Page 1

LM3477/LM3477A

High Efficiency High-Side N-Channel Controller for

Switching Regulator

General Description

The LM3477/A is a high-side N-channel MOSFET switching

regulator controller. It can be used in topologies requiring a

high side MOSFET such as buck, inverting (buck-boost) and

zeta regulators. The LM3477/A’s internal push pull driver

allows compatibility with a wide range of MOSFETs. This, the

wide input voltage range, use of discrete power components

and adjustable current limit allows the LM3477/A to be optimized for a wide variety of applications.

The LM3477/A uses a high switching frequency of 500kHz to

reduce the overall solution size. Current-mode control requires only a single resistor and capacitor for frequency

compensation. The current mode architecture also yields

superior line and load regulation and cycle-by-cycle current

limiting. A 5µA shutdown state can be used for power savings and for power supply sequencing. Other features include internal soft-start and output over voltage protection.

The internal soft-start reduces inrush current. Over voltage

protection is a safety feature to ensure that the output voltage stays within regulation.

The LM3477A is similar to the LM3477. The primary difference between the two is the point at which the device

transitions into hysteretic mode. The hysteretic threshold of

the LM3477A is one-third of the LM3477.

Features

n 500kHz switching frequency

n Adjustable current limit

n 1.5% reference

n Thermal shutdown

n Frequency compensation optimized with a single

capacitor and resistor

n Internal softstart

n Current mode operation

n Undervoltage lockout with hysteresis

n 8-lead Mini-SO8 (MSOP-8) package

Applications

n Local Voltage Regulation

n Distributed Power

n Notebook and Palmtop Computers

n Internet Appliances

n Printers and Office Automation

n Battery operated Devices

n Cable Modems

n Battery Chargers

Hysteretic

Threshold

LM3477 ) 36% of

programmed current

limit

LM3477A ) 12% of

programmed current

limit

*

See Hysteretic Threshold and section for more information.

LM3477/LM3477A High Efficiency High-Side N-Channel Controller for Switching Regulator

June 2002

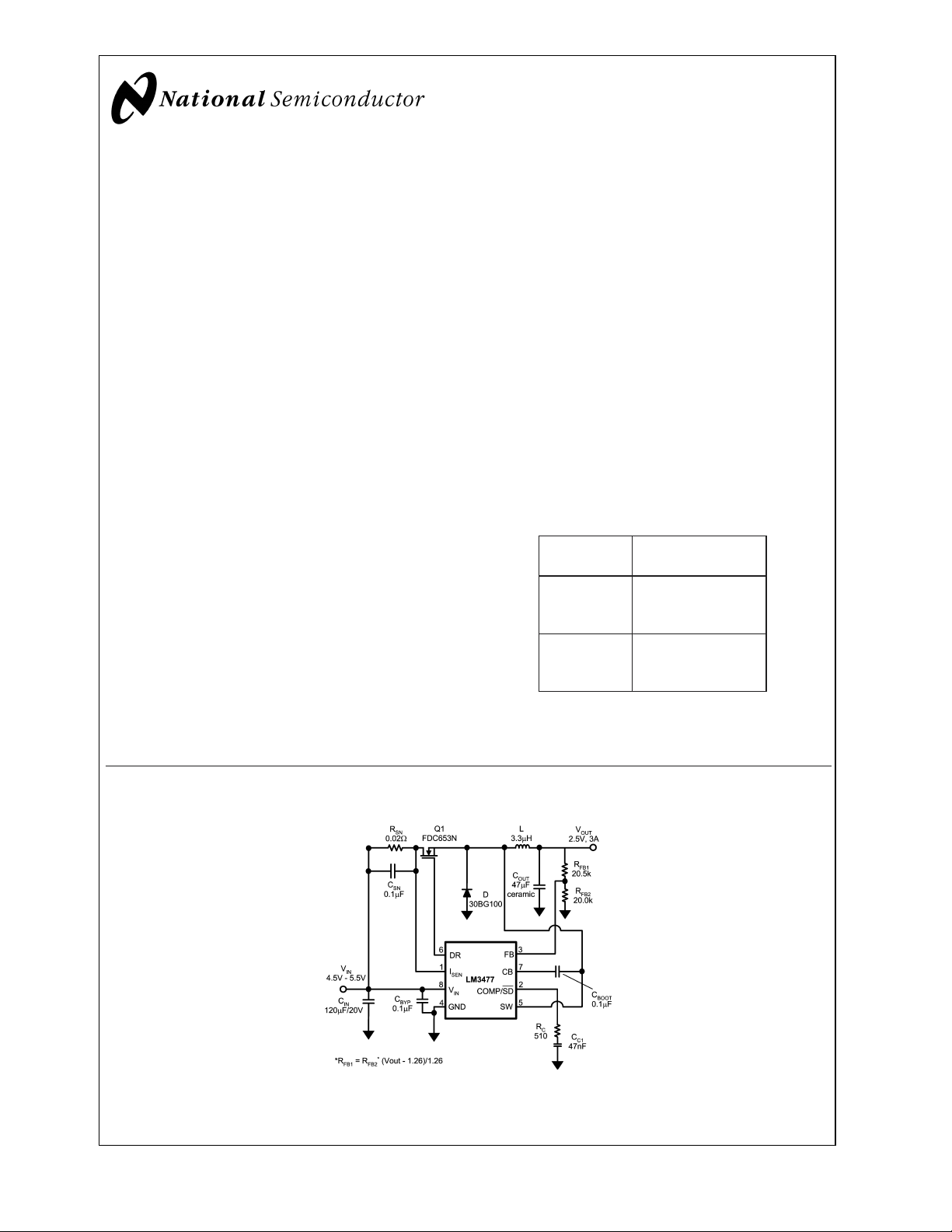

Typical Application Circuit

Typical High Efficiency Step-Down (Buck) Converter

© 2002 National Semiconductor Corporation DS200033 www.national.com

20003333

Page 2

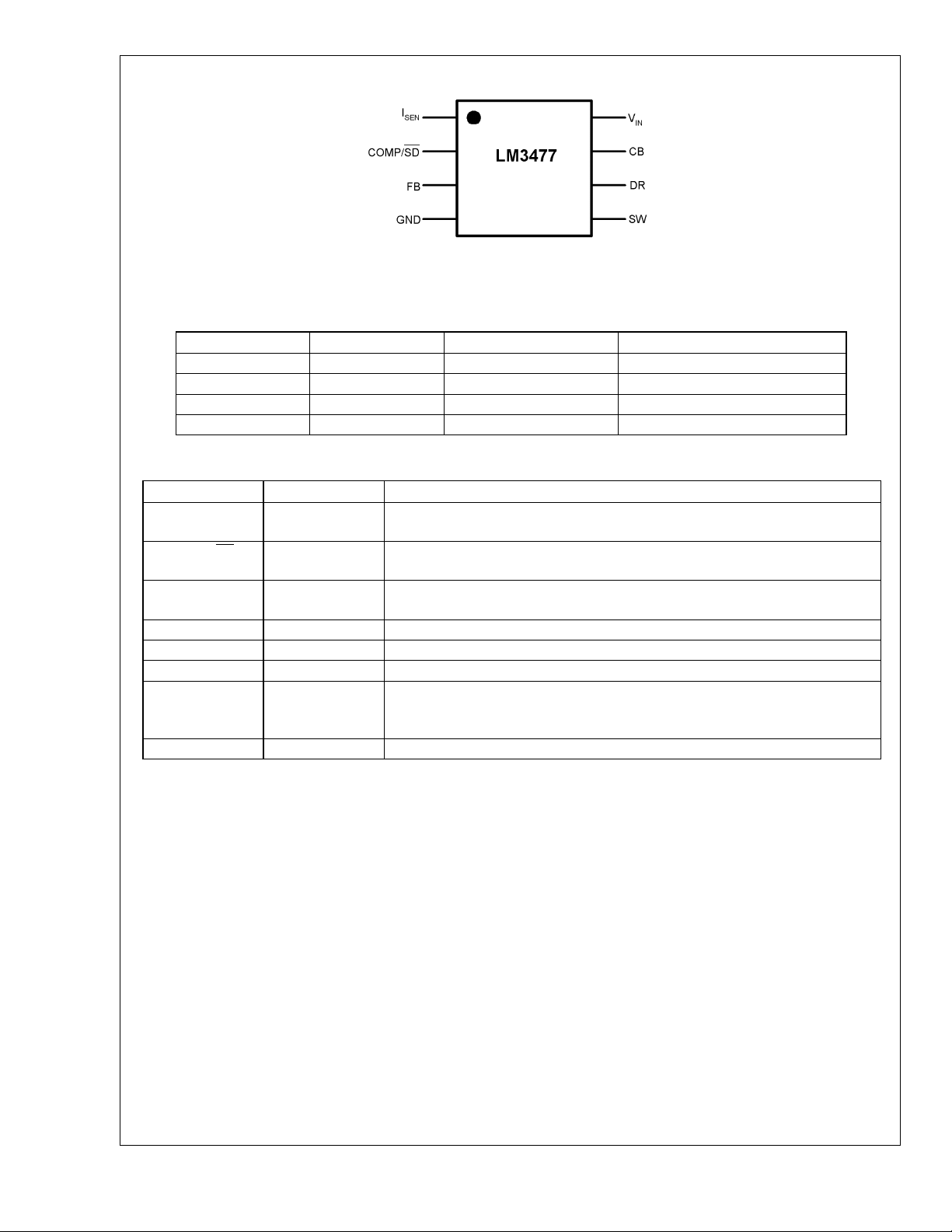

Connection Diagram

LM3477/LM3477A

8 Lead Mini SO8 Package (MSOP-8 Package)

Package Marking and Ordering Information

Order Number Package Type Package Marking Supplied As:

LM3477MM MSOP-8 S13B 1000 units on Tape and Reel

LM3477MMX MSOP-8 S13B 3500 units on Tape and Reel

LM3477AMM MSOP-8 S13A 1000 units on Tape and Reel

LM3477AMMX MSOP-8 S13A 3500 units on Tape and Reel

Pin Description

Pin Name Pin Number Description

I

SEN

COMP/SD

FB 3 Feedback pin. The output voltage should be adjusted using a resistor divider to

GND 4 Ground pin.

SW 5 Switch Node. Source of the external MOSFET is connected to this node.

DR 6 Drive pin. The gate of the external MOSFET should be connected to this pin.

CB 7 Boot-strap pin. A capacitor must be connected between this pin and SW pin (pin 5)

V

IN

1 Current sense input pin. Voltage generated across an external sense resistor is fed

into this pin.

2 Compensation pin. A resistor-capacitor combination connected to this pin provides

compensation for the control loop. Pull this pin below 0.65V to shutdown.

provide 1.270V at this pin.

for proper operation. The voltage developed across this capacitor provides the gate

drive for the external MOSFET.

8 Power Supply Input pin.

20003302

www.national.com 2

Page 3

LM3477/LM3477A

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Lead Temperature for MSOP Package

Vapor Phase (60 sec.)

Infared (15 sec.)

Distributors for availability and specifications.

Input Voltage 36V

<

Peak Driver Output Current (

10µs) 1.0A

CB Pin Voltage (Note 2) 43V

I

Pin Voltage 500mV

SEN

Power Dissipation Internally Limited

Operating Ratings (Note 1)

Supply Voltage 2.97V ≤ V

Junction

Temperature Range −40˚C ≤ T

IN

≤ +125˚C

J

Storage Temperature Range −65˚C to +150˚C

Junction Temperature +150˚C

ESD Susceptibilty (Note 3)

Human Body Model

Machine Model

2kV

200V

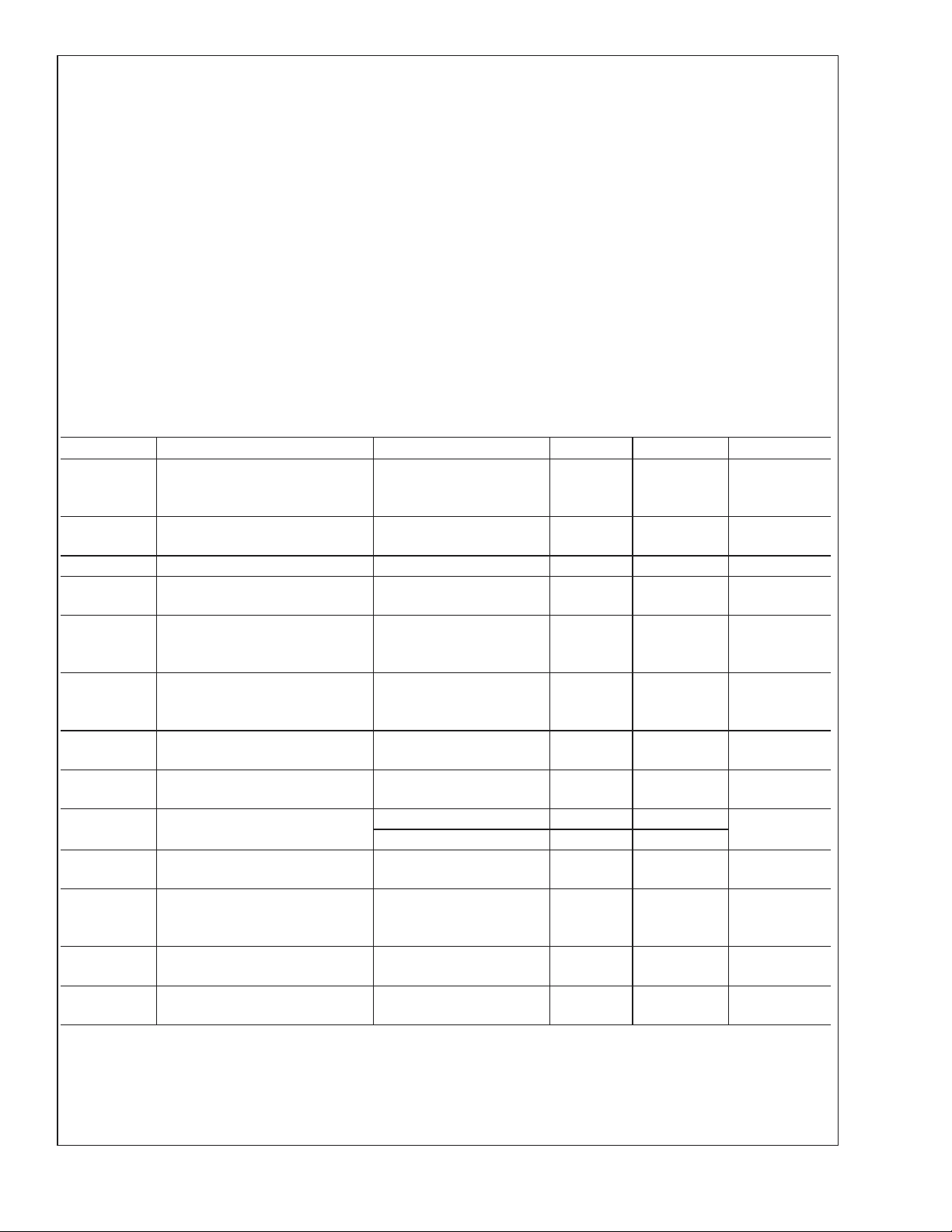

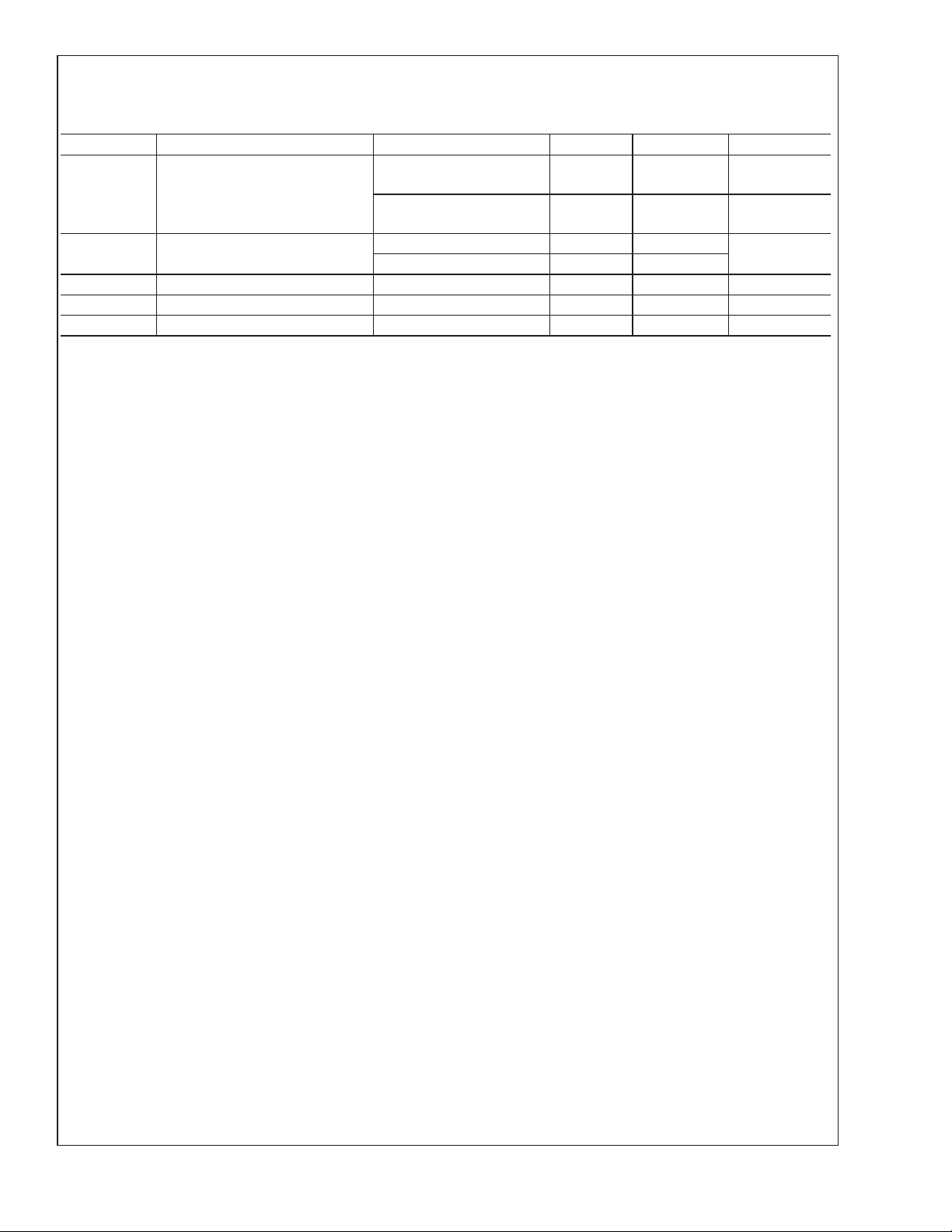

Electrical Characteristics (Note 4)

Specifications in Standard type face are for TJ= 25˚C, and in bold type face apply over the full Operating Temperature

Range. Unless otherwise specified, V

Symbol Parameter Conditions Typical Limit Units

V

∆V

FB

LINE

Feedback Voltage V

Feedback Voltage Line

Regulation

∆V

V

UVLO

V

UV(HYS)

LOAD

Output Voltage Load Regulation

Input Undervoltage Lock-out 2.87

Input Undervoltage Lock-out

Hysteresis

F

SW

R

DS1 (ON)

Switching Frequency 500

Driver Switch On Resistance

(top)

R

DS2 (ON)

Driver Switch On Resistance

(bottom)

(V

CB−VSW)max

D

max

(on) Minimum On Time 330

T

min

I

SUPPLY

I

Q

Maximum Boot Voltage V

Maximum Duty Cycle 93

Supply Current (switching) (Note 5) 2.0

Quiescent Current in Shutdown

Mode

IN

= 12V.

= 1.4V,

COMP

2.97V ≤ V

IN

≤ 36V

1.270

1.260/1.252

1.288/1.290

V(min)

V(max)

2.97V ≤ VIN≤ 36V 0.001 %/V

±

0.5 %/V (max)

2.97

V(max)

180

130

225

435

575

mV (min)

mV (max)

kHz(min)

kHz(max)

IDR= 0.2A, VIN=5V 7 Ω

IDR= 0.2A 4 Ω

<

7.2V V

IN

V

≥ 7.2V 7.2

IN

IN

88

230

495

3.0

%(min)

nsec(min)

nsec(max)

mA (max)

(Note 6), VIN=5V 5

8

µA (max)

215˚C

220˚C

≤ 35V

V

V

mV

kHz

V

%

nsec

mA

µA

www.national.com3

Page 4

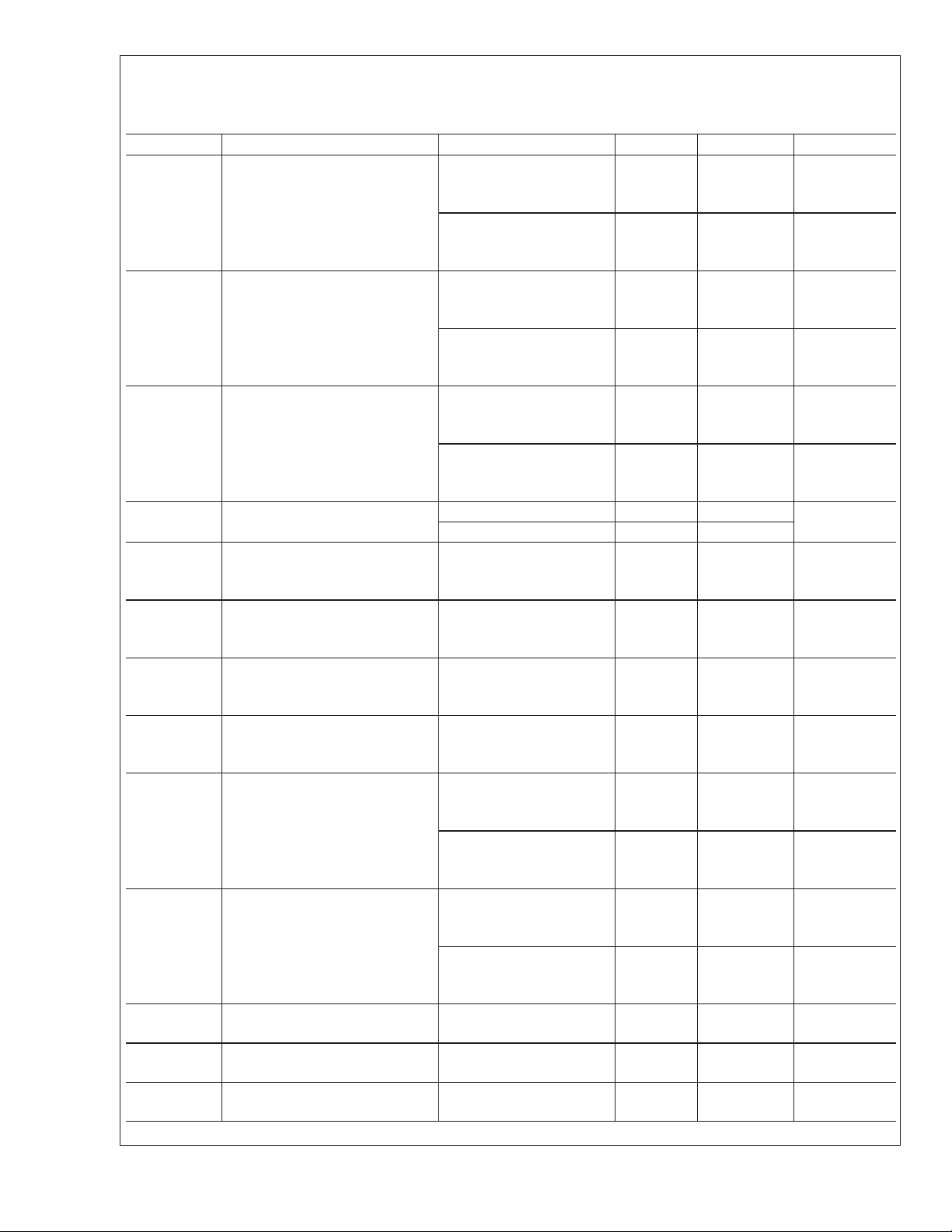

Electrical Characteristics (Note 4) (Continued)

Specifications in Standard type face are for TJ= 25˚C, and in bold type face apply over the full Operating Temperature

Range. Unless otherwise specified, V

Symbol Parameter Conditions Typical Limit Units

V

CL(O)

LM3477/LM3477A

V

CL(100)

Current Limit Voltage at 0% Duty

Cycle

Current Limit Voltage at 100%

Duty Cycle

V

SC

Short-Circuit Current Limit Sense

Voltage

V

SL

Internal Compensation Ramp

Voltage Height

V

OVP

Output Over-voltage Protection

(with respect to feedback

voltage) (Note 7)

V

OVP(HYS)

Output Over-Voltage Protection

Hysteresis(Note 7)

Gm Error Amplifier

Transconductance

A

I

VOL

EAO

Error Amplifier Voltage Gain V

Error Amplifier Output Current

(Source/ Sink)

V

EAO

Error Amplifier Output Voltage

Swing

T

SS

T

r

T

f

Internal Soft-Start Delay VFB= 1.2V, V

Drive Pin Rise Time CGS= 3000pF, VDR=0

Drive Pin Fall Time CGS= 3000pF, VDR=0

IN

= 12V.

LM3477 155

130/125

185/190

LM3477A 165

140/135

195/200

LM3477 74

50/43

98/98

LM3477A 65

41/25

89/98

VIN= 5V, LM3477 350

270

420

= 5V, LM3477A 310

V

IN

260

380

VIN= 5V, LM3477 83 mV

V

= 5V, LM3477A 103

IN

= 1.4V 50

V

COMP

32/25

78/85

V

= 1.4V 60

COMP

20

110

= 1.4V

V

COMP

= 100µA

I

EAO

(Source/Sink)

= 1.4V

COMP

= 100µA

I

EAO

(Source/Sink)

Source, V

V

FB

COMP

=0V

= 1.4V,

750

600/365

1000/1265

38

30

42

100

75/50

130/160

Sink, V

= 1.4V

COMP

= 1.4V, V

FB

−140

−110/−95

−170/−180

Upper Limit

=0V

V

FB

COMP Pin = Floating

Lower Limit

= 1.4V

V

FB

2.2

2.0

2.35

0.75

0.5

0.95

COMP

=

5 msec

Floating

25 ns

to 3V

25 ns

to 3V

mV

mV (min)

mV (max)

mV

mV (min)

mV (max)

mV

mV (min)

mV (max)

mV

mV (min)

mV (max)

mV

mV (min)

mV (max)

mV

mV (min)

mV (max)

mV

mV(min)

mV(max)

mV

mV(min)

mV(max)

µmho

µmho (min)

µmho (max)

V/V

V/V (min)

V/V (max)

µA

µA (min)

µA (max)

µA

µA (min)

µA (max)

V

V(min)

V(max)

V

V(min)

V(max)

www.national.com 4

Page 5

Electrical Characteristics (Note 4) (Continued)

Specifications in Standard type face are for TJ= 25˚C, and in bold type face apply over the full Operating Temperature

Range. Unless otherwise specified, V

Symbol Parameter Conditions Typical Limit Units

V

SD

I

SD

Shutdown Threshold (Note 8) Output = High 1.15

Shutdown Pin Current VSD=5V −1

TSD Thermal Shutdown 165 ˚C

T

SH

θ

JA

Thermal Shutdown Hysteresis 10 ˚C

Thermal Resistance MM Package 200 ˚C/W

IN

= 12V.

Output = Low 0.65

V

=0V +1

SD

1.35

0.3

V (max)

V (min)

µA

LM3477/LM3477A

V

V

www.national.com5

Page 6

Electrical Characteristics (Note 4) (Continued)

Note 1: Absolute Maximum Ratings are limits beyond which damage to the device may occur. Operating Ratings are conditions under which operation of the device

is intended to be functional. For guaranteed specifications and test conditions, see the Electrical Characteristics.

Note 2: The CB pin must not be higher than 8V above the V

Note 3: The human body model is a 100 pF capacitor discharged through a 1.5kΩ resistor into each pin. The machine model is 200 pF capacitor discharged directly

into each pin.

Note 4: All limits are guaranteed at room temperature (standard type face) and at temperature extremes (bold type face). All room temperature limits are 100%

LM3477/LM3477A

tested. All limits at temperature extremes are guaranteed via correlation using standard Statistical Quality Control (SQC) methods. All limits are used to calculate

Average Outgoing Quality Level (AOQL).

Note 5: For this test, the COMP/SD pin must be left floating.

Note 6: For this test, the COMP/SD pin must be pulled low.

Note 7: The over-voltage protection is specified with respect to the feedback voltage. This is because the over-voltage protection tracks the feedback voltage. The

overvoltage protection threshold is given by adding the feedback voltage, V

Note 8: The COMP/SD pin should be pulled to ground to turn the regulator off. The voltage on the COMP/SD pin must be below the limit for Output = Low to keep

the regulator off.

SW

.

to the over-voltage protection specification.

FB

www.national.com 6

Page 7

LM3477/LM3477A

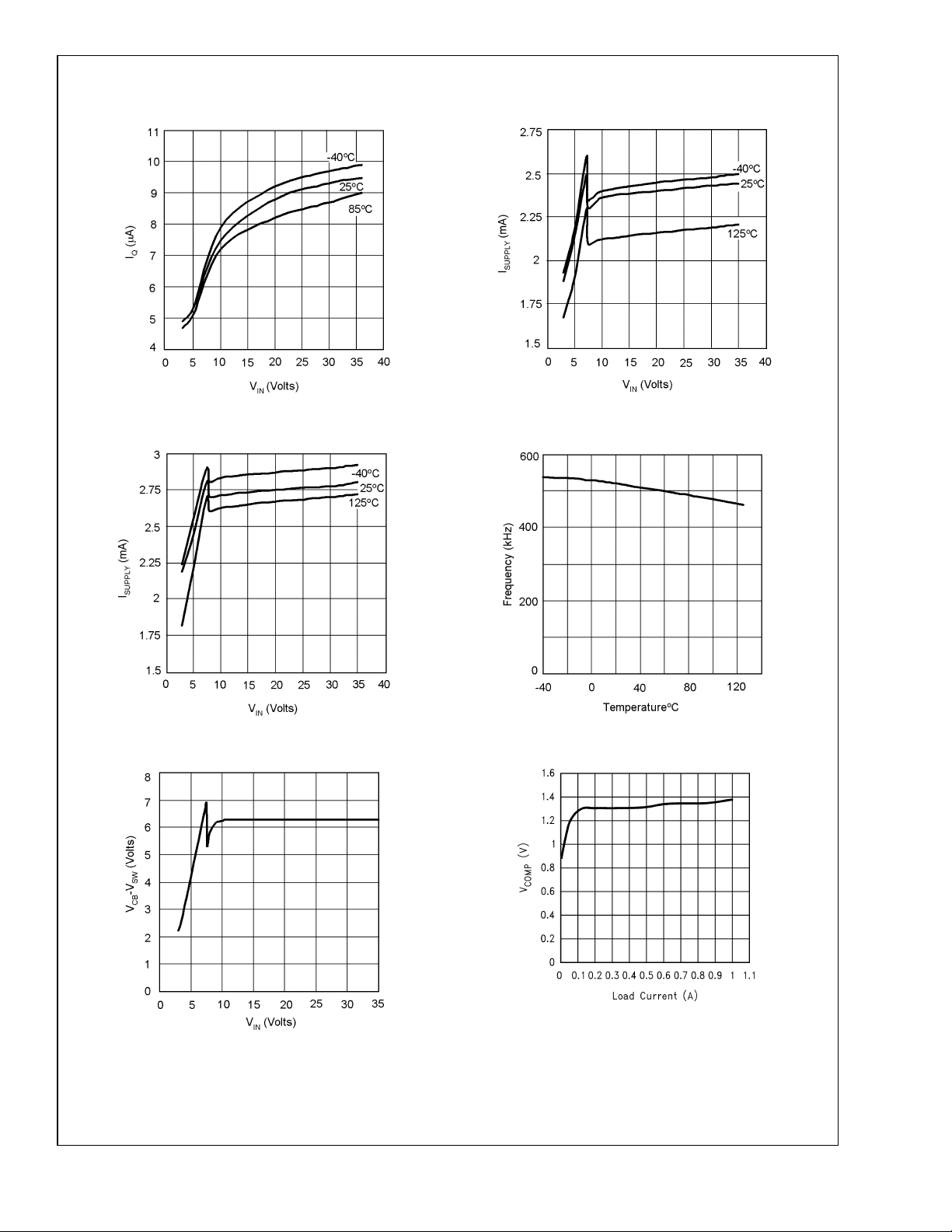

Typical Performance Characteristics Unless otherwise specified, V

(Shutdown) vs Temperature & Supply Voltage I

I

Q

20003313 20003314

I

vs Temperature & Supply Voltage (Switching) Frequency vs Temperature

Supply

vs Temperature & Supply Voltage (Non-Switching)

Supply

= 12V, TJ= 25˚C.

IN

20003315 20003316

VCB−VSWvs Supply Voltage COMP Pin Voltage vs Load Current

20003362

20003320

www.national.com7

Page 8

Typical Performance Characteristics Unless otherwise specified, V

= 12V, TJ= 25˚C. (Continued)

IN

LM3477/LM3477A

Efficiency vs Load Current

(V

= 24V, V

IN

OUT

= 12V)

Efficiency vs Load Current

(V

= 12V, V

IN

= 3.3V) Error Amplifier Gain

OUT

200033J9

Efficiency vs Load Current

(VIN= 5V,

OUT

= 3.3V)

200033K2

200033K1

Error Amplifier Phase Shift COMP Pin Source Current vs Temperature

20003309

www.national.com 8

20003308

20003319

Page 9

LM3477/LM3477A

Typical Performance Characteristics Unless otherwise specified, V

= 12V, TJ= 25˚C. (Continued)

IN

Slope Compensation Ramp vs Slope Compensation

Short Circuit vs Temperature

200033J8

Resistor

Shutdown Threshold Hysteresis vs Temperature Current Sense Voltage vs Duty Cycle

20003312

20003318

200033J7

www.national.com9

Page 10

Functional Block Diagram

LM3477/LM3477A

Functional Description

General Description

The LM3477/A is a switching regulator controller for topologies incorporating a high side switch. The most common of

these topologies is the step-down, or buck, converter. Other

topologies such as the inverting (buck-boost) and inverse

SEPIC (zeta) converters can be realized. This datasheet will

focus on buck converter applications.

The LM3477/A employs current mode control architecture.

Among the many benefits of this architecture are superior

line and load regulation, cycle-by-cycle current limiting, and

simple loop compensation. The LM3477/A features a patented adjustable slope compensation scheme to enable flexible inductor selection. The LM3477/A has a combination of

features that allow its use in a wide variety of applications.

The input voltage can range from 2.97V to 35V, with the

output voltage being positive or negative depending on the

topology. The current limit can be scaled to safely drive a

wide range of loads. An internal soft-start is provided to limit

initial in-rush current. Output over voltage and input under

voltage protection ensure safe operation of the LM3477/A.

Regions of Operation

Pulse width modulation (PWM) is the normal mode of operation. In PWM, the output voltage is well regulated and has a

ripple frequency equal to the switching frequency (500kHz).

20003301

In low load conditions, the part operates in hysteretic mode.

In this mode, the output voltage is regulated between a high

and low value that results in a higher ripple magnitude and

lower ripple frequency than in PWM mode (see OVER VOLT-

AGE PROTECTION section).

200033J2

FIGURE 1. Operating Regions of the LM3477/A

www.national.com 10

Page 11

Functional Description (Continued)

The important differences between the LM3477 and the

LM3477A are summarized in Figure 1. The voltages in Fig-

ure 1 can be referred to the switch current by dividing

through by R

old voltage V

larger load range than the LM3477. Typically, V

for the LM3477, while V

difference in area between the shaded regions give a graphical representation of this. The lightly shaded region is the

extra PWM operating area gained by using the LM3477A.

Thus the benefits of operating in PWM mode such as a well

regulated output voltage with low noise ripple are extended

to a larger load range when the LM3477A is used. While less

significant, the other noteworthy difference between the two

parts is in the short circuit current limit V

is a ceiling limit for the peak sense voltage V

V

SC

the SHORT CIRCUIT CURRENT LIMIT section). V

lower in the LM3477A than in the LM3477 (see the ELEC-

TRICAL CHARACTERISTICS section for limits).

Over Voltage Protection

The LM3477/A has over voltage protection (OVP) for the

output voltage. OVP is sensed at and is in respect to the

feedback pin (pin 3). If at anytime the voltage at the feedback

pin rises to V

CHARACTERISTICS section for limits on V

OVP will cause the drive pin to go low, forcing the power

MOSFET off. With the MOSFET off, the output voltage will

drop. The LM3477/A will begin switching again when the

feedback voltage reaches V

ELECTRICAL CHARACTERISTICS for limits on V

OVP can be triggered by any event that causes the output

voltage to rise out of regulation. There are several common

circumstances in which this can happen, and it is beneficial

for a designer to be aware of these for debugging purposes,

since the mode of operation changes from the normal Pulse

Width Modulation (PWM) mode to the hysteretic mode. In

the hysteretic mode the output voltage is regulated between

a high and low value that results in a higher ripple magnitude

and lower ripple frequency than in the PWM mode, see

Figure 2.

. The LM3477A has a lower hysteretic thresh-

SN

, and thus will operate in PWM mode for a

HYS

FB+VOVP

= 11mV for the LM3477A. The

HYS

.

SC

, OVP is triggered. See ELECTRICAL

+(V

FB

OVP-VOVP(HYS)

FB

HYS

SNpk

and V

OVP(HYS)

= 32mV

(see

SC

OVP

). See

.

LM3477/LM3477A

If the load current becomes too low, the LM3477/A will

increase the duty cycle, causing the voltage to rise and

trigger the OVP. The reasons for this involve the way the

LM3477/A regulates the output voltage, using a control

waveform at the pulse width modulator. This control waveform has upper and lower bounds.

Another way OVP can be tripped is if the input voltage rises

higher than the LM3477/A is able to regulate in pulse width

modulation (PWM) mode. The output voltage is related to

the input voltage by the duty cycle as: V

OUT=VIN

LM3477/A has a minimum duty cycle of 16.5% (typical), due

to the blank-out timing, TMIN. If the input voltage increases

such that the duty cycle wants to be less than D

cycle will hold at D

and the output voltage will increase

MIN

with the input voltage until it trips OVP.

It is useful to plot the operational boundaries in order to

illustrate the point at which the device switches into hyster-

is

etic mode. In Figure 1, the limits shown are with respect to

the peak voltage across the sense resistor R

they can be referred to the peak inductor current by dividing

through by R

SN.VSNpk

normal circumstances V

is bound to the shaded regions. In

is required to be in the shaded

SNpk

region, and the LM3477/A will operate in the PWM mode. If

operating conditions are chosen such that V

normally fall in the shaded regions, then the mode of operation is changed so that V

will be in the shaded region,

SNpk

and the part will operate in the hysteretic mode. What actually happens is that the LM3477/A will not allow V

outside of the shaded regions, so the duty cycle is adjusted.

The output voltage transient response overshoot can also

trigger OVP. As discussed in the OUTPUT CAPACITOR

section, if the capacitance is too low or ESR too high, the

.

output voltage overshoot will rise high enough to trigger

OVP. However, as long as there is room for the duty cycle to

adjust (the converter is not near D

MIN

LM3477/A will return to PWM mode after a few cycles of

hysteretic mode operation.

There is one last way that OVP can be triggered. If the

unregulated input voltage crosses 7.2V, the output voltage

will react as shown in Figure 3. The internal bias of the

LM3477/A switches supplies at 7.2V. When this happens, a

sudden small change in bias voltage is seen by all the

internal blocks of the LM3477/A. The control voltage, VC,

shifts because of the bias change, the PWM comparator

tries to keep regulation. To the PWM comparator, the scenario is identical to step change in the load current, so the

response at the output voltage is the same as would be

observed in a step load change. Hence, the output voltage

overshoot here can also trigger OVP. The LM3477/A will

regulate in hysteretic mode for several cycles, or may not

recover and simply stay in hysteretic mode until the load

current drops. Note that the output voltage is still regulated in

hysteric mode. Predicting whether or not the LM3477/A will

come out of hysteretic mode in this scenario is a difficult

task, however it is largely a function of the output current and

the output capacitance. Triggering hysteretic mode in this

way is only possible at higher load currents. The method to

avoid this is to increase the output capacitance.

MIN

SN

SNpk

or D

*

D. The

, the duty

,(V

SNpk

would not

to be

SNpk

), the

MAX

);

200033C1

FIGURE 2. The Feedback Voltage is related to the

Output Voltage. See different Ripple Components in

PWM and Hysteretic Modes

www.national.com11

Page 12

Functional Description (Continued)

LM3477/LM3477A

FIGURE 3. The Feedback Voltage Experiences an

Oscillation if the Input Voltage Crosses the 7.2V

Internal Bias Threshold

Default/Adjustable Slope Compensation

The LM3477/A uses a current mode control scheme. There

are many advantages in a current mode architecture including inherent cycle-by-cycle current limiting and simple compensation of the control loop. However, there are consequences to using current mode control that one must be

aware of while selecting circuit components. One of these

consequences is the inherent possibility of subharmonic oscillations in the inductor current. This is a form of instability

and should be avoided.

200033J6

switching cycles. The two solid waveforms shown are the

waveforms compared at the internal pulse width modulator,

used to generate the MOSFET drive signal. The top waveform with the slope S

waveform V

. The bottom waveform with slopes Snand Sfis

C

the sensed inductor current waveform V

is the internally generated control

e

. These signals

SEN

are compared at the PWM comparator. There is a feedback

loop involved here. The inductor current is sensed and fed

back to the PWM comparator, where it is compared to V

The output of the comparator in combination with the R/S

latch determine if the MOSFET is on or off, which effectively

controls the amount of current the inductor receives. While

is higher than V

V

C

, the PWM comparator outputs a high

SEN

signal, driving the external power MOSFET on. When MOSFET is on, the inductor current rises at a constant slope,

generating the sensed voltage V

SEN

. When V

equals VC,

SEN

the PWM comparator signals to drive the MOSFET off, and

the sensed inductor current decreases with a slope S

process begins again when R

latch is set by an internal

S

. The

f

oscillator.

The subharmonic oscillation phenomenon is realized when a

load excursion is experienced. The way it is analyzed is to

calculate how the inductor current settles after such an

excursion. Take for example the case when the inductor

current experiences a step increase in its average current,

shown as the dotted line in Figure 4. In the switching period

that the excursion occurs, the inductor current will change by

. In the following switching period, the inductor current will

∆I

0

have a difference ∆I

from its original starting value. The

1

original excursion is being propagated each switching cycle.

What is desired is to find out if this propagation is converging

or diverging. It is apparent that the difference in the inductor

current from one cycle to the next is a function of S

, as follows:

S

e

n,Sf

, and

.

C

200033C2

FIGURE 4. The Current Sensing Loop and

Corresponding Waveforms

As a brief explanation, consider Figure 4. A lot of information

is shown here. The top portion shows a schematic of the

current sensing loop. The bottom portion shows the pulse

width modulation (PWM) comparator waveforms for two

Hence, if the quantity (Sf-Se)/(Sn+Se)is greater than 1, the

inductor current diverges and subharmonic oscillations result. Notice that as S

increases, the factor decreases. Also,

e

when the duty cycle is greater than 50%, as the inductance

become less, the factor increases.

The LM3477/A internally generates enough slope compensation S

height of the compensation slope ramp V

to allow for the use of reasonable inductances. The

e

can be found in

SL

the ELECTRICAL CHARACTERISTICS section. The

LM3477/A incorporates a patented scheme to increase S

e

there is need to use a smaller inductor. With the use of a

single resistor R

, Se can be increased indefinitely. R

SL

increases the compensation slope Se by the amount:

Therefore,

When excursions of the inductor current are divergent, the

current sensing control loop is unstable and produces a

subharmonic oscillation in the inductor current. This oscillation is viewed as a resonance in the outer voltage control

loop at half the switching frequency. In the inductor section,

if

SL

www.national.com 12

Page 13

Functional Description (Continued)

calculations for minimum inductance and necessary slope

resistance R

ing.

Start-up/Soft-start

The LM3477/A incorporates an internal soft-start during

start-up. The soft-start forces the inductor current to rise

slowly and smoothly as it increases towards the steady-state

current. This technique is used to reduce the input inrush

current during soft-start. The soft-start functionality is effective for approximately the first 5ms of start-up.

Note: The LM3477/A will not start-up if the output voltage is being held up

externally by more than 200mV.

If the slope resistor R

of pre load to successfully start up.

Short Circuit Protection

When the voltage across the sense resistor (measured as

the V

IN−ISEN

current limit gets activated. In the short-circuit protection

mode, the external MOSFET is turned off. When the short is

removed, the external MOSFET is turned on after five

cycles. The short circuit protection voltage V

the ELECTRICAL CHARACTERISTICS section. V

lower in the LM3477A than in the LM3477.

are carried out based on this resonant peak-

SL

is used, the LM3477/Amay need up to 100 mA

SL

differential voltage) exceeds VSC, short-circuit

is specified in

SC

SC

LM3477/LM3477A

Design Section

General

Power supply design involves making tradeoffs. To achieve

performance specifications, limitations will be set on component selection. The LM3477/A provides many degrees of

flexibility in choosing external components to accommodate

various performance/component selection optimizations. For

example, the internal slope compensation can be externally

increased to allow smaller inductances to be used. The

design procedures that follow provide instruction on how to

select the external components in a typical LM3477/A buck

circuit in continuous conduction mode, as well as aid in the

optimization of performance and/or component selection.

See Figure 6 for component reference and typical circuit.

The LM3477/A may also be designed to operate in discontinuous conduction mode.

is

Shutdown

The compensation pin (Pin 2) of LM3477/A also functions as

a shutdown pin. If a low signal (refer to the ELECTRICAL

CHARACTERISTICS for definition of low signal) appears on

the COMP/SD pin, the LM3477/A stops switching and goes

into a low supply current mode. The total supply current of

the IC reduces to less than 10µA under these conditions.

Figure 5 shows different implementations of the shutdown

function.

20003325

200033M8

FIGURE 6. LM3477 Buck Converter Reference

Schematic

Programming the Output Voltage

The output voltage can be programmed using a resistor

divider between the output and the feedback pins, as shown

in Figure 6. The resistors are selected such that the voltage

at the feedback pin is 1.27V. R

FB1

and R

can be selected

FB2

using the equation:

V

OUT

= 1.27*(1+ R

FB1/RFB2

)

Calculating the Duty Cycle

In buck converter applications, the duty cycle of the

LM3477/A may be calculated as:

FIGURE 5. Implementing Shutdown in LM3477

20003326

Where

= forward drop of the power diode ) 0.5V

V

D

=VDSof the MOSFET when it is conducting )

V

Q

*

R

I

OUT

DSON

VSN= Voltage across the sense resistor = I

OUTxRSN

www.national.com13

Page 14

Design Section (Continued)

This is the fraction of the switching period that the switch is

on. The switch is off for the remainder of the period. This

fraction is expressed as:

D’=1−D

The LM3477/A has limits for the maximum and minimum

LM3477/LM3477A

duty cycle (see ELECTRICAL CHARACHTERISTICS). The

maximum duty cycle of 93% (typical) will limit how low the

input voltage may drop while maintaining a regulated output

voltage (the dropout voltage). In situations where a very low

dropout voltage is required, it is necessary to include V

and VSNlosses in the maximum duty cycle calculation.

Voltage drops in the inductor will lower the dropout voltage

as well.

The minimum duty cycle of the LM3477/A corresponds to the

minimum on time, or blank out time (see ELECTRICAL

CHARACHTERISTICS).

*

D

MIN=TMIN

This will not limit how high the input voltage can rise, however the LM3477/A will operate in hysteretic mode once the

operating duty cycle decreases to the minimum duty cycle.

f

s

D,VQ

Programming the Current Limit/Hysteretic Threshold

DEFINITIONS:

Current Limit: The current limit is the point at which the

LM3477/A begins to limit the peak switch current. The current limit in the LM3477/A varies with duty cycle, which is a

function of the V

IN−VOUT

differential.

Hysteric Threshold: Hysteretic threshold is the current at

which the LM3477/A enters the hysteretic mode of operation

(see OVER VOLTAGE PROTECTION section). The hyster-

etic threshold is with respect to the peak switch current.

Setting Current Limit and Hysteretic Threshold

The adjustable current limit of the LM3477/A is set by the

sense resistor R

an internal control voltage V

when V

SEN(peak)

here as the differential voltage from the V

. The voltage across RSNis compared to

SN

equals V

. The onset of current limiting is

C

C(max)

,orVCL.V

SEN

pin to the I

IN

is defined

SEN

pin. VCLdecreases as the duty cycle increases, as shown in

Figure 7. Therefore, it is important to know both V

and V

V

IN

condition.

at the maximum operating duty cycle, or lowest

CL(min)

SEN(peak)

200033K3

FIGURE 7. Current Limit and Hysteretic Threshold vs

Duty Cycle

V

where D

CL(MIN)

=V

CL(0)(MIN)

is the duty cycle at the lowest VINcondition.

MAX

−D

(MAX)(VCL(0)(MIN)

−V

CL(100)(MIN)

To avoid current limit,

V

SEN(peak)

<

V

CL(MIN)

Therefore,

)

www.national.com 14

Page 15

Design Section (Continued)

LM3477/LM3477A

Example: V

IN(MIN)

= 4.5V, V

OUT

= 2.5V, I

OUT(MAX)

=3A

The hysteretic threshold is derived in a similar manner, the

only difference being that V

(V

). Notice that V

HYS

does not vary with the duty cycle.

HYS

SEN(peak)

is compared V

C(min)

The hysteretic threshold is predetermined by the selection of

above. The hysteretic threshold is:

R

SN

Continuing with the example above,

If the peak switch current decreases below this threshold,

the LM3477/A will operate in hysteretic mode (see OVER

VOLTAGE PROTECTION section). In some designs, it will

be desired to use R

so that lower valued inductors can be

SL

used (see DEFAULT/ADJUSTABLE SLOPE COMPENSA-

TION section and Inductor section). Using R

current limit and the hysteretic threshold. See Figure 8.R

will lower the

SL

SL

effectively adds an additional slope to the existing slope of

waveform.

the V

C

200033K4

FIGURE 8. Current Limit and Hysteretic Threshold vs

When R

Duty Cycle with R

is used, the following equations apply:

SL

SL

where MIN(V

the two values in the parenthesis and V

0.011V for the LM3477 and LM3477A, respectively. R

− 50x10-6xRSLxD

HYS

, 0) is the smaller of

MAX

is 0.032V and

HYS

can

SL

be used creatively to intentionally lower the hysteretic

threshold, allowing for better performance at lower loads.

However, when R

is used, there may be a minimum load

SL

requirement (see START-UP/SOFT-START section).

Power Inductor Section

The LM3477/A operates at a high switching frequency of

500kHz, which allows the use of small inductors. This is

made apparent in the following set of equations used to

calculate the output voltage ripple.

∆V

OUT(Pk-Pk)

) ∆i

L(Pk-Pk)

xR

ESR

(V)

As the switching frequency fs increases, the inductance

required for a given output voltage ripple decreases. The

equations above for ∆V

and ∆iLprovide criteria for

OUT

choosing the inductance. The maximum voltage ripple in

steady-state, PWM operation can be controlled by limiting

which in turn is set by the inductance value. Alternatively,

∆i

L

one can simply choose ∆i

as a percentage of the maximum

L

output current. Clearly, the size of the output capacitor ESR,

, will have an affect on which criteria is used to choose

R

ESR

the inductance. When the ESR is relatively low (less than

100mΩ), such as in ceramic, OSCON, and some low ESR

tantalum capacitors, it is convenient to choose the inductance based on setting ∆i

high, then it may be necessary to restrict ∆i

to 30% of Iout(max). If the ESR is

L

to a lower value

L

so that the output voltage ripple is not too high. Generally

speaking, the former suggestion of setting ∆i

I

OUT(MAX)

is recommended.

to 30% of

L

The inductance also affects the stability of the converter. The

slopes S

while the compensation ramp, S

and Sfin Figure 4 are functions of the inductance,

n

, is fixed by default. There-

e

fore if the inductance is too small, the converter may experience sub-harmonic oscillations. The LM3477/A provides

sufficient internal slope compensation to allow for inductances chosen according to the ∆i

=0.3xI

L

guideline in

OUT

most cases. Still, one should check to make sure the inductance is not too low before continuing the design process. If

it is found that the selected inductance is too low, a patented

scheme to increase the compensation ramp, S

, is provided

e

in the LM3477/A (see DEFAULT/ADJUSTABLE SLOPE

COMPENSATION section). In the calculations that follow, if it

is found that the chosen inductance is too small, R

SL

can be

used to increase Se so that the inductance can be used.

In a current mode control architecture, there is an inherent

resonance at half the switching frequency (see

DEFAULT/ADJUSTABLE SLOPE COMPENSATION sec-

www.national.com15

Page 16

Design Section (Continued)

tion). A convenient indicator of how much resonance exists is

quality factor Q. If Q is too high, subharmonic oscillations

could occur, if Q is too low, the current mode architecture

begins to act like a voltage mode architecture and the necessary compensation becomes more complex. This is dis-

LM3477/LM3477A

cussed in more detail in the COMPENSATION section, but

here it is important to calculate Q to be sure the selected

inductance will not cause problems to the stability of the

converter. The calculations below call for an inductance that

results in Q between 0.15 and 2. See the COMPENSATION

section if the chosen inductance enforces Q to be out of this

range. By default, no extra slope compensation is needed,

= 0. In general, a Q between 0.5 and 1 is optimal.

so R

SL

Where,

D’ = 1−D

VQ=VDSof the MOSFET when it is conducting

*

R

I

OUT

DS(ON).

V

= Voltage across the sense resistor ) I

SEN

Back solving for L gives a range for acceptable inductances

based on a range for Q:

OUTxRSN

Type of output capacitors

Different type of capacitors often have different combinations

of capacitance, equivalent series resistance (ESR), and voltage ratings. High-capacitance multi-layer ceramic capacitors

(MLCCs) have a very low ESR, typically 12mΩ, but also

relatively low capacitance and low voltage ratings. Tantalum

capacitors can have fairly low ESR, such as 18mΩ, and high

capacitance (up to 1mF) at higher voltage ratings than MLCCs. Aluminum capacitors offer high capacitance and relatively low ESR and are available in high voltage ratings.

OSCON capacitors can achieve ESR values that are even

lower than those of MLCCs and with higher capacitance, but

the voltage ratings are low. Other tradeoffs in capacitor

technology include temperature stability, surge current capability, and capacitance density (physical size vs. capacitance).

Output Capacitor Considerations

Skip to the ’Calculations for the output capacitor’ subsection

if a quick design is desired. While it is generally desired to

use as little output capacitance as possible to keep costs

down, the output capacitor should be chosen with care as it

directly affects the ripple component of the output voltage as

well as other components in the design. The output voltage

ripple is directly proportional to the ESR of the output capacitor (see POWER INDUCTOR section). Therefore, designs

requiring low output voltage ripple should have an output

capacitor with low ESR. Choosing a capacitor with low ESR

has the additional benefit of requiring one less component in

the compensation network, as discussed in the Compensation section.

In addition to the output voltage ripple, the output capacitor

directly affects the output voltage overshoot in a load transient. Two transients are possible: an unloading transient

and a loading transient. An unloading transient occurs when

the load current transitions to a higher current, and charge is

unloaded from the output capacitor. A loading transient is

when the load transitions to a lower current, and charge is

loaded to the output capacitor. How the output voltage reacts

during these transitions is known as the transient response.

Both the capacitance and the ESR of the output capacitor

will affect the transient response.

It is recommended that:

Q(max) = 2, and

Q(min) = 0.15

Values for V

can be found in the ELECTRICAL CHARAC-

SL

TERISTICS section.

Note: Adding slope compensation with R

will decrease the

SL

current limit. An iterative process may be needed to meet

current limit and stability requirements, see PROGRAM-

MING CURRENT LIMIT/HYSTERETIC THRESHOLD section.

Output Capacitor Selection

A capacitance between 47µF - 100µF is typically used. Skip

to ’Calculations for the Output Capacitance’ for minimum

capacitance calculations.

www.national.com 16

200033B9

FIGURE 9. A Loading Transient

The control loop of the LM3477/A can be made fast enough

to saturate the duty cycle when the worst case lode transient

occurs. This means the duty cycle jumps to D

MIN

or D

MAX

depending on the type of load transient. In a loading transient, as shown in Figure 9, the duty cycle drops to D

MIN

while the inductor current falls to match the load current.

During this time, the regulator is heavily dependent on the

output capacitors to handle the load transient. The initial

overshoot is caused by the ESR of the output capacitors.

,

Page 17

Output Capacitor Selection

(Continued)

How the output voltage recovers after that initial excursion

depends on how fast the inductor current falls and how large

the output capacitance is. See Figure 10.

200033B5

FIGURE 10. Output Voltage Overshoot Violation

The ESR and the capacitance of the output capacitor must

be carefully chosen so that the output voltage overshoot is

within the design’s specification V

bined ESR of the output capacitors is not low enough, the

initial output voltage excursion will violate the specification,

see ∆V

. If the ESR is low enough, but there is not enough

C1

output capacitance, the output voltage will travel outside the

specification window due to the extra charge being dumped

into the capacitor, see ∆V

. The LM3477/A has output over

C2

voltage protection (OVP) which could trigger if the transient

overshoot is high enough. If this happens, the controller will

operate in hysteretic mode (see OVER VOLTAGE PROTEC-

TION section) for a few cycles before the output voltage

settles to its steady state. If this behavior is not desired,

substitute V

(referred to the output) for V

OVP

found in the ELECTRICAL CHARACTERISTICS table) to

find the minimum capacitance and maximum ESR of the

output capacitor.

Calculations for the Output Capacitor

During a loading transient, the delta output voltage ∆V

two changing components. One is the voltage difference

across the ESR (∆V

caused by the gained charge (∆V

), the other is the voltage difference

r

q

= ∆Vr+ ∆V

∆V

c

The design objective is to keep ∆Vclower than some maximum overshoot (V

OS(MAX)

). V

OS(MAX)

the output load requirements.

Both voltages ∆V

and ∆Vqwill change with time. For ∆Vrthe

r

equation is:

where,

= the output capacitor ESR

R

ESR

∆I

= the difference between the load current change

OUT

I

OUT(MAX)−IOUT(MIN)

D

= Minimum duty cycle of device (0.165 typical)

MIN

Evaluating this equation at t = 0 gives ∆V

V

OS(MAX)

for ∆V

and solving for R

r(MAX)

. If the total com-

OS(MAX)

OS(MAX)(VOVP

). This gives:

q

is chosen based on

. Substituting

r(max)

gives:

ESR

has

c

LM3477/LM3477A

The expression for ∆Vqis:

From Figure 11 it can be told that ∆VCwill reach its peak

value at some point in time and then decrease. The larger

the output capacitance is, the earlier the peak will occur. To

find the peak position, let the derivative of ∆V

go to zero,

C

and the result is:

200033B6

FIGURE 11. Output Voltage Overshoot Peak

is

The intention is to find the capacitance value that will yield, at

,a∆VCthat equals V

t

peak

equating ∆V

C

OUT(MIN)

C

:

to V

OS(max)

. Substituting tpeak for t and

OS(max)

gives the following solution for

The chosen output capacitance should not be less than

47µF, even if the solution for C

OUT(MIN)

is less than 47µF.

Notice it is already assumed that the total ESR is no greater

than R

ESR(MAX)

, otherwise the term under the square root

will be a negative number.

Power MOSFET Selection

The drive pin of LM3477/A must be connected to the gate of

an external MOSFET. In a buck topology, the drain of the

external N-Channel MOSFET is connected to the input and

the source is connected to the inductor. The C

provides the gate drive needed for an external N-Channel

MOSFET. The gate drive voltage depends on the input voltage (see TYPICAL PERFORMANCE CHARACTERISTICS).

In most applications, a logic level MOSFET can be used. For

very low input voltages, a sub-logic level MOSFET should be

used.

The selected MOSFET directly controls the efficiency. The

critical parameters for selection of a MOSFET are:

1. Minimum threshold voltage, V

2. On-resistance, R

DS

(ON)

TH

(MIN)

pin voltage

B

www.national.com17

Page 18

Power MOSFET Selection (Continued)

3. Total gate charge, Q

4. Reverse transfer capacitance, C

5. Maximum drain to source voltage, V

The off-state voltage of the MOSFET is approximately equal

LM3477/LM3477A

to the input voltage. V

greater than the input voltage. The power losses in the

MOSFET can be categorized into conduction losses and ac

switching or transition losses. R

the conduction losses. The conduction loss, P

2

R loss across the MOSFET. The maximum conduction loss

I

is given by:

where D

is the maximum operating duty cycle:

MAX

The turn-on and turn-off transition times of a MOSFET from

the MOSFET specifications require tens of nano-seconds.

and Qgare needed from the MOSFET specifications to

C

RSS

estimate the large instantaneous power loss that occurs

during these transitions.

The average amount of gate current required to turn the

MOSFET on can be calculated using the formula:

The required gate drive power to turn the MOSFET on is

equal to the switching frequency times the energy required

to deliver the charge to bring the gate charge voltage to V

(see ELECTRICAL CHARACTERISTICS and TYPICAL

PERFORMANCE CHARACTERISTICS for the drive voltage

specification).

It is sometimes helpful or necessary to slow down the turn on

transition of the FET so that less switching noise appears at

the I

R

pin. This can be done by inserting a drive resistor

SEN

in series with the boot-strap capacitor (see Figure 6).

DR

This can help reduce sensing noise that may be preventing

designs from operating at or near the LM3477/A’s minimum

duty cycle limit. Gate drive resistors from 2.2Ω to 51Ω are

recommended.

g

DS(MAX)

I

P

Drive=FS.Qg.VDR

of the MOSFET must be

DS(ON)

G=Qg.FS

RSS

DS(MAX)

is needed to estimate

Power Diode Selection

The output current commutates through the diode when the

external MOSFET turns off. The three most important parameters for the diode are the peak current, peak inverse

voltage, and average power dissipation. Exceeding these

ratings can cause damage to the diode. The average current

through the diode is given by:

I

D(AVG)=IOUT

where D is the duty cycle and I

diode must be rated to handle this current.

The off-state voltage across the diode in a buck converter is

approximately equal to the input voltage. The peak inverse

voltage rating of the diode must be greater than the off-state

voltage of the diode. To improve efficiency, a low forward

drop schottky diode is recommended.

x (1-D)

is the output current. The

OUT

COND

,isthe

DR

Input Capacitor Selection

In a buck converter, the high side switch draws large ripple

currents from the input capacitor. The input capacitor must

be rated to handle this RMS current.

The power dissipated in the input capacitor is given by:

P

D(CIN)=IRMS_CIN

where R

ESR_CIN

2

R

ESR_CIN

,

is the ESR of the input capacitor. The input

capacitor must be selected to handle the rms current and

must be able to dissipate the power. P

D(CIN)

must be lower

than the rated power dissipation of the selected input capacitor. In many cases, several capacitors have to be paralleled

to handle the rms current. In that case, the power dissipated

in each capacitor is given by:

P

D(CIN)

=(I

RMS_CIN

R

ESR_CIN

)/n2, where n is the total num-

2

ber of capacitors paralled at the input.

A 0.1µF or 1µF ceramic bypass capacitor is also recom-

mended on the V

pin (pin 8) of the IC. This capacitor must

IN

be connected very close to pin 8.

Compensation

20003391

FIGURE 12. Control Block Diagram of a Current Mode

Controlled Buck Converter

The LM3477/A is a current mode controller, therefore the

control block diagram representation involves 2 feedback

loops (see Figure 12). The inner feedback loop derives its

feedback from the sensed inductor current, while the outer

loop monitors the output voltage. This section will not give a

rigorous analysis of current mode control, but rather a simplified but accurate method to determine the compensation

network. The first part reveals the results of the model, giving

expressions for solving for component values in the compensation network.

The compensation network is designed around the power

components, or the power stage. An isolated schematic of

the error amplifier and the various compensation components is shown in Figure 13. The error amplifier in conjunction with the compensation network makes up the compensator block in Figure 12. The purpose of the compensator

block is to stabilize the control loop and achieve high performance in terms of the transient response, audio susceptibility and output impedance.

www.national.com 18

Page 19

Compensation (Continued)

There are several different types of compensation that can

be used to improve the frequency response of the control

loop. To determine which compensation scheme to use,

some information about the power stage is needed.

Use V

IN=VIN(MIN)

and R = R

MIN(IOUT(MAX)

) when calculat-

ing compensation components.

LM3477/LM3477A

20003390

FIGURE 13. LM3477 Compensation Components

Figure 14 shows a bode plot of a typical current mode buck

regulator. It is an estimate of the actual plot using the asymptotic approach. The three plots shown are of the compensator, powerstage, and loop gain, which is the product of

the power stage, compensator, and feedback gain. The loop

gain determines both static and dynamic performance of the

converter. The power stage response is fixed by the selection of the power components, therefore the compensator is

designed around the powerstage response to achieve a

good loop response. Specifically, the compensator is added

to increase low frequency magnitude, extend the 0dB frequency (crossover frequency), and improve the phase characteristic.

200033J4

FIGURE 14. Typical Open Loop, Compensator, and

Power Stage Bode Plots for LM3477 Buck Circuits.

Poles, Zeros and Important Measurements are Labeled

Se=fS(VSL+ 50x10−6RSL)

With the power stage known, a compensator can be designed to achieve improved performance and stability. The

LM3477/A will typically require only a single resistor and

capacitor for compensation, but depending on the power

stage it could require three or four external components.

It is a good idea to check that Q is between 0.15 and 2, if it

was not already done when selecting the inductor. If Q is less

than 0.15 or greater than 2, skip to the SAMPLING POLE

QUALITY FACTOR section below before continuing with the

compensator design.

First, a target crossover frequency (f

) for the loop gain must

c

be selected. The crossover frequency is the bandwidth of the

converter. A higher bandwidth generally corresponds to

faster response times and lower overshoots to load transients. However, the bandwidth should not be much higher

than 1/10 the switching frequency. The LM3477/A operates

with a 500kHz switching frequency, so it is recommended to

choose a crossover frequency between 10kHz - 50kHz.

The schematic of the LM3477/A compensator is shown in

Figure 13. The default design uses R

(type 2) compensator. The C

C2

and CC1to form a lag

c

capacitor can be added to

form an additional pole that is typically used to cancel out the

esr zero of the output capacitor. Finally, if extra phase margin

is needed, the Cff capacitor can be added (this does not help

at low output voltages, see below).

www.national.com19

Page 20

Compensation (Continued)

The strategy taken here for choosing R

crossover frequency with R

with C

set R

. Using the selected target crossover frequency, fC,

C1

to:

C

, and set the compensator zero

c

and CC1is to set the

c

LM3477/LM3477A

fC= Crossover frequency in Hertz (20kHz - 50kHz is recommended)

= 50x103Ω

R

GM

GM = 1000x10

The compensator zero, f

sient responses are desired, f

possible, however it should not be higher than the selected

crossover frequency f

choose C

power pole f

frequency fc:

In this compensation scheme, the pole created by CC2is

used to cancel out the zero created by the ESR of the output

capacitor. In other schemes such as the methods discussed

in the SAMPLING POLE QUALITY FACTOR subsection, the

ESR zero is used. For the typical case, use C

−6

A/V

, is set with CC1. When fast tran-

Z1

should be placed as high as

Z1

. The guideline proposed here is to

such that fZ1falls somewhere between the

C1

P1

C

and1⁄2decade before the selected crossover

One can plot the magnitude and phase of the open loop

response to analyze the frequency response.

Example: Compensation Design

4.5V ≤ V

V

OUT

I

OUT

R

SN

≤ 5.5V

IN

= 2.5V

= 3A (R = 0.83Ω)

= 0.02Ω

L = 3.3µH

=0Ω

R

SL

= 100µF

C

OUT

= 0.01Ω

R

ESR

First, calculate the power stage parameters using V

and R

if:

C2

(MAX)

:

IN(MIN)

Plotting the Open Loop Response

The open loop response is expressed as:

T=ADCxACMxHxFp(s)xFc(s)

Where A

A

CM

www.national.com 20

and H are given above and

DC

=GMxR

GM

In this example, a crossover frequency of 20kHz is chosen,

= 20000. RCis now calculated using the power stage

so: f

C

information and the target crossover frequency f

:

C

This sets the high frequency gain of the compensator such

that a crossover frequency of f

sets the compensator zero, fZ2. Set fZ2between the

C

C1

power pole f

over frequency f

and the1⁄2decade before the target cross-

P1

:

C

is obtained. The capacitor

C

Page 21

Compensation (Continued)

Choosing C

the power pole and insuring a −20dB/decade slope in the

low frequency magnitude response. In other words, the

phase margin below the crossover frequency will always be

higher than the phase margin at the crossover frequency.

If better transient response times are desired, a second

method is to set f

target crossover frequency. This trades more low frequency

gain for less phase margin, which translates to faster but

more oscillatory step responses. We pick C

47nF).

If the esr zero of the output capacitor (f

more phase margin is required, additional components may

be added to increase the flexibility of the compensator.

Use C

C2

= 88x10−9F will set fZ2=fP1, canceling out

C1

between fP1and1⁄2decade before fC, the

Z2

C1

) is too low or if

ESR

1

<

if f

ESR

⁄2fS, that is if:

= 49nF (use

stage equations above, Q, describes how much resonance

will be observed. Q is a function of duty cycle and m

. Figure

c

16 shows how the power stage bode plot is affected as Q is

varied from 0.01 to 10. The resonance is caused by two

complex poles at half the switching frequency. If m

is too

c

low, the resonant peaking could become severe coinciding

with subharmonic oscillations in the inductor current. If m

c

too high, the two complex poles split and the converter

begins to act like a voltage mode converter and the compensation scheme used above should be changed.

LM3477/LM3477A

is

For this example, f

= 159 kHz, so use CC2.

ESR

The equations used here for RC,CC1, and CC2are approxi-

<<

mations valid when C

CC1. For exact equations, see

C2

Plotting Open Loop Response earlier in this section. In some

cases, the desired inductance is several times higher than

the optimal inductance set by the internal slope compensation. This results in a Q lower than 0.15, in which case

additional methods of compensating are presented (see

SAMPLING POLE QUALITY FACTOR section).

200033J3

FIGURE 15. Open Loop Frequency Response for

LM3477 Compensation Design Example

200033J5

FIGURE 16. The Quality Factor Q of the Two Complex

Poles is used to qualify how much resonant peaking is

observed in the Power Stage Bode Plot

>

2, the sampling poles are imaginary and are approach-

If Q

ing the right half of the imaginary plane (the system is

becoming unstable). In this case, Q must be decreased by

either increasing the inductance, or more preferably, adding

more slope compensation through the R

resistor (see

SL

DEFAULT/ADJUSTABLE SLOPE COMPENSATION section).

<

0.15, it means that one of the sampling poles is de-

If Q

creasing in frequency towards the dominant power pole, f

p1

There are three ways to compensate for this. Decrease the

crossover frequency, add a phase lead network, or use the

output capacitor’s ESR to cancel out the low frequency

sampling pole.

One option is to decrease the crossover frequency so that

the phase margin is not as severely decreased by the sampling pole. Decreasing the crossover frequency to between

1kHz to 10kHz is advisable here. As a result, there will be a

decrease in transient response performance.

Another option is the use of the feed-forward capacitor, Cff.

This will provide a positive phase shift (lead) which can be

used to increase phase margin. However, it is important to

note that the effectiveness of Cff decreases with output

voltage. This is due to the fact that the frequencies of the

zero f

and pole f

zff

get closer together as the output voltage

pff

is reduced.

The frequency of the feed-forward zero and pole are:

.

Sampling Pole Quality Factor

In a current mode control architecture, there is an inherent

resonace at half the switching frequency. The LM3477/A

internally compensates for this by adding a negative slope to

the PWM control waveform (see DEFAULT/ADJUSTABLE

SLOPE COMPENSATION section). The factor in the power

www.national.com21

Page 22

Compensation (Continued)

LM3477/LM3477A

A third option is to strategically place the ESR zero f

ESR

the output capacitor to cancel out the sampling pole. In this

case, the capacitor C

should be placed around the crossover frequency fc, but

f

ESR

will not be used to cancel out f

C2

ESR

this will depend on how low Q is.

of

.

www.national.com 22

Page 23

Physical Dimensions inches (millimeters)

unless otherwise noted

LM3477/LM3477A High Efficiency High-Side N-Channel Controller for Switching Regulator

8 Lead Mini SO-8 Package

NS Package Number MUA08A

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Corporation

Americas

Email: support@nsc.com

www.national.com

National Semiconductor

Europe

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: ap.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...