Page 1

LM4755

Stereo 11W Audio Power Amplifier with Mute

n P

at 10%THD@1 kHz into 8Ω bridged TO-263 pkg.

General Description

The LM4755 is a stereo audio amplifier capable of delivering

11W per channel of continuous average output power to a

4Ω load or7Wperchannel into 8Ω using a single 24V supply

at 10%THD+N. The internal mute circuit and pre-set gain resistors provide for a very economical design solution.

Output power specifications at both 20V and 24V supplies

and low external component count offer high value to consumer electronic manufacturers for stereo TV and compact

stereo applications. The LM4755 is specifically designed for

single supply operation.

Key Specifications

n Output power at 10%THD with 1 kHz into 4Ω at VCC=

24V 11W(typ)

n Output power at 10%THD with 1 kHz into 8Ω at V

24V 7W(typ)

n Closed loop gain 34 dB(typ)

n P

at 10%THD@1 kHz into 4Ω single-ended TO-263

O

pkg. at V

=

12V 2.5W(typ)

CC

=

CC

O

=

at V

12V 5W(typ)

CC

Features

n Drives 4Ω and 8Ω loads

n Integrated mute function

n Internal Gain Resistors

n Minimal external components needed

n Single supply operation

n Internal current limiting and thermal protection

n Compact 9-lead TO-220 package

Applications

n Stereos TVs

n Compact stereos

n Mini component stereos

LM4755 Stereo 11W Audio Power Amplifier with Mute

February 1999

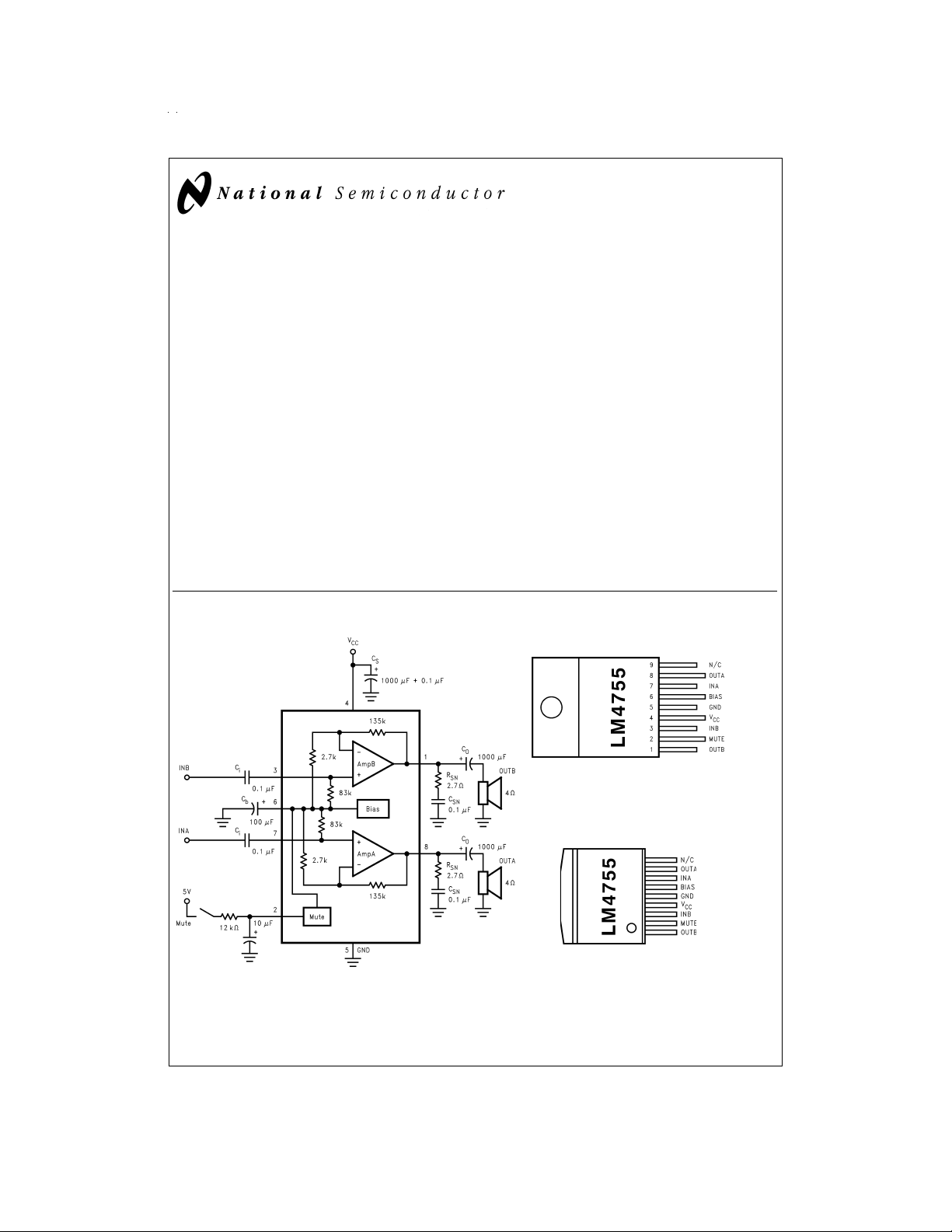

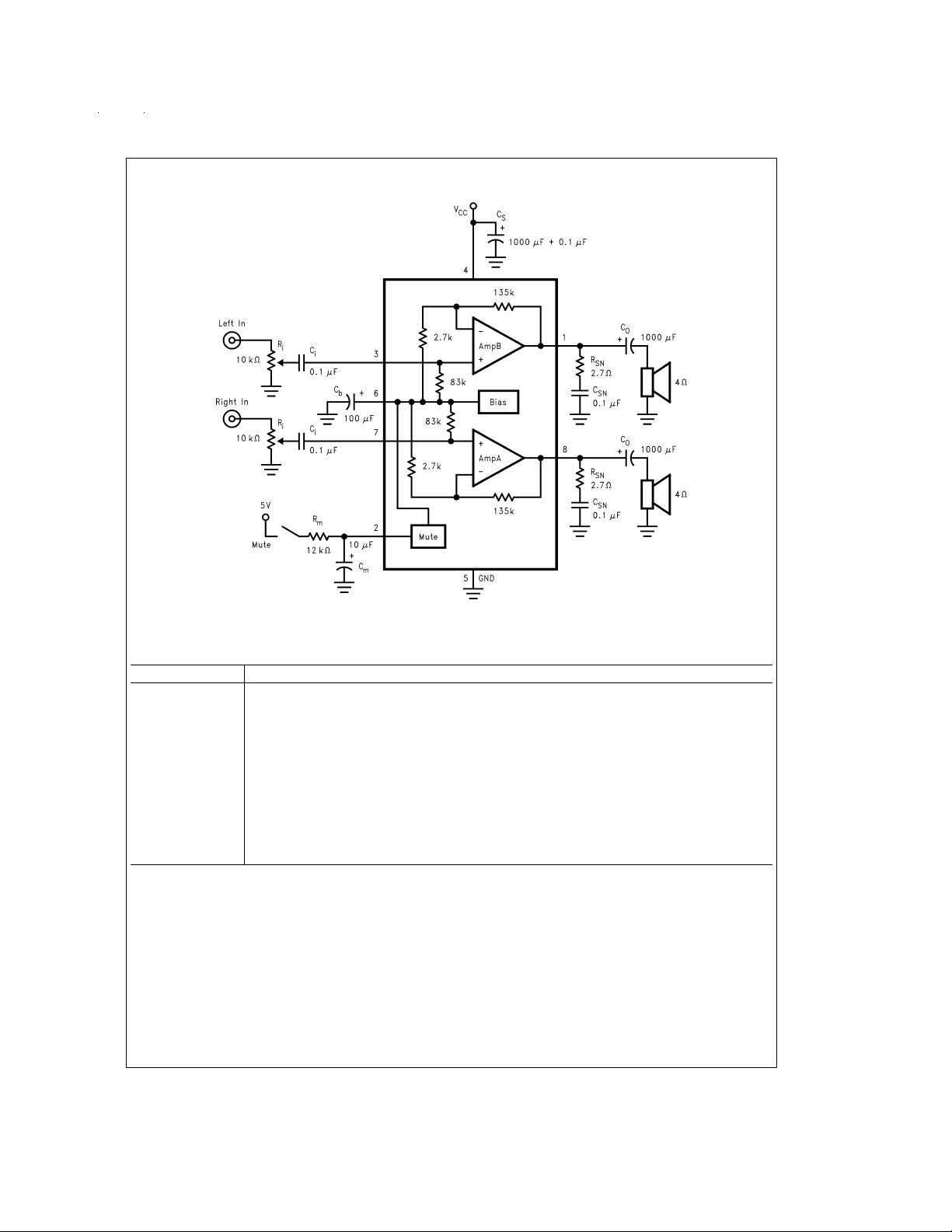

Typical Application Connection Diagrams

Plastic Package

Package Description

Top View

Order Number LM4755T

Package Number TA09A

DS100059-1

FIGURE 1. Typical Audio Amplifier Application Circuit

Top View

Order Number LM4755TS

Package Number TS9A

DS100059-2

DS100059-36

© 1999 National Semiconductor Corporation DS100059 www.national.com

Page 2

Absolute Maximum Ratings (Note 2)

If Military/Aerospace specified devices are required,

T Package (10 seconds) 250˚C

Storage Temperature −40˚C to 150˚C

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage 40V

Input Voltage

±

0.7V

Output Current Internally Limited

Power Dissipation (Note 3) 62.5W

ESD Susceptability (Note 4) 2 kV

Junction Temperature 150˚C

Operating Ratings

Temperature Range

T

≤ TA≤ T

MIN

MAX

Supply Voltage 9V to 32V

θ

JC

θ

JA

−40˚C ≤ TA≤ +85˚C

2˚C/W

76˚C/W

Soldering Information

Electrical Characteristics

The following specifications apply to each channel with VCC= 24V, TA= 25˚C unless otherwise specified.

Symbol Parameter Conditions

I

TOTAL

Total Quiescent Power

Supply Current

Mute Off 10 15 mA(max)

Typical

(Note 5)

Limit

7 mA(min)

Mute On 7 mA

LM4755

P

O

THD Total Harmonic Distortion f = 1 kHz, P

V

OSW

X

TALK

Output Power (Continuous

Average per Channel)

f = 1 kHz, THD+N = 10%,RL=8Ω 7W

f = 1 kHz, THD+N = 10%,R

V

= 20V, RL=8Ω 4W

S

V

= 20V, RL=4Ω 7W

S

f = 1 kHz, THD+N = 10%,R

= 12V, TO-263 Pkg.

V

S

= 1 W/ch, RL=8Ω 0.08

O

=4Ω 11 10 W(min)

L

=4Ω

L

2.5 W

Output Swing PO= 10W, RL=8Ω 15 V

P

= 10W, RL=4Ω 14 V

O

Channel Separation See Apps. Circuit 55 dB

f = 1 kHz, V

= 4 Vrms

O

PSRR Power Supply Rejection Ratio See Apps. Circuit 50 dB

f = 120 Hz, V

V

ODV

Differential DC Output Offset

Voltage

VIN= 0V 0.09 0.4 V(max)

= 1 mVrms

O

SR Slew Rate 2 V/µs

R

IN

PBW Power Bandwidth 3 dB BW at P

A

VCL

e

IN

I

O

Mute Pin

V

IL

V

IH

A

M

Note 1: All voltages are measured with respect to the GND pin (5), unless otherwse specified.

Note 2: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur.Operating Ratings indicate conditions for which the device is func-

tional, but do not guarantee specific performance limits. Electrical Characteristics state DC and AC electrical specifications under particular test conditions which guarantee specific performance limits. This assumes that the device is within the Operating Ratings. Specifications are not guaranteed for parameters where no limit is

given, however, the typical value is a good indication of device performance.

Note 3: For operating at case temperatures above 25˚C, the device must be derated based on a 150˚C maximum junction temperature and a thermal resistance of

= 2˚C/W (junction to case). Refer to the section Determining the Maximum Power Dissipation in the Application Information section for more information.

θ

JC

Note 4: Human body model, 100 pF discharged through a 1.5 kΩ resistor.

Input Impedance 83 kΩ

= 2.5W, RL=8Ω 65 kHz

Closed Loop Gain

RL=8Ω 34 33 dB(min)

(Internally Set)

Noise IHF-A Weighting Filter, RL=8Ω

O

35 dB(max)

0.2 mVrms

Output Referred

Output Short Circuit Limit VIN= 0.5V, RL=2Ω 2 A(min)

Mute Low Input Voltage Not in Mute Mode 0.8 V(max)

Mute High Input Voltage In Mute Mode 2.0 2.5 V(min)

Mute Attenuation V

= 5.0V 80 dB

MUTE

Units

(Limits)

%

www.national.com 2

Page 3

Electrical Characteristics (Continued)

Note 5: Typicals are measured at 25˚C and represent the parametric norm.

Note 6: Limits are guaranteed that all parts are tested in production to meet the stated values.

Note 7: The TO-263 Package is not recommended for V

>

16V due to impractical heatsinking limitations.

S

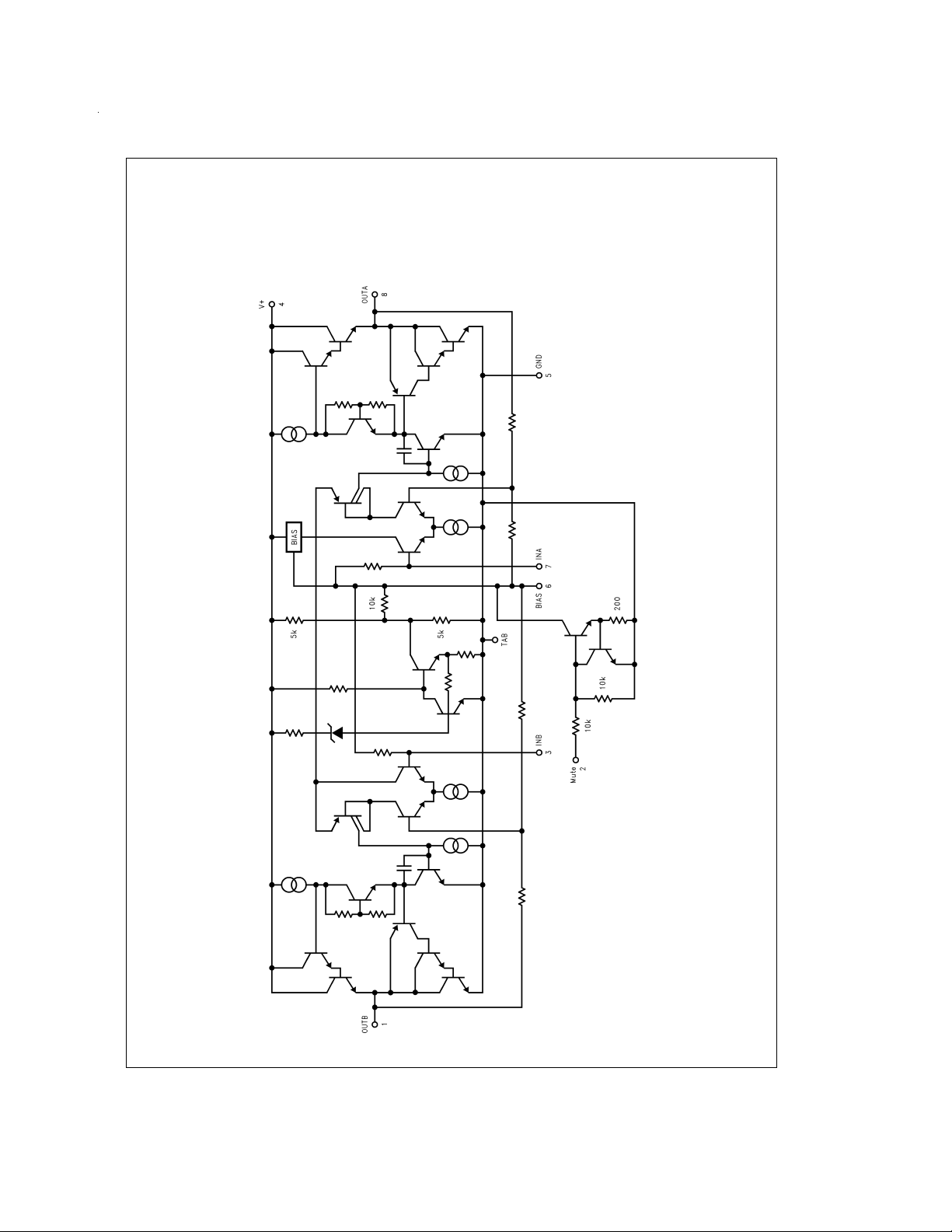

Equivalent Schematic

DS100059-3

www.national.com3

Page 4

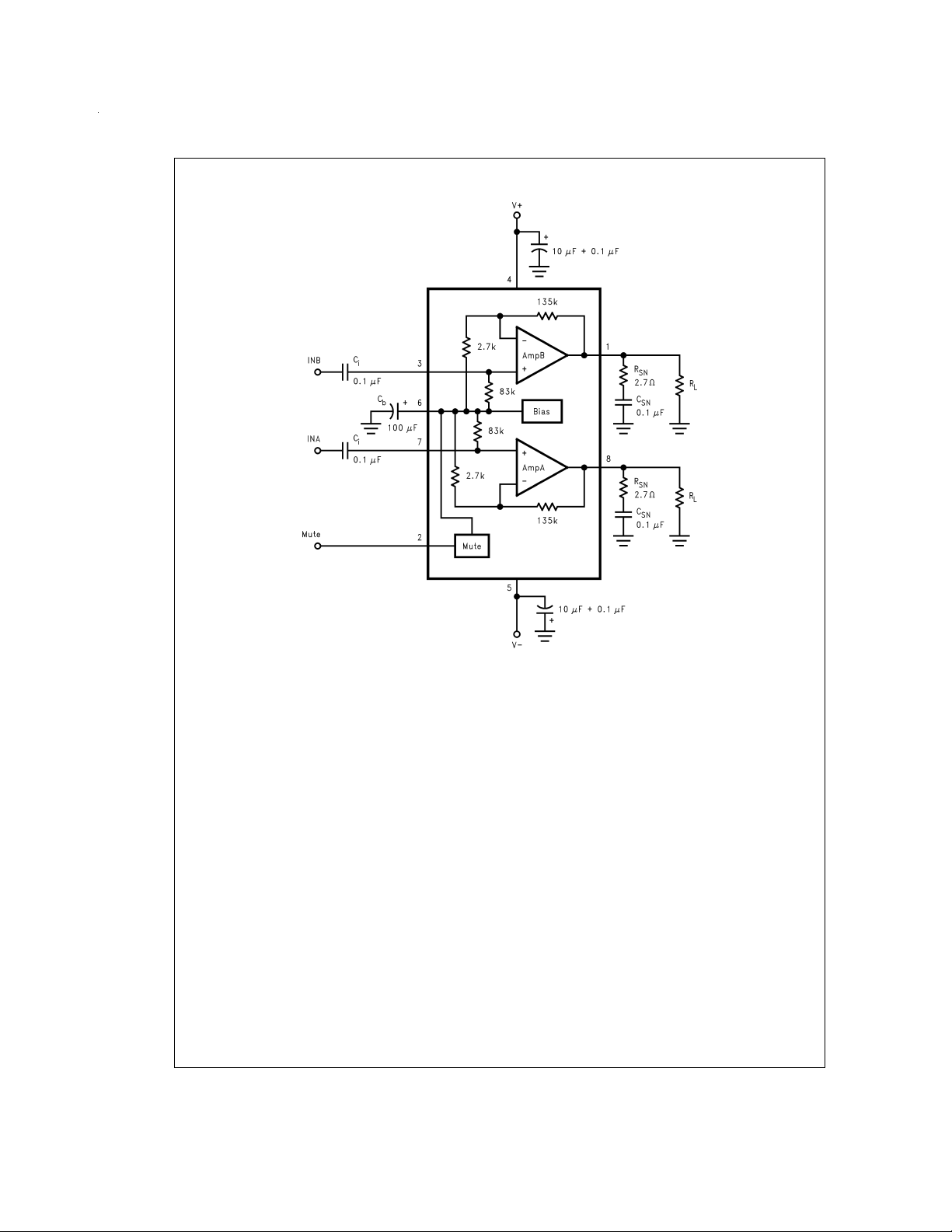

Test Circuit

FIGURE 2. Test Circuit

www.national.com 4

DS100059-4

Page 5

System Application Circuit

FIGURE 3. Circuit for External Components Description

External Components Description

DS100059-5

Components Function Description

1, 2 C

3, 4 R

5, 6 C

7C

8, 9 C

10, 11 C

12, 13 R

14 R

15 C

Provides power supply filtering and bypassing.

S

Works with CSNto stabilize the output stage from high frequency oscillations.

SN

Works with RSNto stabilize the output stage from high frequency oscillations.

SN

Provides filtering for the internally generated half-supply bias generator.

b

Input AC coupling capacitor which blocks DC voltage at the amplifier’s input terminals. Also creates a

i

high pass filter with fc=1/(2

Output AC coupling capacitor which blocks DC voltage at the amplifier’s output terminal. Creates a high

o

pass filter with fc=1/(2

Voltage control - limits the voltage level allowed to the amplifier’s input terminals.

i

Works with Cmto provide mute function timing.

m

Works with Rmto provide mute function timing.

m

•π•

Rin•Cin).

•π•

Rout•Cout).

www.national.com5

Page 6

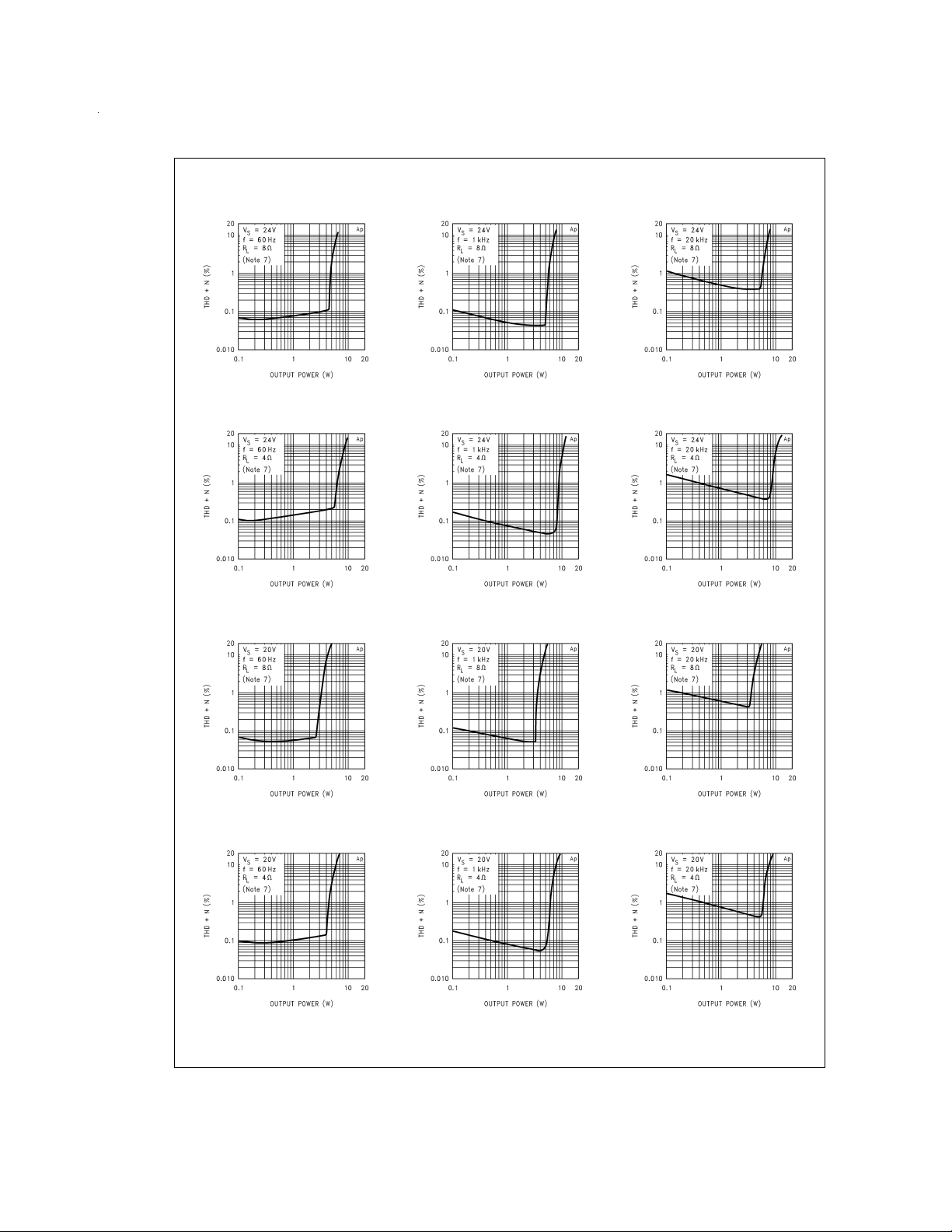

Typical Performance Characteristics(Note 5)

THD+N vs Output Power

THD+N vs Output Power

THD+N vs Output Power

DS100059-12

DS100059-6

THD+N vs Output Power

THD+N vs Output Power

THD+N vs Output Power

DS100059-13

DS100059-7

THD+N vs Output Power

DS100059-14

THD+N vs Output Power

DS100059-8

THD+N vs Output Power

DS100059-15

THD+N vs Output Power

DS100059-9

THD+N vs Output Power

www.national.com 6

DS100059-16

DS100059-10

DS100059-17

THD+N vs Output Power

DS100059-11

Page 7

Typical Performance Characteristics(Note 5) (Continued)

THD+N vs Output Power

THD+N vs Output Power

THD+N vs Output Power

DS100059-38

DS100059-41

THD+N vs Output Power

THD+N vs Output Power

THD+N vs Output Power

DS100059-39

DS100059-42

THD+N vs Output Power

DS100059-40

THD+N vs Output Power

DS100059-43

THD+N vs Output Power

THD+N vs Output Power

DS100059-44

DS100059-47

THD+N vs Output Power

DS100059-45

DS100059-48

DS100059-46

THD+N vs Output Power

DS100059-49

www.national.com7

Page 8

Typical Performance Characteristics(Note 5) (Continued)

Output Power vs Supply Voltage

DS100059-18

THD+N vs Frequency

DS100059-21

Channel Separation

Output Power vs Supply Voltage

DS100059-19

THD+N vs Frequency

DS100059-22

PSRR vs Frequency

Frequency Response

DS100059-20

Frequency Response

DS100059-23

Supply Current vs Supply Voltage

DS100059-24

Power Derating Curve

DS100059-27

Power Dissipation vs Output Power

www.national.com 8

DS100059-25

DS100059-28

DS100059-26

Power Dissipation vs Output Power

DS100059-29

Page 9

Typical Performance Characteristics(Note 5) (Continued)

Power Dissipation vs Output Power

DS100059-60

Power Dissipation vs Output Power

Application Information

The LM4755 contains circuitry to pull down the bias line internally, effectively shutting down the input stage. An external R-C should be used to adjust the timing of the pull-down.

If the bias line is pulled down too quickly, currents induced in

the internal bias resistors will cause a momentary DC voltage to appear across the inputs of each amplifier’s internal

differential pair, resulting in an output DC shift towards Vsupply. An R-C timing circuit should be used to limit the pulldown time such that output “pops” and signal feedthroughs

will be minimized. The pull-down timing is a function of a

number of factors, including the internal mute circuitry, the

voltage used to activate the mute, the bias capacitor, the

half-supply voltage, and internal resistances used in the halfsupply generator.

ues for the external R-C.

TABLE 1. Recommended Values for Mute Circuit

V

MUTE

5V 12V 18 kΩ 10 µF

5V 15V 18 kΩ 10 µF

5V 20V 12 kΩ 10 µF

5V 24V 12 kΩ 10 µF

5V 28V 8.2 kΩ 10 µF

5V 30V 8.2 kΩ 10 µF

Table 1

shows a list of recommended val-

V

CC

Rm Cm

DS100059-61

earlier in the External Components section these capacitors create high-pass filters with their corresponding input/

output impedances. The TypicalApplication Circuit shown

in

Figure 1

shows input and output capacitors of 0.1 µF and

1,000 µF respectively. At the input, with an 83 kΩ typical input resistance, the result is a high pass 3 dB point occurring

at 19 Hz. There is another high pass filter at 39.8 Hz created

with the output load resistance of 4Ω. Careful selection of

these components is necessary to ensure that the desired

frequency response is obtained. The Frequency Response

curves in the Typical Performance Characteristics section

show how different output coupling capacitors affect the low

frequency roll-off.

OPERATING IN BRIDGE-MODE

Though designed for use as a single-ended amplifier, the

LM4755 can be used to drive a load differentially (bridgemode). Due to the low pin count of the package, only the

non-inverting inputs are available. An inverted signal must

be provided to one of the inputs. This can easily be done with

the use of an inexpensive op-amp configured as a standard

inverting amplifier.An LF353 is a good low-cost choice. Care

must be taken, however, for a bridge-mode amplifier must

theoretically dissipate four times the power of a single-ended

type. The load seen by each amplifier is effectively half that

of the actual load being used, thus an amplifier designed to

drive a 4Ω load in single-ended mode should drive an 8Ω

load when operating in bridge-mode.

CAPACITOR SELECTION AND FREQUENCY

RESPONSE

With the LM4755, as in all single supply amplifiers, AC coupling capacitors are used to isolate the DC voltage present at

the inputs (pins 3, 7) and outputs (pins 1, 8). As mentioned

www.national.com9

Page 10

Application Information (Continued)

FIGURE 4. Bridge-Mode Application

DS100059-30

DS100059-31

FIGURE 5. THD+N vs P

OUT

PREVENTING OSCILLATIONS

With the integration of the feedback and bias resistors onchip, the LM4755 fits into a very compact package. However,

due to the close proximity of the non-inverting input pins to

the corresponding output pins, the inputs should be AC terminated at all times. If the inputs are left floating, the amplifier will have a positive feedback path through high impedance coupling, resulting in a high frequency oscillation. In

most applications, this termination is typically provided by

the previous stage’s source impedance. If the application will

www.national.com 10

DS100059-37

for Bridge-Mode Application

require an external signal, the inputs should be terminated to

ground with a resistance of 50 kΩ or less on the AC side of

the input coupling capacitors.

UNDERVOLTAGE SHUTDOWN

If the power supply voltage drops below the minimum operating supply voltage, the internal under-voltage detection circuitry pulls down the half-supply bias line, shutting down the

preamp section of the LM4755. Due to the wide operating

supply range of the LM4755, the threshold is set to just under 9V. There may be certain applications where a higher

Page 11

Application Information (Continued)

threshold voltage is desired. One example is a design requiring a high operating supply voltage, with large supply and

bias capacitors, and there is little or no other circuitry connected to the main power supply rail. In this circuit, when the

power is disconnected, the supply and bias capacitors will

discharge at a slower rate, possibly resulting in audible output distortion as the decaying voltage begins to clip the output signal. An external circuit may be used to sense for the

desired threshold, and pull the bias line (pin 6) to ground to

disable the input preamp.

such a circuit. When the voltage across the zener diode

drops below its threshold, current flow into the base of Q1 is

interrupted. Q2 then turns on, discharging the bias capacitor.

This discharge rate is governed by several factors, including

the bias capacitor value, the bias voltage, and the resistor at

the emitter of Q2.An equation for approximating the value of

the emitter discharge resistor, R, is given below:

R = (0.7v) / (Cb

Note that this is only a linearized approximation based on a

discharge time of 0.1s. The circuit should be evaluated and

adjusted for each application.

As mentioned earlier in the Built-in Mute Circuit section,

when using an external circuit to pull down the bias line, the

rate of discharge will have an effect on the turn-off induced

distortions. Please refer to the Built-in Mute Circuit section

for more information.

FIGURE 6. External Undervoltage Pull-Down

THERMAL CONSIDERATIONS

Heat Sinking

Proper heatsinking is necessary to ensure that the amplifier

will function correctly under all operating conditions. A heatsink that is too small will cause the die to heat excessively

and will result in a degraded output signal as the thermal protection circuitry begins to operate.

The choice of a heatsink for a given application is dictated by

several factors: the maximum power the IC needs to dissipate, the worst-case ambient temperature of the circuit, the

junction-to-case thermal resistance, and the maximum junction temperature of the IC. The heat flow approximation

equation used in determining the correct heatsink maximum

thermal resistance is given below:

T

J–TA=PDMAX

•

where:

Figure 6

(VCC/2) / 0.1s)

•

(θJC+ θCS+ θSA)

shows an example of

DS100059-32

P

= maximum power dissipation of the IC

DMAX

(˚C) = junction temperature of the IC

T

J

(˚C) = ambient temperature

T

A

(˚C/W) = junction-to-case thermal resistance of the IC

θ

JC

(˚C/W) = case-to-heatsink thermal resistance (typically

θ

CS

0.2 to 0.5 ˚C/W)

θ

(˚C/W) = thermal resistance of heatsink

SA

When determining the proper heatsink, the above equation

should be re-written as:

θ

≤ [(TJ–TA)/P

SA

DMAX

]-θJC–θ

CS

TO-263 HEATSINKING

Surface mount applications will be limited by the thermal dissipation properties of printed circuit board area. The TO-263

package is not recommended for surface mount applications

>

with V

There are TO-263 package enhancements, such as clip-on

16V due to limited printed circuit board area.

S

heatsinks and heatsinks with adhesives, that can be used to

improve performance.

Standard FR-4 single-sided copper clad will have an approximate Thermal resistance (θ

1.5 x 1.5 in. sq. 20–27˚C/W (T

2 x 2 in. sq. 16–23˚C/W

The above values for θ

proportions (i.e. variations in width and length will vary θ

SA

) ranging from:

SA

=28˚C, Sine wave

A

testing, 1 oz. Copper)

vary widely due to dimensional

SA

For audio applications, where peak power levels are short in

duration, this part will perform satisfactory with less

heatsinking/copper clad area. As with any high power design

proper bench testing should be undertaken to assure the design can dissipate the required power. Proper bench testing

requires attention to worst case ambient temperature and air

flow.At high power dissipation levels the part will show a tendency to increase saturation voltages, thus limiting the undistorted power levels.

DETERMINING MAXIMUM POWER DISSIPATION

For a single-ended class AB power amplifier, the theoretical

maximum power dissipation point is a function of the supply

voltage, V

following equation:

(single channel)

P

DMAX

, and the load resistance, RLand is given by the

S

2

(W)=[V

2

S

/(2•π

RL)]

•

The above equation is for a single channel class-AB power

amplifier. For dual amplifiers such as the LM4755, the equation for calculating the total maximum power dissipated is:

(dual channel)

P

(W)=2•[V

DMAX

or

2

2

/(π

V

S

RL)

•

(Bridged Outputs)

(W) = 4[V

P

DMAX

S

S

2

/(2π

2

/(2•π

2

RL)]

•

2

RL)]

•

HEATSINK DESIGN EXAMPLE:

Determine the system parameters:

= 24V Operating Supply Voltage

V

S

R

=4Ω Minimum Load Impedance

L

T

= 55˚C Worst Case Ambient Temperature

A

Device parameters from the datasheet:

T

= 150˚C Maximum Junction Temperature

J

).

www.national.com11

Page 12

Application Information (Continued)

θ

= 2˚C/W Junction-to-Case Thermal Resistance

JC

Calculations:

2

P

=2•[V

•

DMAX

= 14.6W

θ

≤ [(TJ-TA)/P

SA

- 2˚C/W–0.2˚C/W = 4.3˚C/W

DMAX

Conclusion: Choose a heatsink with θ

TO-263 HEATSINK DESIGN EXAMPLES:

Example 1: (Stereo Single-Ended Output)

=

T

R

V

θ

DMAX

=

A

=

J

L

S

JC

V

30˚C

150˚C

=

4Ω

=

12V

=

2˚C/W

CC

Given: T

from PDvs POGraph:

P

DMAX

Calculating P

P

DMAX

Calculating Heatsink Thermal Resistance:

<

θ

SA

<

θ

120˚C/3.7W − 2.0˚C/W − 0.2˚C/W=30.2˚C/W

SA

Therefore the recommendation is to use 1.5 x 1.5 square

inch of single-sided copper clad.

Example 2: (Stereo Single-Ended Output)

Given: T

P

DMAX

=

50˚C

A

=

150˚C

T

J

=

4Ω

R

L

=

12V

V

S

=

2˚C/W

θ

JC

from PDvs POGraph:

2

2

S

/2•π

RL)] = (24V)2/(2•π

•

]-θJC–θCS= [ (150˚C - 55˚C) / 14.6W]

≤ 4.3˚C/W.

SA

≈ 3.7W

P

DMAX

:

2

/(π2RL)=(12V)2/π2(4Ω))=3.65W

TJ−TA/P

DMAX

− θJC− θ

CS

2

4Ω)

•

P

≈ 3.7W

DMAX

Calculating P

P

DMAX

:

DMAX

2

=

/(π2RL)=(12V)2/(π2(4Ω))=3.65W

V

CC

Calculating Heatsink Thermal Resistance:

<

[(TJ−TA)/P

θ

SA

<

θ

100˚C/3.7W − 2.0˚C/W − 0.2˚C/W=24.8˚C/W

SA

DMAX

]−θJC− θ

CS

Therefore the recommendation is to use 2.0 x 2.0 square

inch of single-sided copper clad.

Example 3: (Bridged Output)

Given: T

Calculating P

P

DMAX

=

50˚C

A

=

150˚C

T

J

=

8Ω

R

L

=

12V

V

S

=

2˚C/W

θ

JC

:

DMAX

2

=

/(2π2RL)]=4(12V)2/(2π2(8Ω))=3.65W

4[V

CC

Calculating Heatsink Thermal Resistance:

<

[(TJ−TA)/P

θ

SA

<

θ

100˚C / 3.7W − 2.0˚C/W − 0.2˚C/W=24.8˚C/W

SA

DMAX

]−θJC− θ

CS

Therefore the recommendation is to use 2.0 x 2.0 square

inch of single-sided copper clad.

LAYOUT AND GROUND RETURNS

Proper PC board layout is essential for good circuit performance. When laying out a PC board for an audio power amplifier, particular attention must be paid to the routing of the

output signal ground returns relative to the input signal and

bias capacitor grounds. To prevent any ground loops, the

ground returns for the output signals should be routed separately and brought together at the supply ground. The input

signal grounds and the bias capacitor ground line should

also be routed separately. The 0.1 µF high frequency supply

bypass capacitor should be placed as close as possible to

the IC.

www.national.com 12

Page 13

Application Information (Continued)

PC BOARD LAYOUT-COMPOSITE

DS100059-33

www.national.com13

Page 14

Application Information (Continued)

PC BOARD LAYOUT-SILK SCREEN

www.national.com 14

DS100059-34

Page 15

Application Information (Continued)

PC BOARD LAYOUT-SOLDER SIDE

DS100059-35

www.national.com15

Page 16

16

Page 17

Physical Dimensions inches (millimeters) unless otherwise noted

Order Number LM4755T

NS Package Number TA9A

www.national.com17

Page 18

Physical Dimensions inches (millimeters) unless otherwise noted (Continued)

Order Number LM4755TS

NS Package Number TS9A

LM4755 Stereo 11W Audio Power Amplifier with Mute

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or systems which, (a) are intended for surgical implant into

the body, or (b) support or sustain life, and whose failure to perform when properly used in accordance

with instructions for use provided in the labeling, can

be reasonably expected to result in a significant injury

to the user.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80-532 78 32

Français Tel: +49 (0) 1 80-532 93 58

Italiano Tel: +49 (0) 1 80-534 16 80

2. A critical component is any component of a life support

device or system whose failure to perform can be reasonably expected to cause the failure of the life support

device or system, or to affect its safety or effectiveness.

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

Loading...

Loading...