Page 1

LM5116 Evaluation Board

National Semiconductor

Application Note 1596

Robert Sheehan

May 2007

Introduction

The LM5116 evaluation board is designed to provide the design engineer with a fully functional power converter based

on Emulated Current Mode Control to evaluate the LM5116

controller IC. The evaluation board provides a 5V output with

a 7A current capability. The wide input voltage ranges from

7V to 60V. The design operates at 250kHz, a good compromise between conversion efficiency and solution size. The

printed circuit board consists of 4 layers, 2 ounce copper top

and bottom, 1 ounce copper internal layers on FR4 material

with a thickness of 0.06 inches. This application note contains

the evaluation board schematic, Bill-of-Materials (BOM) and

a quick setup procedure. Refer to the LM5116 datasheet for

complete circuit design information.

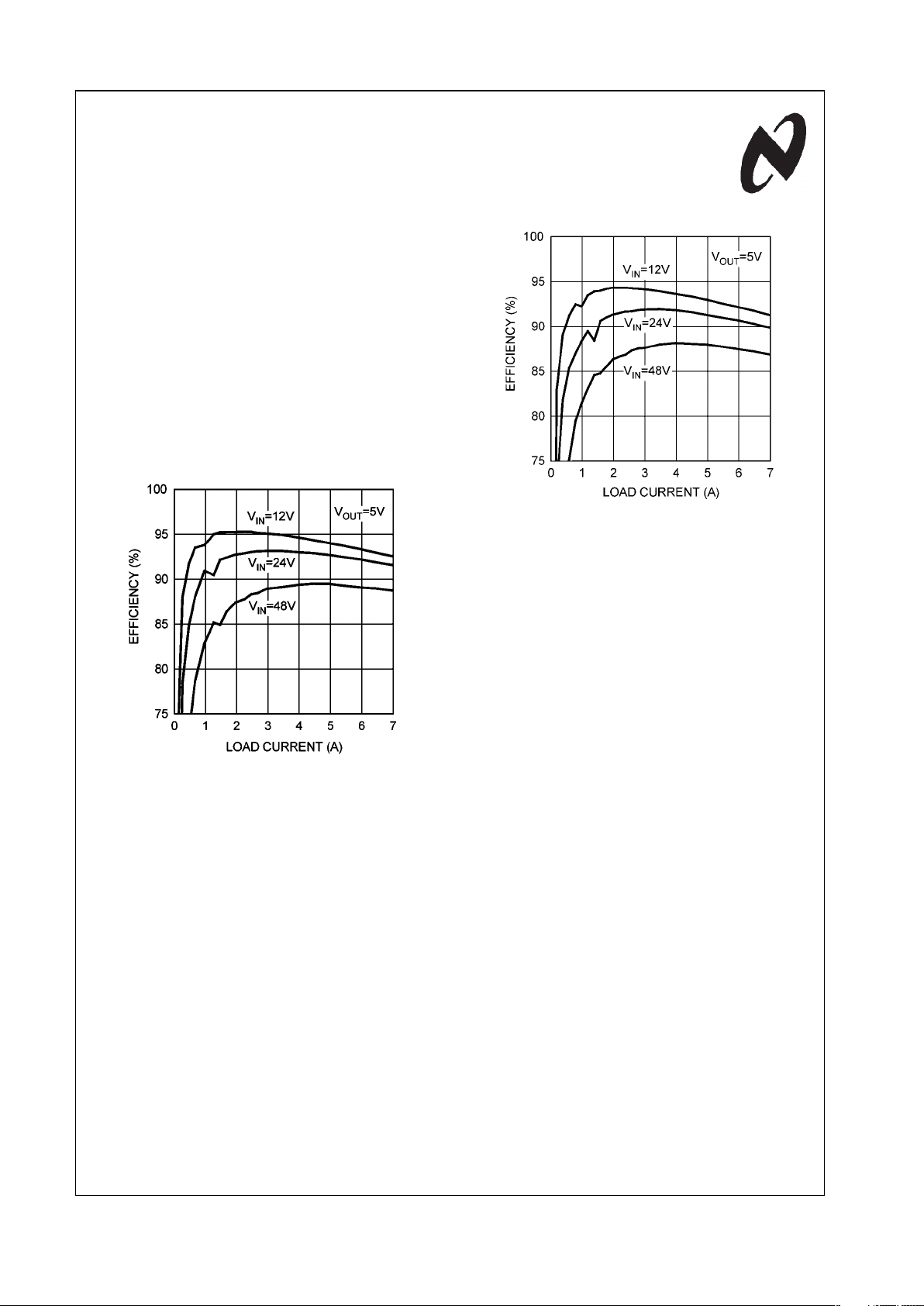

30012225

FIGURE 1. Efficiency with 6 µH Cooper Inductor

The performance of the evaluation board is as follows:

Input Range: 7V to 60V

Output Voltage: 5V

Output Current: 0 to 7A

Frequency of Operation: 250 kHz

Board Size: 2.55 X 2.65 X 0.5 inches

Load Regulation: 1%

Line Regulation: 0.1%

Over Current Limiting

30012223

FIGURE 2. Efficiency with 5.6 µH Pulse Inductor

Powering and Loading

Considerations

Read this entire page prior to attempting to power the evaluation board.

QUICK SETUP PROCEDURE

Step 1: Set the power supply current limit to 15A. Turn off the

power supply. Connect the power supply to the VIN terminals.

Step 2: Connect the load, with a 7A capability, to the V

OUT

terminals. Positive connection to P3 and negative connection

to P4.

Step 3: The EN pin should be left open for normal operation.

Step 4: Set VIN to 48V with no load applied. V

OUT

should be

in regulation with a nominal 5V output.

Step 5: Slowly increase the load while monitoring the output

voltage, V

OUT

should remain in regulation with a nominal 5V

output as the load is increased up to 7 Amps.

Step 6: Slowly sweep the input voltage from 7 to 60V, V

OUT

should remain in regulation with a nominal 5V output.

Step 7: Temporally short the EN pin to GND to check the

shutdown function.

Step 8: Increase the load beyond the normal range to check

current limiting. The output current should limit at approximately 11A. Cooling is critical during this step.

© 2007 National Semiconductor Corporation 300122 www.national.com

LM5116 Evaluation Board AN-1596

Page 2

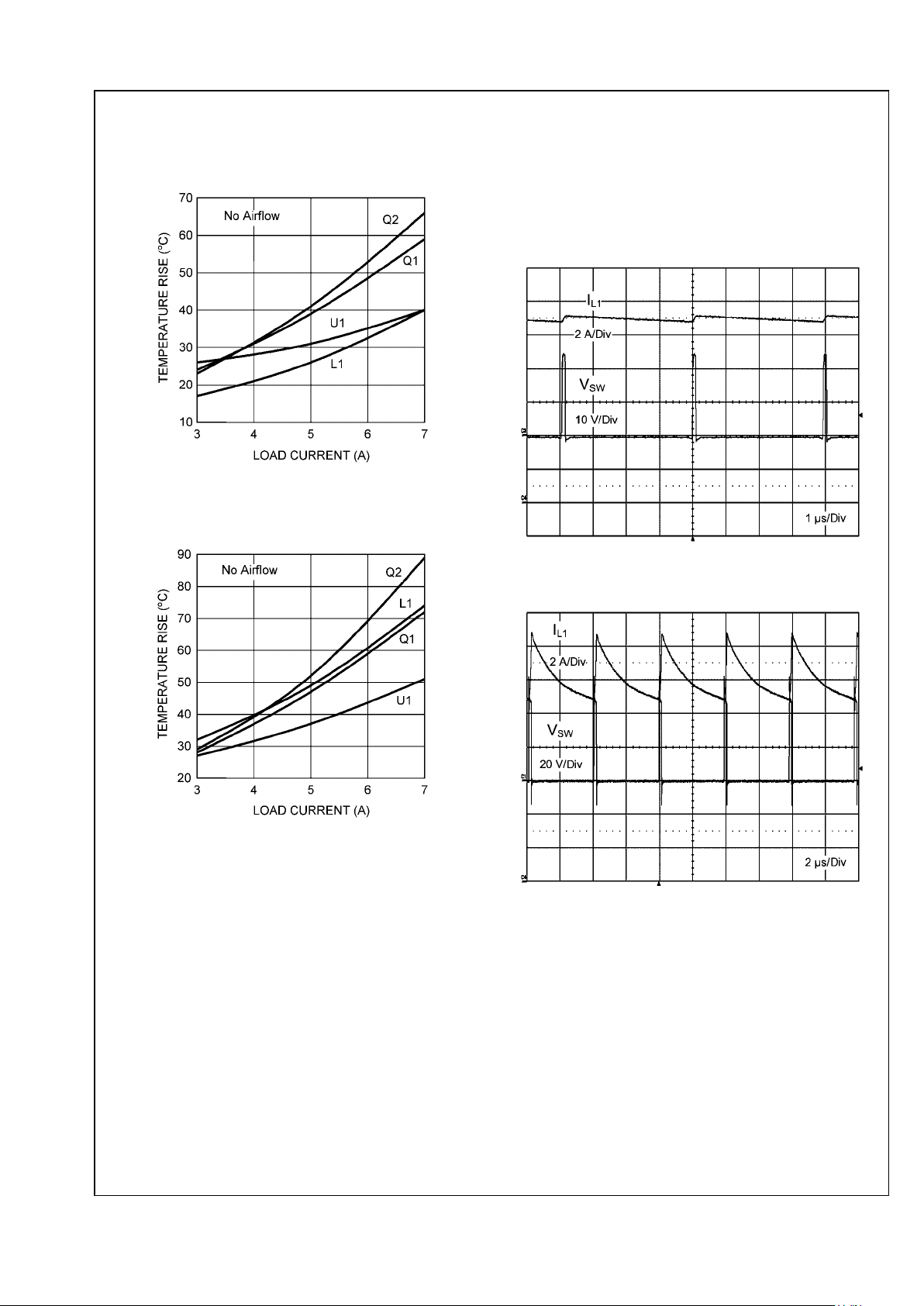

AIR FLOW

Prolonged operation with high input voltage at full power will

cause the MOSFETs to overheat. A fan with a minimum of

200 LFM should always be provided.

30012209

FIGURE 3. Temperature Rise at 48VIN with 6 µH Cooper

Inductor

30012222

FIGURE 4. Temperature Rise at 48VIN with 5.6 µH Pulse

Inductor

POWERING UP

Using the enable pin provided will allow powering up the

source supply with the current level set low. It is suggested

that the load be kept low during the first power up. Set the

current limit of the source supply to provide about 1.5 times

the anticipated wattage of the load. As you remove the connection from the enable pin to ground, immediately check for

5 volts at the output.

A quick efficiency check is the best way to confirm that everything is operating properly. If something is amiss you can

be reasonably sure that it will affect the efficiency adversely.

Few parameters can be incorrect in a switching power supply

without creating losses and potentially damaging heat.

For operation at 7VIN with full load, a 100 µF aluminum electrolytic capacitor installed across VIN will prevent input filter

oscillation for a typical bench test setup. See the LM5116 data

sheet for complete design information.

OVER CURRENT PROTECTION

The evaluation board is configured with over-current protection. The output current is limited to approximately 11A. The

thermal stress is quite severe while in an overloaded condition. Limit the duration of the overload and provide sufficient

cooling (airflow).

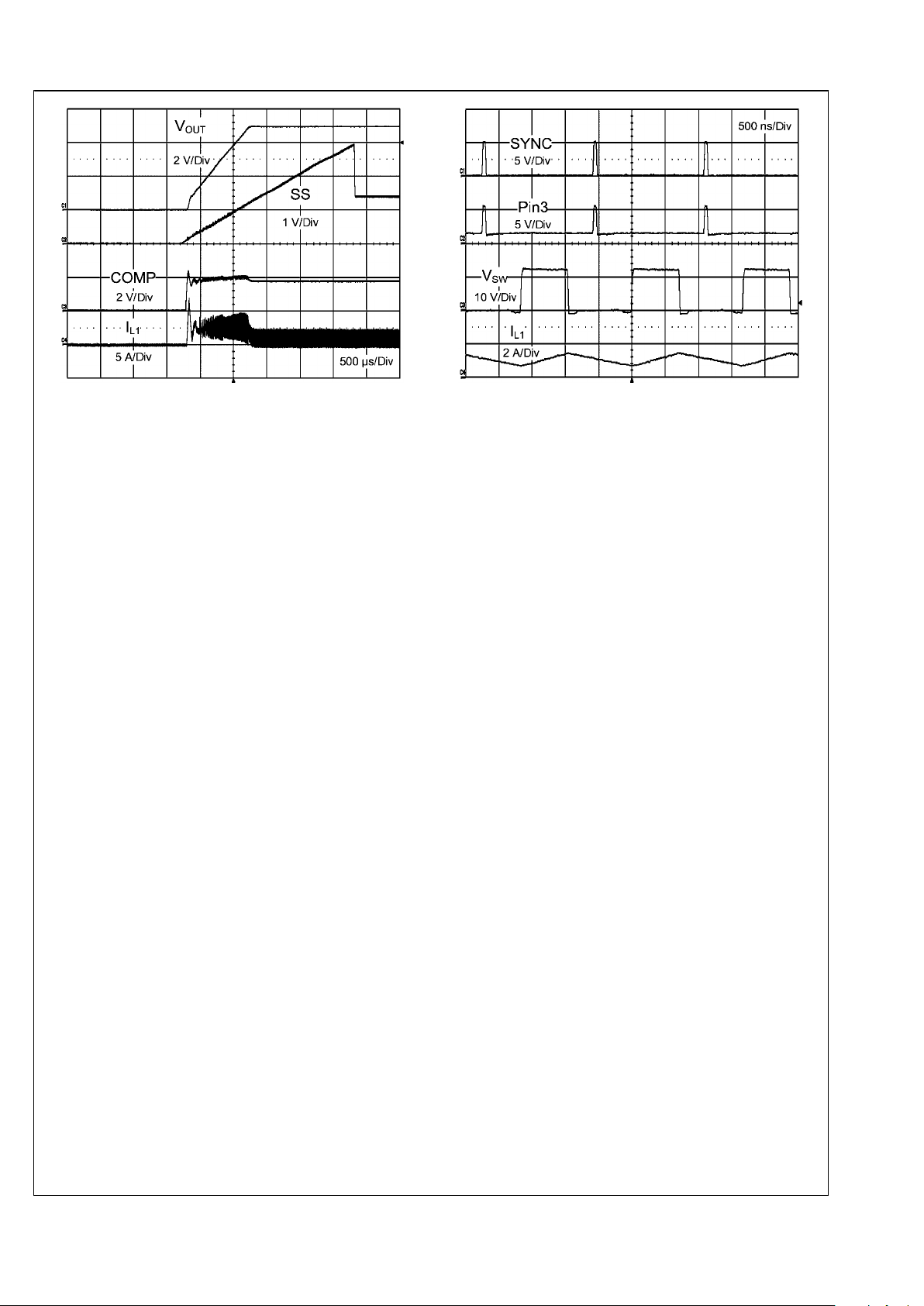

30012202

FIGURE 5. Short Circuit at 24VIN Room Temperature

30012203

FIGURE 6. Short Circuit at 48VIN 125°C

For sustained short circuit protection, adding C7 ≥ 1 µF will

limit the short circuit power dissipation. D2 should be installed

when using C7.

www.national.com 2

AN-1596

Page 3

30012204

FIGURE 7. Short Circuit Recovery into Resistive Load

with C7 = 1 µF and D2 Installed

VCCX

This test point supports evaluation of an auxiliary supply voltage derived from V

OUT

. For output voltages between 7V and

14V, a zero ohm resistor may be installed for R12. The selected MOSFETs need greater than 6V gate drive to fully

enhance them for lowest R

DS(ON)

, so R12 is not recommended

for the 5V output.

Under no circumstances should an external voltage source

be connected to VCCX when VIN < VCC. Damage to the controller will result. A series diode from the input voltage source

to pin 1 is required to accommodate VIN < VCC.

SYNCHRONIZATION

A SYNC pin has been provided on the evaluation board. This

pin can be used to synchronize the regulator to an external

clock. Refer to the LM5116 datasheet for complete information.

30012207

FIGURE 8. Synchronization at 12V

IN

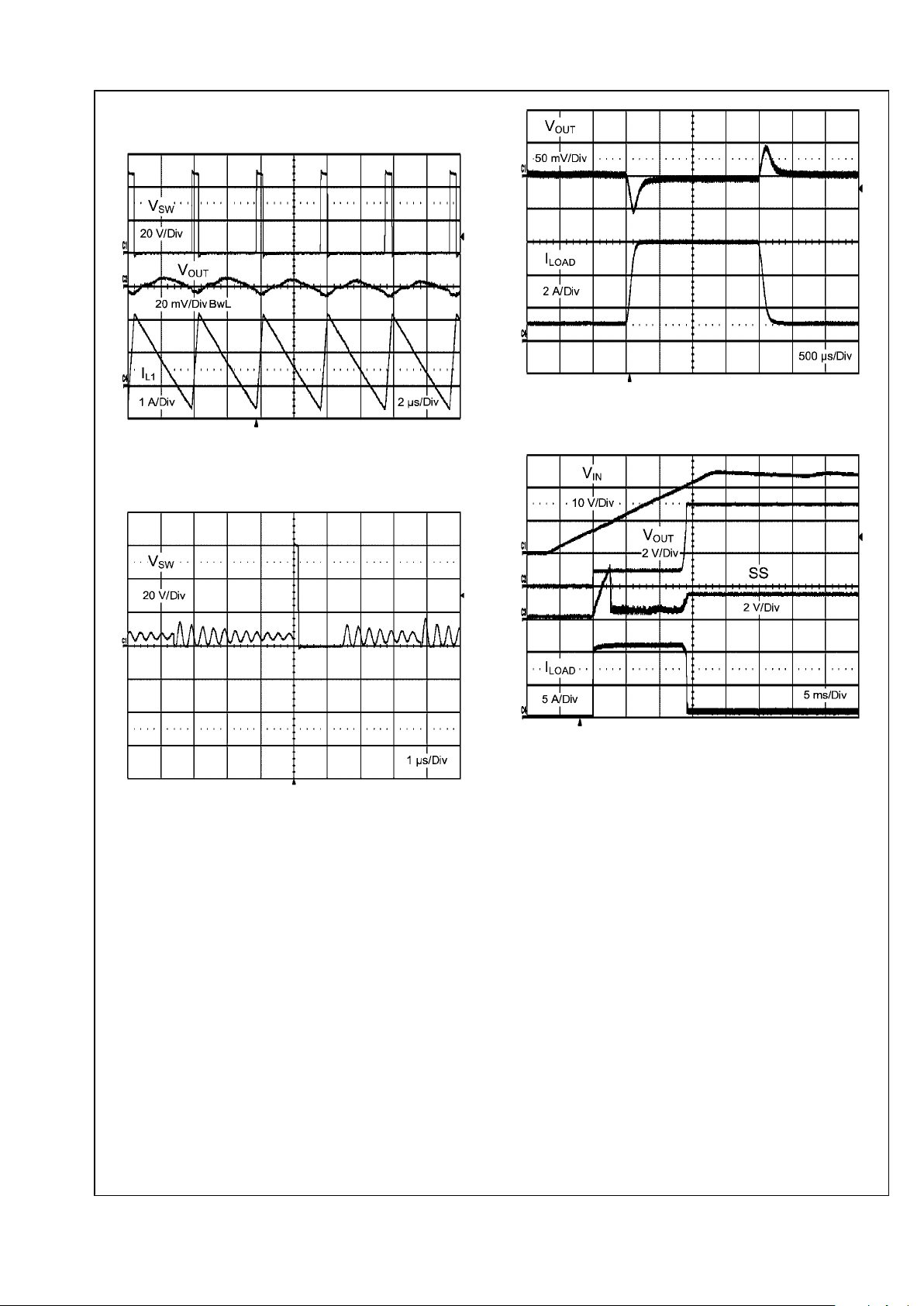

ACTIVE LOADS

Figure 12 shows a typical start-up characteristic into a constant current active load. This type of load can exhibit an initial

short circuit, which is sustained well beyond the normal softstart cycle. Overshoot of the output voltage is possible with

this condition. Increasing the soft-start time to be longer than

the initial short circuit period of the active load will minimize

any possible overshoot. When using C7, the hiccup off-time

may also need adjustment.

3 www.national.com

AN-1596

Page 4

Typical Performance Waveforms

30012206

FIGURE 9. Full Synchronous Operation at 48VIN with

JMP1 Removed

30012201

FIGURE 10. Discontinuous Operation using Diode

Emulation Mode at 60VIN with JMP1 Installed

30012208

FIGURE 11. Transient Response at 24V

IN

30012205

FIGURE 12. Start-up into Active Load at 24V

IN

www.national.com 4

AN-1596

Page 5

Evaluation Board Schematic

30012224

FIGURE 13.

5 www.national.com

AN-1596

Page 6

TABLE 1. Bill of Materials for 7V-60V Input, 5V 7A Output, 250kHz

ID Part Number Type Size Parameters Qty Vendor

C1, C2, C14 C2012X7R1E105K Capacitor, Ceramic 0805 1µF, 25V, X7R 3 TDK

C3 VJ0603Y103KXAAT Capacitor, Ceramic 0603 0.01µF, 50V, X7R 1 Vishay

C4 VJ0603A271JXAAT Capacitor, Ceramic 0603 270pF, 50V, COG, 5% 1 Vishay

C5, C15 VJ0603Y101KXATW

1BC

Capacitor, Ceramic 0603 100pF, 50V, X7R 1 Vishay

C6 VJ0603Y332KXXAT Capacitor, Ceramic 0603 3300pF, 25V, X7R 1 Vishay

C7 Capacitor, Ceramic 0603 Not Used 0

C8, C9, C10,

C11

C4532X7R2A225M Capacitor, Ceramic 1812 2.2µF, 100V X7R 4 TDK

C12 C3225X7R2A105M Capacitor, Ceramic 1210 1µF, 100V X7R 1 TDK

C13 C2012X7R2A104M Capacitor, Ceramic 0805 0.1µF, 100V X7R 1 TDK

C16, C17, C18,

C19, C20

C4532X6S0J107M Capacitor, Ceramic 1812 100µF, 6.3V, X6S, 105°C 5 TDK

C21, C22 Capacitor, Tantalum D Case Not Used 0

C23 Capacitor, Ceramic 0805 Not Used 0

D1 CMPD2003 Diode, Switching SOT-23 200mA, 200V 1 Central

Semi

D2 CMPD2003 Diode, Switching SOT-23 Not Used 0 Central

Semi

JMP1 Connector, Jumper 2 pin sq. post 1

L1 PD0120.532 Inductor 5.6µH, 10.4A 1 Pulse

L1A HC2LP-6R0 Inductor 6µH, 16.5A 0 Cooper

L1A P7611-5R6M Inductor 5.6µH, 17A 0 Profec

P1-P4 1514-2 Turret Terminal .090” dia. 4 Keystone

TP1-TP5 5012 Test Point .040” dia. 5 Keystone

Q1, Q2 Si7850DP N-CH MOSFET SO-8 Power PAK 10.3A, 60V 2 Vishay

Siliconix

R1 CRCW06031023F Resistor 0603

102kΩ, 1%

1 Vishay

R2 CRCW06032102F Resistor 0603

21.0kΩ, 1%

1 Vishay

R3 CRCW06033741F Resistor 0603

3.74kΩ, 1%

1 Vishay

R4 CRCW06031211F Resistor 0603

1.21kΩ, 1%

1 Vishay

R5 Resistor 0603 Not Used 0

R6, R7 CRCW06030R0J Resistor 0603

0Ω

2 Vishay

R8 CRCW0603103J Resistor 0603

10kΩ, 5%

1 Vishay

R9 CRCW06031242F Resistor 0603

12.4kΩ, 1%

1 Vishay

R10 CRCW0603183J Resistor 0603

18kΩ, 5%

1 Vishay

R11 LRC-LRF2010-01-

R010-F

Resistor 2010

0.010Ω, 1%

0 IRC

R11 WSL2010R0100FEA Resistor 2010

0.010Ω, 1%

1 Vishay

R12 Resistor 0603 Not Used 0

R13 CRCW0603105J Resistor 0603

1MΩ, 5%

1 Vishay

R14 Resistor 1206 Not Used 0

U1 LM5116MHX Synchronous Buck

Controller

TSSOP-20EP 1 NSC

www.national.com 6

AN-1596

Page 7

PCB Layout

30012217

30012215

30012210 30012216

7 www.national.com

AN-1596

Page 8

30012219

30012211

30012218 30012212

www.national.com 8

AN-1596

Page 9

30012220

30012213

30012221

9 www.national.com

AN-1596

Page 10

30012214

www.national.com 10

AN-1596

Page 11

Notes

11 www.national.com

AN-1596

Page 12

Notes

AN-1596 LM5116 Evaluation Board

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2007 National Semiconductor Corporation

For the most current product information visit us at www.national.com

National Semiconductor

Americas Customer

Support Center

Email:

new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Customer Support Center

Fax: +49 (0) 180-530-85-86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +49 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor Asia

Pacific Customer Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

www.national.com

Loading...

Loading...