Page 1

June 2007

LM3404/04HV

1.0A Constant Current Buck Regulator for Driving High

Power LEDs

General Description

The LM3404/04HV are monolithic switching regulators designed to deliver constant currents to high power LEDs. Ideal

for automotive, industrial, and general lighting applications,

they contain a high-side N-channel MOSFET switch with a

current limit of 1.5A (typical) for step-down (Buck) regulators.

Hysteretic controlled on-time and an external resistor allow

the converter output voltage to adjust as needed to deliver a

constant current to series and series-parallel connected LED

arrays of varying number and type. LED dimming via pulse

width modulation (PWM), broken/open LED protection, lowpower shutdown and thermal shutdown complete the feature

set.

Features

■

Integrated 1.0A MOSFET

■

VIN Range 6V to 42V (LM3404)

■

VIN Range 6V to 75V (LM3404HV)

■

1.2A Output Current Over Temperature

■

Cycle-by-Cycle Current Limit

■

No Control Loop Compensation Required

■

Separate PWM Dimming and Low Power Shutdown

■

Supports all-ceramic output capacitors and capacitor-less

outputs

■

Thermal shutdown protection

■

SO-8 Package, PSOP-8 Package

Applications

■

LED Driver

■

Constant Current Source

■

Automotive Lighting

■

General Illumination

■

Industrial Lighting

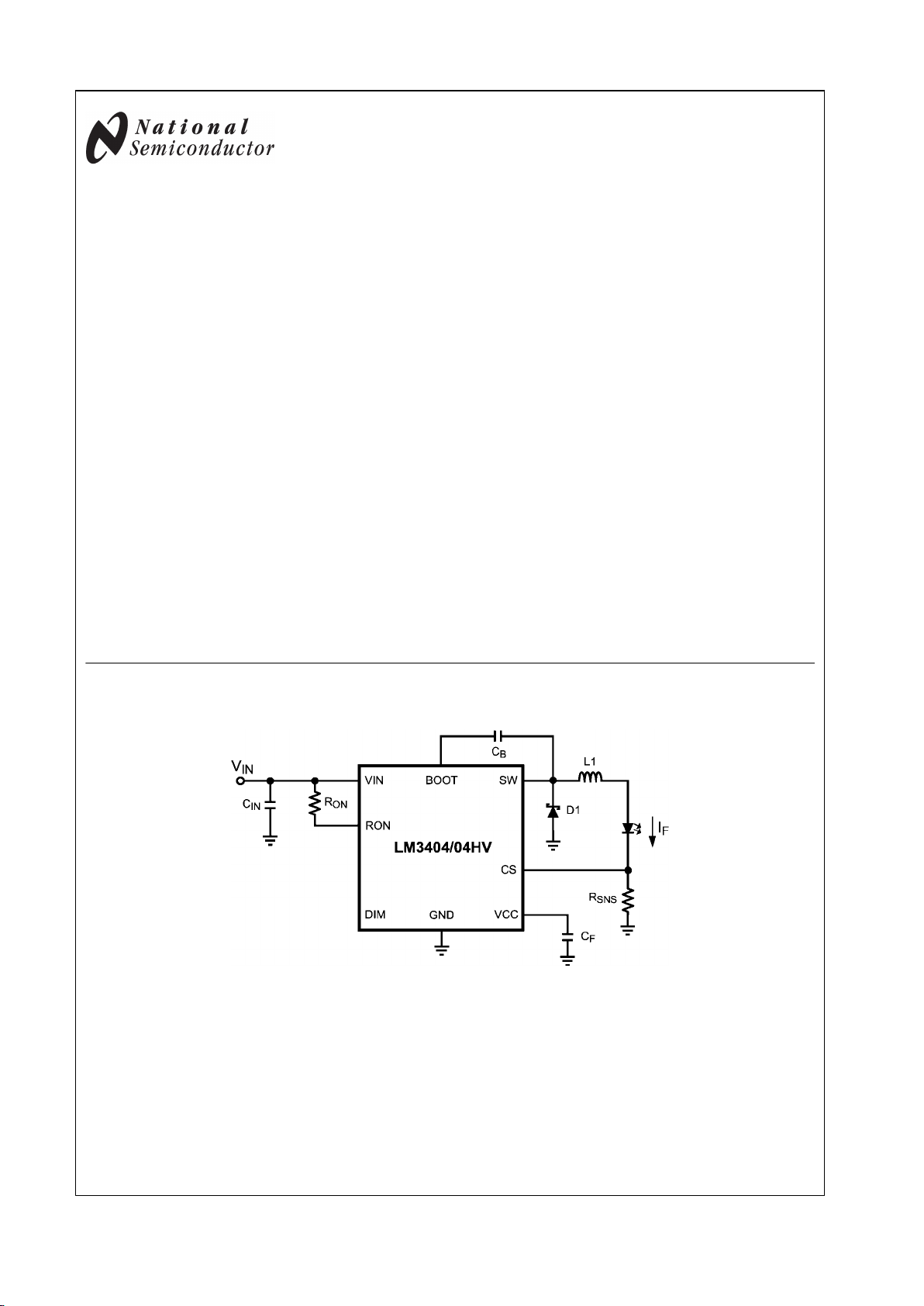

Typical Application

20205401

© 2007 National Semiconductor Corporation 202054 www.national.com

LM3404/04HV 1.0A Constant Current Buck Regulator for Driving High Power LEDs

Page 2

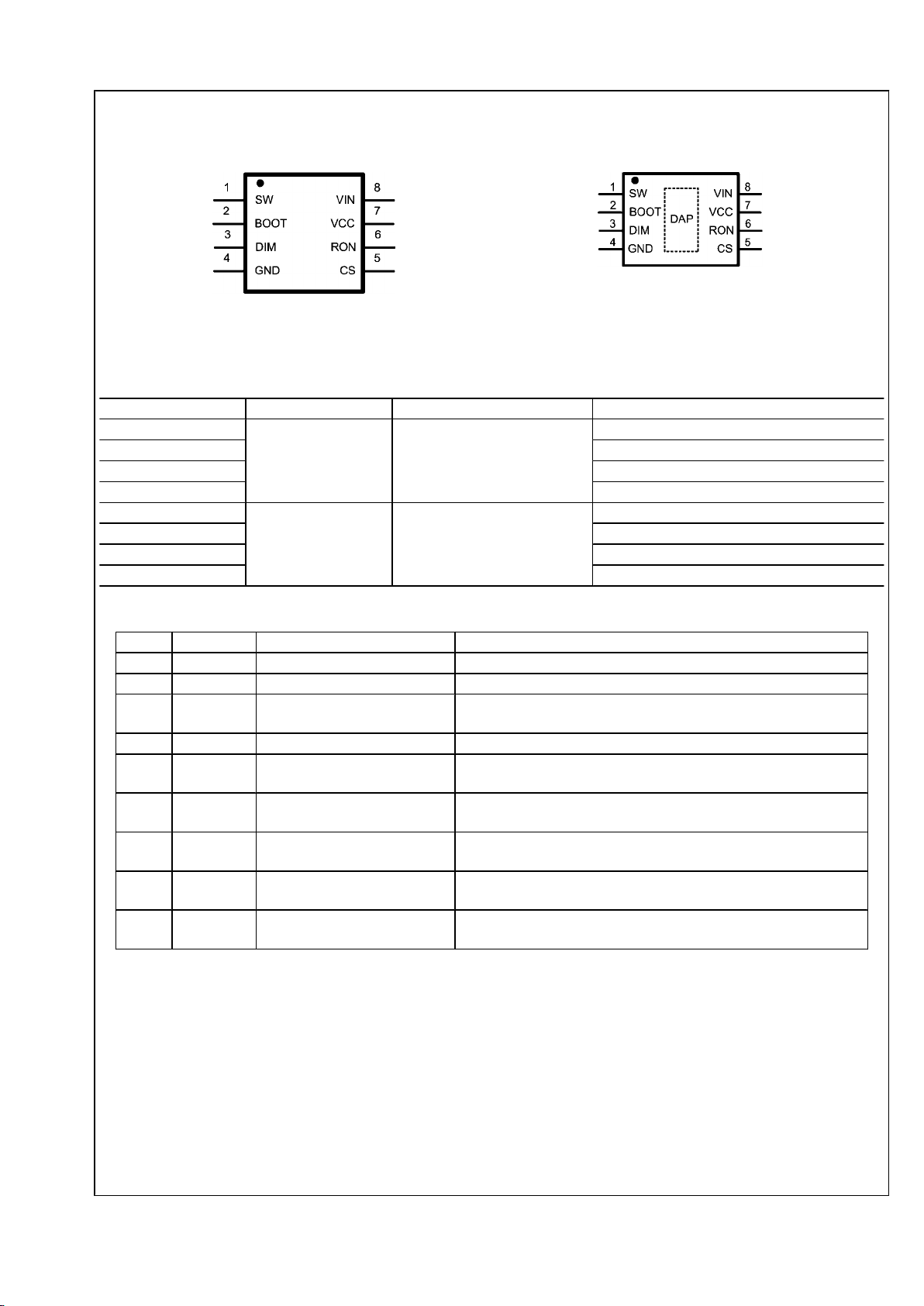

Connection Diagrams

20205402

8-Lead Plastic SO-8 Package

NS Package Number M08A

20205456

8-Lead Plastic PSOP-8 Package

NS Package Number MRA08B

Ordering Information

Order Number Package Type NSC Package Drawing Supplied As

LM3404MA

SO-8 M08A

95 units in anti-static rails

LM3404MAX 2500 units on tape and reel

LM3404HVMA 95 units in anti-static rails

LM3404HVMAX 2500 units on tape and reel

LM3404MR

PSOP-8 MRA08B

95 units in anti-static rails

LM3404MRX 2500 units on tape and reel

LM3404HVMR 95 units in anti-static rails

LM3404HVMRX 2500 units on tape and reel

Pin Descriptions

Pin(s) Name Description Application Information

1 SW Switch pin Connect this pin to the output inductor and Schottky diode.

2 BOOT MOSFET drive bootstrap pin Connect a 10 nF ceramic capacitor from this pin to SW.

3 DIM Input for PWM dimming Connect a logic-level PWM signal to this pin to enable/disable the

power MOSFET and reduce the average light output of the LED array.

4 GND Ground pin Connect this pin to system ground.

5 CS Current sense feedback pin Set the current through the LED array by connecting a resistor from

this pin to ground.

6 RON On-time control pin A resistor connected from this pin to VIN sets the regulator controlled

on-time.

7 VCC Output of the internal 7V linear

regulator

Bypass this pin to ground with a minimum 0.1 µF ceramic capacitor

with X5R or X7R dielectric.

8 VIN Input voltage pin Nominal operating input range for this pin is 6V to 42V (LM3404) or 6V

to 75V (LM3404HV).

DAP GND Thermal Pad Connect to ground. Place 4-6 vias from DAP to bottom layer ground

plane.

www.national.com 2

LM3404/LM3404HV

Page 3

Absolute Maximum Ratings

(LM3404) (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

VIN to GND -0.3V to 45V

BOOT to GND -0.3V to 59V

SW to GND -1.5V to 45V

BOOT to VCC -0.3V to 45V

BOOT to SW -0.3V to 14V

VCC to GND -0.3V to 14V

DIM to GND -0.3V to 7V

CS to GND -0.3V to 7V

RON to GND -0.3V to 7V

Junction Temperature 150°C

Storage Temp. Range -65°C to 125°C

ESD Rating (Note 2) 2kV

Soldering Information

Lead Temperature (Soldering,

10sec) 260°C

Infrared/Convection Reflow (15sec) 235°C

Operating Ratings (LM3404)

(Note 1)

V

IN

6V to 42V

Junction Temperature Range −40°C to +125°C

Thermal Resistance θ

JA

(SO-8 Package) 155°C/W

Thermal Resistance θ

JA

(PSOP-8 Package) (Note 5) 50°C/W

3 www.national.com

LM3404/LM3404HV

Page 4

Absolute Maximum Ratings

(LM3404HV) (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

VIN to GND

-0.3V to 76V

BOOT to GND -0.3V to 90V

SW to GND -1.5V to 76V

BOOT to VCC -0.3V to 76V

BOOT to SW -0.3V to 14V

VCC to GND -0.3V to 14V

DIM to GND -0.3V to 7V

CS to GND -0.3V to 7V

RON to GND -0.3V to 7V

Junction Temperature 150°C

Storage Temp. Range -65°C to 125°C

ESD Rating (Note 2) 2kV

Soldering Information

Lead Temperature (Soldering,

10sec) 260°C

Infrared/Convection Reflow (15sec) 235°C

Operating Ratings (LM3404HV)

(Note 1)

V

IN

6V to 75V

Junction Temperature Range −40°C to +125°C

Thermal Resistance θ

JA

(SO-8 Package) 155°C/W

Thermal Resistance θ

JA

(PSOP-8 Package) (Note 5) 50°C/W

www.national.com 4

LM3404/LM3404HV

Page 5

Electrical Characteristics V

IN

= 24V unless otherwise indicated. Typicals and limits appearing in plain type apply

for TA = TJ = +25°C. (Note 4) Limits appearing in boldface type apply over full Operating Temperature Range. Datasheet min/

max specification limits are guaranteed by design, test, or statistical analysis.

LM3404

Symbol Parameter Conditions Min Typ Max Units

SYSTEM PARAMETERS

t

ON-1

On-time 1

VIN = 10V, RON = 200 kΩ

2.1 2.75 3.4 µs

t

ON-2

On-time 2

VIN = 40V, RON = 200 kΩ

515 675 835 ns

LM3404HV

Symbol Parameter Conditions Min Typ Max Units

SYSTEM PARAMETERS

t

ON-1

On-time 1

VIN = 10V, RON = 200 kΩ

2.1 2.75 3.4 µs

t

ON-2

On-time 2

VIN = 70V, RON = 200 kΩ

325 415 505 ns

LM3404/LM3404HV

Symbol Parameter Conditions Min Typ Max Units

REGULATION AND OVER-VOLTAGE COMPARATORS

V

REF-REG

CS Regulation Threshold CS Decreasing, SW turns on 194 200 206 mV

V

REF-0V

CS Over-voltage Threshold CS Increasing, SW turns off 300 mV

I

CS

CS Bias Current CS = 0V 0.1 µA

SHUTDOWN

V

SD-TH

Shutdown Threshold RON / SD Increasing 0.3 0.7 1.05 V

V

SD-HYS

Shutdown Hysteresis RON / SD Decreasing 40 mV

OFF TIMER

t

OFF-MIN

Minimum Off-time CS = 0V 270 ns

INTERNAL REGULATOR

V

CC-REG

VCC Regulated Output 6.4 7 7.4 V

V

IN-DO

VIN - V

CC

ICC = 5 mA, 6.0V < VIN < 8.0V 300 mV

V

CC-BP-TH

VCC Bypass Threshold VIN Increasing 8.8 V

V

CC-BP-HYS

VCC Bypass Hysteresis VIN Decreasing 230 mV

V

CC-Z-6

VCC Output Impedance

(0 mA < ICC < 5 mA)

VIN = 6V 55

Ω

V

CC-Z-8

VIN = 8V 50

V

CC-Z-24

VIN = 24V 0.4

V

CC-LIM

VCC Current Limit (Note 3) VIN = 24V, VCC = 0V 16 mA

V

CC-UV-TH

VCC Under-voltage Lock-out

Threshold

VCC Increasing 5.3 V

V

CC-UV-HYS

VCC Under-voltage Lock-out

Hysteresis

VCC Decreasing 150 mV

V

CC-UV-DLY

VCC Under-voltage Lock-out

Filter Delay

100 mV Overdrive 3 µs

I

IN-OP

I

IN

Operating Current Non-switching, CS = 0.5V 625 900 µA

I

IN-SD

IIN Shutdown Current RON / SD = 0V 95 180 µA

CURRENT LIMIT

I

LIM

Current Limit Threshold 1.2 1.5 1.8 A

5 www.national.com

LM3404/LM3404HV

Page 6

Symbol Parameter Conditions Min Typ Max Units

DIM COMPARATOR

V

IH

Logic High DIM Increasing 2.2 V

V

IL

Logic Low DIM Decreasing 0.8 V

I

DIM-PU

DIM Pull-up Current DIM = 1.5V 80 µA

MOSFET AND DRIVER

R

DS-ON

Buck Switch On Resistance ISW = 200mA, BST-SW = 6.3V 0.37 0.75

Ω

V

DR-UVLO

BST Under-voltage Lock-out

Threshold

BST–SW Increasing 1.7 3 4 V

V

DR-HYS

BST Under-voltage Lock-out

Hysteresis

BST–SW Decreasing 400 mV

THERMAL SHUTDOWN

T

SD

Thermal Shutdown Threshold 165 °C

T

SD-HYS

Thermal Shutdown Hysteresis 25 °C

THERMAL RESISTANCE

θ

JA

Junction to Ambient SOIC-8 Package 155 °C/W

PSOP-8 Package (Note 5) 50

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

intended to be functional, but specific performance is not guaranteed. For guaranteed specifications and the test conditions, see Electrical Characteristics.

Note 2: The human body model is a 100 pF capacitor discharged through a 1.5 kΩ resistor into each pin.

Note 3: VCC provides self bias for the internal gate drive and control circuits. Device thermal limitations limit external loading.

Note 4: Typical specifications represent the most likely parametric norm at 25°C operation.

Note 5: θJA of 50°C/W with DAP soldered to a minimum of 2 square inches of 1oz. copper on the top or bottom PCB layer.

www.national.com 6

LM3404/LM3404HV

Page 7

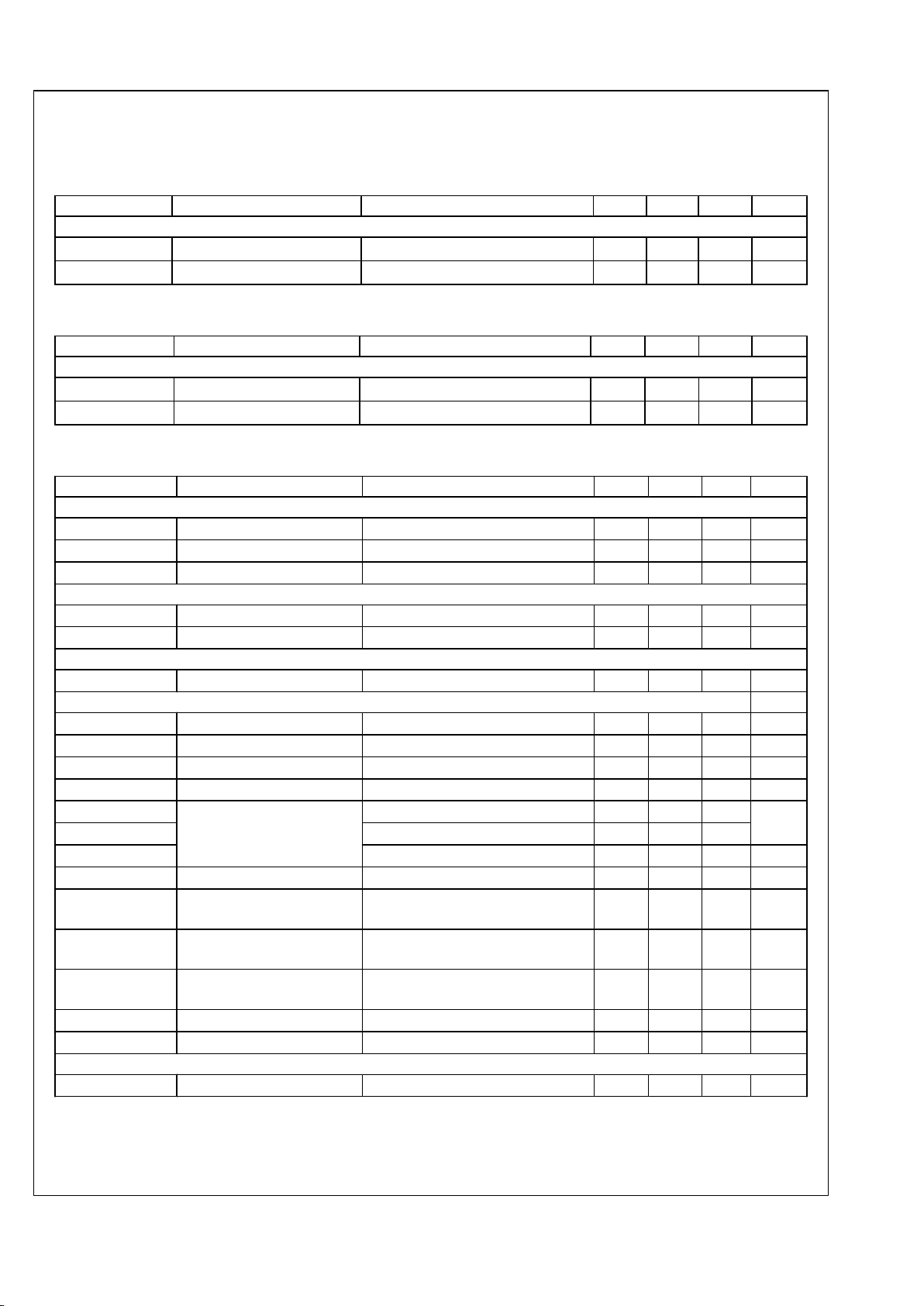

Typical Performance Characteristics

V

REF

vs Temperature (VIN = 24V)

20205450

V

REF

vs VIN, LM3404 (TA = 25°C)

20205451

V

REF

vs VIN, LM3404HV (TA = 25°C)

20205452

Current Limit vs Temperature (VIN = 24V)

20205453

Current Limit vs VIN, LM3404 (TA = 25°C)

20205454

Current Limit vs VIN, LM3404HV (TA = 25°C)

20205455

7 www.national.com

LM3404/LM3404HV

Page 8

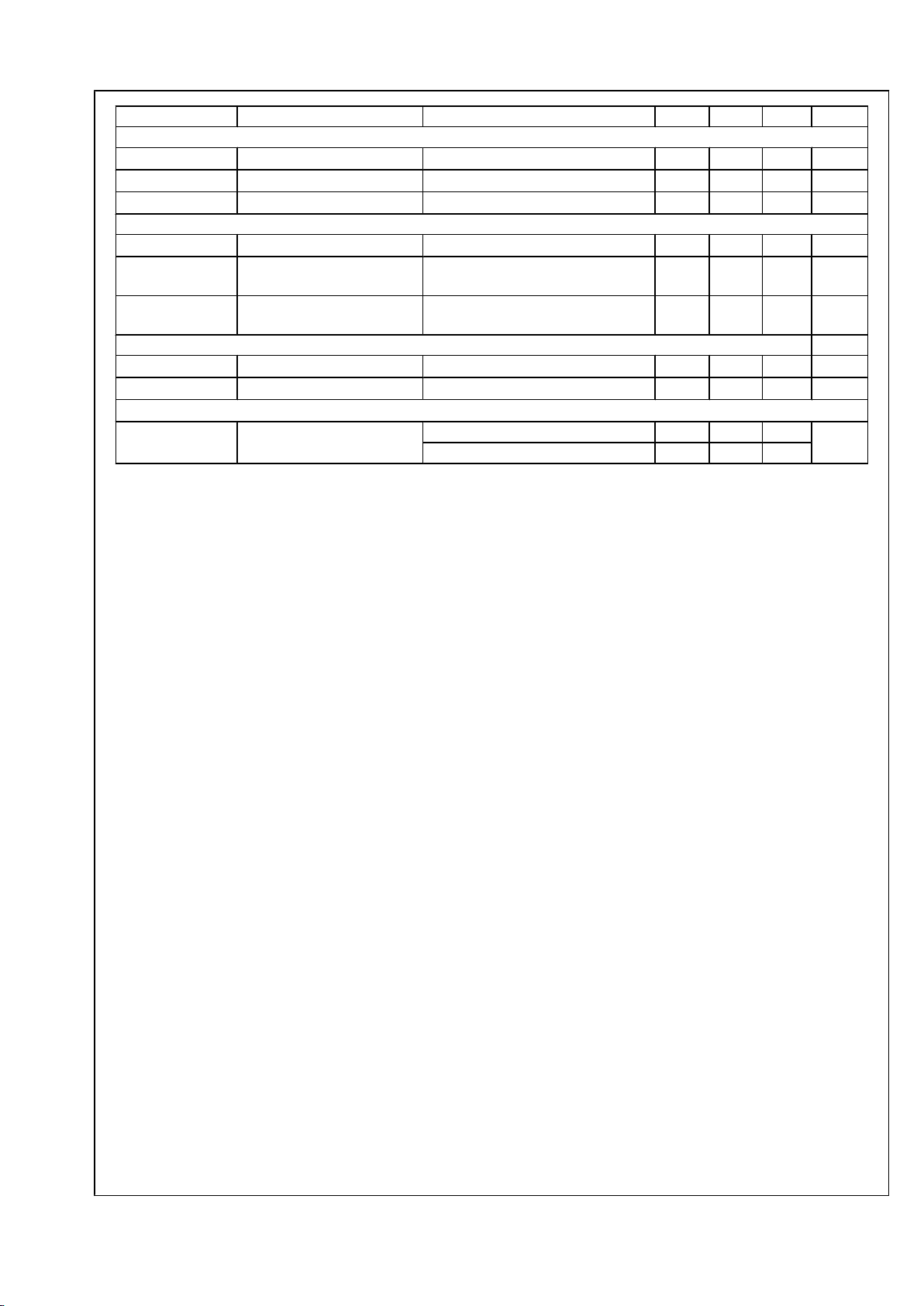

TON vs VIN,

RON = 100 kΩ (TA = 25°C)

20205435

TON vs VIN,

(TA = 25°C)

20205436

TON vs VIN,

(TA = 25°C)

20205437

TON vs RON, LM3404

(TA = 25°C)

20205444

TON vs RON, LM3404HV

(TA = 25°C)

20205438

VCC vs V

IN

(TA = 25°C)

20205439

www.national.com 8

LM3404/LM3404HV

Page 9

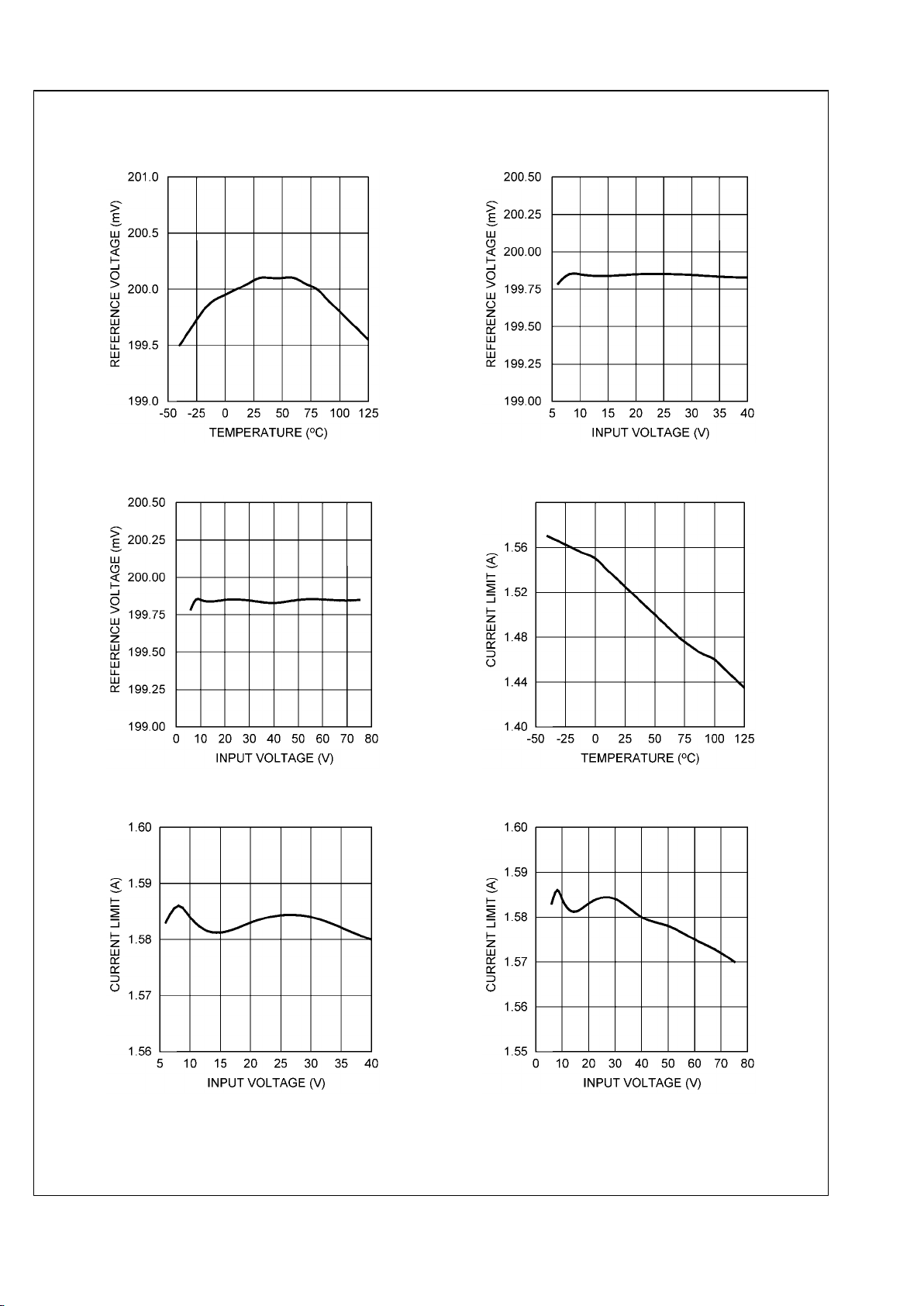

V

O-MAX

vs fSW, LM3404

(TA = 25°C)

20205440

V

O-MIN

vs fSW, LM3404

(TA = 25°C)

20205441

V

O-MAX

vs fSW, LM3404HV

(TA = 25°C)

20205442

V

O-MIN

vs fSW, LM3404HV

(TA = 25°C)

20205443

9 www.national.com

LM3404/LM3404HV

Page 10

Block Diagram

20205403

Application Information

THEORY OF OPERATION

The LM3404 and LM3404HV are buck regulators with a wide

input voltage range, low voltage reference, and a fast output

enable/disable function. These features combine to make

them ideal for use as a constant current source for LEDs with

forward currents as high as 1.2A. The controlled on-time

(COT) architecture is a combination of hysteretic mode control and a one-shot on-timer that varies inversely with input

voltage. Hysteretic operation eliminates the need for smallsignal control loop compensation. When the converter runs in

continuous conduction mode (CCM) the controlled on-time

maintains a constant switching frequency over the range of

input voltage. Fast transient response, PWM dimming, a low

power shutdown mode, and simple output overvoltage protection round out the functions of the LM3404/04HV.

CONTROLLED ON-TIME OVERVIEW

Figure 1 shows the feedback system used to control the current through an array of LEDs. A voltage signal, V

SNS

, is

created as the LED current flows through the current setting

resistor, R

SNS

, to ground. V

SNS

is fed back to the CS pin,

where it is compared against a 200 mV reference, V

REF

. The

on-comparator turns on the power MOSFET when V

SNS

falls

below V

REF

. The power MOSFET conducts for a controlled

on-time, tON, set by an external resistor, RON, and by the input

voltage, VIN. On-time is governed by the following equation:

At the conclusion of tON the power MOSFET turns off for a

minimum off-time, t

OFF-MIN

, of 300 ns. Once t

OFF-MIN

is com-

plete the CS comparator compares V

SNS

and V

REF

again,

waiting to begin the next cycle.

20205405

FIGURE 1. Comparator and One-Shot

The LM3404/04HV regulators should be operated in continuous conduction mode (CCM), where inductor current stays

positive throughout the switching cycle. During steady-state

www.national.com 10

LM3404/LM3404HV

Page 11

CCM operation, the converter maintains a constant switching

frequency that can be selected using the following equation:

VF = forward voltage of each LED, n = number of LEDs in

series

AVERAGE LED CURRENT ACCURACY

The COT architecture regulates the valley of ΔV

SNS

, the AC

portion of V

SNS

. To determine the average LED current (which

is also the average inductor current) the valley inductor current is calculated using the following expression:

In this equation t

SNS

represents the propagation delay of the

CS comparator, and is approximately 220 ns. The average

inductor/LED current is equal to I

L-MIN

plus one-half of the in-

ductor current ripple, ΔiL:

IF = IL = I

L-MIN

+ ΔiL / 2

Detailed information for the calculation of ΔiL is given in the

Design Considerations section.

MAXIMUM OUTPUT VOLTAGE

The 300 ns minimum off-time limits the maximum duty cycle

of the converter, D

MAX

, and in turn the maximum output volt-

age, V

O(MAX)

, determined by the following equations:

The maximum number of LEDs, n

MAX

, that can be placed in

a single series string is governed by V

O(MAX)

and the maxi-

mum forward voltage of the LEDs used, V

F(MAX)

, using the

expression:

At low switching frequency the maximum duty cycle and output voltage are higher, allowing the LM3404/04HV to regulate

output voltages that are nearly equal to input voltage. The

following equation relates switching frequency to maximum

output voltage, and is also shown graphically in the Typical

Performance Characteristics section:

MINIMUM OUTPUT VOLTAGE

The minimum recommended on-time for the LM3404/04HV is

300 ns. This lower limit for tON determines the minimum duty

cycle and output voltage that can be regulated based on input

voltage and switching frequency. The relationship is determined by the following equation, shown on the same graphs

as maximum output voltage in the Typical Performance Characteristics section:

HIGH VOLTAGE BIAS REGULATOR

The LM3404/04HV contains an internal linear regulator with

a 7V output, connected between the VIN and the VCC pins.

The VCC pin should be bypassed to the GND pin with a 0.1

µF ceramic capacitor connected as close as possible to the

pins of the IC. VCC tracks VIN until VIN reaches 8.8V (typical)

and then regulates at 7V as VIN increases. Operation begins

when VCC crosses 5.25V.

INTERNAL MOSFET AND DRIVER

The LM3404/04HV features an internal power MOSFET as

well as a floating driver connected from the SW pin to the

BOOT pin. Both rise time and fall time are 20 ns each (typical)

and the approximate gate charge is 6 nC. The high-side rail

for the driver circuitry uses a bootstrap circuit consisting of an

internal high-voltage diode and an external 10 nF capacitor,

CB. VCC charges CB through the internal diode while the power

MOSFET is off. When the MOSFET turns on, the internal

diode reverse biases. This creates a floating supply equal to

the VCC voltage minus the diode drop to drive the MOSFET

when its source voltage is equal to VIN.

FAST SHUTDOWN FOR PWM DIMMING

The DIM pin of the LM3404/04HV is a TTL compatible input

for low frequency PWM dimming of the LED. A logic low (below 0.8V) at DIM will disable the internal MOSFET and shut

off the current flow to the LED array. While the DIM pin is in

a logic low state the support circuitry (driver, bandgap, VCC)

remains active in order to minimize the time needed to turn

the LED array back on when the DIM pin sees a logic high

(above 2.2V). A 75 µA (typical) pull-up current ensures that

the LM3404/04HV is on when DIM pin is open circuited, eliminating the need for a pull-up resistor. Dimming frequency,

f

DIM

, and duty cycle, D

DIM

, are limited by the LED current rise

time and fall time and the delay from activation of the DIM pin

to the response of the internal power MOSFET. In general,

f

DIM

should be at least one order of magnitude lower than the

steady state switching frequency in order to prevent aliasing.

PEAK CURRENT LIMIT

The current limit comparator of the LM3404/04HV will engage

whenever the power MOSFET current (equal to the inductor

current while the MOSFET is on) exceeds 1.5A (typical). The

power MOSFET is disabled for a cool-down time that is approximately 75x the steady-state on-time. At the conclusion

of this cool-down time the system re-starts. If the current limit

condition persists the cycle of cool-down time and restarting

will continue, creating a low-power hiccup mode, minimizing

thermal stress on the LM3404/04HV and the external circuit

components.

OVER-VOLTAGE/OVER-CURRENT COMPARATOR

The CS pin includes an output over-voltage/over-current

comparator that will disable the power MOSFET whenever

11 www.national.com

LM3404/LM3404HV

Page 12

V

SNS

exceeds 300 mV. This threshold provides a hard limit

for the output current. Output current overshoot is limited to

300 mV / R

SNS

by this comparator during transients.

The OVP/OCP comparator can also be used to prevent the

output voltage from rising to V

O(MAX)

in the event of an output

open-circuit. This is the most common failure mode for LEDs,

due to breaking of the bond wires. In a current regulator an

output open circuit causes V

SNS

to fall to zero, commanding

maximum duty cycle. Figure 2 shows a method using a zener

diode, Z1, and zener limiting resistor, RZ, to limit output voltage to the reverse breakdown voltage of Z1 plus 200 mV. The

zener diode reverse breakdown voltage, VZ, must be greater

than the maximum combined VF of all LEDs in the array. The

maximum recommended value for RZ is 1 kΩ.

As discussed in the Maximum Output Voltage section, there

is a limit to how high VO can rise during an output open-circuit

that is always less than VIN. If no output capacitor is used, the

output stage of the LM3404/04HV is capable of withstanding

V

O(MAX)

indefinitely, however the voltage at the output end of

the inductor will oscillate and can go above VIN or below 0V.

A small (typically 10 nF) capacitor across the LED array

dampens this oscillation. For circuits that use an output capacitor, the system can still withstand V

O(MAX)

indefinitely as

long as CO is rated to handle VIN. The high current paths are

blocked in output open-circuit and the risk of thermal stress is

minimal, hence the user may opt to allow the output voltage

to rise in the case of an open-circuit LED failure.

20205412

FIGURE 2. Output Open Circuit Protection

LOW POWER SHUTDOWN

The LM3404/04HV can be placed into a low power state (I

IN-

SD

= 90 µA) by grounding the RON pin with a signal-level

MOSFET as shown in Figure 3. Low power MOSFETs like the

2N7000, 2N3904, or equivalent are recommended devices

for putting the LM3404/04HV into low power shutdown. Logic

gates can also be used to shut down the LM3404/04HV as

long as the logic low voltage is below the over temperature

minimum threshold of 0.3V. Noise filter circuitry on the RON

pin can cause a few pulses with longer on-times than normal

after RON is grounded or released. In these cases the OVP/

OCP comparator will ensure that the peak inductor or LED

current does not exceed 300 mV / R

SNS

.

20205413

FIGURE 3. Low Power Shutdown

www.national.com 12

LM3404/LM3404HV

Page 13

THERMAL SHUTDOWN

Internal thermal shutdown circuitry is provided to protect the

IC in the event that the maximum junction temperature is exceeded. The threshold for thermal shutdown is 165°C with a

25°C hysteresis (both values typical). During thermal shutdown the MOSFET and driver are disabled.

Design Considerations

SWITCHING FREQUENCY

Switching frequency is selected based on the trade-offs between efficiency (better at low frequency), solution size/cost

(smaller at high frequency), and the range of output voltage

that can be regulated (wider at lower frequency.) Many applications place limits on switching frequency due to EMI sensitivity. The on-time of the LM3404/04HV can be programmed

for switching frequencies ranging from the 10’s of kHz to over

1 MHz. The maximum switching frequency is limited only by

the minimum on-time and minimum off-time requirements.

LED RIPPLE CURRENT

Selection of the ripple current, ΔiF, through the LED array is

analogous to the selection of output ripple voltage in a standard voltage regulator. Where the output ripple in a voltage

regulator is commonly ±1% to ±5% of the DC output voltage,

LED manufacturers generally recommend values for Δi

F

ranging from ±5% to ±20% of IF. Higher LED ripple current

allows the use of smaller inductors, smaller output capacitors,

or no output capacitors at all. The advantages of higher ripple

current are reduction in the solution size and cost. Lower ripple current requires more output inductance, higher switching

frequency, or additional output capacitance. The advantages

of lower ripple current are a reduction in heating in the LED

itself and greater tolerance in the average LED current before

the current limit of the LED or the driving circuitry is reached.

BUCK CONVERTERS WITHOUT OUTPUT CAPACITORS

The buck converter is unique among non-isolated topologies

because of the direct connection of the inductor to the load

during the entire switching cycle. By definition an inductor will

control the rate of change of current that flows through it, and

this control over current ripple forms the basis for component

selection in both voltage regulators and current regulators. A

current regulator such as the LED driver for which the

LM3404/04HV was designed focuses on the control of the

current through the load, not the voltage across it. A constant

current regulator is free of load current transients, and has no

need of output capacitance to supply the load and maintain

output voltage. Referring to the Typical Application circuit on

the front page of this datasheet, the inductor and LED can

form a single series chain, sharing the same current. When

no output capacitor is used, the same equations that govern

inductor ripple current, ΔiL, also apply to the LED ripple current, ΔiF. For a controlled on-time converter such as

LM3404/04HV the ripple current is described by the following

expression:

A minimum ripple voltage of 25 mV is recommended at the

CS pin to provide good signal to noise ratio (SNR). The CS

pin ripple voltage, Δv

SNS

, is described by the following:

Δv

SNS

= ΔiF x R

SNS

BUCK CONVERTERS WITH OUTPUT CAPACITORS

A capacitor placed in parallel with the LED or array of LEDs

can be used to reduce the LED current ripple while keeping

the same average current through both the inductor and the

LED array. This technique is demonstrated in Design Examples 1 and 2. With this topology the output inductance can be

lowered, making the magnetics smaller and less expensive.

Alternatively, the circuit could be run at lower frequency but

keep the same inductor value, improving the efficiency and

expanding the range of output voltage that can be regulated.

Both the peak current limit and the OVP/OCP comparator still

monitor peak inductor current, placing a limit on how large

ΔiL can be even if ΔiF is made very small. A parallel output

capacitor is also useful in applications where the inductor or

input voltage tolerance is poor. Adding a capacitor that reduces ΔiF to well below the target provides headroom for

changes in inductance or VIN that might otherwise push the

peak LED ripple current too high.

Figure 4 shows the equivalent impedances presented to the

inductor current ripple when an output capacitor, CO, and its

equivalent series resistance (ESR) are placed in parallel with

the LED array. The entire inductor ripple current flows through

R

SNS

to provide the required 25 mV of ripple voltage for proper

operation of the CS comparator.

20205415

FIGURE 4. LED and CO Ripple Current

To calculate the respective ripple currents the LED array is

represented as a dynamic resistance, rD. LED dynamic resistance is not always specified on the manufacturer’s

datasheet, but it can be calculated as the inverse slope of the

LED’s VF vs. IF curve. Note that dividing VF by IF will give an

incorrect value that is 5x to 10x too high. Total dynamic resistance for a string of n LEDs connected in series can be

calculated as the rD of one device multiplied by n. Inductor

ripple current is still calculated with the expression from Buck

Regulators without Output Capacitors. The following equations can then be used to estimate ΔiF when using a parallel

capacitor:

The calculation for ZC assumes that the shape of the inductor

ripple current is approximately sinusoidal.

13 www.national.com

LM3404/LM3404HV

Page 14

Small values of CO that do not significantly reduce ΔiF can

also be used to control EMI generated by the switching action

of the LM3404/04HV. EMI reduction becomes more important

as the length of the connections between the LED and the

rest of the circuit increase.

INPUT CAPACITORS

Input capacitors at the VIN pin of the LM3404/04HV are selected using requirements for minimum capacitance and rms

ripple current. The input capacitors supply pulses of current

approximately equal to IF while the power MOSFET is on, and

are charged up by the input voltage while the power MOSFET

is off. Switching converters such as the LM3404/04HV have

a negative input impedance due to the decrease in input current as input voltage increases. This inverse proportionality of

input current to input voltage can cause oscillations (sometimes called ‘power supply interaction’) if the magnitude of the

negative input impedance is greater the the input filter

impedance. Minimum capacitance can be selected by comparing the input impedance to the converter’s negative resistance; however this requires accurate calculation of the input

voltage source inductance and resistance, quantities which

can be difficult to determine. An alternative method to select

the minimum input capacitance, C

IN(MIN)

, is to select the max-

imum input voltage ripple which can be tolerated. This value,

Δv

IN(MAX)

, is equal to the change in voltage across CIN during

the converter on-time, when CIN supplies the load current.

C

IN(MIN)

can be selected with the following:

A good starting point for selection of CIN is to use an input

voltage ripple of 5% to 10% of VIN. A minimum input capacitance of 2x the C

IN(MIN)

value is recommended for all

LM3404/04HV circuits. To determine the rms current rating,

the following formula can be used:

Ceramic capacitors are the best choice for the input to the

LM3404/04HV due to their high ripple current rating, low ESR,

low cost, and small size compared to other types. When selecting a ceramic capacitor, special attention must be paid to

the operating conditions of the application. Ceramic capacitors can lose one-half or more of their capacitance at their

rated DC voltage bias and also lose capacitance with extremes in temperature. A DC voltage rating equal to twice the

expected maximum input voltage is recommended. In addition, the minimum quality dielectric which is suitable for

switching power supply inputs is X5R, while X7R or better is

preferred.

RECIRCULATING DIODE

The LM3404/04HV is a non-synchronous buck regulator that

requires a recirculating diode D1 (see the Typical Application

circuit) to carrying the inductor current during the MOSFET

off-time. The most efficient choice for D1 is a Schottky diode

due to low forward drop and near-zero reverse recovery time.

D1 must be rated to handle the maximum input voltage plus

any switching node ringing when the MOSFET is on. In practice all switching converters have some ringing at the switching node due to the diode parasitic capacitance and the lead

inductance. D1 must also be rated to handle the average current, ID, calculated as:

ID = (1 – D) x I

F

This calculation should be done at the maximum expected

input voltage. The overall converter efficiency becomes more

dependent on the selection of D1 at low duty cycles, where

the recirculating diode carries the load current for an increasing percentage of the time. This power dissipation can be

calculating by checking the typical diode forward voltage,

VD, from the I-V curve on the product datasheet and then

multiplying it by ID. Diode datasheets will also provide a typical

junction-to-ambient thermal resistance, θJA, which can be

used to estimate the operating die temperature of the device.

Multiplying the power dissipation (PD = ID x VD) by θ

JA

gives

the temperature rise. The diode case size can then be selected to maintain the Schottky diode temperature below the

operational maximum.

Design Example 1: LM3404

The first example circuit will guide the user through component selection for an architectural accent lighting application.

A regulated DC voltage input of 24V ±10% will power a 5.4W

"warm white" LED module that consists of four LEDs in a 2 x

2 series-parallel configuration. The module will be treated as

a two-terminal element and driven with a forward current of

700 mA ±5%. The typical forward voltage of the LED module

in thermal steady state is 6.9V, hence the average output

voltage will be 7.1V. The objective of this application is to

place the complete current regulator and LED module in a

compact space formerly occupied by a halogen light source.

(The LED will be on a separate metal-core PCB and heatsink.)

Switching frequency will be 400 kHz to keep switching loss

low, as the confined space with no air-flow requires a maximum temperature rise of 50°C in each circuit component. A

small solution size is also important, as the regulator must fit

on a circular PCB with a 1.5" diameter. A complete bill of materials can be found in Table 1 at the end of this datasheet.

www.national.com 14

LM3404/LM3404HV

Page 15

20205419

FIGURE 5. Schematic for Design Example 1

RON and t

ON

A moderate switching frequency is needed in this application

to balance the requirements of magnetics size and efficiency.

RON is selected from the equation for switching frequency as

follows:

RON = 7.1 / (1.34 x 10

-10

x 4 x 105) = 132.5 kΩ

The closest 1% tolerance resistor is 133 kΩ. The switching

frequency and on-time of the circuit can then be found using

the equations relating RON and tON to fSW:

fSW = 7.1 / (1.33 x 105 x 1.34 x 10

-10

) = 398 kHz

tON = (1.34 x 10

-10

x 1.33 x 105) / 24 = 743 ns

OUTPUT INDUCTOR

Since an output capacitor will be used to filter some of the AC

ripple current, the inductor ripple current can be set higher

than the LED ripple current. A value of 40%

P-P

is typical in

many buck converters:

ΔiL = 0.4 x 0.7 = 0.28A

With the target ripple current determined the inductance can

be chosen:

L

MIN

= [(24 – 7.1) x 7.43 x 10-7] / (0.28) = 44.8 µH

The closest standard inductor value is 47 µH. The average

current rating should be greater than 700 mA to prevent overheating in the inductor. Separation between the LM3404

drivers and the LED arrays means that heat from the inductor

will not threaten the lifetime of the LEDs, but an overheated

inductor could still cause the LM3404 to enter thermal shutdown.

The inductance of the standard part chosen is ±20%. With this

tolerance the typical, minimum, and maximum inductor current ripples can be calculated:

Δi

L(TYP)

= [(24 - 7.1) x 7.43 x 10-7] / 47 x 10

-6

= 266 mA

P-P

Δi

L(MIN)

= [(24 - 7.1) x 7.43 x 10-7] / 56 x 10

-6

= 223 mA

P-P

Δi

L(MAX)

= [(24 - 7.1) x 7.43 x 10-7] / 38 x 10

-6

= 330 mA

P-P

The peak LED/inductor current is then estimated:

I

L(PEAK)

= IL + 0.5 x Δi

L(MAX)

I

L(PEAK)

= 0.7 + 0.5 x 0.330 = 866 mA

In the case of a short circuit across the LED array, the LM3404

will continue to deliver rated current through the short but will

reduce the output voltage to equal the CS pin voltage of 200

mV. The inductor ripple current and peak current in this condition would be equal to:

Δi

L(LED-SHORT)

= [(24 – 0.2) x 7.43 x 10-7] / 38 x 10

-6

= 465 mA

P-P

I

L(PEAK)

= 0.7 + 0.5 x 0.465 = 933 mA

In the case of a short at the switch node, the output, or from

the CS pin to ground the short circuit current limit will engage

15 www.national.com

LM3404/LM3404HV

Page 16

at a typical peak current of 1.5A. In order to prevent inductor

saturation during these fault conditions the inductor’s peak

current rating must be above 1.5A. A 47 µH off-the shelf inductor rated to 1.4A (peak) and 1.5A (average) with a DCR of

0.1Ω will be used.

USING AN OUTPUT CAPACITOR

This application does not require high frequency PWM dimming, allowing the use of an output capacitor to reduce the

size and cost of the output inductor. To select the proper output capacitor the equation from Buck Regulators with Output

Capacitors is re-arranged to yield the following:

The target tolerance for LED ripple current is 100 mA

P-P

, and

a typical value for rD of 1.8Ω at 700 mA can be read from the

LED datasheet. The required capacitor impedance to reduce

the worst-case inductor ripple current of 333 mA

P-P

is there-

fore:

ZC = [0.1 / (0.333 - 0.1] x 1.8 = 0.77Ω

A ceramic capacitor will be used and the required capacitance

is selected based on the impedance at 400 kHz:

CO = 1/(2 x π x 0.77 x 4 x 105) = 0.51 µF

This calculation assumes that impedance due to the equivalent series resistance (ESR) and equivalent series inductance

(ESL) of CO is negligible. The closest 10% tolerance capacitor

value is 1.0 µF. The capacitor used should be rated to 25V or

more and have an X7R dielectric. Several manufacturers produce ceramic capacitors with these specifications in the 0805

case size. A typical value for ESR of 3 mΩ can be read from

the curve of impedance vs. frequency in the product

datasheet.

R

SNS

A preliminary value for R

SNS

was determined in selecting

ΔiL. This value should be re-evaluated based on the calcula-

tions for ΔiF:

t

SNS

= 220 ns, R

SNS

= 0.33Ω

Sub-1Ω resistors are available in both 1% and 5% tolerance.

A 1%, 0.33Ω device is the closest value, and a 0.33W, 1206

size device will handle the power dissipation of 162 mW. With

the resistance selected, the average value of LED current is

re-calculated to ensure that current is within the ±5% tolerance requirement. From the expression for average LED

current:

IF = 0.2 / 0.33 - (7.1 x 2.2 x 10-7) / 47 x 10-6 + 0.266 / 2

= 706 mA, 1% above 700 mA

INPUT CAPACITOR

Following the calculations from the Input Capacitor section,

Δv

IN(MAX)

will be 24V x 2%

P-P

= 480 mV. The minimum re-

quired capacitance is:

C

IN(MIN)

= (0.7 x 7.4 x 10-7) / 0.48 = 1.1 µF

To provide additional safety margin the a higher value of 3.3

µF ceramic capacitor rated to 50V with X7R dielectric in an

1210 case size will be used. From the Design Considerations

section, input rms current is:

I

IN-RMS

= 0.7 x Sqrt(0.28 x 0.72) = 314 mA

Ripple current ratings for 1210 size ceramic capacitors are

typically higher than 2A, more than enough for this design.

RECIRCULATING DIODE

The input voltage of 24V ±5% requires Schottky diodes with

a reverse voltage rating greater than 30V. The next highest

standard voltage rating is 40V. Selecting a 40V rated diode

provides a large safety margin for the ringing of the switch

node and also makes cross-referencing of diodes from different vendors easier.

The next parameters to be determined are the forward current

rating and case size. In this example the low duty cycle (D =

7.1 / 24 = 28%) places a greater thermal stress on D1 than

on the internal power MOSFET of the LM3404. The estimated

average diode current is:

ID = 0.706 x 0.72 = 509 mA

A Schottky with a forward current rating of 1A would be adequate, however reducing the power dissipation is critical in

this example. Higher current diodes have lower forward voltages, hence a 2A-rated diode will be used. To determine the

proper case size, the dissipation and temperature rise in D1

can be calculated as shown in the Design Considerations

section. VD for a case size such as SMB in a 40V, 2A Schottky

diode at 700 mA is approximately 0.3V and the θJA is 75°C/

W. Power dissipation and temperature rise can be calculated

as:

PD = 0.509 x 0.3 = 153 mW

T

RISE

= 0.153 x 75 = 11.5°C

CB AND C

F

The bootstrap capacitor CB should always be a 10 nF ceramic

capacitor with X7R dielectric. A 25V rating is appropriate for

all application circuits. The linear regulator filter capacitor C

F

should always be a 100 nF ceramic capacitor, also with X7R

dielectric and a 25V rating.

EFFICIENCY

To estimate the electrical efficiency of this example the power

dissipation in each current carrying element can be calculated

and summed. Electrical efficiency, η, should not be confused

www.national.com 16

LM3404/LM3404HV

Page 17

with the optical efficacy of the circuit, which depends upon the

LEDs themselves.

Total output power, PO, is calculated as:

PO = IF x VO = 0.706 x 7.1 = 5W

Conduction loss, PC, in the internal MOSFET:

PC = (I

F

2

x R

DSON

) x D = (0.7062 x 0.8) x 0.28 = 112 mW

Gate charging and VCC loss, PG, in the gate drive and linear

regulator:

PG = (I

IN-OP

+ fSW x QG) x V

IN

PG = (600 x 10-6 + 4 x 105 x 6 x 10-9) x 24 = 72 mW

Switching loss, PS, in the internal MOSFET:

PS = 0.5 x VIN x IF x (tR + tF) x f

SW

PS = 0.5 x 24 x 0.706 x 40 x 10-9 x 4 x 105 = 136 mW

AC rms current loss, P

CIN

, in the input capacitor:

P

CIN

= I

IN(rms)

2

x ESR = 0.3172 0.003 = 0.3 mW (negligible)

DCR loss, PL, in the inductor

PL = I

F

2

x DCR = 0.7062 x 0.1 = 50 mW

Recirculating diode loss, PD = 153 mW

Current Sense Resistor Loss, P

SNS

= 164 mW

Electrical efficiency, η = PO / (PO + Sum of all loss terms) =

5 / (5 + 0.687) = 88%

Temperature Rise in the LM3404 IC is calculated as:

T

LM3404

= (PC + PG + PS) x θJA = (0.112 + 0.072 + 0.136) x

155 = 49.2°C

Design Example 2: LM3404HV

The second example circuit will guide the user through component selection for an outdoor general lighting application.

A regulated DC voltage input of 48V ±10% will power ten series-connected LEDs at 500 mA ±10% with a ripple current of

50 mA

P-P

or less. The typical forward voltage of the LED module in thermal steady state is 35V, hence the average output

voltage will be 35.2V. A complete bill of materials can be found

in Table 2 at the end of this datasheet.

20205432

FIGURE 6. Schematic for Design Example 2

RON and t

ON

A low switching frequency, 225 kHz, is needed in this application, as high efficiency and low power dissipation take

precedence over the solution size. RON is selected from the

equation for switching frequency as follows:

RON = 35.2 / (1.34 x 10

-10

x 2.25 x 105) = 1.16 MΩ

The next highest 1% tolerance resistor is 1.18 MΩ. The

switching frequency and on-time of the circuit can then be

found using the equations relating RON and tON to fSW:

fSW = 35.2 / (1.18 x 106 x 1.34 x 10

-10

) = 223 kHz

tON = (1.34 x 10

-10

x 1.18 x 106) / 48 = 3.3 µs

OUTPUT INDUCTOR

Since an output capacitor will be used to filter some of the AC

ripple current, the inductor ripple current can be set higher

than the LED ripple current. A value of 30%

P-P

makes a good

trade-off between the current ripple and the size of the inductor:

ΔiL = 0.3 x 0.5 = 0.15A

17 www.national.com

LM3404/LM3404HV

Page 18

With the target ripple current determined the inductance can

be chosen:

L

MIN

= [(48 – 35.2) x 3.3 x 10-6] / (0.15) = 281 µH

The closest standard inductor value above 281 is 330 µH. The

average current rating should be greater than 0.5A to prevent

overheating in the inductor. In this example the LM3404HV

driver and the LED array share the same metal-core PCB,

meaning that heat from the inductor could threaten the lifetime

of the LEDs. For this reason the average current rating of the

inductor used should have a de-rating of about 50%, or 1A.

The inductance of the standard part chosen is ±20%. With this

tolerance the typical, minimum, and maximum inductor current ripples can be calculated:

Δi

L(TYP)

= [(48 - 35.2) x 3.3 x 10-6] / 330 x 10

-6

= 128 mA

P-P

Δi

L(MIN)

= [(48 - 35.2) x 3.3 x 10-6] / 396 x 10

-6

= 107 mA

P-P

Δi

L(MAX)

= [(48 - 35.2) x 3.3 x 10-6] / 264 x 10

-6

= 160 mA

P-P

The peak inductor current is then estimated:

I

L(PEAK)

= IL + 0.5 x Δi

L(MAX)

I

L(PEAK)

= 0.5 + 0.5 x 0.16 = 0.58A

In the case of a short circuit across the LED array, the

LM3404HV will continue to deliver rated current through the

short but will reduce the output voltage to equal the CS pin

voltage of 200 mV. The inductor ripple current and peak current in this condition would be equal to:

Δi

L(LED-SHORT)

= [(48 – 0.2) x 3.3 x 10-6] / 264 x 10

-6

= 0.598A

P-P

I

L(PEAK)

= 0.5 + 0.5 x 0.598 = 0.8A

In the case of a short at the switch node, the output, or from

the CS pin to ground the short circuit current limit will engage

at a typical peak current of 1.5A. In order to prevent inductor

saturation during these fault conditions the inductor’s peak

current rating must be above 1.5A. A 330 µH off-the shelf inductor rated to 1.9A (peak) and 1.0A (average) with a DCR of

0.56Ω will be used.

USING AN OUTPUT CAPACITOR

This application uses sub-1 kHz frequency PWM dimming,

allowing the use of a small output capacitor to reduce the size

and cost of the output inductor. To select the proper output

capacitor the equation from Buck Regulators with Output Capacitors is re-arranged to yield the following:

The target tolerance for LED ripple current is 50 mA

P-P

, and

the typical value for rD is 10Ω with ten LEDs in series. The

required capacitor impedance to reduce the worst-case

steady-state inductor ripple current of 160 mA

P-P

is therefore:

ZC = [0.05 / (0.16 - 0.05] x 10 = 4.5Ω

A ceramic capacitor will be used and the required capacitance

is selected based on the impedance at 223 kHz:

CO = 1/(2 x π x 4.5 x 2.23 x 105) = 0.16 µF

This calculation assumes that impedance due to the equivalent series resistance (ESR) and equivalent series inductance

(ESL) of CO is negligible. The closest 10% tolerance capacitor

value is 0.15 µF. The capacitor used should be rated to 50V

or more and have an X7R dielectric. Several manufacturers

produce ceramic capacitors with these specifications in the

0805 case size. ESR values are not typically provided for such

low value capacitors, however is can be assumed to be under

100 mΩ, leaving plenty of margin to meet to LED ripple current

requirement. The low capacitance required allows the use of

a 100V rated, 1206-size capacitor. The rating of 100V ensures that the capacitance will not decrease significantly

when the DC output voltage is applied across the capacitor.

R

SNS

A preliminary value for R

SNS

was determined in selecting

ΔiL. This value should be re-evaluated based on the calcula-

tions for ΔiF:

t

SNS

= 220 ns, R

SNS

= 0.43Ω

Sub-1Ω resistors are available in both 1% and 5% tolerance.

A 1%, 0.43Ω device is the closest value, and a 0.25W, 0805

size device will handle the power dissipation of 110 mW. With

the resistance selected, the average value of LED current is

re-calculated to ensure that current is within the ±10% tolerance requirement. From the expression for average LED

current:

IF = 0.2 / 0.43 - (35.2 x 2.2 x 10-7) / 330 x 10-6 + 0.128 / 2

= 505 mA

www.national.com 18

LM3404/LM3404HV

Page 19

INPUT CAPACITOR

Following the calculations from the Input Capacitor section,

Δv

IN(MAX)

will be 48V x 2%

P-P

= 960 mV. The minimum re-

quired capacitance is:

C

IN(MIN)

= (0.5 x 3.3 x 10-6) / 0.96 = 1.7 µF

To provide additional safety margin a 2.2 µF ceramic capacitor rated to 100V with X7R dielectric in an 1812 case size will

be used. From the Design Considerations section, input rms

current is:

I

IN-RMS

= 0.5 x Sqrt(0.73 x 0.27) = 222 mA

Ripple current ratings for 1812 size ceramic capacitors are

typically higher than 2A, more than enough for this design,

and the ESR is approximately 3 mΩ.

RECIRCULATING DIODE

The input voltage of 48V requires Schottky diodes with a reverse voltage rating greater than 50V. The next highest standard voltage rating is 60V. Selecting a 60V rated diode

provides a large safety margin for the ringing of the switch

node and also makes cross-referencing of diodes from different vendors easier.

The next parameters to be determined are the forward current

rating and case size. In this example the high duty cycle (D =

35.2 / 48 = 73%) places a greater thermal stress on the internal power MOSFET than on D1. The estimated average

diode current is:

ID = 0.5 x 0.27 = 135 mA

A Schottky with a forward current rating of 0.5A would be adequate, however reducing the power dissipation is critical in

this example. Higher current diodes have lower forward voltages, hence a 1A-rated diode will be used. To determine the

proper case size, the dissipation and temperature rise in D1

can be calculated as shown in the Design Considerations

section. VD for a case size such as SMA in a 60V, 1A Schottky

diode at 0.5A is approximately 0.35V and the θJA is 75°C/W.

Power dissipation and temperature rise can be calculated as:

PD = 0.135 x 0.35 = 47 mW

T

RISE

= 0.047 x 75 = 3.5°C

CB AND C

F

The bootstrap capacitor CB should always be a 10 nF ceramic

capacitor with X7R dielectric. A 25V rating is appropriate for

all application circuits. The linear regulator filter capacitor C

F

should always be a 100 nF ceramic capacitor, also with X7R

dielectric and a 25V rating.

EFFICIENCY

To estimate the electrical efficiency of this example the power

dissipation in each current carrying element can be calculated

and summed. Electrical efficiency, η, should not be confused

with the optical efficacy of the circuit, which depends upon the

LEDs themselves.

Total output power, PO, is calculated as:

PO = IF x VO = 0.5 x 35.2 = 17.6W

Conduction loss, PC, in the internal MOSFET:

PC = (I

F

2

x R

DSON

) x D = (0.52 x 0.8) x 0.73 = 146 mW

Gate charging and VCC loss, PG, in the gate drive and linear

regulator:

PG = (I

IN-OP

+ fSW x QG) x V

IN

PG = (600 x 10-6 + 2.23 x 105 x 6 x 10-9) x 48 = 94 mW

Switching loss, PS, in the internal MOSFET:

PS = 0.5 x VIN x IF x (tR + tF) x f

SW

PS = 0.5 x 48 x 0.5 x 40 x 10-9 x 2.23 x 105 = 107 mW

AC rms current loss, P

CIN

, in the input capacitor:

P

CIN

= I

IN(rms)

2

x ESR = 0.2222 0.003 = 0.1 mW (negligible)

DCR loss, PL, in the inductor

PL = I

F

2

x DCR = 0.52 x 0.56 = 140 mW

Recirculating diode loss, PD = 47 mW

Current Sense Resistor Loss, P

SNS

= 110 mW

Electrical efficiency, η = PO / (PO + Sum of all loss terms) =

17.6 / (17.6 + 0.644) = 96%

Temperature Rise in the LM3404HV IC is calculated as:

T

LM3404

= (PC + PG + PS) x θJA = (0.146 + 0.094 + 0.107) x

155 = 54°C

Layout Considerations

The performance of any switching converter depends as

much upon the layout of the PCB as the component selection.

The following guidelines will help the user design a circuit with

maximum rejection of outside EMI and minimum generation

of unwanted EMI.

COMPACT LAYOUT

Parasitic inductance can be reduced by keeping the power

path components close together and keeping the area of the

loops that high currents travel small. Short, thick traces or

copper pours (shapes) are best. In particular, the switch node

(where L1, D1, and the SW pin connect) should be just large

enough to connect all three components without excessive

heating from the current it carries. The LM3404/04HV operates in two distinct cycles whose high current paths are shown

in Figure 7:

19 www.national.com

LM3404/LM3404HV

Page 20

20205428

FIGURE 7. Buck Converter Current Loops

The dark grey, inner loop represents the high current path

during the MOSFET on-time. The light grey, outer loop represents the high current path during the off-time.

GROUND PLANE AND SHAPE ROUTING

The diagram of Figure 7 is also useful for analyzing the flow

of continuous current vs. the flow of pulsating currents. The

circuit paths with current flow during both the on-time and offtime are considered to be continuous current, while those that

carry current during the on-time or off-time only are pulsating

currents. Preference in routing should be given to the pulsating current paths, as these are the portions of the circuit most

likely to emit EMI. The ground plane of a PCB is a conductor

and return path, and it is susceptible to noise injection just as

any other circuit path. The continuous current paths on the

ground net can be routed on the system ground plane with

less risk of injecting noise into other circuits. The path between the input source and the input capacitor and the path

between the recirculating diode and the LEDs/current sense

resistor are examples of continuous current paths. In contrast,

the path between the recirculating diode and the input capacitor carries a large pulsating current. This path should be

routed with a short, thick shape, preferably on the component

side of the PCB. Multiple vias in parallel should be used right

at the pad of the input capacitor to connect the component

side shapes to the ground plane. A second pulsating current

loop that is often ignored is the gate drive loop formed by the

SW and BOOT pins and capacitor CB. To minimize this loop

at the EMI it generates, keep CB close to the SW and BOOT

pins.

CURRENT SENSING

The CS pin is a high-impedance input, and the loop created

by R

SNS

, RZ (if used), the CS pin and ground should be made

as small as possible to maximize noise rejection. R

SNS

should

therefore be placed as close as possible to the CS and GND

pins of the IC.

REMOTE LED ARRAYS

In some applications the LED or LED array can be far away

(several inches or more) from the LM3404/04HV, or on a separate PCB connected by a wiring harness. When an output

capacitor is used and the LED array is large or separated from

the rest of the converter, the output capacitor should be

placed close to the LEDs to reduce the effects of parasitic

inductance on the AC impedance of the capacitor. The current

sense resistor should remain on the same PCB, close to the

LM3404/04HV.

www.national.com 20

LM3404/LM3404HV

Page 21

TABLE 1. BOM for Design Example 1

ID Part Number Type Size Parameters Qty Vendor

U1 LM3404 LED Driver SO-8 42V, 1.2A 1 NSC

L1 SLF10145T-470M1R4 Inductor 10 x 10 x 4.5mm 47 µH, 1.4A, 120

mΩ

1 TDK

D1 CMSH2-40 Schottky Diode SMB 40V, 2A 1 Central Semi

Cf VJ0805Y104KXXAT Capacitor 0805 100 nF 10% 1 Vishay

Cb VJ0805Y103KXXAT Capacitor 0805 10 nF 10% 1 Vishay

Cin C3225X7R1H335M Capacitor 1210 3.3 µF, 50V 1 TDK

Co C2012X7R1E105M Capacitor 0805 1.0 µF, 25V 1 TDK

Rsns ERJ8BQFR33V Resistor 1206

0.33Ω 1%

1 Panasonic

Ron CRCW08051333F Resistor 0805

133 kΩ 1%

1 Vishay

TABLE 2. BOM for Design Example 2

ID Part Number Type Size Parameters Qty Vendor

U1 LM3404HV LED Driver SO-8 75V, 1.2A 1 NSC

L1 DO5022P-334 Inductor 18.5 x 15.4 x 7.1mm 330 µH, 1.9A,

0.56Ω

1 Coilcraft

D1 CMSH1-60M Schottky Diode SMA 60V, 1A 1 Central Semi

Cf VJ0805Y104KXXAT Capacitor 0805 100 nF 10% 1 Vishay

Cb VJ0805Y103KXXAT Capacitor 0805 10 nF 10% 1 Vishay

Cin C4532X7R2A225M Capacitor 1812 2.2 µF, 100V 1 TDK

Co C3216X7R2A154M Capacitor 1206 0.15 µF, 100V 1 TDK

Rsns ERJ6BQFR43V Resistor 0805

0.43Ω 1%

1 Panasonic

Ron CRCW08051184F Resistor 0805

1.18 MΩ 1%

1 Vishay

21 www.national.com

LM3404/LM3404HV

Page 22

Physical Dimensions inches (millimeters) unless otherwise noted

SO-8 Package

NS Package Number M08A

PSOP-8 Package

NS Package Number MRA08B

www.national.com 22

LM3404/LM3404HV

Page 23

Notes

23 www.national.com

LM3404/LM3404HV

Page 24

Notes

LM3404/04HV 1.0A Constant Current Buck Regulator for Driving High Power LEDs

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2007 National Semiconductor Corporation

For the most current product information visit us at www.national.com

National Semiconductor

Americas Customer

Support Center

Email:

new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Customer Support Center

Fax: +49 (0) 180-530-85-86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +49 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor Asia

Pacific Customer Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

www.national.com

Loading...

Loading...