Page 1

September 2006

LM3743

N-Channel FET Synchronous Buck Controller for Low

Output Voltages

Reference accuracy: ±1.75%, over full temperature and

General Description

The LM3743 is a voltage mode PWM buck controller which

implements synchronous rectification. It provides a low cost,

fault tolerant, and efficient point of load solution. To reduce

component count several parameters are fixed, such as

switching frequency and the short circuit protection level. For

example the LM3743 has an operating switching frequency

of 300 kHz or 1 MHz and a fixed 500 mV high side current

limit for switch node short-circuit protection. LM3743 is a very

fault tolerant IC with switch node short-circuit, output undervoltage protection, and the ability to self recover after the

removal of the fault. It avoids the need to over design components due to thermal runaway during a fault condition, thus

resulting in a lower cost solution. It employs a proprietary

monotonic glitch free pre-bias start-up method suited for FPGAs and ASIC logic devices. A 0.8V internal reference with

±1.75% accuracy is ideal for sub-volt conversion. An external

programmable soft-start allows for tracking and timing flexibility. The driver features 1.6Ω of pull-up resistance and 1Ω

of pull-down drive resistance for high power density and very

efficient power processing.

Features

Input voltage from 3.0V to 5.5V

■

Output voltage adjustable down to 0.8V

■

■

input voltage range

Low-side sensing programmable current limit

■

Fixed high-side sensing for supplemental short-circuit

■

protection

Undervoltage protection

■

Hiccup mode protection eliminates thermal runaway

■

during fault conditions

Externally programmable soft-start with tracking capability

■

Switching frequency options of 1 MHz or 300 kHz

■

Pre-bias start-up capability

■

MSOP-10 package

■

Applications

ASIC/FPGA/DSP core power

■

Broadband Communications

■

Multi-media Set Top Boxes

■

Networking Equipment

■

Printers/Scanners

■

Servers

■

Low Voltage Distributed Power

■

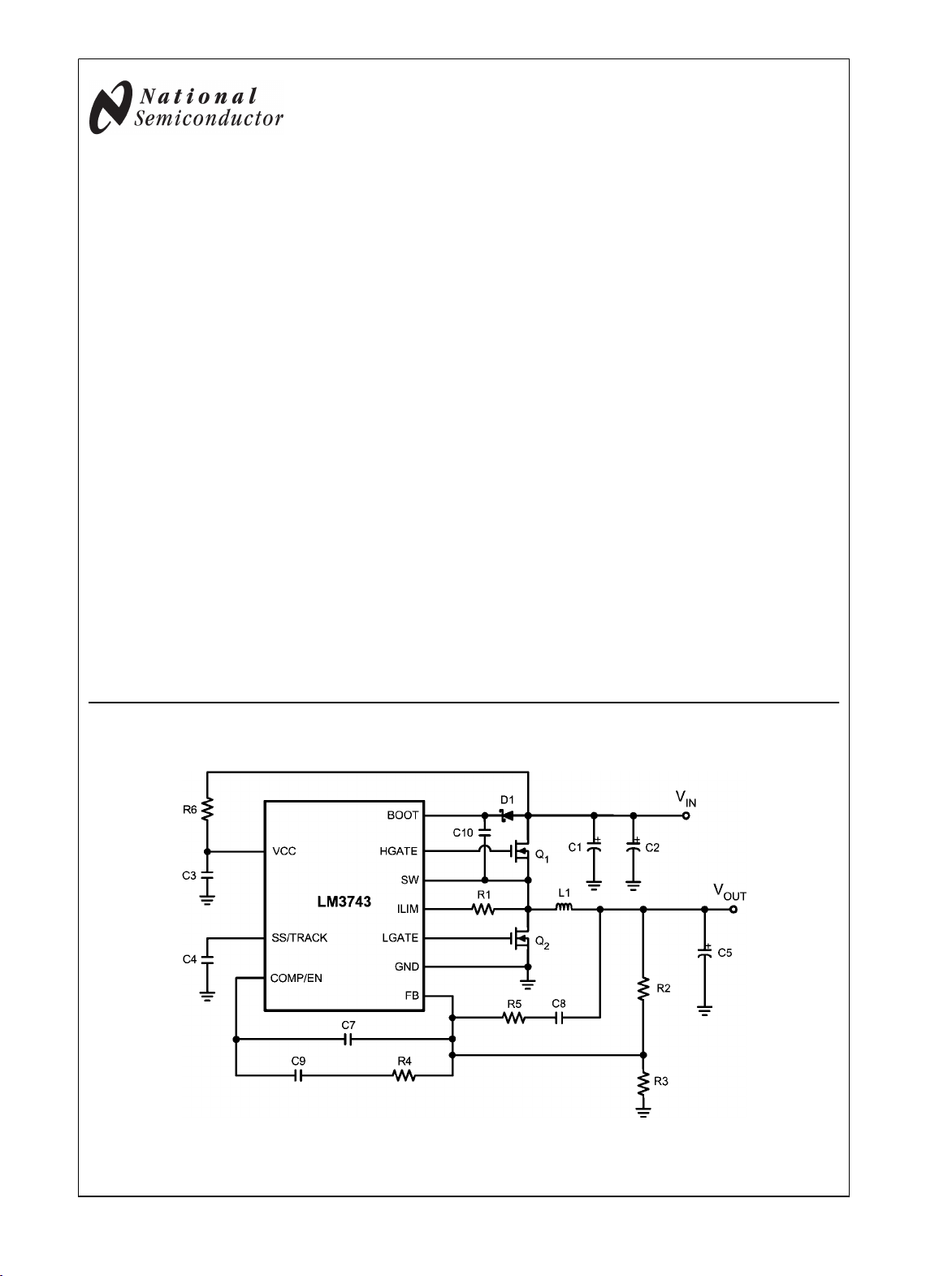

LM3743 N-Channel FET Synchronous Buck Controller for Low Output Voltages

Typical Application

20177401

© 2007 National Semiconductor Corporation 201774 www.national.com

Page 2

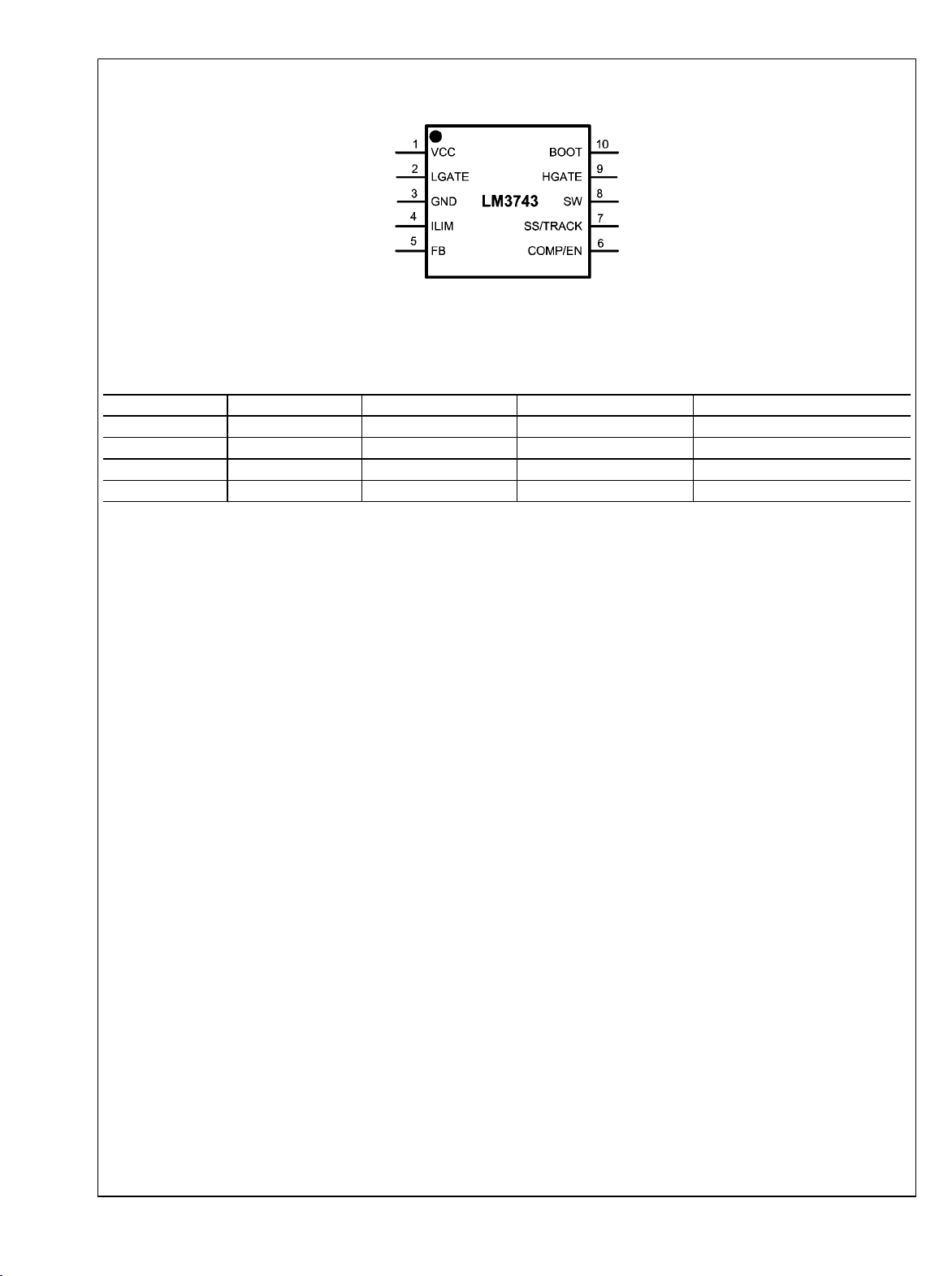

Connection Diagram

LM3743

10-Lead Plastic MSOP

NS Package Number MUB10A

Top View

20177402

Ordering Information

Order Number Frequency Option Top Mark NSC Package Drawing Supplied As

LM3743MM-300 300 kHz SKPB MUB10A 1000 units in Tape and Reel

LM3743MMX-300 300 kHz SKPB MUB10A 3500 units in Tape and Reel

LM3743MM-1000 1 MHz SKNB MUB10A 1000 units in Tape and Reel

LM3743MMX-1000 1 MHz SKNB MUB10A 3500 units in Tape and Reel

Pin Descriptions

VCC (Pin 1) Supply rail for the controller section of the IC. A

minimum capacitance of 1 µF, preferably a multi-layer ceramic capacitor type (MLCC), must be connected as close as

possible to the VCC and GND pin and a 1 to 4.99Ω resistance

must be connected in series from the supply rail to the Vcc

pin. See VCC FILTERING in the Design Consideration section for further details.

LGATE (Pin 2) Gate drive for the low-side N-channel MOSFET. This signal is interlocked with HGATE to avoid a shootthrough problem.

GND (Pin 3) Power ground (PGND) and signal ground

(SGND). Connect the bottom feedback resistor between this

pin and the feedback pin.

ILIM (Pin 4) Low side current limit threshold setting pin. This

pin sources a fixed 50 µA current. A resistor of appropriate

value should be connected between this pin and the drain of

the low-side N-FET.

FB (Pin 5) Feedback pin. This is the inverting input of the error

amplifier used for sensing the output voltage and compensating the control loop.

COMP/EN (Pin 6) Output of the error amplifier and enable

pin. The voltage level on this pin is compared with an internally

generated ramp signal to determine the duty cycle. This pin

is necessary for compensating the control loop. Forcing this

pin to ground will shut down the IC.

SS/TRACK (Pin 7) Soft-start and tracking pin. This pin is

connected to the non-inverting input of the error amplifier during initial soft-start, or any time the voltage is below the

reference. To track the rising ramp of another power supply's

output, connect a resistor divider from the output of that supply to this pin as described in Application Information.

SW (Pin 8) Switch pin. The lower rail of the high-side N-FET

driver. Also used for the high side current limit sensing.

HGATE (Pin 9) Gate drive for the high-side N-channel MOSFET. This signal is interlocked with LGATE to avoid a shootthrough problem.

BOOT (Pin 10) Supply rail for the N-channel MOSFET high

gate drive. The voltage should be at least one gate threshold

above the regulator input voltage to properly turn on the highside N-FET. See MOSFET Gate Drivers in the Application

Information section for more details on how to select MOSFETs.

www.national.com 2

Page 3

LM3743

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

V

CC

SW to GND -0.3V to 6V

Boot to GND -0.3V to 12V

Boot to SW -0.3V to 6V

SS/TRACK, ILIM, COMP/EN,FB

to GND

-0.3V to 6V

-0.3V to V

CC

Storage Temperature −65°C to 150°C

Soldering Information

Lead Temperature (soldering, 10sec) 260°C

Infrared or Convection (20sec) 235°C

ESD Rating (Note 3) + / – 2 kV

Operating Ratings

Supply Voltage Range, VCC (Note 2)

Junction Temperature Range (TJ)

3.0V to 5.5V

−40°C to +125°C

Junction Temperature 150°C

Electrical Characteristics V

= 3.3V, COMP/EN floating unless otherwise indicated in the conditions column.

CC

Limits in standard type are for TJ = 25°C only; limits in boldface type apply over the junction temperature (TJ) range of -40°C to

+125°C. Minimum and Maximum limits are guaranteed through test, design, or statistical correlation. Typical values represent the

most likely parametric norm at TJ = 25°C, and are provided for reference purposes only.

Symbol Parameter Conditions Min Typ Max Units

SYSTEM PARAMETERS

V

V

UVLO

FB pin voltage in regulation

FB

3.0V ≤ VCC ≤ 5.5V

0.786 0.8 0.814 V

UVLO thresholds Input voltage rising 2.84 3.0

Input voltage falling 2.45 2.66

I

VCC

Operating VCC current fSW = 300 kHz, LM3743-300 1.5 2.5 mA

Operating VCC current fSW = 1 MHz, LM3743-1000 1.8 3.0 mA

Shutdown VCC current COMP/EN = 0V 6 50 µA

I

SS/TRACK

I

ILIM

V

ILIM

I

COMP/EN

V

HS-CLIM

SS/TRACK pin source current V

ILIM pin source current V

SS/TRACK

ILIM

= 0V 8 10.2 12.5 µA

= 0V 42.5 50 57.5 µA

Current Limit Trip Level –25 0 25 mV

COMP/EN pin pull-up current V

= 0V 4 µA

COMP/EN

High-side current limit threshold Measured at VCC pin with respect to SW 500 mV

ERROR AMPLIFER

GBW Error Amplifier Unity Gain Bandwidth 30 MHz

G Error Amplifier DC Gain 90 dB

SR Error Amplifier Slew Rate 6 V/ms

I

I

EAO

FB

FB pin Bias Current 10 200 nA

EAO pin sourcing/sinking current capability V

V

= 1.5, VFB = 0.75V 1.7

COMP/EN

= 1.5, VFB = 0.85V -1

COMP/EN

GATE DRIVE

I

SHDN-BOOT

R

HG-UP

R

HG-DN

R

LG-UP

BOOT Pin Shutdown Current V

High Side MOSFET Driver Pull-up ON

resistance

High Side MOSFET Driver Pull-down ON

resistance

Low Side MOSFET Driver Pull-up ON

BOOT-VSW

V

BOOT-VSW

(sourcing)

V

BOOT-VSW

(sinking)

VCC = 3.3V, I

= 3.3V, V

= 3.3V, I

= 3.3V, I

HGATE

HGATE

= 350mA (sourcing) 1.6

LGATE

= 0V 25 50 µA

COMP/EN

= 350mA

= 350mA

1.6

1

resistance

R

LG-DN

Low Side MOSFET Driver Pull-down ON

VCC = 3.3V, I

= 350mA (sinking) 1

LGATE

resistance

OSCILLATOR

f

SW

D

MAX

Oscillator Frequency

3.0V ≤ VCC ≤ 5.5V, LM3743-300

3.0V ≤ VCC ≤ 5.5V, LM3743-1000

255 300 345

850 1000 1150

Max Duty Cycle fSW = 300 kHz, LM3743-300 85 91

fSW = 1 MHz, LM3743-1000 69 76

V

RAMP

PWM Ramp Amplitude 1.0 V

V

mA

Ω

Ω

Ω

Ω

kHz

%

3 www.national.com

Page 4

Symbol Parameter Conditions Min Typ Max Units

LOGIC INPUTS AND OUTPUTS

LM3743

V

COMP/EN-HI

V

COMP/EN-LO

COMP/EN pin logic high trip-point 0.65 0.9 V

COMP/EN pin logic low trip-point 0.1 0.45 V

HICCUP MODE

N

LSCYCLES

Low-side sensing cycles before hiccup

15 Cycles

mode

N

LSRESET

Low-side sensing cycles reset without

32 Cycles

activating current limit

V

UVP

Under Voltage Protection comparator

400 mV

threshold

t

GLICH-UVP

Under Voltage Protection fault time before

7 µs

hiccup mode

t

HICCUP

t

SS

Hiccup timeout 5.5 ms

Soft-start time coming out of hiccup mode 3.6 ms

THERMAL RESISTANCE

θ

JA

Note 1: Absolute maximum ratings indicate limits beyond which damage to the device may occur. Operating ratings indicate conditions for which the device

operates correctly. Operating Ratings do not imply guaranteed performance limits.

Note 2: Practical lower limit of VCC depends on selection of the external MOSFET. See the MOSFET GATE DRIVERS section under Application Information for

further details.

Note 3: ESD using the human body model which is a 100 pF capacitor discharged through a 1.5 kΩ resistor into each pin. Test method is per JESD22–A114.

Junction to Ambient Thermal Resistance 235 °C/W

www.national.com 4

Page 5

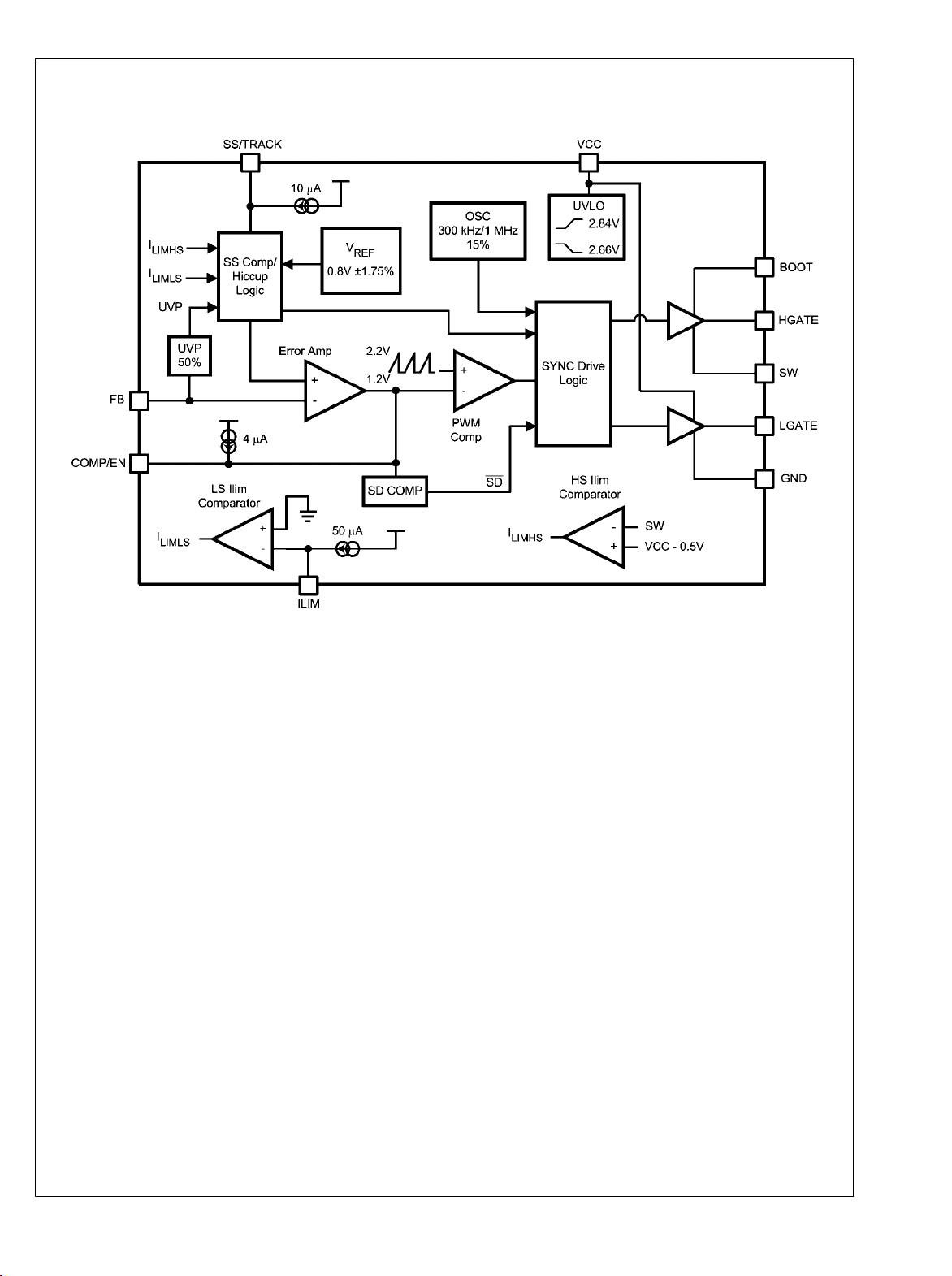

Block Diagram

LM3743

20177403

5 www.national.com

Page 6

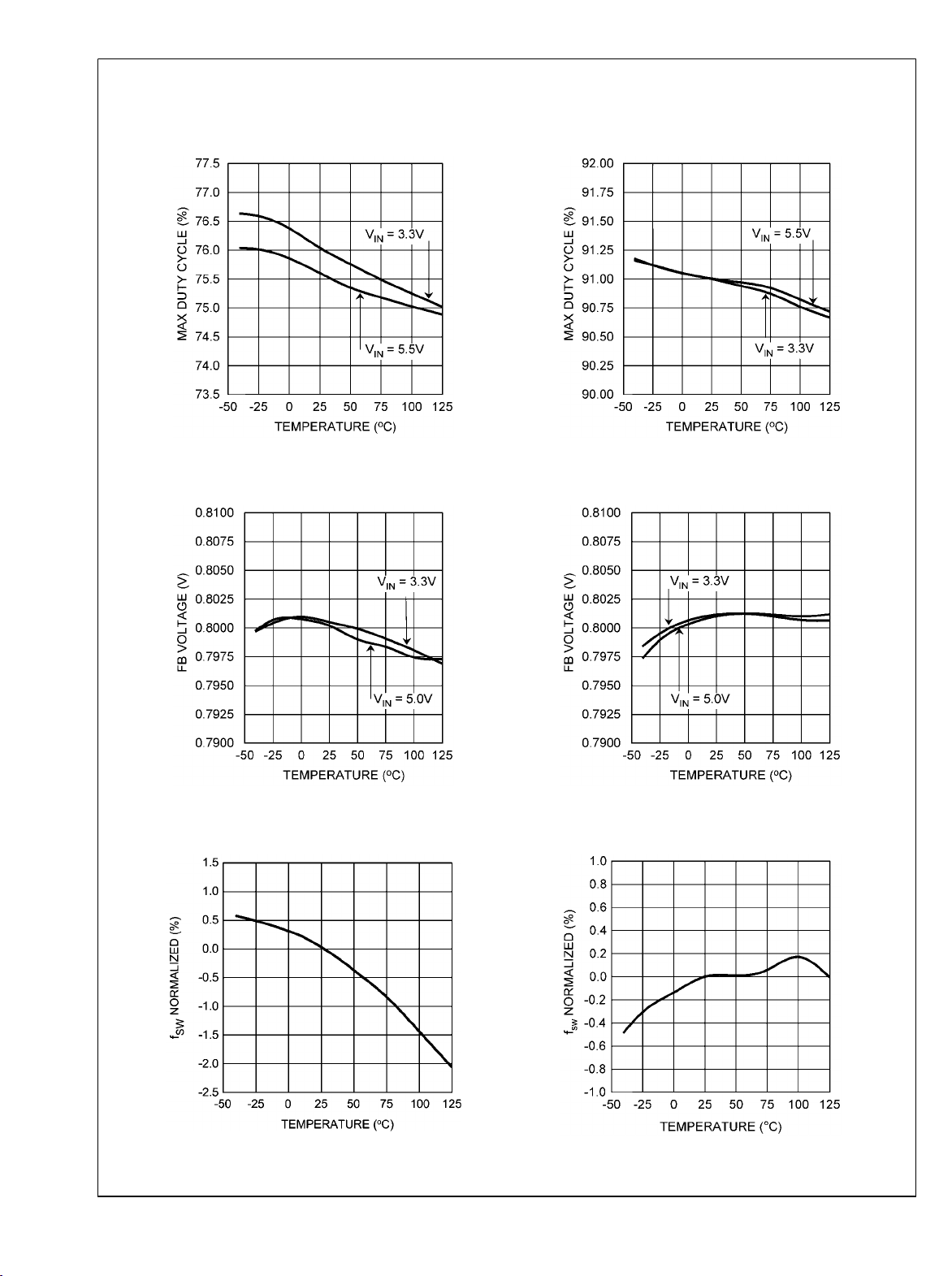

Typical Performance Characteristics V

= 3.3, TJ = 25°C, I

IN

= 1A unless otherwise specified.

LOAD

LM3743

D

vs Temperature

Max

fSW = 1 MHZ

FB vs Temperature

fSW = 1 MHZ

20177455

D

vs Temperature

Max

fSW = 300 kHz

FB vs Temperature

fSW = 300 kHz

20177456

20177457

Frequency vs Temperature

fSW = 1 MHz

20177459

www.national.com 6

20177458

Frequency vs Temperature

fSW = 300 kHz

201774a2

Page 7

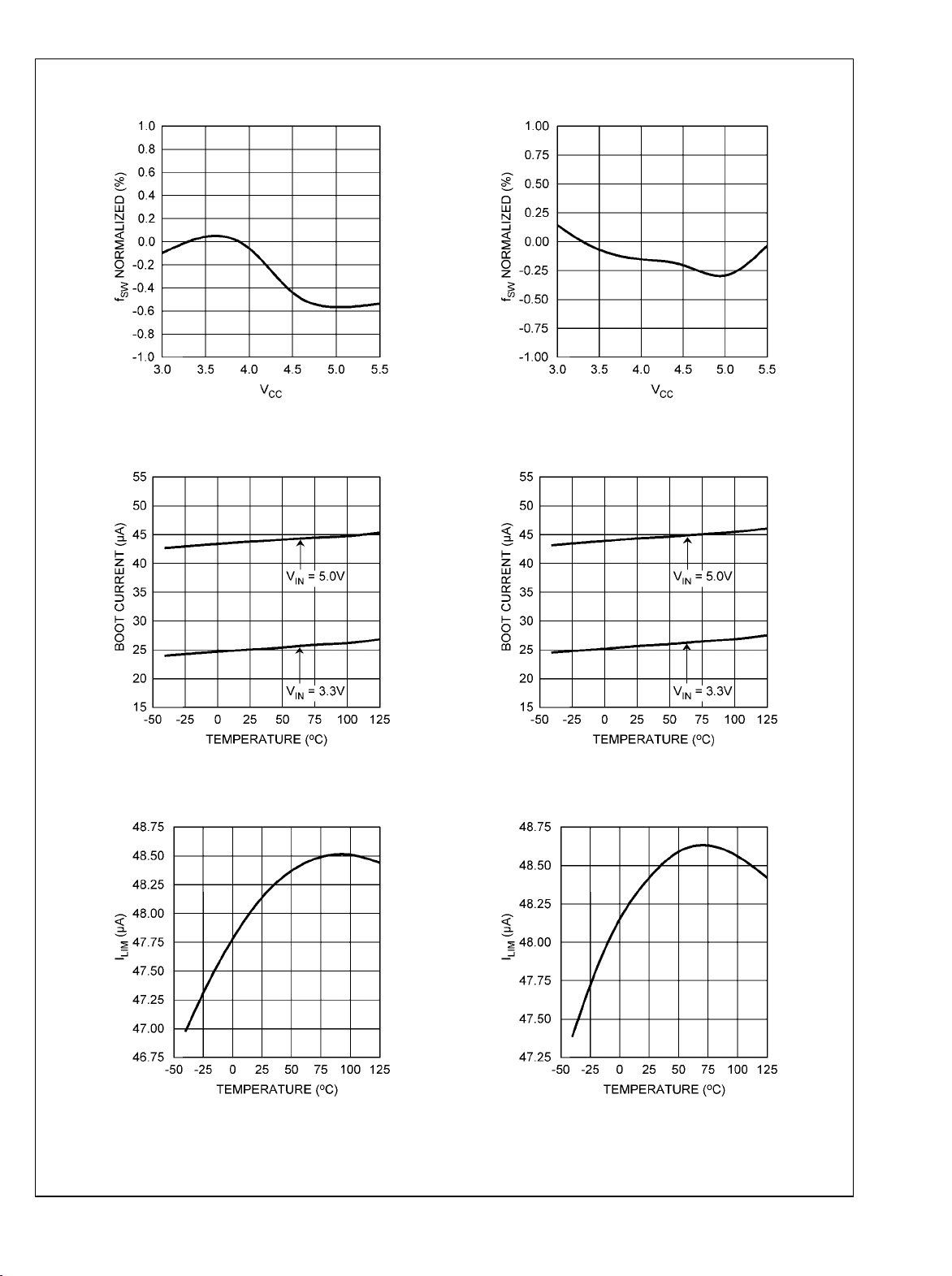

LM3743

Frequency vs V

fSW = 1 MHz

I

SHDN_BOOT

fSW = 1 MHz

CC

vs Temperature

20177461

Frequency vs V

fSW = 300 kHz

I

SHDN_BOOT

fSW = 300 kHz

CC

20177462

vs Temperature

I

vs Temperature

LIM

fSW = 1 MHz

20177463

20177465

20177464

I

vs Temperature

LIM

fSW = 300 kHz

20177466

7 www.national.com

Page 8

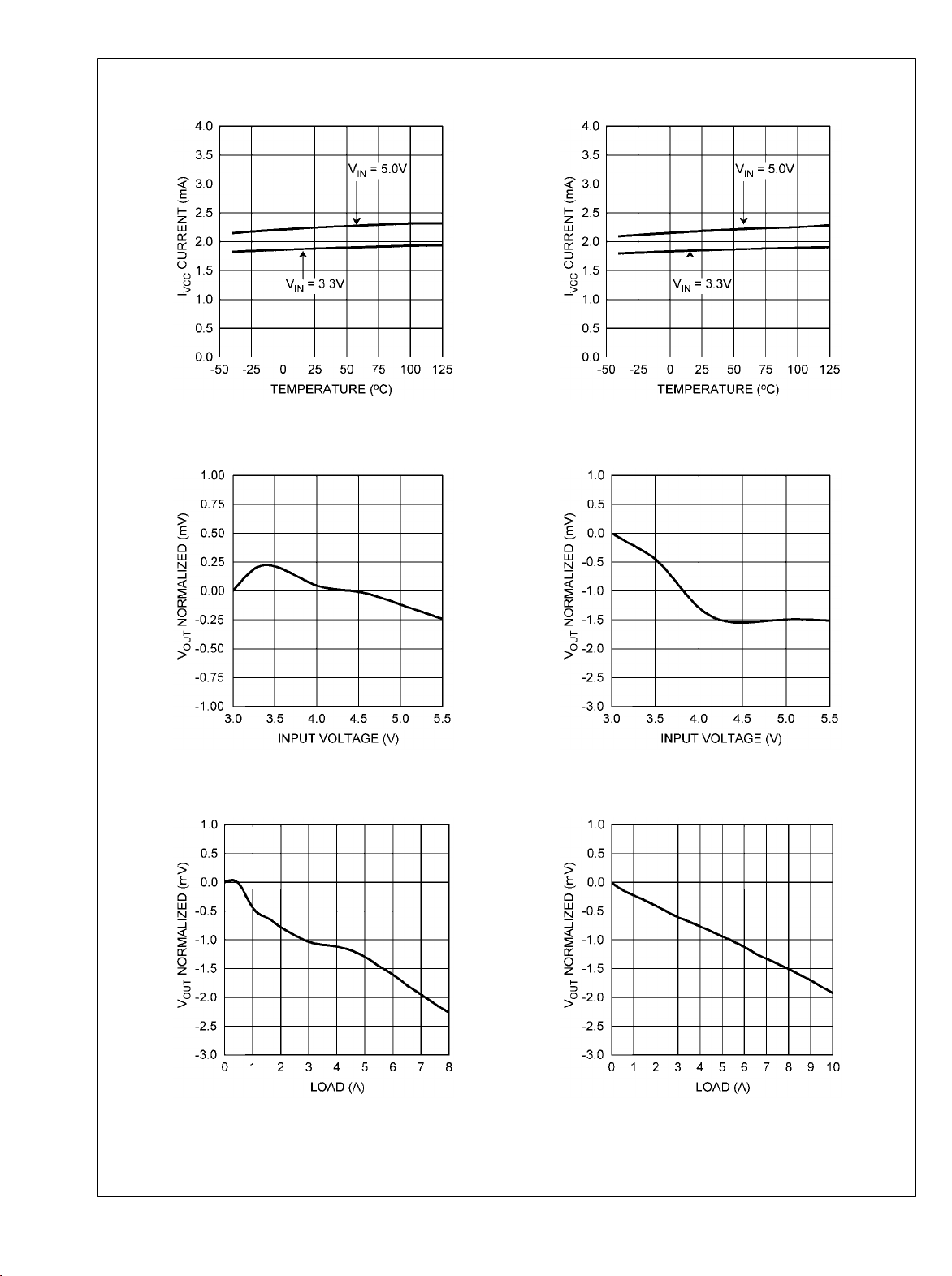

LM3743

I

vs Temperature

VCC

fSW = 1 MHz

I

vs Temperature

VCC

fSW = 300 kHz

V

= 1.2V, I

OUT

OUT

Load Regulation

VIN = 3.3V, fSW = 1 MHz

Line Regulation

= 1A, fSW = 300 kHz

20177467

20177469

V

= 1.5V, I

OUT

= 1A, fSW = 1 MHz

OUT

Load Regulation

VIN = 3.3V, fSW = 300 kHz

Line Regulation

20177468

20177470

20177471

www.national.com 8

20177472

Page 9

LM3743

Efficiency vs Load

fSW = 1 MHz, V

Efficiency vs Load

fSW = 1 MHz, V

OUT

OUT

= 2.5V

= 1.5V

20177489

Efficiency vs Load

fSW = 1 MHz, V

Efficiency vs Load

fSW = 1 MHz, V

OUT

OUT

= 1.8V

20177488

= 1.2V

Efficiency vs Load

fSW = 1 MHz, V

OUT

= 1.0V

20177487

20177473

20177474

Efficiency vs Load

fSW = 1 MHz, V

9 www.national.com

OUT

= 0.8V

20177490

Page 10

LM3743

Efficiency vs Load

fSW = 300 kHz, V

OUT

= 2.5V

Efficiency vs Load

fSW = 300 kHz, V

OUT

= 1.8V

Efficiency vs Load

fSW = 300 kHz, V

Efficiency vs Load

fSW = 300 kHz, V

OUT

OUT

= 1.5V

= 1.0V

20177495

20177493

Efficiency vs Load

fSW = 300 kHz, V

Efficiency vs Load

fSW = 300 kHz, V

OUT

OUT

20177494

= 1.2V

20177492

= 0.8V

20177491

www.national.com 10

20177496

Page 11

LM3743

fSW = 1 MHz, VIN = 3.3V, I

Load Transient Response

(Refer to AN-1450 for BOM)

Shutdown

R

= 1Ω, VIN = 5V

LOAD

= 100 mA to 3.5A

LOAD

20177497

fSW = 300 kHz, VIN = 3.3V, I

Load Transient Response

(Refer to AN-1450 for BOM)

Pre Bias Startup

= 100 mA to 3.5A

LOAD

20177498

20177499

Application Information

THEORY OF OPERATION

The LM3743 is a voltage mode PWM buck controller featuring

synchronous rectification at 300 kHz or 1 MHz. In steady state

operation the LM3743 is always synchronous even at no load,

thus simplifying the compensation design. The LM3743 ensures a smooth and controlled start-up to support pre-biased

outputs. Two levels of current limit protection enhance the robustness of the power supply and requires no current sense

resistor in the power path. The primary level of protection is

the low side current limit and is achieved by sensing the voltage VDS across the low side MOSFET. The second level of

protection is the high side current limit, which protects power

components from extremely high currents, caused by switch

node short to ground.

NORMAL OPERATION

While in normal operation, the LM3743 IC controls the output

voltage by controlling the duty cycle of the power FETs. The

DC level of the output voltage is determined by a pair of feedback resistors using the following equation:

201774a0

(Designators refer to the Typical Application Circuit in the front

page)

For synchronous buck regulators, the duty ratio D is approximately equal to:

START UP

The LM3743 IC begins to operate when the COMP/EN pin is

released from a clamped condition and the voltage at the

VCC pin has exceeded 2.84V. Once these two conditions have

been met the internal 10µA current source begins to charge

the soft-start capacitor connected at the SS/TRACK pin. During soft-start the voltage on the soft-start capacitor is connected internally to the non-inverting input of the error

amplifier. The soft-start period lasts until the voltage on the

soft-start capacitor exceeds the LM3743 reference voltage of

0.8V. At this point the reference voltage takes over at the noninverting error amplifier input. The capacitance determines

the length of the soft-start period, and can be approximated

by:

C4 = (tSS x 10 µA) / 0.8V

11 www.national.com

Page 12

Where tSS is the desired soft-start time. In the event of either

VCC falling below UVLO or COMP/EN pin being pulled below

0.45V, the soft-start pin will discharge C4 to allow the output

LM3743

voltage to recover smoothly.

START UP WITH PRE-BIAS

A pre-bias output is a condition in which current from another

source has charged up the output capacitor of the switching

regulator before it has been turned on. The LM3743 features

a proprietary glitch free monotonic pre-bias start-up method

designed to ramp the output voltage from a pre-biased rail to

the target nominal output voltage. The IC limits the on time of

the low-side FET to 150 ns (typ) during soft-start, while allowing the high-side FET to adjust it's time according to softstart voltage, V

commutation of the load current is carried by the body diode

, and the internal voltage ramp. Any further

OUT

of the low-side FET or an external Schottky diode, if used. The

low side current limit is active during soft-start while allowing

the asynchronous switching. When soft-start is completed,

the on-time of the low-side FET is allowed to increase in a

controlled fashion up to the steady state duty cycle determined by the control loop. A plot of the LM3743 starting up

into a pre-biased condition is shown in the Typical Performance Characteristics section.

Note that the pre-bias voltage must not be greater than the

target output voltage of the LM3743, otherwise the LM3743

will pull the pre-bias supply down during steady state operation.

governing the values of the tracking divider resistors RT1 and

RT2 is:

The top resistance RT2 must be set to 1 kΩ in order to limit

current into the LM3743 during UVLO or shutdown. The final

voltage of the SS/TRACK pin should be slightly higher than

the feedback voltage of 0.8V, say about 0.85V as in the above

equation. The 50 mV difference will ensure the LM3743 to

reach regulation slightly before the master supply. If the master supply voltage was 5V and the LM3743 output voltage was

1.8V, for example, then the value of RT1 needed to give the

two supplies identical soft-start times would be 205Ω. A timing

diagram for the equal soft-start time case is shown in Figure

2.

TRACKING WITH EQUAL SOFT-START TIME

The LM3743 can track the output of a master power supply

during soft-start by connecting a resistor divider to the SS/

TRACK pin. In this way, the output voltage slew rate of the

LM3743 will be controlled by the master supply for loads that

require precise sequencing. When the tracking function is

used, no soft-start capacitor should be connected to the SS/

TRACK pin. However in all other cases, a capacitor value (C4)

of at least 560 pF should be connected between the soft-start

pin and ground.

20177430

20177431

FIGURE 2. Tracking with Equal Soft-Start Time

TRACKING WITH EQUAL SLEW RATES

The tracking feature can alternatively be used not to make

both rails reach regulation at the same time but rather to have

similar rise rates (in terms of output dV/dt). In this case, the

tracking resistors can be determined based on the following

equation:

For the example case of V

RT2 set to 1 kΩ as before, RT1 is calculated from the above

= 5V and V

OUT1

= 1.8V, with

OUT2

equation to be 887Ω. A timing diagram for the case of equal

slew rates is shown in Figure 3.

FIGURE 1. Tracking Circuit

One way to use the tracking feature is to design the tracking

resistor divider so that the master supply’s output voltage

(V

) and the LM3743’s output voltage (represented sym-

OUT1

bolically in Figure 1 as V

the power components) both rise together and reach their

, i.e. without explicitly showing

OUT2

target values at the same time. For this case, the equation

www.national.com 12

Page 13

20177433

FIGURE 3. Tracking with Equal Slew Rate

TRACKING AND SHUTDOWN SEQUENCING

LM3743 is designed to track the output of a master power

supply during start-up, but when the master supply powers

down the output capacitor of the LM3743 will discharge cycle

by cycle through the low-side FET. The off-time will reach

100% when the voltage at the track pin reaches zero volts.

This condition will persist as long as the master output voltage

is zero volts and the drivers of the LM3743 are still on. For

example if the load is required to not be discharged, the

drivers must be shut-off before the master powers down. This

is achieved by shutting down the LM3743 or bring VCC below

UVLO falling threshold. In this case the load will not be discharged.

SHUTDOWN

The LM3743 IC can be put into shutdown mode by bringing

the voltage at the COMP/EN pin below 0.45V (typ). The quiescent current during shutdown is approximately 6 µA (typ).

During shutdown both the high-side and low-side FETs are

disabled. The soft-start capacitor is discharged through an

internal FET so that the output voltage rises in a controlled

fashion when the part is enabled again. When enabled a 4 µA

pull-up current increases the charge of the compensation capacitors.

UNDER VOLTAGE LOCK-OUT (UVLO)

If VCC drops below 2.66V (typ), the chip enters UVLO mode.

UVLO consists of turning off the top and bottom FETs and

remaining in that condition until VCC rises above 2.84V (typ).

As with shutdown, the soft-start capacitor is discharged

through an internal FET, ensuring that the next start-up will

be controlled by the soft-start circuitry.

MOSFET GATE DRIVE

The LM3743 has two gate drivers designed for driving Nchannel MOSFETs in synchronous mode. Power for the high

gate driver is supplied through the BOOT pin, while driving

power for the low gate is provided through the VCC pin. The

BOOT voltage is supplied from a local charge pump structure

which consists of a Schottky diode and 0.1 µF capacitor,

shown in Figure 4. Since the bootstrap capacitor (C10) is

connected to the SW node, the peak voltage impressed on

the BOOT pin is the sum of the input voltage (VIN) plus the

voltage across the bootstrap capacitor (ignoring any forward

drop across the bootstrap diode). The bootstrap capacitor is

charged up by VIN (called V

MOSFET turns off.

here) whenever the upper

BOOT_DC

20177434

FIGURE 4. Charge Pump Circuit and Driver Circuitry

The output of the low-side driver swings between VCC and

ground, whereas the output of the high-side driver swings between VIN + V

FET fully on, the Gate pin voltage of the MOSFET must be

and VIN. To keep the high-side MOS-

BOOT_DC

higher than its instantaneous Source pin voltage by an

amount equal to the 'Miller plateau'. It can be shown that this

plateau is equal to the threshold voltage of the chosen MOSFET plus a small amount equal to I

maximum load current of the application, and g is the

/g. Here I

OUT

OUT

is the

transconductance of this MOSFET (typically about 100 for

logic-level devices). That means we must choose V

to at least exceed the Miller plateau level. This may therefore

BOOT_DC

affect the choice of the threshold voltage of the external MOSFETs, and that in turn may depend on the chosen VIN rail.

So far in the discussion above, the forward drop across the

bootstrap diode has been ignored. But since that does affect

the output of the driver, it is a good idea to include this drop

in the following examples. Looking at the Typical Application

schematic, this means that the difference voltage VIN - VD1,

which is the voltage the bootstrap capacitor charges up to,

must always be greater than the maximum tolerance limit of

the threshold voltage of the upper MOSFET. Here VD1 is the

forward voltage drop across the bootstrap diode D1. This

voltage drop may place restrictions on the type of MOSFET

selected.

The capacitor C10 serves to maintain enough voltage between the top MOSFET gate and source to control the device

even when the top MOSFET is on and its source has risen up

to the input voltage level. The charge pump circuitry is fed

from VIN, which can operate over a range from 3.0V to 5.5V.

Using this basic method the voltage applied to the high side

gate VIN - VD1. This method works well when VIN is 5V±10%,

because the gate drives will get at least 4.0V of drive voltage

during the worst case of V

Logic level MOSFETs generally specify their on-resistance at

= 4.5V and V

IN-MIN

D1-MAX

= 0.5V.

VGS = 4.5V. When VCC = 3.3V±10%, the gate drive at worst

case could go as low as 2.5V. Logic level MOSFETs are not

guaranteed to turn on, or may have much higher on-resistance at 2.5V. Sub-logic level MOSFETs, usually specified at

VGS = 2.5V, will work, but are more expensive and tend to

have higher on-resistance.

LM3743

13 www.national.com

Page 14

LOW-SIDE CURRENT LIMIT

The main current limit of the LM3743 is realized by sensing

LM3743

the voltage drop across the low-side FET as the load current

passes through it. The R

ue; hence the voltage across the MOSFET can be determined

of the MOSFET is a known val-

DSON

as:

VDS = I

OUT

x R

DSON

The current flowing through the low-side MOSFET while it is

on is the falling portion of the inductor current. The current

limit threshold is determined by an external resistor, R1, connected between the switching node and the ILIM pin. A constant current (I

causing a fixed voltage drop. This fixed voltage is compared

) of 50 µA typical is forced through R1,

ILIM

against VDS and if the latter is higher, the current limit of the

chip has been reached. To obtain a more accurate value for

R1 you must consider the operating values of R

I

at their operating temperatures in your application and

ILIM

the effect of slight parameter variations from part to part. R1

can be found by using the following equation using the

R

value of the low side MOSFET at it's expected hot

DSON

temperature and the absolute minimum value expected over

the full temperature range for the I

which is 42.5 µA:

ILIM

R1 = R

DSON-HOT

x I

CLIM

/ I

ILIM

For example, a conservative 15A current limit (I

design with a R

resistor. The LM3743 enters current limit mode if the inductor

DSON-HOT

of 10 mΩ would require a 3.83 kΩ

current exceeds the set current limit threshold. The inductor

current is first sampled 50 ns after the low-side MOSFET turns

on. Note that in normal operation mode the high-side MOSFET always turns on at the beginning of a clock cycle. In

current limit mode, by contrast, the high-side MOSFET onpulse is skipped. This causes inductor current to fall. Unlike

a normal operation switching cycle, however, in a current limit

mode switching cycle the high-side MOSFET will turn on as

soon as inductor current has fallen to the current limit threshold.

CLIM

and

DSON

) in a 10A

normally well defined, but the peaks are variable, according

to the duty cycle, see Figure 5. The PWM error amplifier and

comparator control the pulse of the high-side MOSFET, even

during current limit mode, meaning that peak inductor current

can exceed the current limit threshold. For example, during

an output short-circuit to ground, and assuming that the output inductor does not saturate, the maximum peak inductor

current during current limit mode can be calculated with the

following equation:

Where TSW is the inverse of switching frequency fSW. The 200

ns term represents the minimum off-time of the duty cycle,

which ensures enough time for correct operation of the current sensing circuitry.

In order to minimize the temperature effects of the peak inductor currents, the IC enters hiccup mode after 15 over

current events, or a long current limit event that lasts 15

switching cycles (the counter is reset when 32 non-current

limit cycles occur in between two current limit events). Hiccup

mode will be discussed in further detail in the “Hiccup Mode

and Internal Soft-Start” section.

HIGH-SIDE COARSE CURRENT LIMIT

The LM3743 employs a comparator to monitor the voltage

across the high-side MOSFET when it is on. This provides

protection for short circuits from switch node to ground or the

case when the inductor is shorted, which the low side current

limit cannot detect. A 200 ns blanking time period after the

high-side FET turns on is used to prevent switching transient

voltages from tripping the high-side current limit without

cause. If the difference between VCC pin and SW pin voltage

exceeds 500 mV, the LM3743 will immediately enter hiccup

mode (see Hiccup Mode section).

OUTPUT UNDER-VOLTAGE PROTECTION (UVP)

After the end of soft-start the output UVP comparator is activated. The threshold is 50% of the feedback voltage. Once

the comparator indicates UVP for more than 7 µs typ. (glitch

filter time), the IC goes into hiccup mode.

20177444

FIGURE 5. Current Limit Threshold

The low-side current sensing scheme can only limit the current during the converter off-time, when inductor current is

falling. Therefore in a typical current limit plot the valleys are

www.national.com 14

HICCUP MODE AND INTERNAL SOFT-START

Hiccup protection mode is designed to protect the external

components of the circuit (output inductor, FETs, and input

voltage source) from thermal stress. During hiccup mode, the

LM3743 disables both the high-side and low-side FETs and

begins a cool down period of 5.5 ms. At the conclusion of this

cool down period, the regulator performs an internal 3.6 ms

soft-start. There are three distinct conditions under which the

IC will enter the hiccup protection mode:

1.

The low-side current sensing threshold has exceeded

the current limit threshold for fifteen sampled cycles, see

Figure 6. Each cycle is sampled at the start of each off

time (t

when 32 consecutive non-current limit cycles occur in

). The low-side current limit counter is reset

OFF

between two current limit events.

2.

The high-side current limit comparator has sensed a

differential voltage larger than 500 mV.

3.

The voltage at the FB pin has fallen below 0.4V, and the

UVP comparator has sensed this condition for 7 μs

(during steady state operation).

The band gap reference, the external soft-start, and internal

hiccup soft-start of 3.6 ms (typ) connect to the non-inverting

Page 15

LM3743

input of the error amplifier through a multiplexer. The lowest

voltage of the three connects directly to the non-inverting input. Hiccup mode will not discharge the external soft-start,

only UVLO or shut-down will. When in hiccup mode the internal 5.5 ms timer is set, and the internal soft-start capacitor is

discharged. After the 5.5 ms timeout, the internal 3.6 ms softstart begins, see Figure 7. During soft-start, only low-side

current limit and high side current limit can put the LM3743

into hiccup mode.

20177452

FIGURE 6. Entering Hiccup Mode

DESIGN CONSIDERATIONS

The following is a design procedure for selecting all the components in the Typical Application circuit on the front page.

This design converts 5V (VIN) to 1.8V (V

load of 10A with an efficiency of 90% and a switching fre-

) at a maximum

OUT

quency of 300 kHz. The same procedures can be followed to

create many other designs with varying input voltages, output

voltages, load currents, and switching frequency.

Switching Frequency

Selection of the operating switching frequency is based on

trade-offs between size, cost, efficiency, and response time.

For example, a lower frequency will require larger more expensive inductors and capacitors. While a higher switching

frequency will generally reduce the size of these components,

but will have a reduction in efficiency. Fast switching converters allow for higher loop gain bandwidths, which in turn have

the ability to respond quickly to load and line transients. For

the example application we have chosen a 300 kHz switching

frequency because it will reduce the switching power losses

and in turn allow for higher conduction losses considering the

same power loss criteria, thus it is possible to sustain a higher

load current.

Output Inductor

The output inductor is responsible for smoothing the square

wave created by the switching action and for controlling the

output current ripple (ΔI

the inductor current. The DC current into the load is equal to

) also called the AC component of

OUT

the average current flowing in the inductor. The inductance is

chosen by selecting between trade-offs in efficiency, size, and

response time. The recommended percentage of AC component to DC current is 30% to 40%, this will provide the best

trade-off between energy requirements and size, (read

AN-1197 for theoretical analysis). Another criteria is the ability

to respond to large load transient responses; the smaller the

output inductor, the more quickly the converter can respond.

The equation for output inductor selection is:

20177406

FIGURE 7. Hiccup Time-Out and Internal Soft-Start

For example, if the low-side current limit is 10A, then once in

overload the low-side current limit controls the valley current

and only allows an average amount of 10A plus the ripple

current to pass through the inductor and FETs for 15 switching

cycles. In such an amount of time, the temperature rise is very

small. Once in hiccup mode, the average current through the

high-side FET is:

I

= (I

HSF-AVE

+ ΔI) x [ D(15 cycles x TSW) ] / 5.5 ms

CLIM

equals 71 mA. With an arbitrary D = 60%, ripple current of 3A,

and a 300 kHz switching frequency.

The average current through the low-side FET is:

I

= (I

LSF-AVE

+ ΔI) x [ (1–D) x (15 cycles x TSW) ] / 5.5 ms

CLIM

equals 47 mA,

And the average current through the inductor is:

I

= (I

L-AVE

+ ΔI) x [ (15 cycles x TSW) ] / 5.5 ms

CLIM

equals 118 mA.

Here we have plugged in the values for input voltage, output

voltage, switching frequency, and 30% of the maximum load

current. This yields an inductance of 1.34 µH. The output inductor must be rated to handle the peak current (also equal

to the peak switch current), which is (I

11.5A, for a 10A design and a AC current of 3A.

+ (0.5 x ΔI

OUT

OUT

)) =

The Coiltronics DR125–1R5 is 1.5 µH, is rated to 13.8A RMS

current, and has a direct current resistance (DCR) of 3 mΩ.

After selecting the Coiltronics DR125–1R5 for the output inductor, actual inductor current ripple must be re-calculated

with the selected inductance value. This information is needed to determine the RMS current through the input and output

capacitors. Re-arranging the equation used to select inductance yields the following:

15 www.national.com

Page 16

LM3743

V

is assumed to be 10% above the steady state input

IN(MAX)

voltage, or 5.5V at VIN = 5.0V. The re-calculated current ripple

will then be 2.69A. This gives a peak inductor/switch current

will be 11.35A.

Output Capacitor

The output capacitor in a switching regulator is selected on

the basis of capacitance, equivalent series resistance (ESR),

size, and cost. In this example the output current is 10A and

the expected type of capacitor is an aluminum electrolytic, as

with the input capacitors. An important specification in switching converters is the output voltage ripple ΔV

the impedance of most capacitors is very small compared to

ESR, hence ESR becomes the main selection criteria. In this

design the load requires a 2% ripple , which results in a

ΔV

of 36 mV

OUT

ESR

(Ta), solid aluminum, organic, and niobium (Nb) capacitors

is 13 mΩ. Aluminum electrolytic (Al-E), tantalum

MAX

. Thus the maximum ESR is then:

P-P

are all popular in switching converters. In general, by the time

enough capacitors have been paralleled to obtain the desired

ESR, the bulk capacitance is more than enough to supply the

load current during a transient from no-load to full load. The

number and type of capacitors used depends mainly on their

size and cost. One exception to this is multi-layer ceramic capacitors. MLCCs have very low ESR, but also low capacitance in comparison with other types. This makes them

attractive for lower power designs. For higher power or for fast

load transients the number of MLCCs needed often increases

the size and cost to unacceptable levels. Because the load

could transition quickly from 0 to 10A, more bulk capacitance

is needed than the MLCCs can provide. One compromise is

a solid electrolytic POSCAP from Sanyo or SP-caps from

Panasonic. POSCAP and SPcaps often have large capacitances needed to supply currents for load transients, and low

ESRs. The 6TPD470M by Sanyo has 470 µF, and a maximum

ESR of 10 mΩ. Solid electrolytics have stable ESR relative to

temperature, and capacitance change is relatively immune to

bias voltage. Tantalums (Ta), niobium (Nb), and Al-E are

good solutions for ambient operating temperatures above 0°

C, however their ESR tends to increase quickly below 0°C

ambient operating temperature, so these capacitor types are

not recommended for this area of operation.

Input Capacitor

The input capacitors in a buck converter are subjected to high

RMS current stress. Input capacitors are selected for their

ability to withstand the heat generated by the RMS current

and the ESR as specified by the manufacturer. Input RMS

ripple current is approximately:

Where duty cycle D = V

buck converter occurs during full load and when the duty cycle

. The worst-case ripple for a

OUT/VIN

(D) is 0.5.

OUT

. At 300 kHz

When multiple capacitors of the same type and value are paralleled, the power dissipated by each input capacitor is:

where n is the number of paralleled capacitors, and ESR is

the equivalent series resistance of each capacitor. The equation above indicates that power loss in each capacitor decreases rapidly as the number of input capacitors increases.

For this 5V to 1.8V design the duty cycle is 0.36. For a 10A

maximum load the RMS current is 4.8A.

Connect one or two 22 µF MLCC as close as possible across

the drain of the high-side MOSFET and the source of the lowside MOSFET, this will provide high frequency decoupling

and satisfy the RMS stress. A bulk capacitor is recommended

in parallel with the MLCC in order to prevent switching frequency noise from reflecting back into the input line, this

capacitor should be no more than 1inch away from the MLCC

capacitors.

MOSFETs

Selection of the power MOSFETs is governed by a trade-off

between cost, size, and efficiency. One method is to determine the maximum cost that can be endured, and then select

the most efficient device that fits that price. Using a spreadsheet to estimate the losses in the high-side and low-side

MOSFETs is one way to determine relative efficiencies between different MOSFETs. Good correlation between the

prediction and the bench result is not guaranteed.

Losses in the high-side MOSFET can be broken down into

conduction loss, gate charging loss, and switching loss. Conduction, or I2R loss, is approximately:

For the high side FET:

PC = D (I

OUT

x R

DSON-HI

x 1.3)

2

For the low side FET:

PC = (1 - D) x (I

OUT

x R

DSON-LO

x 1.3)

2

In the above equations the factor 1.3 accounts for the increase in MOSFET R

1.3 can be ignored and the R

using the R

manufacturer datasheet.

vs. Temperature curves in the MOSFET

DSON

due to heating. Alternatively, the

DSON

of the MOSFET estimated

DSON

Gate charging loss results from the current driving the gate

capacitance of the power MOSFETs, and is approximated as:

PGC = (VCC) x QG x f

SW

VCC is the driving voltage (see MOSFET Gate Driver section)

and QG is the gate charge of the MOSFET. If multiple devices

will be placed in parallel, their gate charges can simply be

summed to form a cumulative QG.

Switching loss occurs during the brief transition period as the

high-side MOSFET turns on and off, during which both current

and voltage are present in the channel of the MOSFET. It can

be approximated as:

PSW = 0.5 x VIN x I

x (tr + tf) x f

OUT

SW

where tr and tf are the rise and fall times of the MOSFET.

Switching loss occurs in the high-side MOSFET only.

For this example, the maximum drain-to-source voltage applied to either MOSFET is 5.5V. The maximum drive voltage

at the gate of the high-side MOSFET is 5.0V, and the maximum drive voltage for the low-side MOSFET is 5.5V. For

www.national.com 16

Page 17

designs between 5A and 10A, single MOSFETs in SO-8 provide a good trade-off between size, cost, and efficiency.

VCC Filtering

To ensure smooth DC voltage for the chip supply a 1 µF (C3),

X5R MLCC type or better must be placed as close as possible

to the VCC and GND pin. Together with a small 1 to 4.99Ω

resistor placed between the input rail and the VCC pin, a low

pass filter is formed to filter out high frequency noise from

injecting into the VCC rail. Since VCC is also the sense pin for

the high-side current limit, the resistor should connect close

to the drain of the high-side MOSFET to prevent IR drops due

to trace resistance. A second design consideration is the low

pass filter formed by C3 and R6 on the VCC pin, a fast slew

rate, large amplitude load transient may cause a larger voltage droop on CIN than on VCC pin. This may lead to a lower

current at which high-side protection may occur. Thus increase the bulk input capacitor if the high-side current limit is

engaging due to a dynamic load transient behavior as explained above.

Bootstrap Diode (D1)

The MBR0520 and BAT54 work well as a bootstrap diode in

most designs. Schottky diodes are the preferred choice for

the bootstrap circuit because of their low forward voltage

drop. For circuits that will operate at high ambient temperature

the Schottky diode datasheet must be read carefully to ensure

that the reverse current leakage at high temperature does not

increase enough to deplete the charge on the bootstrap capacitor while the high side FET is on. Some Schottky diodes

increase their reverse leakage by as much as 1000 times at

high temperatures. Fast rectifier and PN junction diodes

maintain low reverse leakage even at high ambient temperature. These diode types have higher forward voltage drop but

can still be used for high ambient temperature operation.

Control Loop Compensation

The LM3743 uses voltage-mode (‘VM’) PWM control to correct changes in output voltage due to line and load transients.

VM requires careful small signal compensation of the control

loop for achieving high bandwidth and good phase margin.

The control loop is comprised of two parts. The first is the

power stage, which consists of the duty cycle modulator, output inductor, output capacitor, and load. The second part is

the error amplifier, which for the LM3743 is a 30 MHz op-amp

used in the classic inverting configuration. Figure 8 shows the

regulator and control loop components.

20177413

FIGURE 8. Power Stage and Error Amp

One popular method for selecting the compensation components is to create Bode plots of gain and phase for the power

stage and error amplifier. Combined, they make the overall

bandwidth and phase margin of the regulator easy to see.

Software tools such as Excel, MathCAD, and Matlab are useful for showing how changes in compensation or the power

stage affect system gain and phase.

The power stage modulator provides a DC gain ADC that is

equal to the input voltage divided by the peak-to-peak value

of the PWM ramp. This ramp is 1.0V

inductor and output capacitor create a double pole at fre-

for the LM3743. The

pk-pk

quency fDP, and the capacitor ESR and capacitance create a

single zero at frequency f

5.0V, these quantities are:

. For this example, with VIN =

ESR

LM3743

In the equation for fDP, the variable RL is the power stage resistance, and represents the inductor DCR plus the on resistance of the top power MOSFET. RO is the output voltage

divided by output current. The power stage transfer function

GPS is given by the following equation, and Figure 9 shows

Bode plots of the phase and gain in this example.

a = LCO(RO + RC)

17 www.national.com

Page 18

b = L + CO(RORL + RORC + RCRL)

c = RO + R

LM3743

L

20177418

of the switching frequency, or 60 kHz for this example. The

generic equation for the error amplifier transfer function is:

In this equation the variable AEA is a ratio of the values of the

capacitance and resistance of the compensation components, arranged as shown in Figure 8. AEA is selected to

provide the desired bandwidth. A starting value of 80,000 for

AEA should give a conservative bandwidth. Increasing the

value will increase the bandwidth, but will also decrease

phase margin. Designs with 45-60° are usually best because

they represent a good trade-off between bandwidth and

phase margin. In general, phase margin is lowest and gain

highest (worst-case) for maximum input voltage and minimum

output current. One method to select AEA is to use an iterative

process beginning with these worst-case conditions.

1.

Increase A

2.

Check overall bandwidth and phase margin

3.

Change VIN to minimum and recheck overall bandwidth

EA

and phase margin

4.

Change IO to maximum and recheck overall bandwidth

and phase margin

The process ends when both bandwidth and phase margin

are sufficiently high. For this example input voltage can vary

from 4.5V to 5.5V and output current can vary from 0 to 10A,

and after a few iterations a moderate gain factor of 90 dB is

used.

The error amplifier of the LM3743 has a unity-gain bandwidth

of 30 MHz. In order to model the effect of this limitation, the

open-loop gain can be calculated as:

20177419

FIGURE 9. Power Stage Gain and Phase

The double pole at 6 kHz causes the phase to drop to approximately -140° at around 15 kHz. The ESR zero, at 33.9

kHz, provides a +90° boost that prevents the phase from

dropping to -180º. If this loop were left uncompensated, the

bandwidth would be approximately 15 kHz and the phase

margin 40°. In theory, the loop would be stable, but would

suffer from poor DC regulation (due to the low DC gain) and

would be slow to respond to load transients (due to the low

bandwidth.) In practice, the loop could easily become unstable due to tolerances in the output inductor, capacitor, or

changes in output current, or input voltage. Therefore, the

loop is compensated using the error amplifier and a few passive components.

For this example, a Type III, or three-pole-two-zero approach

gives optimal bandwidth and phase.

In most voltage mode compensation schemes, including

Type III, a single pole is placed at the origin to boost DC gain

as high as possible. Two zeroes fZ1 and fZ2 are placed at the

double pole frequency to cancel the double pole phase lag.

Then, a pole, fP1 is placed at the frequency of the ESR zero.

A final pole fP2 is placed at one-half of the switching frequency.

The gain of the error amplifier transfer function is selected to

give the best bandwidth possible without violating the Nyquist

stability criteria. In practice, a good crossover point is one-fifth

The new error amplifier transfer function that takes into account unity-gain bandwidth is:

The gain and phase of the error amplifier are shown in Figure

10.

www.national.com 18

Page 19

20177423

20177424

FIGURE 10. Error Amp. Gain and Phase

In VM regulators, the top feedback resistor R2 forms a part of

the compensation. Setting R2 to 10 kΩ±1%, usually gives

values for the other compensation resistors and capacitors

that fall within a reasonable range. (Capacitances > 1 pF, resistances <1 MΩ) C7, C8, C9, R4, and R5 are selected to

provide the poles and zeroes at the desired frequencies, using the following equations:

LM3743

In practice, a good trade off between phase margin and bandwidth can be obtained by selecting the closest ±10% capacitor values above what are suggested for C7 and C8, the

closest ±10% capacitor value below the suggestion for C9,

and the closest ±1% resistor values below the suggestions

for R4, R5. Note that if the suggested value for R5 is less than

100Ω, it should be replaced by a short circuit. Following this

guideline, the compensation components will be:

C7 = 47 pF±10%, C9 = 1.5 nF±10%

C8 = 2.2 nF±10%, R4 = 22.6 kΩ±1%

R5 = 2.1 kΩ±1%

The transfer function of the compensation block can be de-

rived by considering the compensation components as

impedance blocks ZF and ZI around an inverting op-amp:

As with the generic equation, G

take into account the limited bandwidth of the error amplifier.

EA-ACTUAL

must be modified to

The result is:

19 www.national.com

Page 20

The total control loop transfer function H is equal to the power

stage transfer function multiplied by the error amplifier transfer function.

LM3743

H = GPS x H

EA

The bandwidth and phase margin can be read graphically

from Bode plots of HEA as shown in Figure 11.

FIGURE 11. Overall Loop Gain and Phase

The bandwidth of this example circuit is 59 kHz, with a phase

margin of 60°.

EFFICIENCY CALCULATIONS

The following is a sample calculation.

A reasonable estimation of the efficiency of a switching buck

controller can be obtained by adding together the Output

Power (P

) loss and the Total Power loss (P

OUT

20177429

20177450

LOSS

FET Switching Loss (PSW)

PSW = P

PSW = 0.5 x VIN x I

SW(ON)

+ P

SW(OFF)

x (tr + tf) x f

OUT

SW

PSW = 0.5 x 5V x 10A x 300 kHz x 67 ns

PSW = 503 mW

The Si4866DY has a typical turn-on rise time tr and turn-off

fall time tf of 32 ns and 35 ns, respectively. The switching

losses for the upper FET (Q1) is 0.503W. The low side FET

(Q2) does not incur switching losses.

FET Conduction Loss (P

P

CND

P

= I

CND1

P

= I

CND2

R

= 4.5 mΩ and the k factor accounts for the increase

DS(ON)

in R

due to heating. k = 1.3 at TJ = 100°C

DS(ON)

P

= (10A)2 x 4.5 mΩ x 1.3 x 0.36

CND1

P

= (10A)2 x 4.5 mΩ x 1.3 x (1 - 0.36)

CND2

P

CND

P

= 211 mW + 374 mW = 585 mW

CND

FET Gate Charging Loss (P

P

= n x ( VCC - VD1 ) x QGS x f

GATE_H

P

GATE_L

P

= [ 1 x ( 5.0V - 0.4V ) x 22 nC x 300 kHz ] + [ 1 x ( 5.0V )

GATES

P

x 22 nC x 300 kHz ]

= 29 mW + 33 mW = 62 mW

GATES

)

CND

2

= P

2

OUT

= P

OUT

CND1

x R

x R

CND1

DS(ON)

GATE

+ P

CND2

DS(ON)

x k x (1-D)

+ P

CND2

)

x k x D

= n x VCC x QGS x f

SW

SW

The value n is the total number of FETs used and QGS is the

typical gate-source charge value, which is 21 nC. For the

Si4866DY the gate charging loss is 62 mW.

Thus the total MOSFET losses are:

P

= PSW + P

FET

CND

+ P

GATES

=

503 mW + 585 mW + 62 mW

P

= 1.15 W

FET

There are few additional losses that are taken into account:

IC Loss (PIC)

POP = I

PDR = [[ (n x QGS x fSW) / D] +[ (n x QGS x fSW) / (1–D) ]] x V

where POP is the operating loss, PDR is the driver loss, I

is the typical operating VCC current

VCC

Q_VCC

x V

CC

CC

Q-

POP= ( 1.3 mA x 5.0V )

PDR= [( 1 x 22 nC x 300 kHz ) / .36 ] + [( 1 x 22 nC x 300

kHz ) / .64 ] x V

):

PIC= POP + P

CC

DR

PIC= 6.5 mW + 137 mW = 143.5 mW

Input Capacitor Loss (P

CAP

)

The Output Power (P

design is (1.8V x 10A) = 18W. The Total Power (P

an efficiency calculation to complement the design, is shown

) for the Typical Application Circuit

OUT

LOSS

), with

below.

The majority of the power losses are due to the low side and

high side MOSFET’s losses. The losses in any MOSFET are

switching (PSW), conduction losses (P

losses (P

www.national.com 20

GATE

)

), and gate charging

CND

where,

Page 21

LM3743

Here n is the number of paralleled capacitors, ESR is the

equivalent series resistance of each, and P

tion in each. So for example if we use only one input capacitor

is the dissipa-

CAP

of 10mΩ.

P

= 230 mW

CAP

Output Inductor Loss (P

P

IND

IND

= I

2

)

OUT

x DCR

where DCR is the DC resistance. Therefore, for example

P

= (10A)2 x 3 mΩ

IND

P

= 302 mW

IND

Total System Efficiency

P

= P

LOSS

+ PIC + P

FET

CAP

+ P

IND

PCB LAYOUT CONSIDERATIONS

To produce an optimal power solution with the LM3743, good

layout and design of the PCB are as important as component

selection. The following are several guidelines to aid in creating a good layout. For an extensive PCB layout explanation

refer to AN-1229.

Separate Power Ground and Signal Ground

Good layout techniques include a dedicated ground plane,

preferably on an internal layer. Signal level components like

the compensation and feedback resistors should be connected to a section of this internal plane, signal ground. The signal

ground section of the plane should be connected to the power

ground at a single point. The best place to connect the signal

ground and power ground is right at the GND pin of the IC.

Low Impedance Power Path

The power path includes the input capacitors, power FETs,

output inductor, and output capacitors. Keep these components on the same side of the PCB and connect them with

thick traces or copper planes on the same layer. Vias add

resistance and inductance to the power path, and have high

impedance connections to internal planes than do top or bottom layers of a PCB. If heavy switching currents must be

routed through vias and/or internal planes, use multiple vias

in parallel to reduce their resistance and inductance. The

power components must be kept close together. The longer

the paths that connect them, the more they act as antennas,

radiating unwanted EMI.

Minimize the Switch Node Copper

The plane that connects the power FETs and output inductor

together radiates more EMI as it gets larger. Use just enough

copper to give low impedance to the switching currents.

Kelvin Traces For Sense Lines

The drain and the source of the high-side FET should be connected as close as possible to the VCC filter resistor (R6) and

the SW pin and each pin should connect with a separate trace.

The feedback trace should connect the positive node of the

output capacitor and connect to the top feedback resistor

(R2). Keep this trace away from the switch node and from the

output inductor. If driving the COMP pin low with a signal BJT

or MOSFET make sure to keep the signal transistor as close

as possible to the pin and keep the trace away from EMI radiating nodes and components.

21 www.national.com

Page 22

Physical Dimensions inches (millimeters) unless otherwise noted

LM3743

MSOP-10 Pin Package

NS Package Number MUB10A

www.national.com 22

Page 23

Notes

LM3743

23 www.national.com

Page 24

Notes

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

LM3743 N-Channel FET Synchronous Buck Controller for Low Output Voltages

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2007 National Semiconductor Corporation

For the most current product information visit us at www.national.com

www.national.com

National Semiconductor

Americas Customer

Support Center

Email:

new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Customer Support Center

Fax: +49 (0) 180-530-85-86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +49 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor Asia

Pacific Customer Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...