Page 1

LM363 Precision Instrumentation Amplifier

General Description

The LM363 is a monolithic true instrumentation amplifier. It

requires no external parts for fixed gains of 10, 100 and

1000. High precision is attained by on-chip trimming of offset voltage and gain. A super-beta bipolar input stage gives

very low input bias current and voltage noise, extremely low

offset voltage drift, and high common-mode rejection ratio.

A two-stage amplifier design yields an open loop gain of

10,000,000 and a gain bandwidth product of 30 MHz, yet

remains stable for all closed loop gains. The LM363 operates with supply voltages from

g

5V tog18V with only

1.5 mA current drain.

The LM363’s low voltage noise, low offset voltage and offset voltage drift make it ideal for amplifying low-level, lowimpedance transducers. At the same time, its low bias current and high input impedance (both common-mode and

differential) provide excellent performance at high impedance levels. These features, along with its ultra-high common-mode rejection, allow the LM363 to be used in the

most demanding instrumentation amplifier applications, replacing expensive hybrid, module or multi-chip designs. Because the LM363 is internally trimmed, precision external

resistors and their associated errors are eliminated.

The 16-pin dual-in-line package provides pin-strappable

gains of 10, 100 or 1000. Its twin differential shield drivers

eliminate bandwidth loss due to cable capacitance. Compensation pins allow overcompensation to reduce bandwidth and output noise, or to provide greater stability with

capacitive loads. Separate output force, sense and reference pins permit gains between 10 and 10,000 to be programmed using external resistors.

On the 8-pin metal can package, gain is internally set at 10,

100 or 500 but may be increased with external resistors.

The shield driver and offset adjust pins are omitted on the

8-pin versions.

The LM363 is rated for 0

Features

Y

Offset and gain pretrimmed

Y

12 nV/0Hz input noise (Ge500/1000)

Y

130 dB CMRR typical (Ge500/1000)

Y

2 nA bias current typical

Y

No external parts required

Y

Dual shield drivers

Y

Can be used as a high performance op amp

Y

Low supply current (1.5 mA typ)

Cto70§C.

§

LM363 Precision Instrumentation Amplifier

April 1991

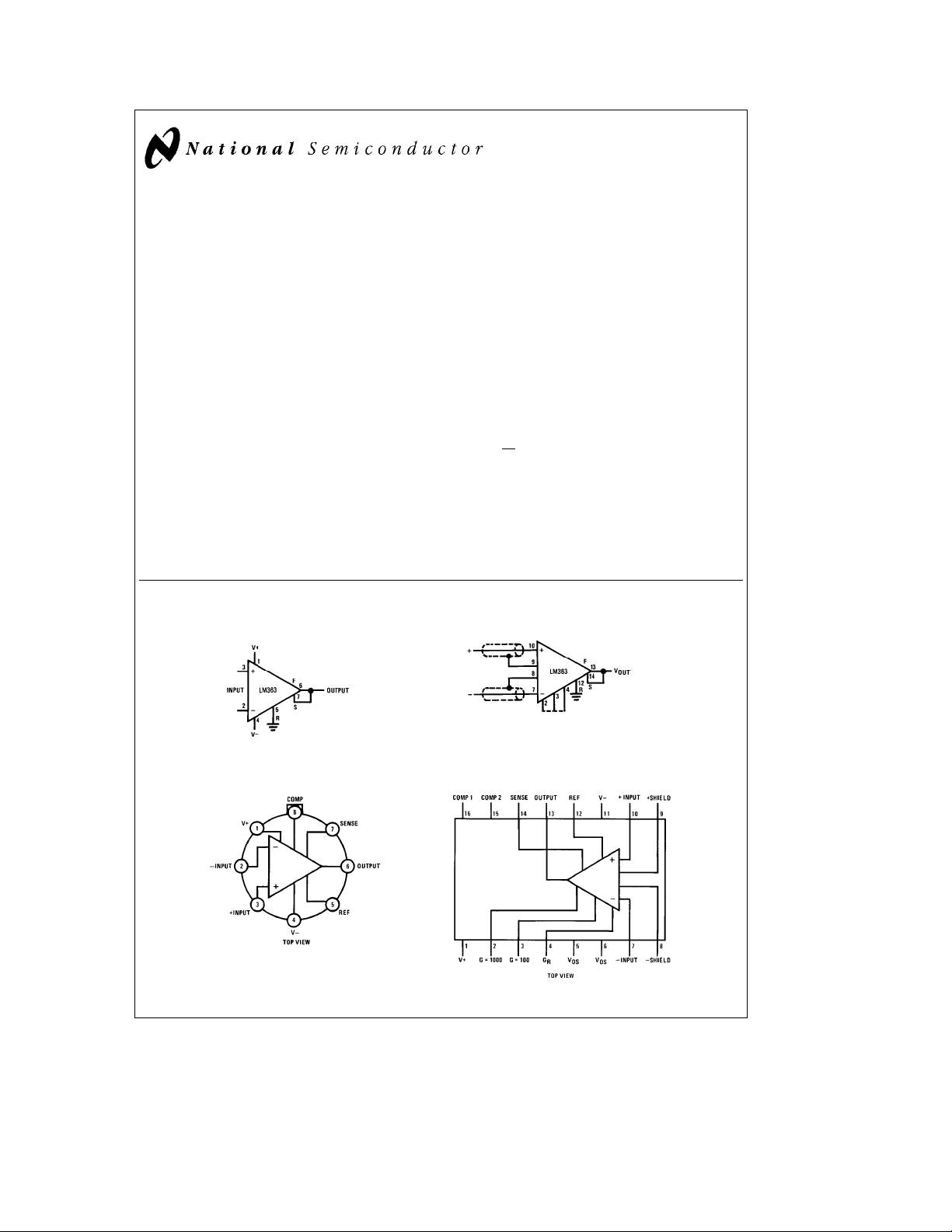

Typical Connections

8-Pin Package

TL/H/5609– 1

16-Pin Package

Ge10 2, 3, 4, open

e

100 3 –4 shorted

G

e

1000 2 –4 shorted

G

TL/H/5609– 33

Connection Diagrams

Metal Can Package 16-Pin Dual-In-Line Package

Order Number LM363H-10,

LM363H-100 or LM363H-500

See NS Package Number H08C

C

1995 National Semiconductor Corporation RRD-B30M115/Printed in U. S. A.

TL/H/5609

Order Number 363D

See NS Package Number D16C

TL/H/5609– 2

Page 2

Absolute Maximum Ratings (Note 5)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales

Office/Distributors for availability and specifications.

g

g

18V

g

10V

20 mA

Supply Voltage

Differential Input Voltage

Input Current

Input Voltage Equal to Supply Voltage

Reference and Sense Voltage

Lead Temp. (Soldering, 10 sec.) 300§C

ESD rating to be determined.

LM363 Electrical Characteristics (Notes 1 and 2)

LM363

Parameter Conditions

Typ Limit Limit

FIXED GAIN (8-PIN)

Input Offset Voltage Ge500 30 150 400 mV

e

G

100 50 250 700 mV

e

G

10 0.5 2.5 6 mV

Input Offset Voltage Drift Ge500 1 4 mV/§C

e

G

100 2 8 mV/§C

e

G

10 20 75 mV/§C

Gain Error Ge500 0.1 0.8 0.9 %

g

(

10V Swing, 2 kX Load) Ge100 0.07 0.7 0.8 %

e

G

10 0.05 0.6 0.7 %

PROGRAMMABLE GAIN (16-PIN)

Input Offset Voltage Ge1000 50 250 500 mV

e

G

100 100 450 900 mV

e

G

10 1 3.5 8 mV

Input Offset Voltage Drift Ge1000 1 5 mV/§C

e

G

100 2 10 mV/§C

e

G

10 10 100 mV/§C

Gain Error Ge1000 2.0 3.0 3.5 %

g

(

10V Swing, 2 kX Load) Ge100 0.1 0.7 0.8 %

e

G

10 0.6 2.0 2.3 %

FIXED GAIN AND PROGRAMMABLE

Gain Temperature Coefficient Ge1000 40 ppm/§C

e

G

500 20 ppm/§C

e

G

100, 10 10 ppm/§C

Gain Non-Linearity Ge10, 100 0.01 0.03 0.04 %

g

(

10V Swing, 2 kX Load) Ge500, 1000 0.01 0.05 0.06 %

Tested Design

(Note 3) (Note 4)

g

Units

25V

2

Page 3

LM363 Electrical Characteristics (Continued) (Notes 1 and 2)

LM363

Parameter Conditions

Typ Limit Limit

Common-Mode Rejection Ge1000, 500 130 114 104 dB

Ratio (

b

10VsV

s

10V) Ge100 120 94 84 dB

CM

Ge10 105 90 80 dB

Positive Supply Rejection Ge1000, 500 130 110 100 dB

Ratio (5V to 15V) G

e

100 120 100 95 dB

e

G

10 100 85 78 dB

Negative Supply Rejection Ge1000, 500 120 100 90 dB

b

Ratio (

5V tob15V) Ge100 106 85 75 dB

e

G

10 86 70 60 dB

Input Bias Current 2 10 20 nA

Input Offset Current 1 3 5 nA

Common-Mode Input 100 8 GX

Resistance

Differential Mode Input Ge1000, 500 0.2 GX

Resistance G

e

100 2 GX

Ge10 20 GX

Input Offset Current Change

b

11VsV

s

13V 20 100 300 pa/V

CM

Reference and Sense 50 kX

Resistance Min 30 27 kX

Max 80 83 kX

Open Loop Gain G

e

1000, 500 10 1 V/mV

CL

Supply Current Positive 1.2 2.4 3.0 mA

Negative 1.6 2.8 3.4 mA

a

b

e

eb

Note 1: These conditions apply unless otherwise noted; V

e

25§C.

T

j

Note 2: Boldface limits are guaranteed over full temperature range. Operating ambient temperature range is 0

Note 3: Guaranteed and 100% production tested.

Note 4: Guaranteed but not 100% tested. These limits are not used in determining outgoing quality levels.

Note 5: Maximum rated junction temperature is 100

for the ceramic DIP (D).

15V, V

C for the LM363. Thermal resistance, junction to ambient, is 150§C/W for the TO-99(H) package and 100§C/W

§

15V, V

e

0V, R

CM

L

Tested Design

(Note 3) (Note 4)

e

2kX, reference pin grounded, sense pin connected to output and

Cto70§C for the LM363.

§

Units

3

Page 4

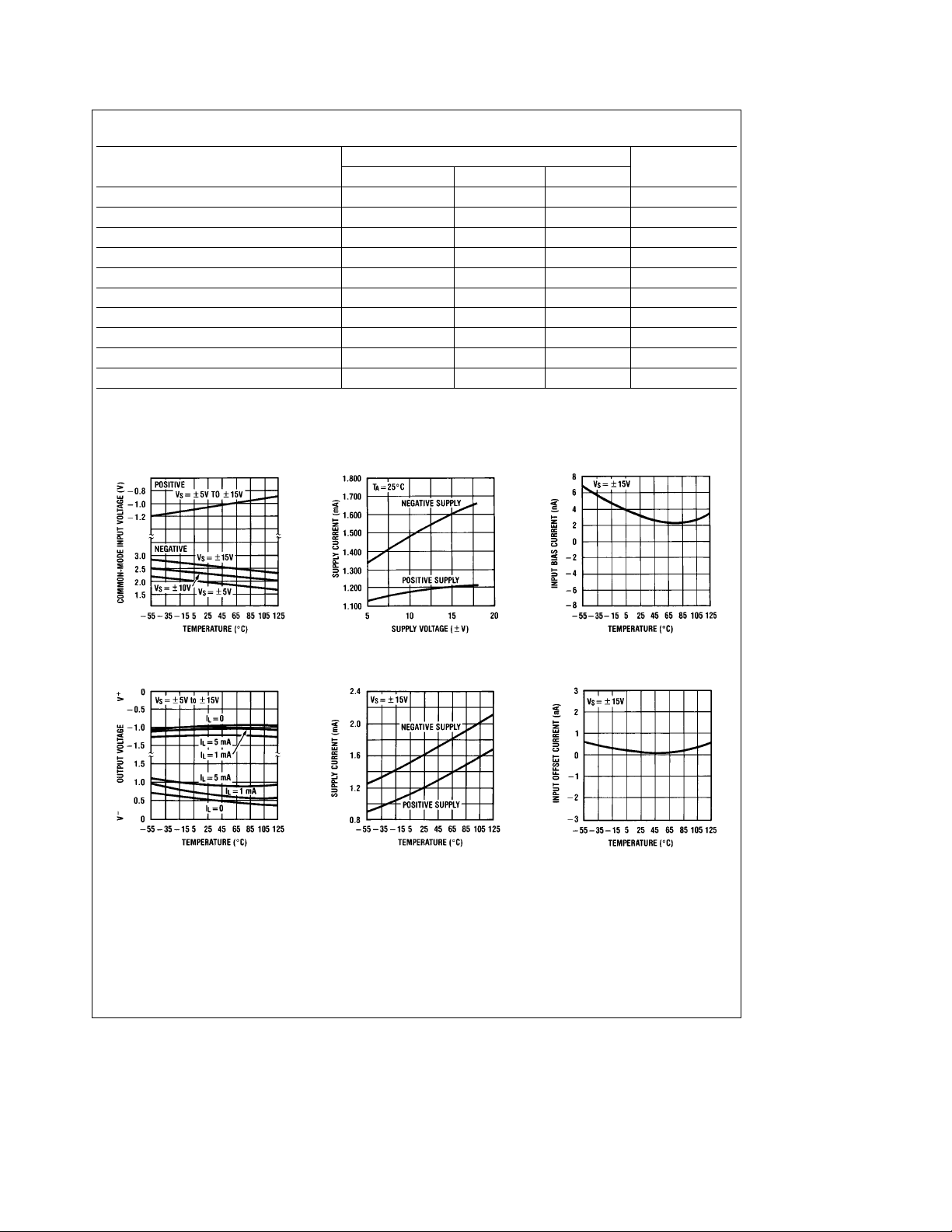

Typical Performance Characteristics T

Parameter

e

25§C

A

Fixed Gain and Programmable

1000/500 100 10

Input Voltage Noise, rms, 1 kHz 12 18 90 nV/SHz

Input Voltage Noise (Note 6) 0.4 1.5 10 mVp-p

Input Current Noise, rms, 1 kHz 0.2 0.2 0.2 pA/SHz

Input Current Noise (Note 6) 40 40 40 pAp-p

Bandwidth 30 100 200 kHz

Slew Rate 1 0.36 0.24 V/ms

Settling Time, 0.1% of 10V 70 25 20 ms

Offset Voltage Warm-Up Drift (Note 7) 5 15 50 mV

Offset Voltage Stability (Note 8) 5 10 100 mV

Gain Stability (Note 8) 0.01 0.005 0.05 %

Note 6: Measured for 100 seconds in a 0.01 Hz to 10 Hz bandwidth.

Note 7: Measured for 5 minutes in still air, V

a

b

e

eb

15V, V

15V. Warm-up drift is proportionally reduced at lower supply voltages.

Units

Common-Mode Input

Voltage Limit

Output Swing Referred to

Supplies

Supply Current vs Supply

Voltage

Supply Current vs

Temperature

Input Bias Current vs

Temperature

Input Offset Current vs

Temperature

TL/H/5609– 3

4

Page 5

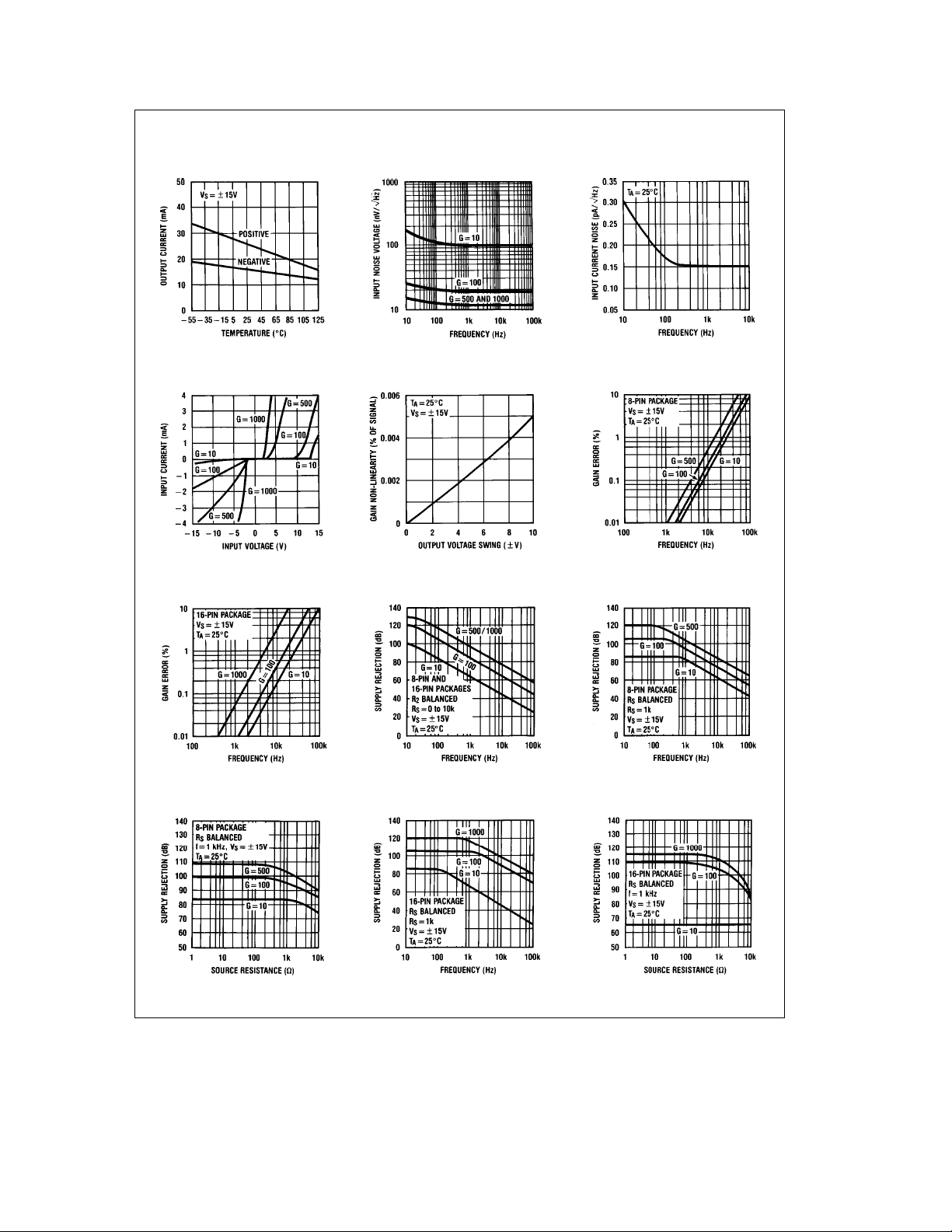

Typical Performance Characteristics (Continued)

Output Current Limit Input Noise Voltage Input Current Noise

Input Current vs Voltage

Overdrive Gain Non-Linearity Gain Error vs Frequency*

*Trimmed to zero at 100 Hz

Gain Error vs Frequency* Rejection Rejection

Positive Power Supply Negative Power Supply

*Trimmed to zero at 100 Hz

Negative Power Supply Negative Power Supply Negative Power Supply

Rejection Rejection Rejection

5

TL/H/5609– 4

Page 6

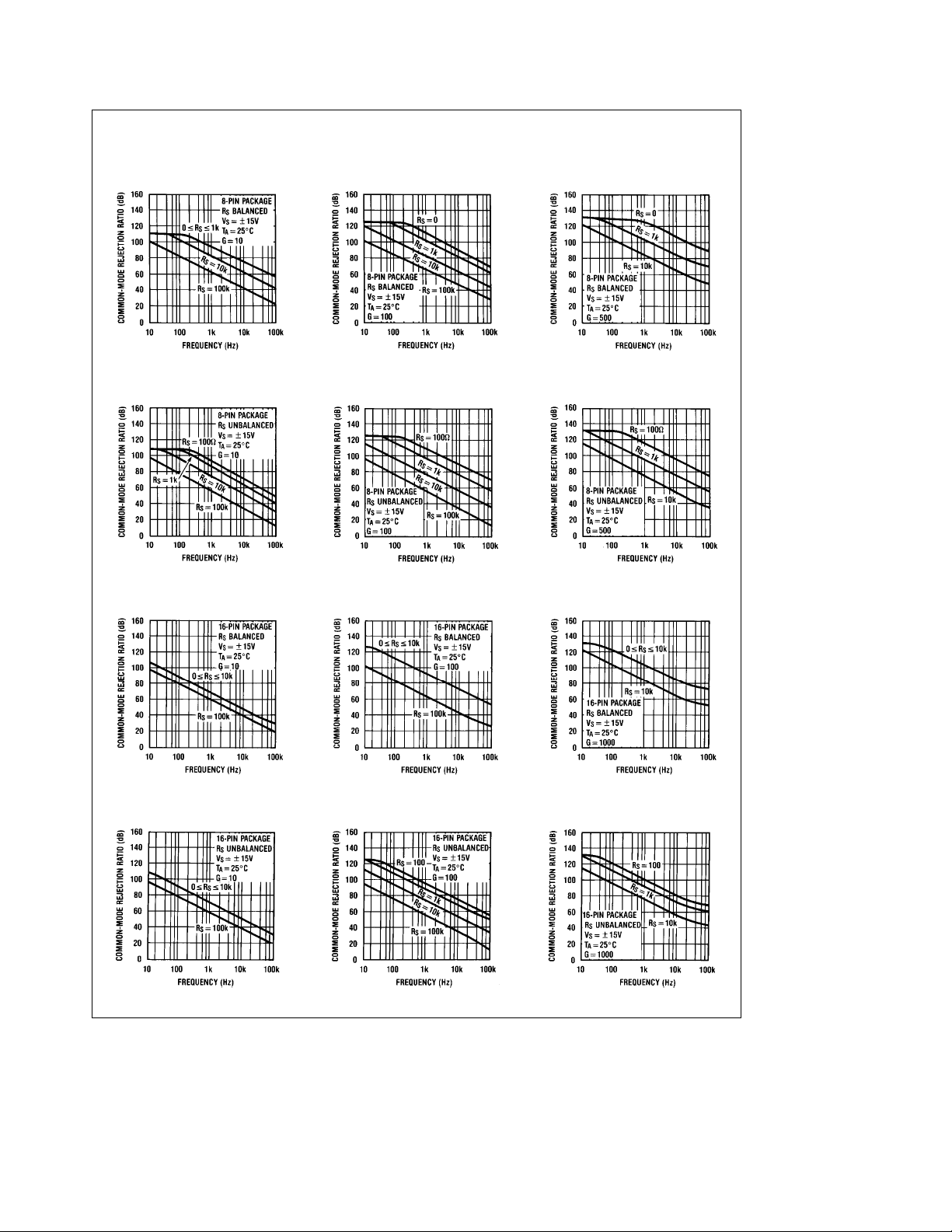

Typical Performance Characteristics (Continued)

CMRR with Balanced CMRR with Balanced CMRR with Balanced

Source Resistance Source Resistance Source Resistance

CMRR with Unbalanced CMRR with Unbalanced CMRR with Unbalanced

Source Resistance Source Resistance Source Resistance

CMRR with Balanced CMRR with Balanced CMRR with Balanced

Source Resistance Source Resistance Source Resistance

CMRR with Unbalanced CMRR with Unbalanced CMRR with Unbalanced

Source Resistance Source Resistance Source Resistance

TL/H/5609– 5

6

Page 7

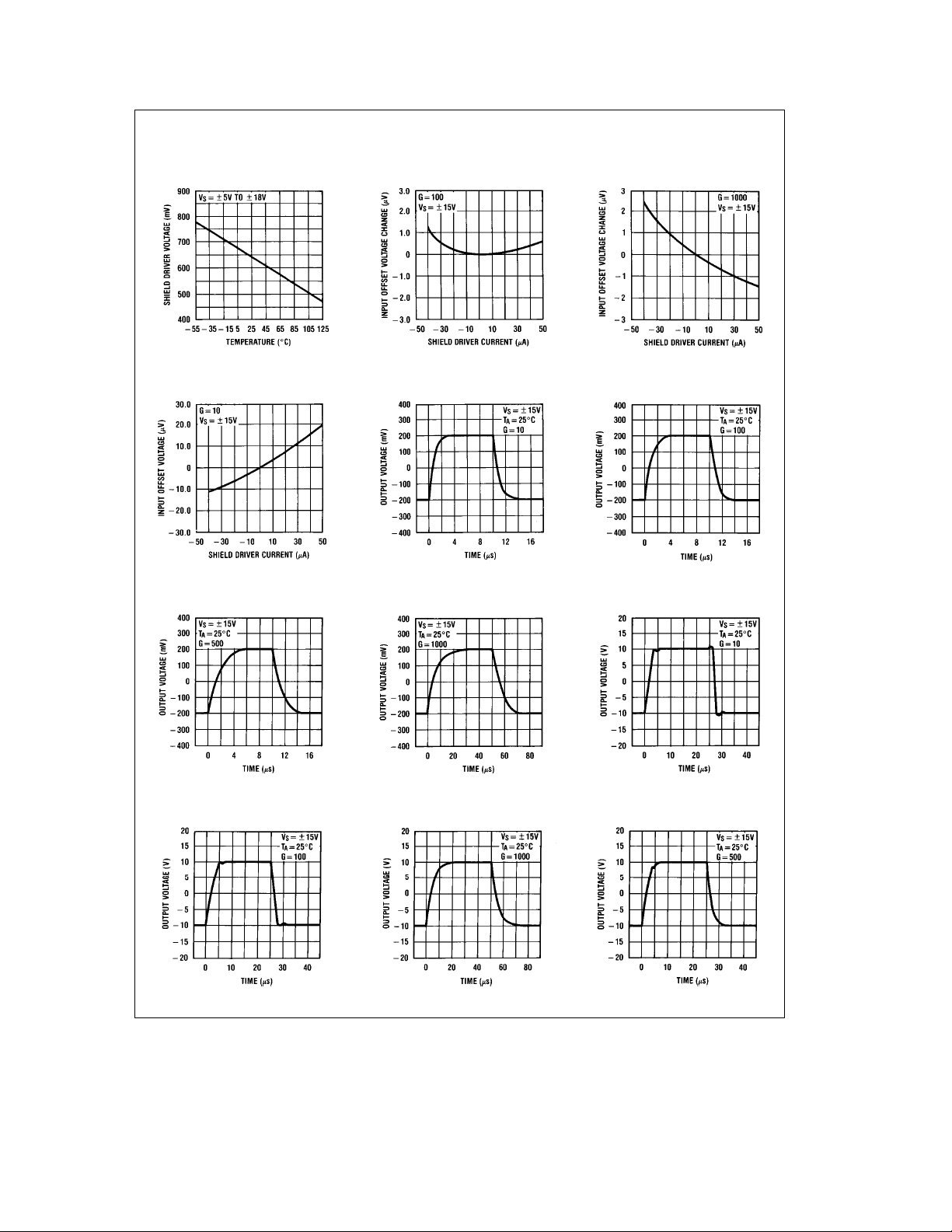

Typical Performance Characteristics (Continued)

Shield Driver Bias Voltage Shield Driver Loading Error Shield Driver Loading Error

Shield Driver Loading Error Response

Small Signal Transient

Response

Large Signal Transient

Response

Small Signal Transient

Small Signal Transient

Response

Large Signal Transient

Response

Small Signal Transient

Response

Large Signal Transient

Response

Large Signal Transient

Response

TL/H/5609– 6

7

Page 8

Simplified Schematic (pin numbers in parentheses are for 8-pin package)

TL/H/5609– 7

Theory of Operation

Referring to the Simplified Schematic, it can be seen that

the input voltage is applied across the bases of Q1 and Q2

and appears between their emitters. If R

ance across these emitters, a differential current equal to

V

IN/RE1-2

stage amplifier shown maintains Q1 and Q2 at equal collec-

flows from Q1’s emitter to Q2’s. The second

tor currents by negative feedback to Q4. The emitter currents of Q3 and Q4 must therefore be unbalanced by an

amount equal to the current flow across R

eR5a

R

E3-4

of Q4 to Q3 is equal to

R6, the differential voltage across the emitters

V

IN

c

R

E 1-2

E3-4

R

.

is the resist-

E1-2

E1-2

. Defining

This voltage divided by the attenuation factor

R4

R3aR4

e

R1aR2

R2

is equal to the output-to-reference voltage. Hence, the overall gain is given by

V

R3aR4

OUT

e

e

G

V

IN

R4

R

E3-4

c

.

R

E1-2

8

Page 9

Application Hints

The LM363 was designed to be as simple to use as possible, but several general precautions must be taken. The differential inputs are directly coupled and need a return path

to power supply common. Worst-case bias currents are only

10 nA for the LM363, so the return impedance can be as

high as 100 MX. Ground drops between signal return and IC

supply common should not be ignored. While the LM363

has excellent common-mode rejection, signals must remain

within the proper common-mode range for this specification

to apply. Operating common-mode range is guaranteed

b

from

10V toa10V withg15V supplies.

The high-gain (500 or 1000) versions have large gain-bandwidth products (15 MHz or 30 MHz) so board layout is fairly

critical. The differential input leads should be kept away

from output force and sense leads, especially at high impedances. Only 1 pF from output to positive input at 100 kX

source impedance can cause oscillations. The gain adjust

leads on the 16-pin package should be treated as inputs

and kept away from the output wiring.

POWER SUPPLY

The LM363 may be powered from split supplies from

g

to

18V (or single-ended supplies from 10V to 36V). Positive supply current is typically 1.2 mA independent of supply

voltage. The negative supply current is higher than the positive by the current drawn through the voltage dividers for the

reference and sense inputs (typ 600 mA total). The LM363’s

excellent PSRR often makes regulated supplies unnecessary. Actually, supply voltage can be as low as 7V total but

PSRR is severely degraded, so that well-regulated supplies

are recommended below 10V total. Split supplies need not

be balanced; output swing and input common-mode range

will simply not be symmetrical with unbalanced supplies. For

example, at

range is typically

to

a

12V andb5V supplies, input common-mode

a

b

4V.

10.5V tob2V and output swing isa11V

When using ultra-low offset versions, best results are ob-

g

tained at

set voltage is guaranteed within 150 mVat

Running at

ror of 10V (

15V supplies. For example, the LM363-500’s off-

g

5V results in a worst-case negative PSRR er-

b

15V tob5V) multiplied by 3.2X10

g

or 32 mV, increasing the worst-case offset. Positive PSRR

results in another 10 mV worst-case change.

INPUTS

The LM363 input circuitry is depicted in the Simplified Schematic. The input stage is run relatively rich (50 mA) for low

voltage noise and wide bandwidth; super-beta transistors

and bias-current cancellation (not shown) keep bias currents low. Due to the bias-current cancellation circuitry, bias

current may be either polarity at either input. While input

current noise is high relative to bias current, it is not significant until source resistance approaches 100 kX.

Input common-mode range is typically from 3V above V

1.5V below V

a

, so that a large potential drop between the

input signal and output reference can be accommodated.

However, a return path for the input bias current must be

provided; the differential input stage is not isolated from the

supplies. Differential input swing in the linear region is equal

to output swing divided by gain, and typically ranges from

1.3V at G

e

10 to 13 mV at Ge1000.

Clamp diodes are provided to prevent zener breakdown and

resulting degradation of the input transistors. At large input

g

5V

15V at 25§C.

b

6

(110 dB)

b

overdrives these diodes conduct, greatly increasing input

currents. This behavior is illustrated in the I

the Typical Performance Characteristics. (The graph is not

symmetrical because at large input currents a portion of the

current into the device flows out the V

The input protection resistors allow a full 10V differential

input voltage without degradation even at G

voltages more than one diode drop below V

drops above V

a

input, current increases rapidly. Diode

b

terminal.)

vs VINplot in

IN

e

1000. At input

b

or two diode

clamps to the supplies, or external resistors to limit current

to 20 mA, will prevent damage to the device.

REFERENCE AND SENSE INPUTS

The equivalent circuit is shown in the schematic diagram.

Limitations for correct operation are as follows. Maximum

differential

cally

swing between reference and sense pins is typi-

g

15V (g10V guaranteed). If this limit is exceeded, the

sense pin no longer controls the output, which then pegs

high or low. The

b

V

. (This is permissible because R2 and R4 are returned to

a node biased higher than V

negative

common-mode limit is 1.5V below

b

.) If large

positive

voltages are

applied to the reference and sense pins, the common-mode

range of the signal inputs begins to suffer as the drop

across R13 and R16 increases. For example, at

plies, V

b

range drops to

pins can be as much as 10V above V

ed signal common-mode range (

e

REF

12V toa13.5V. At V

e

V

SENSE

b

11V toa13.5V. The reference and sense

0V, signal input range is typically

e

V

REF

SENSE

a

b

10V min) can be tolerat-

g

15V sup-

e

15V, signal input

as long as a restrict-

ed.

For maximum bipolar output swing at

g

15V supplies, the

reference pin should be returned to a voltage close to

ground. At lower supply voltages, the reference pin need

not be halfway between the supplies for maximum output

swing. For example, at V

grounding the reference pin still allows a

a

ea

12V and V

a

b

eb

5V,

11V tob4V

swing. For single-supply systems, the reference pin can be

tied to either supply if a single output polarity is all that is

required. For a bipolar input and output, create a low impedance reference with an op amp and voltage divider or a

regulator (e.g., LM336, LM385, LM317L). This forms the reference for all succeeding signal-processing stages. (Don’t

connect the reference terminal directly to a voltage divider;

this degrades gain error.) See

to

a. Usual configuration maximizes bipolar output swing.

b. Unequal supplies, output ground referred. Full output swing pre-

served referred to supplies.

Figure 1

.

TL/H/5609– 8

FIGURE 1. Reference Connections

9

Page 10

Application Hints (Continued)

c. Single Supply, Unipolar Output d. Single Supply, Bipolar Output

FIGURE 1. Reference Connections (Continued)

OUTPUTS

The LM363’s output can typically swing within 1V of the

supplies at light loads. While specified to drivea2kXload

g

to

10V, current limit is typically 15 mA at room temperature. The output can stably drive capacitive loads up to

400 pF. For higher load capacitance, the amplifier may be

overcompensated (see COMPENSATION section, following). The output may be continuously shorted to ground

without damaging the device.

OFFSET VOLTAGE

The LM363’s offset voltage is internally trimmed to a very

low value. Note that data sheet values are given at

e

T

25§C, V

j

tions, warm-up drift, temperature drift, common-mode rejec-

CM

e

0V and V

a

b

e

e

V

15V. For other condi-

tion and power supply rejection must be taken into account.

Warm-up drift, due to chip and package thermal gradients, is

an effect separate from temperature drift. Typical warm-up

drift is tabulated in the Electrical Characteristics; settling

time is approximately 5 minutes in still air. At load currents

up to 5 mA, thermal feedback effects are negligible

s

(DV

2mVatGe1000).

OS

Care must be taken in measuring the extremely low offset

voltages of the high gain amplifiers. Input leads must be

held isothermal to eliminate thermocouple effects. Oscillations, due to either heavy capacitive loading or stray capacitance from input to output, can cause erroneous readings.

In either case, overcompensation will help. High frequency

noise fed into the inputs may be rectified internally, and pro-

TL/H/5609– 9

duce an offset shift. A simple low-pass RC filter will usually

cure this problem (

Figure 2

). Use film type resistors for their

low thermal EMF. In highly noisy environments, LC filters

can be substituted for increased RF attenuation.

FIGURE 2. Low Pass Filter Prevents RF Rectification

TL/H/5609– 10

Instrumentation amplifiers have both an input offset voltage

(V

) and an output offset voltage (V

IOS

referred offset voltage (V

tation amplifier gain (G) as follows: V

) is related to the instrumen-

OSRTI

G. The offset voltage given in the LM363 specifications is

). The total input-

OOS

e

V

OSRTI

IOS

a

V

OOS

the total input-referred offset. As long as only one gain is

used, offset voltage can be nulled at either input or output

as shown in

used at multiple gain settings, both V

be nulled to get minimum offset at all gains, as shown in

Figure 3c

output at G

Figures 3a

. The correct procedure is to trim V

e

10, then trim V

and3b. When the 16-pin device is

and V

IOS

at Ge1000.

IOS

OOS

OOS

should

for zero

/

FIGURE 3. Offset Voltage Trimming

10

TL/H/5609– 11

Page 11

Application Hints (Continued)

Because the LM363’s offset voltage is so low to begin with,

offset nulling has a negligible effect on offset temperature

drift. For example, zeroing a 100 mV offset, assuming external

resistor TC of 200 ppm/

TC, results in an additional drift component of 0.08 mV/

For this reason, drift specifications are guaranteed, with or

C and worst-case internal resistor

§

C.

§

without external offset nulling.

GAIN ADJUSTMENT

Gain may be increased by adding an external voltage divider between output force and sense and reference; the preferred connection is shown in

sense and reference pins look like 50 kX (

Figure 4

. Since both the

g

20 kX)toVb,

impedances presented to both pins must be equal to avoid

offset error. For example, a 100X imbalance can create a

R1 and R2 should be as low as possible to avoid errors due to 50 k X

input impedance of reference and sense pins. Total resistance

a

2R1) should be above 4 kX, however, to prevent excessive load

(R2

TL/H/5609– 12

on the LM363 output. The exact formula for calculating gain (G) is:

G

G

The last term may be ignored in applications where gain accuracy is not

critical. The table below gives suggested values for R1 and R2 along

with the calculated error due to ‘‘closest value’’ standard 1% resistors.

Total gain error tolerance includes contributions from LM363 G

and resistor tolerance (

every case.

Pinout shown is for 16-pin package. This same technique can also be

used with 8-pin versions.

e

G

e

O

2R1

a

1

O

R2

#

preset gain

Gain Increase 1.522.5345678910

R1 1.21k 1.21k 2k 2k 1.78k 2k 2.49k 2.94k 3.48k 3.92k 4.42k

R2 5k 2.49k 2.74k 2.05k 1.21k 1k 1k 1k 1k 1k 1k

Error (typ)

a

0.6%b0.2% 0

b

0.3%b0.6%a0.8%a0.5%b0.9%a0.4%b0.9%b0.7%

FIGURE 4. Increasing Gain

worst-case output offset of 50 mV, creating an input-referred error of 5 mV at G

e

10 or 50 mVatGe1000.

Increasing gain this way increases output offset error. An

LM363H-100 may have an output offset of 5 mV, resulting in

input referred offset component of 50 mV. Raising the gain

to 200 yields a 10 mV error at the output and changes input

referred error by an additional 50 mV.

External resistors connected to the reference and sense

pins can only

ance is not critical, the technique in

increase

the gain. If ultra-low output imped-

Figure 5

trim the gain to nominal value. Alternatively, the V

ment terminals on the 16-pin package may be used to trim

the gain (

R1

a

50k

J

g

1%) and works out to approximately 2.5% in

Figure 10b

).

error

O

can be used to

adjust-

OS

FIGURE 5. Adjusting Gain, Alternate Technique

11

Pinout shown is for 8-pin versions.

This same technique can also be used

with 16-pin version.

TL/H/5609– 13

Page 12

Application Hints (Continued)

COMPENSATION AND OUTPUT CLAMPING

The LM363 is internally compensated for unity feedback

from output to sense. Increasing gain with external dividers

will decrease the bandwidth and increase stability margin.

Without external compensation, the amplifier can stably

drive capacitive loads up to 400 pF. When used as an op

amp (sense and reference pins grounded, feedback to inverting input), the LM363 is stable for gains of 100 or more.

For greater stability, the device may be over-compensated

as in

Figure 6

tion components along with the resulting changes in large

and small signal bandwidth for the 8-pin and 16-pin packages, respectively.

Note that the RC network from pin 8 of the 8-pin device to

ground has a large effect on power bandwidth, especially at

low gains. The Miller capacitance utilized for overcompensating the 16-pin device permits higher slew rate and larger

load capacitance for the same bandwidth, and is preferred

when bandwidth must be greatly reduced (e.g., to reduce

output noise).

. Tables I and II depict suggested compensa-

TABLE I. Overcompensation on 8-Pin Package

Compensation Network 3 dB Bandwidth Capacitive

Gain

500 1000 pF, 5k 45 1.8k 800

100 1000 pF, 5k 80 1.8k 1200

10 1000 pF, 5k 90 1.8k 1200

*Also stable for C

²

Pin 15 to ground on 16-pin package

(Pin 8 to Ground)

Ð 125 100k 400

100 pF, 15k 95 15k 600

0.01 mF,500X 10 200 1000*

0.1 mF 1 20 1000*

Ð 240 100k 400

100 pF, 15k 170 15k 900

0.01 mF, 500X 20 200 1600*

0.1 mF 2 20 2000*

Ð 240 100k 400

100 pF, 15k 170 15k 900

0.01 mF, 500X 20 200 1600*

0.1 mF 2 20 2000*

t

0.05 mF

L

Small Signal Power Maximum

²

Bandwidth (g10V Swing) Load

TABLE II. Overcompensation on 16-Pin Package

Gain Capacitor

1000 100 pF 2.5k 2.5k 2500*

100 100 pF 7.5k 7.5k 2000*

*Also stable for C

Compensation

(Pin 15 to 16)

Ð 45k 45k 1000*

10 pF 16k 16k 2000*

1000 pF 250 250 3000*

0.01 mF 25 25 3000*

Ð 140k 100k 900

10 pF 50k 50k 1600

1000 pF 750 750 2000*

0.01 mF 75 75 2000*

Ð 180k 90k 600

10 100 pF 9k 9k 1600

10 pF 60k 50k 1100

1000 pF 900 900 2000*

0.01 mF 90 90 2000*

t

0.05 mF

L

Small Signal Power Maximum

3 dB Bandwidth Capacitive

Bandwidth (

(Hz) (Hz) (pF)

Heavy Miller overcompensation on the 16-pin package can

degrade AC PSRR. A large capacitor between pins 15 and

16 couples transients on the positive supply to the output

buffer. Since the amplifier bandwidth is severely rolled off it

cannot keep the output at the correct state at moderate

frequencies. Hence, for good PSRR, either keep the Miller

capacitance under 1000 pF or use the pin 15-to-ground

compensation shown in Table I.

FIGURE 6. Overcompensation

(kHz) (Hz) (pF)

g

10V Swing) Load

12

TL/H/5609– 14

Page 13

Application Hints (Continued)

Because the LM363’s output voltage is approximately one

diode drop below the voltage at pin 15 (pin 8 for the 8-pin

device), this point may be used to limit output swing as seen

in

Figure 7a

that zeners must have a sharp breakdown to clamp accurately. Alternatively, a diode tied to a voltage source could

be used as in

. Current available from this pin is only 50 mA, so

Figure 7b

.

50 pF to ground at both shield driver outputs. Do not use

only one shield driver for a single-ended signal as oscillations can result; shield driver to input capacitance must be

roughly balanced (

g

30%). To further reduce noise pickup,

the shielded signal lines may be enclosed together in a

grounded shield. If a large amount of RF noise is the problem, the only sure cure is a filter capacitor at both inputs;

otherwise the RFI may be internally rectified, producing an

offset.

DC loading on the shield drivers should be minimized. The

drivers can only source approximately 40 mA; above this

value the input stage bias voltages change, degrading V

and CMRR. While the shield drivers can sink several mA,

V

may degrade severely at loads above 100 mA (see

OS

Shield Driver Loading Error curve in Typical Performance

OS

Characteristics). Because the shield drivers are one diode

drop above the input levels, unbalanced leakage paths from

shield to input can produce an input offset at high source

impedances. Buffering with emitter-followers (

Figure 8b

) reduces this leakage current by reducing the voltage differential and eliminates any loading on the amplifier.

FIGURE 7. Output Clamp

TL/H/5609– 15

SHIELD DRIVERS

When differential signals are sent through long cables, three

problems occur. First, noise, both common-mode and differential, is picked up. Second, signal bandwidth is reduced by

the RC low-pass filter formed by the source impedance and

the cable capacitance. Finally, when these RC time constants are not identical (unbalanced source impedance

and/or unbalanced capacitance), AC common-mode rejection is degraded, amplifying both induced noise and

‘‘ground’’ noise. Either filtering at the amplifier inputs or

slowing down the amplifier by overcompensating will indeed

reduce the noise, but the price is slower response. The

LM363D’s dual shield drivers can actually increase bandwidth while reducing noise.

The way this is done is by bootstrapping out shield capacitance. The shield drivers follow the input signal. Since both

sides of the shield capacitance swing the same amount, it is

effectively out of the circuit at frequencies of interest.

Hence, the input signal is not rolled off and AC CMRR is not

degraded (

Figure 8

). The LM363D’s shield drivers can handle capacitances (shield to center conductor) as high as

1000 pF with source resistances up to 100 kX.

For best results, identical shielded cables should be used

for both signal inputs, although small mismatches in shield

driver to ground capacitance (

s

500 pF) do not cause problems. At certain low values of cable capacitance (50 pF –

200 pF), high frequency oscillations can occur at high

source resistance (

t

10 kX). This is alleviated by adding

FIGURE 8. Driving Shielded Cables

TL/H/5609– 16

MISCELLANEOUS TRIMMING

The V

pin package may be used to trim the other parameters besides offset voltage, as illustrated in

adjust and shield driver pins available on the 16-

OS

Figure 10

. The bias-current trim relies on the fact that the voltage on the shield

driver and gain setting pins is one diode drop respectively

above and below the input voltage. Input bias current can

be held to within 100 pA over the entire common-mode

range, and input offset current always stays under 30 pA.

The CMRR trims use the shield driver pins to drive the V

adjust pins, thus maintaining the LM363’s ultra-high input

OS

impedance.

13

Page 14

Application Hints (Continued)

If power supply rejection is critical, frequently only the negative PSRR need be adjusted, since the positive PSRR is

more tightly specified. Any or all of the trim schemes of

Figure 10

ter tap of the 100k trimpot is returned to a voltage 200 mV

below V

can be combined as desired. As long as the cen-

a

, the trim schemes shown will not greatly affect

TL/H/5609– 17

VOS. Both the gain and DC CMRR trims can degrade positive PSRR; the positive PSRR can then be nulled out if desired. The correct order of trimming from first to last is bias

current, gain, CMRR, negative PSRR, positive PSRR and

V

.

OS

Top Trace: Cable Shield Grounded

Bottom Trace: Cable Shield Bootstrapped

FIGURE 9. Improved Response using Shield Drivers

FIGURE 10. Other Trims for 16-Pin Package

TL/H/5609– 18

TL/H/5609– 19

14

Page 15

Typical Applications

4 mA-20 mA Two Wire Current Transmitter

The LM329 reference provides excellent line regulation and gain stability. When bridge is balanced

e

4 mA), there’s no drop across R3 and R4, so that gain and offset adjustments are non-in-

(I

OUT

teractive. The LM334 configured as a zero-TC current source supplies quiescent current to circuit.

R11 provides current limiting.

Design Equations

e

I

(I

OS

R6

DI

OUT

e

Gain

DV

when A

V

e

Pick I

334

e

I

I

MAX

334

I

BRIDGE(MAX)

R2

a

a

IR7)#1

R1

A

R2

V

j

X

R1

R3aR4

IN

e

LM363 voltage gain

0.68V

68 mV

a

R9

R10

b

V

2.4V

Z

a

R11

j

I

334-I363-IZ

e

J

aR3a

e

4mA

j

3.8 mA

26 mA

j

R4

j

1.5mA

10 mA

mV

Precision Current Source (Low Output Current)

R1eR2

V

IN

e

I

TL/H/5609– 21

OUT

GR1

,

Precision Voltage to Current Converter (Low Input Voltage)

TL/H/5609– 20

s

V

10V

l

l

IN

R1eR2

e

Req

R1ll50 kX

GV

GV

IN

Req

IN

e

1kX

e

I

OUT

TL/H/5609– 22

15

Page 16

Typical Applications (Continued)

Curvature Corrected Platinum RTD Thermometer

TL/H/5609– 23

*70k and 2k should track to 5 ppm/§C

**Less than 5 ppm/

²

Less than 100 ppm/§C drift

²²

These resistors should track to 20 ppm/§C

³

Equivalent circuit, showing lead resistance

This thermometer is capable of 0.01

a

150§C. A unique trim arrangement eliminates cumbersome trim interactions so that zero, gain, and nonlinearity correction can be trimmed in

one oven trip. Extra op amps provide full Kelvin sensing on the sensor

without adding drift and offset terms found in other designs. A2 is configured as a Howland current pump, biasing the sensor with a fixed

current.

Resistors R2, R3, R4 and R5 from a bridge driven into balance by A1. In

balance, both inputs of A1 are at the same voltage. Since R6

draws equal currents from both legs of the bridge. Any loading of the

R4/R5 leg by the sensor would unbalance the bridge; therefore, both

bridge taps are given to the sensor open circuit voltage and no current

is drawn.

C drift

§

C accuracy overb50§Cto

§

e

R7, A1

*Ultronix 105A wirewound

e

Thermistor

Setpoint stability

Yellow SpringsÝ44032

e

2.5X10

Precision Temperature Controller

TL/H/5609– 24

b

4

C/Hr

§

16

Page 17

Typical Applications (Continued)

Low Frequency Rolloff (AC Coupling)

1

e

f1

2qC1(50 k X)

e

f2

100 f1e100Hz

Reduced DC voltage gain

attenuates offset error and

1/f noise by a factor of 100.

TL/H/5609– 25

Precision Comparator with Balanced Inputs and Variable Offset Boosted Current Source with Limiting

j

t

15 mS at 1 mV overdrive

pd

eV2a

DV

Hysteresis

Offset

OUT

e

DV

G(R1aR2)

e

V

SENSE

g

1.3V range

OUT

0.6V

e

2mV

/G

e

1Hz

R1

I

I

MAX

e

R2

GV

IN

e

O

R2

V

BE

e

R2

j

60 mA

TL/H/5609– 26

Thermocouple Amplifier with Cold Junction Compensation

Input protection circuitry allows

thermocouple to short to 120 V

damaging amplifier.

Calibration:

1) Apply 50 mV signal in place of thermocouple.

Trim R3 for V

2) Reconnect thermocouple. Trim R9 for correct

output.

OUT

17

e

12.25V.

without

AC

TL/H/5609– 27

Page 18

Typical Applications (Continued)

Synchronous Demodulator

*Use square wave drive produced by optical chopper to run LF13333 switch inputs.

Pulsed Bridge Driver/Amplifier

TL/H/5609– 28

TL/H/5609– 29

18

Page 19

Typical Applications (Continued)

**Parallel trim for 28.00×Hge0V

²

Parallel trim for 32.00×Hge4V out

*B.L.H. Electronics

Pressure Transducer,

350X input impedance.

e

Output

Ý

DHF-444114

1 mV/volt excitation/psi

Precision Barometer

TL/H/5609– 30

Removing Large DC Offsets

*Optional bandlimiting to reduce noise.

e

Pick R1C1

f

l

LM363 bias currents flowing into R1 and R2.

R2C2eR3C3/10

1

e

2qf

l

e

0.1 Hz for values shown. Integrator nulls out offset error to

Removing Small DC Offsets

*Optional bandlimiting to reduce noise.

Low frequency break

frequency f

Accommodates out referred offset of several volts. Limit is set by max

differential between reference and sense terminals.

e

l

2qR1C1

1

e

0.01 Hz

TL/H/5609– 31

TL/H/5609– 32

19

Page 20

20

Page 21

Physical Dimensions inches (millimeters)

Order Number LM363H-10, LM363H-100 or LM363H-500

Metal Can Package (H)

NS Package Number H08C

21

Page 22

Physical Dimensions inches (millimeters) (Continued)

Hermetic Dual-In-Line Package (D)

LM363 Precision Instrumentation Amplifier

Order Number LM363D

NS Package Number D16C

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL

SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or 2. A critical component is any component of a life

systems which, (a) are intended for surgical implant support device or system whose failure to perform can

into the body, or (b) support or sustain life, and whose be reasonably expected to cause the failure of the life

failure to perform, when properly used in accordance support device or system, or to affect its safety or

with instructions for use provided in the labeling, can effectiveness.

be reasonably expected to result in a significant injury

to the user.

National Semiconductor National Semiconductor National Semiconductor National Semiconductor

Corporation Europe Hong Kong Ltd. Japan Ltd.

1111 West Bardin Road Fax: (

Arlington, TX 76017 Email: cnjwge@tevm2.nsc.com Ocean Centre, 5 Canton Rd. Fax: 81-043-299-2408

Tel: 1(800) 272-9959 Deutsch Tel: (

Fax: 1(800) 737-7018 English Tel: (

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Fran3ais Tel: (

Italiano Tel: (

a

49) 0-180-530 85 86 13th Floor, Straight Block, Tel: 81-043-299-2309

a

49) 0-180-530 85 85 Tsimshatsui, Kowloon

a

49) 0-180-532 78 32 Hong Kong

a

49) 0-180-532 93 58 Tel: (852) 2737-1600

a

49) 0-180-534 16 80 Fax: (852) 2736-9960

Loading...

Loading...