Page 1

LM62

2.7V, 15.6 mV/˚C SOT-23 Temperature Sensor

LM62 2.7V, 15.6 mV/˚C, SOT-23 Temperature Sensor

June 1999

General Description

The LM62 is a precision integrated-circuit temperature sensor that can sense a 0˚C to +90˚C temperature range while

operating from a single +3.0V supply. The LM62’s output

voltage is linearly proportional to Celsius (Centigrade) temperature (+15.6 mV/˚C) and has a DC offset of +480 mV.

The offset allows reading temperatures down to 0˚C without

the need for a negative supply.The nominal output voltage of

the LM62 ranges from +480 mV to +1884 mV for a 0˚C to

+90˚C temperature range. The LM62 is calibrated to provide

accuracies of

−2.0˚C over the full 0˚C to +90˚C temperature range.

The LM62’s linear output, +480mV offset, and factory cali-

bration simplify external circuitry required in a single supply

environment where reading temperatures down to 0˚C is required. Because the LM62’s quiescent current is less than

130 µA, self-heating is limited to a very low 0.2˚C in still air.

Shutdown capability for the LM62 is intrinsic because its inherent low power consumption allows it to be powered directly from the output of many logic gates.

±

2.0˚C at room temperature and +2.5˚C/

Features

n Calibrated linear scale factor of +15.6 mV/˚C

n Rated for full 0˚C to +90˚C range with 3.0V supply

n Suitable for remote applications

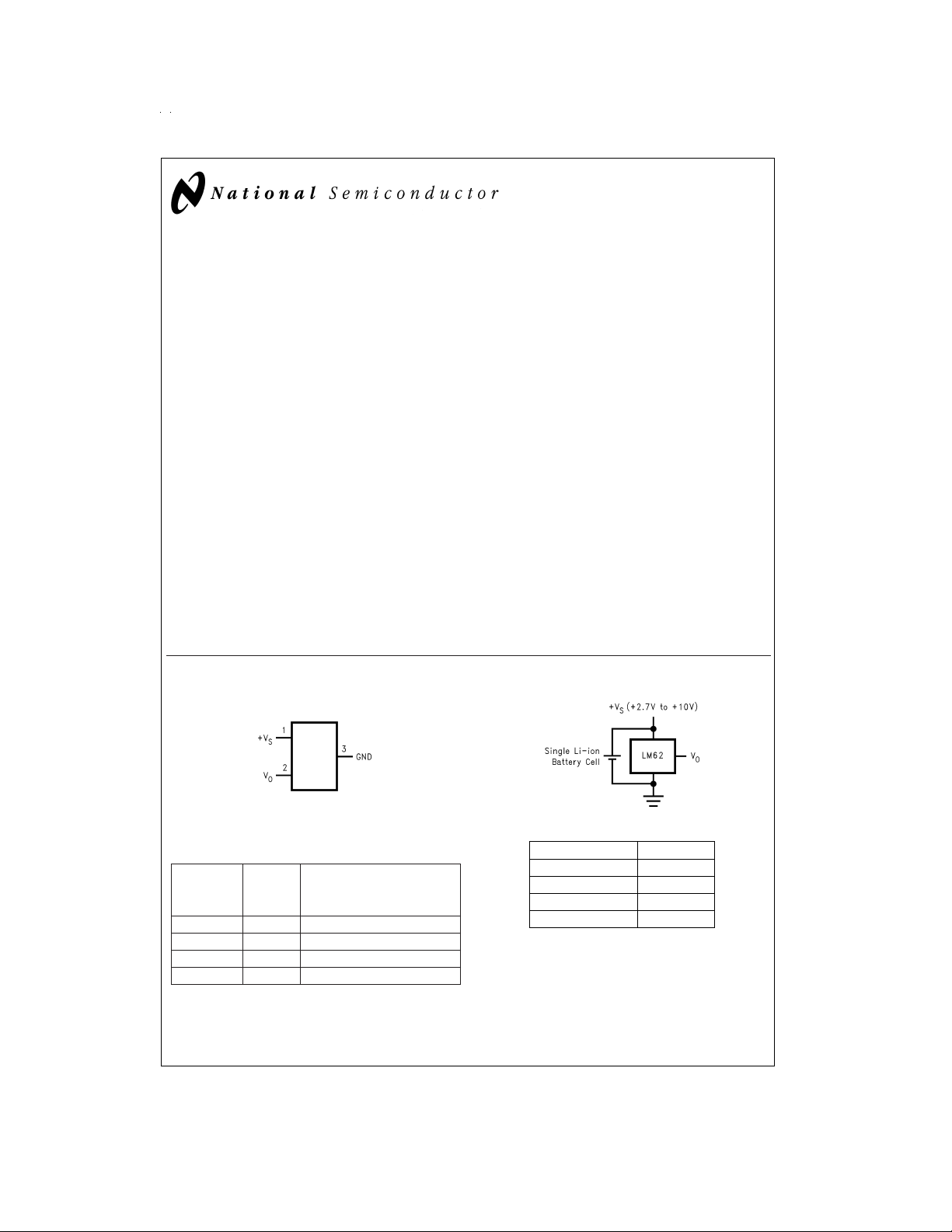

Connection Diagram

SOT-23

Applications

n Cellular Phones

n Computers

n Power Supply Modules

n Battery Management

n FAX Machines

n Printers

n HVAC

n Disk Drives

n Appliances

Key Specifications

n Accuracy at 25˚C

n Temperature Slope +15.6 mV/˚C

n Power Supply Voltage Range +2.7V to +10V

n Current Drain

n Nonlinearity

n Output Impedance 4.7 kΩ (max)

@

25˚C 130 µA (max)

±

2.0 or±3.0˚C

(max)

±

0.8˚C (max)

Typical Application

DS100893-1

See NS Package Number MA03B

Top View

Ordering Information

Order SOT-23

Number Device Supplied As

Marking

LM62BIM3 T7B 1000 Units on Tape and Reel

LM62BIM3X T7B 3000 Units on Tape and Reel

LM62CIM3 T7C 1000 Units on Tape and Reel

LM62CIM3X T7C 3000 Units on Tape and Reel

© 1999 National Semiconductor Corporation DS100893 www.national.com

=

V

(+15.6 mV/˚C x T˚C) + 480 mV

O

Temperature (T) Typical V

+90˚C +1884 mV

+70˚C +1572 mV

+25˚C 870 mV

0˚C +480 mV

FIGURE 1. Full-Range Centigrade Temperature Sensor

(0˚C to +90˚C) Stabilizing a Crystal Oscillator

DS100893-2

O

Page 2

Absolute Maximum Ratings (Note 1)

Supply Voltage +12V to −0.2V

Output Voltage (+V

Output Current 10 mA

Input Current at any pin (Note 2) 5 mA

Storage Temperature −65˚C to +150˚C

Maximum Junction Temperature (T

) +125˚C

JMAX

ESD Susceptibility (Note 3) :

Human Body Model 2500V

Machine Model 250V

+ 0.6V) to

S

−0.6V

Lead Temperature:

SOT Package (Note 4) :

Vapor Phase (60 seconds) +215˚C

Infrared (15 seconds) +220˚C

Operating Ratings(Note 1)

Specified Temperature Range: T

LM62B, LM62C 0˚C ≤ TA≤ +90˚C

Supply Voltage Range (+V

Thermal Resistance, θ

) +2.7V to +10V

S

(Note 5) 450˚C/W

JA

MIN

≤ TA≤ T

MAX

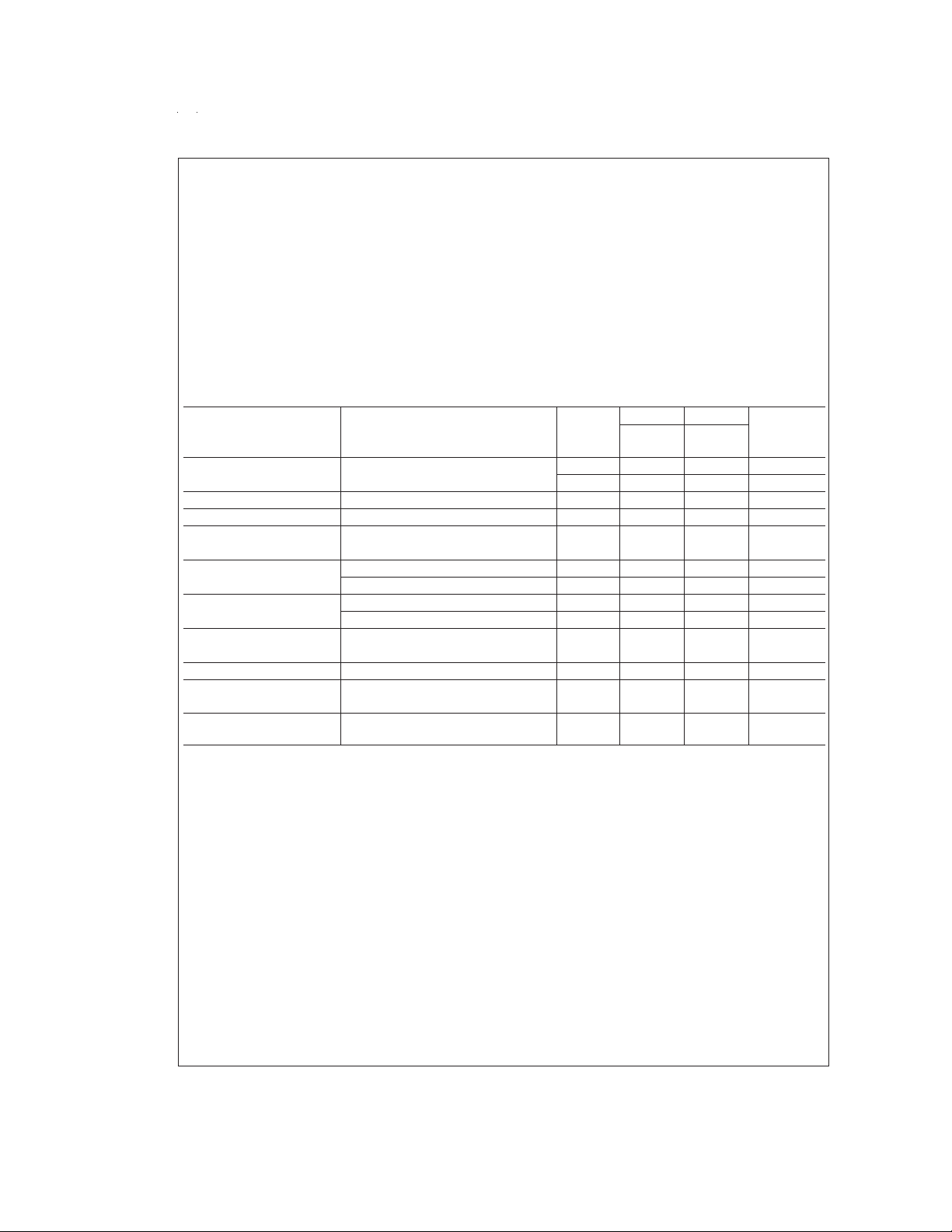

Electrical Characteristics

Unless otherwise noted, these specifications apply for +V

other limits T

=

=

T

25˚C.

A

J

Parameter Conditions Typical

=

S

. Boldface limits apply for T

+3.0 V

DC

(Note 6)

LM62B LM62C Units

Limits Limits

(Note 7) (Note 7)

Accuracy (Note 8)

±

+2.5/−2.0 +4.0/−3.0 ˚C (max)

Output Voltage at 0˚C +480 mV

Nonlinearity (Note 9)

±

Sensor Gain +16 +16.1 +16.3 mV/˚C (max)

(Average Slope) +15.1 +14.9 mV/˚C (min)

Output Impedance +3.0V ≤ +V

0˚C ≤ T

Line Regulation (Note 10) +3.0V ≤ +V

+2.7V ≤ +V

Quiescent Current +2.7V ≤ +V

≤ +10V 4.7 4.7 kΩ (max)

S

≤ +75˚C, +V

A

≤ +10V

S

≤ +3.3V, 0˚C ≤ TA≤ +75˚C

S

≤ +10V 82 130 130 µA (max)

S

=

+2.7V 4.4 4.4 kΩ (max)

S

±

1.13

±

165 165 µA (max)

Change of Quiescent Current +2.7V ≤ +V

≤ +10V

S

±

5µA

Temperature Coefficient of 0.2 µA/˚C

Quiescent Current

=

Long Term Stability (Note 11) T

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is functional, but do not guarantee specific performance limits. For guaranteed specifications and test conditions, see the Electrical Characteristics. The guaranteed specifications apply only for the test conditions listed. Some performance characteristics may degrade when the device is not operated under the listed test conditions.

Note 2: When the input voltage (V

Note 3: The human body model is a 100 pF capacitor discharged through a 1.5 kΩ resistor into each pin. The machine model is a 200 pF capacitor discharged di-

rectly into each pin.

Note 4: See AN-450 “Surface Mounting Methods and Their Effect on Product Reliability” or the section titled “Surface Mount” found in any post 1986 National Semi-

conductor Linear Data Book for other methods of soldering surface mount devices.

Note 5: The junction to ambient thermal resistance (θ

Note 6: Typicals are at T

Note 7: Limits are guaranteed to National’s AOQL (Average Outgoing Quality Level).

Note 8: Accuracy is defined as the error between the output voltage and +15.6 mV/˚C times the device’s case temperature plus 480 mV, at specified conditions of

voltage, current, and temperature (expressed in ˚C).

Note 9: Nonlinearity is defined as the deviation of the output-voltage-versus-temperature curve from the best-fit straight line, over the device’s rated temperature

range.

Note 10: Regulation is measured at constant junction temperature, using pulse testing with a low duty cycle. Changes in output due to heating effects can be com-

puted by multiplying the internal dissipation by the thermal resistance.

Note 11: For best long-term stability, any precision circuit will give best results if the unit is aged at a warm temperature, and/or temperature cycled for at least 46

hours before long-term life test begins. This is especially true when a small (Surface-Mount) part is wave-soldered; allow time for stress relaxation to occur. The majority of the drift will occur in the first 1000 hours at elevated temperatures. The drift after 1000 hours will not continue at the first 1000 hour rate.

) at any pin exceeds power supplies (V

I

=

=

T

25˚C and represent most likely parametric norm.

J

A

=

T

+100˚C,

J

MAX

for 1000 hours

JA

<

I

) is specified without a heat sink in still air.

GND or V

>

+VS), the current at that pin should be limited to 5 mA.

I

±

0.2 ˚C

2.0

0.8

9.7

=

=

T

T

A

J

MIN

±

3.0 ˚C (max)

±

1.0 ˚C (max)

±

1.13 mV/V (max)

±

9.7 mV (max)

to T

MAX

(Limit)

; all

www.national.com 2

Page 3

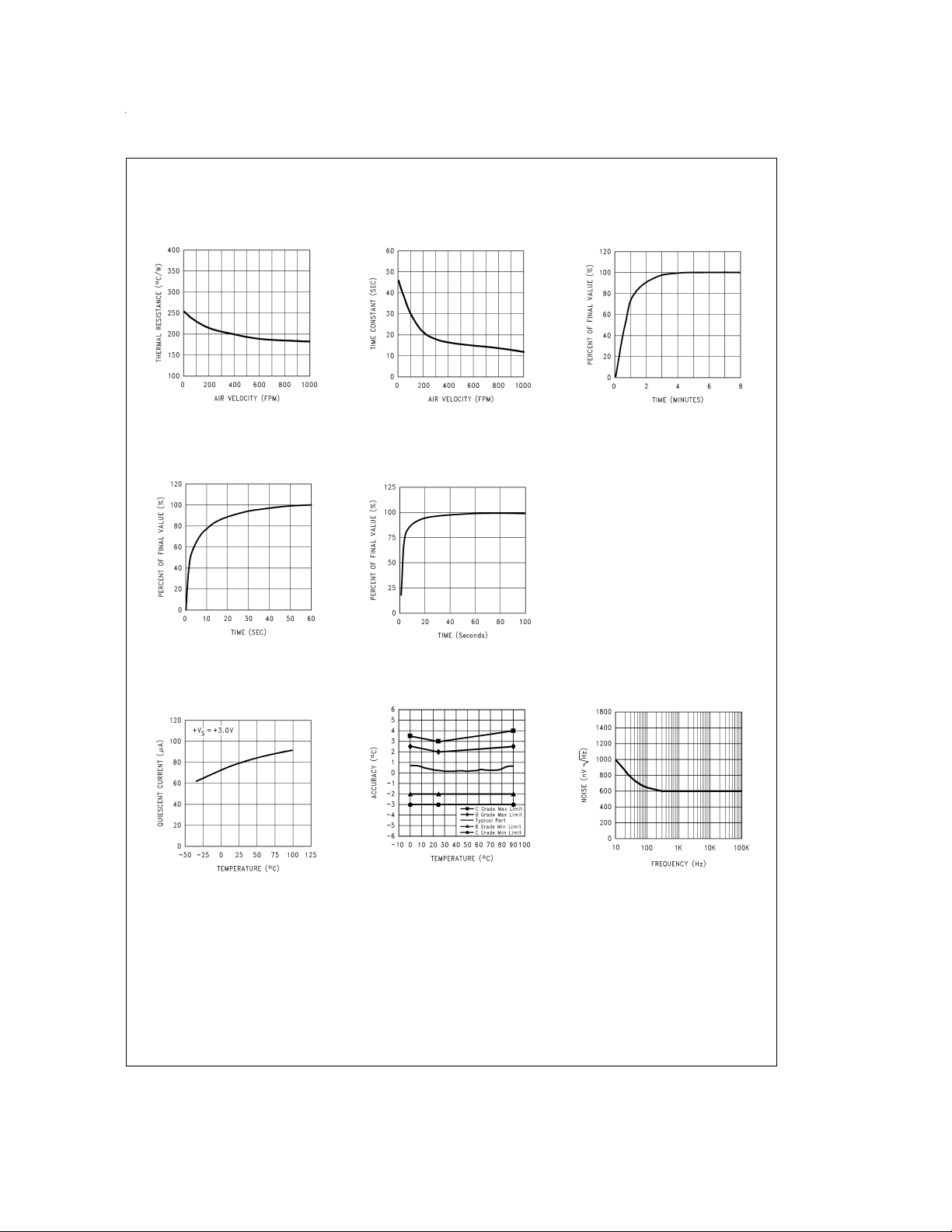

Typical PerformanceCharacteristics To generate these curves the LM62 was mounted to a printed

circuit board as shown in

Figure 2

.

Thermal Resistance

Junction to Air

Thermal Response

in Stirred Oil Bath

with Heat Sink

DS100893-3

DS100893-6

Thermal Time Constant

Thermal Response in Still

Air without a Heat Sink

DS100893-4

DS100893-8

Thermal Response in

Still Air with Heat Sink

DS100893-5

Quiescent Current

vs. Temperature

DS100893-9

Accuracy vs Temperature

DS100893-10

Noise Voltage

DS100893-11

www.national.com3

Page 4

Typical Performance Characteristics To generate these curves the LM62 was mounted to a

printed circuit board as shown in

Figure 2

. (Continued)

Supply Voltage

vs Supply Current

Start-Up Response

DS100893-22

DS100893-12

FIGURE 2. Printed Circuit Board Used

for Heat Sink to Generate All Curves.

1

⁄2" Square Printed Circuit Board

with 2 oz. Copper Foil or Similar.

1.0 Mounting

The LM62 can be applied easily in the same way as other

integrated-circuit temperature sensors. It can be glued or cemented to a surface. The temperature that the LM62 is sensing will be within about +0.2˚C of the surface temperature

that LM62’s leads are attached to.

This presumes that the ambient air temperature is almost the

same as the surface temperature; if the air temperature were

much higher or lower than the surface temperature, the actual temperature measured would be at an intermediate temperature between the surface temperature and the air temperature.

To ensure good thermal conductivity the backside of the

LM62 die is directly attached to the GND pin. The lands and

traces to the LM62 will, of course, be part of the printed circuit board, which is the object whose temperature is being

measured. These printed circuit board lands and traces will

not cause the LM62’s temperature to deviate from the desired temperature.

www.national.com 4

DS100893-14

Alternatively, the LM62 can be mounted inside a sealed-end

metal tube, and can then be dipped into a bath or screwed

into a threaded hole in a tank. As with any IC, the LM62 and

accompanying wiring and circuits must be kept insulated and

dry, to avoid leakage and corrosion. This is especially true if

the circuit may operate at cold temperatures where condensation can occur. Printed-circuit coatings and varnishes such

as Humiseal and epoxy paints or dips are often used to ensure that moisture cannot corrode the LM62 or its connections.

The thermal resistance junction to ambient (θ

rameter used to calculate the rise of a device junction tem-

) is the pa-

JA

perature due to its power dissipation. For the LM62 the

equation used to calculate the rise in the die temperature is

as follows:

=

T

+ θJA[(+VSIQ) + (+VS−VO)IL]

T

J

A

is the quiescent current and ILis the load current on

where I

Q

the output. Since the LM62’s junction temperature is the actual temperature being measured care should be taken to

minimize the load current that the LM62 is required to drive.

Page 5

1.0 Mounting (Continued)

The table shown in

perature of the LM62 without any loading, and the thermal

resistance for different conditions.

Still air 450 0.17 260 0.1

Moving

air

Note 12: Heat sink used is1⁄2" square printed circuit board with 2 oz. foil with

part attached as shown in

Note 13: Part soldered to 30 gauge wire.

FIGURE 3. Temperature Rise of LM62 Due to

Self-Heating and Thermal Resistance (θ

Figure 3

summarizes the rise in die tem-

SOT-23 SOT-23

no heat sink small heat fin

(Note 13) (Note 12)

θ

TJ−T

JA

θ

A

TJ−T

JA

(˚C/W) (˚C) (˚C/W) (˚C)

180 0.07

Figure 2

.

)

JA

A

2.0 Capacitive Loads

The LM62 handles capacitive loading well. Without any special precautions, the LM62 can drive any capacitive load as

shown in

Figure 4

LM62 has a maximum output impedance of 4.7 kΩ.Inanextremely noisy environment it may be necessary to add some

filtering to minimize noise pickup. It is recommended that

. Over the specified temperature range the

0.1 µF be added from +V

ply voltage, as shown in

to GND to bypass the power sup-

S

Figure 5

. In a noisy environment it

may be necessary to add a capacitor from the output to

ground. A 1 µF output capacitor with the 4.7 kΩ maximum

output impedance will form a 34 Hz lowpass filter. Since the

thermal time constant of the LM62 is much slower than the

30 ms time constant formed by the RC, the overall response

time of the LM62 will not be significantly affected. For much

larger capacitors this additional time lag will increase the

overall response time of the LM62.

DS100893-15

FIGURE 4. LM62 No Decoupling Required for

Capacitive Load

DS100893-16

FIGURE 5. LM62 with Filter for Noisy Environment

FIGURE 6. Simplified Schematic

DS100893-17

www.national.com5

Page 6

3.0 Applications Circuits

FIGURE 8. Conserving Power Dissipation with Shutdown

DS100893-18

FIGURE 7. Centigrade Thermostat

DS100893-19

www.national.com 6

Page 7

Physical Dimensions inches (millimeters) unless otherwise noted

SOT-23 Molded Small Outline Transistor Package (M3)

Order Number LM62BIM3 or LM62CIM3

NS Package Number MA03B

LM62 2.7V, 15.6 mV/˚C, SOT-23 Temperature Sensor

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80-532 78 32

Français Tel: +49 (0) 1 80-532 93 58

Italiano Tel: +49 (0) 1 80-534 16 80

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

Loading...

Loading...