Page 1

LM4753

Dual 10W Audio Power Amplifier w/Mute, Standby and

Volume Control

General Description

The LM4753 is a stereo audio amplifier capable of delivering

10W/channel at 10%distortion into a 8Ω load. The power

amp has an internally set gain of 30 dB. A 0V–5V DC controlled volume block provides80dBofattenuationfrom input

to line-out. Line outputs are available after the volume control for signal routing.

The amplifier has a smooth transition fade-in/out mute and a

power conserving standby function which are controlled

through TTL or CMOS logic. Both functions provide over

75 dB of attenuation.

The LM4753 maintains an excellent Signal-to-Noise ratio of

greater than 70 dB with a low noise floor less than 2 mV.The

IC also maintains above 50 dB of channel separation.

The LM4753 is available in a 15-lead non-isolated plastic

package and is designed for use in TV applications requiring

single supply operation.

Key Specifications

n Output power into 8Ω at 10%THD 10W

n Maximum operating voltage 28V

n Power output stage Noise floor 2 mV

n Line output Noise floor 55 µV

n 0V–5V DC controlled volume attenuation 80 dB

n Mute attenuation 75 dB

n Standby-mode supply current 7 mA

Features

n Quiet fade-in/out mute function

n Stereo variable line-out pins

n AC output short circuit protection

n Thermal shutdown protection

Applications

n Stereo TVs

n Component stereo

n Compact stereo

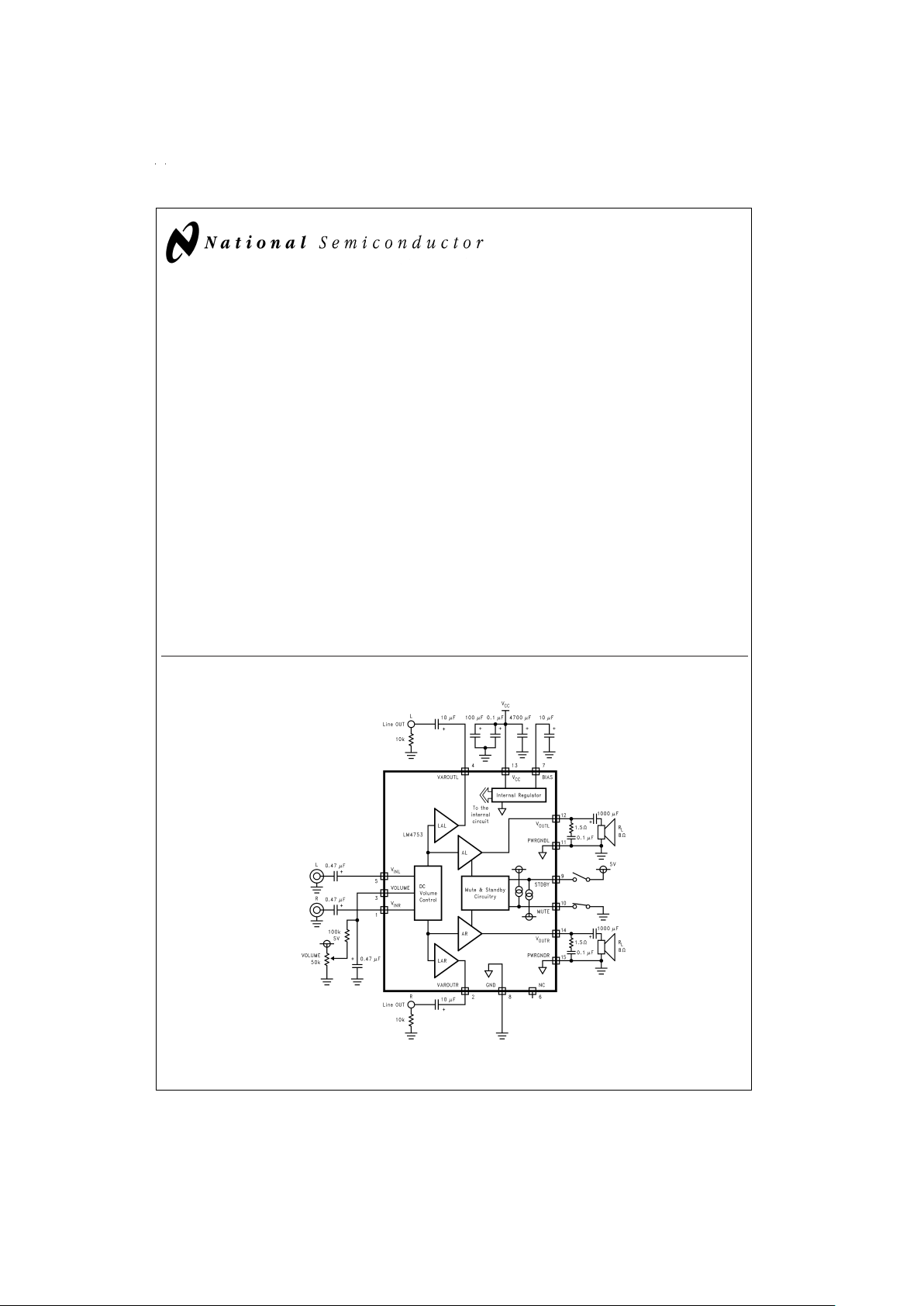

Typical Application

DS100043-1

FIGURE 1. Typical Audio Amplifier Application Circuit

June 1999

LM4753 Dual 10W Audio Power Amplifier w/Mute, Standby and Volume Control

© 1999 National Semiconductor Corporation DS100043 www.national.com

Page 2

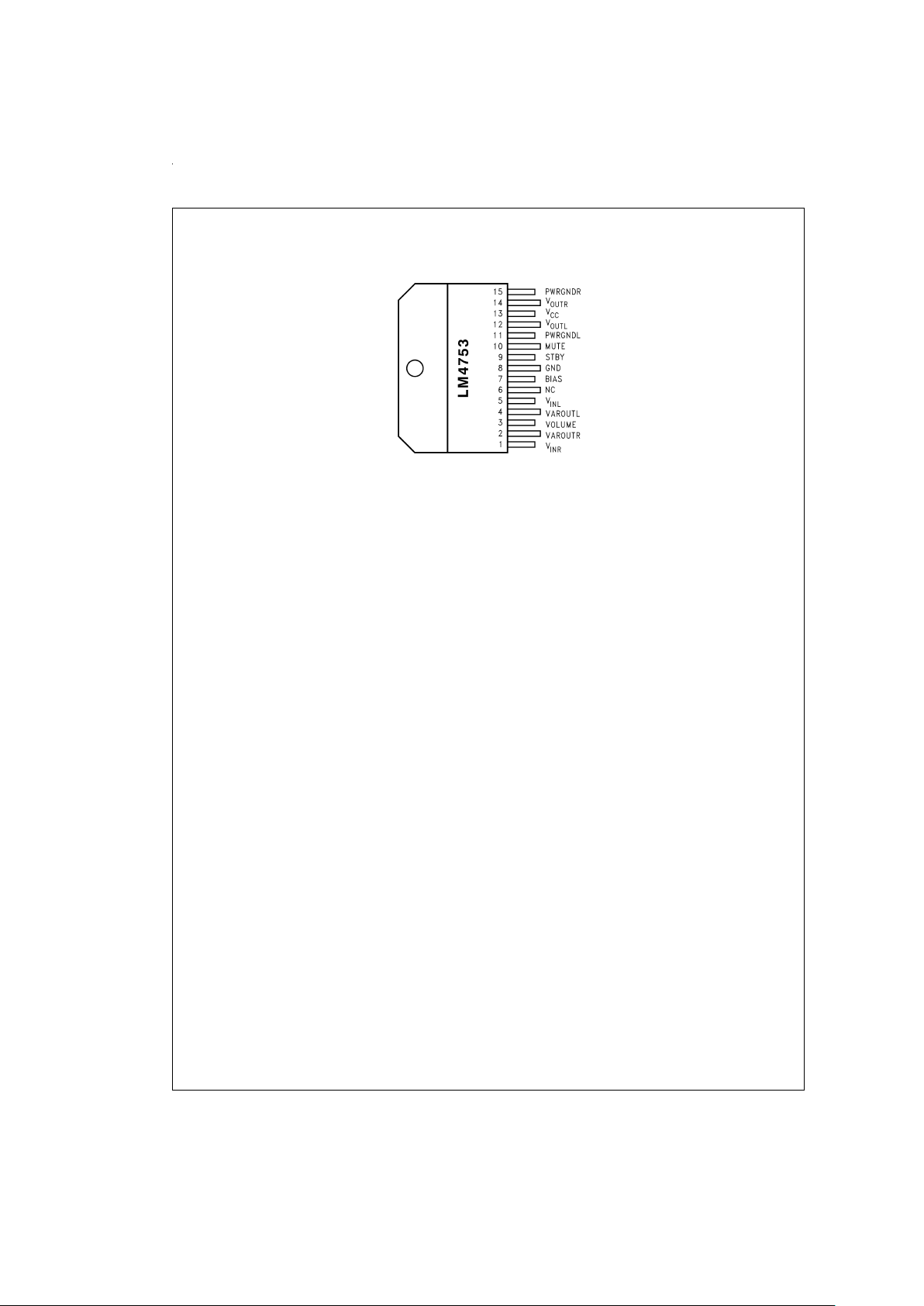

Connection Diagram

Plastic Package

DS100043-2

Top View

Order Number

See NS Package Number TA15A for

Staggered Lead Non-Isolated Package

www.national.com 2

Page 3

Absolute Maximum Ratings (Notes 3, 4)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage 32V

Output Current Internally Limited

Power Dissipation (Note 5) 22W

ESD Susceptibility (Note 6) 2000V

ESD Susceptibility (Note 7) 250V

Junction Temperature 150˚C

Soldering Information

T Package (10 sec) 260˚C

Storage Temperature −40˚C to +150˚C

Input Signal Voltage Range

±

3V

Operating Ratings (Notes 3, 4)

Temperature Range

T

MIN

≤ TA≤ T

MAX

−40˚C ≤ TA≤ +85˚C

Supply Voltage 15V to 28V

θ

JA

(Junction to Ambient) 35˚C/W

θ

JC

(Junction to Case) 1.5˚C/W

Electrical Characteristics (Notes 3, 4)

The following specifications apply for VCC= +22V, and Volume@0 dB unless otherwise specified. Limits apply for TA= 25˚C.

Symbol Parameter Conditions

LM4753

Units

(Limits)

Typical

(Note 8)

Limit

(Note 9)

I

CQ

(Note 1)

Total Quiescent Power Supply

Current

V

CM

= 0V, Vo= 0V, Io= 0 mA 20 mA (min)

80 140 mA (max)

I

STBY

(Note 1)

Standby Current V

STDBY

= 5V, Standby-on 7 10 mA (max)

I

MUTE

Mute Current V

MUTE

= 5V Mute-on 13 20 mA

A

M

(Note 2)

Mute Attenuation V

MUTE

= 5V, V

STDBY

= 0V. Mute-on

Signal Input

75 60 dB (min)

V

MUTE

= 0V. V

STDBY

= 0V. Mute-off

2 Vrms

±

5dB

Volume Attenuation Range 80 70 dB (min)

Volume Absolute Attenuation

Line-out

Pin 3

@

0V=80 dB, 2V=14 dB,

3V=8 dB, 4V=3 dB, 5V=0dB

±

3

±

5 dB (max)

Line-out Offset Voltage 20 40 mV (max)

P

O

(Note 1)

Output Power (Continuous Average) THD+N = 10%(max)

f = 1 kHz, R

L

=8Ω,VCC= 28 11.8 W

f = 1 kHz, R

L

=8Ω,VCC= 22V 7 6.5 W(min)

THD+N

(Note 2)

Total Harmonic Distortion Plus Noise P

o

=1W,f=1kHz, RL=8Ω 0.4 1

%

(max)

Xtalk

(Note 2)

Channel Separation f = 1 kHz, P

o

= 5W, RL=8Ω 50 dB

Power Amp Closed-Loop Gain Error Internal Gain = 30 dB 0.5

±

1 dB (max)

SR

(Note 2)

Slew Rate V

IN

= 100 mVp-p, t

RISE

= 2 ns, RL=8Ω 3 V/µs

R

IN

(Note 1)

Input Impedance 32 kΩ

I

O

(Note 1)

Output Current Limit V

IN

= 100 mV DC, tON= 1 ms, RL=1Ω 2.5 2.0 A(min)

PSRR

(Note 2)

Power Supply Rejection Ratio Vpin 13 AC = 1 Vrms, f = 100 Hz 50 dB

V

CM

= 0V, Io=0mA

GBWP Gain-Bandwidth Product f

o

= 100 kHz, VIN= 50 mvrms 2 MHz

Power Bandwidth −3 dB Bandwidth at 5W 90 kHz

eVCA

out

VCA Output Noise IHF - A Weighting Filter

R

IN

=25Ω

55 µV

e

out

Power Amp Output Noise IHF - A Weighting Filter

R

IN

=25Ω

1.8 mV

SNR Signal-to-Noise Ratio Measured at 1 kHz, R

s

=25Ω

P

o

= 4.8W, A - Weighted, 70 dB

www.national.com3

Page 4

Electrical Characteristics (Notes 3, 4) (Continued)

The following specifications apply for VCC= +22V, and Volume@0 dB unless otherwise specified. Limits apply for TA= 25˚C.

Symbol Parameter Conditions

LM4753

Units

(Limits)

Typical

(Note 8)

Limit

(Note 9)

Standby

V

IL

Standby Low Input Voltage 0.8 V (max)

V

IH

Standby High Input Voltage 2.0 V (min)

Mute

V

IL

Mute Low Input Voltage 0.8 V (max)

V

IH

Mute High Input Voltage 2.0 V (min)

Note 1: DC Electrical Test.

Note 2: AC Electrical Test.

Note 3: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

functional, but do not guarantee specific performance limits. Electrical Characteristics state DC and AC electrical specifications under particular test conditions

which guarantee specific performance limits. This assumes that the device is within the Operating Ratings. Specifications are not guaranteed for parameters where

no limit is given, however, the typical value is a good indication of device performance.

Note 4: All voltages are measured with respect to the ground (pin 8), unless otherwise specified.

Note 5: The maximum power dissipation must be derated at elevated temperatures and is dictated by T

JMAX

, θJA, and the ambient temperature, TA. The maximum

allowable power dissipation is PDMAX = (T

JMAX-TA

)/θJAor the number given in the Absolute Maximum Ratings, whichever is lower. For operating at case tempera-

tures above 25˚C, the device must be derated based on a 150˚C maximum junction temperature and a thermal resistance of θ

JC

= 5˚C/W (junction to case).

Note 6: Human body model, 100 pF discharged through a 1.5 kΩ resistor.

Note 7: Machine model, 200 pF–240 pF discharge through all pins.

Note 8: Typicals are measured at 25˚C and represent the parametric norm.

Note 9: Limits are guarantees that all parts are tested in production to meet the stated values.

Standby Mute Pin Function Table

Standby (Pin 9) Mute (Pin 10) Operating Condition

“L” or Open “L” Play

“L” or Open “H” or Open Mute

“H” “L” Standby

“H” “H” or Open Standby

www.national.com 4

Page 5

Typical Performance Characteristics

THD+N vs Frequency

DS100043-8

THD+N vs Frequency

DS100043-9

Output Power vs

Supply Voltage

DS100043-10

THD+N vs Frequency

DS100043-11

THD+N vs Frequency

DS100043-12

Output Power vs

Supply Voltage

DS100043-13

THD+N vs Output Power

DS100043-14

THD+N vs Output Power

DS100043-15

THD+N vs Output Power

DS100043-16

THD+N vs Output Power

DS100043-17

THD+N vs Output Power

DS100043-18

THD+N vs Output Power

DS100043-19

www.national.com5

Page 6

Typical Performance Characteristics (Continued)

Application Information

GENERAL FEATURES

The LM4753 has a number of valuable functions that make

this audio amplifier IC an all-in-one solution. The IC has a

stereo audio path from input to output with a DC voltage controlled volume attenuator in the preamp section. After the

volume attenuator is a line-out connection for preamp-out

control. The attenuation curve versus DC voltage can be

found by referring to the Volume Attenuation vs DC Voltage

graph in the Typical Performance Characteristics section.

The IC also possesses a mute function to provide audio attenuation as used on a remote control for a TV, as well as a

standby function for power conservation when not being

used. The IC is well protected with thermal shutdown and

output AC short circuit protection.

Mute Function

The muting function of the LM4753 allows the user to mute

the music going into the amplifier, providing over 60 dB of attenuation from input to output. The function is enabled by

placing a logic “1” or 5V onto the mute pin, pin 10. Todisable

the function, allowing music to be passed to the output, a

logic “0” or 0V should be placed on the mute pin. By placing

the device into mute mode, each of the power amplifier outputs are simultaneously muted. The DC volume control and

line-out amplifiers are not affected by the mute function.

Please refer to

Table 1

for each input condition.

To prevent mechanical switch bouncing from adversely affecting the functionality of the IC, an RC lowpass filter should

be used as shown in

Figure 2

. This circuit replaces the need

for a debounce circuit when using a mechanical switch to

control the IC logic functions. However, most systems typically utilize a microprocessor or COP microcontroller to interface with the logic control functions of the LM4753. When a

clean logic signal is used, as from a microcontroller, the RC

lowpass filter is not required.

Standby Function

The standby function allows the user to place the LM4753

into a power conserving mode that draws less than 10 mA of

quiescent power supply current. With the IC in this mode,

while using +22V for the supply voltage, the IC draws about

150 mW of power.

The standby function is enabled by placing a logic “1” or 5V

onto the standby pin, pin 9. To disable the function allowing

music to be passed to the output, a logic “0” or 0V should be

placed on the standby pin. When the standby function is en-

Supply Current

vs Supply Voltage

DS100043-20

Power Dissipation vs

Output Power

DS100043-21

Power Dissipation vs

Output Power

DS100043-22

Channel Separation

vs Frequency

DS100043-23

Attenuation vs Frequency

DS100043-24

Volume Attenuation vs

DC Voltage

DS100043-25

DS100043-26

FIGURE 2. Mute and Standby Pin Lowpass Filters

www.national.com 6

Page 7

Application Information (Continued)

abled, it overrides the mute function and places the IC in its

power conserving mode. If the mute function is enabled

while in standby mode, the IC will continue to remain in

standby mode. After the standby function is disabled, the IC

will be placed into mute mode. Please refer to the

Table1

for

each input condition.

TABLE 1. Mute and Standby Functional Conditions

Standby

(Pin 9)

Mute

(Pin 10)

Operating

Conditions

0V or open 0V Music Plays

0V or open 5V or open Mute Mode

5V 0V Standby Mode

5V 5V or open Standby Mode

To prevent mechanical switch bouncing from adversely affecting the functionality of an IC, an RC lowpass filter should

be used as shown in

Figure 2

. This circuit replaces the need

for a debounce circuit when using a mechanical switch to

control the IC logic functions. However, most systems typically utilize a microprocessor or COP microcontroller to interface with the logic control functions of the LM4753. When a

clean logic signal is used, as from a microcontroller, the RC

lowpass filter is not required.

DC Volume Control

The DC volume control for the LM4753 works between 0V

and 5V. When the volume pin (pin 3) is 0V, the IC’s preamp

stage is fully attenuated to 80 dB. When the volume pin is at

5V, the preamp stage passes audio at 0 dB.

The DC volume attenuation curve for the LM4753 is intended to provide smooth accurate attenuation changes at

higher DC voltages, but then attenuate fast to 80 dB at lower

DC voltages. This means that when the volume control is

turned down, the amplification is quickly attenuated, while at

normal listening levels, attenuation changes are more

gradual. Please refer to the VolumeAttenuation vs DC Voltage curve in the Typical Performance Characteristics section.

The DC voltage to pin 3 can be controlled with a potentiometer as shown in

Figures 1, 3

. A 100 kΩ resistor anda1µF

capacitor form an RC lowpass filter that keeps any unnecessary noise from coupling into the device. Any noise that is

coupled into the device is gained up by 40 dB.

Turn On/Off Characteristics

In order to minimize turn on and off pops, the LM4753 should

be powered up by using the sequence described below.

Figure 4

shows the sequence for turn on and off.

Since the power supply voltage of the power amplifier is

about 4 times more than a 5V power supply, it is assumed

that the logic voltage supply for the standby and mute functions is up before the large power supply reservoir capacitors

are charged. The LM4753 should be placed into standby

mode before the undervoltage protection circuitry is disabled. The undervoltage protection circuitry will keep the outputs of the LM4753 at 0V until the voltage from V

CC

to GND

is about 9.5V. If the standby function is disabled when the

supply voltage exceeds this value, the single-supply biasing

of the output stage will then begin to charge up to V

CC

/2. The

pop performance under this condition is quite good, however, it is highly recommended that the Mute and Standby

pin voltages are high at 5V while the main power supply voltage, V

CC

, is ramping up.

Once the main supply voltage is up to its full value, the

standby function can then be brought low to 0V. The biasing

of the amplifier and the output stage will then begin to charge

up to V

CC

/2. Notice that the supply current draw is approximately 7 mA until the standby function is disabled, at which

point, the supply current increases to approximately 13 mA

while in mute mode.

Once the single-supply biasing is established, the mute pin

voltage can be brought down to 0V,allowing the IC to amplify

the input signal.As shown in

Figure 4

, the input signal that is

applied to the IC all throughout the power-up process is not

passed to the speaker until the mute function is disabled.

The typical quiescent power supply current while in play

mode is approximately 80 mA.

The same sequence should be applied when powering down

the device. First the IC should be placed into mute mode,

muting the output, then placed into standby mode where the

bias and output coupling caps are gradually discharged to

ground. Once the biasing of the IC is brought to ground, the

main power supplies can be powered down. This power-up

and power-down sequence is highly recommended. Abrupt

changes in output current from enabling standby while the

output is driving an inductive load (like a speaker) may cause

the IC to handle extreme levels of power due to inductive

kickback. The IC may not be able to handle this and should

be avoided.

DS100043-27

FIGURE 3. Volume Pin Lowpass Filter

www.national.com7

Page 8

Application Information (Continued)

If the sequence described above and shown in

Figure 4

is

not used, then the external circuitry shown in Figure 5 should

be used to minimize turn-on/off pops and protect the output

stage against SOA violations.

In

Figure 5

there are only a few components that are different than the ones described earlier for lowpass filtering the

pin voltages. The new components are Q1, R2, R3, D1 and

D2. All of the other components will perform the same functions that were previously described.

The explanation of how the circuit in

Figure 5

works will be

related to the timing waveforms in

Figure 6

. The circuit in

Figure 5

protects the LM4753 from SOA violations by ensuring that the enabling of the standby function when music is

playing will not quickly bring the biasing to ground before the

input signal is smoothly attenuated through the volume function. Again, this is important because any quick changes in

output current when driving an inductive load will cause a flyback voltage that may damage the IC.

As shown in

Figure 6

, first notice that music is playing at the

output. When the mechanical standby switch is toggled from

ground (play mode) to 5V (standby mode), transistor Q1 is

quickly turned on, discharging capacitor C7, bringing the

voltage at the volume pin, pin 3, to ground. This quickly attenuates the audio signal at the output as shown in

Figure 6

.

While the input signal is being attenuated, the diode D1 becomes reverse biased and the voltage at the standby pin

starts to charge through R4, C8 and C9. There is also a finite

amount of current flowing through R5 as well, but because of

its high resistance, we can neglect it in the charge-up timing

of pin 9. Note that when the standby switch was grounded,

the diode D1 was clamping the standby pin low, setting the

initial voltage condition of C8 at a low voltage. Once C8

starts charging up, diode D2 becomes forward biased and

C9 also starts charging up. This brings the standby and mute

pin voltages up simultaneously. By the time the standby pin

voltage enables the standby function, the voltage at the volume pin will already have been ramped down to 0V and the

output signal will be close to 0V.

When the IC is in standby mode the biasing of the IC is

brought down to ground and the quiescent supply current is

around 7 mA. When the standby switch in

Figure 5

is toggled

DS100043-28

FIGURE 4. Turn-On/Off Sequence

www.national.com 8

Page 9

Application Information (Continued)

to ground for play mode, transistor Q1 is quickly cut off and

diode D1 is forward biased. When D1 is forward biased, capacitor C8 is quickly discharged to ground, bringing the

standby pin voltage to 0V. When C8 is discharged, diode D2

becomes reverse biased allowing capacitor C9 to discharge

to ground through R5. Diode D2 was clamping the voltage

on C9 to the same voltage as C8. Because R5 is 10 times

R4 it takes longer for the mute function to be disabled. While

the mute voltage is decreasing, the biasing of the amplifier is

charging up, since the standby function has already been

disabled. While the mute pin voltage is decreasing the volume pin voltage is slowly increasing through the charge-up

capacitor C7. Charging of the volume pin is from the 5V

through the volume control pot, R6 and C7. Notice that the

time constant of the volume pin charging is greater than the

mute pin discharging.As shown in

Figure 6

, the volume control function finally ramps up the input signal, allowing music

to be amplified at the output.

Please notice that with this circuit the standby switch will

override the mute switch as required in the IC’s functional

truth table in

Table 1

.

Also note once again that most systems typically utilize a microprocessor or COP microcontroller to interface with the

logic control functions of the LM4753. When a clean logic

signal is used, as from a microcontroller, RC lowpass filtering

is not required for the mute and standby functions.

DS100043-29

FIGURE 5. Turn-On/Off External Circuitry

www.national.com9

Page 10

Application Information (Continued)

Line Out

The line out function for the LM4753 is intended to provide

preamp output control for signal routing to an external power

amplifier.Anexample of this would be in a TV where the TV’s

remote control provides volume control on the audio signals

that may be sent to a home theater receiver.The line out amplifier is only able to drive high impedance loads like 2 kΩ

and 10 kΩ. Since the LM4753 utilizes a single +22V power

supply, the output of the line out amplifier is biased at

1

⁄2of

V

CC

or +11V. Because of this, its output should be capacitor

coupled to any other processing IC. The value of the capacitor is chosen by using

Equation (1)

.

f=1/2πRC (1)

where R is the processing IC input impedance and f is the

lowest audio frequency to be passed, like 20 Hz. The value

of capacitance is then calculated. For a 10 kΩ impedance,

C=1µF.

AC Short Circuit Protection

The LM4753 isAC short circuit protected with a current limiting setting minimum of 2.0A. Current limiting protection

works on AC waveforms only. DC shorts from the output to

ground are not protected. Generally this is not a concern as

there is a DC blocking capacitor on the output to protect the

speaker from single-supply DC bias.

Thermal Shutdown Protection

The LM4753 has a thermal shutdown protection scheme that

limits the drive capability of each amplifier output when the

internal die temperature reaches the temperature trip point

of 150˚C. The limiting of the output current drive capability is

proportional to increasing die temperature.

When the IC is in thermal shutdown mode, all of the DC biases of the IC remain unchanged. It is only the current drive

capability of the output power transistors that is limited. This

thermal shutdown mechanism provides for smooth audio attenuation rather than abruptly pulling the outputs to ground.

When the outputs are being limited, the maximum voltage

swing will be reduced, creating a clipping effect as shown in

Figure 7

. With further increases in die temperature the maxi-

mum voltage swing will be further reduced.

The thermal sensing mechanism monitors the global die

temperature and is not intended to operate quickly enough to

shutdown the IC for extremely high power dissipation pulses

created by driving very low impedance loads.

DS100043-30

FIGURE 6. Turn-On/Off External Circuitry Sequence

www.national.com 10

Page 11

Application Information (Continued)

In

Figure 7

, a 50 kHz input signal is used to show the clipping

and attenuating effect of the LM4753 when coming out of

thermal shutdown.

THERMAL CONSIDERATIONS

Determining Maximum Power Dissipation

It is important to determine the maximum amount of package

power dissipation in order to choose an adequate heat sink.

Improper heat sinking can lead to premature thermal shutdown operation, causing music to cut out.

Equation (2)

can

be used to calculate the approximate maximum integrated

circuit power dissipation for your amplifier design, given the

supply voltage, and rated load, with both channels being

driven simultaneously.

P

DMAX

=

2(V

CCtot

2

/2π2RL) (2)

To ensure that a proper heat sink is chosen, be sure to take

into account the effects of the unregulated power supply voltage variation and the highly reactive load impedance variation over frequency.

A poorly regulated power supply can have a supply voltage

variation of more than 10V. Be sure to take into account the

no-load power supply voltage.

A nominally rated 8Ω load can have an impedance dip down

to 5Ω at low frequencies. As well, the load is not purely resistive, and this causes the amplifier output current to be out of

phase with the output voltage. When the current and voltage

are out of phase, the internal power dissipation actually increases.

Equation (2)

can be directly applied to the Power Dissipation

vs Output Power curves in the Typical Performance Characteristics section. However, the curves take into account quiescent power dissipation which

Equation (2)

does not. The

curves are to be used as a guideline in determining the required heat sink and are not intended to provide exact power

dissipation values.

Heat Sinking

Choosing a heat sink for a high-power audio amplifier is

made entirely to keep the die temperature below its maximum junction temperature, so that the thermal protection circuitry does not operate under normal circumstances. The

heat sink should be chosen to dissipate the maximum IC

power for the maximum no-load supply voltage and the minimum load impedance.

Referring to

Figure 8

, the thermal resistance from the die

(junction) to the outside air (ambient) is a combination of

three thermal resistances, θ

JC

, θCSand θSA. Two of these

thermal resistances are provided by National, θ

JC

and θCS.

Since convection heat flow (power dissipation) is analogous

to current flow, thermal resistance is analogous to electrical

resistance, and temperature drops are analogous to voltage

drops, the power dissipation out of the LM4753 is equal to

the following:

P

DMAX

=

(T

JMAX–TAMB

)/θ

JA

(3)

The thermal resistance, θ

JA

is equal to θJC+ θCS+ θSA,

where θ

JC

is the junction-to-case thermal resistance, θCSis

the case-to-sink thermal resistance (thermal compound),

and θ

SA

is the sink-to-ambient thermal resistance.

Once the maximum power dissipation is calculated from

Equation (2)

above, the minimum heat sink thermal resis-

tance can be calculated from

Equation (4)

below.

θ

SA

=

[(T

JMAX–TAMB

)–P

DMAX(θJC

+ θCS)]/P

DMAX

(4)

Example:

V

CC

=

+22V

R

L

=

8Ω

θ

JC

=

1˚C/W

θ

CS

=

0.5˚C/W

(1) P

DMAX

=

2((22V)

2

/2π2(8Ω))=6W

(2) θ

SA

=

[(150˚C–25˚C) – 6W(1˚C/W + 0.5˚C/W)]/6W

=

19˚C/W

Therefore, the minimum heat sink thermal resistance re-

quired is 19˚C/W for both channels being driven simultaneously at maximum power dissipation into an 8Ω load using

a +22V voltage supply.Again, remember to take into account

the unregulated supply voltage and reactive load impedance

dips.

Should it be necessary to isolate the tab of the IC from the

heat sink, an insulating washer can be used. There are many

different types of insulating washers with varying thermal resistances. Good washers can be obtained from Thermalloy

or Berquist. Refer to the References list for contact information for these manufacturers.

Supply Bypassing

The LM4753 has good power supply rejection, however, for

all power amplifiers, proper power supply bypassing is required. To prevent oscillations and instability, all op amps

and power op amps should have their supply leads bypassed with low-inductance capacitors having short leads.

All high frequency bypass capacitors should be located as

close to the package terminals as possible and have a clear

unobstructed current return path to ground. It is typical to use

capacitor values that are a factor of 100 different from each

other to minimize interaction with each other. The LM4753

should be bypassed with 0.1 µF ceramic and 100 µF tantalum capacitors for optimum performance. The 100 µF tantalum can be replaced with an electrolytic, but the bypassing

DS100043-31

FIGURE 7. Thermal Shutdown Response

DS100043-32

FIGURE 8. Thermal Model

www.national.com11

Page 12

Application Information (Continued)

performance of the tantalum will be better. There should also

be large supply reservoir capacitors of about 4700 µF on

each supply rail. A larger reservoir capacitor will reduce the

supply ripple and will supply larger current burst requirements instead of requiring those large currents to come from

the main power supply transformer.

If adequate bypassing is not provided, the current in the supply leads, which is a rectified component of the load current,

may be fed back into internal circuitry.This signal may cause

signal distortion to increase.

Layout and Ground Loops

When designing a printed circuit board layout, it is important

to return the load ground, any output compensation ground,

and the low-level (feedback and input) grounds to the circuit

board common ground point through separate paths. Large

currents flowing along a ground conductor will generate voltages which effectively act as signals to the input ground ref-

erence. This can result in high frequency oscillation or excessive distortion. Output compensation components and

the high frequency supply bypass capacitors should be

placed as close as possible to the IC to reduce the effectsof

PCB trace resistance and inductance. For cases where long

traces must exist, widen the traces to minimize their inductance.

References

International Electronic Research Corporation

P.O. Box 7704,

Burbank, California 91510-7704,

(818) 842-7277

Thermalloy Inc.

P.O. Box 810839,

Dallas, Tx 75381-0839,

(214) 243-4321,

www.thermalloy.com

www.national.com 12

Page 13

Physical Dimensions inches (millimeters) unless otherwise noted

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

labeling, can be reasonably expected to result in a

significant injury to the user.

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80-532 78 32

Français Tel: +49 (0) 1 80-532 93 58

Italiano Tel: +49 (0) 1 80-534 16 80

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

www.national.com

Staggered Lead Non-Isolated Package

NS Package Number TA15A

LM4753 Dual 10W Audio Power Amplifier w/Mute, Standby and Volume Control

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...