Page 1

July 2007

LM3668

1A, High Efficiency Dual Mode Single Inductor Buck-Boost

DC/DC Converter

General Description

The LM3668 is a synchornous buck-boost DC-DC converter

optimized for powering low voltage circuits from a Li-Ion battery and input voltage rails between 2.5V and 5.5V. It has the

capability to support up to 1A output current over a output

voltage range of 2.8V/3.3V. The LM3668 regulates the output

voltage over the complete input voltage range by automatically switching between buck or boost modes depending on

the input voltage.

The LM3668 has 2 N-channel MOSFETS and 2 P-channel

MOSFETS arranged in a topology that provides continuous

operation through the buck and boost operating modes.

There is a MODE pin that allows the user to choose between

an intelligent automatic PFM-PWM mode operation and

forced PWM operation. During PWM mode, a fixed-frequency

2.2MHz (typ.) is used. PWM mode drives load up to 1A. Hysteretic PFM mode extends the battery life through reduction

of the quiescent current to 45µA (typ.) at light loads during

system standby. Internal synchronous rectification provides

high efficiency. In shutdown mode (Enable pin pulled low) the

device turns off and reduces battery consumption to 0.01µA

(typ.).

The LM3668 is available in a 12-pin LLP package. A high

switching frequency of 2.2MHz (typ.) allows the use of tiny

surface-mount components including a 2.2µH inductor, a

10µF input capacitor, and a 22µF output capacitor.

Features

■

45µA typical quiescent current

■

1A maximum load current for VIN = 2.8V to 5.5V

■

800mA maximum load current for VIN = 2.7V

■

600mA maximum load current for VIN = 2.5V

■

2.2 MHz PWM fixed switching frequency (typ.)

■

Automatic PFM-PWM Mode or Forced PWM Mode

■

Wide Input Voltage Range: 2.5V to 5.5V

■

Output Voltage Range: 2.8V/3.3V

■

Internal synchronous rectification for high efficiency

■

Internal soft start: 600µs Maximum start-up time

■

0.01µA typical shutdown current

■

Current overload and Thermal shutdown protection

■

Frequency Sync Pin: 1.6Mhz to 2.7MHz

Applications

■

Handset Peripherals

■

MP3 players

■

Pre-Regulation for linear regulators

■

PDAs

■

Portable Hard Disk Drives

■

WiMax Modems

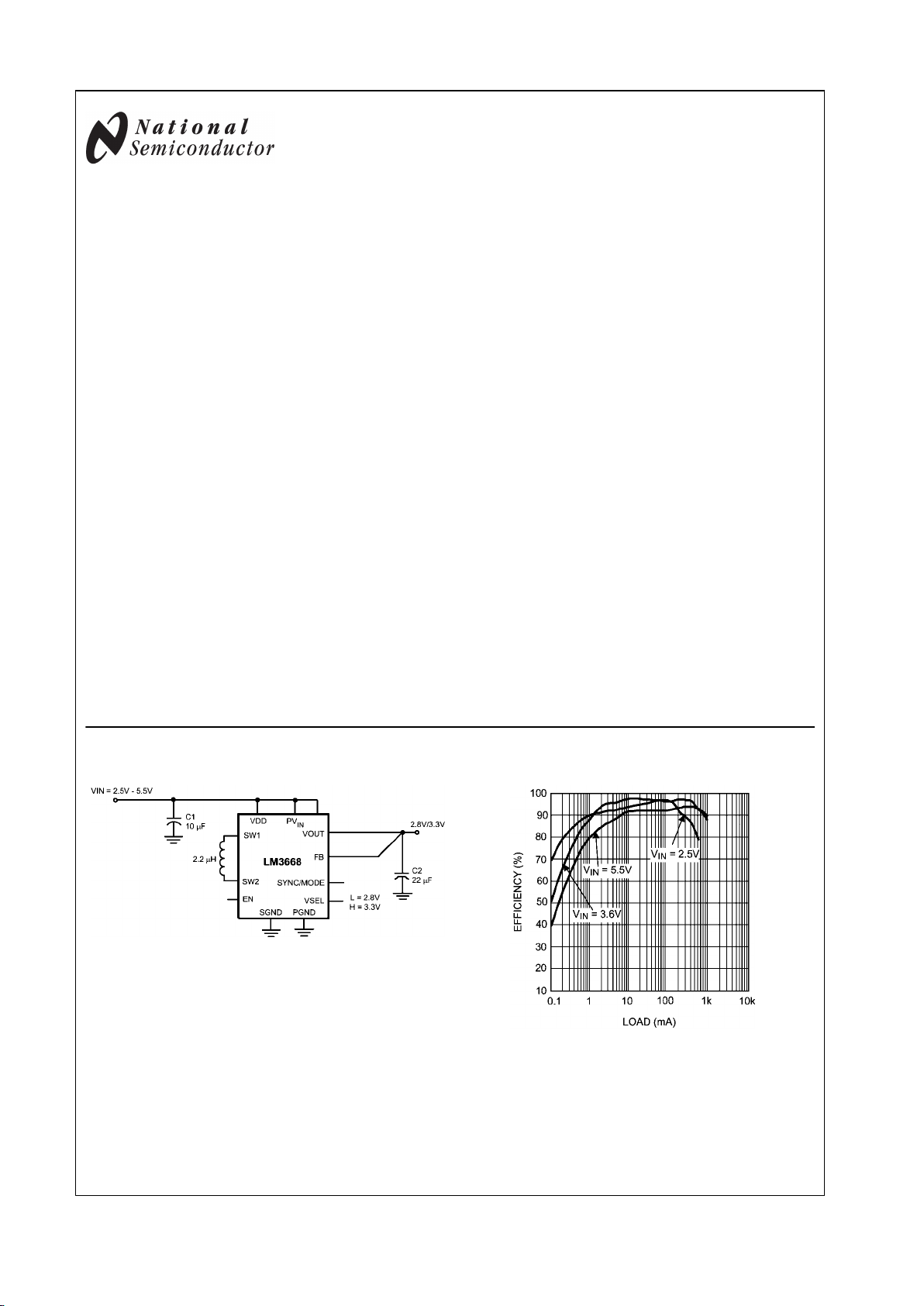

Typical Applications

20191401

Typical Application Circuit

20191425

Efficiency at 3.3V Output

© 2007 National Semiconductor Corporation 201914 www.national.com

LM3668 1A, High Efficiency Dual Mode Single Inductor Buck-Boost DC/DC Converter

Page 2

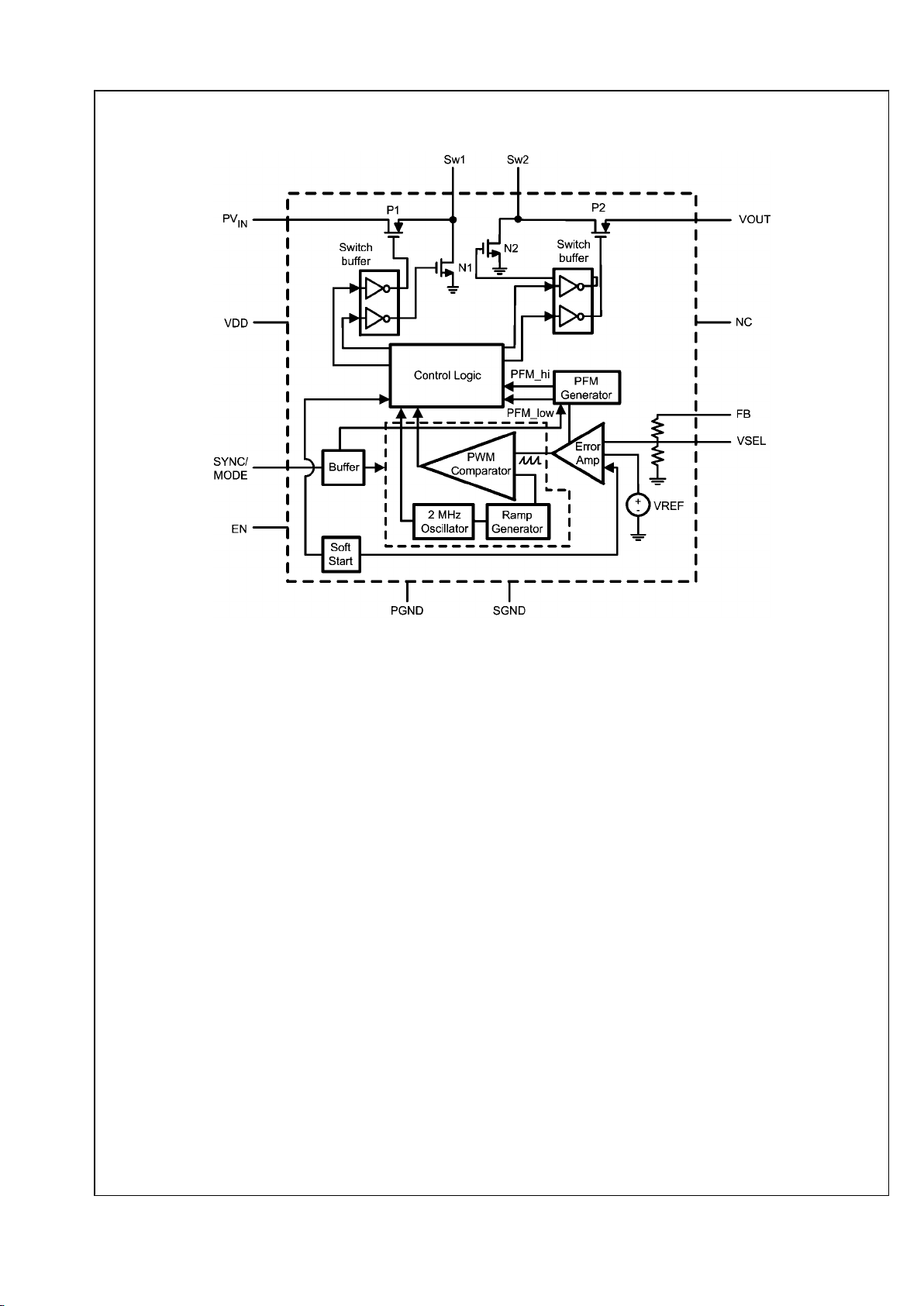

Functional Block Diagram

20191404

FIGURE 1. Functional Block Diagram

www.national.com 2

LM3668

Page 3

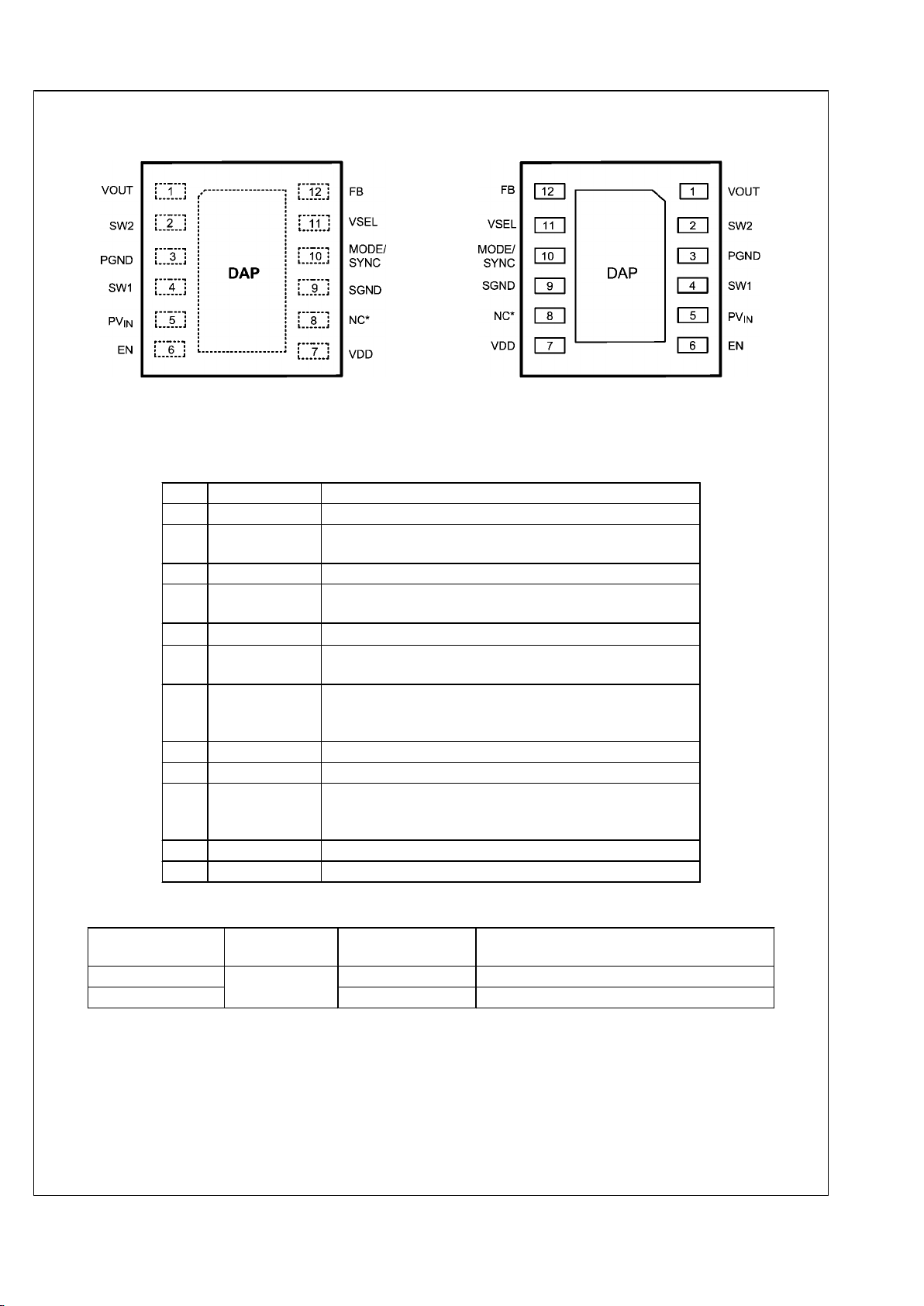

Connection Diagrams and Package Mark Information

20191402

Top View

20191403

Bottom View

Pin Descriptions

Pin # Pin Name Description

1 VOUT Connect to output capacitor.

2 SW2 Switching Node connection to the internal PFET switch (P2) and

NFET synchronous rectifier (N2).

3 PGND Power Ground.

4 SW1 Switching Node connection to the internal PFET switch (P1) and

NFET synchronous rectifier (N1).

5 PV

IN

Supply to the power switch, connect to the input capacitor.

6 EN Enable Input. Set this digital input high for normal operation. For

shutdown, set low.

7 VDD Signal Supply input. If board layout is not optimum an optional

1µF ceramic capacitor is suggested as close to this pin as

possible.

8 NC* No connect. Connect this pin to GND on PCB layout.

9 SGND Analog and Control Ground.

10 MODE/SYNC Mode = LOW, Automatic Mode. Mode= HI, Forced PWM Mode

SYNC = external clock synchronization from 1.6MHz to 2.7MHz

(When SYNC function is used, device is forced in PWM mode).

11 VSEL Logic input low = 2.8V and logic high = 3.3V to set output Voltage.

12 FB Feedback Analog Input. Connect to the output at the output filter.

Ordering Information

Order Number Package

NSC Package

Marking

Supplied As

LM3668SD - 3.3

LLP-12

S016B 1000 units, Tape and Reel

LM3668SDX - 3.3 S016B 4500 units, Tape and Reel

3 www.national.com

LM3668

Page 4

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

PV

IN, VDD

Pin, SW1, SW2 & V

OUT

:

Voltage to SGND & PGND

−0.2V to +6.0V

FB, EN,MODE,SYNC pin: (PGND &

SGND-0.2V) to

(PVIN + 0.2)

PGND to SGND -0.2V to 0.2V

Continuous Power Dissipation

(Note 3)

Internally Limited

Maximum Junction Temperature

(T

J-MAX

)

+125°C

Storage Temperature Range −65°C to +150°C

Maximum Lead Temperature

(Soldering, 10 sec)

+260°C

Operating Ratings

Input Voltage Range 2.5V to 5.5V

Recommended Load Current 0mA to 1A

Junction Temperature (TJ) Range −40°C to +125°C

Ambient Temperature (TA) Range

(Note 3)

−40°C to +85°C

Thermal Properties

Junction-to-Ambient Thermal Resistance (θJA),

34°C/W

Leadless Lead frame Package (Note 5)

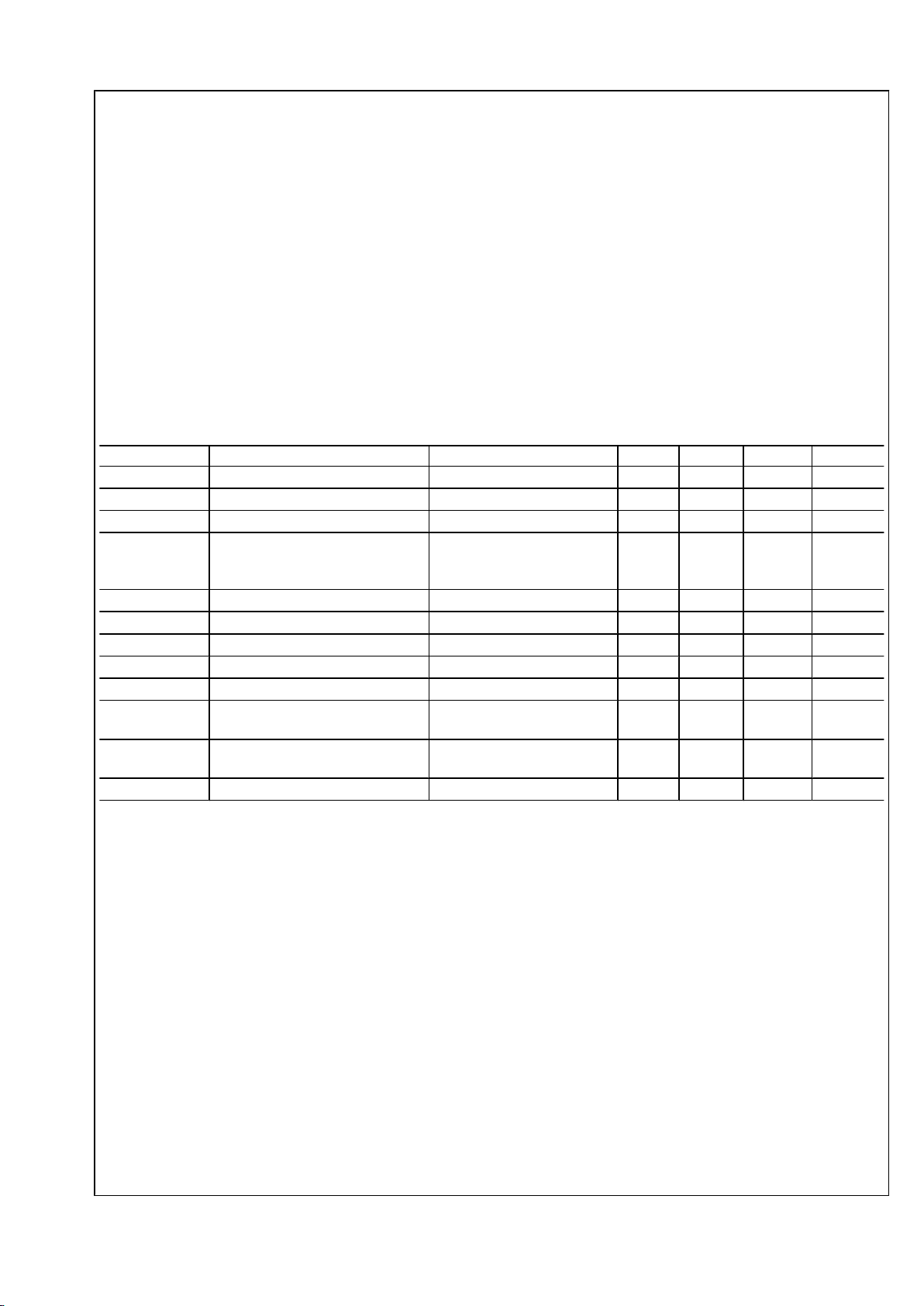

Electrical Characteristics (Notes 6, 7) Limits in standard typeface are for T

J

= +25°C. Limits in boldface type

apply over the full operating ambient temperature range (−40°C ≤ = TA ≤ +85°C). Unless otherwise noted: specifications apply to

the LM3668. VIN = 3.6V = EN, V

OUT

= 3.3V, CIN = 10 µF & C

OUT

= 22µF (Note 8).

Symbol Parameter Conditions Min Typ Max Units

V

FB

Feedback Voltage (Note 7)

-3 3 %

I

LIM

Switch Peak Current Limit Open loop(Note 2)

1.6 1.85 2.05 A

I

SHDN

Shutdown Supply Current EN =0V

0.01

1

µA

I

Q_PFM

DC Bias Current in PFM No load, device is not switching

(FB Forced higher than

programmed output voltage)

45 60 µA

I

Q_PWM

DC Bias Current in PWM PWM Mode, No Switching

600 750 µA

R

DSON(P)

Pin-Pin Resistance for PFET Switches P1 and P2

130 180

mΩ

R

DSON(N)

Pin-Pin Resistance for NFET Switches N1 and N2

100 150

mΩ

F

OSC

Internal Oscillator Frequency PWM Mode

1.9 2.2 2.5 MHz

F

SYNC

Sync Frequency Range VIN = 3.6V

1.6 2.7 MHz

V

IH

Logic High Input for EN, MODE/

SYNC pins

1.1 V

V

IL

Logic Low Input for EN, MODES/

SYNC pins

0.4 V

I

EN, MODE, SYNC

EN,MODES/SYNC pin Input Current

0.3 1 µA

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the component may occur. Operating Ratings are conditions under which operation

of the device is guaranteed. Operating Ratings do not imply guaranteed performance limits. For guaranteed performance limits and associated test conditions,

see the Electrical Characteristics tables.

Note 2: Electrical Characteristic table reflects open loop data (FB = 0V and current drawn from SW pin ramped up until cycle by cycle current limits is activated).

Closed loop current limit is the peak inductor current measured in the application circuit by increasing output current until output voltage drops by 10%.

Note 3: In applications where high power dissipation and/or poor package thermal resistance is present, the maximum ambient temperature may have to be

derated. Maximum ambient temperature (T

A-MAX

) is dependent on the maximum operating junction temperature (T

J-MAX-OP

= 125ºC), the maximum power

dissipation of the device in the application (P

D-MAX

), and the junction-to ambient thermal resistance of the part/package in the application (θJA), as given by the

following equation: T

A-MAX

= T

J-MAX-OP

– (θJA × P

D-MAX

).

Note 4: The Human body model is a 100 pF capacitor discharged through a 1.5 kΩ resistor into each pin. The machine model is a 200 pF capacitor discharged

directly into each pin. MIL-STD-883 3015.7

Note 5: Junction-to-ambient thermal resistance (θJA) is taken from a thermal modeling result, performed under the conditions and guidelines set forth in the

JEDEC standard JESD51-7. The test board is a 4-layer FR-4 board measuring 101.6mm x 76.2mm x 1.6mm. Thickness of the copper layers are 2oz/1oz/1oz/

2oz. The middle layer of the board is 60mm x 60mm. Ambient temperature in simulation is 22°C, still air.

Junction-to-ambient thermal resistance is highly application and board-layout dependent. In applications where high maximum power dissipation exists, special

care must be paid to thermal dissipation issues in board design.

Note 6: All voltage is with respect to SGND.

Note 7: Min and Max limits are guaranteed by design, test, or statistical analysis. Typical numbers are not guaranteed, but do represent the most likely norm.

Note 8: CIN and C

OUT

: Low-ESR Surface-Mount Ceramic Capacitors (MLCCs) used in setting electrical characteristics.

www.national.com 4

LM3668

Page 5

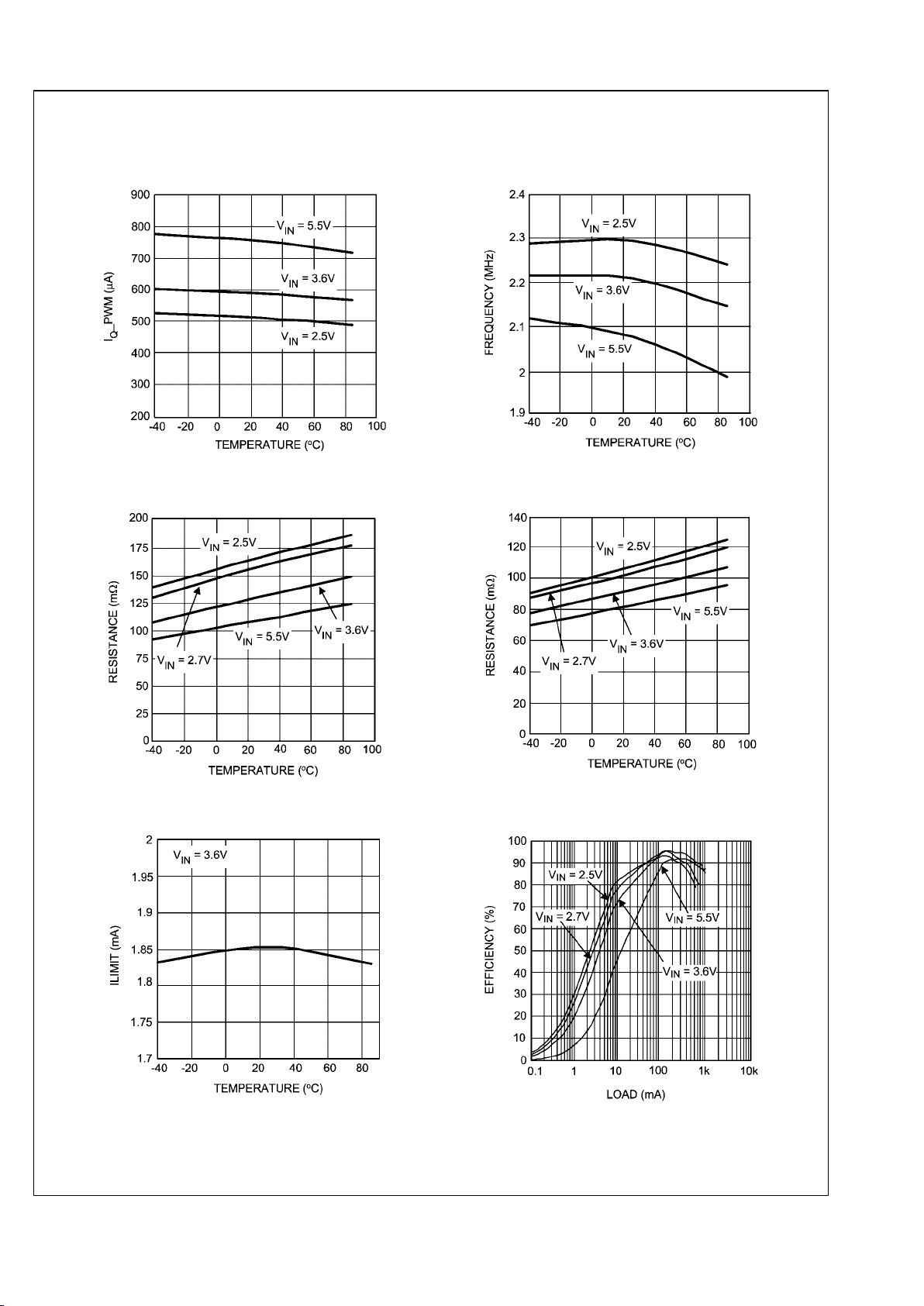

Typical Performance Characteristics Typical Application circuit Figure 1, V

IN

= 3.6V, L = 2.2µH, CIN =

10µF, C

OUT

= 22µF , TA = 25°C , Unless otherwise Stated.

Supply Current vs. Temperature ( Not switching)

20191439

Switching Frequency vs. Temperature

20191438

P_FET R

DS(ON)

vs. Temperature

20191442

N_FET R

DS(ON)

vs. Temperature

20191441

ILimit vs. Temperature

20191437

Efficiency at V

OUT

= 2.8V ( Forced PWM Mode)

20191427

5 www.national.com

LM3668

Page 6

Efficiency at V

OUT

= 2.8V ( Auto Mode)

20191428

Efficiency at V

OUT

= 3.3V ( Forced PWM Mode)

20191426

Efficiency V

OUT

= 3.3V ( Auto Mode)

20191425

Line Transient in Buck Mode

( V

OUT

= 3.3V, Load = 500mA)

20191431

Line Transient in Boost Mode

( V

OUT

= 3.3V, Load = 500mA)

20191432

Line Transient in Buck or Boost Mode

( V

OUT

= 3.3V, Load = 500mA)

20191433

www.national.com 6

LM3668

Page 7

Load Transient in Buck Mode ( PWM Mode)

VIN = 4.2V, V

OUT

= 3.3V, Load = 0-500mA

20191420

Load Transient in Boost Operation ( PWM Mode)

VIN = 2.7V, V

OUT

= 3.3V, Load = 0-500mA

20191422

Load Transient in Buck-Boost Operation ( PWM Mode)

V

IN

= 3.4V, V

OUT

= 3.3V, Load = 0-500mA

20191421

Load Transient in Boost Operation (Auto Mode)

VIN = 2.7V, V

OUT

= 3.3V, Load = 50-150mA

20191434

Load Transient in Buck Operation ( Auto Mode)

VIN = 4.2V, V

OUT

= 3.3V, Load = 50-150mA

20191436

Load Transient in Buck - Boost Mode ( Auto Mode)

VIN = 3.6V, V

OUT

= 3.3V, Load = 50-150mA

20191435

7 www.national.com

LM3668

Page 8

Typical PWM Switching Waveform ( Boost operation)

VIN = 3V, V

OUT

= 3.3V, Load = 500mA

20191416

Typical PWM Switching Waveform ( Buck operation)

VIN = 4V, V

OUT

= 3.3V, Load = 500mA

20191417

Typical PFM Switching Waveform ( Buck operation)

VIN = 4V, V

OUT

= 3.3V,Load = 50mA

20191418

Typical PFM Switching Waveform ( Boost operation)

VIN = 3V, V

OUT

= 3.3V, Load = 50mA

20191419

Start up in PWM Mode

20191429

Start up in PWM Mode

20191430

www.national.com 8

LM3668

Page 9

Circuit Description

The LM3668, a high efficiency Buck or Boost DC-DC converter, delivers a constant voltage from either a single Li-Ion

or three cell NIMH/NiCd battery to portable devices such as

mobiles phone and PDAs. Using a voltage mode architectures with synchronous rectification, the LM3668 has the

ability to deliver up to 1A depending on the input voltage, output voltage, ambient temperature and the chosen inductor.

In addition, the device incorporates a seamless transition

from buck to boost or boost to buck mode. The internal error

amplifier continuously monitors the output to determine the

transition from buck to boost or boost to buck operation. Fig-

ure 2 shows the four switches network used for the buck and

boost operation. Table 1 summarizes the state of the swtiches

in different Modes.

There are three modes of operation depending on the current

required: PWM (Pulse Width Modulation), PFM (Pulse Frequency Modulation), and shutdown. The device operates in

PWM mode at load currents of approximately 80mA or higher

to improve efficiency. Lighter load current causes the device

to automatically switch into PFM mode to reduce current consumption and extend battery life. Shutdown mode turns off

the device, offering the lowest current consumption.

20191405

FIGURE 2. Simplified Diagram of Switches

State of Switches in Different Modes

Mode Always ON Always

OFF

Switching

Buck SW P2 SW N2 SW P1 & N1

Boost SW P1 SW N1 SW N2 & P2

TABLE 1

Buck Operation

When the input voltage is greater than the output voltage, the

device operates in buck mode where switch P2 is always ON

and P1 & N1 control the output . Figure 4 shows the simplified

circuit for buck mode operation.

20191406

FIGURE 3. Simplified Circuit for Buck Operation

Boost Operation

When the input voltage is smaller than the output voltage, the

device enters boost mode operation where P1 is always ON,

while Switches N2 & P2 control the output. Figure 5 shows

the simplified circuit for boost mode operation.

20191408

FIGURE 4. Simplified Circuit for Boost Operation

PWM Operation

In PWM operation, the output voltage is regulated by switching at a constant frequency and then modulating the energy

per cycle to control power to the load. In Normal operation,

the internal error amplifier provides an error signal, Vc, from

the feedback voltage and Vref. The error amplifier signal, Vc,

is compared with a voltage, Vcenter, and used to generate

the PWM signals for both Buck & Boost Modes. Signal Vcenter is a DC signal which sets the transition point of the buck

and boost modes. Below are three regions of operation:

•

Region I, If Vc is less than Vcenter, Buck mode.

•

Region II, If Vc and Vcenter are equal, both PMOS

switches (P1, P2) are on and both NMOS switches (N1,

N2) are off. The power passes directly from input to output

via P1 & P2

•

Region III, If Vc is greater than Vcenter, Boost Mode.

The Buck-boost operation is avoided, to improve the efficiency across VIN and load range.

20191415

FIGURE 5. PWM Generator Block Diagram

9 www.national.com

LM3668

Page 10

Internal Synchronous Rectification

While in PWM mode, the LM3668 uses an internal MOSFET

as a synchronous rectifier to reduce rectifier forward voltage

drop and associated power loss. Synchronous rectification

provides a significant improvement in efficiency whenever the

output voltage is relatively low compare to the voltage drop

across an ordinary rectifier diode.

PFM Operation

At very light loads, the converter enters PFM mode and operates with reduced switching frequency and supply current

to maintain high efficiency. The part automatically transitions

into PFM mode when either of two following conditions occur

for a duration of 128 or more clock cycles:

A. The inductor current reaches zero.

B. The peak inductor current drops below the I

MODE

level,

(Typically I

MODE

< 45mA + VIN/80 Ω ).

In PFM operation, the compensation circuit in the error amplifier is turned off. The error amplifier works as a hysteretic

comparator. The PFM comparator senses the output voltage

via the feedback pin and controls the switching of the output

FETs such that the output voltage ramps between ~0.8% and

~1.6% of the nominal PWM output voltage (Figure 6). If the

output voltage is below the ‘high’ PFM comparator threshold,

the P1 & P2 (Buck mode) or N2 & P1 (Boost mode) power

switches are turned on. It remains on until the output voltage

reaches the ‘high’ PFM threshold or the peak current exceeds

the I

PFM

level set for PFM mode. The typical peak current in

PFM mode is: I

PFM

= 220mA

Once the P1 ( Buck mode) or N2 ( Boost mode) power switch

is turned off, the N1 & P2 ( Buck mode) or P1 & P2 (Boost

mode) power switches are turned on until the inductor current

ramps to zero. When the zero inductor current condition is

detected, the N1( Buck mode) or P2 ( Boost mode) power

switches are turned off. If the output voltage is below the ‘high’

PFM comparator threshold, the P1 & P2 (Buck mode) or N2

& P1 ( Boost mode) switches are again turned on and the

cycle is repeated until the output reaches the desired level.

Once the output reaches the ‘high’ PFM threshold, the N1 &

P2 (Buck mode) or P1 & P2 ( Boost mode) switches are turned

on briefly to ramp the inductor current to zero and then both

output switches are turned off and the part enters an extremely low power mode. Quiescent supply current during this

‘sleep’ mode is 45µA (typ), which allows the part to achieve

high efficiency under extremely light load conditions.

20191413

FIGURE 6. PFM to PWM Mode Transition

In addition to the auto mode transition, the LM3668 operates

in PFM Buck or PFM Boost based on the following conditions.

There is a small delta (~500mV) known as dv1(~200mV) &

dv2(~300mV) when V

OUT_TARGET

is very close to V

IN

where

the LM3668 can be in either buck or boost mode. For example

when V

OUT_TARGET

= 3.3V and VIN is between 3.1V & 3.6V,

the LM3668 can be in either mode depending on the VIN vs

V

OUT_TARGET

.

•

Region I: If VIN < V

OUT_TARGET

- dv1, the regulator operates

in boost mode.

•

Region II: If V

OUT_TARGET

- dv1 < VIN < V

OUT_TARGET

+

dv2 ,the regulator operates in either buck or boost mode.

•

Region III: If VIN > V

OUT_TARGET

+ dv2, the regulator

operates in buck mode.

20191414

FIGURE 7. V

OUT

vs VIN Transition

www.national.com 10

LM3668

Page 11

In the buck PFM operation, P2 is always turned on and N2 is

always turned off , P1 and N1 power switches are switching.

P1 and N1 are turned off to enter " sleep mode" when the

output voltage reaches the "high" comparator threshold. In

boost PFM operation, P2 and N2 are switching. P1 is turned

on and N1 is turned off when the output voltage is below the

"high" threshold. Unlike in buck mode, all four power switches

are turned off to enter "sleep" mode when the output voltage

reaches the "high" threshold in boost mode. In addition, the

internal current sensing of the I

PFM

is used to determine the

precise condition to switch over to buck or boost mode via the

PFM generator.

Current Limit Protection

The LM3668 has current limit protection to prevent excessive

stress on itself and external components during overload conditions. The internal current limit comparator will disable the

power device at a typical switch peak current limit of 1.85A

(typ.).

Under Voltage Protection

The LM3668 has an UVP comparator to turn the power device

off in case the input voltage or battery voltage is too low . The

typical UVP threshold is around 2V.

Short Circuit Protection

When the output of the LM3668 is shorted to GND, the current

limit is reduced to about half of the typical current limit value

until the short is removed.

Thermal Shutdown

The LM3668 has an internal thermal shutdown function to

protect the die from excessive temperatures. The thermal

shutdown trip point is typically 150°C, Normal operation resumes when the temperature drops below 125°C.

Start-up

The LM3668 has a soft-start circuit that smooth the output

voltage and ramp current during start-up. During start-up the

bandgap reference is slowly ramped up and switch current

limit is reduced to half the typical value. Soft start is activated

only if EN goes from logic low to logic high after Vin reaches

2.5V. The start-up time thereby depends on the output capacitor and load current demanded at start-up. It is not recommended to start up the device at full load while in softstart.

Application Information

SYNC/MODE PIN

If the SYNC/MODE pin is set high, the device is set to operate

at PWM mode only. If SYNC/MODE pin is set low, the device

is set to automatically transition from PFM to PWM or PWM

to PFM depending on the load current. Do not leave this pin

floating. The SYNC/MODE pin can also be driven by an external clock to set the desired switching frequency between

1.6MHz to 2.7MHz.

V

SEL

Pin

The LM3668 has built in logic for conveniently setting the output voltage, with V

SEL

high, the output is set to 3.3V; with

V

SEL

low the output is set to 2.8V. It is not recommended to

use this function for dynamically switching between 2.8V and

3.3V.

Maximum Current

The LM3668 is designed to operate up to 1A. For input voltages at 2.5V, the maximum operating current is 600mA and

800mA for 2.7V input voltage. In any mode it is recommended

to avoid starting up the device at minmum input voltage and

maximum load. Special attention must be taken to avoid operating near thermal shutdown when operating in boost mode

at maximum load (1A). A simple calculation can be used to

determine the power dissipation at the operating condition;

P

D-MAX

= (T

J-MAX-OP

– T

A-MAX

)/θJA . The LM3668 has thermal

resistance θ

JA

= 34°C/W ((Note 3) and (Note 5)), and maximum operating ambient of 85°C. As a result, the maximum

power dissipation using the above formula is around

1176mW. Refer to dissipation table below for P

D-MAX

value at

different ambient temperatures.

Dissipation Rating Table

θ

JA

TA ≤ 25°C TA ≤ 60°C TA ≤ 85°C

34°C/W ( 4

layers board

per JEDEC

standard)

2941mW 1912mW 1176mW

Inductor Selection

There are two main considerations when choosing an inductor; the inductor should not saturate, and the inductor current

ripple should be small enough to achieve the desired output

voltage ripple. Different saturation current rating specifications are followed by different manufacturers so attention

must be given to details. Saturation current ratings are typically specified at 25°C. However, ratings at the maximum

ambient temperature of application should be requested from

the manufacturer. Shielded inductors radiate less noise and

should be preferred.

In the case of the LM3668, there are two modes ( Buck &

Boost) of operation that must be consider when selecting an

inductor with appropriate saturation current. The saturation

current should be greater than the sum of the maximum load

current and the worst case average to peak inductor current.

The first equation shows the buck mode operation for worst

case conditions and the second equation for boost condition.

•

I

RIPPLE

: peak inductor current

•

I

OUTMAX

: maximum load current

•

VIN: maximum input voltage in application

11 www.national.com

LM3668

Page 12

•

L : min inductor value including worst case tolerances

(30% drop can be considered)

•

f : minimum switching frequency

•

V

OUT

: output voltage

•

D: Duty Cycle for CCM Operation

•

V

OUT

: Output Voltage

•

VIN: Input Voltage

Example using above equations:

•

VIN = 2.8V to 4V

•

V

OUT

= 3.3V

•

I

OUT

= 500mA

•

L = 2.2µH

•

F = 2MHz

•

Buck: I

SAT

= 567mA

•

Boost: I

SAT

= 638mA

As a result the inductor should be selected according to the

highest of the two I

SAT

values.

A more conservative and recommended approach is to

choose an inductor that has a saturation current rating greater

than the maximum current limit of 2.05A.

A 2.2 µH inductor with a saturation current rating of at least

2.05A is recommended for most applications.The inductor’s

resistance should be less than 100mΩ for good efficiency. For

low-cost applications, an unshielded bobbin inductor could be

considered. For noise critical applications, a toroidal or shielded-bobbin inductor should be used. A good practice is to lay

out the board with overlapping footprints of both types for design flexibility. This allows substitution of a low-noise shielded

inductor, in the event that noise from low-cost bobbin model

is unacceptable.

Suggest Inductors and Suppliers

Model Vendor Dimension

s

LxWxH

(mm)

D.C.R

(max)

I

SAT

LPS4012-

222L

Coilcraft 4 x 4 x 1.2

100 mΩ

2.1A

LPS4018-

222L

Coilcraft 4 x 4 x 1.8

70 mΩ

2.5A

1098AS-2

R0M (2µF)

TOKO 3 x 2.8x 1.2

67 mΩ

1.8A

( lower

current

application

s)

Input Capacitor Selection

A ceramic input capacitor of at least 10 µF, 6.3V is sufficient

for most applications. Place the input capacitor as close as

possible to the PVIN pin of the device. A larger value may be

used for improved input voltage filtering. Use X7R or X5R

types; do not use Y5V. DC bias characteristics of ceramic capacitors must be considered when selecting case sizes like

0805 or 0603. The input filter capacitor supplies current to

the PFET switch of the LM3668 in the first half of each cycle

and reduces voltage ripple imposed on the input power

source. A ceramic capacitor’s low ESR provides the best

noise filtering of the input voltage spikes due to this rapidly

changing current.

Output Capacitor Selection

A ceramic output capacitor of 22µF, 6.3V is sufficient for most

applications. Multilayer ceramic capacitors such as X5R or

X7R with low ESR is a good choice for this as well. These

capacitors provide an ideal balance between small size, cost,

reliability and performance. Do not use Y5V ceramic capacitors as they have poor dielectric performance over temperature and poor voltage characteristic for a given value.

Extra attention is required if a smaller case size capacitor is

used in the application. Smaller case size capacitors typically

have less capacitance for a given bias voltage as compared

to a larger case size capacitor with the same bias voltage.

Please contact the capacitor manufacturer for detail information regarding capacitance verses case size. Table 1 lists

several capacitor suppliers.

The output filter capacitor smoothes out current flow from the

inductor to the load, helps maintain a steady output voltage

during transient load changes and reduces output voltage

ripple. These capacitors must be selected with sufficient capacitance and sufficiently low ESR to perform these functions.

Note that the output voltage ripple is dependent on the inductor current ripple and the equivalent series resistance of the

output capacitor (R

ESR

).

The R

ESR

is frequency dependent (as well as temperature

dependent); make sure the value used for calculations is at

the switching frequency of the part.

TABLE 1. Suggested Capacitors and Suppliers

Model Type Vendor Voltage Rating

Case Size

Inch (mm)

10 µF for C

IN

GRM21BR60J106K Ceramic, X5R Murata 6.3V 0805 (2012)

JMK212BJ106K Ceramic, X5R Taiyo-Yuden 6.3V 0805 (2012)

C2012X5R0J106K Ceramic, X5R TDK 6.3V 0805 (2012)

22 µF for C

OUT

JMK212BJ226MG Ceramic, X5R Taiyo-Yuden 6.3V 0805 (2012)

www.national.com 12

LM3668

Page 13

Layout Considerations

As for any high frequency switcher, it is important to place the

external components as close as possible to the IC to maximize device performance. Below are some layout recommendations:

1) Place input filter and output filter capacitors close to the IC

to minimize copper trace resistance which will directly effect

the overall ripple voltage.

2) Route noise sensitive trace away from noisy power components. Separate power GND ( Noisy GND) and Signal GND

( quiet GND) and star GND them at a single point on the PCB

prefereably close to the device GND pin.

3) Connect the ground pins and filter capacitors together via

a ground plane to prevent switching current circulating

through the ground plane. Additional layout consideration regarding the LLP package can be found in Application AN1187

13 www.national.com

LM3668

Page 14

Physical Dimensions inches (millimeters) unless otherwise noted

12–Pin LLP

NS Package Number SDF12A

www.national.com 14

LM3668

Page 15

Notes

15 www.national.com

LM3668

Page 16

Notes

LM3668 1A, High Efficiency Dual Mode Single Inductor Buck-Boost DC/DC Converter

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2007 National Semiconductor Corporation

For the most current product information visit us at www.national.com

National Semiconductor

Americas Customer

Support Center

Email:

new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Customer Support Center

Fax: +49 (0) 180-530-85-86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +49 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor Asia

Pacific Customer Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

www.national.com

Loading...

Loading...