Page 1

LM34

Precision Fahrenheit Temperature Sensors

LM34 Precision Fahrenheit Temperature Sensors

November 2000

General Description

The LM34 series are precision integrated-circuit temperature

sensors, whose output voltage is linearly proportional to the

Fahrenheit temperature. The LM34 thus has an advantage

over linear temperature sensors calibrated in degrees

Kelvin, as the user is not required to subtract a large constant voltage from its output to obtain convenient Fahrenheit

scaling. The LM34 does not require any external calibration

or trimming to provide typical accuracies of

temperature and

ture range. Low cost is assured by trimming and calibration

at the wafer level. The LM34’s low output impedance, linear

output, and precise inherent calibration make interfacing to

readout or control circuitry especially easy. It can be used

with single power supplies or with plus and minus supplies.

As it draws only 75 µA from its supply, it has very low

self-heating, less than 0.2˚F in still air. The LM34 is rated to

operate over a −50˚ to +300˚F temperature range, while the

LM34C is rated for a −40˚ to +230˚F range (0˚F with improved accuracy). The LM34 series is available packaged in

±

11⁄2˚F over a full −50 to +300˚F tempera-

1

±

⁄2˚F at room

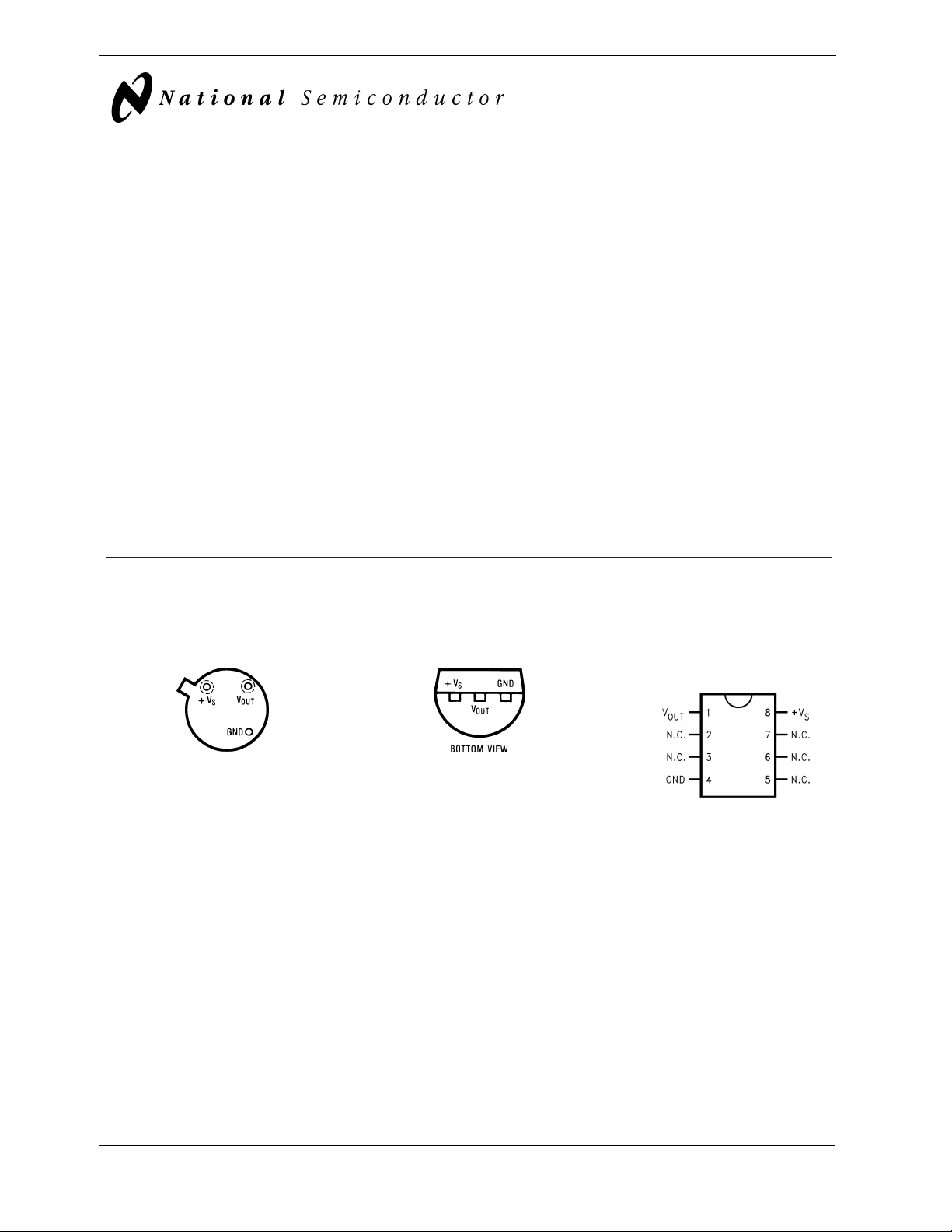

Connection Diagrams

TO-46

Metal Can Package

(Note 1)

Plastic Package

hermetic TO-46 transistor packages, while the LM34C,

LM34CA and LM34D are also available in the plastic TO-92

transistor package. The LM34D is also available in an8-lead

surface mount small outline package.TheLM34isacomplement to the LM35 (Centigrade) temperature sensor.

Features

n Calibrated directly in degrees Fahrenheit

n Linear +10.0 mV/˚F scale factor

n 1.0˚F accuracy guaranteed (at +77˚F)

n Rated for full −50˚ to +300˚F range

n Suitable for remote applications

n Low cost due to wafer-level trimming

n Operates from 5 to 30 volts

n Less than 90 µA current drain

n Low self-heating, 0.18˚F in still air

n Nonlinearity only

n Low-impedance output, 0.4Ω for 1 mA load

TO-92

±

0.5˚F typical

SO-8

Small Outline

Molded Package

DS006685-1

Order Numbers LM34H,

LM34AH, LM34CH,

LM34CAH or LM34DH

See NS Package

Number H03H

Note 1: Case is connected to negative pin (GND).

© 2000 National Semiconductor Corporation DS006685 www.national.com

Order Number LM34CZ,

LM34CAZ or LM34DZ

See NS Package

DS006685-2

Number Z03A

DS006685-20

N.C. = No Connection

Top View

Order Number LM34DM

See NS Package Number M08A

Page 2

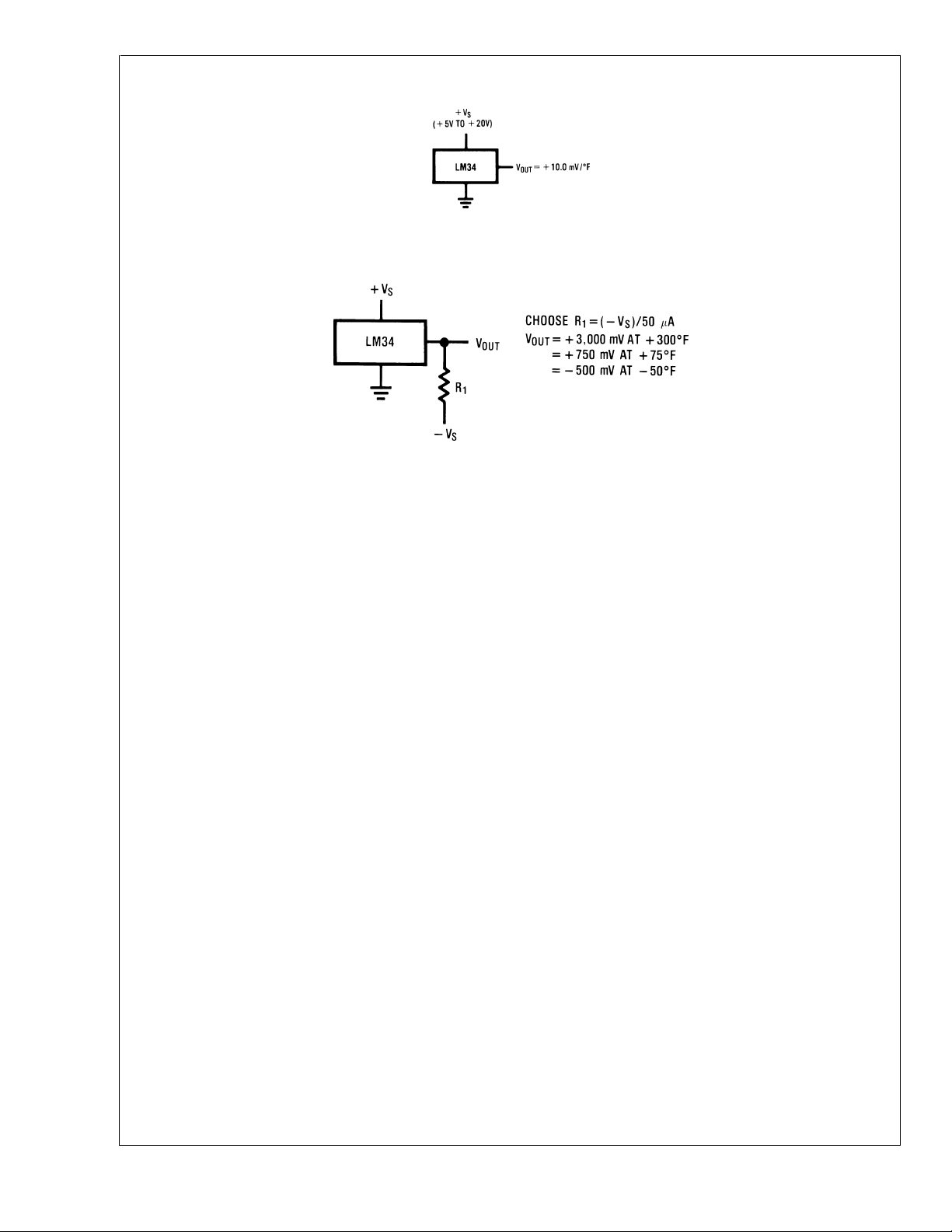

Typical Applications

LM34

DS006685-3

FIGURE 1. Basic Fahrenheit Temperature Sensor

(+5˚ to +300˚F)

DS006685-4

FIGURE 2. Full-Range Fahrenheit Temperature Sensor

www.national.com 2

Page 3

LM34

Absolute Maximum Ratings (Note 11)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage +35V to −0.2V

Output Voltage +6V to −1.0V

Output Current 10 mA

Storage Temperature,

TO-46 Package −76˚F to +356˚F

TO-92 Package −76˚F to +300˚F

SO-8 Package −65˚C to +150˚C

ESD Susceptibility (Note 12) 800V

TO-46 Package

(Soldering, 10 seconds) +300˚C

TO-92 Package

(Soldering, 10 seconds) +260˚C

SO Package (Note 13)

Vapor Phase (60 seconds) 215˚C

Infrared (15 seconds) 220˚C

Specified Operating Temp. Range (Note 3)

to T

T

MIN

MAX

LM34, LM34A −50˚F to +300˚F

LM34C, LM34CA −40˚F to +230˚F

LM34D +32˚F to +212˚F

Lead Temp.

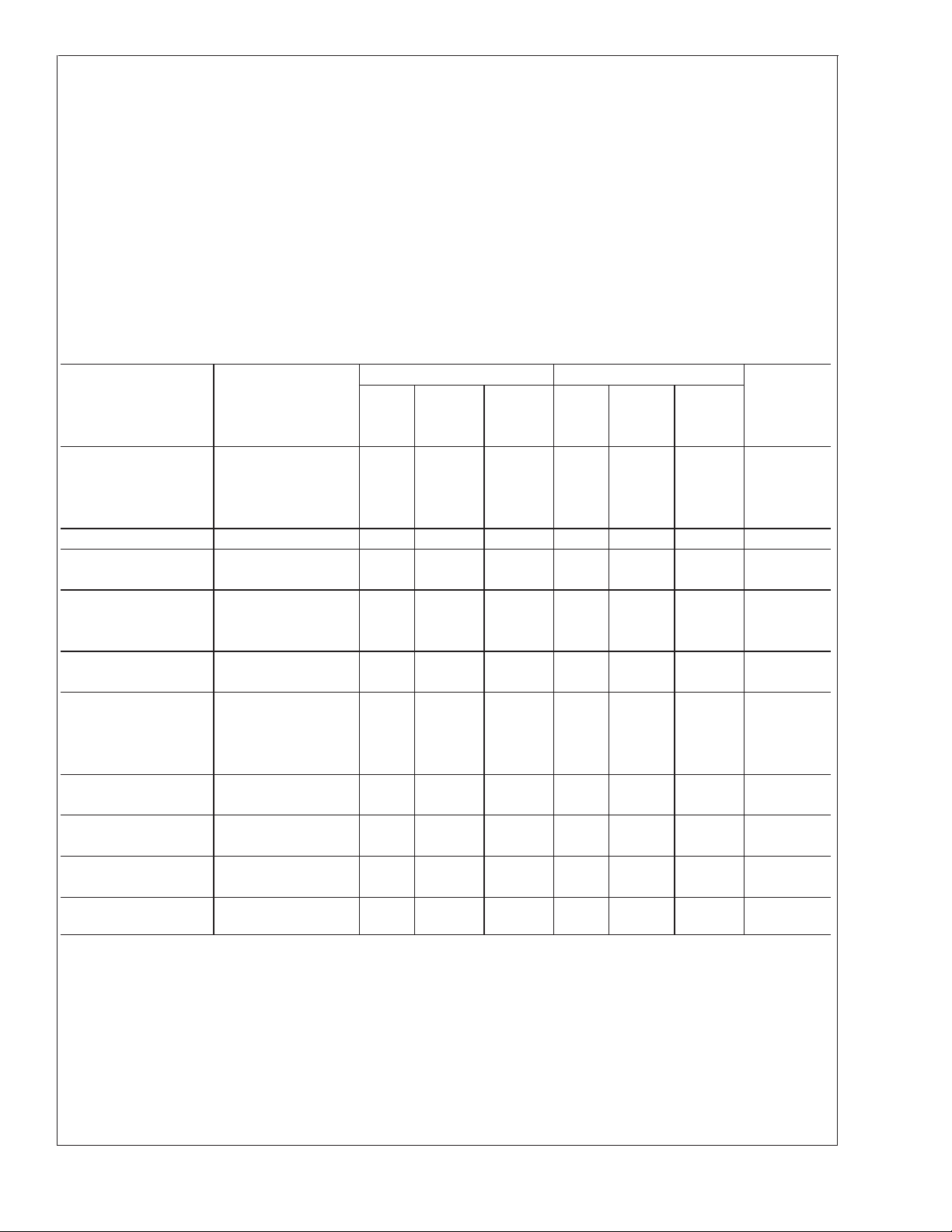

DC Electrical Characteristics (Notes 2, 7)

LM34A LM34CA

Parameter Conditions Tested Design Tested Design Units

Typical Limit Limit Typical Limit Limit (Max)

(Note 5) (Note 6) (Note 5) (Note 6)

Accuracy (Note 8) T

Nonlinearity (Note 9) T

Sensor Gain T

= +77˚F

A

T

= 0˚F

A

T

A=TMAX

T

A=TMIN

MIN

MIN

≤ TA≤ T

≤ TA≤ T

MAX

MAX

±

0.4

±

0.6

±

0.8

±

0.8

±

0.35

+10.0 +9.9, +10.0 +9.9, mV/˚F, min

(Average Slope) +10.1 +10.1 mV/˚F, max

Load Regulation T

(Note 4) T

Line Regulation T

A

MIN

0 ≤ I

A

= +77˚F

L

= +77˚F

(Note 4) 5V ≤ V

Quiescent Current V

(Note 10) V

= +5V, +77˚F 75 90 75 90 µA

S

= +5V 131 160 116 139 µA

S

V

= +30V, +77˚F 76 92 76 92 µA

S

V

= +30V 132 163 117 142 µA

S

Change of Quiescent 4V ≤ V

Current (Note 4) 5V ≤ V

≤ TA≤ T

MAX

≤ 1mA

≤ 30V

S

≤ 30V, +77˚F +0.5 2.0 0.5 2.0 µA

S

≤ 30V +1.0 3.0 1.0 3.0 µA

S

±

±

±

±

0.4

0.5

0.01

0.02

Temperature Coefficient +0.30 +0.5 +0.30 +0.5 µA/˚F

of Quiescent Current

Minimum Temperature In circuit of

for Rated Accuracy I

Long-Term Stability T

=0

L

j=TMAX

Figure 1

, +3.0 +5.0 +3.0 +5.0 ˚F

±

0.16

for 1000 hours

Note 2: Unless otherwise noted, these specifications apply: −50˚F ≤ Tj≤ + 300˚F for the LM34 and LM34A; −40˚F ≤ Tj≤ +230˚F for the LM34C and LM34CA; and

+32˚F ≤T

also apply from +5˚F to T

Note 3: Thermal resistance of the TO-46 package is 720˚F/W junction toambient and 43˚F/W junction to case. Thermal resistanceof the TO-92 package is 324˚F/W

junction to ambient. Thermal resistance of the small outline molded package is 400˚F/W junction to ambient. For additional thermal resistance information see table

in the Typical Applications section.

Note 4: Regulation ismeasured atconstant junctiontemperature usingpulse testing with a low duty cycle. Changes in output due to heating effects can be computed

by multiplying the internal dissipation by the thermal resistance.

Note 5: Tested limits are guaranteed and 100% tested in production.

Note 6: Design limits are guaranteed (but not 100% production tested) over the indicated temperature and supply voltage ranges. These limits are not used to

calculate outgoing quality levels.

Note 7: Specification in BOLDFACE TYPE apply over the full rated temperature range.

≤ + 212˚F forthe LM34D.VS= +5 Vdc and I

j

in the circuit of

MAX

Figure 1

= 50 µA in the circuitof

LOAD

.

±

±

±

±

±

1.0

2.0

2.0

±

0.7

1.0

±

3.0

0.05

±

0.1

Figure 2

; +6 Vdc forLM34 andLM34A for 230˚F ≤ Tj≤ 300˚F.These specifications

±

0.4

±

0.6

±

0.8

±

0.8

±

0.30

±

0.4

±

0.5

±

0.01

±

0.02

±

0.16 ˚F

±

1.0 ˚F

±

2.0 ˚F

±

2.0 ˚F

±

3.0 ˚F

±

0.6 ˚F

±

1.0 mV/mA

±

3.0 mV/mA

±

0.05 mV/V

±

0.1 mV/V

www.national.com3

Page 4

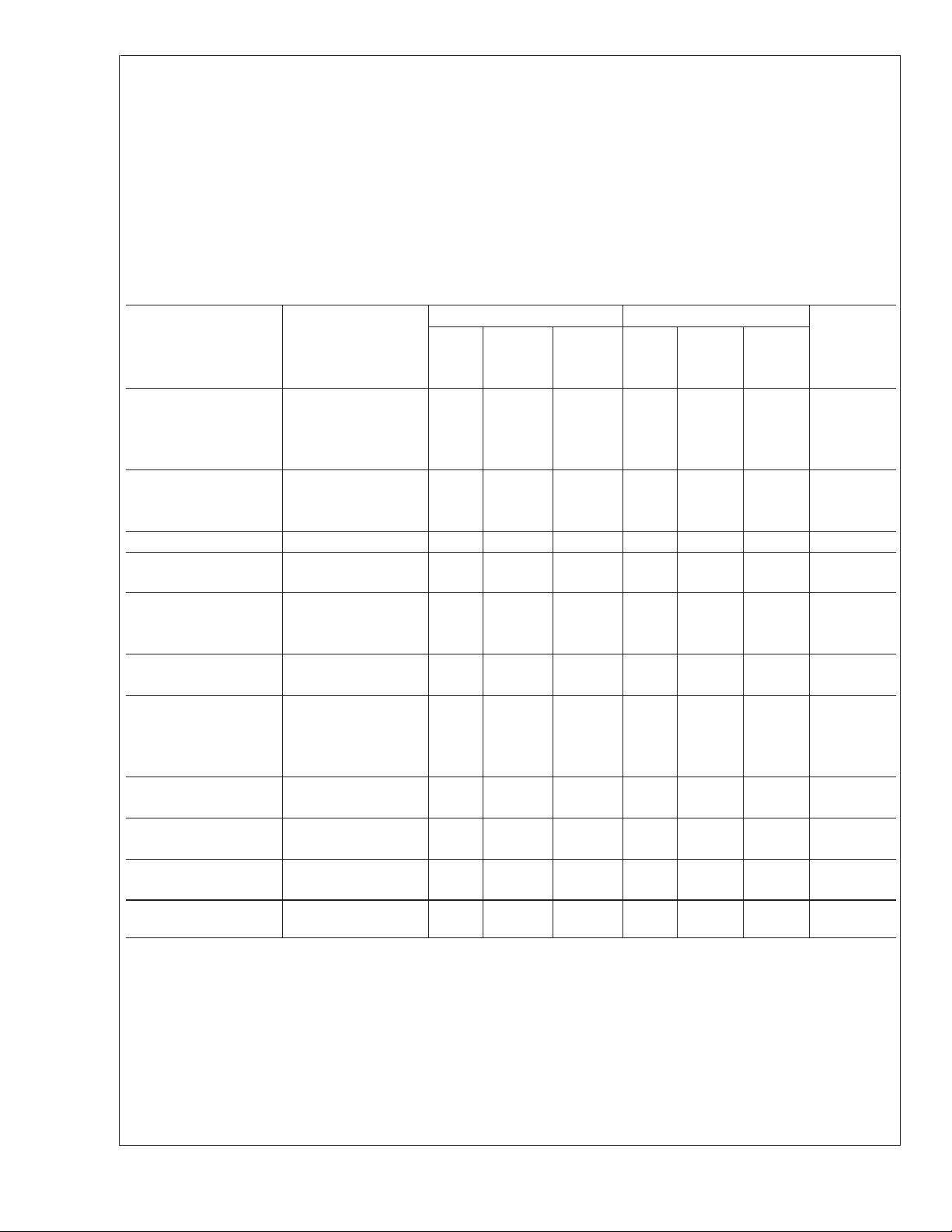

DC Electrical Characteristics (Notes 2, 7) (Continued)

LM34

Note 8: Accuracy is defined as the error between the output voltage and 10 mV/˚F times the device’s case temperature at specified conditions of voltage, current,

and temperature (expressed in ˚F).

Note 9: Nonlinearity is defined as the deviation of the output-voltage-versus-temperature curve from the best-fit straight line over the device’s rated temperature

range.

Note 10: Quiescent current is defined in the circuit of

Note 11: Absolute Maximum Ratings indicate limits beyond which damage to thedevice may occur. DC and AC electrical specifications do not apply when operating

the device beyond its rated operating conditions (Note 2).

Note 12: Human body model, 100 pF discharged through a 1.5 kΩ resistor.

Note 13: See AN-450 “Surface Mounting Methods and Their Effect on Product Reliability” or the section titled “Surface Mount” found in a current National

Semiconductor Linear Data Book for other methods of soldering surface mount devices.

Figure 1

.

DC Electrical Characteristics (Notes 2, 7)

LM34 LM34C, LM34D

Parameter Conditions Tested Design Tested Design Units

Typical Limit Limit Typical Limit Limit (Max)

(Note 5) (Note 6) (Note 5) (Note 6)

Accuracy, LM34, LM34C T

(Note 8) T

Accuracy, LM34D T

(Note 8) T

Nonlinearity (Note 9) T

Sensor Gain T

= +77˚F

A

= 0˚F

A

T

A=TMAX

T

A=TMIN

= +77˚F

A

A=TMAX

T

A=TMIN

MIN

MIN

≤ TA≤ T

≤ TA≤ T

MAX

MAX

±

0.8

±

1.0

±

1.6

±

1.6

±

0.6

+10.0 +9.8, +10.0 +9.8, mV/˚F, min

(Average Slope) +10.2 +10.2 mV/˚F, max

Load Regulation T

(Note 4) T

Line Regulation T

A

MIN

0 ≤ I

A

= +77˚F

L

= +77˚F

(Note 4) 5V ≤ V

Quiescent Current V

(Note 10) V

= +5V, +77˚F 75 100 75 100 µA

S

= +5V 131 176 116 154 µA

S

V

= +30V, +77˚F 76 103 76 103 µA

S

V

= +30V 132 181 117 159 µA

S

Change of Quiescent 4V ≤ V

Current (Note 4) 5V ≤ V

≤ TA≤ +150˚F

≤ 1mA

≤ 30V

S

≤ 30V, +77˚F +0.5 3.0 0.5 3.0 µA

S

≤ 30V +1.0 5.0 1.0 5.0 µA

S

±

±

±

±

0.4

0.5

0.01

0.02

Temperature Coefficient +0.30 +0.7 +0.30 +0.7 µA/˚F

of Quiescent Current

Minimum Temperature In circuit of

for Rated Accuracy I

Long-Term Stability T

=0

L

j=TMAX

Figure 1

, +3.0 +5.0 +3.0 +5.0 ˚F

±

0.16

for 1000 hours

±

2.0

±

3.0

±

3.0

±

1.0

±

2.5

±

6.0

±

0.1

±

0.2

±

0.8

±

1.0

±

1.6

±

1.6

±

1.2

±

1.8

±

1.8

±

0.4

±

0.4

±

0.5

±

0.01

±

0.02

±

0.16 ˚F

±

2.0 ˚F

±

3.0 ˚F

±

3.0 ˚F

±

4.0 ˚F

±

3.0 ˚F

±

4.0 ˚F

±

4.0 ˚F

±

1.0 ˚F

±

2.5 mV/mA

±

6.0 mV/mA

±

0.1 mV/V

±

0.2 mV/V

www.national.com 4

Page 5

Typical Performance Characteristics

LM34

Thermal Resistance

Junction to Air

Thermal Response in

Stirred Oil Bath

DS006685-22

Thermal Time Constant

Minimum Supply Voltage

vs. Temperature

DS006685-23

Thermal Response in

Still Air

Quiescent Current vs.

Temperature

(In Circuit of

Figure 1

DS006685-24

)

Quiescent Current vs. Temperature (In Circuit of

−V

= −5V, R1 = 100k)

S

Figure 2

DS006685-25

;

DS006685-28

Accuracy vs. Temperature

(Guaranteed)

DS006685-26

DS006685-29

DS006685-27

Accuracy vs. Temperature

(Guaranteed)

DS006685-30

www.national.com5

Page 6

Typical Performance Characteristics (Continued)

LM34

Noise Voltage

DS006685-31

Typical Applications

The LM34 can be applied easily in the same way as other

integrated-circuit temperature sensors. It can be glued or

cemented to a surface and its temperature will be within

about 0.02˚F of the surface temperature.This presumesthat

the ambient air temperature is almost the same as the

surface temperature; if the air temperature were much

higher or lower than the surface temperature, the actual

temperature of the LM34 die would be at an intermediate

temperature between the surface temperature and the air

temperature. This is expecially true for the TO-92 plastic

package, where the copper leads are the principal thermal

path to carry heat into the device, so its temperature might

be closer to the air temperature than to the surface temperature.

To minimize this problem, be sure that the wiring to the

LM34, as it leaves the device, is held at the same temperature as the surface of interest. The easiest way to do this is

to cover up these wires with a bead of epoxy which will

insure that the leads and wires are all at the same temperature as the surface, and that the LM34 die’s temperature will

not be affected by the air temperature.

The TO-46 metal package can also be soldered to a metal

surface or pipe without damage. Of course in that case, the

V

terminal of the circuit will be grounded to that metal.

−

Alternatively, the LM34 can be mounted inside a sealed-end

metal tube, and can then be dipped into a bath or screwed

into a threaded hole in a tank.As with any IC, the LM34 and

accompanying wiring and circuits must be keptinsulatedand

dry, to avoid leakage and corrosion. This is especially true if

the circuit may operate at cold temperatures where condensation can occur.Printed-circuitcoatings and varnishes such

as Humiseal and epoxy paints or dips are often used to

insure that moisture cannot corrode the LM34 or its connections.

Start-Up Response

DS006685-32

These devices are sometimes soldered to a small,

light-weight heat fin to decrease the thermal time constant

and speed up the response in slowly-moving air. On the

other hand, a small thermal mass may be added to the

sensor to give the steadiest reading despite small deviations

in the air temperature.

Capacitive Loads

Like most micropower circuits, the LM34 has a limited ability

to drive heavy capacitive loads. The LM34 by itself is able to

drive 50 pF without special precautions. If heavier loads are

anticipated, it is easy to isolate or decouple the load with a

resistor; see

capacitance with a series R-C damper from output to

ground; see

load resistor (as shown), it is relatively immune to wiring

capacitance because the capacitance forms a bypass from

ground to input, not on the output. However, as with any

linear circuit connected to wires in a hostile environment, its

performance can be affected adversely by intense electromagnetic sources such as relays, radio transmitters, motors

with arcing brushes, SCR’s transients, etc., as its wiring can

act as a receiving antenna and its internal junctions can act

as rectifiers. For best results in such cases, a bypass capacitor from V

75Ω in series with 0.2or1µF from output to ground are often

useful. These are shown in the following circuits.

Figure 3

Figure 4

. Or you can improve the tolerance of

. When the LM34 is applied with a 499Ω

to ground and a series R-C damper such as

IN

DS006685-6

www.national.com 6

Page 7

Typical Applications

DS006685-7

FIGURE 3. LM34 with Decoupling from Capacitive Load

DS006685-8

Temperature Rise of LM34 Due to Self-Heating (Thermal Resistance)

Conditions TO-46, TO-46, TO-92, TO-92, SO-8 SO-8

No Heat

Sink

Small Heat Fin

(Note 14)

No Heat

Sink

Still air 720˚F/W 180˚F/W 324˚F/W 252˚F/W 400˚F/W 200˚F/W

Moving air 180˚F/W 72˚F/W 162˚F/W 126˚F/W 190˚F/W 160˚F/W

Still oil 180˚F/W 72˚F/W 162˚F/W 126˚F/W

Stirred oil 90˚F/W 54˚F/W 81˚F/W 72˚F/W

(Clamped to metal, (43˚F/W) (95˚F/W)

infinite heat sink)

FIGURE 4. LM34 with R-C Damper

Small Heat Fin

(Note 15)

No Heat

Sink

Small Heat Fin

(Note 15)

LM34

Note 14: Wakefield type 201 or 1" disc of 0.020" sheet brass, soldered to case, or similar.

Note 15: TO-92 and SO-8 packages glued and leads soldered to 1" square of 1/16" printed circuit board with 2 oz copper foil, or similar.

Two-Wire Remote Temperature Sensor

V

= 10mV/˚F (TA+3˚F)

OUT

FROM +3˚F TO + 100˚F

(Grounded Sensor)

DS006685-9

Two-Wire Remote Temperature Sensor

(Output Referred to Ground)

DS006685-10

www.national.com7

Page 8

Typical Applications (Continued)

LM34

4-to-20 mA Current Source

(0 to +100˚F)

DS006685-11

Expanded Scale Thermometer

(50˚ to 80˚ Fahrenheit, for Example Shown)

Fahrenheit Thermometer

(Analog Meter)

DS006685-12

Temperature-to-Digital Converter

(Serial Output, +128˚F Full Scale)

DS006685-13

LM34 with Voltage-to-Frequency Converter and Isolated Output

(3˚F to + 300˚F; 30 Hz to 3000 Hz)

DS006685-15

DS006685-14

www.national.com 8

Page 9

Typical Applications (Continued)

LM34

Bar-Graph Temperature Display

(Dot Mode)

*

= 1% or 2% film resistor

—Trim R

—Trim R

—Trim R

—Example, VA= 3.285V at 80˚F

for VB= 3.525V

B

for VC= 2.725V

C

for VA= 0.085V + 40 mV/˚F x T

A

(Parallel TRI-STATE

AMBIENT

Temperature-to-Digital Converter

®

Outputs for Standard Data Bus to µP Interface, 128 ˚F Full Scale)

DS006685-17

DS006685-16

www.national.com9

Page 10

Typical Applications (Continued)

LM34

Block Diagram

Temperature Controller

DS006685-18

www.national.com 10

DS006685-19

Page 11

Physical Dimensions inches (millimeters) unless otherwise noted

Order Number LM34H, LM34AH, LM34CH,

LM34CAH or LM34DH

NS Package H03H

LM34

Order Number LM34DM

NS Package Number M08A

www.national.com11

Page 12

Physical Dimensions inches (millimeters) unless otherwise noted (Continued)

LM34 Precision Fahrenheit Temperature Sensors

Order Number LM34CZ, LM34CAZ or LM34DZ

NS Package Z03A

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

labeling, can be reasonably expected to result in a

significant injury to the user.

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: ap.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

Loading...

Loading...