Page 1

LM5000

High Voltage Switch Mode Regulator

General Description

The LM5000 is a monolithic integrated circuit specifically

designed and optimized for flyback, boost or forward power

converter applications. The internal power switch is rated for

a maximum of 80V, with a current limit set to 2A. Protecting

the power switch are current limit and thermal shutdown

circuits. The current mode control scheme provides excellent

rejection of line transients and cycle-by-cycle current limiting.

An external compensation pin and the built-in slope compensation allow the user to optimize the frequency compensation. Other distinctive features include softstart to reduce

stresses during start-up and an external shutdown pin for

remote ON/OFF control. There are two operating frequency

ranges available. The LM5000-3 is pin selectable for either

300kHz (FS Grounded) or 700kHz (FS Open). The

LM5000-6 is pin selectable for either 600kHz (FS Grounded)

or 1.25MHz (FS Open). The device is available in a low

profile 16-lead TSSOP package (available now) or a thermally enhanced 16-lead LLP package (coming in Q3CY03).

Features

n 80V internal switch

n Operating input voltage range of 3.1V to 40V

n Pin selectable operating frequency

300kHz/700kHz (-3)

600kHz/1.25MHz (-6)

n Adjustable output voltage

n External compensation

n Input undervoltage lockout

n Softstart

n Current limit

n Over temperature protection

n External shutdown

n Small 16-Lead TSSOP or 16-Lead LLP package

Applications

n Flyback Regulator

n Forward Regulator

n Boost Regulator

n DSL Modems

n Distributed Power Converters

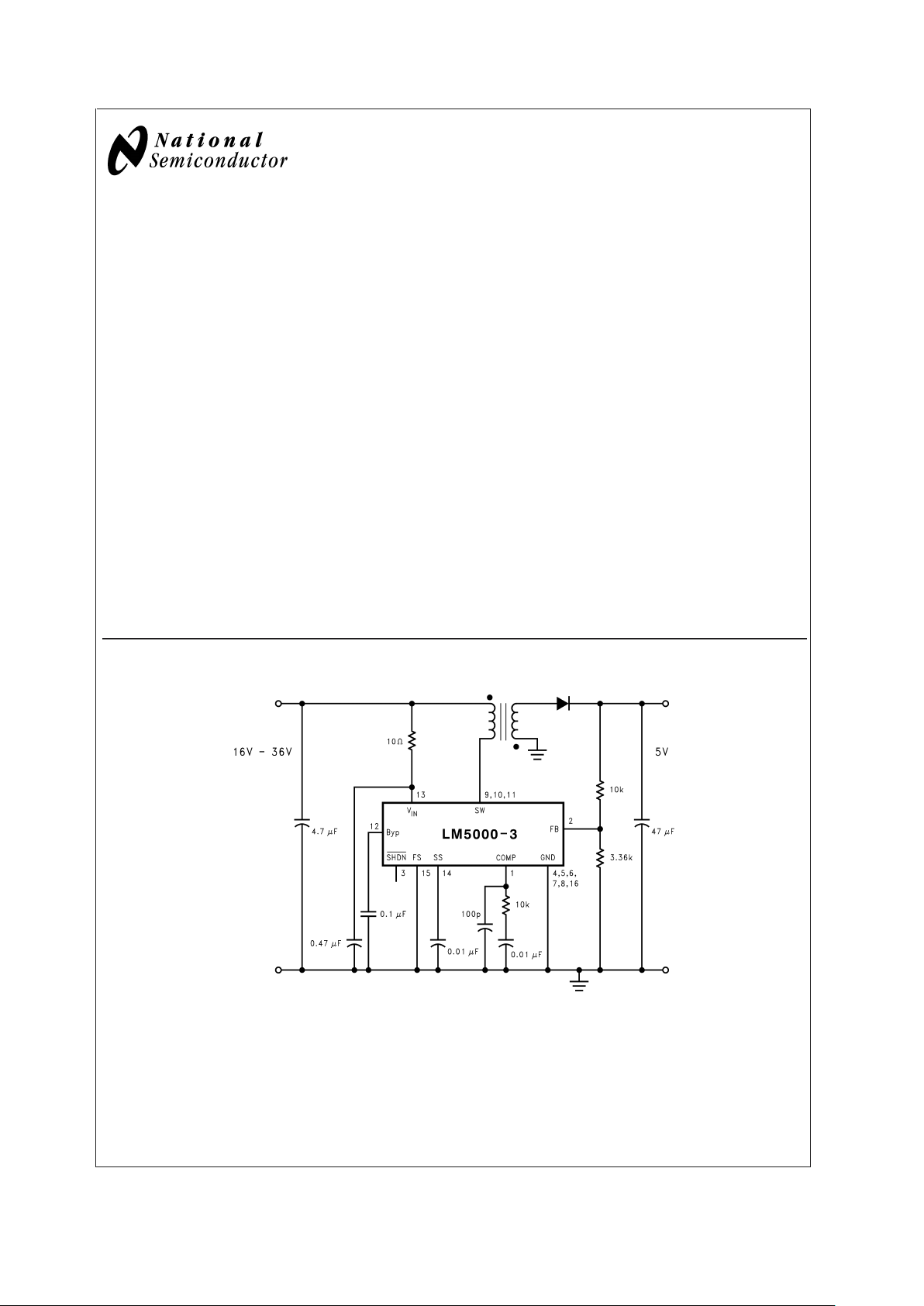

Typical Application Circuit

20031901

LM5000 Flyback Converter

July 2003

LM5000 High Voltage Switch Mode Regulator

© 2003 National Semiconductor Corporation DS200319 www.national.com

Page 2

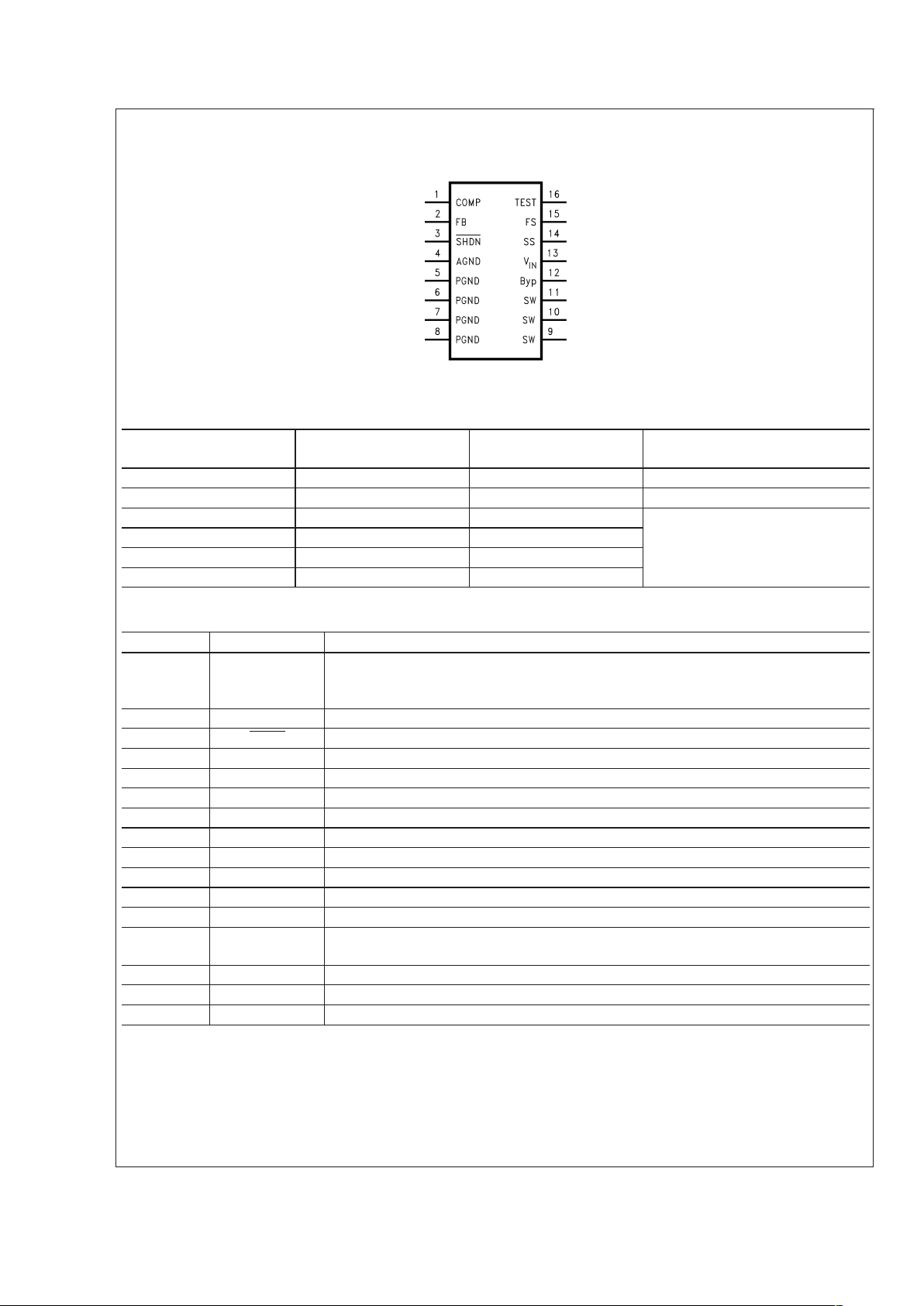

Connection Diagram

Top View

20031904

Ordering Information

Order Number Package Type NSC Package

Drawing

Supplied As

LM5000-3MTC TSSOP-16 MTC16 94 Units, Rail

LM5000-3MTCX TSSOP-16 MTC16 2500 Units, Tape and Reel

LM5000SD-3 LLP-16 SDA16

Coming in Q3CY03

LM5000SDX-3 LLP-16 SDA16

LM5000SD-6 LLP-16 SDA16

LM5000SDX-6 LLP-16 SDA16

Pin Description

Pin Name Function

1 COMP Compensation network connection. Connected to the output of the voltage error amplifier.

The RC compenstion network should be connected from this pin to AGND. An additional

100pF high frequency capacitor to AGND is recommended.

2 FB Output voltage feedback input.

3 SHDN

Shutdown control input, Open = enable, Ground = disable.

4 AGND Analog ground, connect directly to PGND.

5 PGND Power ground.

6 PGND Power ground.

7 PGND Power ground.

8 PGND Power ground.

9 SW Power switch input. Switch connected between SW pins and PGND pins

10 SW Power switch input. Switch connected between SW pins and PGND pins

11 SW Power switch input. Switch connected between SW pins and PGND pins

12 BYP Bypass-Decouple Capacitor Connection, 0.1µF ceramic capacitor recommended.

13 V

IN

Analog power input. A small RC filter is recommended, to suppress line glitches. Typical

values of 10Ω and ≥ 0.1µF are recommended.

14 SS Softstart Input. External capacitor and internal current source sets the softstart time.

15 FS Switching frequency select input. Open = F

high

. Ground = F

low

16 TEST Factory test pin, connect to ground.

LM5000

www.national.com 2

Page 3

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

V

IN

-0.3V to 40V

SW Voltage -0.3V to 80V

FB Voltage -0.3V to 5V

COMP Voltage -0.3V to 3V

All Other Pins -0.3V to 7V

Maximum Junction Temperature 150˚C

Power Dissipation(Note 2) Internally Limited

Lead Temperature 216˚C

Infrared (15 sec.) 235˚C

ESD Susceptibility (Note 3)

Human Body Model 2kV

Machine Model 200V

Storage Temperature −65˚C to +150˚C

Operating Conditions

Operating Junction

Temperature Range

(Note 7) −40˚C to +125˚C

Supply Voltage (Note 7) 3.1V to 40V

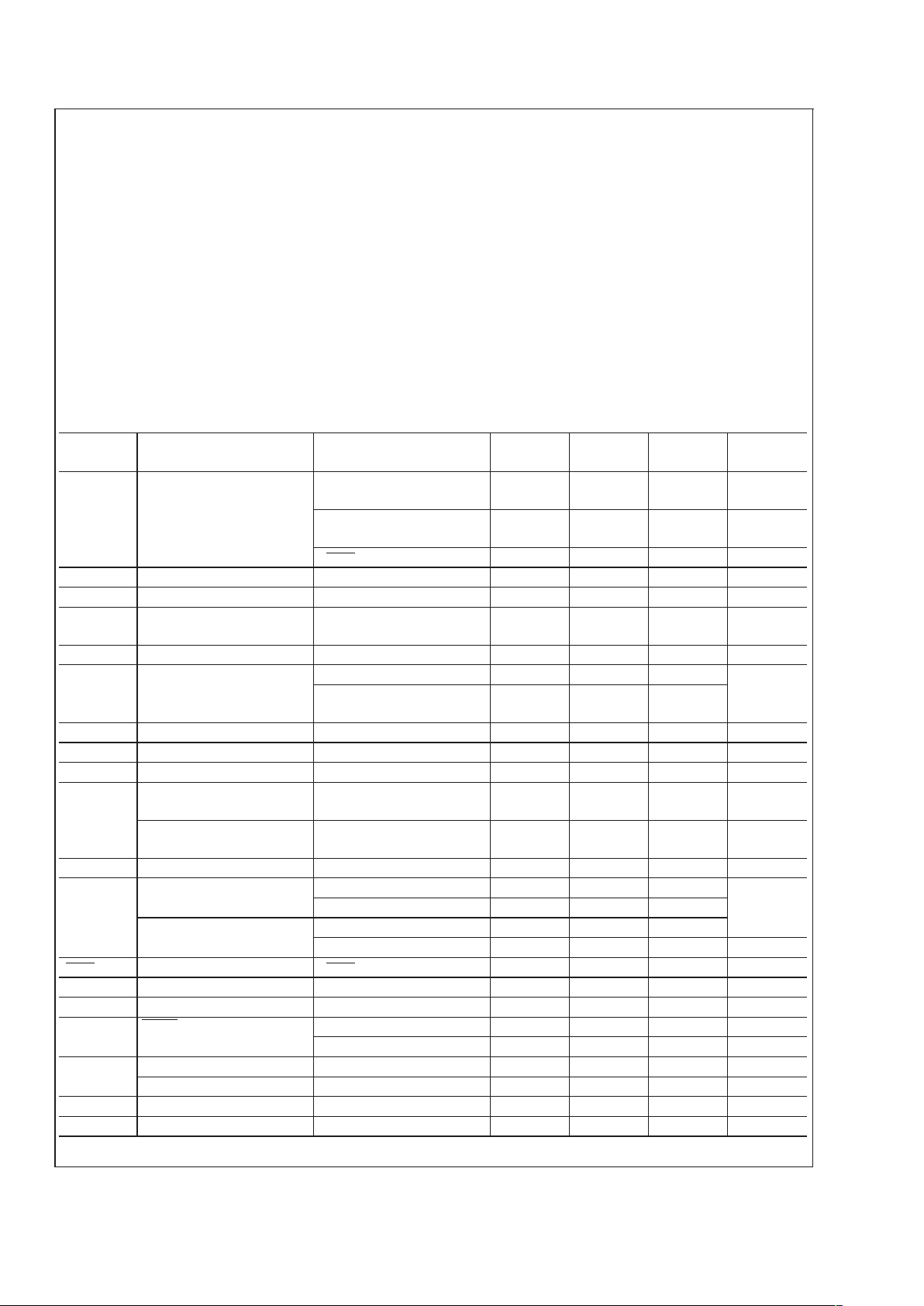

Electrical Characteristics

Specifications in standard type face are for TJ= 25˚C and those with boldface type apply over the full Operating Temperature Range (T

J

= −40˚C to +125˚C) Unless otherwise specified. VIN= 12V and IL= 0A, unless otherwise specified.

Symbol Parameter Conditions

Min

(Note 4)

Typ

(Note 5)

Max

(Note 4)

Units

I

Q

Quiescent Current FB = 2V (Not Switching)

FS=0V

2.0 2.5 mA

FB = 2V (Not Switching)

FS = Open

2.1 2.5 mA

V

SHDN

=0V 18 30 µA

V

FB

Feedback Voltage 1.2330 1.259 1.2840 V

I

CL

Switch Current Limit 1.35 2.0 2.7 A

%V

FB

/∆VINFeedback Voltage Line

Regulation

3.1V ≤ VIN≤ 40V 0.001 0.04 %/V

I

B

FB Pin Bias Current (Note 6) 55 200 nA

BV Output Switch Breakdown

Voltage

T

J

= 25˚C, ISW= 0.1µA 80 V

T

J

= -40˚C to + 125˚C, ISW=

0.5µA

76

V

IN

Input Voltage Range 3.1 40 V

g

m

Error Amp Transconductance ∆I = 5µA 150 410 750 µmho

A

V

Error Amp Voltage Gain 280 V/V

D

MAX

Maximum Duty Cycle

LM5000-3

FS=0V 85 90 %

Maximum Duty Cycle

LM5000-6

FS = 0V TBD 90 %

T

MIN

Minimum On Time 165 ns

f

S

Switching Frequency

LM5000-3

FS=0V 240 300 360

kHz

FS = Open 550 700 840

Switching Frequency

LM5000-6

FS=0V TBD 600 TBD

FS = Open TBD 1.25 TBD MHz

I

SHDN

Shutdown Pin Current V

SHDN

=0V −1 -2 µA

I

L

Switch Leakage Current VSW= 80V 0.008 5 µA

R

DSON

Switch R

DSON

ISW= 1A 160 445 mΩ

Th

SHDN

SHDN Threshold Output High 0.9 0.6 V

Output Low 0.6 0.3 V

UVLO On Threshold 2.74 2.92 3.10 V

Off Threshold 2.60 2. 77 2.96 V

OVP V

COMP

Trip 0.67 V

I

SS

Softstart Current 8 11 14 µA

LM5000

www.national.com3

Page 4

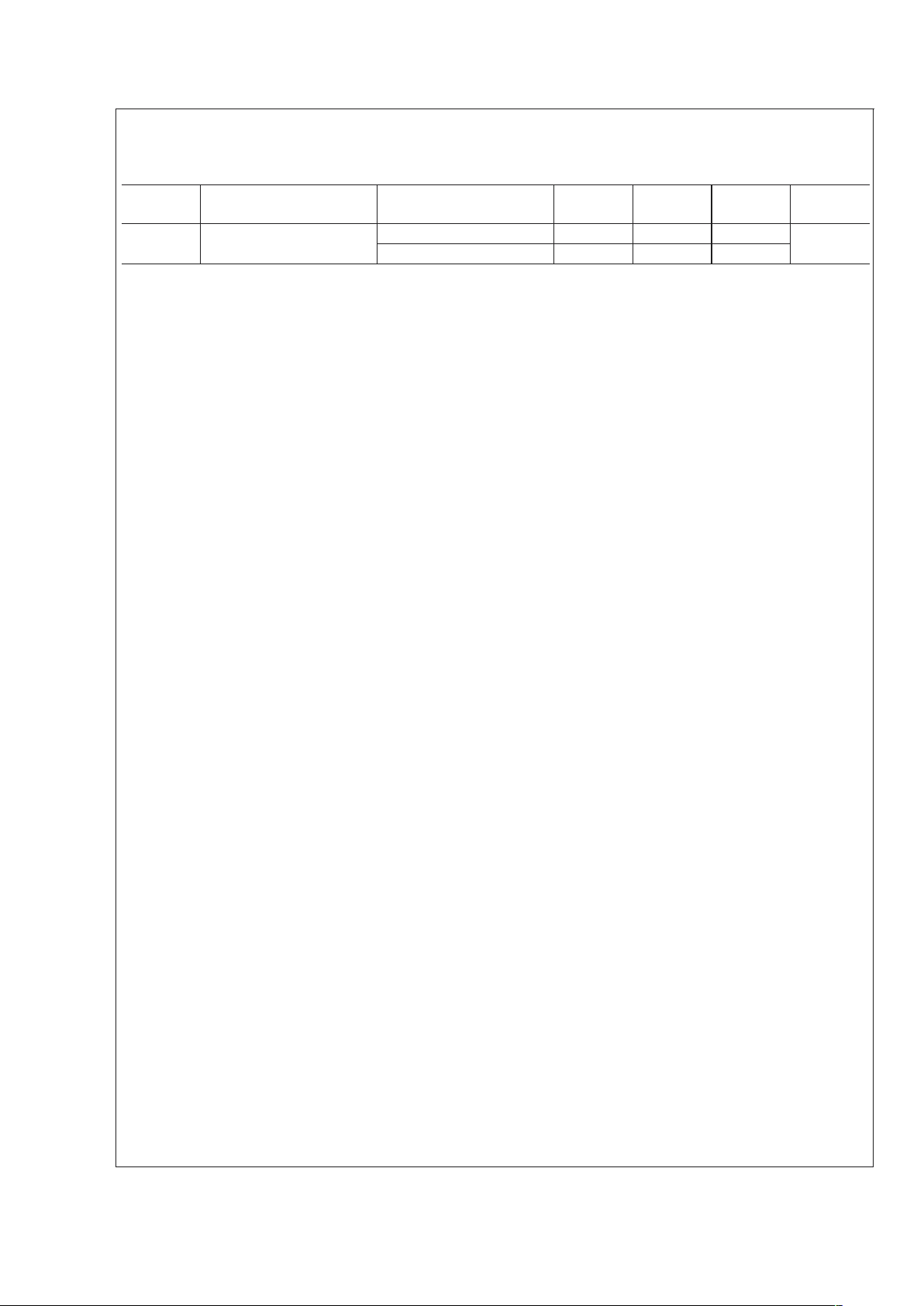

Electrical Characteristics (Continued)

Specifications in standard type face are for TJ= 25˚C and those with boldface type apply over the full Operating Temperature Range (T

J

= −40˚C to +125˚C) Unless otherwise specified. VIN= 12V and IL= 0A, unless otherwise specified.

Symbol Parameter Conditions

Min

(Note 4)

Typ

(Note 5)

Max

(Note 4)

Units

θ

JA

Thermal Resistance TSSOP, Package only 150 ˚C/W

LLP, Package only 45

Note 1: Absolute maximum ratings are limits beyond which damage to the device may occur. Operating Ratings are conditions for which the device is intended to

be functional, but device parameter specifications may not be guaranteed. For guaranteed specifications and test conditions, see the Electrical Characteristics.

Note 2: The maximum allowable power dissipation is a function of the maximum junction temperature, T

J

(MAX), the junction-to-ambient thermal resistance, θJA,

and the ambient temperature, T

A

. See the Electrical Characteristics table for the thermal resistance of various layouts. The maximum allowable power dissipation

at any ambient temperature is calculated using: P

D

(MAX) = (T

J(MAX)−TA

)/θJA. Exceeding the maximum allowable power dissipation will cause excessive die

temperature, and the regulator will go into thermal shutdown.

Note 3: The human body model is a 100 pF capacitor discharged through a 1.5kΩ resistor into each pin. The machine model is a 200pF capacitor discharged

directly into each pin.

Note 4: All limits guaranteed at room temperature (standard typeface) and at temperature extremes (bold typeface). All room temperature limits are 100%

production tested. All limits at temperature extremes are guaranteed via correlation using standard Statistical Quality Control (SQC) methods. All limits are used to

calculate Average Outgoing Quality Level (AOQL).

Note 5: Typical numbers are at 25˚C and represent the most likely norm.

Note 6: Bias current flows into FB pin.

Note 7: Supply voltage, bias current product will result in aditional device power dissipation. This power may be significant. The thermal dissipation design should

take this into account.

LM5000

www.national.com 4

Page 5

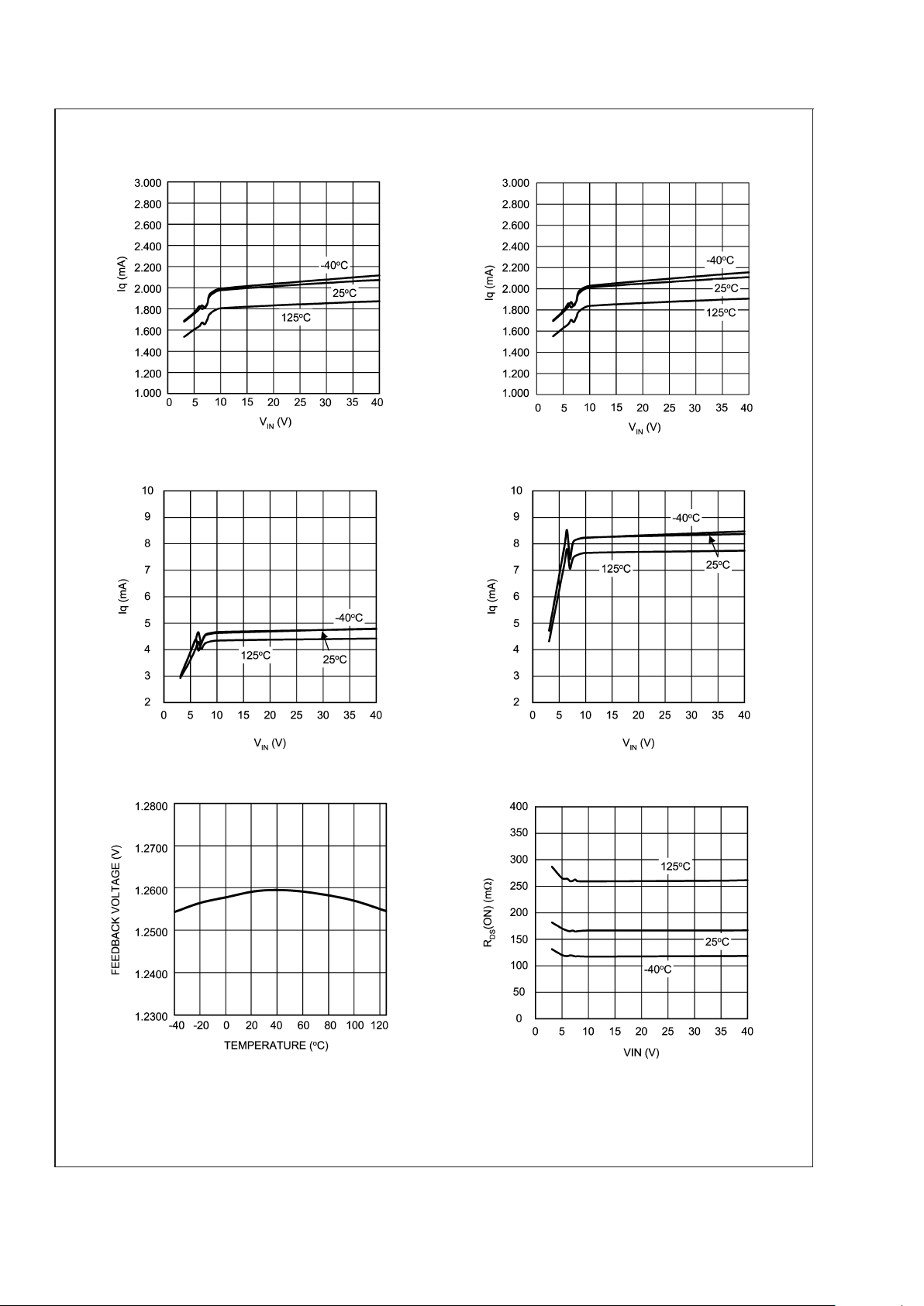

Typical Performance Characteristics

Iq (non-switching) vs V

IN

@

fSW= 300kHz Iq (non-switching) vs V

IN

@

fSW= 700kHz

20031920

20031921

Iq (switching) vs V

IN

@

fSW= 300kHz Iq (switching) vs V

IN

@

fSW= 700kHz

20031922 20031923

Vfbvs Temperature R

DS(ON)

vs V

IN

@

ISW=1A

20031924

20031925

LM5000

www.national.com5

Page 6

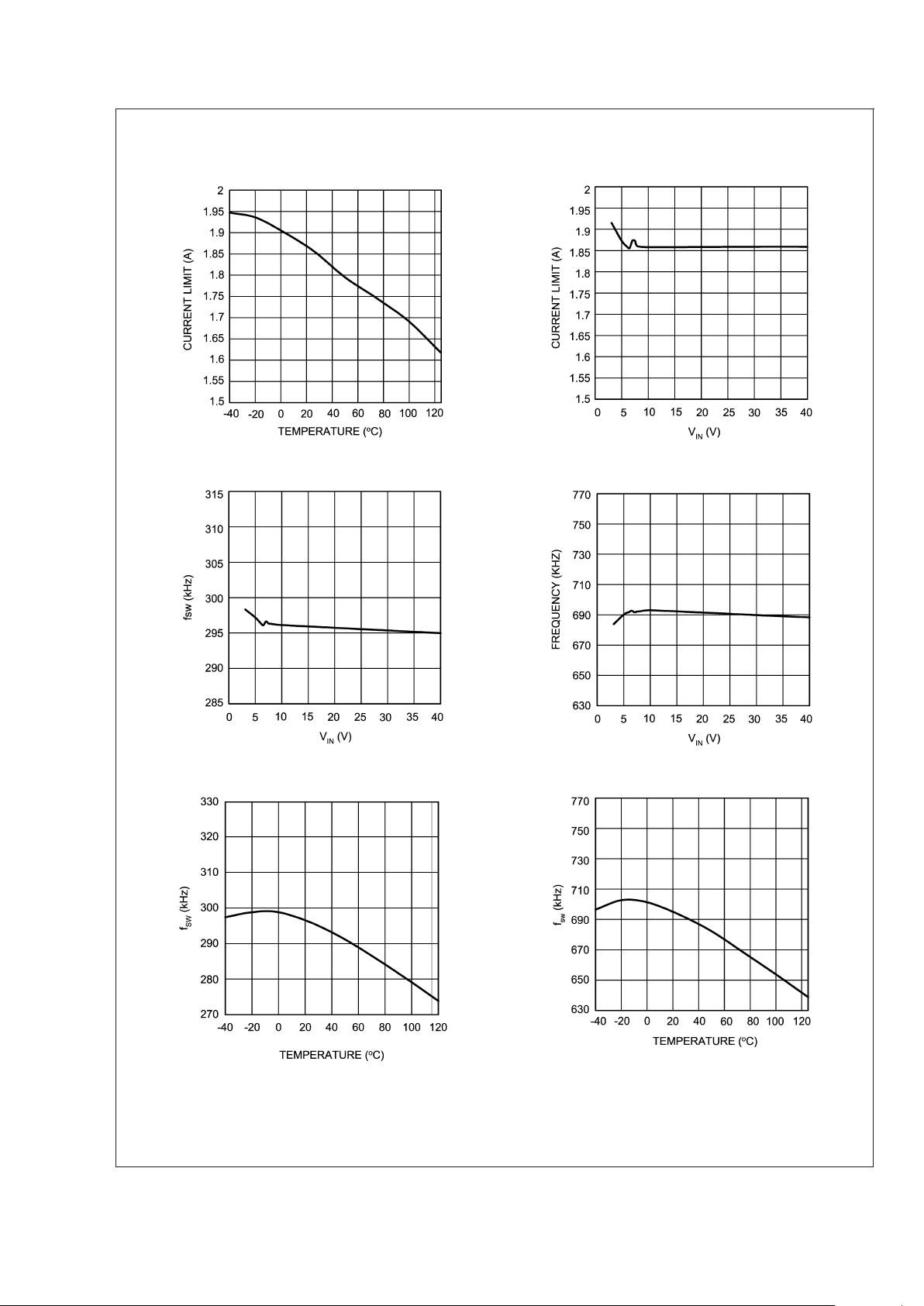

Typical Performance Characteristics (Continued)

Current Limit vs Temperature Current Limit vs V

IN

20031926

20031927

fSWvs. V

IN

@

FS = Low (-3) fSWvs. V

IN

@

FS = High (-3)

20031928

20031929

fSWvs. Temperature@FS = Low (-3) fSWvs. Temperature@FS = High (-3)

20031930

20031931

LM5000

www.national.com 6

Page 7

Typical Performance Characteristics (Continued)

Error Amp. Transconductance vs Temp. BYP Pin Voltage vs V

IN

20031932

20031933

LM5000

www.national.com7

Page 8

20031953

FIGURE 1. 300 kHz operation, 48V output

20031954

FIGURE 2. 700 kHz operation, 48V output

LM5000

www.national.com 8

Page 9

Block Diagram

20031903

Boost Regulator Operation

The LM5000 utilizes a PWM control scheme to regulate the

output voltage over all load conditions. The operation can

best be understood referring to the block diagram and Figure

3. At the start of each cycle, the oscillator sets the driver logic

and turns on the NMOS power device conducting current

through the inductor, cycle 1 of Figure 3 (a). During this

cycle, the voltage at the COMP pin controls the peak inductor current. The COMP voltage will increase with larger loads

and decrease with smaller. This voltage is compared with the

summation of the SW volatge and the ramp compensation.The ramp compensation is used in PWM architectures to

eliminate the sub-harmonic oscillations that occur during

duty cycles greater than 50%. Once the summation of the

ramp compensation and switch voltage equals the COMP

voltage, the PWM comparator resets the driver logic turning

off the NMOS power device. The inductor current then flows

through the output diode to the load and output capacitor,

cycle 2 of Figure 3 (b). The NMOS power device is then set

by the oscillator at the end of the period and current flows

through the inductor once again.

The LM5000 has dedicated protection circuitry running during the normal operation to protect the IC. The Thermal

Shutdown circuitry turns off the NMOS power device when

the die temperature reaches excessive levels. The UVP

comparator protects the NMOS power device during supply

power startup and shutdown to prevent operation at voltages

less than the minimum input voltage. The OVP comparator is

used to prevent the output voltage from rising at no loads

allowing full PWM operation over all load conditions. The

LM5000 also features a shutdown mode. An external capacitor sets the softstart time by limiting the error amp output

range, as the capacitor charges up via an internal 10µA

current source.

The LM5000 is available in two operating frequency ranges.

The LM5000-3 is pin selectable for either 300kHz (FS

Grounded) or 700kHz (FS Open). The LM5000-6 is pin

selectable for either 600kHz (FS Grounded) or 1.25MHz (FS

Open)

LM5000

www.national.com9

Page 10

Operation

CONTINUOUS CONDUCTION MODE

The LM5000 is a current-mode, PWM regulator. When used

as a boost regulator the input voltage is stepped up to a

higher output voltage. In continuous conduction mode (when

the inductor current never reaches zero at steady state), the

boost regulator operates in two cycles.

In the first cycle of operation, shown in Figure 3 (a), the

transistor is closed and the diode is reverse biased. Energy

is collected in the inductor and the load current is supplied by

C

OUT

.

The second cycle is shown in Figure 3 (b). During this cycle,

the transistor is open and the diode is forward biased. The

energy stored in the inductor is transferred to the load and

output capacitor.

The ratio of these two cycles determines the output voltage.

The output voltage is defined approximately as:

where D is the duty cycle of the switch, D and D' will be

required for design calculations.

SETTING THE OUTPUT VOLTAGE

The output voltage is set using the feedback pin and a

resistor divider connected to the output as shown in Figure 1.

The feedback pin is always at 1.259V, so the ratio of the

feedback resistors sets the output voltage.

INTRODUCTION TO COMPENSATION

20031902

FIGURE 3. Simplified Boost Converter Diagram

(a) First Cycle of Operation (b) Second Cycle Of Operation

20031905

FIGURE 4. (a) Inductor current. (b) Diode current.

LM5000

www.national.com 10

Page 11

Operation (Continued)

The LM5000 is a current mode PWM regulator. The signal

flow of this control scheme has two feedback loops, one that

senses switch current and one that senses output voltage.

To keep a current programmed control converter stable

above duty cycles of 50%, the inductor must meet certain

criteria. The inductor, along with input and output voltage,

will determine the slope of the current through the inductor

(see Figure 4 (a)). If the slope of the inductor current is too

great, the circuit will be unstable above duty cycles of 50%.

The LM5000 provides a compensation pin (COMP) to customize the voltage loop feedback. It is recommended that a

series combination of R

C

and CCbe used for the compensation network, as shown in Figure 1. The series combination of R

C

and CCintroduces pole-zero pair according to the

following equations:

where ROis the output impedance of the error amplifier,

850kΩ. For most applications, performance can be optimized by choosing values within the range 5kΩ≤R

C

≤ 20kΩ

and 680pF ≤ C

C

≤ 4.7nF.

COMPENSATION

This section will present a general design procedure to help

insure a stable and operational circuit. The designs in this

datasheet are optimized for particular requirements. If different conversions are required, some of the components may

need to be changed to ensure stability. Below is a set of

general guidelines in designing a stable circuit for continuous conduction operation (loads greater than 100mA), in

most all cases this will provide for stability during discontinuous operation as well. The power components and their

effects will be determined first, then the compensation components will be chosen to produce stability.

INDUCTOR SELECTION

To ensure stability at duty cycles above 50%, the inductor

must have some minimum value determined by the minimum input voltage and the maximum output voltage. This

equation is:

where fs is the switching frequency, D is the duty cycle, and

R

DSON

is the ON resistance of the internal switch. This

equation is only good for duty cycles greater than 50%

(D

>

0.5).

The inductor ripple current is important for a few reasons.

One reason is because the peak switch current will be the

average inductor current (input current) plus ∆i

L

. Care must

be taken to make sure that the switch will not reach its

current limit during normal operation. The inductor must also

be sized accordingly. It should have a saturation current

rating higher than the peak inductor current expected. The

output voltage ripple is also affected by the total ripple current.

DC GAIN AND OPEN-LOOP GAIN

Since the control stage of the converter forms a complete

feedback loop with the power components, it forms a closedloop system that must be stabilized to avoid positive feedback and instability. A value for open-loop DC gain will be

required, from which you can calculate, or place, poles and

zeros to determine the crossover frequency and the phase

margin. A high phase margin (greater than 45˚) is desired for

the best stability and transient response. For the purpose of

stabilizing the LM5000, choosing a crossover point well below where the right half plane zero is located will ensure

sufficient phase margin. A discussion of the right half plane

zero and checking the crossover using the DC gain will

follow.

OUTPUT CAPACITOR SELECTION

The choice of output capacitors is somewhat more arbitrary.

It is recommended that low ESR (Equivalent Series Resistance, denoted R

ESR

) capacitors be used such as ceramic,

polymer electrolytic, or low ESR tantalum. Higher ESR capacitors may be used but will require more compensation

which will be explained later on in the section. The ESR is

also important because it determines the output voltage

ripple according to the approximate equation:

∆V

OUT

) 2∆iLR

ESR

(in Volts)

After choosing the output capacitor you can determine a

pole-zero pair introduced into the control loop by the following equations:

Where RLis the minimum load resistance corresponding to

the maximum load current. The zero created by the ESR of

the output capacitor is generally very high frequency if the

ESR is small. If low ESR capacitors are used it can be

neglected. If higher ESR capacitors are used see the High

Output Capacitor ESR Compensation section.

RIGHT HALF PLANE ZERO

A current mode control boost regulator has an inherent right

half plane zero (RHP zero). This zero has the effect of a zero

in the gain plot, causing an imposed +20dB/decade on the

rolloff, but has the effect of a pole in the phase, subtracting

another 90˚ in the phase plot. This can cause undesirable

effects if the control loop is influenced by this zero. To ensure

the RHP zero does not cause instability issues, the control

loop should be designed to have a bandwidth of

1

⁄2the

frequency of the RHP zero or less. This zero occurs at a

frequency of:

LM5000

www.national.com11

Page 12

Operation (Continued)

where I

LOAD

is the maximum load current.

SELECTING THE COMPENSATION COMPONENTS

The first step in selecting the compensation components R

C

and CCis to set a dominant low frequency pole in the control

loop. Simply choose values for R

C

and CCwithin the ranges

given in the Introduction to Compensation section to set this

pole in the area of 10Hz to 100Hz. The frequency of the pole

created is determined by the equation:

where ROis the output impedance of the error amplifier,

850kΩ. Since R

C

is generally much less than RO, it does not

have much effect on the above equation and can be neglected until a value is chosen to set the zero f

ZC.fZC

is

created to cancel out the pole created by the output capacitor, f

P1

. The output capacitor pole will shift with different load

currents as shown by the equation, so setting the zero is not

exact. Determine the range of f

P1

over the expected loads

and then set the zero f

ZC

to a point approximately in the

middle. The frequency of this zero is determined by:

Now RCcan be chosen with the selected value for CC.

Check to make sure that the pole f

PC

is still in the 10Hz to

100Hz range, change each value slightly if needed to ensure

both component values are in the recommended range. After

checking the design at the end of this section, these values

can be changed a little more to optimize performance if

desired. This is best done in the lab on a bench, checking the

load step response with different values until the ringing and

overshoot on the output voltage at the edge of the load steps

is minimal. This should produce a stable, high performance

circuit. For improved transient response, higher values of R

C

(within the range of values) should be chosen. This will

improve the overall bandwidth which makes the regulator

respond more quickly to transients. If more detail is required,

or the most optimal performance is desired, refer to a more

in depth discussion of compensating current mode DC/DC

switching regulators.

HIGH OUTPUT CAPACITOR ESR COMPENSATION

When using an output capacitor with a high ESR value, or

just to improve the overall phase margin of the control loop,

another pole may be introduced to cancel the zero created

by the ESR. This is accomplished by adding another capacitor, C

C2

, directly from the compensation pin VCto ground, in

parallel with the series combination of R

C

and CC. The pole

should be placed at the same frequency as f

Z1

, the ESR

zero. The equation for this pole follows:

To ensure this equation is valid, and that CC2can be used

without negatively impacting the effects of R

C

and CC,f

PC2

must be greater than 10fPC.

CHECKING THE DESIGN

The final step is to check the design. This is to ensure a

bandwidth of

1

⁄2or less of the frequency of the RHP zero.

This is done by calculating the open-loop DC gain, A

DC

. After

this value is known, you can calculate the crossover visually

by placing a −20dB/decade slope at each pole, and a +20dB/

decade slope for each zero. The point at which the gain plot

crosses unity gain, or 0dB, is the crossover frequency. If the

crossover frequency is at less than

1

⁄2the RHP zero, the

phase margin should be high enough for stability. The phase

margin can also be improved some by adding C

C2

as dis-

cussed earlier in the section. The equation for A

DC

is given

below with additional equations required for the calculation:

mc ) 0.072fs (in A/s)

where RLis the minimum load resistance, VINis the maximum input voltage, and R

DSON

is the value chosen from the

graph "R

DSON

vs. VIN"intheTypical Performance Charac-

teristics section.

SWITCH VOLTAGE LIMITS

In a flyback regulator, the maximum steady-state voltage

appearing at the switch, when it is off, is set by the transformer turns ratio, N, the output voltage, V

OUT

, and the

maximum input voltage, V

IN

(Max):

V

SW(OFF)

=VIN(Max) + (V

OUT+VF

)/N

where V

F

is the forward biased voltage of the output diode,

and is typically 0.5V for Schottky diodes and 0.8V for ultrafast recovery diodes. In certain circuits, there exists a voltage spike, V

LL

, superimposed on top of the steady-state

voltage . Usually, this voltage spike is caused by the transformer leakage inductance and/or the output rectifier recovery time. To “clamp” the voltage at the switch from exceeding

its maximum value, a transient suppressor in series with a

diode is inserted across the transformer primary.

If poor circuit layout techniques are used, negative voltage

transients may appear on the Switch pin. Applying a negative voltage (with respect to the IC’s ground) to any monolithic IC pin causes erratic and unpredictable operation of

that IC. This holds true for the LM5000 IC as well. When

used in a flyback regulator, the voltage at the Switch pin can

go negative when the switch turns on. The “ringing” voltage

LM5000

www.national.com 12

Page 13

Operation (Continued)

at the switch pin is caused by the output diode capacitance

and the transformer leakage inductance forming a resonant

circuit at the secondary(ies). The resonant circuit generates

the “ringing” voltage, which gets reflected back through the

transformer to the switch pin. There are two common methods to avoid this problem. One is to add an RC snubber

around the output rectifier(s). The values of the resistor and

the capacitor must be chosen so that the voltage at the

Switch pin does not drop below −0.4V. The resistor may

range in value between 10Ω and1kΩ, and the capacitor will

vary from 0.001 µF to 0.1 µF. Adding a snubber will (slightly)

reduce the efficiency of the overall circuit.

The other method to reduce or eliminate the “ringing” is to

insert a Schottky diode clamp between the SW pin and the

PGND pin. The reverse voltage rating of the diode must be

greater than the switch off voltage.

OUTPUT VOLTAGE LIMITATIONS

The maximum output voltage of a boost regulator is the

maximum switch voltage minus a diode drop. In a flyback

regulator, the maximum output voltage is determined by the

turns ratio, N, and the duty cycle, D, by the equation:

V

OUT

≈ NxVINxD/(1−D)

The duty cycle of a flyback regulator is determined by the

following equation:

Theoretically, the maximum output voltage can be as large

as desired — just keep increasing the turns ratio of the transformer. However, there exists some physical limitations that

prevent the turns ratio, and thus the output voltage, from

increasing to infinity. The physical limitations are capaci-

tances and inductances in the LM5000 switch, the output

diode(s), and the transformer — such as reverse recovery

time of the output diode (mentioned above).

INPUT LINE CONDITIONING

A small, low-pass RC filter should be used at the input pin of

the LM5000 if the input voltage has an unusually large

amount of transient noise. Additionally, the RC filter can

reduce the dissipation within the device when the input

voltage is high.

Flyback Regulator Operation

The LM5000 is ideally suited for use in the flyback regulator

topology. The flyback regulator can produce a single output

voltage, or multiple output voltages.

The operation of a flyback regulator is as follows: When the

switch is on, current flows through the primary winding of the

transformer, T1, storing energy in the magnetic field of the

transformer. Note that the primary and secondary windings

are out of phase, so no current flows through the secondary

when current flows through the primary. When the switch

turns off, the magnetic field collapses, reversing the voltage

polarity of the primary and secondary windings. Now rectifier

D5 is forward biased and current flows through it, releasing

the energy stored in the transformer. This produces voltage

at the output.

The output voltage is controlled by modulating the peak

switch current. This is done by feeding back a portion of the

output voltage to the error amp, which amplifies the difference between the feedback voltage and a 1.259V reference.

The error amp output voltage is compared to a ramp voltage

proportional to the switch current (i.e., inductor current during the switch on time). The comparator terminates the

switch on time when the two voltages are equal, thereby

controlling the peak switch current to maintain a constant

output voltage.

LM5000

www.national.com13

Page 14

Flyback Regulator Operation (Continued)

ITEM PART NUMBER DESCRIPTION VALUE

C 1 C4532X7R2A105MT Capacitor, CER, TDK 1µ, 100V

C 2 C4532X7R2A105MT Capacitor, CER, TDK 1µ, 100V

C 3 C1206C224K5RAC Capacitor, CER, KEMET 0.22µ, 50V

C 4 C1206C104K5RAC Capacitor, CER, KEMET 0.1µ, 50V

C 5 C1206C104K5RAC Capacitor, CER, KEMET 0.1µ, 50V

C 6 C1206C101K1GAC Capacitor, CER, KEMET 100p, 100V

C 7 C1206C104K5RAC Capacitor, CER, KEMET 0.1µ, 50V

C 8 C4532X7S0G686M Capacitor, CER, TDK 68µ, 4V

C 9 C4532X7S0G686M Capacitor, CER, TDK 68µ, 4V

C 10 C1206C221K1GAC Capacitor, CER, KEMET 220p, 100V

C 11 C1206C102K5RAC Capacitor, CER, KEMET 1000p, 500V

D 1 BZX84C10-NSA Central, 10V Zener, SOT-23

D 2 CMZ5930B-NSA Central, 16V Zener, SMA

D 3 CMPD914-NSA Central, Switching, SOT-23

D 4 CMPD914-NSA Central, Switching, SOT-23

D 5 CMSH3-40L-NSA Central, Schottky, SMC

20031972

FIGURE 5. LM5000 Flyback Converter

LM5000

www.national.com 14

Page 15

ITEM PART NUMBER DESCRIPTION VALUE

T 1 A0009-A Coilcraft, Transformer

R 1 CRCW12064992F Resistor 49.9K

R 2 CRCW12061001F Resistor 1K

R 3 CRCW12061002F Resistor 10K

R 4 CRCW12066191F Resistor 6.19K

R 5 CRCW120610R0F Resistor 10

R 6 CRCW12062003F Resistor 200K

R 7 CRCW12061002F Resistor 10K

Q 1 CXT5551-NSA Central, NPN, 180V

U 1 LM5000-3 Regulator, National

LM5000

www.national.com15

Page 16

Physical Dimensions inches (millimeters)

unless otherwise noted

TSSOP-16 Pin Package (MTC)

For Ordering, Refer to Ordering Information Table

NS Package Number MTC16

LLP-16 Pin Package (SDA)

For Ordering, Refer to Ordering Information Table

NS Package Number SDA16A

LM5000

www.national.com 16

Page 17

Notes

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

labeling, can be reasonably expected to result in a

significant injury to the user.

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

www.national.com

LM5000 High Voltage Switch Mode Regulator

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...