Page 1

December 10, 2007

LM5015

High Voltage Monolithic Two-Switch Forward DC-DC

Regulator

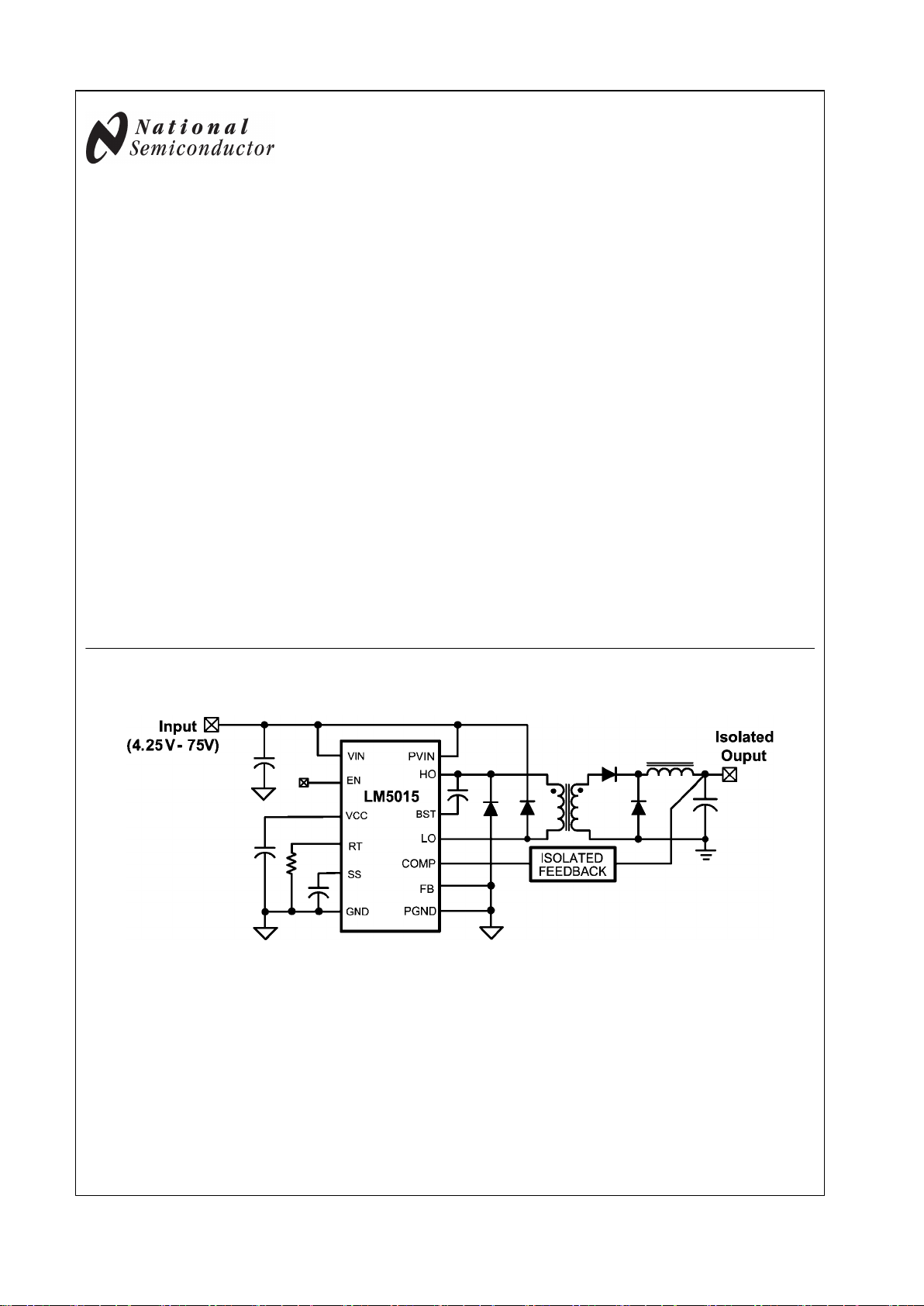

General Description

The LM5015 high voltage switch mode regulator features all

the functions necessary to implement efficient high voltage

Two-Switch Forward and Two-Switch Flyback regulators, using a minimum of external components. This easy to use

regulator integrates high side and low side 75 Volt N-Channel

MOSFETs with a minimum 1 Amp peak current limit. The

voltage across the MOSFETs employed in the two-switch

topology is clamped to the input voltage, allowing the input

voltage range to approach the rating of the MOSFETs. The

regulator control method is based on current mode control

providing inherent ease of loop compensation and line feedforward for superior rejection of input transients.

The operating frequency is set with a single resistor and is

programmable up to 750 kHz. The oscillator can also be synchronized to an external clock. Additional protection features

include cycle-by-cycle current limiting, thermal shutdown, under-voltage lockout and remote shutdown capability. The device is available in the TSSOP-14EP package featuring an

exposed die attach pad to enhance thermal dissipation.

Features

■

Dual Integrated 75V N-Channel MOSFETs

■

Ultra-wide input voltage range: 4.25V to 75V

■

Integrated high voltage bias regulator

■

Adjustable output voltage

■

1.5% feedback reference accuracy

■

Current mode control with selectable compensation

■

Wide bandwidth error amplifier

■

Integrated current sensing and limiting

■

50% maximum duty cycle limit

■

Single resistor oscillator programming

■

Oscillator synchronization capability

■

Programmable soft-start

■

Enable / Under-voltage Lockout (UVLO) pin

■

Thermal shutdown

Package

■

TSSOP-14EP (Exposed Pad)

Typical Application Schematic

30034601

© 2007 National Semiconductor Corporation 300346 www.national.com

LM5015 High Voltage Monolithic Two-Switch Forward DC-DC Regulator

Page 2

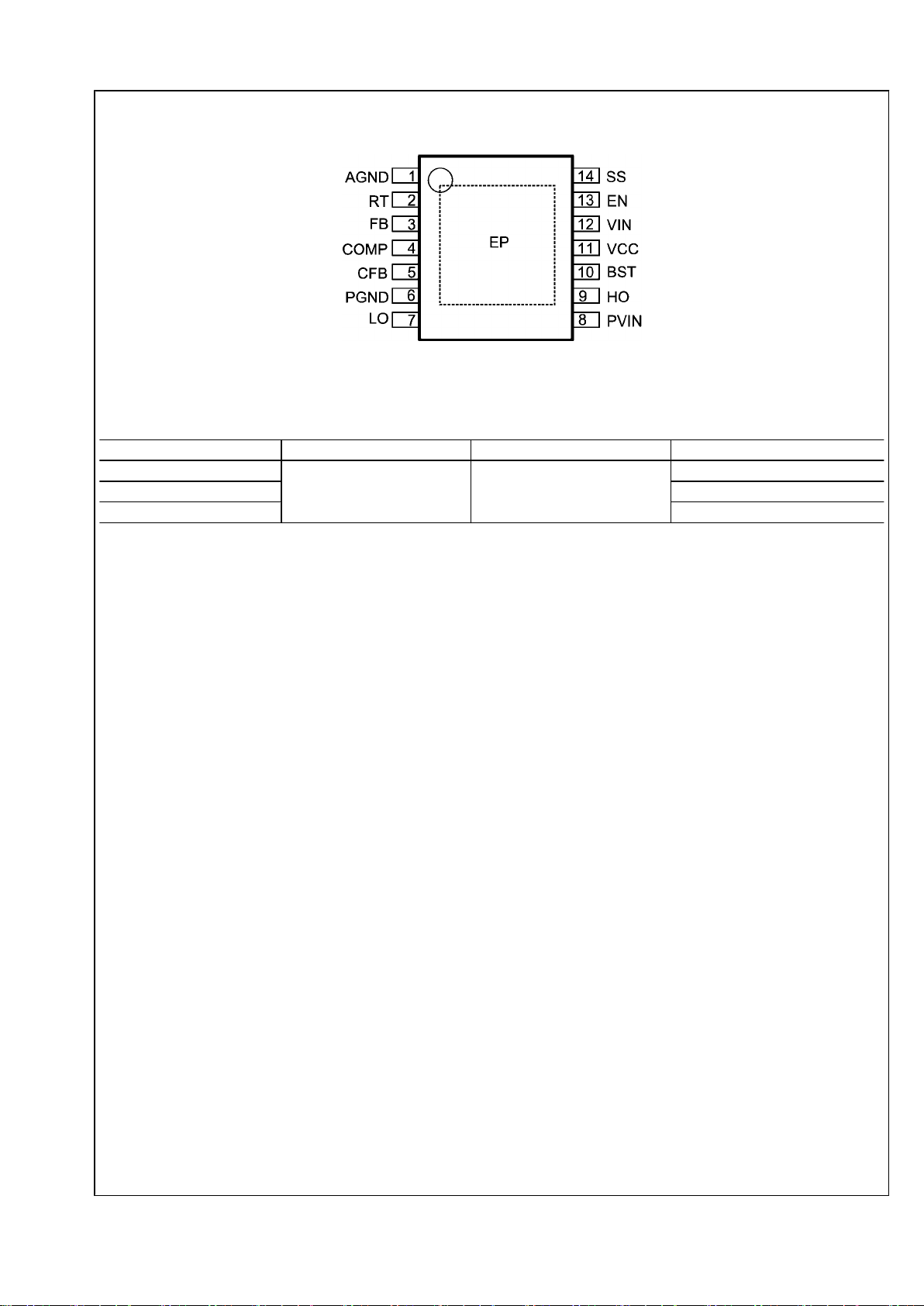

Connection Diagram

30034602

Top View

TSSOP-14 EP Package

Ordering Information

Order Number Package Type NSC Package Drawing Supplied As

LM5015MH

TSSOP-14 EP MXA14A

94 Units per Antistatic Tube

LM5015MHE 250 Units on Tape and Reel

LM5015MHX 2500 Units on Tape and Reel

www.national.com 2

LM5015

Page 3

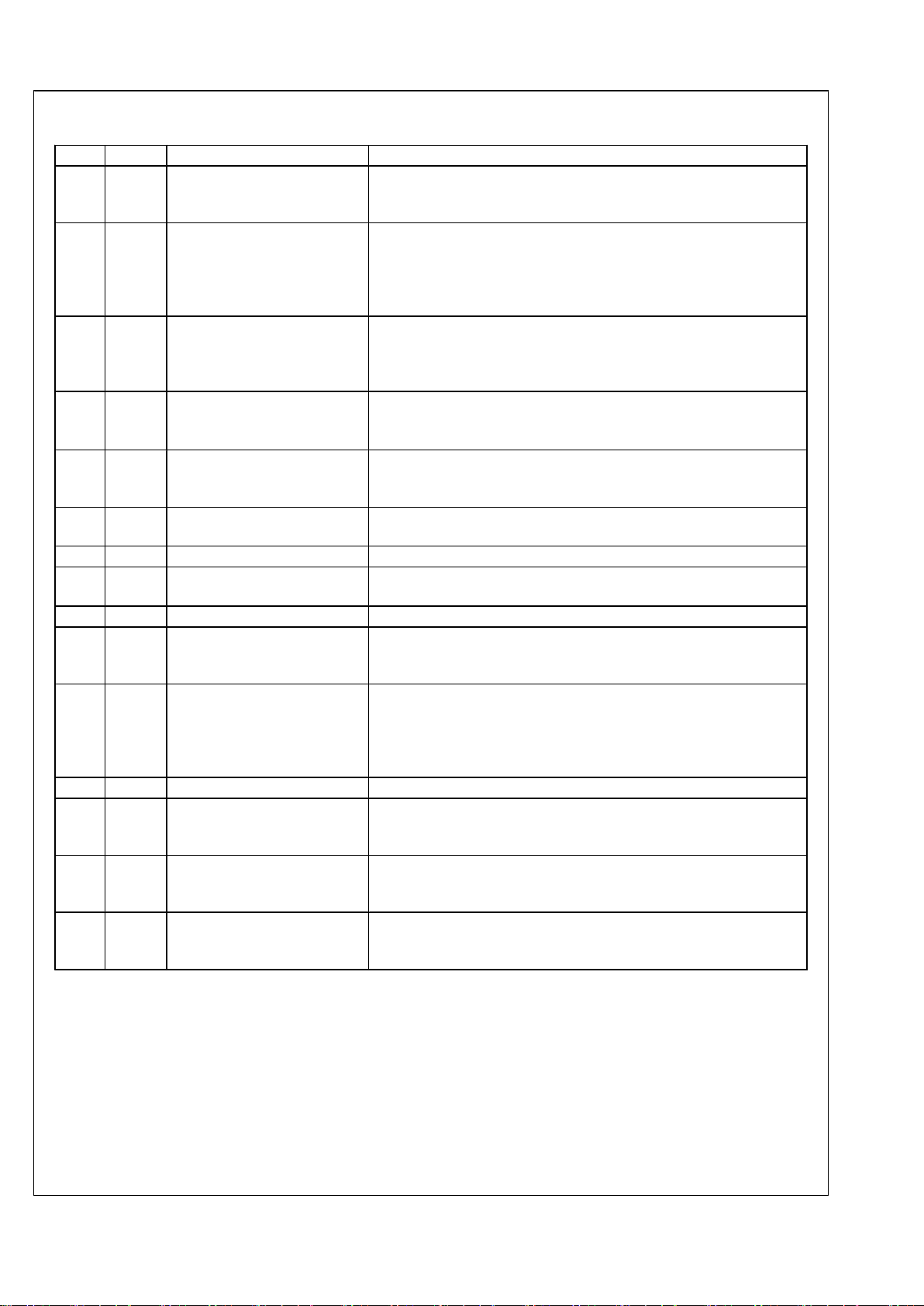

Pin Descriptions

Pin Name Description Application Information

1 AGND Analog ground Internal reference for the regulator control functions. The AGND pin and

the PGND pin should be connected directly to minimize switching noise and

prevent erratic operation.

2 RT Oscillator frequency

programming and optional

synchronization input

The internal oscillator is set with a resistor between this pin and the AGND

pin. The recommended switching frequency range is 25KHz to 750 kHz.

The RT pin can accept synchronization pulses from an external clock. A

100 pF capacitor is recommended for coupling the synchronizing clock to

the RT pin.

3 FB Feedback input of the internal

error amplifier, for non-isolated

applications

This pin is connected to the inverting input of the internal error amplifier.

The 1.26V reference is internally connected to the non-inverting input of

the error amplifier. In isolated application using an external error amplifier,

this pin should be connected to the AGND pin.

4 COMP Control input for the PWM

comparator

Internally connected to the open drain output of the internal error amplifier.

COMP pull-up is provided by an internal 5 kΩ resistor which may be used

to bias an opto-coupler transistor in isolated applications.

5 CFB Current feedback pin Feedback in put for high bandwidth isolated applications. An NPN current

mirror couples the external opto-coupler current to the PWM comparator

while maintaining a relatively constant opto-coupler voltage.

6 PGND Power ground Internally connected to the current sense resistor in the source of the low

side MOSFET switch.

7 LO Low side switch drain The drain terminal of the internal low side power MOSFET.

8 PVIN Input supply pin for high side

switch

Internally connected to the drain of the high side power MOSFET.

9 HO High side switch source The source terminal of the high side power MOSFET.

10 BST High side bootstrap bias An external capacitor is required between the BST and the HO pins. A

minimum capacitor value of 0.022 µF is recommended. The capacitor is

charged from VCC via an internal diode during the power MOSFET off-time.

11 VCC Bias regulator output, or input for

external bias supply

VCC tracks VIN up to 6.9V. At higher VIN voltages, VCC is regulated to 6.9

Volts. A 0.47µF or greater ceramic decoupling capacitor is required on the

VCC pin. An external bias voltage between 7V and 14V applied to the VCC

pin will disable the internal VCC regulator, reduce internal power

dissipation, and improve the converter efficiency.

12 VIN Analog input voltage pin Power supply Input for the switching regulator control blocks.

13 EN Enable / Under-Voltage Lock-

Out / Shutdown input

An external voltage divider can be used to set the input under-voltage

lockout threshold. If the EN pin is left unconnected, a 6 µA pull-up current

source pulls the EN pin high to enable the regulator.

14 SS Soft-start An internal 11 µA current source charges an external capacitor connected

to the SS pin to soft-start the switching regulator by gradually raising the

COMP pin voltage.

NA EP Exposed Pad Exposed metal pad on the underside of the package. It is recommended to

connect this pad to the PGND and AGND pins, and also to the PC board

ground plane in order to improve heat dissipation.

3 www.national.com

LM5015

Page 4

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

VIN to AGND 76V

BST to AGND 90V

PVIN to HO, LO, PGND 76V

HO to PGND (Steady State) -3V to 76V

LO to PGND (Steady State) -0.3V to 76V

BST to VCC 76V

BST to HO 14V

VCC, EN to AGND 14V

COMP, FB, RT, SS to AGND -0.3V to 7V

PGND to AGND -0.3V to +0.3V

CFB Sink Current 10 mA

Maximum Junction Temperature 150°C

Storage Temperature −65°C to + 150°C

ESD Rating

Human Body Model 2 kV

Operating Ratings

V

IN

4.25V to 75V

Operation Junction Temperature −40°C to + 125°C

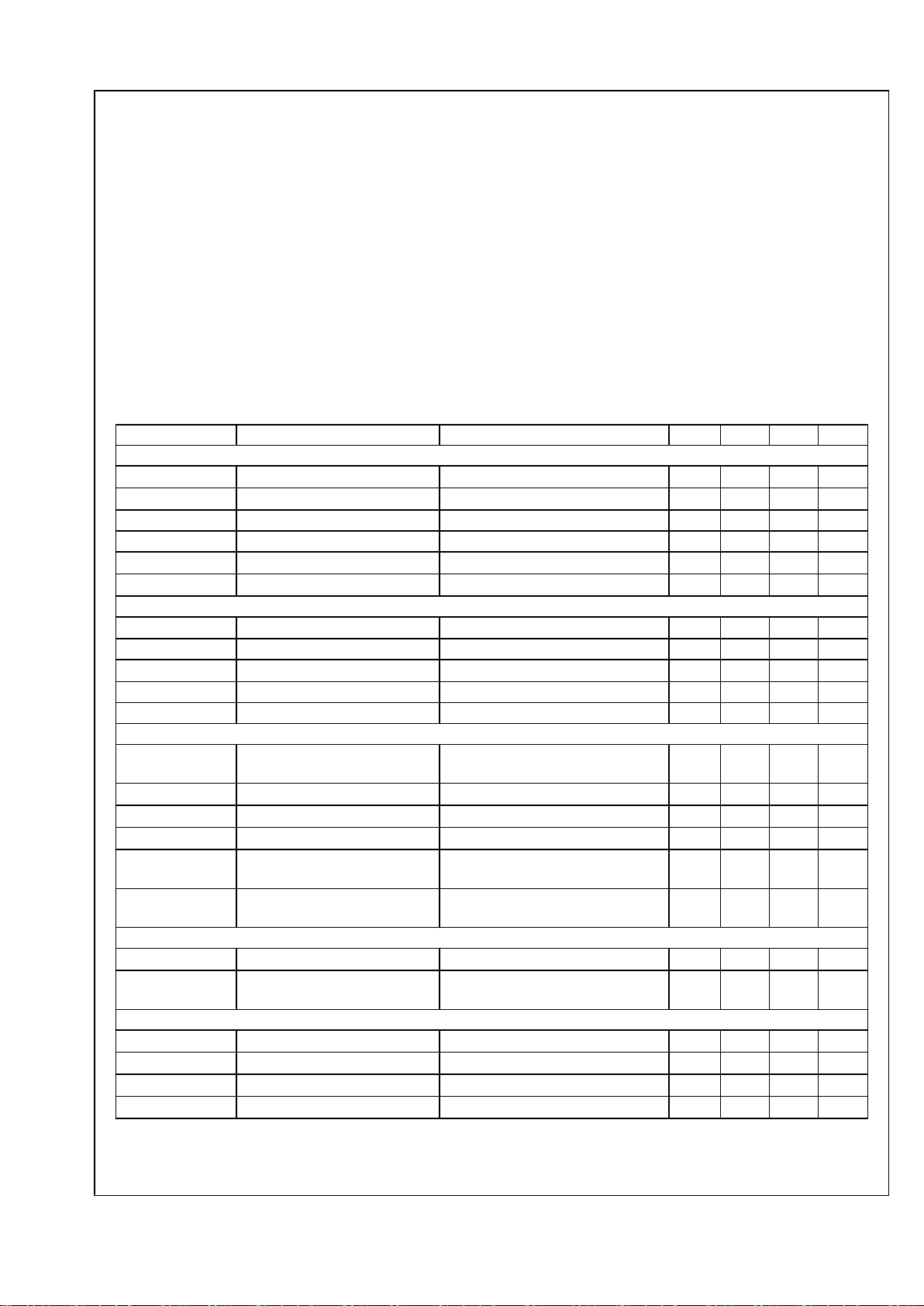

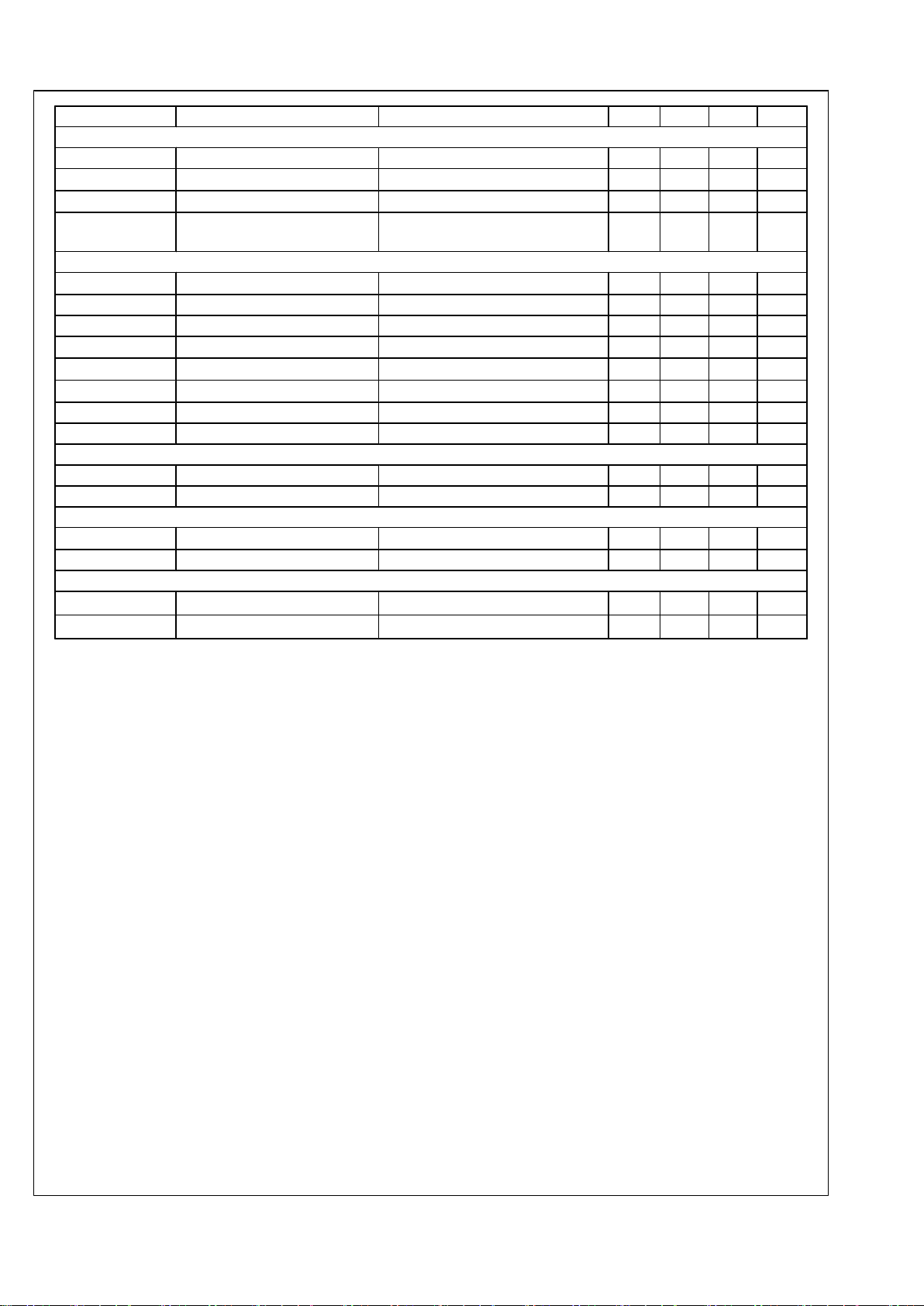

Electrical Characteristics Limits in standard type are for T

J

= 25°C only; limits in boldface type apply over the

junction temperature (TJ) range of −40°C to + 125°C. Minimum and Maximum limits are guaranteed through test, design, or

statistical correlation. Typical values represent the most likely parametric norm at TJ = 25°C, and are provided for reference

purposes only. V

VIN

= 48V, RRT = 31.6 kΩ unless otherwise stated. See (Note 3).

Symbol Parameters Conditions Min Typ Max Units

STARTUP REGULATOR

V

VCC-REG

VCC Regulator Output 6.35 6.85 7.25 V

VCC Current Limit V

VCC

= 6V 20 25 mA

VCC UVLO Threshold VCC increasing, VIN = VCC, EN=open 3.45 3.75 4.05 V

VCC UVLO Hysteresis VIN = VCC, EN = open 0.15 V

Bias Current (IIN) VFB = 1.5V 3.1 4.5 mA

I

Q

Shutdown Current (IIN) VEN = 0V 110 170 µA

EN THRESHOLDS

EN Shutdown Threshold VEN increasing 0.25 0.45 0.65 V

EN Shutdown Hysteresis 0.1 V

EN Standby Threshold VEN increasing 1.19 1.26 1.3 V

EN Standby Hysteresis 0.1 V

EN Current Source 6 µA

MOSFET CHARACTERSTICS

Low side MOSFET RDS(ON) plus

Current Sense Resistance

ID = 0.6A 0.49 0.93

Ω

MOSFET Leakage Current VLO = 75V 0.05 5 µA

High side MOSFET RDS(ON) ID = 0.6A 0.45 0.90

Ω

MOSFET Leakage Current V

PVIN

= 75V, VHO = PGND 0.05 5 µA

Total Gate Charge including both

Low and High side MOSFETs

V

VCC

= 8V 9 nC

Pre-charge Switch ON Voltage

including series blocking diode

ID = 1 mA 0.82 V

CURRENT LIMIT

I

LIM

Cycle by Cycle Current Limit 1 1.2 1.4 A

Cycle by Cycle Current Limit

Delay

130 ns

OSCILLATOR

F

SW1

Frequency1 RRT = 31.6k 180 200 220 kHz

F

SW2

Frequency2 RRT = 15.4k 365 405 445 kHz

V

RT-SYNC

SYNC Threshold VRT Increasing 3.2 V

SYNC Pulse Width Minimum VRT > V

RT-SYNC

+ 0.5V 15 ns

www.national.com 4

LM5015

Page 5

Symbol Parameters Conditions Min Typ Max Units

PWM COMPARATOR

Maximum Duty Cycle 49 %

Min On-time V

COMP

> V

COMP-OS

140 ns

Min On-time V

COMP

< V

COMP-OS

0 ns

V

COMP-OS

COMP to PWM Comparator

Offset

0.9 1.3 1.55 V

ERROR AMPLIFIER

V

FB-REF

Feedback Reference Voltage Internal reference, VFB = V

COMP

1.236 1.26 1.274 V

FB Bias Current 10 nA

DC Gain 72 dB

COMP Sink Current V

COMP

= 250mV 2 mA

COMP Short Circuit Current VFB = 0, V

COMP

= 0 0.9 1.2 1.5 mA

COMP Open Circuit Voltage VFB = 0 4.5 5.15 5.95 V

COMP to SW Delay 50 ns

Unity Gain Bandwidth 4 MHz

SOFT START

Soft-start Current Source 8 11 14 µA

Soft-start to COMP Offset 0.3 0.5 0.7 V

THERMAL SHUTDOWN

T

SD

Thermal Shutdown Threshold 165 °C

Thermal Shutdown Hysteresis 25 °C

THERMAL RESISTANCE

θ

JC

Junction to Case 6.6 °C/W

θ

JA

Junction to Ambient 40 °C/W

Note 1: Absolute Maximum Ratings are limits beyond which damage to the device may occur. Operating Ratings are conditions under which operation of the

device is intended to be functional. For guaranteed specifications and test conditions, see the Electrical Characteristics.

Note 2: The human body model is a 100pF capacitor discharged through a 1.5 kΩ resistor into each pin. Test Method is per JESD-22-A114.

Note 3: Min and Max limits are 100% production tested at 25°C. Limits over the operating temperature range are guaranteed through correlation using Statistical

Quality Control (SQC) methods. Limits are used to calculate National’s Average Outgoing Quality Level (AOQL).

5 www.national.com

LM5015

Page 6

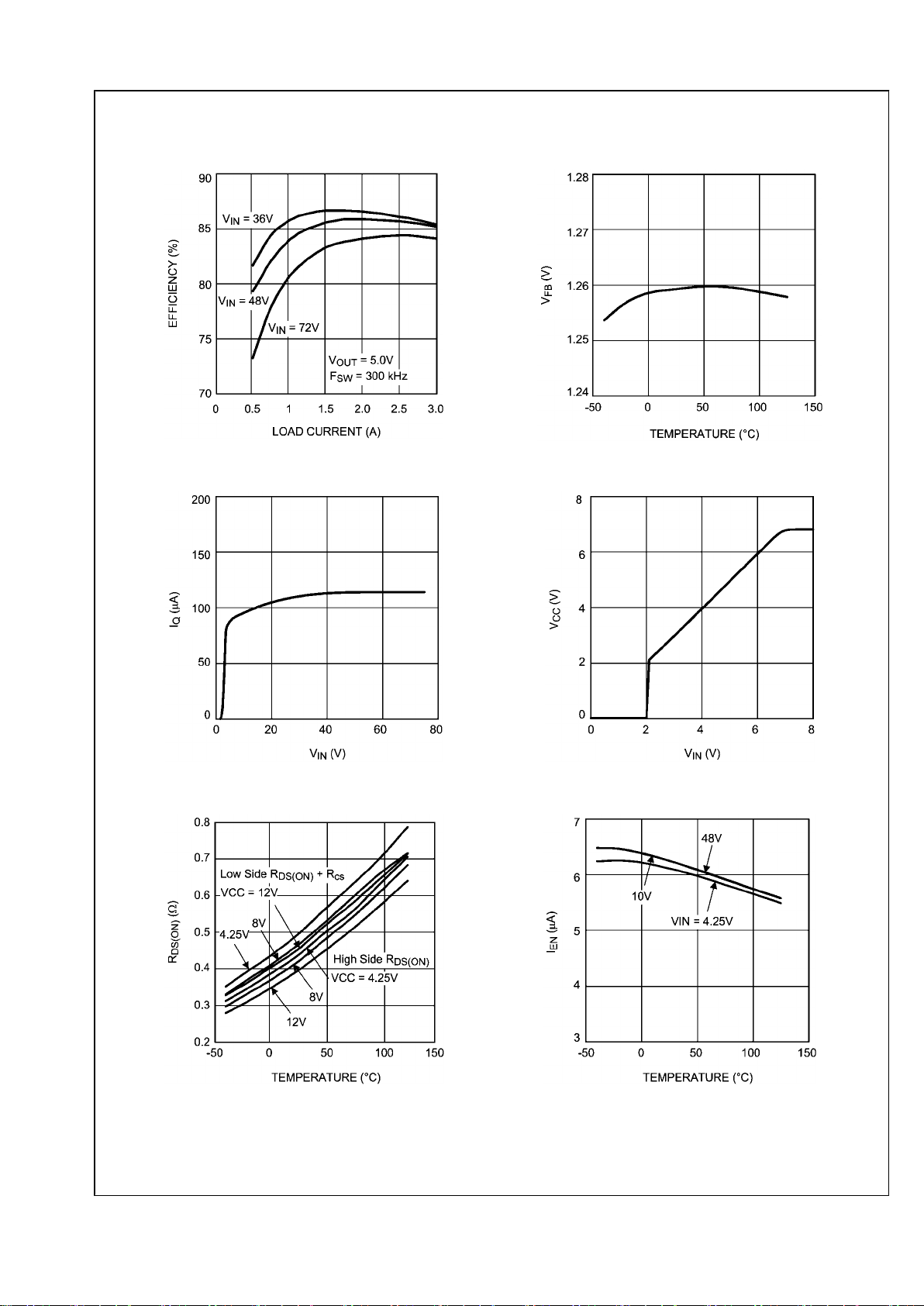

Typical Performance Characteristics

Demo-board Efficiency vs I

OUT

and V

IN

30034603

VFB vs Temperature

30034604

IQ (non-switching) vs VIN

30034605

VCC vs VIN

30034606

RDS(ON) vs VCC vs Temperature

30034607

IEN vs VIN vs Temperature

30034608

www.national.com 6

LM5015

Page 7

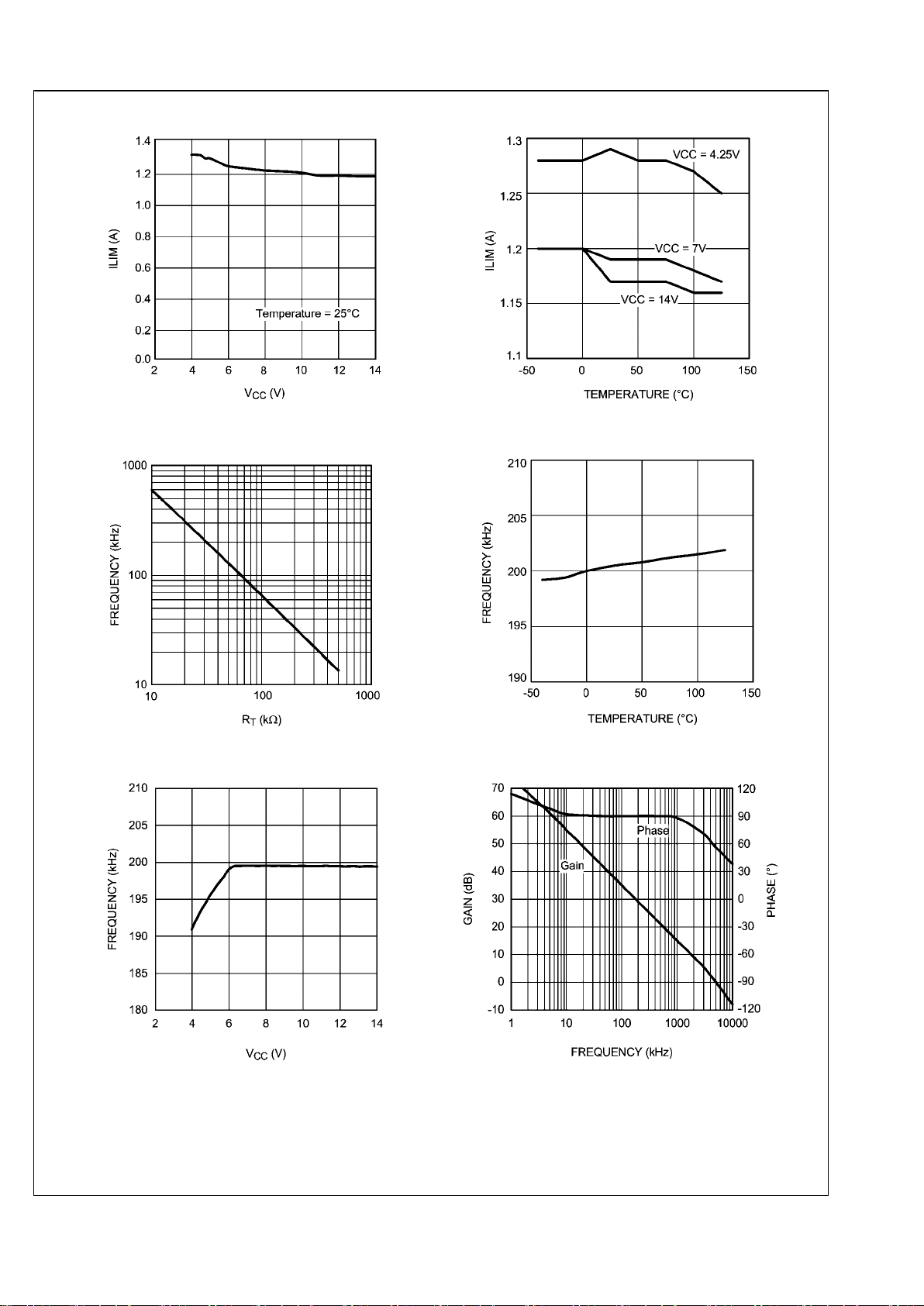

ILIM vs VCC

30034609

ILIM vs VCC vs Temperature

30034610

Fsw vs R

RT

30034611

Fsw vs Temperature

30034612

Fsw vs VCC

30034613

Error Amplifier Gain/Phase

30034614

7 www.national.com

LM5015

Page 8

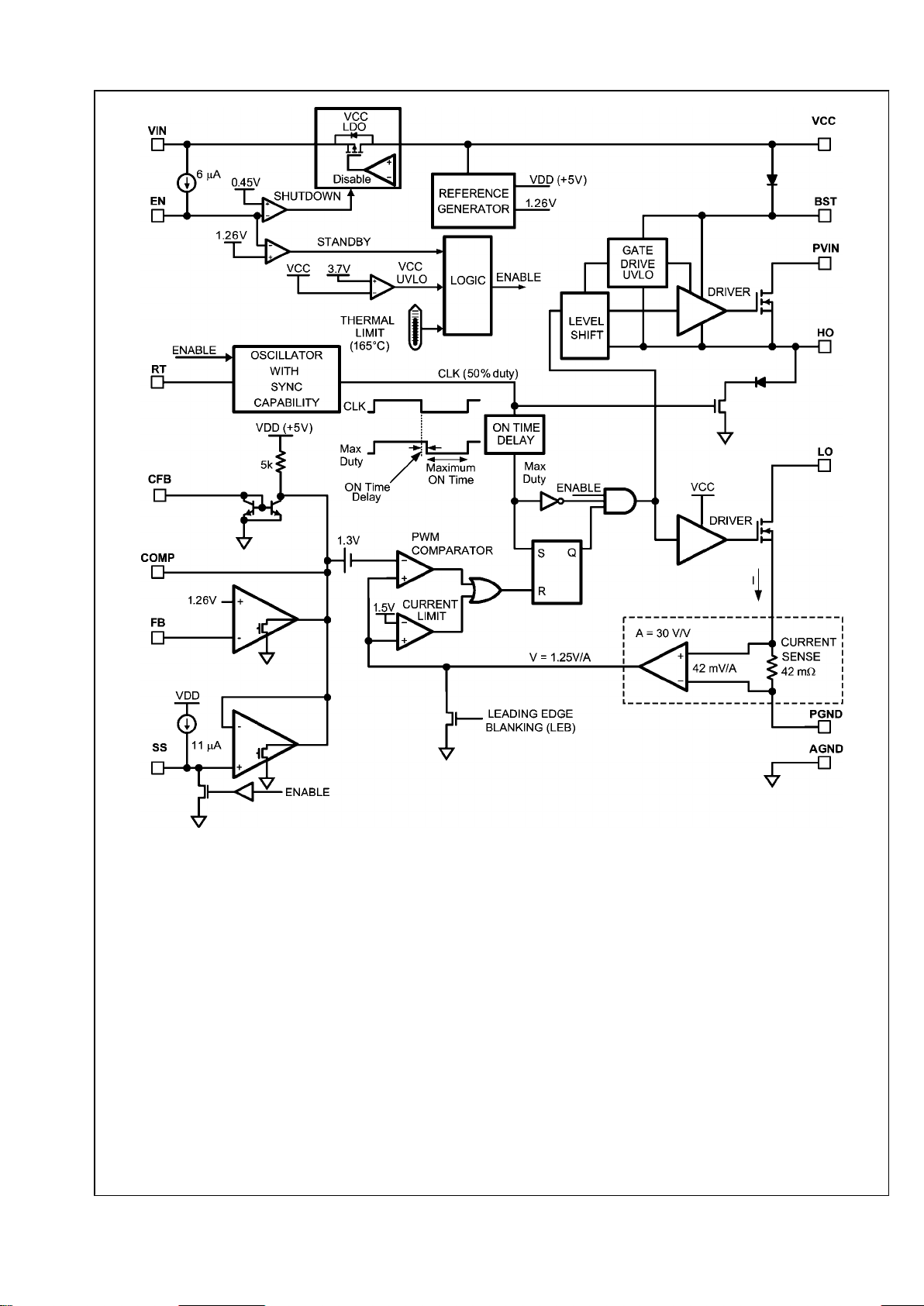

30034615

FIGURE 1. Block Diagram

www.national.com 8

LM5015

Page 9

Functional Description

The LM5015 high voltage switching regulator features all the

functions necessary to implement an efficient power converter using a Two-Switch Forward or Two-Switch Flyback topology. The voltage across the MOSFETs employed in the twoswitch topology is clamped to the input voltage, allowing the

input voltage range to approach the rating of the MOSFETs.

The regulator control method is based upon current mode

control providing cycle-by-cycle current limit, inherent input

voltage feed-forward and simple feedback loop compensation.

Referring to the functional block diagram shown in Figure1,

the operating principle of the LM5015 regulator is as follows:

At the beginning of each switching cycle, the oscillator sets

the driver logic and turns on both the high and low side power

MOSFETs to conduct current through the inductor or power

transformer. The peak current in the MOSFET is controlled

by the voltage at the COMP pin. The COMP voltage, which is

determined by the feedback circuit, is compared with the

sensed current signal of the internal low side power MOSFET.

When the current signal exceeds the COMP voltage, the

PWM comparator resets the driver logic, turning off both power MOSFETs. At the end of the switching cycle the driver logic

is set again by the oscillator to initiate the next switching period.

The LM5015 also contains dedicated circuitry to protect the

IC from abnormal operating conditions. Cycle-by-cycle current limiting prevents the power MOSFET current from exceeding 1 Amp. Thermal Shutdown circuitry holds the driver

logic in reset when the die temperature reaches 165°C, and

returns to normal operation when the die temperature drops

by approximately 25°C. The EN pin can be used as an input

voltage under-voltage lockout (UVLO) during start-up to pre-

vent operation with less than the minimum desired input

voltage.

Bias Input (VIN) and Power Input

(PVIN)

The LM5015 provides two separate input power pins, VIN and

PVIN, allowing for flexible decoupling options. The VIN pin

provides power to the low drop-out VCC bias regulator which

powers all internal control blocks. The PVIN connects directly

to the high side MOSFET drain.

If used with a single input source, the recommended configuration is shown in Figure 2a. Separate input pins allow the

bias input (VIN) to be de-coupled from the main power input

as shown. It is possible to directly connect the VIN and PVIN

pins for applications with localized de-coupling capacitors.

For applications where a lower voltage auxiliary source is

available, the configuration shown in Figure 2b can be used.

Powering the VIN pin with a relatively low voltage auxiliary

source reduces the IC power dissipation and increases the

conversion efficiency, especially when the main power source

for PVIN is relatively large. The VIN and PVIN pins are independent and can be separately biased at any voltages within

the 4.25V to 75V recommended operating range.

In high voltage applications extra care should be taken to ensure that the VIN and PVIN pins do not exceed the Absolute

Maximum Voltage Ratings of 76V. Voltage ringing on the input line during line transients that exceeds the Absolute Maximum Ratings can damage the IC. Both careful PC board

layout and the use of quality bypass capacitors located close

to the VIN and AGND pins, and to the PVIN to PGND pins,

are essential.

30034616

FIGURE 2. Analog and Power Input Ports

9 www.national.com

LM5015

Page 10

The PVIN and PGND pins are internally connected to the high

and low side power MOSFETs, respectively. When designing

the PC board, the input filter capacitor should connect directly

to these pins with short connection traces.

The VIN operating range is 4.25V to 75V. The current drawn

into the VIN pin depends primarily on the gate charge of the

internal power MOSFETs, the switching frequency, and any

external load on the VCC pin. It is recommended that a small

filter shown in Figure 2 be used for the VIN input to suppress

transients which may occur at the input supply. This is particularly important when VIN is operated close to the maximum operating rating of the LM5015.

High Voltage VCC Regulator

The LM5015 VCC Low Drop Out (LDO) regulator allows the

LM5015 to operate at the lowest possible input voltage. When

power is applied to the VIN pin and the EN pin voltage is

greater than 0.45V, the VCC regulator is enabled, supplying

current into the external capacitor connected to the VCC pin.

When the VIN voltage is between 4.25V and 6.9V, the VCC

voltage is approximately equal to the VIN voltage. When the

voltage on the VIN pin exceeds 6.9V, the VCC pin voltage is

regulated at 6.9V. The total input operating range of the VCC

LDO regulator is 4.25V to 75V.

The output of the VCC regulator is current limited to 20mA.

During power-up, the VCC regulator supplies current into the

required decoupling capacitor (0.47 µF or greater ceramic

capacitor) at the VCC pin. When the voltage at the VCC pin

exceeds the VCC UVLO threshold of 3.75V and the EN pin is

greater than 1.26V the PWM controller is enabled and switching begins. The controller remains enabled until VCC falls

below 3.60V or the EN pin falls below 1.16V.

An auxiliary supply voltage can be applied to the VCC pin to

reduce the IC power dissipation. If the auxiliary voltage is

greater than 6.9V, the internal regulator will essentially shutoff, and internal power dissipation will be decreased by the

VIN-VCC voltage difference times the operating current. The

externally applied VCC voltage should not exceed 14V. The

VCC regulator series pass MOSFET includes a body diode

(see Figure 1) between VCC and VIN that should not be forward biased in normal operation. Therefore, the auxiliary VCC

voltage should never exceed the VIN voltage.

High Side Bootstrap Bias

The high side bootstrap bias provides power to drive the high

side power MOSFET. An external capacitor is required between the BST and the HO pins. A minimum capacitor value

of 0.022 µF is recommended. The capacitor is charged from

VCC via an internal diode during each power MOSFET offtime.

Oscillator

A single external resistor connected between RT and AGND

pins sets the LM5015 oscillator frequency. To set a desired

oscillator frequency (FSW), the necessary value for the RT resistor can be calculated from the following equation:

The tolerance of the external resistor and the frequency tolerance indicated in the Electrical Characteristics table must

be taken into account when determining the total variation of

the switching frequency.

External Synchronization

The LM5015 can be synchronized to the rising edge of an

external clock. Because the oscillator uses a divide-by-two

circuit, the switching frequency FSW in the above equation is

actually half the native oscillator frequency. Therefore, in order to synchronize, the external clock must have a frequency

higher than twice the free running FSW set by the RT resistor.

The clock signal should be coupled through a 100 pF capacitor into the RT pin. A peak voltage level greater than 3.2V at

the RT pin is required for detection of the sync pulse. The DC

voltage across the RT resistor is internally regulated at 1.5

volts. The negative portion of the AC voltage of the synchronizing clock is clamped to 1.5V by an amplifier inside the

LM5015 with approximately 100Ω output impedance. Therefore, the AC pulse superimposed on the RT resistor must have

positive pulse amplitude of 1.7V or greater to successfully

synchronize the oscillator. The sync pulse width measured at

the RT pin should have a duration greater than 15 ns and less

than 5% of the switching period. The RT resistor is always

required, whether the oscillator is free running or externally

synchronized. The RT resistor should be located very close to

the device and connected directly to the RT and AGND pins

of the LM5015.

Enable / Standby

The LM5015 contains a dual level Enable circuit. When the

EN pin voltage is below 0.45V, the IC is in a low current shutdown mode with the VCC LDO disabled. When the EN pin

voltage is raised above the 0.45V shutdown threshold but below the 1.26V standby threshold, the VCC LDO regulator is

enabled, while the remainder of the IC is disabled. When the

EN pin voltage is raised above the 1.26V standby threshold,

all functions are enabled and normal operation begins. An internal 6 µA current source pulls up the EN pin to activate the

IC when the EN pin is left disconnected.

An external set-point resistor divider from VIN to AGND can

be used to determine the minimum operating input voltage of

the regulator. The divider must be designed such that the EN

pin exceeds the 1.26V standby threshold when VIN is in the

desired operating range. The internal 6 µA current source

should be included when determining the resistor values. The

shutdown and standby thresholds have 100 mV hysteresis to

prevent noise from toggling between modes. The EN pin is

internally protected by a 6V Zener diode through a 1 kΩ resistor. The enabling voltage may exceed the Zener voltage,

however the Zener current should be limited to less than 4

mA.

Error Amplifier and PWM

Comparator

An internal high gain error amplifier generates an error signal

proportional to the difference between the regulated output

voltage and an internal precision reference. The output of the

error amplifier is connected to the COMP pin allowing the user

to add loop compensation, typically a Type II network, as illustrated in Figure 3. This network creates a pole at the origin

that rolls off the high DC gain of the amplifier, which is necessary to accurately regulate the output voltage. A zero provides phase boost near the open loop unity gain frequency,

and a high frequency pole attenuates switching noise. The

PWM comparator compares the current sense signal from the

current sense amplifier to the error amplifier output voltage at

the COMP pin.

www.national.com 10

LM5015

Page 11

30034618

FIGURE 3. Type II Compensator

When isolation between primary and secondary circuits is required, the Error Amplifier is usually disabled by connecting

the FB pin to AGND. This allows the COMP pin to be driven

directly by the collector of an opto-coupler. In isolated designs

the error amplifier is located on the secondary circuit and

drives the opto-coupler LED. The compensation network is

connected to the secondary side error amplifier. An example

of an isolated regulator with an opto-coupler is shown in Figure 13.

Current Sense Amplifier

The LM5015 employs peak current mode control which also

provides a cycle-by-cycle over current protection feature. An

internal 42 milli-Ohm current sense resistor measures the

current in the low side power MOSFET source. The sense

resistor voltage is amplified 30 times to provide a 1.25V/A

signal into the current limit comparator. Current limiting is initiated if the internal current limit comparator input exceeds the

1.5V threshold, corresponding to 1.2A. When the current limit

comparator is triggered, the HO and LO output pins immediately switches to the high impedance state.

The current sense signal provides the PWM comparator with

a control signal that reaches 1.5V when the MOSFET current

is 1.2A. To prevent erratic operation at low duty cycle, a leading edge blanking circuit attenuates the current sense signal

for 100 ns when the power MOSFET is turned on. When the

MOSFET is initially turned on, current spikes from the power

MOSFET drain-source and gate-source capacitances flow

through the current sense resistor. These transient currents

normally cease within 50 ns with proper selection of rectifier

diodes and proper PC board layout.

Thermal Protection

Internal Thermal Shutdown circuitry is provided to protect the

IC in the event the maximum junction temperature is exceeded. When the 165°C junction temperature threshold is

reached, the regulator is forced into a low power standby

state, disabling all functions except the VCC regulator. Thermal hysteresis allows the IC to cool down by 25°C before it is

re-enabled.

Power MOSFETs

The LM5015 switching regulator includes two N-Channel

MOSFETs each with 450 mΩ nominal on-resistance. The

drain of the high side MOSFET is the PVIN pin, and the source

the HO pin. The drain of the low side MOSFET is the LO pin,

and the source is internally connected to the PGND pin via

the 42 mΩ internal current sense resistor. The on-resistance

of the LM5015 MOSFETs varies with temperature as shown

in the Typical Performance Characteristics graph. The typical

gate charge for each MOSFETs is 4.5 nC which is supplied

from the VCC and BST pins, respectively, when the MOSFETs are turned on.

The maximum duty cycle of the power MOSFETs is limited

less than 50%. This is achieved by an oscillator divide-by-two

circuit with an additional 50 ns of forced off-time introduced

between the CLK and RS Flip-Flop. Consequently, the maximum duty cycle is limited by the following equation:

Duty

Max_Limit

=(0.5 - 50 ns x FSW) x 100%

Where FSW is the switching frequency in Hertz (Hz). The purpose of limiting the maximum duty cycle less than 50% is to

guarantee successful reset of the power transformer in the

Two-Switch Forward converter topology. See applications information below for more detail.

11 www.national.com

LM5015

Page 12

Application Information

The following information is intended to provide guidelines for

the power supply designer using the LM5015.

TWO-SWITCH FORWARD TOPOLOGY

Two-Switch Forward converter, like the conventional SingleSwitch Forward converter, is derived from the Buck converter

topology. The main difference between a Forward converter

and a Buck is that a power transformer is introduced in the

forward converter. The transformer realizes the input-output

isolation, and the turns ratio provides a means to optimize the

duty cycle for the particular input and output voltage requirements of the application.

The Two-Switch Forward converter employs two power MOSFET switches instead of the one switch of the Single-Switch

Forward converter. However the two-switch approach offers

two major advantages over its single-switch counterpart:

1.

The voltage across the power MOSFET switches in a

Two-Switch Forward converter is clamped to the input

voltage, allowing the input voltage range to approach the

rating of the MOSFETs. Whereas, the maximum

operating voltage of a Single-Switch Forward converter

is typically limited to half the MOSFET voltage rating.

2.

The power transformer of a Two-Switch Forward

converter is simpler, and hence costs less, than that of a

Single-Switch Forward converter, because the TwoSwitch converter transformer eliminates the tertiary reset

winding that is normally required in the Single-Switch

converter.

Figure 4 illustrates the Two-Switch Forward converter topology. The power circuit consists of an input capacitor CIN, two

MOSFET switches QH and QL, two clamp diodes DH and DL,

a power transformer T1, two rectifier diodes D1 and D2, an

output inductor LO, and an output capacitor Co. Since the

LM5015 integrates both QH and QL, a low cost Two-Switch

Forward converter can be realized without a need for discrete

power MOSFETs. With a slightly higher cost, the two rectifier

diodes D1 and D2 on the secondary side of the power transformer can be replaced with synchronous rectifier MOSFETs

to improve efficiency in applications with relatively low output

voltage.

30034619

FIGURE 4. Two-Switch Forward Converter Topology

www.national.com 12

LM5015

Page 13

Figure 5 shows the two operating modes of the Two-Switch

Forward converter. During operation, the two MOSFETS are

turned ON and OFF simultaneously. The output voltage is

regulated by modulating the duty cycle of the MOSFETs. The

relationship between the input voltage VIN, output voltage

V

OUT

, duty cycle D, rectifier diode forward drop VF, and trans-

former turns ratio k is defined by the following equation.

When the MOSFETS are turned ON, as shown in Figure 5(a),

the input voltage is applied to the power transformer primary.

The power transformer is magnetized by the application of the

input voltage, and power flows to the secondary side circuit

via transformer coupling. When the MOSFETS are turned

OFF, as shown in Figure 5(b), the power flow to the primary

is cut off. The residual magnetizing inductance of the power

transformer reverses the voltage across the primary winding

and forces the two clamp diodes DH and DL to conduct. This

effectively clamps the MOSFETs voltage to the input voltage,

and applies the input voltage in reversed polarity to the power

transformer primary winding to demagnetize and reset the

transformer.

30034621

FIGURE 5. Operating Modes of Two-Switch Forward Converter

13 www.national.com

LM5015

Page 14

Note that the power transformer primary receives the voltage

of the nearly equal magnitude but opposite polarities during

the ON and OFF period of the power MOSFETs. In order to

guarantee the volt-second balance between the magnetizing

and demagnetizing intervals, the LM5015 limits the maximum

duty cycle less than 50%. Therefore, an LM5015 Two-Switch

Forward regulator always achieves a complete reset of the

power transformer during each switching cycle.

The LM5015 can also be used to implement a Two-Switch

Flyback regulator (Figure 14). The voltage across the MOS-

FETs employed in the Two-Switch Flyback converter is also

clamped to the input voltage, allowing the input voltage range

to approach the rating of the MOSFETs. Generally the Flyback converter is simpler and costs less than the Forward

converter. However, the Flyback converter will have higher

ripple current and voltages, and the conversion efficiency is

typically lower.

www.national.com 14

LM5015

Page 15

EN / UVLO VOLTAGE DIVIDER SELECTION

Two dedicated comparators connected to the EN pin are used

to implement input under-voltage lockout and a shutdown

condition. When the EN pin voltage is below 0.45V, the controller is in a low current shutdown mode where the VIN

current is reduced to 110 µA. For an EN pin voltage greater

than 0.45V but less than 1.26V the controller is in standby

mode, with all internal circuits operational, but with the power

MOSFETs disabled. Once the EN pin voltage is greater than

1.26V, the controller is fully enabled and the HO and LO outputs commence switching. Two external resistors can be

used to program the minimum operational voltage for the

power converter as shown in Figure 6. When the EN pin voltage falls below the 1.26V threshold, an internal 100 mV

threshold hysteresis prevents noise from toggling the state.

Therefore, the voltage at the EN pin must be reduced to 1.16V

to transition to the standby state. Resistance values for R1

and R2 can be determined from the following equations,

where V

PWR

is the desired turn-on voltage and I

DIVIDER

is the

user-defined current through R1 and R2.

For example, if the LM5015 is to be enabled when V

PWR

reaches 16V, I

DIVIDER

could be chosen as 500 µA which would

set R1 to 29.4 kΩ and R2 to 2.49 kΩ. If the voltage at the EN

pin can exceed 6V, then the current into the 6V protection

Zener must be limited below 4 mA by the external resistors.

Be sure to check both the power and voltage rating for the

selected R1 resistor (some 0603 resistors are rated as low as

50V maximum operating voltage).

30034623

FIGURE 6. Basic EN (UVLO) Configuration

A remote enable function can be accomplished with open

drain device(s) connected to the EN pin as shown in Figure

7. A MOSFET or an NPN transistor connected to the EN pin

will force the regulator into the low power ‘off’ state. Adding a

PN diode in the drain (or collector) provides the offset to

achieve the standby state. The advantage of standby is that

the VCC LDO is not disabled and external circuitry powered

by VCC remains functional.

30034624

FIGURE 7. Remote Standby and Disable Control

15 www.national.com

LM5015

Page 16

SOFT-START

Soft-start is implemented with an external capacitor CSS connected to the SS pin as shown in Figure 8. The SS discharge

MOSFET conducts during Shutdown and Standby modes.

When the SS pin is low, the COMP voltage is held below the

PWM offset voltage (1.3V) by the SS buffer amplifier, thus

inhibiting PWM pulses. When the EN pin exceeds the 1.26V

standby threshold, the ENABLE signal will turn-off the SS

discharge MOSFET and allow the internal 11 µA current

source to charge the SS capacitor. The COMP voltage will

follow the SS voltage under the control of the open-drain SS

buffer amplifier. The CSS capacitor will cause the COMP voltage to gradually increase, until the output voltage achieves

regulation, and the error amplifier assumes control of the

COMP and the PWM duty cycle. The CSS capacitor continues

charging by the internal 11 µA current source, preventing the

SS voltage from interfering with the normal error amplifier

function. During shutdown, the SS discharge MOSFET conducts to discharge the CSS capacitor.

30034625

FIGURE 8. Soft-Start

www.national.com 16

LM5015

Page 17

CONVENTIONAL ISOLATED OUTPUT FEEDBACK

DESIGNS

When isolation between the primary and secondary circuits is

required, the internal error amplifier is usually disabled by

connecting the FB pin to AGND, and an external error amplifier is employed on the secondary side of the isolation boundary. An opto-coupler is normally used to send the feedback

signal across the isolation boundary, as shown in Figure 9.

The LM5015 provides built-in pull-up for the collector of the

opto-coupler at the COMP pin through a 5 kΩ internal resistor.

Similar compensation network used in Figure 3 is applicable

to the external, secondary-side error amplifier. The LM431A

shown in Figure 9 provides both the voltage reference and

error amplifier required to regulate the isolated output voltage.

30034626

FIGURE 9. Conventional Isolated Feedback

HIGH BANDWIDTH ISOLATED FEEDBACK DESIGN

USING THE CFB PIN

The LM5015 also includes a current mirror circuit for optional

high bandwidth feedback loop design. As shown in Figure 10,

the emitter of the opto-coupler transistor can be connected to

the CFB pin, and the collector connected to VCC through an

external 1 kΩ resistor. The 1 kΩ resistor to VCC is used to

protect the CFB pin by limiting the opto-coupler current to less

than 10 mA. The 1 kΩ resistor from the opto-coupler collector

to ground is introduced to protect the opto-coupler from excess voltage by limiting its VCE to less than 50% of Vcc max.

When the output voltage is below regulation, no current flows

into the CFB pin and the PWM of the LM5015 operates at

maximum duty cycle.

17 www.national.com

LM5015

Page 18

30034627

FIGURE 10. High bandwidth Isolated Feedback Using CFB Pin

The two external pull-up and pull-down resistors are effectively connected in parallel for ac signal, yielding a collector

resistance on the opto-coupler of 0.5 kΩ. This resistance is

10 times smaller than the internal pull up resistor and the pole

associated with the collector-base capacitance of the optocoupler transistor is pushed out to a decade higher frequency.

Moving the opto-coupler pole to a higher frequency allows

higher loop bandwidth capability than conventional isolated

feedback designs (see Figure 9).

OUTPUT VOLTAGE

Output voltage is normally set with a resistor divider shown in

Figure 11. To set the regulator’s output voltage to VO, the two

resistors must satisfy the following equation:

where V

REF

is the reference voltage of the error amplifier,

which is 1.26V for the LM5015’s internal error amplifier.

30034629

FIGURE 11. Output Voltage Setting

In isolated designs, the reference and error amplifier are located on the secondary side. To obtain a 5V output in an

isolated feedback design using LMV431A (whose nominal

V

REF

is1.24V), the feedback divider resistors ratio specified

by above equation is 0.330. Selecting 24.3 kΩ for RO1, then

RO2 should be 8.06 kΩ. In a similar non-isolated converter

design using the internal error amplifier, the divider’s resistors

ratio is 0.337, therefore if 24.3 kΩ is selected for RO1, then

RO2 should be 8.20 kΩ.

Multiple resistors in series or parallel combinations for either

RO1, or RO2, or both, may be necessary to set a required output voltage. Note that the accuracy of the output voltage

setting is determined by the tolerance of the divider resistors

as well as the accuracy of V

REF

. The accuracy of the LM5015

internal V

REF

is 1.5%, and the most popular chip resistors

have a tolerance of 1%, therefore the achievable output accuracy with the internal error amplifier and 1% resistors is

about 2.5%. To achieve better output voltage accuracy, use

an external voltage reference with higher precision and resistors of tighter tolerance, such as the 0.1%, resistors for

RO1 and RO2.

PRINTED CIRCUIT BOARD LAYOUT

The LM5015 Current Sense and PWM comparators are very

fast and may respond to short duration noise pulses. The

components at the HO, LO, COMP, EN, VCC and the RT pins

should be as physically close as possible to the IC, thereby

minimizing noise pickup on the PC board tracks. The HO and

LO output pins of the LM5015 should have short, wide conductors to the power path inductors, transformers and capacitors in order to minimize parasitic inductance that reduces

efficiency and increases conducted and radiated noise. Ceramic decoupling capacitors are recommended between the

VIN pin to the AGND pin, between the PVIN pin and PGND

pin, and between the VCC pin to the AGND pin. Use short,

direct connections to avoid clock jitter due to ground voltage

differentials. Small package surface mount X7R or X5R capacitors are preferred for high frequency performance and

limited variation over temperature and applied voltage.

If an application using the LM5015 produces high junction

temperatures during normal operation, multiple vias from the

exposed metal pad on the underside of the IC package to a

PC board ground plane will help conduct heat away from the

www.national.com 18

LM5015

Page 19

IC. Judicious positioning of the PC board within the end product, along with use of any available air flow will help reduce

the junction temperature. If using forced air cooling, avoid

placing the LM5015 in the airflow shadow of large components, such as input or output capacitors, inductors or transformers.

Application Examples

The following schematics present four examples dc-dc converters utilizing the LM5015 switching regulator IC:

1.

Non-Isolated Two-Switch Forward for 48V input and 5V

2.5A output,

2.

Isolated Two-Switch Forward for 48V input and 5V 2.5A

output

3.

Isolated Two-Switch Flyback converter for 48V input and

5V 2.5A output,

4.

A 1:1 dc-dc transformer with the input/output operating

range of 5V to 15V

48V NON-ISOLATED TWO-SWITCH FORWARD

The Non-Isolated Two-Switch Forward converter shown in

Figure 12 utilizes the internal voltage reference for the regulation set-point. The output is +5V at 2.5A while the input

voltage can vary from 36V to 72V. The switching frequency is

300 kHz. An auxiliary winding on transformer (T1) provides

10V to power the LM5015 when the output is in regulation.

This disables the internal high voltage VCC LDO regulator

and improves efficiency. The converter can be shut down by

driving the EN input below 1.26V with an open-collector or

open-drain transistor. An external synchronizing frequency

can be applied to the SYNC input.

30034630

FIGURE 12. Non-Isolated Two-Switch Forward

19 www.national.com

LM5015

Page 20

48V ISOLATED TWO-SWITCH FORWARD

The Isolated Two-Switch Forward converter shown in Figure

13 utilizes a 1.24V voltage reference (LMV431A) located on

the isolated secondary side for the regulation set-point. The

LM5015 internal error amplifier is disabled by grounding the

FB pin. The LMV431A controls the current through the opto-

coupler LED, which sets the COMP pin voltage. The output is

+5V at 2.5A and the input voltage ranges from 36V to 72V.

The switching frequency is 300 kHz. The functions of the EN

and SYNC inputs are the same as in the previous example

circuit.

30034631

FIGURE 13. Isolated Two-Switch Forward

ISOLATED TWO-SWITCH FLYBACK

The Isolated Two-Switch Flyback converter shown in Figure

14 utilizes a 1.24V voltage reference (LMV431A) located on

the isolated secondary side for the regulation set-point. The

LM5015 internal error amplifier is disabled by grounding the

FB pin. The LMV431A controls the current through the optocoupler LED, which sets the COMP pin voltage. The output is

+5V at 2.5A and the input voltage ranges from 36V to 72V.

The switching frequency is 300 kHz. The Flyback converter

is less complex than the previous Forward converter example

in Figure 13. However, the Flyback converter produces higher

input and output ripples of voltage and currents, and lower

conversion efficiency by about 2%. The functions of the EN

and SYNC inputs are the same as in the previous example

circuits.

This circuit can be used with the LM5073 for a low cost isolated Power over Ethernet (PoE) Power Device (PD) application that does not require a discrete power MOSFET.

30034632

FIGURE 14. Isolated Two-Switch Flyback

www.national.com 20

LM5015

Page 21

DC-DC TRANSFORMER

The DC-DC transformer shown in Figure 15 provides a 1:1

input voltage to output voltage conversion with ground isolation. The circuit operates in open loop manner operating at

the maximum duty cycle limit of the LM5015. The power

transformer primary-secondary turns ratio is 1:2 (primary to

secondary). Therefore, at the maximum duty cycle of 0.5, the

output voltage will be approximately equal to the input voltage. A Zener diode Z1 is used at the output rail as a simple

means to protect the output against over-voltage under light

and no load conditions. The maximum load of this example

circuit is 0.3A, and the operating voltage range is from 5V to

15V.

30034633

FIGURE 15. DC-DC Transformer

21 www.national.com

LM5015

Page 22

Physical Dimensions inches (millimeters) unless otherwise noted

14-Lead Exposed Pad Package

NS Package Number MXA14A

www.national.com 22

LM5015

Page 23

Notes

23 www.national.com

LM5015

Page 24

Notes

LM5015 High Voltage Monolithic Two-Switch Forward DC-DC Regulator

For more National Semiconductor product information and proven design tools, visit the following Web sites at:

Products Design Support

Amplifiers www.national.com/amplifiers WEBENCH www.national.com/webench

Audio www.national.com/audio Analog University www.national.com/AU

Clock Conditioners www.national.com/timing App Notes www.national.com/appnotes

Data Converters www.national.com/adc Distributors www.national.com/contacts

Displays www.national.com/displays Green Compliance www.national.com/quality/green

Ethernet www.national.com/ethernet Packaging www.national.com/packaging

Interface www.national.com/interface Quality and Reliability www.national.com/quality

LVDS www.national.com/lvds Reference Designs www.national.com/refdesigns

Power Management www.national.com/power Feedback www.national.com/feedback

Switching Regulators www.national.com/switchers

LDOs www.national.com/ldo

LED Lighting www.national.com/led

PowerWise www.national.com/powerwise

Serial Digital Interface (SDI) www.national.com/sdi

Temperature Sensors www.national.com/tempsensors

Wireless (PLL/VCO) www.national.com/wireless

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2007 National Semiconductor Corporation

For the most current product information visit us at www.national.com

National Semiconductor

Americas Customer

Support Center

Email:

new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Customer Support Center

Fax: +49 (0) 180-530-85-86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +49 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor Asia

Pacific Customer Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

www.national.com

Loading...

Loading...