Page 1

November 2002

LM3354-3.7

Regulated 90mA Buck-Boost Switched Capacitor DC/DC

Converter

LM3354-3.7 Regulated 90mA Buck-Boost Switched Capacitor DC/DC Converter

General Description

The LM3354 is a CMOS switched capacitor DC/DC converter that produces a regulated output voltage by automatically stepping up (boost) or stepping down (buck) the input

voltage. It accepts an input voltage between 2.5V and 5.5V.

The LM3354 is also available with standard output voltages

of 1.8V, 3.3V, 3.7V, 4.1V (ideal for white LED applications),

and 5.0V. If other output voltage options between 1.8V and

5.0V are desired, please contact your National Semiconductor representative.

The LM3354’s proprietary buck-boost architecture enables

up to 90mA of load current at an average efficiency greater

than 75%. Typical operating current is only 375 µA and the

typical shutdown current is only 2.3 µA.

The LM3354 is available in a 10-pin MSOP package. This

package has a maximum height of only 1.1 mm.

The high efficiency of the LM3354, low operating and shutdown currents, small package size, and the small size of the

overall solution make this device ideal for battery powered,

portable, and hand-held applications.

See the LM3352 for up to 200mA of output current or the

LM3355 for up to 50mA of output current.

Features

n Regulated V

n Standard output voltages of 1.8V, 3.3V, 4.1V, and 5.0V

also available

n Custom output voltages available from 1.8V to 5.0V in

100 mV increments with volume order

n 2.5V to 5.5V input voltage range

n Up to 90mA output current

>

n

75% average efficiency

n Uses few, low-cost external components

n Very small solution size

n 375 µA typical operating current

n 2.3 µA typical shutdown current

n 1 MHz typical switching frequency

n Architecture and control methods provide high load

current and good efficiency

n MSOP-10 package

n Over-temperature protection

with±3% accuracy

OUT

Applications

n White LED display backlights

n 1-cell Lilon battery-operated equipment including PDAs,

hand-held PCs, cellular phones

n Flat panel displays

n Hand-held instruments

n Li-Ion, NiCd, NiMH, or alkaline battery powered systems

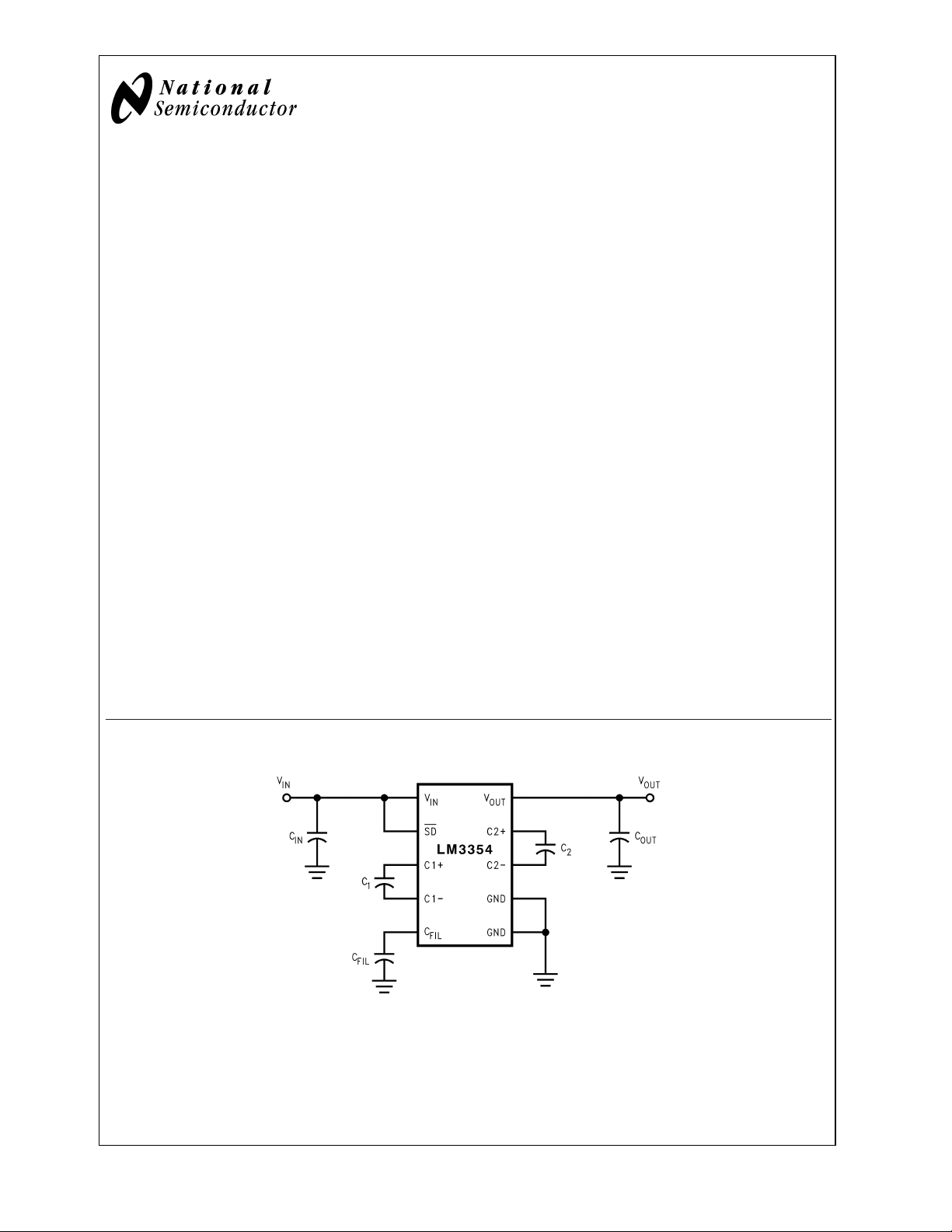

Typical Operating Circuit

20057301

© 2002 National Semiconductor Corporation DS200573 www.national.com

Page 2

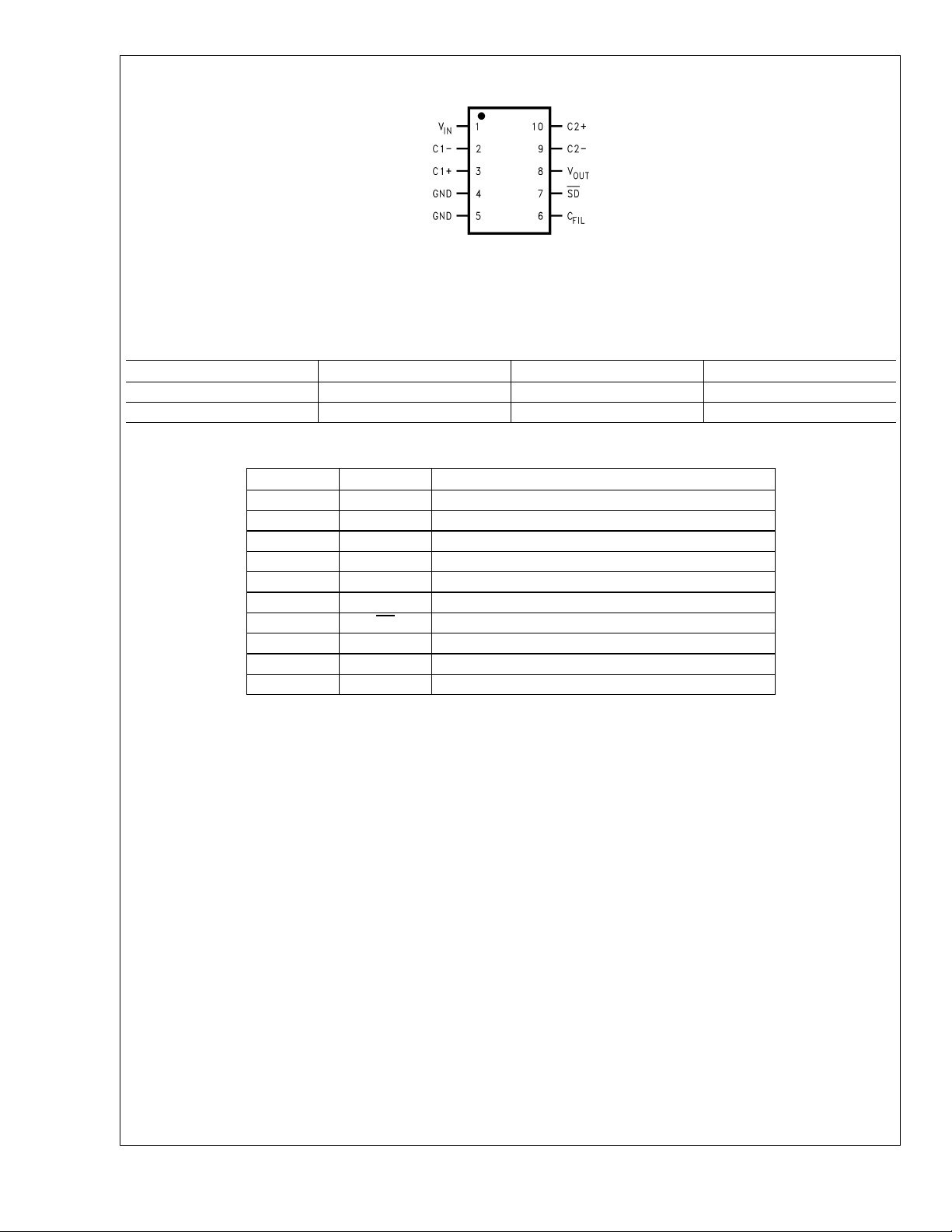

Connection Diagram

LM3354-3.7

Top View

MSOP-10 Pin Package

See NS Package Number MM

20057302

Ordering Information

Order Number Package Type NSC Package Drawing Supplied As

LM3354MMX-3.7 MSOP-10 MUB10A 3.5k Units, Tape and Reel

LM3354MM-3.7 MSOP-10 MUB10A 1k Units, Tape and Reel

Pin Description

Pin Number Name Function

1V

2 C1− Negative Terminal for C1

3 C1+ Positive Terminal for C1

4 GND Ground

5 GND Ground

6C

7SD

8V

9 C2− Negative Terminal for C2

10 C2+ Positive Terminal for C2

IN

FIL

OUT

Input Supply Voltage

Filter Capacitor, a 1µF capacitor is recommended.

Shutdown, active low

Regulated Output Voltage

www.national.com 2

Page 3

LM3354-3.7

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

ESD Rating (Note 3)

Human Body Model

Machine Model

1.5 kV

Distributors for availability and specifications.

All Pins −0.5V to 5.6V

Power Dissipation (T

= 25˚C)

A

(Note 2) Internally Limited

(Note 2) 150˚C

T

JMAX

θ

(Note 2) 250˚C/W

JA

Storage Temperature −65˚C to +150˚C

Operating Ratings

Input Voltage (VIN) 2.5V to 5.5V

Output Voltage (V

Ambient Temperature (T

Junction Temperature (T

) 1.8V to 5.0V

OUT

) (Note 2) −40˚C to +85˚C

A

) (Note 2) −40˚C to +120˚C

J

Lead Temperature (Soldering, 5

sec.) 260˚C

Electrical Characteristics

Limits in standard typeface are for TA= 25˚C, and limits in boldface type apply over the full operating temperature range. Unless otherwise specified: C

= 0.33 µF; CIN= 10 µF; C

1=C2

Parameter Conditions Min

(Note 5)

LM3354-3.7

Output Voltage (V

OUT

)

Efficiency I

Output Voltage

Ripple

(Peak-to-Peak)

V

= (2.7, 5.5) V

IN

= (1, 70) mA

I

L

V

= (2.8, 4.0) V

IN

= (1, 90) mA

I

L

V

= (4.3, 5.5) V

IN

= (1, 90) mA

I

L

=15mA 75

LOAD

I

=70mA 70

LOAD

=50mA

I

LOAD

=10µF

C

OUT

3.589/3.552 3.7 3.811/3.848

3.589/3.552 3.7 3.811/3.848

3.589/3.552 3.7 3.811/3.848

ceramic

LM3354-ALL OUTPUT VOLTAGE VERSIONS

Operating Quiescent

Current

Shutdown Quiescent

Current

Switching

Measured at Pin

;

V

IN

= 0A (Note 6)

I

LOAD

SD Pin at 0V (Note

7)

0.6 1 1.4 MHz

Frequency

<

SD Input Threshold

2.5V

<

V

5.5V 0.2 V

IN

Low

SD Input Threshold

2.5V<V

<

5.5V 0.8 V

IN

IN

High

SD Input Current Measured at SD

Pin;

SD Pin = V

Note 1: “Absolute Maximum Ratings” indicate limits beyond which damage to the device may occur. Operating Ratings are conditions for which the device is

intended to be functional, but device parameter specifications may not be guaranteed. For guaranteed specifications and test conditions, see “Electrical

Characteristics”.

Note 2: As long as T

The 5V option requires that T

Note 3: The human body model is a 100 pF capacitor discharged through a 1.5 kΩ resistor into each pin. The machine model is a 200 pF capacitor discharged

directly into each pin.

Note 4: Typical numbers are at 25˚C and represent the most likely norm.

Note 5: All limits guaranteed at room temperature (standard typeface) and at temperature extremes (bold typeface). All room temperature limits are 100% tested

or guaranteed through statistical analysis. All limits at temperature extremes are guaranteed by correlation using standard Statistical Quality Control methods (SQC).

All limits are used to calculate Average Outgoing Quality Level (AOQL).

≤ +85˚C, all electrical characteristics hold true and the junction temperature should remain below +120˚C except for the 5V output option.

A

≤ +60˚C.

A

IN

= 5.5V

OUT

= 10 µF; C

(Note 4)

= 1 µF; VIN= 3.5V.

FIL

Typ

Max

(Note 5)

75 mV

375 475 µA

2.3 5 µA

IN

0.3 µA

Units

V

%

P-P

V

V

100V

www.national.com3

Page 4

Electrical Characteristics (Continued)

Note 6: The V

Note 7: The output capacitor C

LM3354-3.7

pin is forced to 200 mV above the typical V

OUT

is fully discharged before measurement.

OUT

. This is to insure that the internal switches are off.

OUT

www.national.com 4

Page 5

LM3354-3.7

Typical Performance Characteristics Unless otherwise specified T

vs. V

V

OUT

IN

Efficiency vs. V

20057341 20057342

IN

V

Load Transient Response

A

OUT

= 25˚C.

vs. V

IN

Operating Quiescent

Current vs. V

IN

20057320

20057324

Switching Frequency vs. V

20057314

IN

20057323

www.national.com5

Page 6

Typical Performance Characteristics Unless otherwise specified T

= 25˚C. (Continued)

A

LM3354-3.7

Maximum V

Ripple vs. C

OUT

OUT

20057332

Maximum V

Ripple vs. C

OUT

OUT

20057330

www.national.com 6

Page 7

Applications Information

LM3354-3.7

20057303

FIGURE 1. Block Diagram

Operating Principle

The LM3354 is designed to provide a step-up/step-down

voltage regulation in battery powered systems. It combines

switched capacitor circuitry, reference, comparator, and

shutdown logic in a single 10-pin MSOP package. The

LM3354 can provide a regulated voltage between 1.8V and

5.0V from an input voltage between 2.5V and 5.5V. It can

supply a load current up to 90 mA (refer to Electrical Char-

acteristics).

As shown in Figure 1, the LM3354 employs two feedback

loops to provide regulation in the most efficient manner

possible. The first loop is from V

COMP, the AND gate G

switch array. The comparator’s output is high when V

less than the reference V

gating the clock to the switch array. In this manner, charge is

transferred to the output only when needed. The second

loop controls the gain configuration of the switch array. This

loop consists of the comparator, the digital control block, the

phase generator, and the switch array. The digital control

block computes the most efficient gain from a set of five

gains based on inputs from the A/D and the comparator. The

gain signal is sent to the phase generator which then sends

the appropriate timing and configuration signals to the switch

array. This dual loop provides regulation over a wide range of

loads efficiently.

Since efficiency is automatically optimized, the curves for

vs. VINand Efficiency vs. VINin the Typical Perfor-

V

OUT

mance Characteristics section exhibit small variations. The

reason is that as input voltage or output load changes, the

digital control loops are making decisions on how to optimize

efficiency. As the switch array is reconfigured, small variations in output voltage and efficiency result. In all cases

where these small variations are observed, the part is operating correctly; minimizing output voltage changes and optimizing efficiency.

, the phase generator, and the

1

REF

through the comparator

OUT

. Regulation is provided by

OUT

Charge Pump Capacitor Selection

A 0.33 µF ceramic capacitor is suggested for C1 and C2. To

ensure proper operation over temperature variations, an

X7R dielectric material is recommended.

Filter Capacitor Selection

a) CAPACITOR TECHNOLOGIES

The three major technologies of capacitors that can be used

as filter capacitors for LM3354 are: i) tantalum, ii) ceramic

and iii) polymer electrolytic technologies.

is

i) Tantalum

Tantalum capacitors are widely used in switching regulators.

Tantalum capacitors have the highest CV rating of any technology; as a result, high values of capacitance can be obtained in relatively small package sizes. It is also possible to

obtain high value tantalum capacitors in very low profile

<

1.2 mm) packages. This makes the tantalums attractive

(

for low-profile, small size applications. Tantalums also possess very good temperature stability; i.e., the change in the

capacitance value, and impedance over temperature is relatively small. However, the tantalum capacitors have relatively

high ESR values which can lead to higher voltage ripple and

their frequency stability (variation over frequency) is not very

good, especially at high frequencies (

ii) Ceramic

Ceramic capacitors have the lowest ESR of the three technologies and their frequency stability is exceptionally good.

These characteristics make the ceramics an attractive

choice for low ripple, high frequency applications. However,

the temperature stability of the ceramics is bad, except for

the X7R and X5R dielectric types. High capacitance values

>

1 µF) are achievable from companies such as

(

Taiyo-yuden which are suitable for use with regulators. Ceramics are taller and larger than the tantalums of the same

capacitance value.

>

1 MHz).

www.national.com7

Page 8

Filter Capacitor Selection (Continued)

iii) Polymer Electrolytic

Polymer electrolytic is a third suitable technology. Polymer

LM3354-3.7

capacitors provide some of the best features of both the

ceramic and the tantalum technologies. They provide very

low ESR values while still achieving high capacitance val-

the same size. Polymers offer good frequency stability (comparable to ceramics) and good temperature stability (comparable to tantalums). The Aluminum Polymer Electrolytics

offered by Cornell-Dubilier and Panasonic, and the POSCAPs offered by Sanyo fall under this category.

Table 1 compares the features of the three capacitor tech-

nologies.

ues. However, their ESR is still higher than the ceramics,

and their capacitance value is lower than the tantalums of

TABLE 1. Comparison of Capacitor Technologies

Ceramic Tantalum

ESR Lowest High Low

Relative Height Low for Small Values (

<

10 µF); Taller for

Lowest Low

Higher Values

Relative Footprint Large Small Largest

Temperature Stability X7R/X5R-Acceptable Good Good

Frequency Stability Good Acceptable Good

<

V

Ripple Magnitude

OUT

V

Ripple Magnitude

OUT

dv/dt of V

OUT

Ripple@All Loads Lowest High Low

@

50 mA Low High Low

>

@

100 mA Low Slightly Higher Low

Polymer

Electrolytic

b) CAPACITOR SELECTION

low input and output ripple as well as size a 10 µF polymer

electrolytic or ceramic, or 15 µF tantalum capacitor is rec-

i) Output Capacitor (C

The output capacitor C

the output ripple voltage so C

lected. The graphs titled V

Performance Characteristics section show how the ripple

voltage magnitude is affected by the C

capacitor technology. These graphs are taken at the gain at

which worst case ripple is observed. In general, the higher

the value of C

, the lower the output ripple magnitude. At

OUT

lighter loads, the low ESR ceramics offer a much lower V

ripple than the higher ESR tantalums of the same value. At

higher loads, the ceramics offer a slightly lower V

magnitude than the tantalums of the same value. However,

the dv/dt of the V

OUT

electrolytics is much lower than the tantalums under all load

conditions. The tantalums are suggested for very low profile,

small size applications. The ceramics and polymer electrolytics are a good choice for low ripple, low noise applications

where size is less of a concern.

ii) Input Capacitor (C

The input capacitor C

input ripple voltage, and to a lesser degree the V

A higher value C

IN

)

OUT

directly affects the magnitude of

OUT

OUT

should be carefully se-

OUT

Ripple vs. C

OUT

value and the

OUT

in the Typical

OUT

ripple

OUT

ripple with the ceramics and polymer

)

IN

directly affects the magnitude of the

IN

OUT

ripple.

will give a lower VINripple. To optimize

ommended. This will ensure low input ripple at 90 mA load

current. If lower currents will be used or higher input ripple

can be tolerated then a smaller capacitor may be used to

reduce the overall size of the circuit. The lower ESR ceram-

ics and polymer electrolytics achieve a lower V

ripple than

IN

the higher ESR tantalums of the same value. Tantalums

make a good choice for small size, very low profile applica-

tions. The ceramics and polymer electrolytics are a good

choice for low ripple, low noise applications where size is

less of a concern. The 10 µF polymer electrolytics are physi-

cally much larger than the 15 µF tantalums and 10 µF

ceramics.

iii) C

FIL

A 1 µF, X7R ceramic capacitor should be connected to pin

. This capacitor provides the filtering needed for the

C

FIL

internal supply rail of the LM3354.

Of the different capacitor technologies, a sample of vendors

that have been verified as suitable for use with the LM3354

are shown in Table 2.

TABLE 2. Capacitor Vendor Information

Manufacturer Tel Fax Website

Ceramic Taiyo-yuden (408) 573-4150 (408) 573-4159 www.t-yuden.com

AVX (803) 448-9411 (803) 448-1943 www.avxcorp.com

Sprague/Vishay (207) 324-4140 (207) 324-7223 www.vishay.com

Tantalum

Nichicon (847) 843-7500 (847) 843-2798 www.nichicon.com

Polymer Electrolytic Cornell-Dubilier (ESRD) (508) 996-8561 (508) 996-3830 www.cornell-dubilier.com

Sanyo (POSCAP) (619) 661-6322 (619) 661-1055 www.sanyovideo.com

www.national.com 8

Page 9

LM3354-3.7

Maximum Load Under Start-Up

Due to the LM3354’s unique start-up sequence, it is not able

to start up under all load conditions. Starting with 60 mA or

less will allow the part to start correctly under any temperature or input voltage conditions. After the output is in regulation, any load up to the maximum as specified in the

Electrical Characteristics may be applied. Using a Power On

Reset circuit, such as the LP3470, is recommended if

greater start up loads are expected. Under certain conditions

the LM3354 can start up with greater load currents without

the use of a Power On Reset Circuit.

Typical Application Circuits

Thermal Protection

During output short circuit conditions, the LM3354 will draw

high currents causing a rise in the junction temperature.

On-chip thermal protection circuitry disables the charge

pump action once the junction temperature exceeds the

thermal trip point, and re-enables the charge pump when the

junction temperature falls back to a safe operating point.

20057333

FIGURE 2. Basic Buck/Boost Regulator

FIGURE 3. Low Output Noise and Ripple Buck/Boost Regulator

20057315

www.national.com9

Page 10

Typical Application Circuits (Continued)

LM3354-3.7

20057340

FIGURE 4. White LED Driver

Driving Light Emitting Diodes

The LM3354 can be used to drive LED’s of nearly any color.

The 4.1V option is ideal for driving the White LED’s required

for the backlight of small color displays. Figure 4 shows the

circuit used to power White LED’s. The LED current is set by

the resistors R

by using the equation I

B

where VFis the typical forward voltage drop of the LED used.

The brightness of the diodes may be controlled using the

shutdown pin. A PWM signal on the shutdown pin may be

used to adjust the brightness by varying the duty cycle. A

signal between 60Hz and 200Hz may be used for best

linearity. In this case the equivalent LED current is approxi-

= (4.1V − VF)/R

LED

mately equal to the maximum current multiplied by the duty

cycle. Using frequencies above 200Hz may cause less linear

results as the charge and discharge time of the output

capacitor becomes more significant.

B

Layout Considerations

Due to the 1 MHz typical switching frequency of the LM3354,

careful board layout is a must. It is important to place the

capacitors as close to the IC as possible and to keep the

traces between the capacitors and the IC short and direct.

Use of a ground plane is recommended. Figure 5 shows a

typical layout as used in the LM3354 evaluation board.

FIGURE 5. Typical Layout, Top View (magnification 1.5X)

www.national.com 10

20057316

Page 11

Physical Dimensions inches (millimeters)

unless otherwise noted

LM3354-3.7 Regulated 90mA Buck-Boost Switched Capacitor DC/DC Converter

MSOP-10 Pin Package (MM)

For Ordering, Refer to Ordering Information Table

NS Package Number MUB10A

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Corporation

Americas

Email: support@nsc.com

www.national.com

National Semiconductor

Europe

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: ap.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...