Datasheet LM3420M5-16.8, LM3420M5-12.6, LM3420AM5X-4.2, LM3420AM5X-16.8, LM3420AM5-8.4 Datasheet (NSC)

...Page 1

LM3420-4.2, -8.2, -8.4, -12.6, -16.8

Lithium-Ion Battery Charge Controller

General Description

The LM3420 series of controllers are monolithic integrated

circuits designed for charging and end-of-charge control for

Lithium-Ion rechargeable batteries. The LM3420 is available

in fivefixedvoltage versions for one through four cell charger

applications (4.2V, 8.2V/8.4V, 12.6V and 16.8V respectively).

Included in a very small package is an (internally compensated) op amp, a bandgap reference, an NPN output transistor, and voltage setting resistors. The amplifier’s inverting input is externally accessible for loop frequency

compensation. The output is an open-emitter NPN transistor

capable of driving up to 15 mA of output current into external

circuitry.

A trimmed precision bandgap reference utilizes temperature

drift curvature correction for excellent voltage stability over

the operating temperature range. Available with an initial tolerance of 0.5%for the A grade version, and 1%for the standard version, the LM3420 allows for precision end-of-charge

control for Lithium-Ion rechargeable batteries.

The LM3420 is available in a sub-miniature 5-lead SOT23-5

surface mount package thus allowing very compact designs.

Features

n Voltage options for charging 1, 2, 3 or 4 cells

n Tiny SOT23-5 package

n Precision (0.5%) end-of-charge control

n Drive capability for external power stage

n Low quiescent current, 85 µA (typ.)

Applications

n Lithium-Ion battery charging

n Suitable for linear and switching regulator charger

designs

LM3420-4.2, -8.2, -8.4, -12.6, -16.8 Lithium-Ion Battery Charge Controller

May 1998

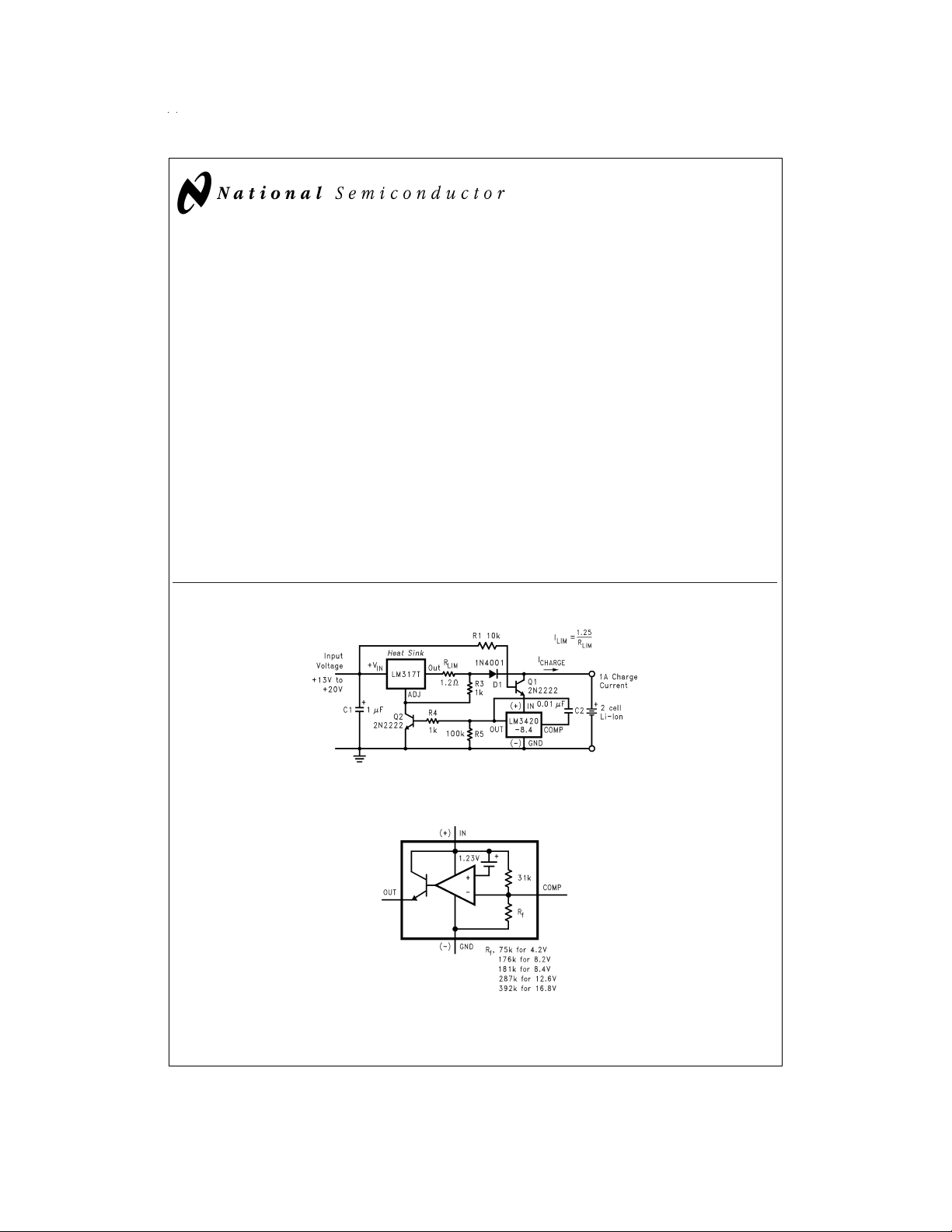

Typical Application and Functional Diagram

DS012359-1

Typical Constant Current/Constant Voltage

SIMPLE SWITCHER®is a registered trademark of National Semiconductor Corporation.

© 1999 National Semiconductor Corporation DS012359 www.national.com

Li-Ion Battery Charger

DS012359-2

LM3420 Functional Diagram

Page 2

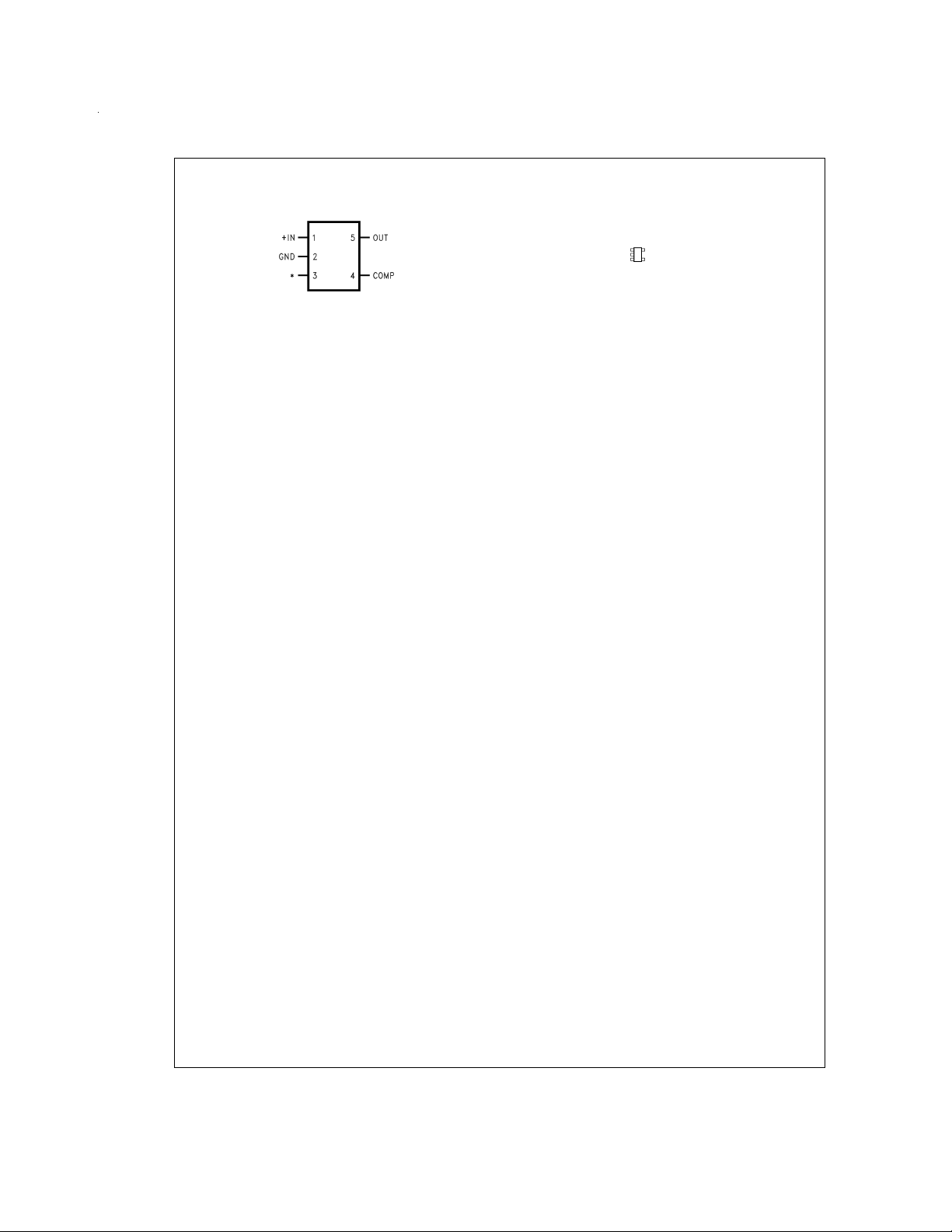

Connection Diagrams and Order Information

5-Lead Small Outline Package (M5)

Actual Size

DS012359-4

*No internal connection, but should be soldered to PC board for best heat

transfer.

DS012359-3

Top View

For Ordering Information

See

Figure 1

See NS Package Number MA05B

in this Data Sheet

www.national.com 2

Page 3

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Input Voltage V(IN) 20V

Output Current 20 mA

Junction Temperature 150˚C

Storage Temperature −65˚C to +150˚C

Lead Temperature

Vapor Phase (60 seconds) +215˚C

ESD Susceptibility (Note 3)

Human Body Model 1500V

See AN-450 “Surface Mounting Methods and Their Effect

on Product Reliability” for methods on soldering

surface-mount devices.

Operating Ratings (Notes 1, 2)

Ambient Temperature Range −40˚C ≤ T

Junction Temperature Range −40˚C ≤ T

Output Current 15 mA

≤ +85˚C

A

≤ +125˚C

J

Infrared (15 seconds) +220˚C

=

Power Dissipation (T

(Note 2) 300 mW

25˚C)

A

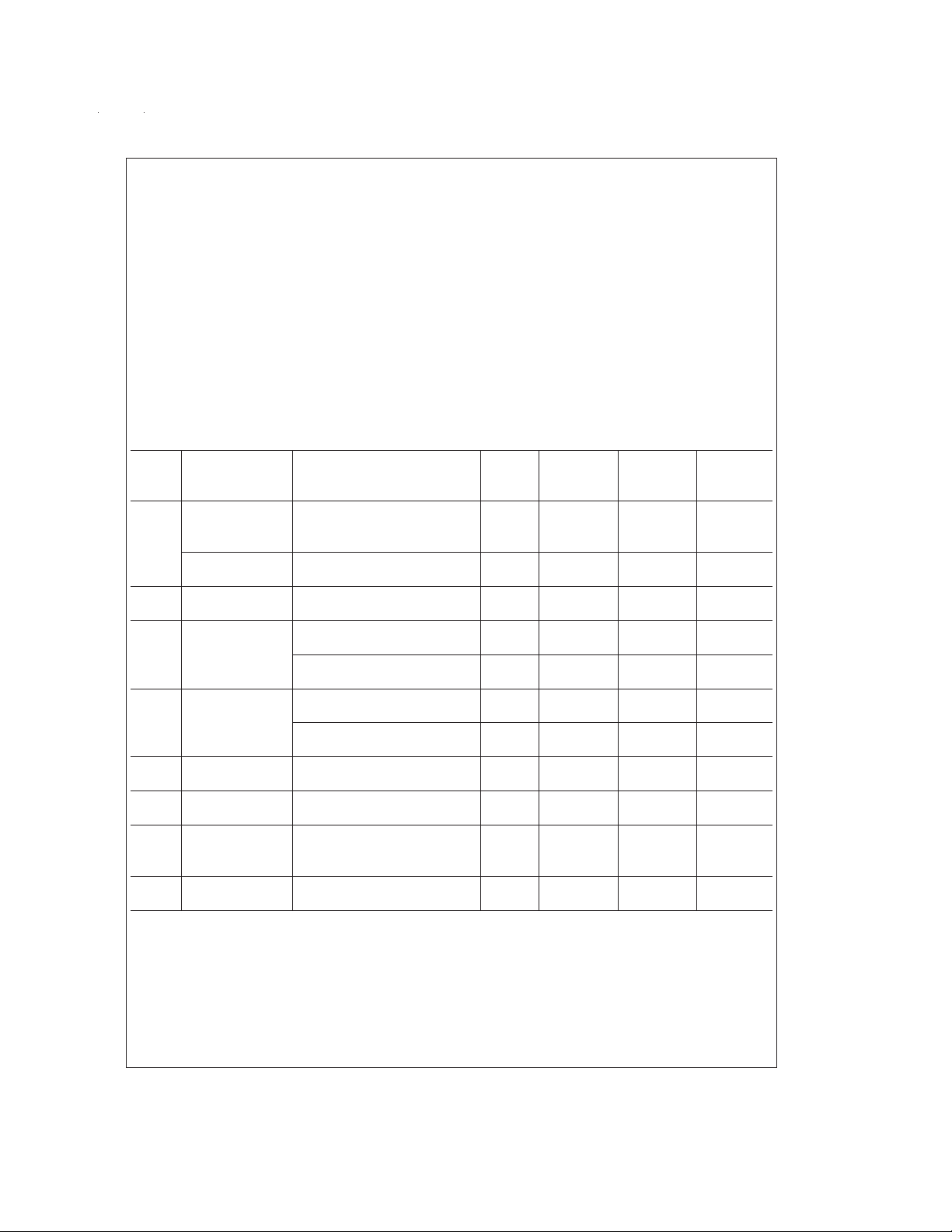

LM3420-4.2

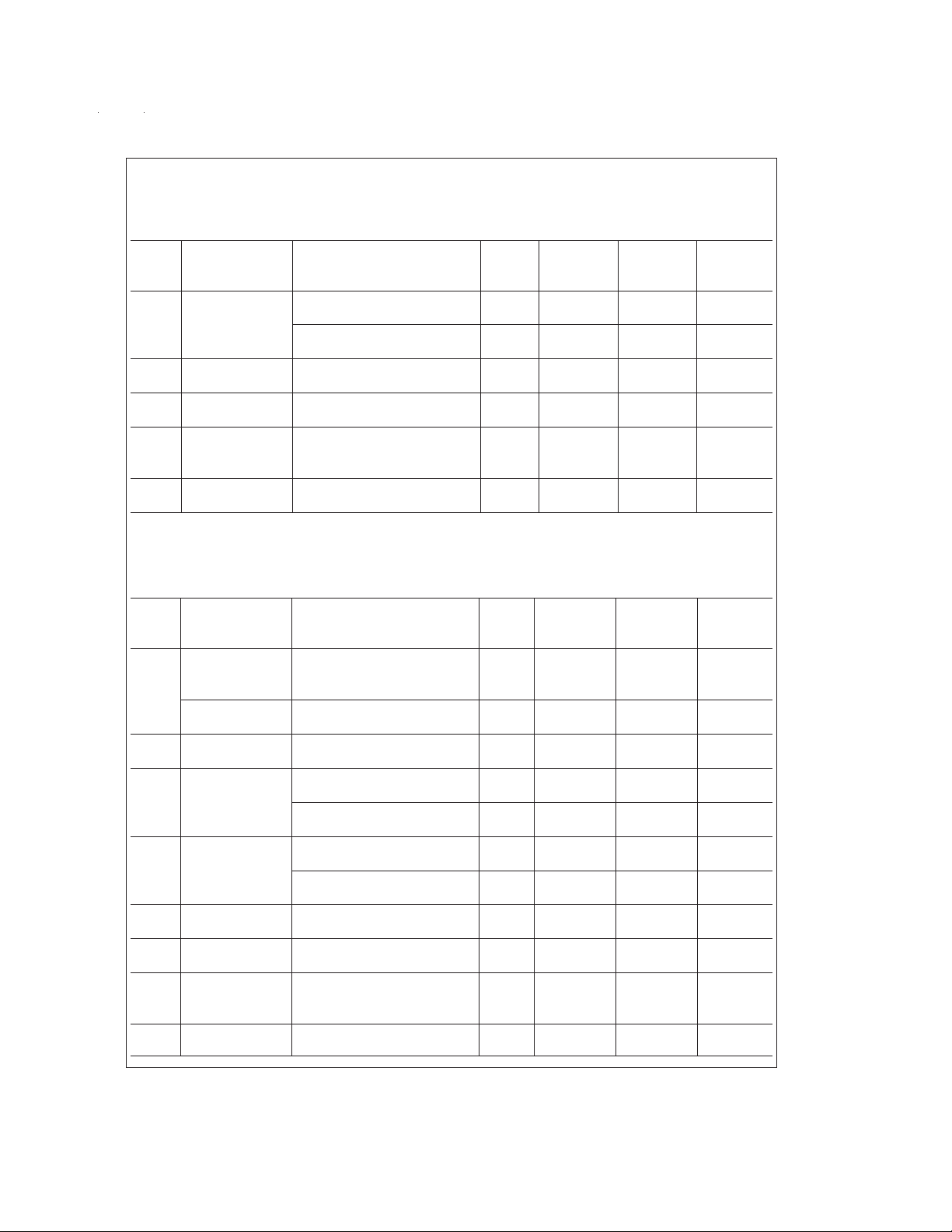

Electrical Characteristics

Specifications with standard type face are for T

ture Range. Unless otherwise specified, V(IN)=V

Symbol Parameter Conditions Typical LM3420A-4.2 LM3420-4.2 Units

V

REG

Regulation Voltage I

Regulation Voltage I

OUT

OUT

=

=

Tolerance

I

q

G

Quiescent Current I

Transconductance 20 µA ≤ I

m

∆I

/∆V

OUT

REG

=

OUT

=

V

OUT

1mA≤I

=

V

A

V

Voltage Gain 1V ≤ V

∆V

/∆V

OUT

REG

OUT

=

R

200Ω (Note 6) 550/250 450/200 V/V(min)

L

1V ≤ V

=

R

2kΩ 1500/900 1000/700 V/V(min)

OUT

L

OUT

=

=

V

SAT

Output Saturation V(IN)=V

(Note 7) I

I

L

Output Leakage V(IN)=V

Current V

R

f

Internal Feedback 75 kΩ

Resistor (Note 8) 94 94 kΩ(max)

E

n

Output Noise I

OUT

=

Voltage

=

25˚C, and those with boldface type apply over full Operating Tempera-

J

REG,VOUT

=

1.5V.

(Note 4) Limit Limit (Limits)

(Note 5) (Note 5)

1 mA 4.2 V

4.221/4.242 4.242/4.284 V(max)

4.179/4.158 4.158/4.116 V(min)

1mA

±

0.5/±1

±1/±

2

%

(max)

1mA 85 µA

110/115 125/150 µA(max)

≤ 1 mA 3.3 mA/mV

OUT

2V 1.3/0.75 1.0/0.50 mA/mV(min)

≤ 15 mA 6.0 mA/mV

OUT

2V 3.0/1.5 2.5/1.4 mA/mV(min)

≤ V

OUT

OUT

REG

− 1.2V (−1.3) 1000 V/V

REG

≤ V

− 1.2V (−1.3) 3500 V/V

REG

+100 mV 1.0 V

15 mA 1.2/1.3 1.2/1.3 V(max)

−100 mV 0.1 µA

REG

0V 0.5/1.0 0.5/1.0 µA(max)

56 56 kΩ(min)

1 mA, 10 Hz ≤ f ≤ 10 kHz 70 µV

RMS

www.national.com3

Page 4

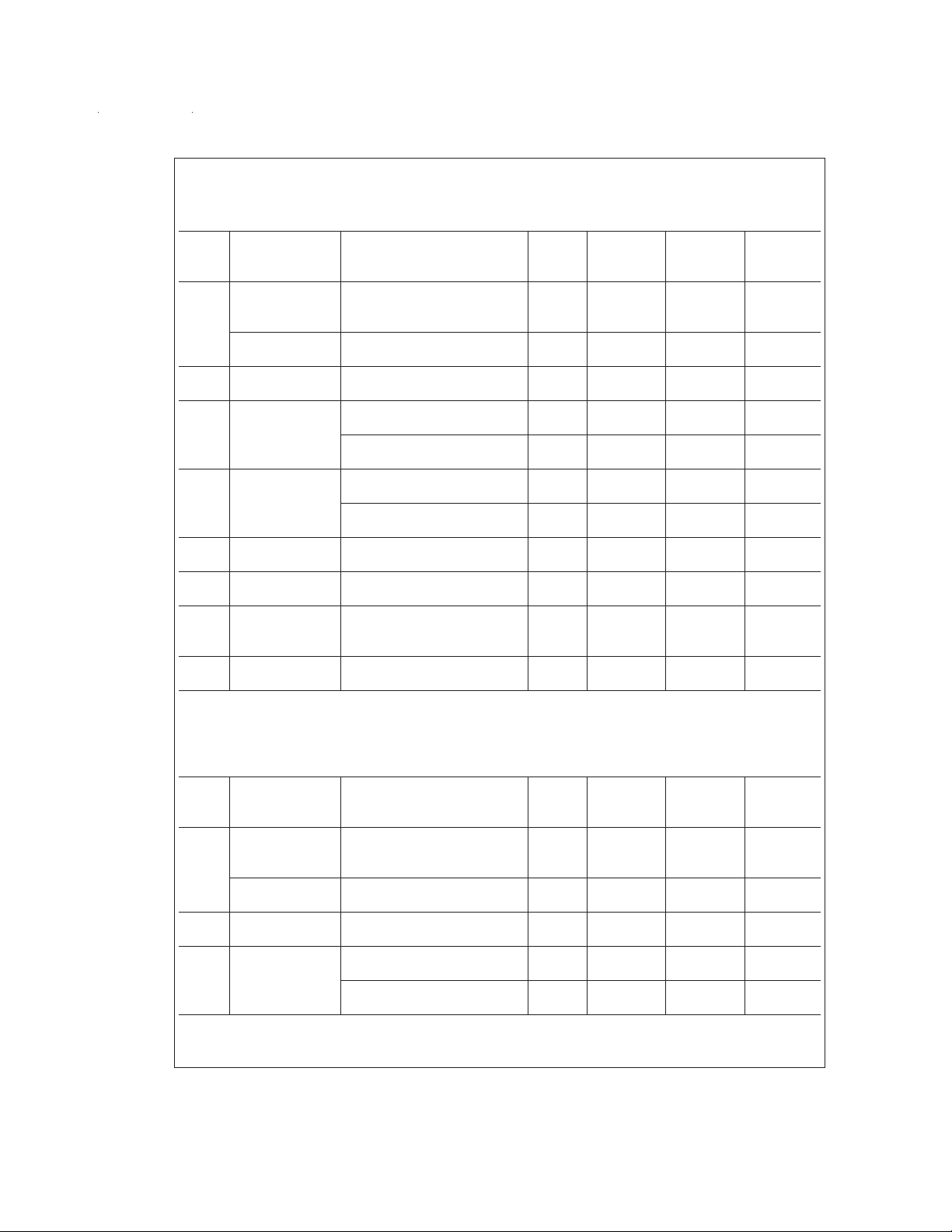

LM3420-8.2

Electrical Characteristics

Specifications with standard type face are for T

ture Range. Unless otherwise specified, V(IN)=V

Symbol Parameter Conditions Typical LM3420A-8.2 LM3420-8.2 Units

V

REG

Regulation Voltage I

Regulation Voltage I

OUT

OUT

=

=

Tolerance

I

q

G

Quiescent Current I

Transconductance 20 µA ≤ I

m

∆I

/∆V

OUT

REG

=

OUT

=

V

OUT

1mA≤I

=

V

A

V

Voltage Gain 1V ≤ V

∆V

/∆V

OUT

REG

OUT

=

R

470Ω (Note 6) 550/250 450/200 V/V(min)

L

1V ≤ V

=

R

5kΩ 1500/900 1000/700 V/V(min)

OUT

L

OUT

=

=

V

SAT

Output Saturation V(IN)=V

(Note 7) I

I

L

Output Leakage V(IN)=V

Current V

R

f

Internal Feedback 176 kΩ

Resistor (Note 8) 220 220 kΩ(max)

E

n

Output Noise I

OUT

=

Voltage

=

25˚C, and those with boldface type apply over full Operating Tempera-

J

REG,VOUT

=

1.5V.

(Note 4) Limit Limit (Limits)

(Note 5) (Note 5)

1 mA 8.2 V

8.241/8.282 8.282/8.364 V(max)

8.159/8.118 8.118/8.036 V(min)

1mA

±

0.5/±1

±1/±

2

%

(max)

1mA 85 µA

110/115 125/150 µA(max)

≤ 1 mA 3.3 mA/mV

OUT

6V 1.3/0.75 1.0/0.50 mA/mV(min)

≤ 15 mA 6.0 mA/mV

OUT

6V 3.0/1.5 2.5/1.4 mA/mV(min)

≤ V

OUT

OUT

REG

− 1.2V (−1.3) 1000 V/V

REG

≤ V

− 1.2V (−1.3) 3500 V/V

REG

+100 mV 1.0 V

15 mA 1.2/1.3 1.2/1.3 V(max)

−100 mV 0.1 µA

REG

0V 0.5/1.0 0.5/1.0 µA(max)

132 132 kΩ(min)

1 mA, 10 Hz ≤ f ≤ 10 kHz 140 µV

RMS

LM3420-8.4

Electrical Characteristics

Specifications with standard type face are for T

ture Range. Unless otherwise specified, V(IN)=V

Symbol Parameter Conditions Typical LM3420A-8.4 LM3420-8.4 Units

V

REG

Regulation Voltage I

Regulation Voltage I

OUT

OUT

=

=

Tolerance

I

q

G

Quiescent Current I

Transconductance 20 µA ≤ I

m

∆I

/∆V

OUT

REG

=

OUT

=

V

OUT

1mA≤I

=

V

OUT

www.national.com 4

=

25˚C, and those with boldface type apply over full Operating Tempera-

J

REG,VOUT

=

1.5V.

(Note 4) Limit Limit (Limits)

(Note 5) (Note 5)

1 mA 8.4 V

8.442/8.484 8.484/8.568 V(max)

8.358/8.316 8.316/8.232 V(min)

1mA

±

0.5/±1

±1/±

2

%

1mA 85 µA

110/115 125/150 µA(max)

≤ 1 mA 3.3 mA/mV

OUT

6V 1.3/0.75 1.0/0.50 mA/mV(min)

≤ 15 mA 6.0 mA/mV

OUT

6V 3.0/1.5 2.5/1.4 mA/mV(min)

(max)

Page 5

LM3420-8.4

Electrical Characteristics

Specifications with standard type face are for T

ture Range. Unless otherwise specified, V(IN)=V

Symbol Parameter Conditions Typical LM3420A-8.4 LM3420-8.4 Units

A

V

V

SAT

I

L

R

f

E

n

Voltage Gain 1V ≤ V

∆V

OUT

/∆V

REG

R

L

1V ≤ V

R

L

Output Saturation V(IN)=V

(Note 7) I

OUT

Output Leakage V(IN)=V

Current V

OUT

Internal Feedback 181 kΩ

Resistor (Note 8) 227 227 kΩ(max)

Output Noise I

OUT

Voltage

(Continued)

=

25˚C, and those with boldface type apply over full Operating Tempera-

J

REG,VOUT

=

1.5V.

(Note 4) Limit Limit (Limits)

(Note 5) (Note 5)

≤ V

OUT

=

470Ω (Note 6) 550/250 450/200 V/V(min)

OUT

=

5kΩ 1500/900 1000/700 V/V(min)

=

15 mA 1.2/1.3 1.2/1.3 V(max)

=

0V 0.5/1.0 0.5/1.0 µA(max)

− 1.2V (−1.3) 1000 V/V

REG

≤ V

− 1.2V (−1.3) 3500 V/V

REG

+100 mV 1.0 V

REG

−100 mV 0.1 µA

REG

135 135 kΩ(min)

=

1 mA, 10 Hz ≤ f ≤ 10 kHz 140 µV

RMS

LM3420-12.6

Electrical Characteristics

Specifications with standard type face are for T

Range. Unless otherwise specified, V(IN)=V

Symbol Parameter Conditions Typical LM3420A-12.6 LM3420-12.6 Units

V

REG

Regulation Voltage I

Regulation Voltage I

OUT

OUT

=

=

Tolerance

I

q

G

m

Quiescent Current I

Transconductance 20 µA ≤ I

∆I

/∆V

OUT

REG

=

OUT

=

V

OUT

1mA≤I

=

V

A

V

Voltage Gain 1V ≤ V

∆V

/∆V

OUT

REG

OUT

=

R

750Ω (Note 6) 550/250 450/200 V/V(min)

L

1V ≤ V

=

R

10 kΩ 1500/900 1000/700 V/V(min)

OUT

L

OUT

=

=

V

SAT

Output Saturation V(IN)=V

(Note 7) I

I

L

Output Leakage V(IN)=V

Current V

R

f

Internal Feedback 287 kΩ

Resistor (Note 8) 359 359 kΩ(max)

E

n

Output Noise

Voltage

=

I

OUT

=

25˚C, and those with boldface type apply over full Operating Temperature

J

REG,VOUT

=

1.5V.

(Note 4) Limit Limit (Limits)

(Note 5) (Note 5)

1 mA 12.6 V

12.663/12.726 12.726/12.852 V(max)

12.537/12.474 12.474/12.348 V(min)

1mA

±

0.5/±1

±1/±

2

%

(max)

1mA 85 µA

110/115 125/150 µA(max)

≤ 1 mA 3.3 mA/mV

OUT

10V 1.3/0.75 1.0/0.5 mA/mV(min)

≤ 15 mA 6.0 mA/mV

OUT

10V 3.0/1.5 2.5/1.4 mA/mV(min)

≤ V

OUT

OUT

REG

− 1.2V (−1.3) 1000 V/V

REG

≤ V

− 1.2V (−1.3) 3500 V/V

REG

+100 mV 1.0 V

15 mA 1.2/1.3 1.2/1.3 V(max)

−100 mV 0.1 µA

REG

0V 0.5/1.0 0.5/1.0 µA(max)

215 215 kΩ(min)

1 mA, 10 Hz ≤ f ≤ 10 kHz

210 µV

RMS

www.national.com5

Page 6

LM3420-16.8

Electrical Characteristics

Specifications with standard type face are for T

Range. Unless otherwise specified, V(IN)=V

Symbol Parameter Conditions Typical LM3420A-16.8 LM3420-16.8 Units

V

Regulation Voltage I

REG

Regulation Voltage I

OUT

OUT

=

=

Tolerance

I

q

G

Quiescent Current I

Transconductance 20 µA ≤ I

m

∆I

/∆V

OUT

REG

=

OUT

=

V

OUT

1mA≤I

=

V

A

Voltage Gain 1V ≤ V

V

∆V

/∆V

OUT

REG

OUT

=

R

1kΩ(Note 6) 550/250 450/200 V/V(min)

L

1V ≤ V

=

R

15 kΩ 1200/750 1000/650 V/V(min)

OUT

L

OUT

=

=

V

Output Saturation V(IN)=V

SAT

(Note 7) I

I

L

Output Leakage V(IN)=V

Current V

R

Internal Feedback 392 kΩ

f

Resistor (Note 8) 490 490 kΩ(max)

E

Output Noise

n

Voltage

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is intended to be functional, but do not guarantee specific performance limits. For guaranteed specifications and test conditions, see the Electrical Characteristics. The

guaranteed specifications apply only for the test conditions listed. Some performance characteristics may degrade when the device is not operated under the listed

test conditions.

Note 2: The maximum power dissipation must be derated at elevated temperatures and is dictated by T

bient thermal resistance), and T

given in the Absolute Maximum Ratings, whichever is lower. The typical thermal resistance (θ

for the M5 package.

Note 3: The human body model is a 100 pF capacitor discharged through a 1.5 kΩ resistor into each pin.

Note 4: Typical numbers are at 25˚C and represent the most likely parametric norm.

Note 5: Limits are 100%production tested at 25˚C. Limits over the operating temperature range are guaranteed through correlation using Statistical Quality Control

(SQC) methods. The limits are used to calculate National’s Averaging Outgoing Quality Level (AOQL).

Note 6: Actual test is done using equivalent current sink instead of a resistor load.

Note 7: V

Note 8: See Applications and Typical Performance Characteristics sections for information on this resistor.

SAT

=

V(IN) − V

(ambient temperature). The maximum allowable power dissipation at any temperature is P

A

, when the voltage at the IN pin is forced 100 mV above the nominal regulating voltage (V

OUT

=

I

OUT

=

25˚C, and those with boldface type apply over full Operating Temperature

J

REG,VOUT

=

1.5V.

(Note 4) Limit Limit (Limits)

(Note 5) (Note 5)

1 mA 16.8 V

16.884/16.968 16.968/17.136 V(max)

16.716/16.632 16.632/16.464 V(min)

1mA

±

0.5/±1

±1/±

2

%

(max)

1mA 85 µA

110/115 125/150 µA(max)

≤ 1 mA 3.3 mA/mV

OUT

15V 0.8/0.4 0.7/0.35 mA/mV(min)

≤ 15 mA 6.0 mA/mV

OUT

15V 2.9/0.9 2.5/0.75 mA/mV(min)

≤ V

OUT

OUT

REG

− 1.2V (−1.3) 1000 V/V

REG

≤ V

− 1.2V (−1.3) 3500 V/V

REG

+100 mV 1.0 V

15 mA 1.2/1.3 1.2/1.3 V(max)

−100 mV 0.1 µA

REG

0V 0.5/1.0 0.5/1.0 µA(max)

294 294 kΩ(min)

1 mA, 10 Hz ≤ f ≤ 10 kHz

280 µV

(maximum junction temperature), θJA(junction to am-

Jmax

) when soldered to a printed circuit board is approximately 306˚C/W

JA

REG

Dmax

).

=

(T

Jmax−TA

)/θJAor the number

RMS

www.national.com 6

Page 7

Typical Performance Characteristics

4.2V

Bode Plot

8.2V and 8.4V

Bode Plot

12.6V

Bode Plot

DS012359-17

DS012359-20

Response Time

for 4.2V Version

Response Time for

8.2V, 8.4V Versions

Response Time

for 12.6V Version

DS012359-18

DS012359-21

Response Time

for 4.2V Version

DS012359-19

Response Time for

8.2V, 8.4V Versions

DS012359-22

Response Time

for 12.6V Version

16.8V

Bode Plot

DS012359-23

DS012359-26

Response Time

for 16.8V Version

DS012359-24

DS012359-27

DS012359-25

Response Time

for 16.8V Version

DS012359-28

www.national.com7

Page 8

Typical Performance Characteristics (Continued)

Regulation Voltage vs

Output Voltage and

Load Resistance

Regulation Voltage vs

Output Voltage and

Load Resistance

DS012359-29

DS012359-32

Circuit Used for Bode Plots

Quiescent Current

DS012359-30

DS012359-33

Circuit Used for Response Time

DS012359-31

Internal Feedback

Resistor (Rf)

Tempco

DS012359-34

Regulation Voltage vs

Output Voltage and

Load Resistance

DS012359-35

www.national.com 8

Normalized

Temperature Drift

DS012359-36

Output Saturation

Voltage (V

SAT

)

DS012359-37

Page 9

Typical Performance Characteristics (Continued)

Regulation Voltage vs

Output Voltage and

Load Resistance

DS012359-38

www.national.com9

Page 10

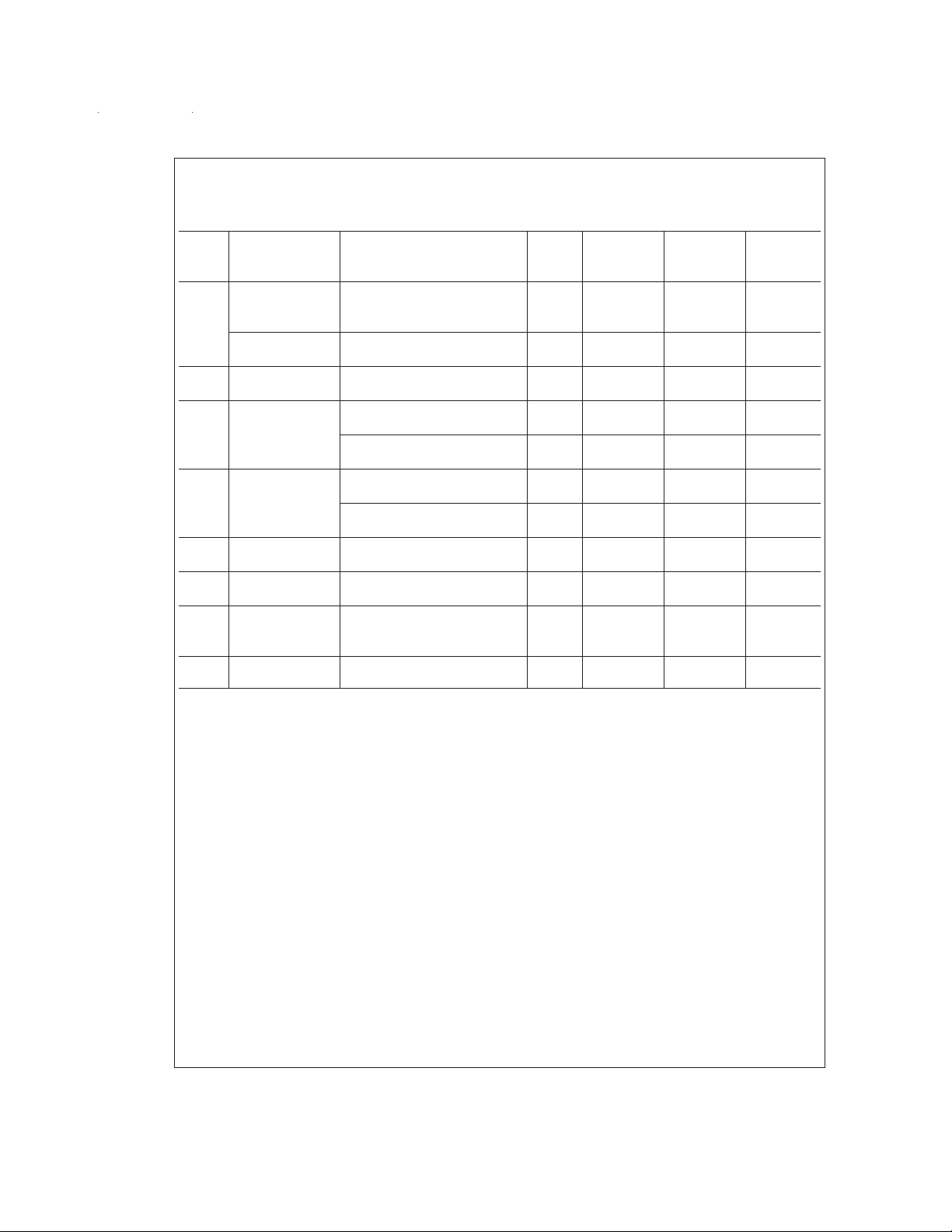

Five Lead Surface Mount Package Information

The small SOT23-5 package allows only 4 alphanumeric characters to identify the product. The table below contains the field information marked on the package.

Voltage Grade Order Package Supplied as

Information Marking

4.2V A (Prime) LM3420AM5-4.2 D02A 250 unit increments on tape and reel

4.2V A (Prime) LM3420AM5X-4.2 D02A 3k unit increments on tape and reel

4.2V B (Standard) LM3420M5-4.2 D02B 250 unit increments on tape and reel

4.2V B (Standard) LM3420M5X-4.2 D02B 3k unit increments on tape and reel

8.2V A (Prime) LM3420AM5-8.2 D07A 250 unit increments on tape and reel

8.2V A (Prime) LM3420AM5X-8.2 D07A 3k unit increments on tape and reel

8.2V B (Standard) LM3420M5-8.2 D07B 250 unit increments on tape and reel

8.2V B (Standard) LM3420M5X-8.2 D07B 3k unit increments on tape and reel

8.4V A (Prime) LM3420AM5-8.4 D03A 250 unit increments on tape and reel

8.4V A (Prime) LM3420AM5X-8.4 D03A 3k unit increments on tape and reel

8.4V B (Standard) LM3420M5-8.4 D03B 250 unit increments on tape and reel

8.4V B (Standard) LM3420M5X-8.4 D03B 3k unit increments on tape and reel

12.6V A (Prime) LM3420AM5-12.6 D04A 250 unit increments on tape and reel

12.6V A (Prime) LM3420AM5X-12.6 D04A 3k unit increments on tape and reel

12.6V B (Standard) LM3420M5-12.6 D04B 250 unit increments on tape and reel

12.6V B (Standard) LM3420M5X-12.6 D04B 3k unit increments on tape and reel

16.8V A (Prime) LM3420AM5-16.8 D05A 250 unit increments on tape and reel

16.8V A (Prime) LM3420AM5X-16.8 D05A 3k unit increments on tape and reel

16.8V B (Standard) LM3420M5-16.8 D05B 250 unit increments on tape and reel

16.8V B (Standard) LM3420M5X-16.8 D05B 3k unit increments on tape and reel

FIGURE 1. SOT23-5 Marking

The first letter “D” identifies the part as a Driver, the next two numbers indicate the voltage, “02” for a 4.2V part, “07” for an 8.2V

part, “03” for an 8.4V part, “04” for a 12.6V part, and “05” for a 16.8V part. The fourth letter indicates the grade, “B” for standard

grade, “A” for the prime grade.

The SOT23-5 surface mount package is only available on tape in quantity increments of 250 on tape and reel (indicated by the

letters “M5” in the part number), or in quantity increments of 3000 on tape and reel (indicated by the letters “M5X” in the part number).

Product Description

The LM3420 is a shunt regulator specifically designed to be

the reference and control section in an overall feedback loop

of a Lithium-Ion battery charger. The regulated output voltage is sensed between the IN pin and GROUND pin of the

LM3420. If the voltage at the IN pin is less than the LM3420

regulating voltage (V

As the voltage at the IN pin approaches the V

the OUT pin begins sourcing current. This current is then

), the OUT pin sources no current.

REG

REG

voltage,

used to drive a feedback device (opto-coupler), or a power

device (linear regulator, switching regulator, etc.), which servos the output voltage to be the same value as V

REG

.

In some applications, (even under normal operating conditions) the voltage on the IN pin can be forced above the

V

voltage. In these instances, the maximum voltage ap-

REG

plied to the IN pin should not exceed 20V. In addition, an external resistor may be required on the OUT pin to limit the

maximum current to 20 mA.

Compensation

The inverting input of the error amplifier is brought out to allow overall closed-loop compensation. In many of the applications circuits shown here, compensation is provided by a

single capacitor (C

to the out pin of the LM3420. The capacitor values shown in

the schematics are adequate under most conditions, but

they can be increased or decreased depending on the desired loop response. Applying a load pulse to the output of a

regulator circuit and observing the resultant output voltage

response is an easy method of determining the stability of

the control loop.

Analyzing more complex feedback loops requires additional

information.

The formula for AC gain at a frequency (f) is as follows;

where Rf≈ 75 kΩ for the 4.2V part, Rf≈ 181 kΩ for the 8.4V

part, R

≈ 287 kΩ for the 12.6V part, and Rf≈ 392 kΩ for the

f

16.8V part.

The resistor (R

on the die. Since this resistor value will affect the phase margin, the worst case maximum and minimum values are im-

) connected from the compensation pin

C

) in the formula is an internal resistor located

f

www.national.com 10

Page 11

Compensation (Continued)

portant when analyzing closed loop stability. The minimum

and maximum room temperature values of this resistor are

specified in the Electrical Characteristics section of this data

sheet, and a curve showing the temperature coefficient is

shown in the curves section. Minimum values of R

lower phase margins.

result in

f

FIGURE 2. LM3420 Test Circuit

Test Circuit

The test circuit shown in

and verify various LM3420 parameters. Test conditions are

set by forcing the appropriate voltage at the V

point and selecting the appropriate R

the Electrical Characteristics section. Use a DVM at the

“measure” test points to read the data.

Figure 2

can be used to measure

or I

L

DS012359-7

OUT

as specified in

OUT

Set test

V

External Voltage Trim

REG

The regulation voltage (V

nally trimmed by adding a single resistor from the COMP pin

) of the LM3420 can be exter-

REG

to the +IN pin or from the COMP pin to the GND pin, depending on the desired trim direction. Trim adjustments up to

±

10%of V

the temperature coefficient. (See temperature coefficient

curve shown in

can be realized, with only a small increase in

REG

Figure 3

below.)

DS012359-8

Normalized Temperature Drift with

Output Externally Trimmed

DS012359-9

Increasing V

Decreasing V

FIGURE 4. Changing V

REG

DS012359-10

REG

REG

Formulas for selecting trim resistor values are shown below,

based on the percent of increase (%incr) or percent of decrease (%decr) of the output voltage from the nominal voltage.

For LM3420-4.2

R

decrease

R

increase

=

(53x10

5

=

/%incr

22x10

5

/%decr) − 75x10

3

For LM3420-8.2

www.national.com11

Page 12

V

External Voltage Trim (Continued)

REG

R

decrease

For LM3420-8.4

R

decrease

For LM3420-12.6

R

decrease

For LM3420-16.8

R

decrease

R

R

R

R

increase

=

(150x10

increase

=

(154x10

increase

=

(259x10

increase

=

(364x10

5

=

/%incr

26x10

5

/%decr) − 176x10

5

=

/%incr

26x10

5

/%decr) − 181x10

5

=

/%incr

28x10

5

/%decr) − 287x10

5

=

/%incr

29x10

5

/%decr) − 392x10

3

3

3

3

Application Information

The LM3420 regulator/driver provides the reference and

feedback drive functions for a Lithium-Ion battery charger. It

can be used in many different charger configurations using

both linear and switching topologies to provide the precision

needed for charging Lithium-Ion batteries safely and efficiently. Output voltage tolerances better than 0.5%are possible without using trim pots or precision resistors. The cir-

cuits shown are designed for 2 cell operation, but they can

readily be changed for either 1, 3 or 4 cell charging applications.

One itemto keep in mind when designing with the LM3420 is

that there are parasitic diodes present. In some designs, under special electrical conditions, unwanted currents may

flow. Parasitic diodes exist from OUT to IN, as well as from

GROUND to IN. In both instances the diode arrow is pointed

toward the IN pin.

Application Circuits

The circuit shown in

constant-voltage charging of two Li-Ion cells. At the beginning of the charge cycle, when the battery voltage is less

than 8.4V, the LM3420 sources no current from the OUT pin,

keeping Q2 off, thus allowing the LM317 Adjustable voltage

regulator to operate as a constant-current source. (The

LM317 is rated for currents up to 1.5A, and the LM350 and

LM338 can be used for higher currents.) The LM317 forces

a constant 1.25V across R

current of

Figure 5

I

LIM

performs constant-current,

, thus generating a constant

LIM

=

1.25V/R

LIM

FIGURE 5. Constant Current/Constant Voltage Li-Ion Battery Charger

FIGURE 6. Low Drop-Out Constant Current/Constant Voltage 2-Cell Charger

Transistor Q1 provides a disconnect between the battery

and the LM3420 when the input voltage is removed. This

prevents the 85 µA quiescent current of the LM3420 from

eventually discharging the battery. In this application Q1 is

used as a low offset saturated switch, with the majority of the

base drive current flowing through the collector and crossing

over to the emitter as the battery becomes fully charged. It

provides a very low collector to emitter saturation voltage

www.national.com 12

DS012359-1

DS012359-11

(approximately 5 mV). Diode D1 is also used to prevent the

battery current from flowing through the LM317 regulator

from the output to the input when the DC input voltage is removed.

As the battery charges, its voltage begins to rise, and is

sensed at the IN pinof the LM3420. Once the battery voltage

reaches 8.4V, the LM3420 begins to regulate and starts

sourcing current to the base of Q2. Transistor Q2 begins

Page 13

Application Circuits (Continued)

controlling the ADJ. pin of the LM317 which begins to regulate the voltage across the battery and the constant voltage

portion of the charging cycle starts. Once the charger is in

the constant voltage mode, the charger maintains a regulated 8.4V across the battery and the charging current is dependent on the state of charge of the battery.As the cells approach a fully charged condition, the charge current falls to a

very low value.

Figure 6

shows a Li-Ion battery charger that features a dropout voltage of less than one volt. This charger is a

constant-current, constant-voltage charger (it operates in

constant-current mode at the beginning of the charge cycle

and switches over to a constant-voltage mode near the end

of the charging cycle). The circuit consists of two basic feedback loops. The first loop controls the constant charge current delivered to the battery, and the second determines the

final voltage across the battery.

With a discharged battery connected to the charger, (battery

voltage is less than 8.4V) the circuit begins the charge cycle

with a constant charge current. The value of this current is

set by using the reference section of the LM10C to force 200

mV across R7 thus causing approximately 100 µA of emitter

current to flow through Q1, and approximately 1 mA of emitter current to flow through Q2. The collector current of Q1 is

also approximately 100 µA, and this current flows through

R2 developing 50 mV across it. This 50 mV is used as a reference to develop the constant charge current through the

current sense resistor R1.

The constant current feedback loop operates as follows. Initially, the emitter and collector current of Q2 are both approximately 1 mA, thus providing gate drive to the MOSFET

Q3, turning it on. The output of the LM301A op-amp is low.

As Q3’s current reaches 1A, the voltage across R1 approaches 50 mV, thus canceling the 50 mV drop across R2,

and causing the op-amp’s output to start going positive, and

begin sourcing current into R8.As more current is forced into

R8 from the op-amp, the collector current of Q2 is reduced

by the same amount, which decreases the gate drive to Q3,

to maintaina constant 50 mV across the 0.05Ωcurrent sensing resistor, thus maintaining a constant 1A of charge current.

The current limit loop is stabilized by compensating the

LM301A with C1 (the standard frequency compensation

used with this op-amp) and C2, which is additional compensation needed when D3 is forward biased. This helps speed

up the response time during the reverse bias of D3. When

the LM301A output is low, diode D3 reverse biases and prevents the op-amp from pullingmore current throughthe emitter of Q2. This is important when the battery voltage reaches

8.4V,and the 1A charge current is no longer needed. Resistor R5 isolates the LM301A feedback node at the emitter of

Q2.

The battery voltage is sensed and buffered by the op-amp

section of the LM10C, connected as a voltage follower driving the LM3420. When the battery voltage reaches 8.4V, the

LM3420 will begin regulating by sourcing current into R8,

which controls the collector current of Q2, which in turn reduces the gate voltage of Q3 and becomes a constant voltage regulator for charging the battery. Resistor R6 isolates

the LM3420 from the common feedback node at the emitter

of Q2. If R5 and R6 are omitted, oscillations could occur during the transition from the constant-current to the

constant-voltage mode. D2 and the PNP transistor input

stage of the LM10C will disconnect the battery from the

charger circuit when the input supply voltage is removed to

prevent the battery from discharging.

DS012359-12

FIGURE 7. High Efficiency Switching Regulator

Constant Current/Constant Voltage 2-Cell Charger

DS012359-13

FIGURE 8. Low Dropout Constant Current/Constant

Voltage Li-Ion Battery Charger

A switching regulator, constant-current, constant-voltage

two-cell Li-Ion battery charging circuit is shown in

Figure 7

This circuit provides much better efficiency,especially over a

wide input voltage range than the linear topologies. For a 1A

charger an LM2575-ADJ. switching regulator IC is used in a

standard buck topology. For other currents, or other packages, other members of the SIMPLE SWITCHER

™

buck

regulator family may be used.

Circuit operation is as follows. With a discharged battery

connected to the charger, the circuit operates as a constant

current source. The constant-current portion of thecharger is

formed by the loop consisting of one half of the LM358 op

amp along with gain setting resistors R3 and R4, current

sensing resistor R5, and the feedback reference voltage of

1.23V. Initially the LM358’s output is low causing the output

of the LM2575-ADJ. to rise thus causing some charging current to flow into the battery. When the current reaches 1A, it

is sensed by resistor R5 (50 mΩ), and produces 50 mV. This

50 mV is amplified by the op-amps gain of 25 to produce

www.national.com13

.

Page 14

Application Circuits (Continued)

1.23V, which is applied to the feedback pin of the

LM2575-ADJ. to satisfy the feedback loop.

Once the battery voltage reaches 8.4V, the LM3420 takes

over and begins to control the feedback pin of the

LM2575-ADJ. The LM3420 now regulates the voltage across

the battery, and the charger becomes a constant-voltage

charger. Loop compensation network R6 and C3 ensure

stable operation of the charger circuit under both

constant-current andconstant-voltage conditions. If the input

supply voltage is removed, diode D2 and the PNP input

stage of the LM358 become reversed biased and disconnects the battery to ensure thatthe battery is notdischarged.

Diode D3 reverse biases to prevent the op-amp from sinking

current when the charger changesto constant voltage mode.

The minimum supply voltage for this charger is approximately 11V, and the maximum is around 30V (limited by the

32V maximum operating voltage of the LM358). If another

op-amp is substituted for the LM358, make sure that the input common-mode range of the op-amp extends down to

ground so that it can accurately sense 50 mV.R1 is included

to provide a minimum load for the switching regulator to assure that switch leakage current will not cause the output to

rise when the battery is removed.

The circuit in

switching regulator has been replaced with a low dropout linear regulator, allowing the input voltage to be as low as 10V.

The constant current and constant voltage control loops are

the same as the previous circuit. Diode D2 has been

changed to a Schottky diode to provide a reduction in the

overall dropout voltage of this circuit, but Schottky diodes

typically have higher leakage currents than a standard silicon diode. This leakage current could discharge the battery

if the input voltage is removed for an extended period of

time.

Another variation of a constant current/constant voltage

switch mode charger is shown in

back loops for current and voltage are similar to the previous

circuits. This circuit has the current sensing resistor, for the

constant current part of the feedback loop, on the positive

side of the battery,thus allowing a common ground between

the input supply and the battery.Also, the LMC7101 op-amp

is available in a very small SOT23-5 package thus allowing a

very compact pc board design. Diode D4 prevents the battery from discharging through thecharger circuitry ifthe input

voltage is removed, although the quiescent current of the

LM3420 will still be present (approximately 85 µA).

Figure 8

is very similar to

Figure 9

Figure 7

, except the

. The basic feed-

FIGURE 9. High Efficiency Switching Charger

with High Side Current Sensing

www.national.com 14

DS012359-14

Page 15

Application Circuits (Continued)

FIGURE 10. (Fast) Pulsed Constant Current 2-Cell Charger

DS012359-15

www.national.com15

Page 16

Application Circuits (Continued)

A rapid charge Lithium-Ion battery charging circuit is shown

in

Figure 10

deliver the charging current in a series of constant current

pulses. At the beginning of the charge cycle

(constant-current mode), this circuit performs identically to

the previous LM2575 charger by charging the battery at a

constant current of 1A. As the battery voltage reaches 8.4V,

this charger changes from a constant continuous current of

1A to a 5 second pulsed 1A. This allows the total battery

charge time to be reduced considerably. This is different

from the other charging circuits that switch from a constant

current charge to a constant voltage charge once the battery

voltage reaches 8.4V.After charging the battery with 1A for 5

seconds, the charge stops, and the battery voltage begins to

drop. When it drops below 8.4V, the LM555 timer again

starts the timing cycle and charges the battery with 1Afor another 5 seconds. This cycling continues with a constant 5

second charge time, and a variable off time. In this manner,

the battery will be chargedwith 1Afor 5 seconds, followed by

an off period (determined by the battery’s state of charge),

setting up a periodic 1A charge current. The off time is determined by how long it takes the battery voltage to decrease

back down to 8.4V. When the battery first reaches 8.4V, the

. This configuration uses a switching regulator to

off time will be very short (1 ms or less), but when the battery

approaches full charge, the off time will begin increasing to

tens of seconds, then minutes, and eventually hours.

The constant-current loop for this charger and the method

used for programming the 1A constant current is identical to

the previous LM2575-ADJ. charger. In this circuit, a second

LM3420-8.4 has its V

400 mV(via R2), and is used to limit the output voltage of the

increased by approximately

REG

charger to 8.8V in the event of a bad battery connection, or

the battery is removed or possibly damaged.

The LM555 timer is connected as a one-shot, and is used to

provide the 5 second charging pulses. As long as the battery

voltage is less than the 8.4V, the output of IC3 will be held

low,and the LM555 one-shot will never fire (the output of the

LM555 will be held high) and the one-shot will have no effect

on the charger. Once the battery voltage exceeds the 8.4V

regulation voltage of IC3, the trigger pin of the LM555 is

pulled high, enabling the one shot to begin timing. The

charge current will now be pulsed into the battery at a 5 second rate, with the off time determined by the battery’s state

of charge. The LM555 output will go high for 5 seconds (pulling down the collector of Q1) which allows the 1A

constant-current loop to control the circuit.

FIGURE 11. MOSFET Low Dropout Charger

Figure 11

shows a low dropout constant voltage charger using a MOSFET as the pass element, but this circuit does not

include current limiting. This circuit uses Q3 and a Schottky

diode to isolate the battery from the charging circuitry when

the input voltage is removed, to prevent the battery from discharging. Q2 should be a high current (0.2Ω) FET, while Q3

can be a low current (2Ω) device.

Note: Although the application circuits shown here have

been built and tested, they should be thoroughly evaluated with the same type of battery the charger will eventually be used with.

www.national.com 16

DS012359-16

Different battery manufacturers may use a slightly different battery chemistry which may require different

charging characteristics. Always consult the battery

manufacturer for information on charging specifications

and battery details, and always observe the manufacturers precautions when using their batteries. Avoid overcharging or shorting Lithium-Ion batteries.

Page 17

Physical Dimensions inches (millimeters) unless otherwise noted

LM3420-4.2, -8.2, -8.4, -12.6, -16.8 Lithium-Ion Battery Charge Controller

For Ordering Information See

Figure 1

In This Data Sheet

NS Package Number MA05B

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

5-Lead Small Outline Package (M5)

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80-532 78 32

Français Tel: +49 (0) 1 80-532 93 58

Italiano Tel: +49 (0) 1 80-534 16 80

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

Loading...

Loading...