Page 1

LM3488

High Efficiency Low-Side N-Channel Controller for

Switching Regulators

±

n

General Description

The LM3488 is a versatile Low-Side N-FET high performance controller for switching regulators. It is suitable for

use in topologies requiring low side FET, such as boost,

flyback, SEPIC, etc. Moreover, the LM3488 can be operated

at extremely high switching frequency in order to reduce the

overall solution size. The switching frequency of LM3488 can

be adjusted to any value between 100kHz and 1MHz by

using a single external resistor or by synchronizing it to an

external clock. Current mode control provides superior bandwidth and transient response, besides cycle-by-cycle current

limiting. Output current can be programmed with a single

external resistor.

The LM3488 has built in features such as thermal shutdown,

short-circuit protection and over voltage protection. Power

saving shutdown mode reduces the total supply current to

5µA and allows power supply sequencing. Internal soft-start

limits the inrush current at start-up.

Key Specifications

n Wide supply voltage range of 2.97V to 40V

n 100kHz to 1MHz Adjustable and Synchronizable clock

frequency

1.5% (over temperature) internal reference

n 5µA shutdown current (over temperature)

Features

n 8-lead Mini-SO8 (MSOP-8) package

n Internal push-pull driver with 1A peak current capability

n Current limit and thermal shutdown

n Frequency compensation optimized with a capacitor and

a resistor

n Internal softstart

n Current Mode Operation

n Undervoltage Lockout with hysteresis

Applications

n Distributed Power Systems

n Notebook, PDA, Digital Camera, and other Portable

Applications

n Offline Power Supplies

n Set-Top Boxes

LM3488 High Efficiency Low-Side N-Channel Controller for Switching Regulators

May 2003

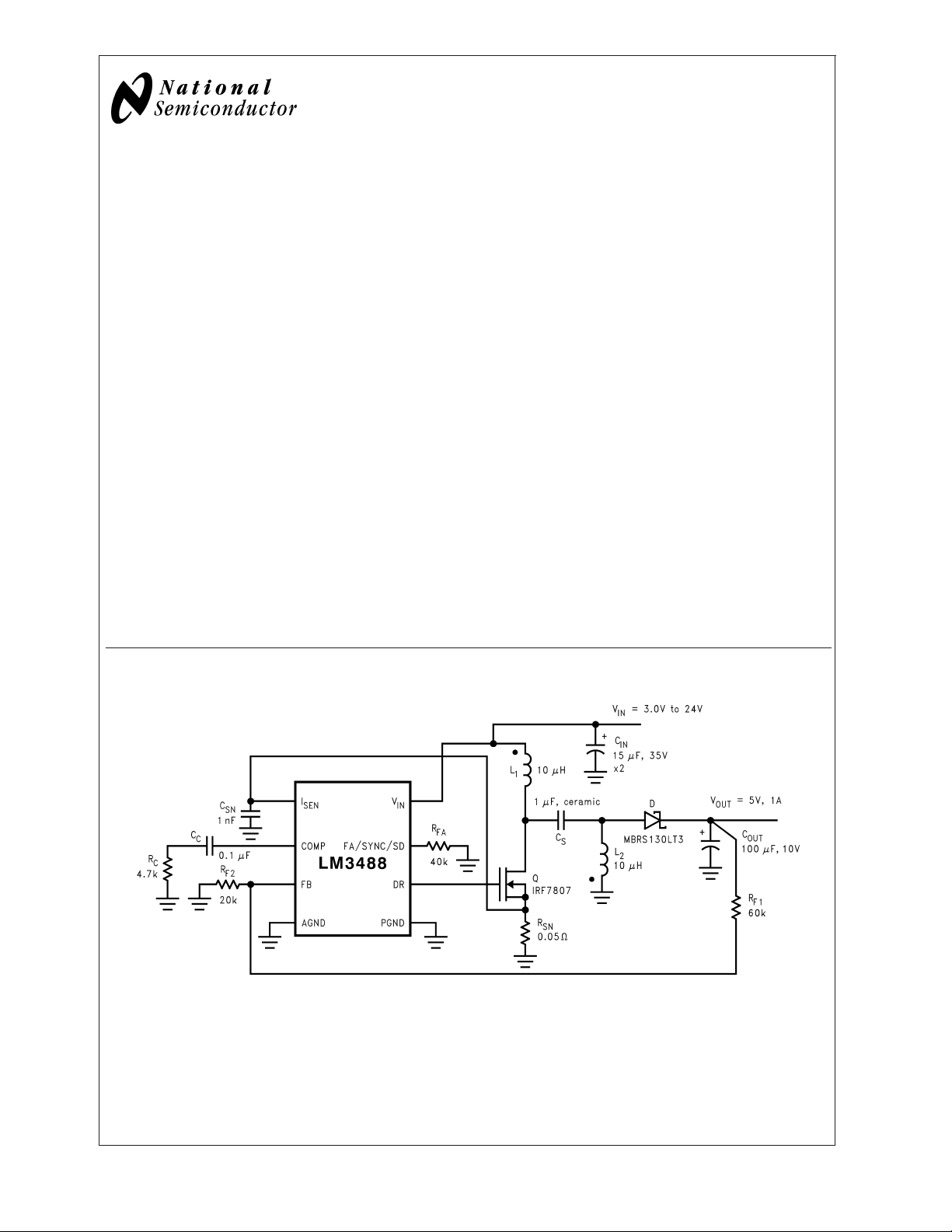

Typical Application Circuit

Typical SEPIC Converter

10138844

© 2003 National Semiconductor Corporation DS101388 www.national.com

Page 2

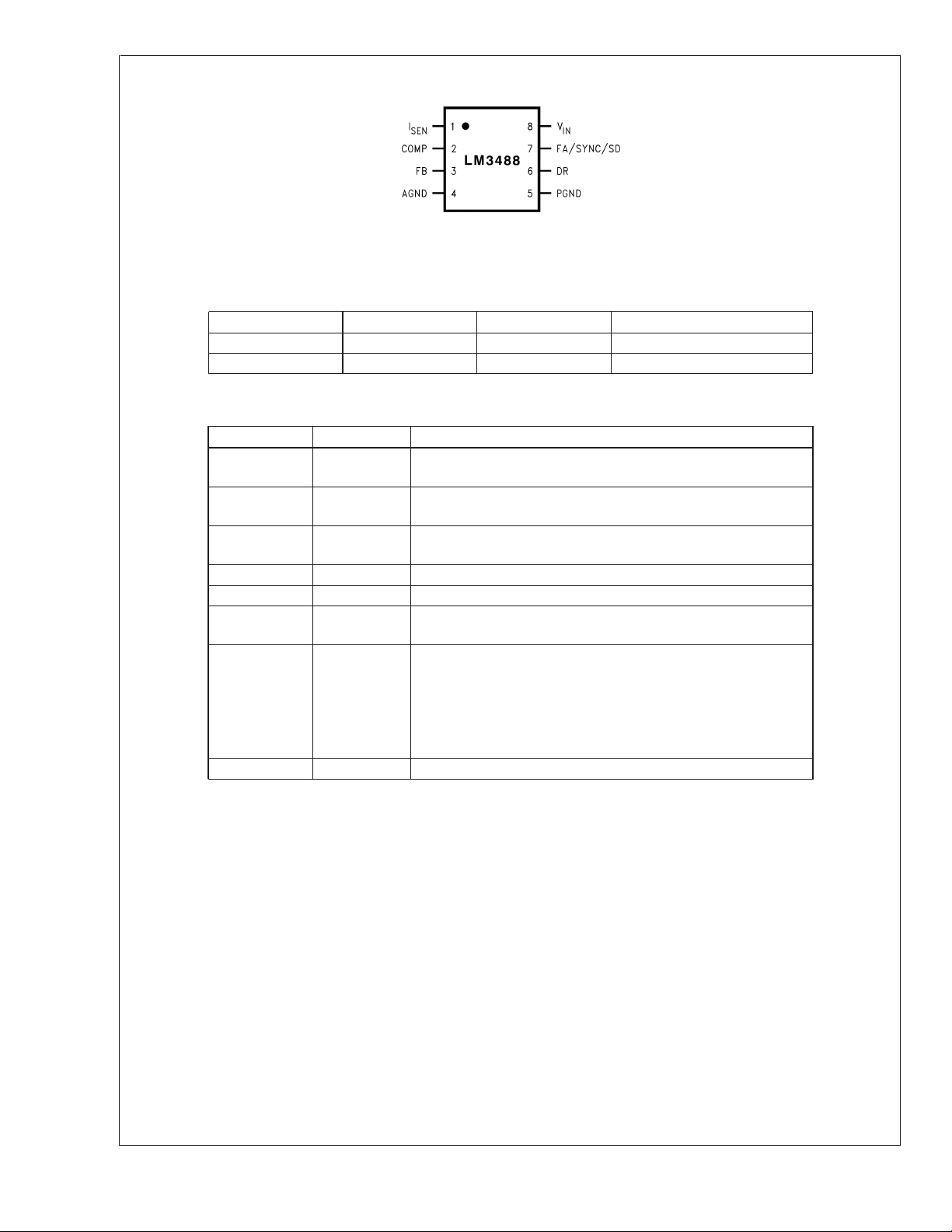

Connection Diagram

LM3488

8 Lead Mini SO8 Package (MSOP-8 Package)

Package Marking and Ordering Information

Order Number Package Type Package Marking Supplied As:

LM3488MM MSOP-8 S21B 1000 units on Tape and Reel

LM3488MMX MSOP-8 S21B 3500 units on Tape and Reel

Pin Description

Pin Name Pin Number Description

I

SEN

COMP 2 Compensation pin. A resistor, capacitor combination connected to

FB 3 Feedback pin. The output voltage should be adjusted using a

AGND 4 Analog ground pin.

PGND 5 Power ground pin.

DR 6 Drive pin of the IC. The gate of the external MOSFET should be

FA/SYNC/SD 7 Frequency adjust, synchronization, and Shutdown pin. A resistor

V

IN

1 Current sense input pin. Voltage generated across an external

sense resistor is fed into this pin.

this pin provides compensation for the control loop.

resistor divider to provide 1.26V at this pin.

connected to this pin.

connected to this pin sets the oscillator frequency. An external

clock signal at this pin will synchronize the controller to the

frequency of the clock. A high level on this pin for ≥ 30µs will turn

the device off. The device will then draw less than 10µA from the

supply.

8 Power supply input pin.

10138802

www.national.com 2

Page 3

LM3488

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Input Voltage 45V

<

<

FA/SYNC/SD

V

FB

<

FB Pin Voltage -0.4V

FA/SYNC/SD Pin Voltage -0.4V

V

Peak Driver Output Current (

<

10µs) 1.0A

Power Dissipation Internally Limited

Storage Temperature Range −65˚C to +150˚C

Junction Temperature +150˚C

ESD Susceptibilty

7V

<

7V

Lead Temperature

MM Package

Vapor Phase (60 sec.)

Infared (15 sec.)

DR Pin Voltage −0.4V ≤ VDR ≤ 8V

I

Pin Voltage 600mV

LIM

Operating Ratings (Note 1)

Supply Voltage 2.97V ≤ V

Junction

Temperature Range −40˚C ≤ TJ≤ +125˚C

Switching Frequency 100kHz ≤ F

SW

IN

≤ 1MHz

Human Body Model (Note 2) 2kV

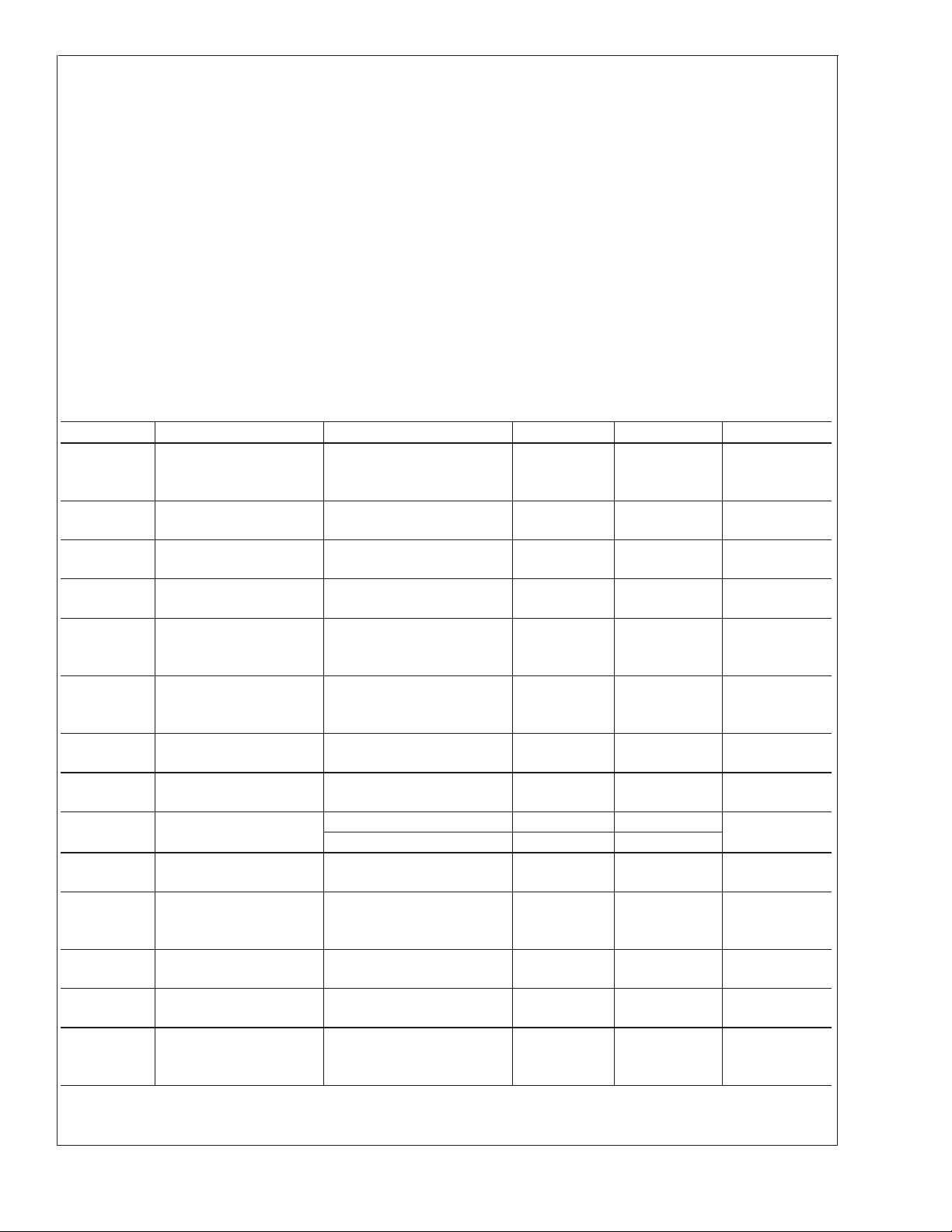

Electrical Characteristics

Specifications in Standard type face are for TJ= 25˚C, and in bold type face apply over the full Operating Temperature

Range. Unless otherwise specified, V

Symbol Parameter Conditions Typical Limit Units

V

∆V

FB

LINE

Feedback Voltage V

Feedback Voltage

Line Regulation

∆V

LOAD

Output Voltage Load

Regulation

V

UVLO

Input Undervoltage

Lock-out

V

UV(HYS)

Input Undervoltage

Lock-out Hysteresis

F

nom

Nominal Switching

Frequency

R

DS1 (ON)

Driver Switch On

Resistance (top)

R

DS2 (ON)

Driver Switch On

Resistance (bottom)

V

DR (max)

Maximum Drive

Voltage Swing(Note 6)

D

max

Maximum Duty

Cycle(Note 7)

(on) Minimum On Time 325

T

min

I

SUPPLY

Supply Current

(switching)

I

Q

Quiescent Current in

Shutdown Mode

V

SENSE

Current Sense

Threshold Voltage

= 12V, RFA= 40kΩ

IN

COMP

2.97 ≤ V

= 1.4V,

≤ 40V

IN

1.26

1.2507/1.24

1.2753/1.28

2.97 ≤ VIN≤ 40V 0.001 %/V

I

EAO

Source/Sink

±

0.5 %/V (max)

2.85

2.97

170

130

210

RFA= 40KΩ 400

370

420

IDR= 0.2A, VIN=5V 16 Ω

IDR= 0.2A 4.5 Ω

<

V

7.2V V

IN

V

≥ 7.2V 7.2

IN

IN

100 %

230

550

(Note 9)

V

FA/SYNC/SD

10), V

IN

= 5V(Note

=5V

2.0

5

2.6

7

VIN= 5V 165

140/ 135

195/ 200

V(min)

V(max)

V(max)

mV (min)

mV (max)

kHz

kHz(min)

kHz(max)

nsec

nsec(min)

nsec(max)

mA (max)

µA (max)

mV (min)

mV (max)

215˚C

220˚C

≤ 40V

V

V

mV

V

mA

µA

mV

www.national.com3

Page 4

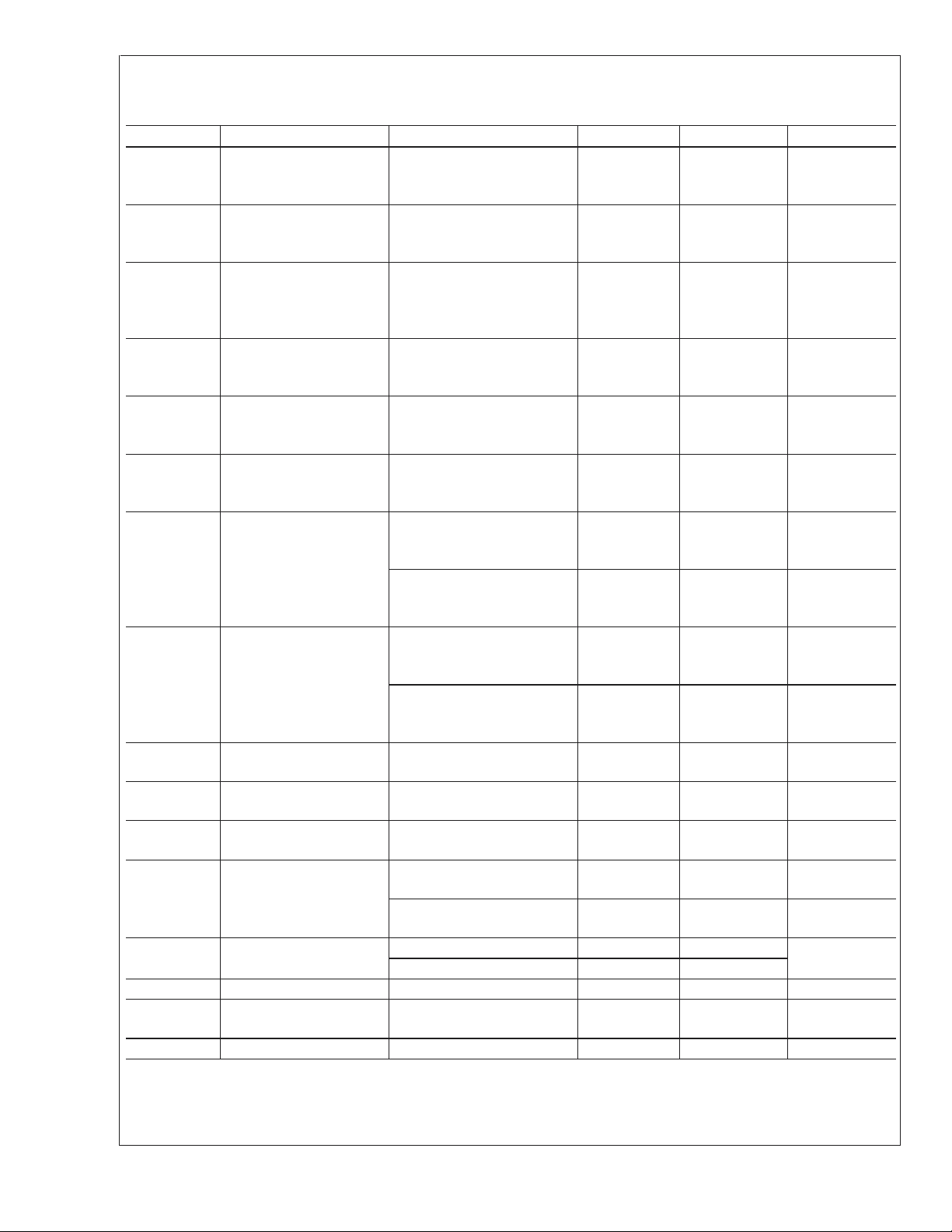

Electrical Characteristics (Continued)

Specifications in Standard type face are for TJ= 25˚C, and in bold type face apply over the full Operating Temperature

LM3488

Range. Unless otherwise specified, V

Symbol Parameter Conditions Typical Limit Units

V

SC

Short-Circuit Current

Limit Sense Voltage

V

SL

Internal Compensation

Ramp Voltage

V

OVP

Output Over-voltage

Protection (with

respect to feedback

voltage) (Note 8)

V

OVP(HYS)

Output Over-Voltage

Protection

Hysteresis(Note 8)

Gm Error Ampifier

Transconductance

A

VOL

Error Amplifier Voltage

Gain

I

EAO

Error Amplifier Output

Current (Source/ Sink)

V

EAO

Error Amplifier Output

Voltage Swing

T

SS

Internal Soft-Start

Delay

T

r

T

f

Drive Pin Rise Time Cgs = 3000pf, VDR=0to

Drive Pin Fall Time Cgs = 3000pf, VDR=0to

VSD Shutdown and

Synchronization signal

threshold (Note 5)

I

SD

Shutdown Pin Current VSD=5V −1 µA

TSD Thermal Shutdown 165 ˚C

T

sh

Thermal Shutdown

Hysteresis

θ

JA

Thermal Resistance MM Package 200 ˚C/W

= 12V, RFA= 40kΩ

IN

VIN= 5V 325

VIN=5V 92

= 1.4V 50

V

COMP

= 1.4V 60

V

COMP

= 1.4V

V

COMP

= 100µA

I

EAO

(Source/Sink)

V

= 1.4V

COMP

= 100µA

I

EAO

(Source/Sink)

Source, V

=0V

V

FB

Sink, V

COMP

COMP

= 1.4V, V

= 1.4V,

FB

= 1.4V

Upper Limit

=0V

V

FB

COMP Pin = Floating

Lower Limit

= 1.4V

V

FB

VFB= 1.2V, V

COMP

=

Floating

3V

3V

Output = High 1.27

Output = Low 0.65

V

=0V +1

SD

235

395

52

132

32/ 25

78/ 85

20

110

800

600/ 365

1000/ 1265

38

26

44

110

80/ 50

140/ 180

−140

−100/ −85

−180/ −185

2.2

1.8

2.4

0.56

0.2

1.0

4 msec

25 ns

25 ns

1.35

0.35

10 ˚C

mV

mV (min)

mV (max)

mV

mV(min)

mV(max)

mV

mV(min)

mV(max)

mV

mV(min)

mV(max)

µmho

µmho (min)

µmho (max)

V/V

V/V (min)

V/V (max)

µA

µA (min)

µA (max)

µA

µA (min)

µA (max)

V

V(min)

V(max)

V

V(min)

V(max)

V

V (max)

V

V (min)

www.national.com 4

Page 5

Electrical Characteristics (Continued)

Note 1: Absolute Maximum Ratings are limits beyond which damage to the device may occur. Operating Ratings are conditions under which operation of the device

is intended to be functional. For guaranteed specifications and test conditions, see the Electrical Characteristics.

Note 2: The human body model is a 100 pF capacitor discharged through a 1.5kΩ resistor into each pin.

Note 3: All limits are guaranteed at room temperature (standard type face) and at temperature extremes (bold type face). All room temperature limits are 100%

tested. All limits at temperature extremes are guaranteed via correlation using standard Statistical Quality Control (SQC) methods. All limits are used to calculate

Average Outgoing Quality Level (AOQL).

Note 4: Typical numbers are at 25˚C and represent the most likely norm.

Note 5: The FA/SYNC/SD pin should be pulled to V

Note 6: The voltage on the drive pin, V

than or equal to 7.2V.

Note 7: The limits for the maximum duty cycle can not be specified since the part does not permit less than 100% maximum duty cycle operation.

Note 8: The over-voltage protection is specified with respect to the feedback voltage. This is because the over-voltage protection tracks the feedback voltage. The

over-voltage thresold can be calculated by adding the feedback voltage, V

Note 9: For this test, the FA/SYNC/SD Pin is pulled to ground using a 40K resistor .

Note 10: For this test, the FA/SYNC/SD Pin is pulled to 5V using a 40K resistor.

is equal to the input voltage when input voltage is less than 7.2V. VDRis equal to 7.2V when the input voltage is greater

DR

through a resistor to turn the regulator off.

IN

to the over-voltage protection specification.

FB

LM3488

www.national.com5

Page 6

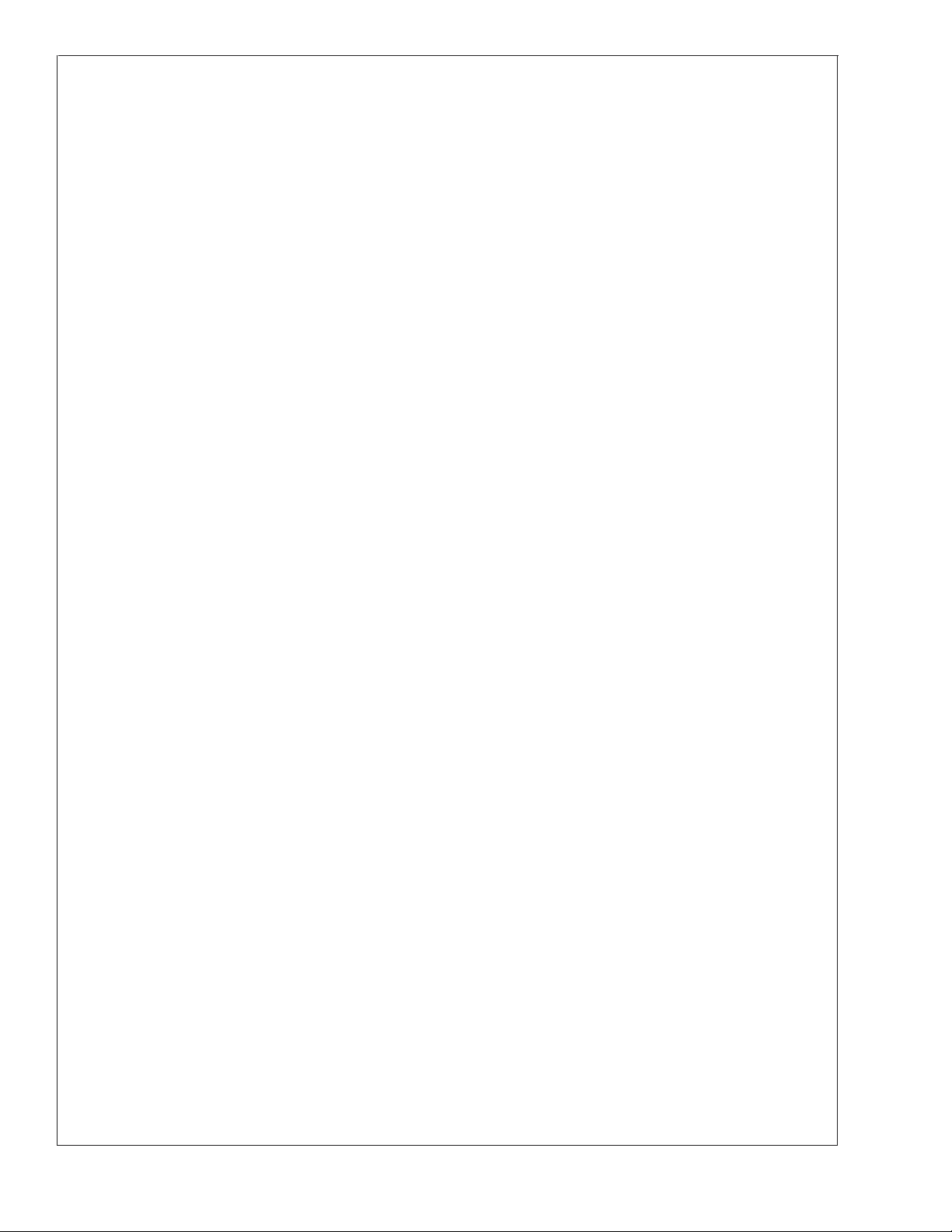

Typical Performance Characteristics Unless otherwise specified, V

LM3488

vs Temperature & Input Voltage I

I

Q

Supply

= 12V, TJ= 25˚C.

IN

vs Input Voltage (Non-Switching)

10138803

I

Supply

vs V

IN

10138835

Switching Frequency vs RFA

Frequency vs Temperature Drive Voltage vs Input Voltage

10138834

10138804

10138854

www.national.com 6

10138805

Page 7

LM3488

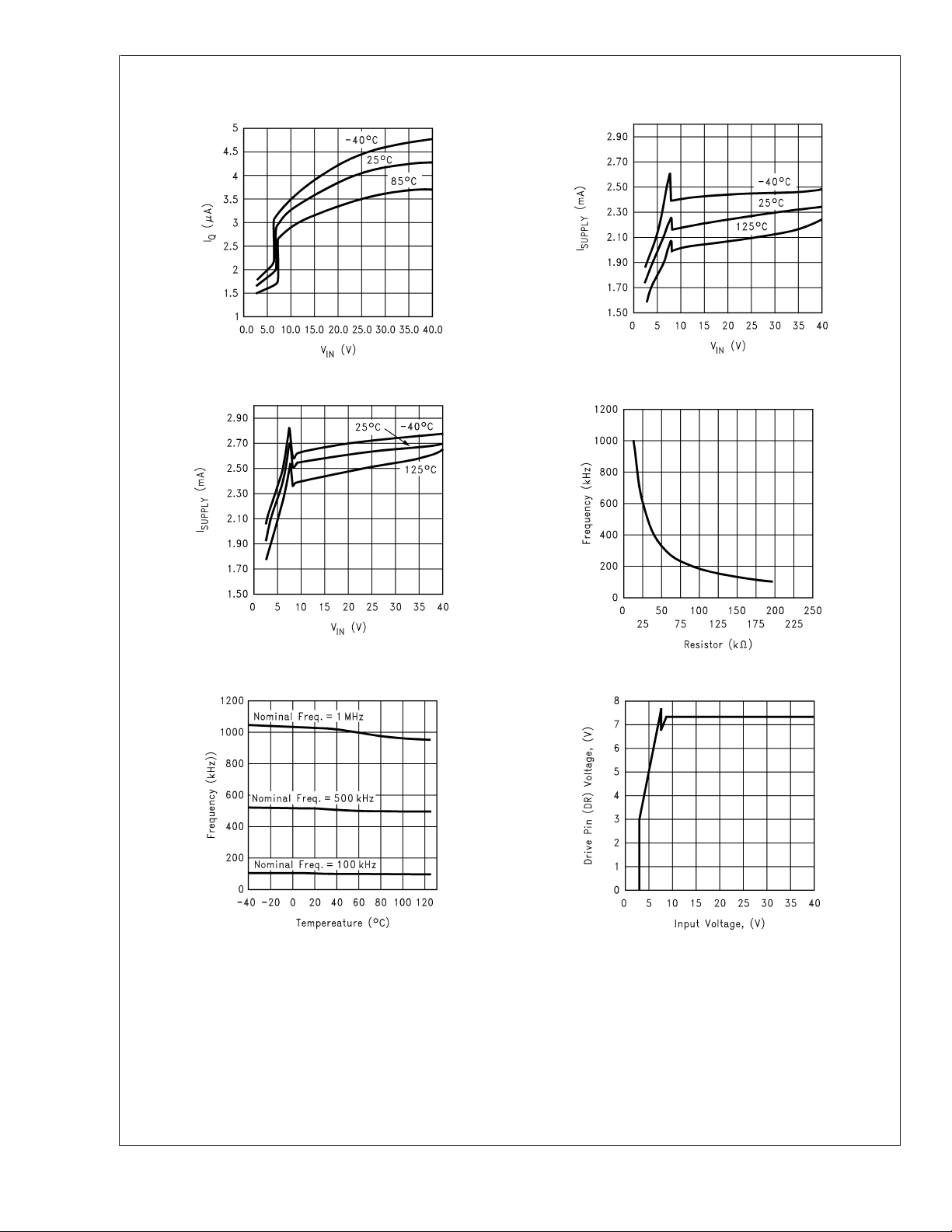

Typical Performance Characteristics Unless otherwise specified, V

= 12V, TJ= 25˚C. (Continued)

IN

Current Sense Threshold vs Input Voltage COMP Pin Voltage vs Load Current

10138845

Efficiency vs Load Current (3.3V In and 12V Out) Efficiency vs Load Current (5V In and 12V Out)

10138862

10138859 10138858

Efficiency vs Load Current (9V In and 12V Out) Efficiency vs Load Current (3.3V In and 5V Out)

10138860

10138853

www.national.com7

Page 8

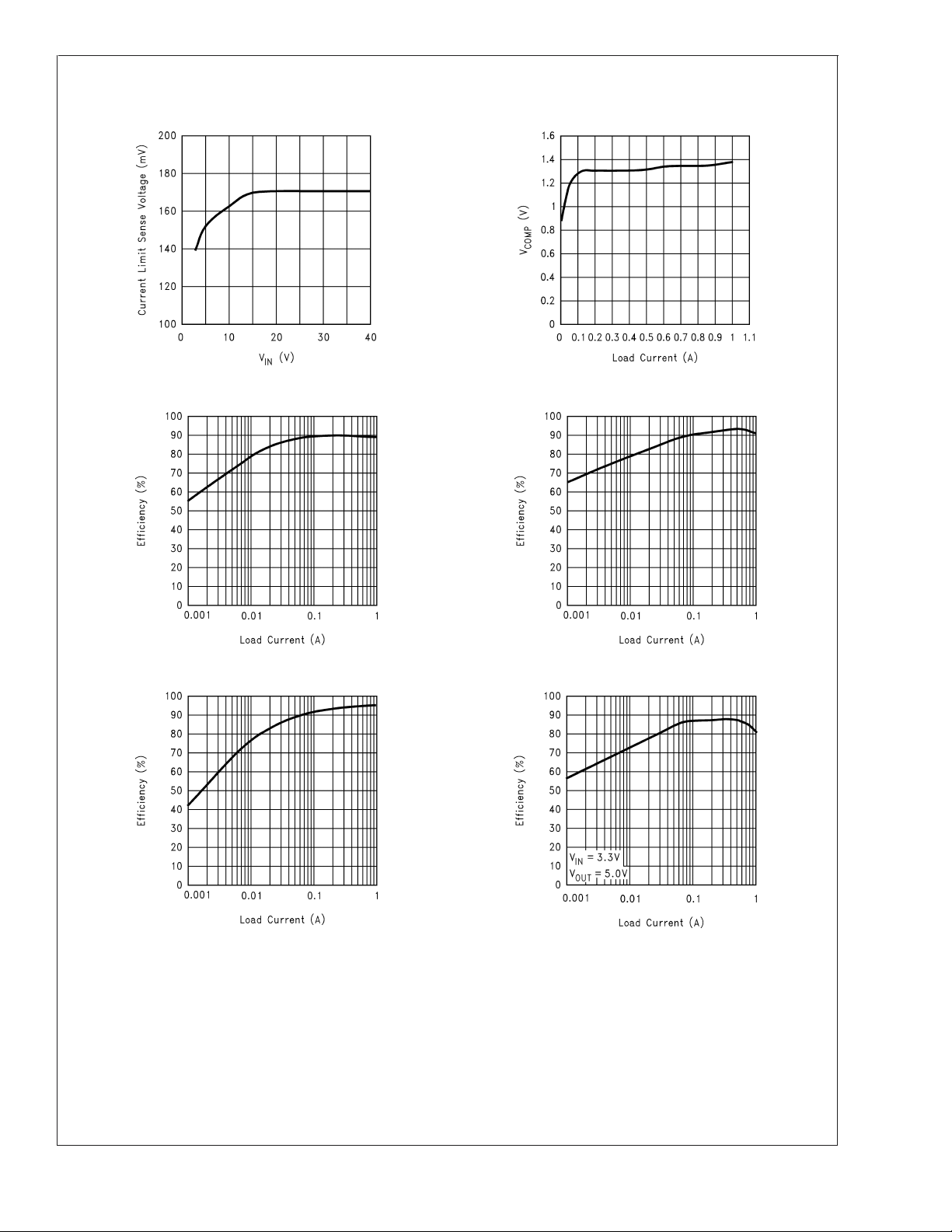

Typical Performance Characteristics Unless otherwise specified, V

LM3488

COMP Pin Source Current vs Temperature Short Circuit Protection vs Input Voltage

Error Amplifier Gain Error Amplifier Phase

10138855 10138856

= 12V, TJ= 25˚C. (Continued)

IN

10138836

10138857

Compensation Ramp vs Compensation Resistor Shutdown Threshold Hysteresis vs Temperature

10138851

10138846

www.national.com 8

Page 9

LM3488

Typical Performance Characteristics Unless otherwise specified, V

Current Sense Voltage vs Duty Cycle

10138852

= 12V, TJ= 25˚C. (Continued)

IN

www.national.com9

Page 10

Functional Block Diagram

LM3488

Functional Description

The LM3488 uses a fixed frequency, Pulse Width Modulated

(PWM), current mode control architecture. In a typical application circuit, the peak current through the external MOSFET is sensed through an external sense resistor. The voltage across this resistor is fed into the I

is then level shifted and fed into the positive input of the

PWM comparator. The output voltage is also sensed through

an external feedback resistor divider network and fed into

the error amplifier negative input (feedback pin, FB). The

output of the error amplifier (COMP pin) is added to the slope

compensation ramp and fed into the negative input of the

PWM comparator.

At the start of any switching cycle, the oscillator sets the RS

latch using the SET/Blank-out and switch logic blocks. This

forces a high signal on the DR pin (gate of the external

MOSFET) and the external MOSFET turns on. When the

voltage on the positive input of the PWM comparator exceeds the negative input, the RS latch is reset and the

external MOSFET turns off.

pin. This voltage

SEN

10138806

The voltage sensed across the sense resistor generally

contains spurious noise spikes, as shown in Figure 1. These

spikes can force the PWM comparator to reset the RS latch

prematurely. To prevent these spikes from resetting the

latch, a blank-out circuit inside the IC prevents the PWM

comparator from resetting the latch for a short duration after

the latch is set. This duration is about 150ns and is called the

blank-out time.

Under extremely light load or no-load conditions, the energy

delivered to the output capacitor when the external MOSFET

is on during the blank-out time is more than what is delivered

to the load. An over-voltage comparator inside the LM3488

prevents the output voltage from rising under these conditions. The over-voltage comparator senses the feedback (FB

pin) voltage and resets the RS latch under these conditions.

The latch remains in reset state till the output decays to the

nominal value.

www.national.com 10

Page 11

Functional Description (Continued)

FIGURE 1. Basic Operation of the PWM comparator

LM3488

10138807

SLOPE COMPENSATION RAMP

The LM3488 uses a current mode control scheme. The main

advantages of current mode control are inherent cycle-bycycle current limit for the switch, and simpler control loop

characteristics. It is also easy to parallel power stages using

current mode control since as current sharing is automatic.

Current mode control has an inherent instability for duty

cycles greater than 50%, as shown in Figure 2.InFigure 2,

a small increase in the load current causes the switch current to increase by ∆I

. The effect of this load change, ∆I1,is

O

:

From the above equation, when D>0.5, ∆I1will be greater

than ∆I

. In other words, the disturbance is divergent. So a

O

very small perturbation in the load will cause the disturbance

to increase.

To prevent the sub-harmonic oscillations, a compensation

ramp is added to the control signal, as shown in Figure 3.

With the compensation ramp,

FIGURE 2. Sub-Harmonic Oscillation for D>0.5

10138809

www.national.com11

Page 12

Functional Description (Continued)

LM3488

FIGURE 3. Compensation Ramp Avoids Sub-Harmonic Oscillation

The compensation ramp has been added internally in

LM3488. The slope of this compensation ramp has been

selected to satisfy most of the applications. The slope of the

internal compensation ramp depends on the frequency. This

slope can be calculated using the formula:

M

C=VSL.FS

In the above equation, V

compensation ramp. Limits for V

the electrical characteristics.

In order to provide the user additional flexibility, a patented

scheme has been implemented inside the IC to increase the

slope of the compensation ramp externally, if the need

arises. Adding a single external resistor, R

Figure 4) increases the slope of the compensation ramp, M

by :

Volts/second

is the amplitude of the internal

SL

have been specified in

SL

SL

(as shown in

10138811

In this equation, ∆VSLis equal to 40.10-6RSL. Hence,

∆VSLversus RSLhas been plotted in Figure 5 for different

frequencies.

C

www.national.com 12

Page 13

Functional Description (Continued)

LM3488

FIGURE 4. Increasing the Slope of the Compensation Ramp

FIGURE 5. ∆VSLvs R

FREQUENCY ADJUST/SYNCHRONIZATION/SHUTDOWN

The switching frequency of LM3488 can be adjusted between 100kHz and 1MHz using a single external resistor.

This resistor must be connected between FA/SYNC/SD pin

and ground, as shown in Figure 6. Please refer to the typical

performance characteristics to determine the value of the

resistor required for a desired switching frequency.

The LM3488 can be synchronized to an external clock. The

external clock must be connected to the FA/SYNC/SD pin

through a resistor, R

as shown in Figure 7. The value of

SYNC

10138813

10138851

SL

this resistor is dependent on the off time of the synchronization pulse, T

OFF(SYNC)

to be used for a given T

. Table 1 shows the range of resistors

OFF(SYNC)

.

TABLE 1.

T

OFF(SYNC)

(µsec) R

SYNC

range (kΩ)

1 5 to 13

2 20to40

3 40to65

www.national.com13

Page 14

Functional Description (Continued)

LM3488

T

OFF(SYNC)

It is also necessary to have the width of the synchronization

pulse narrower than the duty cycle of the converter. It is also

necessary to have the synchronization pulse width ≥

300nsecs.

TABLE 1. (Continued)

(µsec) R

SYNC

range (kΩ)

4 55to90

5 70to110

6 85to140

7 100 to 160

8 120 to 190

9 135 to 215

10 150 to 240

The FA/SYNC/SD pin also functions as a shutdown pin. If a

high signal (refer to the electrical characteristics for definition

of high signal) appears on the FA/SYNC/SD pin, the LM3488

stops switching and goes into a low current mode. The total

supply current of the IC reduces to less than 10µA under

these conditions.

Figure 8 and Figure 9 show implementation of shutdown

function when operating in Frequency adjust mode and synchronization mode respectively. In frequency adjust mode,

connecting the FA/SYNC/SD pin to ground forces the clock

to run at a certain frequency. Pulling this pin high shuts down

the IC. In frequency adjust or synchronization mode, a high

signal for more than 30ms shuts down the IC.

FIGURE 6. Frequency Adjust

FIGURE 7. Frequency Synchronization

10138816

10138815

FIGURE 8. Shutdown Operation in Frequency Adjust Mode

www.national.com 14

10138816

Page 15

Functional Description (Continued)

FIGURE 9. Shutdown Operation in Synchronization Mode

SHORT-CIRCUIT PROTECTION

When the voltage across the sense resistor (measured on

Pin) exceeds 350mV, short-circuit current limit gets

I

SEN

activated. A comparator inside LM3488 reduces the switching frequency by a factor of 5 and maintains this condition till

the short is removed.

Typical Applications

The LM3488 may be operated in either continuous or discontinuous conduction mode. The following applications are

designed for continuous conduction operation. This mode of

operation has higher efficiency and lower EMI characteristics

than the discontinuous mode.

LM3488

10138817

ferred to the load and output capacitor. The ratio of these two

cycles determines the output voltage. The output voltage is

defined as:

BOOST CONVERTER

The most common topology for LM3488 is the boost or

step-up topology. The boost converter converts a low input

voltage into a higher output voltage. The basic configuration

for a boost regulator is shown in Figure 10. In continuous

conduction mode (when the inductor current never reaches

zero at steady state), the boost regulator operates in two

cycles. In the first cycle of operation, MOSFET Q is turned

on and energy is stored in the inductor. During this cycle,

diode D is reverse biased and load current is supplied by the

output capacitor, C

OUT

.

In the second cycle, MOSFET Q is off and the diode is

forward biased. The energy stored in the inductor is trans-

(ignoring the drop across the MOSFET and the diode), or

where D is the duty cycle of the switch, VDis the forward

voltage drop of the diode, and V

is the drop across the

Q

MOSFET when it is on. The following sections describe

selection of components for a boost converter.

www.national.com15

Page 16

Typical Applications (Continued)

LM3488

FIGURE 10. Simplified Boost Converter Diagram (a) First cycle of operation. (b) Second cycle of operation

10138822

POWER INDUCTOR SELECTION

The inductor is one of the two energy storage elements in a

boost converter. Figure 11 shows how the inductor current

varies during a switching cycle. The current through an

inductor is quantified as:

www.national.com 16

10138824

FIGURE 11. A. Inductor current B. Diode current

If VL(t) is constant, diL(t)/dt must be constant. Hence, for a

given input voltage and output voltage, the current in the

inductor changes at a constant rate.

Page 17

Typical Applications (Continued)

The important quantities in determining a proper inductance

value are I

inductor current ripple). If ∆iLis larger than IL, the inductor

current will drop to zero for a portion of the cycle and the

converter will operate in discontinuous conduction mode. If

is smaller than IL, the inductor current will stay above

∆i

L

zero and the converter will operate in continuous conduction

mode. All the analysis in this datasheet assumes operation

in continuous conduction mode. To operate in continuous

conduction mode, the following conditions must be met:

Choose the minimum I

common choice is to set ∆i

appropriate core size for the inductor involves calculating the

average and peak currents expected through the inductor. In

a boost converter,

and I

L_peak=IL

where

(the average inductor current) and ∆iL(the

L

>

∆i

I

L

L

to determine the minimum L. A

OUT

to 30% of IL. Choosing an

L

(max) + ∆iL(max),

PROGRAMMING THE OUTPUT VOLTAGE AND OUTPUT CURRENT

The output voltage can be programmed using a resistor

divider between the output and the feedback pins, as shown

in Figure 12. The resistors are selected such that the voltage

at the feedback pin is 1.26V. R

and RF2can be selected

F1

using the equation,

A 100pF capacitor may be connected between the feedback

and ground pins to reduce noise.

The maximum amount of current that can be delivered at the

output can be controlled by the sense resistor, R

SEN

. Current

limit occurs when the voltage that is generated across the

sense resistor equals the current sense threshold voltage,

V

SENSE

. Limits for V

have been specified in the elec-

SENSE

trical characteristics. This can be expressed as:

*

R

SEN

=V

SENSE

V

I

sw(peak)

represents the maximum value of the control signal

SENSE

as shown in Figure 2. This control signal, however, is not a

constant value and changes over the course of a period as a

result of the internal compensation ramp (see Figure 3).

Therefore the current limit will also change as a result of the

internal compensation ramp. The actual command signal,

, can be better expressed as a function of the sense

V

CS

voltage and the internal compensation ramp:

V

CS=VSENSE

is defined as the internal compensation ramp voltage,

V

SL

−(D*VSL)

limits are specified in the electrical characteristics.

The peak current through the switch is equal to the peak

inductor current.

I

sw(peak)=IL

+ ∆i

L

Therefore for a boost converter

LM3488

A core size with ratings higher than these values should be

chosen. If the core is not properly rated, saturation will

dramatically reduce overall efficiency.

The LM3488 can be set to switch at very high frequencies.

When the switching frequency is high, the converter can be

operated with very small inductor values. With a small inductor value, the peak inductor current can be extremely higher

than the output currents, especially under light load conditions.

The LM3488 senses the peak current through the switch.

The peak current through the switch is the same as the peak

current calculated above.

Combining the three equation yields an expression for R

www.national.com17

SEN

Page 18

Typical Applications (Continued)

LM3488

10138820

FIGURE 12. Adjusting the Output Voltage

CURRENT LIMIT WITH ADDITIONAL SLOPE COMPENSATION

If an external slope compensation resistor is used (see

Figure 4) the internal control signal will be modified and this

will have an effect on the current limit. The control signal is

given by:

V

CS=VSENSE

Where V

and VSLare defined parameters in the elec-

SENSE

trical characteristics section. If R

−(D*VSL)

is used, then this will add

SL

to the existing slope compensation. The command voltage

will then be given by:

V

CS=VSENSE

Where ∆V

and can be calculated by use of Figure 5 or is equal to 40 x

−6

10

is the additional slope compensation generated

SL

*RSL. This changes the equation for R

−(D*(VSL+ ∆VSL))

SEN

to:

Therefore RSLcan be used to provide an additional method

for setting the current limit.

POWER DIODE SELECTION

Observation of the boost converter circuit shows that the

average current through the diode is the average load current, and the peak current through the diode is the peak

current through the inductor. The diode should be rated to

handle more than its peak current. The peak diode current

can be calculated using the formula:

I

D(Peak)=IOUT

/ (1−D) + ∆I

L

In the above equation, I

is the output current and ∆ILhas

OUT

been defined in Figure 11

The peak reverse voltage for boost converter is equal to the

regulator output voltage. The diode must be capable of

handling this voltage. To improve efficiency, a low forward

drop schottky diode is recommended.

POWER MOSFET SELECTION

The drive pin of LM3488 must be connected to the gate of an

external MOSFET. In a boost topology, the drain of the

external N-Channel MOSFET is connected to the inductor

and the source is connected to the ground. The drive pin

(DR) voltage depends on the input voltage (see typical performance characteristics). In most applications, a logic level

MOSFET can be used. For very low input voltages, a sublogic level MOSFET should be used.

The selected MOSFET directly controls the efficiency. The

critical parameters for selection of a MOSFET are:

1. Minimum threshold voltage, V

2. On-resistance, R

3. Total gate charge, Q

DS

(ON)

g

4. Reverse transfer capacitance, C

5. Maximum drain to source voltage, V

TH

(MIN)

RSS

DS(MAX)

The off-state voltage of the MOSFET is approximately equal

to the output voltage. V

DS(MAX)

of the MOSFET must be

greater than the output voltage. The power losses in the

MOSFET can be categorized into conduction losses and ac

switching or transition losses. R

the conduction losses. The conduction loss, P

2

R loss across the MOSFET. The maximum conduction loss

I

is needed to estimate

DS(ON)

COND

,isthe

is given by:

www.national.com 18

Page 19

LM3488

Typical Applications (Continued)

where D

The turn-on and turn-off transitions of a MOSFET require

times of tens of nano-seconds. C

estimate the large instantaneous power loss that occurs

during these transitions.

The amount of gate current required to turn the MOSFET on

can be calculated using the formula:

The required gate drive power to turn the MOSFET on is

equal to the switching frequency times the energy required

to deliver the charge to bring the gate charge voltage to V

(see electrical characteristics and typical performance characteristics for the drive voltage specification).

INPUT CAPACITOR SELECTION

Due to the presence of an inductor at the input of a boost

converter, the input current waveform is continuous and

triangular, as shown in Figure 11. The inductor ensures that

the input capacitor sees fairly low ripple currents. However,

as the input capacitor gets smaller, the input ripple goes up.

The rms current in the input capacitor is given by:

The input capacitor should be capable of handling the rms

current. Although the input capacitor is not as critical in a

boost application, low values can cause impedance interactions. Therefore a good quality capacitor should be chosen

in the range of 100µF to 200µF. If a value lower than 100µF

is used, then problems with impedance interactions or

switching noise can affect the LM3478. To improve performance, especially with V

to use a 20Ω resistor at the input to provide a RC filter. The

resistor is placed in series with the V

capacitor attached to the V

0.1µF or 1µF ceramic capacitor is necessary in this configuration. The bulk input capacitor and inductor will connect on

the other side of the resistor with the input power supply.

is the maximum duty cycle.

MAX

I

G=Qg.FS

P

Drive=FS.Qg.VDR

below 8 volts, it is recommended

IN

IN

and Qgare needed to

RSS

DR

pin with only a bypass

IN

pin directly (see Figure 13). A

OUTPUT CAPACITOR SELECTION

The output capacitor in a boost converter provides all the

output current when the inductor is charging. As a result it

sees very large ripple currents. The output capacitor should

be capable of handling the maximum rms current. The rms

current in the output capacitor is:

Where

and D, the duty cycle is equal to (V

OUT−VIN

)/V

OUT

.

The ESR and ESL of the output capacitor directly control the

output ripple. Use capacitors with low ESR and ESL at the

output for high efficiency and low ripple voltage. Surface

Mount tantalums, surface mount polymer electrolytic and

polymer tantalum, Sanyo- OSCON, or multi-layer ceramic

capacitors are recommended at the output.

Designing SEPIC Using LM3488

Since the LM3488 controls a low-side N-Channel MOSFET,

it can also be used in SEPIC (Single Ended Primary Inductance Converter) applications. An example of SEPIC using

LM3488 is shown in Figure 14. As shown in Figure 14, the

output voltage can be higher or lower than the input voltage.

The SEPIC uses two inductors to step-up or step-down the

input voltage. The inductors L1 and L2 can be two discrete

inductors or two windings of a coupled transformer since

equal voltages are applied across the inductor throughout

the switching cycle. Using two discrete inductors allows use

of catalog magnetics, as opposed to a custom transformer.

The input ripple can be reduced along with size by using the

coupled windings of transformer for L1 and L2.

Due to the presence of the inductor L1 at the input, the

SEPIC inherits all the benefits of a boost converter. One

main advantage of SEPIC over boost converter is the inherent input to output isolation. The capacitor CS isolates the

input from the output and provides protection against

shorted or malfunctioning load. Hence, the A SEPIC is useful

for replacing boost circuits when true shutdown is required.

This means that the output voltage falls to 0V when the

switch is turned off. In a boost converter, the output can only

fall to the input voltage minus a diode drop.

10138893

FIGURE 13. Reducing IC Input Noise

www.national.com19

Page 20

Designing SEPIC Using LM3488

(Continued)

LM3488

The duty cycle of a SEPIC is given by:

In the above equation, VQis the on-state voltage of the

MOSFET, Q, and V

diode.

is the forward voltage drop of the

DIODE

FIGURE 14. Typical SEPIC Converter

POWER MOSFET SELECTION

As in boost converter, the parameters governing the selection of the MOSFET are the minimum threshold voltage,

V

Q

, the on-resistance, R

TH(MIN)

, the reverse transfer capacitance, C

g

mum drain to source voltage, V

, the total gate charge,

DS(ON)

DS(MAX)

, and the maxi-

RSS

. The peak switch

voltage in a SEPIC is given by:

V

SW(PEAK)

=VIN+V

OUT+VDIODE

The selected MOSFET should satisfy the condition:

>

V

DS(MAX)

V

SW(PEAK)

The peak switch current is given by:

The rms current through the switch is given by:

10138844

SELECTION OF INDUCTORS L1 AND L2

Proper selection of the inductors L1 and L2 to maintain

constant current mode requires calculations of the following

parameters.

Average current in the inductors:

I

L2AVE=IOUT

Peak to peak ripple current, to calculate core loss if necessary:

POWER DIODE SELECTION

The Power diode must be selected to handle the peak

current and the peak reverse voltage. In a SEPIC, the diode

peak current is the same as the switch peak current. The

off-state voltage or peak reverse voltage of the diode is V

+V

. Similar to the boost converter, the average diode

OUT

IN

current is equal to the output current. Schottky diodes are

recommended.

www.national.com 20

maintains the condition I

mode.

>

∆iLto ensure constant current

L

Page 21

Designing SEPIC Using LM3488

(Continued)

Peak current in the inductor, to ensure the inductor does not

saturate:

I

must be lower than the maximum current rating set by

L1PK

the current sense resistor.

The value of L1 can be increased above the minimum rec-

ommended to reduce input ripple and output ripple. However, once D

is less than 20% of I

IL1

output ripple is minimal.

By increasing the value of L2 above the minimum recom-

mended, ∆

can be reduced, which in turn will reduce the

IL2

output ripple voltage:

, the benefit to

L1AVE

having high rms current ratings relative to size. Ceramic

capacitors could be used, but the low C values will tend to

cause larger changes in voltage across the capacitor due to

the large currents. High C value ceramics are expensive.

Electrolytics work well for through hole applications where

the size required to meet the rms current rating can be

accommodated. There is an energy balance between CS

and L1, which can be used to determine the value of the

capacitor. The basic energy balance equation is:

Where

is the ripple voltage across the SEPIC capacitor, and

is the ripple current through the inductor L1. The energy

balance equation can be solved to provide a minimum value

:

for C

S

LM3488

where ESR is the effective series resistance of the output

capacitor.

If L1 and L2 are wound on the same core, then L1 = L2 = L.

All the equations above will hold true if the inductance is

replaced by 2L. A good choice for transformer with equal

turns is Coiltronics CTX series Octopack.

SENSE RESISTOR SELECTION

The peak current through the switch, I

SW(PEAK)

justed using the current sense resistor, R

certain output current. Resistor R

can be selected using

SEN

can be ad-

, to provide a

SEN

the formula:

Sepic Capacitor Selection

The selection of SEPIC capacitor, CS, depends on the rms

current. The rms current of the SEPIC capacitor is given by:

The SEPIC capacitor must be rated for a large ACrms current relative to the output power. This property makes the

SEPIC much better suited to lower power applications where

the rms current through the capacitor is relatively small

(relative to capacitor technology). The voltage rating of the

SEPIC capacitor must be greater than the maximum input

voltage. Tantalum capacitors are the best choice for SMT,

Input Capacitor Selection

Similar to a boost converter, the SEPIC has an inductor at

the input. Hence, the input current waveform is continuous

and triangular. The inductor ensures that the input capacitor

sees fairly low ripple currents. However, as the input capacitor gets smaller, the input ripple goes up. The rms current in

the input capacitor is given by:

The input capacitor should be capable of handling the rms

current. Although the input capacitor is not as critical in a

boost application, low values can cause impedance interactions. Therefore a good quality capacitor should be chosen

in the range of 100µF to 200µF. If a value lower than 100µF

is used, then problems with impedance interactions or

switching noise can affect the LM3478. To improve performance, especially with V

below 8 volts, it is recommended

IN

to use a 20Ω resistor at the input to provide a RC filter. The

resistor is placed in series with the V

capacitor attached to the V

pin directly (see Figure 13). A

IN

pin with only a bypass

IN

0.1µF or 1µF ceramic capacitor is necessary in this configuration. The bulk input capacitor and inductor will connect on

the other side of the resistor with the input power supply.

Output Capacitor Selection

The ESR and ESL of the output capacitor directly control the

output ripple. Use low capacitors with low ESR and ESL at

www.national.com21

Page 22

Output Capacitor Selection

(Continued)

LM3488

the output for high efficiency and low ripple voltage. Surface

mount tantalums, surface mount polymer electrolytic and

polymer tantalum, Sanyo- OSCON, or multi-layer ceramic

capacitors are recommended at the output.

The output capacitor of the SEPIC sees very large ripple

currents (similar to the output capacitor of a boost converter.

The rms current through the output capacitor is given by:

The ESR and ESL of the output capacitor directly control the

output ripple. Use low capacitors with low ESR and ESL at

the output for high efficiency and low ripple voltage. Surface

mount tantalums, surface mount polymer electrolytic and

polymer tantalum, Sanyo- OSCON, or multi-layer ceramic

capacitors are recommended at the output for low ripple.

www.national.com 22

Page 23

Other Application Circuits

FIGURE 15. Typical High Efficiency Step-Up (Boost) Converter

LM3488

10138843

www.national.com23

Page 24

Physical Dimensions inches (millimeters)

unless otherwise noted

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

LM3488 High Efficiency Low-Side N-Channel Controller for Switching Regulators

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...