.

Note 11: The output rise time is measured from (V

Note 12: The output fall time is measured from (V

Note 13: Holding the SMBData and/or SMBCLK lines Low for a time interval greater than t

SMBDAT and SMBCLK pins to a high impedance state.

www.national.com 8

= 25˚C and represent most likely parametric norm. They are to be used as general reference values not for critical design calculations.

A

IL max

IH min

- 0.15 V) to (V

+ 0.15 V) to (V

IH min

IL min

+ 0.15 V).

- 0.15 V).

will reset the LM64’s SMBus state machine, therefore setting

TIMEOUT

Page 9

1.0 Functional Description

The LM64 Remote Diode Temperature Sensor with Integrated Fan Control incorporates a ∆V

sensor using a Local or Remote diode and a 10-bit plus sign

∆Σ ADC (Delta-Sigma Analog-to-Digital Converter). The

pulse-width modulated (PWM) open-drain output, with a

pull-up resistor, can drive a switching transistor to modulate

the fan. The LM64 can measure the fan speed on the pulses

from the fan’s open-collector tachometer output, pulled up by

a 1.5 kΩ resistor to V

. The ALERT open-drain output will

DD

be pulled low under certain conditions descibed in the sections below. The T_Crit open-drain output will be pulled low

when the T_Crit setpoint temperature limit is exceeded. This

behaves as a typical comparator function without any latching.

The LM64’s two-wire interface is compatible with the SMBus

Specification 2.0 . For more information the reader is directed to www.smbus.org.

In the LM64, digital comparators are used to compare the

measured Local Temperature (LT) to the Local High Setpoint

user-programmable temperature limit register. The measured Remote Temperature (RT) is digitally compared to the

Remote High Setpoint (RHS), the Remote Low Setpoint

(RLS), and the Remote T_CRIT Setpoint (RCS) userprogrammable temperature limits. An ALERT output will occur when the measured temperature is: (1) higher than either

the High Setpoint or the T_CRIT Setpoint, or (2) lower than

the Low Setpoint. The ALERT Mask register allows the user

to prevent the generation of these ALERT outputs.

The temperature hysteresis is set by the value placed in the

Hysteresis Register (TH).

The LM64 may be placed in a low power Standby mode by

setting the Standby bit found in the Configuration Register. In

the Standby mode continuous conversions are stopped. In

Standby mode the user may choose to allow the PWM

output signal to continue, or not, by programming the PWM

Disable in Standby bit in the Configuration Register.

The Local Temperature reading and setpoint data registers

are 8-bits wide. The format of the 11-bit remote temperature

data is a 16-bit left justified word. Two 8-bit registers, high

and low bytes, are provided for each setpoint as well as the

temperature reading. Two Remote Temperature Offset

(RTO) Registers: High Byte and Low Byte (RTOHB and

RTOLB) may be used to correct the temperature readings by

adding or subtracting a fixed value based on a different

non-ideality factor of the thermal diode if different from the

graphics processor thermal diode. See Section 4.1 Thermal

Diode Non-Ideality.

1.1 CONVERSION SEQUENCE

The LM64 takes approximately 31.25 ms to convert the

Local Temperature (LT), Remote Temperature (RT), and to

update all of its registers. The Conversion Rate may be

modified using the Conversion Rate Register. When the

conversion rate is modified a delay is inserted between

conversions, the actual conversion time remains at

31.25 ms. Different Conversion Rates will cause the LM64 to

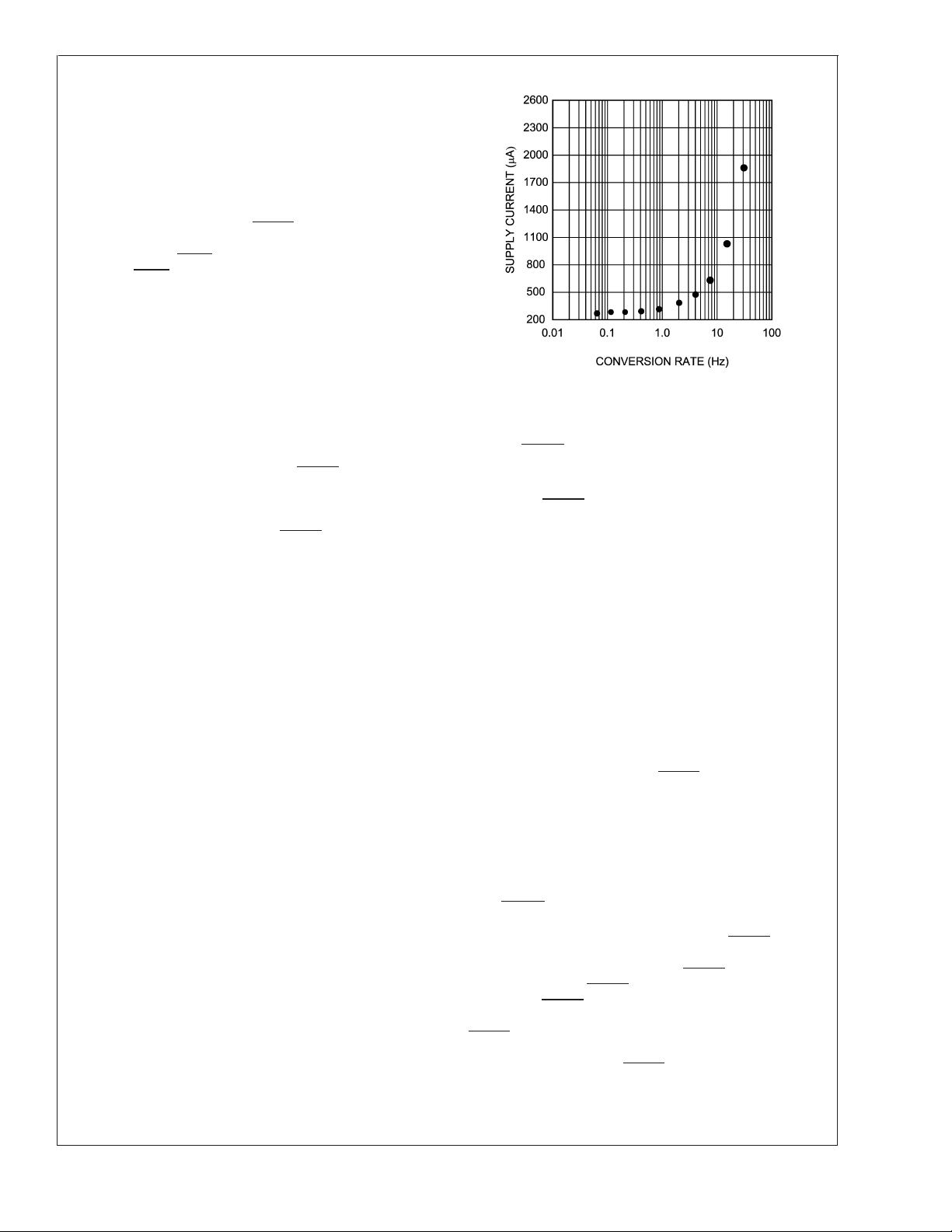

draw different amounts of supply current as shown in Figure

3.

-based temperature

BE

LM64

20065506

FIGURE 3. Supply Current vs Conversion Rate

1.2 THE ALERT OUTPUT

When the ALERT Mask bit in the Configuration register is

written as zero the ALERT interrupts are enabled.

The LM64’s ALERT pin is versatile and can produce three

different methods of use to best serve the system designer:

(1) as a temperature comparator (2) as a temperature-based

interrupt flag, and (3) as part of an SMBus ALERT System.

The three methods of use are further described below. The

ALERT and interrupt methods are different only in how the

user interacts with the LM64.

The remote temperature (RT) reading is associated with a

T_CRIT Setpoint Register, and both local and remote temperature (LT and RT) readings are associated with a HIGH

setpoint register (LHS and RHS). The RT is also associated

with a LOW setpoint register (RLS). At the end of every

temperature reading a digital comparison determines

whether that reading is above its HIGH or T_CRIT setpoint or

below its LOW setpoint. If so, the corresponding bit in the

ALERT Status Register is set. If the ALERT mask bit is low,

any bit set in the ALERT Status Register, with the exception

of Busy or Open, will cause the ALERT output to be pulled

low. Any temperature conversion that is out of the limits

defined in the temperature setpoint registers will trigger an

ALERT. Additionally, the ALERT Mask Bit must be cleared to

trigger an ALERT in all modes.

The three different ALERT modes will be discussed in the

following sections.

1.2.1 ALERT Output as a Temperature Comparator

When the LM64 is used in a system in which does not

require temperature-based interrupts, the ALERT output

could be used as a temperature comparator. In this mode,

once the condition that triggered the ALERT to go low is no

longer present, the ALERT is negated (Figure 4). For example, if the ALERT output was activated by the comparison

of LT>LHS, when this condition is no longer true, the

ALERT will return HIGH. This mode allows operation without

software intervention, once all registers are configured during set-up. In order for the ALERT to be used as a temperature comparator, the Comparator Mode bit in the Remote

Diode Temperature Filter and Comparator Mode Register

must be asserted. This is not the power-on default state.

www.national.com9

Page 10

1.0 Functional Description (Continued)

LM64

20065508

20065507

FIGURE 4. ALERT Output as Temperature Comparator

Response Diagram

1.2.2 ALERT Output as an Interrupt

The LM64’s ALERT output can be implemented as a simple

interrupt signal when it is used to trigger an interrupt service

routine. In such systems it is desirable for the interrupt flag to

repeatedly trigger during or before the interrupt service routine has been completed. Under this method of operation,

during the read of the ALERT Status Register the LM64 will

set the ALERT Mask bit in the Configuration Register if any

bit in the ALERT Status Register is set, with the exception of

Busy and Open. This prevents further ALERT triggering until

the master has reset the ALERT Mask bit, at the end of the

interrupt service routine. The ALERT Status Register bits are

cleared only upon a read command from the master (see

Figure 5) and will be re-asserted at the end of the next

conversion if the triggering condition(s) persist(s). In order

for the ALERT to be used as a dedicated interrupt signal, the

Comparator Mode bit in the Remote Diode Temperature

Filter and Comparator Mode Register must be set low. This

is the power-on default state. The following sequence describes the response of a system that uses the ALERT

output pin as an interrupt flag:

1. Master senses ALERT low.

2. Master reads the LM64 ALERT Status Register to determine what caused the ALERT.

3. LM64 clears ALERT Status Register, resets the ALERT

HIGH and sets the ALERT Mask bit in the Configuration

Register.

4. Master attends to conditions that caused the ALERT to

be triggered. The fan is started, setpoint limits are adjusted, etc.

5. Master resets the ALERT Mask bit in the Configuration

Register.

FIGURE 5. ALERT Output as an Interrupt Temperature

Response Diagram

1.2.3 ALERT Output as an SMBus ALERT

An SMBus alert line is created when the ALERT output is

connected to: (1) one or more ALERT outputs of other

SMBus compatible devices, and (2) to a master. Under this

implementation, the LM64’s ALERT should be operated using the ARA (Alert Response Address) protocol. The SMBus

2.0 ARA protocol, defined in the SMBus specification 2.0, is

a procedure designed to assist the master in determining

which part generated an interrupt and to service that interrupt.

The SMBus alert line is connected to the open-drain ports of

all devices on the bus, thereby AND’ing them together. The

ARA method allows the SMBus master, with one command,

to identify which part is pulling the SMBus alert line LOW. It

also prevents the part from pulling the line LOW again for the

same triggering condition. When an ARA command is received by all devices on the bus, the devices pulling the

SMBus alert line LOW: (1) send their address to the master

and (2) release the SMBus alert line after acknowledgement

of their address.

The SMBus Specifications 1.1 and 2.0 state that in response

to and ARA (Alert Response Address) “after acknowledging

the slave address the device must disengage its ALERT

pulldown”. Furthermore, “if the host still sees ALERT low

when the message transfer is complete, it knows to read the

ARA again.” This SMBus “disengaging ALERT requirement

prevents locking up the SMBus alert line. Competitive parts

may address the “disengaging of ALERT” differently than the

LM64 or not at all. SMBus systems that implement the ARA

protocol as suggested for the LM64 will be fully compatible

with all competitive parts.

The LM64 fulfills “disengaging of ALERT” by setting the

ALERT Mask Bit in the Configuration Register after sending

out its address in response to an ARA and releasing the

ALERT output pin. Once the ALERT Mask bit is activated,

the ALERT output pin will be disabled until enabled by

software. In order to enable the ALERT the master must read

the ALERT Status Register, during the interrupt service routine and then reset the ALERT Mask bit in the Configuration

Register to 0 at the end of the interrupt service routine.

The following sequence describes the ARA response protocol.

1. Master senses SMBus alert line low

www.national.com 10

Page 11

LM64

1.0 Functional Description (Continued)

2. Master sends a START followed by the Alert Response

Address (ARA) with a Read Command.

3. Alerting Device(s) send ACK.

4. Alerting Device(s) send their address. While transmitting

their address, alerting devices sense whether their address has been transmitted correctly. (The LM64 will

reset its ALERT output and set the ALERT Mask bit once

its complete address has been transmitted successfully.)

5. Master/slave NoACK

6. Master sends STOP

7. Master attends to conditions that caused the ALERT to

be triggered. The ALERT Status Register is read and fan

started, setpoints adjusted, etc.

8. Master resets the ALERT Mask bit in the Configuration

Register.

The ARA, 000 1100, is a general call address. No device

should ever be assigned to this address.

The ALERT Configuration bit in the Remote Diode Temperature Filter and Comparator Mode Register must be set low in

order for the LM64 to respond to the ARA command.

The ALERT output can be disabled by setting the ALERT

Mask bit in the Configuration Register. The power-on default

is to have the ALERT Mask bit and the ALERT Configuration

bit low.

1.3 SMBus INTERFACE

Since the LM64 operates as a slave on the SMBus, the

SMBCLK line is an input and the SMBDAT line is bidirectional. The LM64 never drives the SMBCLK line and it

does not support clock stretching. The LM64 has two

hardware-selectable 7-bit slave addresses. The user may

input a logical High or Low on the A0 Address pin to select

one of the two pre-programmed SMBus slave addresses.

The options are as follows:

A0

SMBus

Pin

Address

0x[Hex]

0 18 0011000

1 4E 1001110

1.4 POWER-ON RESET (POR) DEFAULT STATES

For information on the POR default states see Section 2.2

LM64 Register Map in Functional Order.

SMBus Slave Address Bits

A6 A5 A4 A3 A2 A1 A0

20065509

FIGURE 6. ALERT Output as an SMBus ALERT

Temperature Response Diagram

www.national.com11

Page 12

1.0 Functional Description (Continued)

LM64

1.5 TEMPERATURE DATA FORMAT

Temperature data can only be read from the Local and

Remote Temperature registers. The High, Low and T_CRIT

setpoint registers are Read/Write.

Actual vs. LM64 Remote Temperature Conversion

Actual Remote Diode

Temperature,˚C

LM64 Remote Diode

Temperature Register, ˚C

120 +104 0110 1000 0000 0000 6800h

125 +109 0110 1101 0000 0000 6D00h

126 +110 0110 1110 0000 0000 6E00h

130 +114 0111 0010 0010 0000 7200h

135 +119 0111 0111 0000 0000 7700h

140 +124 0111 1100 0000 0000 7C00h

Output is 11-bit two’s complement word. LSB = 0.125 ˚C.

Actual vs. Remote T_Crit Setpoint Example

Actual Remote Diode

T_Crit Setpoint,˚C

Remote T_CRIT

High Setpoint, ˚C

126 +110 0110 1110 6Eh

Remote temperature data is represented by an 11-bit, two’s

complement word with a Least Significant Bit (LSB) equal to

0.125˚C. The data format is a left justified 16-bit word available in two 8-bit registers. Some examples of temperature

conversions are shown below.

Binary Results in LM64

Remote Temperature Register

Hex Remote

Temperature

Register

Binary Remote T_CRIT

High Setpoint Value

Hex Remote T_CRIT

High Setpoint Value

Local Temperature data is represented by an 8-bit, two’s

complement byte with an LSB equal to 1˚C:

Temperature

Digital Output

Binary Hex

+125˚C 0111 1101 7D

+25˚C 0001 1001 19

+1˚C 0000 0001 01

0˚C 0000 0000 00

−1˚C 1111 1111 FF

−25˚C 1110 0111 E7

−55˚C 1100 1001 C9

1.6 OPEN-DRAIN OUTPUTS, INPUTS, AND PULL-UP RESISTORS

The SMBDAT, ALERT, T_Crit, GPIO and PWM open-drain

outputs and the GPD, TACH, and A0 inputs are pulled-up by

pull-up resistors to V

as suggested in the table below.

DD

Pin Name Pin Number Suggested Pull-up Resistor

Range Typical

SMBCLK 17 1 kΩ to2kΩ 1.5 kΩ

SMBDAT 16 1 kΩ to2kΩ 1.5 kΩ

ALERT 14 1 kΩ to5kΩ 3kΩ

T_Crit 8 1 kΩ to5kΩ 3kΩ

A0 12 5 kΩ to 20 kΩ 10 kΩ

GPIOx 1-3;18,19 5 kΩ to 20 kΩ 10 kΩ

GPDx 20-24 5 kΩ to 20 kΩ 10 kΩ

PWM 4 (Note 14) (Note 14)

TACH 15 1 kΩ to5kΩ 3kΩ

Note 14: Depends on the fan drive circuitry connected to this pin. In the

absence of fan control circuitry usea1kΩ pull-up resistor to V

.

DD

1.7 DIODE FAULT DETECTION

The LM64 can detect fault conditions caused by the remote

diode. If the D+ pin is detected to be shorted to V

, or open:

DD

(1) the Remote Temperature High Byte (RTHB) register is

loaded with 127˚C, (2) the Remote Temperature Low Byte

(RTLB) register is loaded with 0, and (3) the OPEN bit (D2)

in the status register is set. Therefore, if the Remote T_CRIT

setpoint register (RCS): (1) is set to a value less than +127˚C

and (2) the ALERT Mask is disabled, then the ALERT output

pin will be pulled low. If the Remote High Setpoint High Byte

(RHSHB) is set to a value less than +127˚C and (2) the

ALERT Mask is disabled, then the ALERT and T_Crit outputs will be pulled low. The OPEN bit by itself will not trigger

an ALERT.

If the D+ pin is shorted to either ground or D−, then the

Remote Temperature High Byte (RTHB) register is loaded

with −128˚C (1000 0000) and the OPEN bit in the ALERT

Status Register will not be set. A temperature reading of

−128˚C indicates that D+ is shorted to either ground or D-. If

the value in the Remote Low Setpoint High Byte (RLSHB)

Register is more than −128˚C and the ALERT Mask is Disabled, ALERT will be pulled low.

1.8 COMMUNICATING WITH THE LM64

Each data register in the LM64 falls into one of four types of

user accessibility:

1. Read Only

2. Write Only

3. Read/Write same address

4. Read/Write different address

A Write to the LM64 is comprised of an address byte and a

command byte. A write to any register requires one data

byte.

Reading the LM64 Registers can take place after the requisite register setup sequence takes place. See Section 2.1.1

LM64 Required Initial Fan Control Register Sequence.

www.national.com 12

Page 13

1.0 Functional Description (Continued)

The data byte has the Most Significant Bit (MSB) first. At the

end of a read, the LM64 can accept either Acknowledge or

No-Acknowledge from the Master. Note that the NoAcknowledge is typically used as a signal for the slave

indicating that the Master has read its last byte.

1.9 DIGITAL FILTER

The LM64 incorporates a user-configured digital filter to

suppress erroneous Remote Temperature readings due to

noise. The filter is accessed in the Remote Diode Temperature Filter and Comparator Mode Register. The filter can be

set according to the following table.

Level 2 is maximum filtering.

Digital Filter Selection Table

D2 D1 Filter

0 0 No Filter

0 1 Level 1

1 0 Level 1

1 1 Level 2

LM64

20065511

FIGURE 8. Impulse Response of the Digital Filter

20065510

FIGURE 7. Step Response of the Digital Filter

20065512

FIGURE 9. Digital Filter Response in an Intel Pentium 4

processor System. The Filter on and off curves were

purposely offset to better show noise performance.

www.national.com13

Page 14

1.0 Functional Description (Continued)

LM64

1.10 FAULT QUEUE

The LM64 incorporates a Fault Queue to suppress erroneous ALERT triggering . The Fault Queue prevents false

triggering by requiring three consecutive out-of-limit HIGH,

LOW, or T_CRIT temperature readings. See Figure 10. The

Fault Queue defaults to OFF upon power-up and may be

activated by setting the RDTS Fault Queue bit in the Configuration Register to a 1.

20065513

1.11 ONE-SHOT REGISTER

The One-Shot Register is used to initiate a single conversion

and comparison cycle when the device is in standby mode,

after which the data returns to standby. This is not a data

register. A write operation causes the one-shot conversion.

The data written to this address is irrelevant and is not

stored. A zero will always be read from this register.

1.12 SERIAL INTERFACE RESET

In the event that the SMBus Master is reset while the LM64

is transmitting on the SMBDAT line, the LM64 must be

returned to a known state in the communication protocol.

This may be done in one of two ways:

1. When SMBDAT is Low, the LM64 SMBus state machine

resets to the SMBus idle state if either SMBData or

SMBCLK are held Low for more than 35 ms (t

TIMEOUT

All devices are to timeout when either the SMBCLK or

SMBDAT lines are held Low for 25 ms – 35 ms. Therefore, to insure a timeout of all devices on the bus, either

the SMBCLK or the SMBData line must be held Low for

at least 35 ms.

2. With both SMBDAT and SMBCLK High, the master can

initiate an SMBus start condition with a High to Low

transition on the SMBDAT line. The LM64 will respond

properly to an SMBus start condition at any point during

the communication. After the start the LM64 will expect

an SMBus Address address byte.

).

FIGURE 10. Fault Queue Temperature Response

Diagram

www.national.com 14

Page 15

2.0 LM64 Registers

The following pages include: Section 2.1, a Register Map in Hexadecimal Order, which shows a summary of all registers and their

bit assignments, Section 2.2, a Register Map in Functional Order, and Section 2.3, a detailed explanation of each register. Do not

address the unused or manufacturer’s test registers.

2.1 LM64 REGISTER MAP IN HEXADECIMAL ORDER

The following is a Register Map grouped in hexadecimal address order. Some address locations have been left blank to maintain

compatibility with LM86. Addresses in parenthesis are mirrors of “Same As” address for backwards compatibility with some older

software. Reading or writing either address will access the same 8-bit register.

LM64

Register

0x[HEX]

00 Local Temperature LT7 LT6 LT5 LT4 LT3 LT2 LT1 LT0

01 Rmt Temp MSB RTHB

02 ALERT Status BUSY LHIGH 0 RHIGH RLOW RDFA RCRIT TACH

03 Configuration ALTMSK STBY PWMDIS 0 0 ALT/TCH TCRITOV FLTQUE

04 Conversion Rate 0 0 0 0 CONV3 CONV2 CONV1 CONV0

05 Local High Setpoint LHS7 LHS6 LHS5 LHS4 LHS3 LHS2 LHS1 LHS0

06 [Reserved] Not Used

07 Rmt High Setpoint MSB RHSHB15 RHSHB14 RHHBS13 RHSHB12 RHSHB11 RHSHB10 RHSHB9 RHSHB8

08 Rmt Low Setpoint MSB RLSHB15 RLSHB14 RLSHB13 RLSHB12 RLHBS11 RLSHB10 RLSHB9 RLSHB8

(09) Same as 03

(0A) Same as 04

(0B) Same as 05

0C [Reserved] Not Used

(0D) Same as 07

(0E) Same as 08

0F One Shot Write Only. Write command triggers one temperature conversion cycle.

10 Rmt Temp LSB RTLB7 RTLB6 RTLB5 00000

11 Rmt Temp Offset MSB RTOHB15 RTOHB14 RTOHB13 RTOHB12 RTOHB11 RTOHB10 RTOHB9 RTOHB8

12 Rmt Temp Offset LSB RTOLB7 RTOLB6 RTOLB5 00000

13 Rmt High Setpoint LSB RHSLB7 RHSLB6 RHSLB5 00000

14 Rmt Low Setpoint LSB RLSLB7 RLSLB6 RLSLB5 00000

15 [Reserved] Not Used

16 ALERT Mask 1 ALTMSK6 1 ALTMSK4 ALTMSK3 1 ALTMSK1 ALTMSK0

17 [Reserved] Not Used

18 [Reserved] Not Used

19 Rmt TCRIT Setpoint RCS7 RCS6 RCS5 RCS4 RCS3 RCS2 RCS1 RCS0

1A General Purpose Input 0 0 0 GPI5 GPI4 GPI3 GPI2 GPI1

1B General Purpose Output 0 0 0 GPO5 GPO4 GPO3 GPO2 GPO1

1C–1F [Reserved] Not Used

20 [Reserved] Not Used

21 Rmt TCRIT Hysteresis RTH7 RTH6 RTH5 RTH4 RTH3 RTH2 RTH1 RTH0

22–2F [Reserved] Not Used

30–3F [Reserved] Not Used

40–45 [Reserved] Not Used

46 Tach Count LSB TCLB5 TCLB4 TCLB3 TCLB2 TCLB1 TCLB0 TEDGE1 TEDGE0

47 Tach Count MSB TCHB13 TCHB12 TCHB11 TCHB10 TCHB9 TCHB8 TCHB7 TCHB6

48 Tach Limit LSB TLLB7 TLLB6 TLLB5 TLLB4 TLLB3 TLLB2 Not Used Not Used

49 Tach Limit MSB TLHB15 TLHB14 TLHB13 TLHB12 TLHB11 TLHB10 TLHB9 TLHB8

4A PWM and RPM 0 0 PWPGM PWOUT

4B Fan Spin-Up Config 0 0 SPINUP SPNDTY1 SPNDTY0 SPNUPT2 SPNUPT1 SPNUPT0

4C PWM Value 0 0 PWVAL5 PWVAL4 PWVAL3 PWVAL2 PWVAL1 PWVAL0

Register Name

D7 D6 D5 D4 D3 D2 D1 D0

±

RTHB14 RTHB13 RTHB12 RTHB11 RTHB10 RTHB9 RTHB8

DATA BITS

±

PWCKSL 0 TACH1 TACH0

www.national.com15

Page 16

2.0 LM64 Registers (Continued)

LM64

Register

0x[HEX]

4D PWM Frequency 0 0 0 PWMF4 PWMF3 PWMF2 PWMF1 PWMF0

4E [Reserved] Not Used

4F Lookup Table Hystersis 0 0 0 LOOKH4 LOOKH3 LOOKH2 LOOKH1 LOOKH0

50–5F Lookup Table Lookup Table of up to 8 PWM and Temp Pairs in 8-bit Registers

60–BE [Reserved] Not Used

BF Rmt Diode Temp Filter 0 0 0 0 0 RDTF1 RDTF0 ALTCOMP

C0–FD [Reserved] Not Used

FE Manufacturer’s ID 0 0 000001

FF Stepping/Die Rev. ID 0 1 010001

2.2 LM64 REGISTER MAP IN FUNCTIONAL ORDER

The following is a Register Map grouped in Functional Order. Some address locations have been left blank to maintain

compatibility with LM86. Addresses in parenthesis are mirrors of named address. Reading or writing either address will access

the same 8-bit register. The Fan Control and Configuration Registers are listed first, as there is a required order to setup these

registers first and then setup the others. The detailed explanations of each register will follow the order shown below. POR =

Power-On-Reset.

Register Name

D7 D6 D5 D4 D3 D2 D1 D0

DATA BITS

Register

[HEX]

FAN CONTROL REGISTERS

4A PWM and RPM R/W 20

4B Fan Spin-Up Configuration R/W 3F

4D PWM Frequency R/W 17

4C PWM Value

50–5F Lookup Table R/W See Table

4F Lookup Table Hysteresis R/W 04

CONFIGURATION REGISTER

03 (09) Configuration R/W 00

TACHOMETER COUNT AND LIMIT REGISTERS

46 Tach Count LSB Read Only N/A

47 Tach Count MSB Read Only N/A

48 Tach Limit LSB R/W FF

49 Tach Limit MSB R/W FF

LOCAL TEMPERATURE AND LOCAL SETPOINT REGISTERS

00 Local Temperature Read Only N/A

05 (0B) Local High Setpoint R/W 46 (70˚)

REMOTE DIODE TEMPERATURE AND SETPOINT REGISTERS

01 Remote Temperature MSB Read Only N/A

10 Remote Temperature LSB Read Only N/A

11 Remote Temperature Offset MSB R/W 00

12 Remote Temperature Offset LSB R/W 00

07 (0D) Remote High Setpoint MSB R/W 46 (70˚C)

13 Remote High Setpoint LSB R/W 00

08 (0E) Remote Low Setpoint MSB R/W 00 (0˚C)

14 Remote Low Setpoint LSB R/W 00

19 Remote TCRIT Setpoint R/W 55 (85˚C)

21 Remote TCRIT Hys R/W 0A (10˚C)

BF Remote Diode Temperature Filter R/W 00

Register Name Read/Write

Read Only

(R/W if Override Bit is Set)

POR Default

[HEX]

00

www.national.com 16

Page 17

2.0 LM64 Registers (Continued)

LM64

Register

[HEX]

Register Name Read/Write

POR Default

CONVERSION AND ONE-SHOT REGISTERS

04 (0A) Conversion Rate R/W 08

0F One-Shot Write Only N/A

ALERT STATUS AND MASK REGISTERS

02 ALERT Status Read Only N/A

16 ALERT Mask R/W A4

ID REGISTERS

FE Manufacturer’s ID Read Only 01

FF Stepping/Die Rev. ID Read Only 51

GENERAL PURPOSE REGISTERS

1A General Purpose Input Read Only (Note 15)

1B General Purpose Output R/W (Note 16)

[RESERVED] REGISTERS —NOT USED

06 Not Used N/A N/A

0C Not Used N/A N/A

15 Not Used N/A N/A

17 Not Used N/A N/A

18 Not Used N/A N/A

1C–1F Not Used N/A N/A

20 Not Used N/A N/A

22–2F Not Used N/A N/A

30–3F Not Used N/A N/A

40–45 Not Used N/A N/A

4E Not Used N/A N/A

60–BE Not Used N/A N/A

C0–FD Not Used N/A N/A

Note 15: For Register 0x1A the Power-On-Reset for the five LSB’s are the logic states present on the 5 GPIOx pins.

Note 16: For Register 0x1B the Power-On-Reset for the five LSB’s are the logic states present on the 5 GPDx pins.

[HEX]

2.3 LM64 INITIAL REGISTER SEQUENCE AND REGISTER DESCRIPTIONS IN FUNCTIONAL ORDER

The following is a Register Map grouped in functional and sequence order. Some address locations have been left blank to

maintain compatibility with LM86. Addresses in parenthesis are mirrors of named address for backwards compatibility with some

older software. Reading or writing either address will access the same 8-bit register.

2.3.1 LM64 Required Initial Fan Control Register Sequence

Important! The BIOS must follow the sequence below to configure the following Fan Registers for the LM64 before using any of

the Fan or Tachometer or PWM registers:

Step [Register]

and Setup Instructions

HEX

1 [4A] Write bits 0 and 1; 3 and 4. This includes tach settings if used, PWM internal clock select (1.4 kHz or

360 kHz) and PWM Output Polarity.

2 [4B] Write bits 0 through 5 to program the spin-up settings.

3 [4D] Write bits 0 through 4 to set the frequency settings. This works with the PWM internal clock select.

4 Choose, then write, only one of the following:

A. [4F–5F] the Lookup Table, or

B. [4C] the PWM value bits 0 through 5.

5 If Step 4A, Lookup Table, was chosen and written then write [4A] bit 5 = 0.

All other registers can be written at any time after the above sequence.

www.national.com17

Page 18

2.0 LM64 Registers (Continued)

LM64

2.4 LM64 REGISTER DESCRIPTIONS IN FUNCTIONAL ORDER

Fan Control Registers

Address

Hex

4A

HEX

4A R/W

4B

HEX

4B R/W

Read/

Write

PWM AND RPM REGISTER

FAN SPIN-UP CONFIGURATION REGISTER

Bits

POR

Value

7:6 00

51

40

30

2 0 [Reserved] Always write 0 to this bit.

1:0 00

7:6 0

51

4:3 11

2:0 111

Name Description

PWM

Program

PWM

Output

Polarity

PWM Clock

Select

Tachometer

Mode

Fast

Tachometer

Spin-Up

PWM

Spin-Up

Duty Cycle

PWM

Spin-Up

Time

These bits are unused and always set to 0.

0: the PWM Value (register 4C) and the Lookup Table (50–5F) are

read-only. The PWM value (0 to 100%) is determined by the current

remote diode temperature and the Lookup Table, and can be read from

the PWM value register.

1: the PWM value (register 4C) and the Lookup Table (Register 50–5F)

are read/write enabled. Writing the PWM Value register will set the

PWM output. This is also the state during which the Lookup Table can

be written.

0: the PWM output pin will be 0 V for fan OFF and open for fan ON.

1: the PWM output pin will be open for fan OFF and 0 V for fan ON.

if 0, the master PWM clock is 360 kHz

if 1, the master PWM clock is 1.4 kHz.

00: Traditional tach input monitor, false readings when under minimum

detectable RPM.

01: Traditional tach input monitor, FFFF reading when under minimum

detectable RPM.

10: Most accurate readings, FFFF reading when under minimum

detectable RPM.

11: Least effort on programmed PWM of fan, FFFF reading when under

minimum detectable RPM.

Note: If the PWM Clock is 360 kHz, mode 00 is used regardless of the

setting of these two bits.

These bits are unused and always set to 0

If 0, the fan spin-up uses the duty cycle and spin-up time, bits 0– 4.

If 1, the LM64 sets the PWM output to 100% until the spin-up times out

(per bits 0–2) or the minimum desired RPM has been reached (per the

Tachometer Setpoint setting) using the tachometer input, whichever

happens first. This bit overrides the PWM Spin-Up Duty Cycle register

(bits 4:3) — PWM output is always 100%.

If PWM Spin-Up Time (bits 2:0) = 000, the Spin-Up cycle is bypassed,

regardless of the state of this bit.

00: Spin-Up cycle bypassed (no Spin-Up), unless Fast Tachometer

Terminated Spin-Up (bit 5) is set.

01: 50%

10: 75%–81% Depends on PWM Frequency. See Applications Notes.

11: 100%

000: Spin-Up cycle bypassed (No Spin-Up)

001: 0.05 seconds

010: 0.1 s

011: 0.2 s

100: 0.4 s

101: 0.8 s

110: 1.6 s

111: 3.2 s

www.national.com 18

Page 19

2.0 LM64 Registers (Continued)

Fan Control Registers (Continued)

Address

Hex

4D

HEX

4D R/W

4C

HEX

4C

Read/

Write

FAN PWM FREQUENCY REGISTER

PWM VALUE REGISTER

Read

(Write

only if

reg

4A bit

5 = 1.)

Bits

POR

Value

7:5 000

4:0 10111

7:6 00

5:0 000000

Frequency

Name Description

PWM

PWM

Value

LM64

These bits are unused and always set to 0

The PWM Frequency = PWM_Clock / 2n, where PWM_Clock = 360

kHz or 1.4 kHz (per the PWM Clock Select bit in Register 4A), and n =

value of the register. Note: n = 0 is mapped to n = 1. See the

Application Note at the end of this datasheet.

These bits are unused and always set to 0

If PWM Program (register 4A, bit 5) = 0 this register is read only and

reflects the LM64’s current PWM value from the Lookup Table.

If PWM Program (register 4A, bit 5) = 1, this register is read/write and

the desired PWM value is written directly to this register, instead of

from the Lookup Table, for direct fan speed control.

This register will read 0 during the Spin-Up cycle.

See Application Notes section at the end of this datasheet for more

information regarding the PWM Value and Duty Cycle in %.

www.national.com19

Page 20

2.0 LM64 Registers (Continued)

LM64

Fan Control Registers (Continued)

Address

Hex

50

HEX

50

51

52

53

54

55

56

57

58

59

5A

5B

5C

5D

5E

5F

4F

HEX

4F R/W

Read/

Write

to 5F

HEX

Read.

(Write

only if

4A bit

5 = 1.)

LOOKUP TABLE HYSTERESIS

Bits

LOOKUP TABLE (7 Bits for Temperature and 6 Bits for PWM for each Temperature/PWM Pair)

reg

POR

Value

70

6:0 0x7F

7:6 00

5:0 0x3F The PWM value corresponding to the temperature limit in register 50.

70

6:0 0x7F

7:6 00

5:0 0x3F The PWM value corresponding to the temperature limit in register 52.

70

6:0 0x7F

7:6 00

5:0 0x3F The PWM value corresponding to the temperature limit in register 54.

70

6:0 0x7F

7:6 00

5:0 0x3F The PWM value corresponding to the temperature limit in register 56.

70

6:0 0x7F

7:6 00

5:0 0x3F The PWM value corresponding to the temperature limit in register 58.

70

6:0 0x7F

7:6 00

5:0 0x3F The PWM value corresponding to the temperature limit in register 5A.

70

6:0 0x7F

7:6 00

5:0 0x3F The PWM value corresponding to the temperature limit in register 5C.

70

6:0 0x7F

7:6 00

5:0 0x3F The PWM value corresponding to the temperature limit in register 5E.

7:5 000

4:0 00100 The amount of hysteresis applied to the Lookup Table. (1 LSB = 1˚C).

Name Description

Lookup Table

Temperature

Entry 1

Lookup Table

PWM Entry 1

Lookup Table

Temperature

Entry 2

Lookup Table

PWM Entry 2

Lookup Table

Temperature

Entry 3

Lookup Table

PWM Entry 3

Lookup Table

Temperature

Entry 4

Lookup Table

PWM Entry 4

Lookup Table

Temperature

Entry 5

Lookup Table

PWM Entry 5

Lookup Table

Temperature

Entry 6

Lookup Table

PWM Entry 6

Lookup Table

Temperature

Entry 7

Lookup Table

PWM Entry 7

Lookup Table

Temperature

Entry 8

Lookup Table

PWM Entry 8

Lookup

Table

Hysteresis

This bit is unused and always set to 0.

If the remote diode temperature exceeds this value, the PWM output

will be the value in Register 51.

These bits are unused and always set to 0.

This bit is unused and always set to 0.

If the remote diode temperature exceeds this value, the PWM output

will be the value in Register 53.

These bits are unused and always set to 0.

This bit is unused and always set to 0.

If the remote diode temperature exceeds this value, the PWM output

will be the value in Register 55.

These bits are unused and always set to 0.

This bit is unused and always set to 0.

If the remote diode temperature exceeds this value, the PWM output

will be the value in Register 57.

These bits are unused and always set to 0.

This bit is unused and always set to 0.

If the remote diode temperature exceeds this value, the PWM output

will be the value in Register 59.

These bits are unused and always set to 0.

This bit is unused and always set to 0.

If the remote diode temperature exceeds this value, the PWM output

will be the value in Register 5B.

These bits are unused and always set to 0.

This bit is unused and always set to 0.

If the remote diode temperature exceeds this value, the PWM output

will be the value in Register 5D.

These bits are unused and always set to 0.

This bit is unused and always set to 0.

If the remote diode temperature exceeds this value, the PWM output

will be the value in Register 5F.

These bits are unused and always set to 0.

These bits are unused and always set to 0

www.national.com 20

Page 21

2.0 LM64 Registers (Continued)

Configuration Register

ADDRESS

Hex

03 (09)

03 (09) R/W

Read/

Write

CONFIGURATION REGISTER

HEX

POR

Bits

Value

70

6 0 STANDBY

50

4:1 0000 These bits are unused and always set to 0.

00

PWM Disable

in STANDBY

RDTS Fault

Name Description

ALERT

Mask

Queue

When this bit is a 0, ALERT interrupts are enabled.

When this bit is set to a 1, ALERT interrupts are masked, and the

ALERT pin is always in a high impedance (open) state.

When this bit is a 0, the LM64 is in operational mode, converting,

comparing, and updating the PWM output continuously.

When this bit is a 1, the LM64 enters a low power standby mode.

In STANDBY, continuous conversions are stopped, but a

conversion/comparison cycle may be initiated by writing any value to

register 0x0F. Operation of the PWM output in STANDBY depends on

the setting of bit 5 in this register.

When this bit is a 0, the LM64’s PWM output continues to output the

current fan control signal while in STANDBY.

When this bit is a 1, the PWM output is disabled (as defined by the

PWM polarity bit) while in STANDBY.

0: an ALERT will be generated if any Remote Diode conversion result is

above the Remote High Set Point or below the Remote Low

Setpoint.

1: an ALERT will be generated only if three consecutive Remote Diode

conversions are above the Remote High Set Point or below the

Remote Low Setpoint.

LM64

Tachometer Count And Limit Registers

ADDRESS

Hex

47

HEX

MSB and ensure MSB and LSB are from the same reading)

47

46

49

HEX

49 R/W 7:0 0xFF

48

Read/

Write

TACHOMETER COUNT (MSB) and 46

Read

Only

Read

Only

Read

Only

TACHOMETER LIMIT (MSB) and 48

R/W 7:2 0xFF

R/W 1:0 [Reserved] Not Used.

POR

Bits

Value

7:0 N/A

7:2 N/A

1:0 00

Name Description

HEX

Tachometer

Count (MSB)

Tachometer

Count (LSB)

Tachometer

Edge Count

TACHOMETER LIMIT (LSB) REGISTERS

HEX

Tachometer

Limit MSB)

Tachometer

Limit (LSB)

TACHOMETER COUNT (LSB) REGISTERS (16 bits: Read LSB first to lock

These registers contain the current 16-bit Tachometer Count, representing

the period of time between tach pulses.

Note that the 16-bit tachometer MSB and LSB are reversed from the

16-bit temperature readings.

Bits Edges Used Tach_Count_Multiple

00: Reserved - do not use

01: 2 4

10: 3 2

11: 5 1

Note: If PWM_Clock_Select = 360 kHz, then Tach_Count_Multiple = 1

regardless of the setting of these bits.

These registers contain the current 16-bit Tachometer Count, representing

the period of time between tach pulses. Fan RPM = (f

(Tachometer Count), where f = 1 for 2 pulses/rev fan; f = 2 for 1 pulse/rev

fan; and f = 2/3 for 3 pulses/rev fan. See the Applications Notes section

for more tachometer information. Note that the 16-bit tachometer MSB and

LSB are reversed from the 16 bit temperature readings.

*

5,400,000) /

www.national.com21

Page 22

2.0 LM64 Registers (Continued)

LM64

Local Temperature And Local High Setpoint Registers

ADDRESS

Hex

00

HEX

05 (0B)

Read/

Write

LOCAL TEMPERATURE REGISTER (8-bits)

00

05 R/W 7:0

Read

Only

LOCAL HIGH SETPOINT REGISTER (8-bits)

HEX

POR

Bits

Value

7:0 N/A Local Temperature Reading (8-bit) 8-bit temperature of the LM64.

0x46

(70˚)

Local HIGH Setpoint High Setpoint for the internal diode.

Name Description

Remote Diode Temperature, Offset And Setpoint Registers

ADDRESS

Hex

01

10

11 R/W 7:5 00

12 R/W

07 (0D) R/W 7:0

13 R/W

08 (0E) R/W 7:0

14 R/W

19 R/W 7:0

21 R/W 7:0

BF R/W

Read/

Write

Read

Only

Read

Only

POR

Bits

Value

7:0 N/A

7:5 N/A

4:0 00 Always 00.

7:5 00

4:0 00 Always 00.

0x46

(70˚C)

7:5 00

4:0 00 Always 00.

00

(0˚C)

7:5 00

4:0 00 Always 00.

0x55

(85˚C)

0x0A

(10˚C)

7:3 00000 These bits are unused and should always set to 0.

2:1 00

00

Name Description

Remote Diode

Temperature

Reading (MSB)

Remote Diode

Temperature

Reading (LSB)

Remote

Temperature

OFFSET (MSB)

Remote

Temperature

OFFSET (LSB)

Remote HIGH

Setpoint (MSB)

Remote HIGH

Setpoint (LSB)

Remote LOW

Setpoint (MSB)

Remote LOW

Setpoint (LSB)

Remote Diode

T_CRIT Limit

Remote Diode

T_CRIT

Hysteresis

Remote Diode

Temperature

Filter

Comparator

Mode

This is the MSB of the LM64 remote diode temperature value, 2’s

complement. Bit 7 is the sign bit, bit 6 has a weight 64˚C, and bit 0 has

a weight of 1˚C. Read this byte first. The actual remote diode

temperature is 16˚C higher than the values in registers 0x01 and 0x10.

This is the LSB of the LM64 remote diode temperature value, in 2’s

complement. Bit 7 has a weight 0.5˚C, bit 6 has a weight of 0.25˚C, and

bit 5 has a weight of 0.125˚C. The actual remote diode temperature is

16˚C higher than the values in registers 0x01 and 0x10.

These registers contain the offset value added to, or subtracted from, the

remote diode’s reading to compensate for the different non-ideality

factors of different processors, diodes, etc. The 2’s complement value, in

these registers is added to the output of the LM64’s ADC to form the

temperature reading contained in registers 01 and 10.

High setpoint temperature for remote diode. Same format as Remote

Temperature Reading (registers 01 and 10).

Low setpoint temperature for remote diode. Same format as Remote

Temperature Reading (registers 01 and 10).

This 8-bit integer storing the T_CRIT limit is initially 85˚C (101˚C actual

remote T_Crit limit). This value can be changed at any time after

power-up.

8-bit integer storing T_CRIT hysteresis. T_CRIT stays activated until the

remote diode temperature goes below [(T_CRIT Limit) —(T_CRIT

Hysteresis)].

00: Filter Disabled

01: Filter Level 1 (minimal filtering, same as 10)

10: Filter Level 1 (minimal filtering, same as 01)

11: Filter Level 2 (maximum filtering)

0: the ALERT pin functions as an Interrupt or ARA mode.

1: the ALERT pin behaves as a comparator, asserting itself when an

ALERT condition exists, de-asserting itself when the ALERT condition

goes away.

www.national.com 22

Page 23

2.0 LM64 Registers (Continued)

ALERT Status And Mask Registers

ADDRESS

Hex

02

HEX

at the time of the read.)

0x02

16

HEX

16 R/W

Read/

Write

ALERT STATUS REGISTER (8-bits) (All Alarms are latched until read, then cleared if alarm condition was removed

Read

Only

ALERT MASK REGISTER (8-bits)

POR

Bits

Value

7 0 Busy

60

5 0 This bit is unused and always read as 0.

40

30

20

10

0 0 Tach Alarm

7 1 This bit is unused and always read as 1.

60

5 1 This bit is unused and always read as 1.

40

30

2 1 This bit is unused and always read as 1.

10

00

Name Description

When this bit is a 0, the ADC is not converting.

When this bit is set to a 1, the ADC is performing a conversion. This bit

does not affect ALERT status.

When this bit is a 0, the internal temperature of the LM64 is at or below

Local

High Alarm

Remote

High Alarm

Remote

Low Alarm

Remote Diode

Fault Alarm

Remote

T_CRIT Alarm

Local High

Alarm Mask

Remote

High Alarm Mask

Remote

Low Alarm

Mask

Remote

T_CRIT

Alarm Mask

Tach

Alarm Mask

the Local High Setpoint.

When this bit is a 1, the internal temperature of the LM64 is above the

Local High Setpoint, and an ALERT is triggered.

When this bit is a 0, the temperature of the Remote Diode is at or below

the Remote High Setpoint.

When this bit is a 1, the temperature of the Remote Diode is above the

Remote High Setpoint, and an ALERT is triggered.

When this bit is a 0, the temperature of the Remote Diode is at or above

the Remote Low Setpoint.

When this bit is a 1, the temperature of the Remote Diode is below the

Remote Low Setpoint, and an ALERT is triggered.

When this bit is a 0, the Remote Diode appears to be correctly

connected.

When this bit is a 1, the Remote Diode may be disconnected or shorted.

This Alarm does not trigger an ALERT.

When this bit is a 0, the temperature of the Remote Diode is at or below

the T_CRIT Limit.

When this bit is a 1, the temperature of the Remote Diode is above the

T_CRIT Limit, and an ALERT is triggered.

When this bit is a 0, the Tachometer count is lower than or equal to the

Tachometer Limit (the RPM of the fan is greater than or equal to the

minimum desired RPM).

When this bit is a 1, the Tachometer count is higher than the

Tachometer Limit (the RPM of the fan is less than the minimum desired

RPM), and an ALERT is triggered.

When this bit is a 0, a Local High Alarm event will generate an ALERT.

When this bit is a 1, a Local High Alarm will not generate an ALERT

When this bit is a 0, Remote High Alarm event will generate an ALERT.

When this bit is a 1, a Remote High Alarm event will not generate an

ALERT.

When this bit is a 0, a Remote Low Alarm event will generate an

ALERT.

When this bit is a 1, a Remote Low Alarm event will not generate an

ALERT.

When this bit is a 0, a Remote T_CRIT event will generate an ALERT.

When this bit is a 1, a Remote T_CRIT event will not generate an

ALERT.

When this bit is a 0, a Tach Alarm event will generate an ALERT.

When this bit is a 1, a Tach Alarm event will not generate an ALERT.

LM64

www.national.com23

Page 24

2.0 LM64 Registers (Continued)

LM64

Conversion Rate And One-Shot Registers

ADDRESS

Hex

04 (0A)

04 (0A) R/W 7:0 0x08

04 (0A)

0F

Read/

Write

CONVERSION RATE REGISTER (8-bits)

HEX

Bits

POR

Value

Name Description

Conversion

ONE-SHOT REGISTER (8-bits)

HEX

Write

Only

7:0 N/A

One Shot

Trigger

Rate

Sets the conversion rate of the LM64.

00000000 = 0.0625 Hz

00000001 = 0.125 Hz

00000010 = 0.25 Hz

00000011 = 0.5 Hz

00000100 = 1 Hz

00000101 = 2 Hz

00000110 = 4 Hz

00000111 = 8 Hz

00001000 = 16 Hz

00001001 = 32 Hz

All other values = 32 Hz

With the LM64 in the STANDBY mode a single write to this register will

initiate one complete temperature conversion cycle.

ID Registers

ADDRESS

Hex

FF

STEPPING / DIE REVISION ID REGISTER (8-bits)

HEX

FF

FE

MANUFACTURER’S ID REGISTER (8-bits)

HEX

FE

Read/

Write

Read

Only

Read

Only

Bits

POR

Value

7:0 0x51

7:0 0x01 Manufacturer’s ID 0x01 = National Semiconductor

Name Description

Stepping/Die

Revision ID

Version of LM64

General Purpose Registers

ADDRESS

Hex

1A

HEX

1A

1B

HEX

1B R/W

Note 17: For Register 0x1A the Power-On-Reset for the five LSB’s are the logic states present on the 5 GPIOx pins.

Note 18: For Register 0x1B the Power-On-Reset for the five LSB’s are the logic states present on the 5 GPDx pins.

www.national.com 24

Read/

Write

Bits

POR

Value

Name Description

GENERAL PURPOSE INPUT REGISTER (8-bits)

7:5 000 These bits are unused and always set to 0.

Read

Only

4:0 (Note 17)

General

Purpose

Input

GENERAL PURPOSE OUTPUT REGISTER (8-bits)

7:5 000 These bits are unused and always set to 0.

General

4:0 (Note 18)

Purpose

Output

These 5 bits reflect the logic states of the GPIOx pins.

These 5 bits reflect the GPI register bits [4:0] except for

Power-On-Default when they are the 5 logic states of the

General Pupose Default (GPD) input pins.

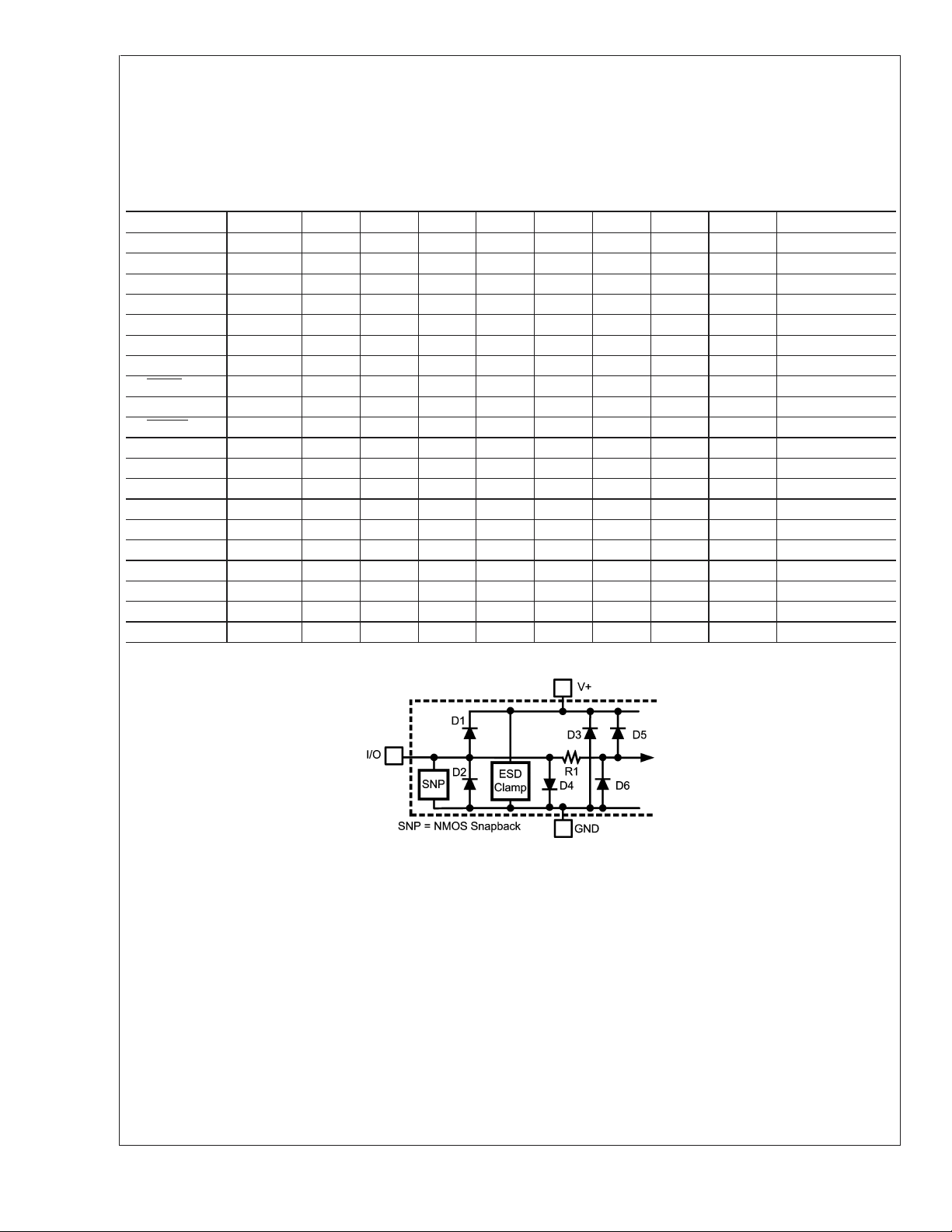

Page 25

3.0 Application Notes

3.1 FAN CONTROL DUTY CYCLE VS. REGISTER SETTINGS AND FREQUENCY

LM64

PWM

Freq

4D

[4:0]

0 Address 0 is mapped to Address 1

1 50 2 1 1 180.0 703.1 50.0

2 25 4 3 2 90.00 351.6 75.0

3 16.7 6 5 3 60.00 234.4 83.3

4 12.5 8 6 4 45.00 175.8 75.0

5 10.0 10 8 5 36.00 140.6 80.0

6 8.33 12 9 6 30.00 117.2 75.0

7 7.14 14 11 7 25.71 100.4 78.6

8 6.25 16 12 8 22.50 87.9 75.0

9 5.56 18 14 9 20.00 78.1 77.8

10 5.00 20 15 10 18.00 70.3 75.0

11 4.54 22 17 11 16.36 63.9 77.27

12 4.16 24 18 12 15.00 58.6 75.00

13 3.85 26 20 13 13.85 54.1 76.92

14 3.57 28 21 14 12.86 50.2 75.00

15 3.33 30 23 15 12.00 46.9 76.67

16 3.13 32 24 16 11.25 43.9 75.00

17 2.94 34 26 17 10.59 41.4 76.47

18 2.78 36 27 18 10.00 39.1 75.00

19 2.63 38 29 19 9.47 37.0 76.32

20 2.50 40 30 20 9.00 35.2 75.00

21 2.38 42 32 21 8.57 33.5 76.19

22 2.27 44 33 22 8.18 32.0 75.00

23 2.17 46 35 23 7.82 30.6 76.09

24 2.08 48 36 24 7.50 29.3 75.00

25 2.00 50 38 25 7.20 28.1 76.00

26 1.92 52 39 26 6.92 27.0 75.00

27 1.85 54 41 27 6.67 26.0 75.93

28 1.79 56 42 28 6.42 25.1 75.00

29 1.72 58 44 29 6.21 24.2 75.86

30 1.67 60 45 30 6.00 23.4 75.00

31 1.61 62 47 31 5.81 22.7 75.81

Step

Resolution,

%

PWM

Value

4D [5:0]

for 100%

PWM

Value

4C [5:0] for

about 75%

PWM

Value

4C [5:0]

for 50%

PWM

Freq at

360 kHz

Internal

Clock, kHz

PWM

Freq at

1.4 kHz

Internal

Clock, Hz

Actual Duty

Cycle, % When

75% is Selected

3.1.1 Computing Duty Cycles for a Given Frequency

Select a PWM Frequency from the first column corresponding to the desired actual frequency in columns 6 or 7. Note

the PWM Value for 100% Duty Cycle.

Find the Duty Cycle by taking the PWM Value of Register 4C

and computing:

Example: For a PWM Frequency of 24, a PWM Value at

100% = 48 and PWM Value actual = 28, then the Duty Cycle

is (28/48) x 100% = 58.3%.

www.national.com25

Page 26

3.0 Application Notes (Continued)

LM64

3.2 USE OF THE LOOKUP TABLE FOR NON-LINEAR PWM VALUES VS TEMPERATURE

The Lookup Table, Registers 50 through 5F, can be used to

create a non-linear PWM vs Temperature curve that could be

used to reduce the acoustic noise from processor fan due to

linear or step transfer functions. An example is given below:

EXAMPLE:

In a particular system it was found that the best acoustic fan

noise performance was found to occur when the PWM vs

Temperature transfer function curve was parabolic in shape.

From 25˚C to 105˚C the fan is to go from 20% to 100%.

Since there are 8 steps to the Lookup Table we will break up

the Temperature range into 8 separate temperatures. For the

80˚C over 8-steps = 10˚C per step. This takes care of the

x-axis.

For the PWM Value, we first select the PWM Frequency. In

this example we will make the PWM Frequency (Register

4C) 20.

For 100% Duty Cycle then, the PWM value is 40. For 20%

the minimum is 40 x (0.2) = 8.

We can then arrange the PWM, Temperature pairs in a

parabolic fashion in the form of y = 0.005

Temperature

PWM Value

Calculated

(x −25)2+8

•

Closest PWM

25 8.0 8

35 8.5 9

45 10.0 10

55 12.5 13

65 16.0 16

75 20.5 21

85 26.0 26

95 32.5 33

105 40.0 40

We can then program the Lookup Table with the temperature

and Closest PWM Values required for the curve required in

our example.

Value

IC’s temperature, independent of the LM64’s temperature.

The LM64 has been optimized for use with a MMBT3904

diode-connected transistor.

A discrete diode can also be used to sense the temperature

of external objects or ambient air. Remember that a discrete

diode’s temperature will be affected, and often dominated by,

the temperature of its leads.

Most silicon diodes do not lend themselves well to this

application. It is recommended that a diode-connected

MMBT3904 transistor be used. The base of the transistor is

connected to the collector and becomes the anode. The

emitter is the cathode.

3.3.1 Diode Non_Ideality

When a transistor is connected to a diode the following

relationship holds for V

, T, and IF:

be

where

q = 1.6x10

•

T = Absolute Temperature in Kelvin

•

k = 1.38x10

•

η is the non-ideality factor of the manufacturing process

•

−19

Coulombs (the electron charge)

−23

joules/K (Boltzmann’s constant)

used to make the thermal diode

Is= Saturation Current and is process dependent

•

If= Forward Current through the base emitter junction

•

Vbe= Base Emitter Voltage Drop

•

In the active region, the −1 term is negligible and may be

eliminated, yielding the following equation

3.3 NON-IDEALITY FACTOR AND TEMPERATURE ACCURACY

The LM64 can be applied to remote diode sensing in the

same way as other integrated-circuit temperature sensors. It

can be soldered to a printed-circuit board, and because the

path of best thermal conductivity is between the die and the

pins, its temperature will effectively be that of the printedcircuit board lands and traces soldered to its pins. This

presumes that the ambient air temperature is nearly the

same as the surface temperature of the printed-circuit board.

If the air temperature is much higher or lower than the

surface temperature, the actual temperature of the LM64 die

will be an intermediate temperature between the surface and

air temperatures. Again, the primary thermal conduction path

is through the leads, so the circuit board surface temperature

will contribute to the die temperature much more than the air

temperature.

To measure the temperature external to the die use a remote

diode. This diode can be located on the die of the target IC,

such as a CPU processor chip, allowing measurement of the

www.national.com 26

In the above equation, η and Isare dependent upon the

process that was used in the fabrication of the particular

diode. By forcing two currents with a very controlled ratio (N)

and measuring the resulting voltage difference, it is possible

to eliminate the I

term. Solving for the forward voltage

s

difference yields the relationship:

The non-ideality factor, η, is the only other parameter not

accounted for and depends on the diode that is used for

measurement. Since ∆V

is proportional to both η and T, the

be

variations in η cannot be distinguished from variations in

temperature. Since the temperature sensor does not control

the non-ideality factor, it will directly add to the inaccuracy of

the sensor.

Page 27

3.0 Application Notes (Continued)

HEX

±

0.1%

±

1˚C

and

For example, if a processor manufacturer specifies a

variation in η from part to part. As an example, assume that

a temperature sensor has an accuracy specification of

at room temperature of 25˚C. The resulting accuracy will be:

=±1˚C+(±0.1% of 298˚K) =±1.3˚C

T

ACC

The additional inaccuracy in the temperature measurement

caused by η, can be eliminated if each temperature sensor is

calibrated with the remote diode that it will be paired with.

Refer to the processor datasheet for the non-ideality factor.

3.3.2 Compensating for Diode Non-Ideality

In order to compensate for the errors introduced by nonideality, the temperature sensor is calibrated for a particular

processor. National Semiconductor temperature sensors are

always calibrated to the typical non-ideality of a particular

processor type.

The LM64 is calibrated for a MMBT3904 diode-connected

transistor.

When a temperature sensor, calibrated for a specific type of

processor is used with a different processor type or a given

processor type has a non-ideality that strays form the typical

value, errors are introduced.

Temperature errors associated with non-ideality may be introduced in a specific temperature range of concern through

the use of the Temperature Offset Registers 11

.

12

HEX

The user is encouraged to send an e-mail to

@

hardware.monitor.team

nsc.com to further request infor-

mation on our recommended setting of the offset register for

different processor types.

revolution fan tachometer, such as the fans supplied with the

Pentium 4 boxed processors. The RPM of the fan can be

computed from the Tach Count Registers 46

HEX

and 47

HEX

This can best be shown through an example.

Example:

Given: the fan used has a tachometer output with 2 per

revolution.

Let:

Register 46 (LSB) is BF

= Decimal (11 x 16) + 15 = 191

HEX

and

Register 47 (MSB) is 7

= Decimal (7 x 256) = 1792.

HEX

The total Tach Count, in decimal, is 191 + 1792 = 1983.

The RPM is computed using the formula

where

f = 1 for 2 pulses/rev fan tachometer output;

f = 2 for 1 pulse/rev fan tachometer output, and

f = 2 / 3 for 3 pulses/rev fan tachometer output

For our example

LM64

.

3.4 COMPUTING RPM OF THE FAN FROM THE TACH COUNT

The Tach Count Registers 46

HEX

and 47

count the num-

HEX

ber of periods of the 90 kHz tachometer clock in the LM64 for

the tachometer input from the fan assuming a 2 pulse per

www.national.com27

Page 28

3.0 Application Notes (Continued)

LM64

3.5 PCB LAYOUT FOR MINIMIZING NOISE

FIGURE 11. Ideal Diode Trace Layout

In a noisy environment, such as a processor mother board,

layout considerations are very critical. Noise induced on

traces running between the remote temperature diode sensor and the LM64 can cause temperature conversion errors.

Keep in mind that the signal level the LM64 is trying to

measure is in microvolts. The following guidelines should be

followed:

1. Place a 0.1 µF power supply bypass capacitor as close

as possible to the V

pin and the recommended 2.2 nF