Page 1

October 17, 2008

LM3151/LM3152/LM3153

SIMPLE SWITCHER® CONTROLLER, 42V Synchronous

Step-Down

LM3151/LM3152/LM3153 SIMPLE SWITCHER

General Description

The LM3151/2/3 SIMPLE SWITCHER® Controller is an easy

to use and simplified step down power controller capable of

providing up to 12A of output current in a typical application.

Operating with an input voltage range of 6V-42V, the

LM3151/2/3 features a fixed output voltage of 3.3V, and features switching frequencies of 250 kHz, 500 kHz, and 750

kHz. The synchronous architecture provides for highly efficient designs. The LM3151/2/3 controller employs a Constant

On-Time (COT) architecture with a proprietary Emulated Ripple Mode (ERM) control that allows for the use of low ESR

output capacitors, which reduces overall solution size and

output voltage ripple. The Constant On-Time (COT) regulation architecture allows for fast transient response and requires no loop compensation, which reduces external component count and reduces design complexity.

Fault protection features such as thermal shutdown, undervoltage lockout, over-voltage protection, short-circuit protection, current limit, and output voltage pre-bias startup allow for

a reliable and robust solution.

The LM3151/2/3 SIMPLE SWITCHER® concept provides for

an easy to use complete design using a minimum number of

external components and National’s WEBENCH® online design tool. WEBENCH® provides design support for every step

of the design process and includes features such as external

component calculation with a new MOSFET selector, electrical simulation, thermal simulation, and Build-It boards for

prototyping.

Features

PowerWise® step-down controller

■

6V to 42V Wide input voltage range

■

Fixed output voltage of 3.3V

■

Fixed switching frequencies of 250 kHz/500 kHz/750 kHz

■

No loop compensation required

■

Fully WEBENCH® enabled

■

Low external component count

■

Constant On-Time control

■

Ultra-Fast transient response

■

Stable with low ESR capacitors

■

Output voltage pre-bias startup

■

Valley current limit

■

Programmable soft-start

■

Typical Applications

Telecom

■

Networking Equipment

■

Routers

■

Security Surveillance

■

Power Modules

■

®

CONTROLLER, 42V Synchronous Step-Down

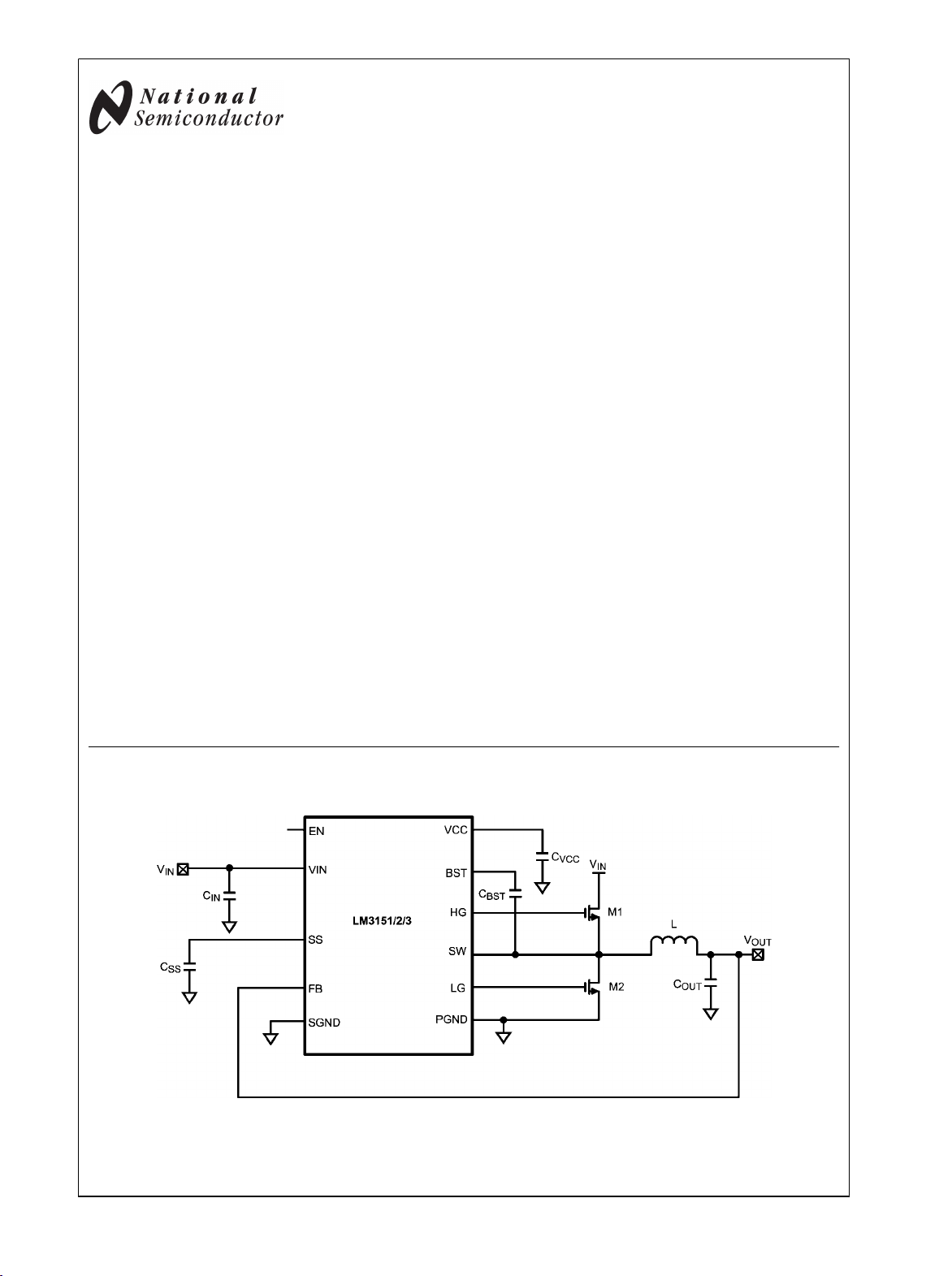

Typical Application

30053201

SIMPLE SWITCHER® is a registered trademark of National Semiconductor Corporation

© 2008 National Semiconductor Corporation 300532 www.national.com

Page 2

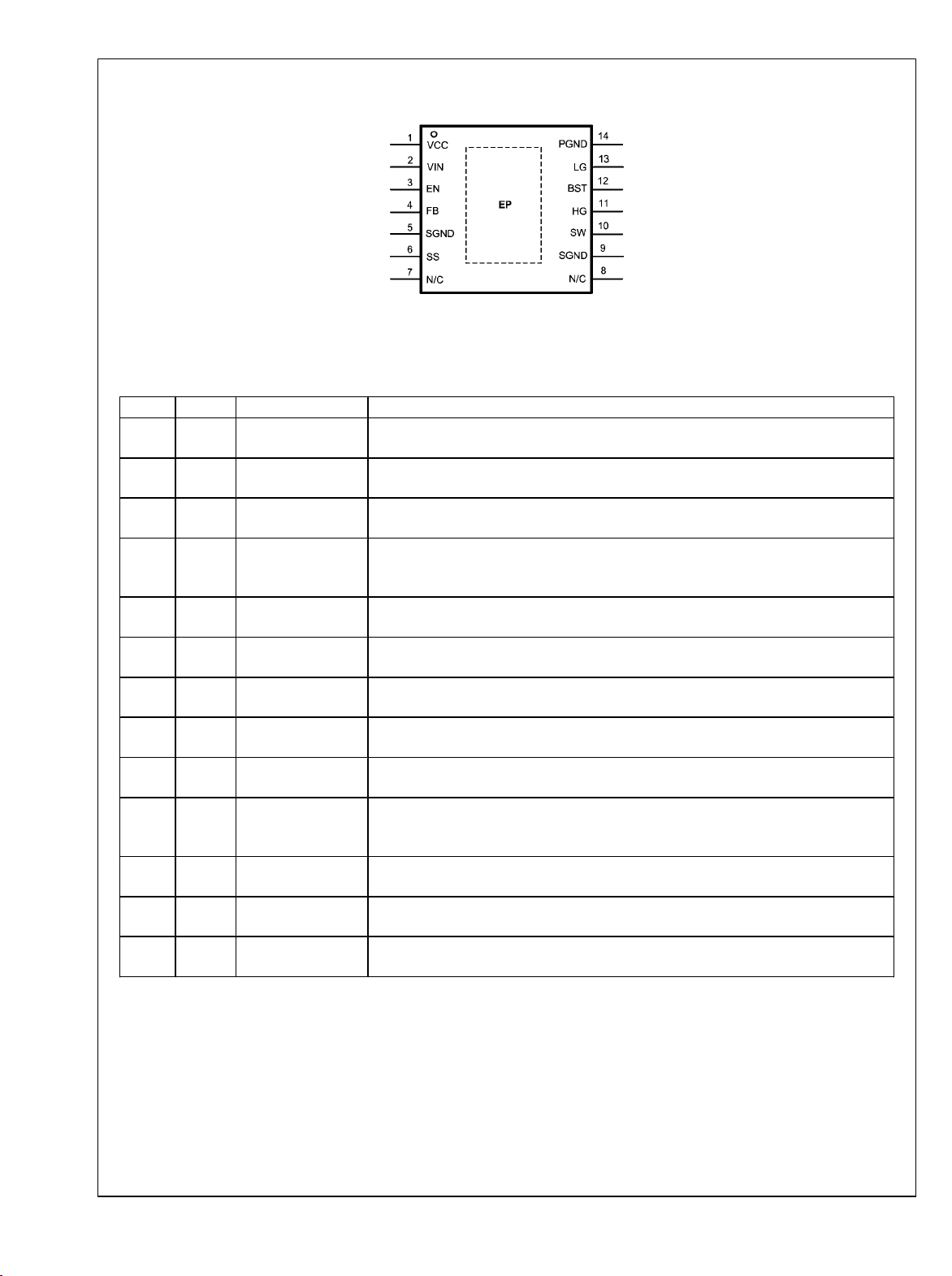

Connection Diagram

LM3151/LM3152/LM3153

Pin Descriptions

Pin Name Description Function

1 VCC

2 VIN Input Supply Voltage

3 EN Enable

4 FB Feedback

5,9 SGND Signal Ground

6 SS Soft-Start

7,8 N/C Not Connected

10 SW Switch Node

11 HG

12 BST

13 LG Low-Side Gate Drive

14 PGND Power Ground

EP EP Exposed Pad

Supply Voltage for

FET Drivers

High-Side Gate

Drive

Connection for

Bootstrap Capacitor

Nominally regulated to 5.95V. Connect a 1 µF to 2.2 µF decoupling capacitor from this

pin to ground.

Supply pin to the device. Nominal input range is 6V to 42V. See ordering information

for Vin limitations.

To enable the IC apply a logic high signal to this pin greater than 1.26V typical or leave

floating. To disable the part, ground the EN pin.

Internally connected to the resistor divider network which sets the fixed output voltage.

This pin also senses the output voltage faults such a over-voltage and short circuit

conditions.

Ground for all internal bias and reference circuitry. Should be connected to PGND at a

single point.

An internal 7.7 µA current source charges an external capacitor to provide the soft-start

function.

Internally not electrically connected. These pins may be left unconnected or connected

to ground.

Switch pin of controller and high-gate driver lower supply rail. A boost capacitor is also

connected between this pin and BST pin

Gate drive signal to the high-side NMOS switch. The high-side gate driver voltage is

supplied by the differential voltage between the BST pin and SW pin.

High-gate driver upper supply rail. Connect a 0.33 µF-0.47 µF capacitor from SW pin to

this pin. An internal diode charges the capacitor during the high-side switch off-time. Do

not connect to an external supply rail.

Gate drive signal to the low-side NMOS switch. The low-side gate driver voltage is

supplied by VCC.

Synchronous rectifier MOSFET source connection. Tie to power ground plane. Should

be tied to SGND at a single point.

Exposed die attach pad should be connected directly to SGND. Also used to help

dissipate heat out of the IC.

eTSSOP-14

30053202

www.national.com 2

Page 3

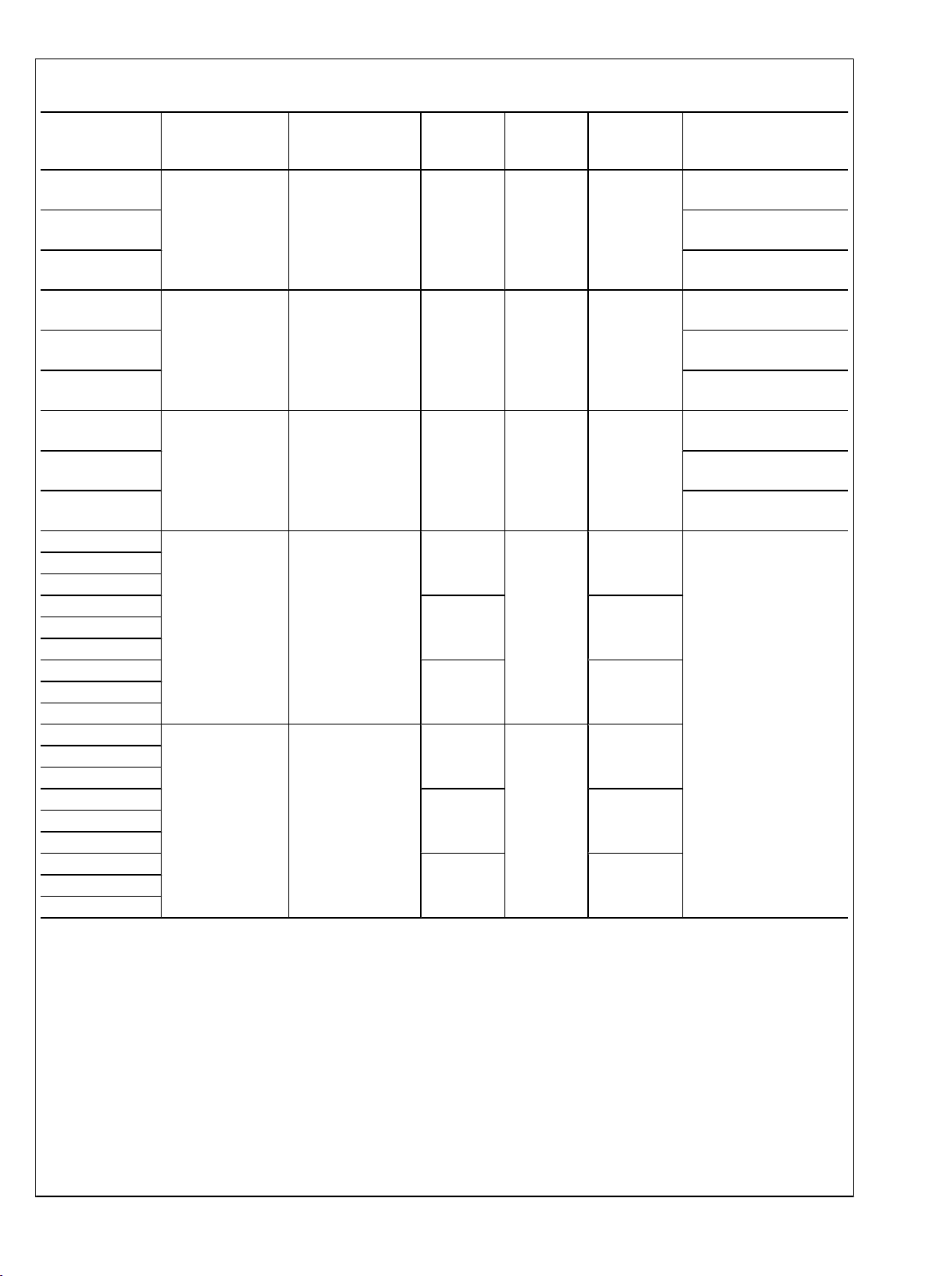

Ordering Information

LM3151/LM3152/LM3153

Order Number Package Type NSC Package

Drawing

LM3151MH-3.3

LM3151MHE-3.3 250 Units in Tape and

LM3151MHX-3.3 2500 Units in Tape and

LM3152MH-3.3

LM3152MHE-3.3 250 Units in Tape and

LM3152MHX-3.3 2500 Units in Tape and

LM3153MH-3.3

LM3153MHE-3.3 250 Units in Tape and

LM3153MHX-3.3 2500 Units in Tape and

LM3151MH-2.5

LM3151MHE-2.5

LM3151MHX-2.5

LM3152MH-2.5

LM3152MHX-2.5

LM3153MH-2.5

LM3153MHX-2.5

LM3151MH-5.0

LM3151MHX-5.0

LM3152MH-5.0

LM3152MHX-5.0

LM3153MH-5.0

LM3153MHX-5.0

eTSSOP-14 MXA14A 6V - 42V 3.3V 250KHz

eTSSOP-14 MXA14A 6V - 33V 3.3V 500KHz

eTSSOP-14 MXA14A 8V - 18V 3.3V 750KHz

eTSSOP-14 MXA14A

eTSSOP-14 MXA14A

Input

Voltage

Range

*

* 500KHzLM3152MHE-2.5

* 750KHzLM3153MHE-2.5

*

* 500KHzLM3152MHE-5.0

* 750KHzLM3153MHE-5.0

Output

Voltage

2.5V

5.0V

Switching

Frequency

250KHz

250KHzLM3151MHE-5.0

Supplied As

94 Units per Anti-Static

Tube

Reel

Reel

94 Units per Anti-Static

Tube

Reel

Reel

94 Units per Anti-Static

Tube

Reel

Reel

*Coming Soon

3 www.national.com

Page 4

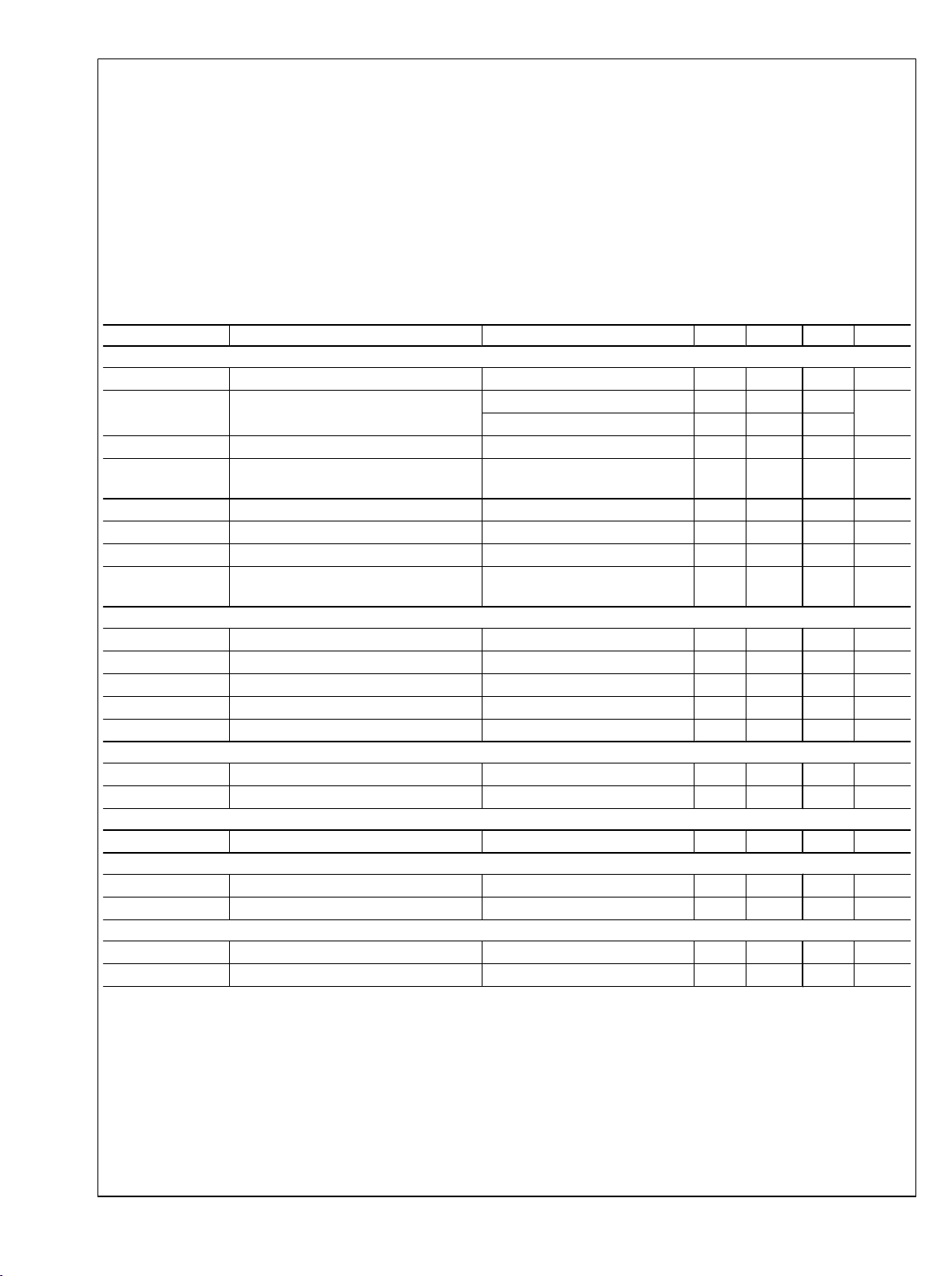

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

All Other Inputs to GND -0.3V to 7V

ESD Rating (Note 2) 2kV

Storage Temperature Range -65°C to +150°C

Distributors for availability and specifications.

VIN to GND -0.3V to 47V

SW to GND -3V to 47V

BST to SW -0.3V to 7V

BST to GND -0.3V to 52V

LM3151/LM3152/LM3153

Electrical Characteristics Limits in standard type are for T

Operating Ratings (Note 1)

V

IN

Junction Temperature Range (TJ)

EN 0V to 5V

= 25°C only; limits in boldface type apply over the

J

−40°C to + 125°C

junction temperature (TJ) range of -40°C to +125°C. Minimum and Maximum limits are guaranteed through test, design, or statistical

correlation. Typical values represent the most likely parametric norm at TJ = 25°C, and are provided for reference purposes only.

Unless otherwise stated the following conditions apply: VIN = 18V.

Symbol Parameter Conditions Min Typ Max Units

Start-Up Regulator, VCC

V

CC

VIN - V

I

VCCL

VCC

UVLO

V

CC-UVLO-HYS

t

CC-UVLO-D

I

IN

I

IN-SD

CC

VIN - VCC Dropout Voltage

VCC Current Limit (Note 3) VCC = 0V 65 100

VCC Under-voltage Lockout threshold

(UVLO)

VCC UVLO Hysteresis

VCC UVLO Filter Delay

Input Operating Current No Switching

Input Operating Current, Device

Shutdown

C

= 1 µF, 0 mA to 40 mA 5.65 5.95 6.25

VCC

I

= 2 mA, Vin = 5.5V 40

VCC

I

= 30 mA, Vin = 5.5V 330

VCC

VCC Increasing

VCC Decreasing

4.75 5.1 5.40

475

3

3.6 5.2

VEN = 0V

32 55

GATE Drive

I

Q-BST

R

DS-HG-Pull-Up

R

DS-HG-Pull-Down

R

DS-LG-Pull-Up

R

DS-LG-Pull-Down

Boost Pin Leakage

HG Drive Pull–Up On-Resistance

HG Drive Pull–Down On-Resistance

LG Drive Pull–Up On-Resistance

LG Drive Pull–Down On-Resistance

V

– VSW = 6V 2

BST

IHG Source = 200 mA 5

IHG Sink = 200 mA 3.4

ILG Source = 200 mA 3.4

ILG Sink = 200 mA 2

Soft-Start

I

SS

I

SS-DIS

SS Pin Source Current

SS Pin Discharge Current

VSS = 0V 5.9 7.7 9.5

200

Current Limit

V

CL

Current Limit Voltage Threshold

175 200 225

ON/OFF Timer

t

ON-MIN

t

OFF

ON Timer Minimum Pulse Width

OFF Timer Minimum Pulse Width

200

370 525

Enable Input

V

V

EN-HYS

EN

EN Pin Input Threshold Trip Point

EN Pin threshold Hysteresis

VEN Rising 1.14 1.20 1.26

VEN Falling 120

6V to 42V

V

mV

mA

V

mV

µs

mA

µA

nA

Ω

Ω

Ω

Ω

mA

µA

mV

ns

ns

V

mV

www.national.com 4

Page 5

Symbol Parameter Conditions Min Typ Max Units

Boost Diode

I

= 2 mA 0.7

V

f

Forward Voltage

BST

I

= 30 mA 1

BST

V

V

Thermal Characteristics

T

SD

θ

JA

Thermal Shutdown Rising 165 °C

Thermal Shutdown Hysteresis Falling 15 °C

Junction to Ambient

4 Layer JEDEC Printed Circuit

Board, 9 Vias, No Air Flow

2 Layer JEDEC Printed Circuit

40

140

°C/W

Board. No Air Flow

θ

JC

Junction to Case No Air Flow

4

°C/W

3.3V Output Option

Symbol Parameter Conditions Min Typ Max Units

V

V

OUT-OV

OUT

Output Voltage

Output Voltage Over-Voltage Threshold

3.234 3.3 3.366

3.83 4.00 4.17

V

V

LM3151-3.3 42

V

IN-MAX

Maximum Input Voltage (Note 4)

VLM3152-3.3 33

LM3153-3.3 18

LM3151-3.3 6

V

IN-MIN

Minimum Input Voltage (Note 4)

VLM3152-3.3 6

LM3153-3.3 8

LM3151-3.3, RON = 115 kΩ

f

S

Switching Frequency

LM3152-3.3, RON = 51 kΩ

LM3153-3.3, RON = 32 kΩ

LM3151-3.3, RON = 115 kΩ

t

ON

On-Time

LM3152-3.3, RON = 51 kΩ

LM3153-3.3, RON = 32 kΩ

R

FB

FB Resistance to Ground

250

500

750

730

400

330

566

kHz

ns

kΩ

LM3151/LM3152/LM3153

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

intended to be functional, but does not guarantee specific performance limits. For guaranteed specifications and conditions, see the Electrical Characteristics.

Note 2: The human body model is a 100 pF capacitor discharged through a 1.5 kΩ resistor into each pin. Test Method is per JESD-22-A114.

Note 3: VCC provides self bias for the internal gate drive and control circuits. Device thermal limitations limit external loading.

Note 4: The input voltage range is dependent on minimum on-time, off-time, and therefore frequency, and is also affected by optimized MOSFET selection.

5 www.national.com

Page 6

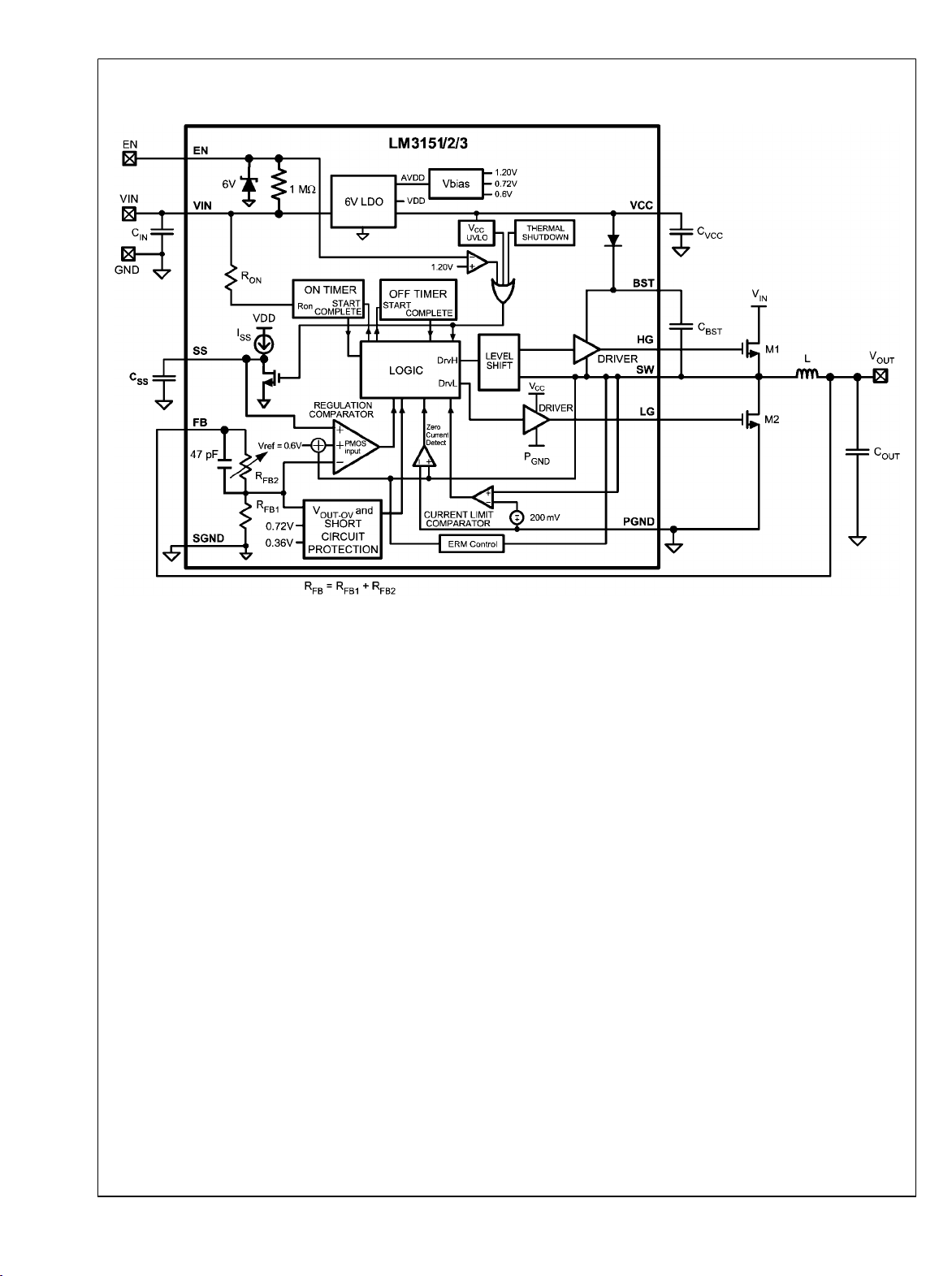

Simplified Block Diagram

LM3151/LM3152/LM3153

30053203

www.national.com 6

Page 7

Typical Performance Characteristics

LM3151/LM3152/LM3153

Boost Diode Forward Voltage vs. Temperature

30053240

Soft-Start Current vs. Temperature

Quiescent Current vs. Temperature

30053242

VCC Current Limit vs. Temperature

VCC Dropout vs. Temperature

30053243

30053248

30053247

VCC vs. Temperature

30053249

7 www.national.com

Page 8

VCL vs. Temperature

LM3151/LM3152/LM3153

On-Time vs. Temperature (250 kHz)

On-Time vs. Temperature (500 kHz)

30053282

30053284

30053283

On-Time vs. Temperature (750 kHz)

30053286

www.national.com 8

Page 9

LM3151/LM3152/LM3153

Theory of Operation

The LM3151/2/3 synchronous step-down SIMPLE SWITCHER® Controller employs a Constant On-Time (COT) architecture which is a derivative of the hysteretic control scheme.

COT relies on a fixed switch on-time to regulate the output.

The on-time of the high-side switch is set internally by resistor

RON. The LM3151/2/3 automatically adjusts the on-time inversely with the input voltage to maintain a constant frequency. Assuming an ideal system and VIN is much greater than

1V, the following approximations can be made:

The on-time, tON:

Where K = 100 pC, and RON is specified in the electrical characteristics table.

Control is based on a comparator and the on-timer, with the

output voltage feedback (FB) attenuated and then compared

with an internal reference of 0.6V. If the attenuated FB level

is below the reference, the high-side switch is turned on for a

fixed time, tON, which is determined by the input voltage and

the internal resistor, RON. Following this on-time, the switch

remains off for a minimum off-time, t

Electrical Characteristics table or until the attenuated FB voltage is less than 0.6V. This switching cycle will continue while

maintaining regulation. During continuous conduction mode

(CCM), the switching frequency depends only on duty cycle

and on-time. The duty cycle can be calculated as:

, as specified in the

OFF

1) Minimum off time as specified in the electrical characteristics table

2) The error comparator sampled voltage falls below 0.6V

Over-Voltage Comparator

The over-voltage comparator is provided to protect the output

from over-voltage conditions due to sudden input line voltage

changes or output loading changes. The over-voltage comparator continuously monitors the attenuated FB voltage versus a 0.72V internal reference. If the voltage at FB rises above

0.72V the on-time pulse is immediately terminated. This condition can occur if the input or the output load changes suddenly. Once the over-voltage protection is activated, the HG

and LG signals remain off until the attenuated FB voltage falls

below 0.72V.

Current Limit

Current limit detection occurs during the off-time by monitoring the current through the low-side switch. If during the offtime the current in the low-side switch exceeds the user

defined current limit value, the next on-time cycle is immediately terminated. Current sensing is achieved by comparing

the voltage across the low-side switch against an internal reference value, VCL, of 200 mV. If the voltage across the lowside switch exceeds 200 mV, the current limit comparator will

trigger logic to terminate the next on-time cycle. The current

limit ICL, can be determined as follows:

Where the switching frequency of a COT regulator is:

Typical COT hysteretic controllers need a significant amount

of output capacitor ESR to maintain a minimum amount of

ripple at the FB pin in order to switch properly and maintain

efficient regulation. The LM3151/2/3 however utilizes proprietary, Emulated Ripple Mode Control Scheme (ERM) that

allows the use of ceramic output capacitors without additional

equivalent series resistance (ESR) compensation. Not only

does this reduce the need for output capacitor ESR, but also

significantly reduces the amount of output voltage ripple seen

in a typical hysteretic control scheme. The output ripple voltage can become so low that it is comparable to voltage-mode

and current-mode control schemes.

Regulation Comparator

The output voltage is sampled through the FB pin and then

divided down by two internal resistors and compared to the

internal reference voltage of 0.6V by the error comparator. In

normal operation, an on-time period is initiated when the sampled output voltage at the input of the error comparator falls

below 0.6V. The high-side switch stays on for the specified

on-time, causing the sampled voltage on the error comparator

input to rise above 0.6V. After the on-time period, the highside switch stays off for the greater of the following:

Where I

value, R

at the expected maximum FET junction temperature, VCL is

the internal current limit reference voltage and Tj is the junction temperature of the LM3151/2/3.

Figure 1 illustrates the inductor current waveform. During normal operation, the output current ripple is dictated by the

switching of the FETs. The current through the low-side

switch, I

and compared to the current limit threshold voltage, VCL. The

valley current can be calculated as follows:

Where I

to-peak inductor ripple current.

If an overload condition occurs, the current through the lowside switch will increase which will cause the current limit

comparator to trigger the logic to skip the next on-time cycle.

The IC will then try to recover by checking the valley current

during each off-time. If the valley current is greater than or

equal to ICL, then the IC will keep the low-side FET on and

allow the inductor current to further decay.

Throughout the whole process, regardless of the load current,

the on-time of the controller will stay constant and thereby the

positive ripple current slope will remain constant. During each

on-time the current ramps up an amount equal to:

is the user-defined average output current limit

OCL

DS(ON)max

valley

OUT

is the resistance value of the low-side FET

, is sampled at the end of each switching cycle

is the average output current and ΔIL is the peak-

9 www.national.com

Page 10

The valley current limit feature prevents current runaway conditions due to propagation delays or inductor saturation since

LM3151/LM3152/LM3153

FIGURE 1. Inductor Current - Current Limit Operation

the inductor current is forced to decay following any overload

conditions.

30053212

Short-Circuit Protection

The LM3151/2/3 will sense a short-circuit on the output by

monitoring the output voltage. When the attenuated feedback

voltage has fallen below 60% of the reference voltage, V

0.6 (≈ 0.36V), short-circuit mode of operation will start. During

ref

short-circuit operation, the SS pin is discharged and the output voltage will fall to 0V. The SS pin voltage, VSS, is then

ramped back up at the rate determined by the SS capacitor

and ISS until VSS reaches 0.7V. During this re-ramp phase, if

the short-circuit fault is still present the output current will be

equal to the set current limit. Once the soft-start voltage

reaches 0.7V the output voltage is sensed again and if the

attenuated VFB is still below V

charged again and the cycle repeats until the short-circuit fault

x 0.6 then the SS pin is dis-

ref

is removed.

Soft-Start

The soft-start (SS) feature allows the regulator to gradually

reach a steady-state operating point, which reduces start-up

stresses and current surges. At turn-on, while VCC is below

the under-voltage threshold, the SS pin is internally grounded

and V

ramp VFB from 0V to it's final output voltage as programmed

by the internal resistor divider. By changing the soft-start capacitor value, the duration of start-up can be changed accordingly. The start-up time can be calculated using the

following equation:

Where tSS is measured in seconds, V

soft-start pin source current, which is typically 7.7 µA (refer to

electrical characteristics table).

is held at 0V. The SS capacitor is used to slowly

OUT

= 0.6V and ISS is the

ref

An internal switch grounds the SS pin if VCC is below the

under-voltage lockout threshold, if a thermal shutdown occurs, or if the EN pin is grounded. By using an externally

controlled switch, the output voltage can be shut off by

x

grounding the SS pin.

During startup the LM3151/2/3 will operate in diode emulation

mode, where the low-side gate LG will turn off and remain off

when the inductor current falls to zero. Diode emulation mode

allows for start up into a pre-biased output voltage. When softstart is greater than 0.7V, the LM3151/2/3 will remain in

continuous conduction mode. During diode emulation mode

at current limit the low-gate will remain off when the inductor

current is off.

The soft start time should be greater than the rise time specified by,

tSS ≥ (V

OUT

x C

OUT

) / (I

OCL

- I

OUT

)

Enable/Shutdown

The EN pin can be activated by either leaving the pin floating

due to an internal pull up resistor to VIN or by applying a logic

high signal to the EN pin of 1.26V or greater. The LM3151/2/3

can be remotely shut down by taking the EN pin below 1.02V.

Low quiescent shutdown is achieved when VEN is less than

0.4V. During low quiescent shutdown the internal bias circuitry is turned off.

The LM3151/2/3 has certain fault conditions that can trigger

shutdown, such as over-voltage protection, current limit, under-voltage lockout, or thermal shutdown. During shutdown,

the soft-start capacitor is discharged. Once the fault condition

is removed, the soft-start capacitor begins charging, allowing

the part to start up in a controlled fashion. In conditions where

there may be an open drain connection to the EN pin, it may

be necessary to add a 1000 pF bypass capacitor to this pin.

This will help decouple noise from the EN pin and prevent

false disabling.

www.national.com 10

Page 11

LM3151/LM3152/LM3153

Thermal Protection

The LM3151/2/3 should be operated such that the junction

temperature does not exceed the maximum operating junction temperature. An internal thermal shutdown circuit, which

activates at 165°C (typical), takes the controller to a low-power reset state by disabling the buck switch and the on-timer,

and grounding the SS pin. This feature helps prevent catastrophic failures from accidental device overheating. When the

junction temperature falls back below 150°C the SS pin is released and normal operation resumes.

Design Guide

The design guide provides the equations required to design

with the LM3151/2/3 SIMPLE SWITCHER® Controller.

WEBENCH® design tool can be used with or in place of this

section for a more complete and simplified design process.

1. Define Power Supply Operating Conditions

a. Maximum and Minimum DC Input voltage

b. Maximum Expected Load Current during normal operation

c. Target Switching Frequency

2. Determine which IC Controller to Use

The desired input voltage range will determine which version

of the LM3151/2/3 controller will be chosen. The higher

switching frequency options allow for physically smaller inductors but efficiency may decrease.

3. Determine Inductor Required Using Figure 2

To use the nomograph below calculate the inductor volt-microsecond constant ET from the following formula:

Where fS is in kHz units. The intersection of the Load Current

and the Volt-microseconds lines on the chart below will determine which inductors are capable for use in the design. The

chart shows a sample of parts that can be used. The offline

calculator tools and WEBENCH® will fully calculate the requirements for the components needed for the design.

FIGURE 2. Inductor Nomograph

11 www.national.com

30053252

Page 12

TABLE 1. Inductor Selection Table

Inductor Designator Inductance (µH) Current (A) Part Name Vendor

L01 47 7-9

L02 33 7-9 SER2817H-333KL COILCRAFT

L03 22 7-9 SER2814H-223KL COILCRAFT

L04 15 7-9 7447709150 WURTH

L05 10 7-9 RLF12560T-100M7R5 TDK

LM3151/LM3152/LM3153

L06 6.8 7-9 B82477-G4682-M EPCOS

L07 4.7 7-9 B82477-G4472-M EPCOS

L08 3.3 7-9 DR1050-3R3-R COOPER

L09 2.2 7-9 MSS1048-222 COILCRAFT

L10 1.5 7-9 SRU1048-1R5Y BOURNS

L11 1 7-9 DO3316P-102 COILCRAFT

L12 0.68 7-9 DO3316H-681 COILCRAFT

L13 33 9-12

L14 22 9-12 SER2918H-223 COILCRAFT

L15 15 9-12 SER2814H-153KL COILCRAFT

L16 10 9-12 7447709100 WURTH

L17 6.8 9-12 SPT50H-652 COILCRAFT

L18 4.7 9-12 SER1360-472 COILCRAFT

L19 3.3 9-12 MSS1260-332 COILCRAFT

L20 2.2 9-12 DR1050-2R2-R COOPER

L21 1.5 9-12 DR1050-1R5-R COOPER

L22 1 9-12 DO3316H-102 COILCRAFT

L23 0.68 9-12

L24 0.47 9-12

L25 22 12-15 SER2817H-223KL COILCRAFT

L26 15 12-15

L27 10 12-15 SER2814L-103KL COILCRAFT

L28 6.8 12-15 7447709006 WURTH

L29 4.7 12-15 7447709004 WURTH

L30 3.3 12-15

L31 2.2 12-15

L32 1.5 12-15 MLC1245-152 COILCRAFT

L33 1 12-15

L34 0.68 12-15 DO3316H-681 COILCRAFT

L35 0.47 12-15

L36 0.33 12-15 DR73-R33-R COOPER

L37 22 15-

L38 15 15- SER2817H-153KL COILCRAFT

L39 10 15- SER2814H-103KL COILCRAFT

L40 6.8 15-

L41 4.7 15- SER2013-472ML COILCRAFT

L42 3.3 15- SER2013-362L COILCRAFT

L43 2.2 15-

L44 1.5 15- HA3778-AL COILCRAFT

L45 1 15- B82477-G4102-M EPCOS

L46 0.68 15-

L47 0.47 15-

L48 0.33 15-

www.national.com 12

Page 13

4. Determine Output Capacitance

Typical hysteretic COT converters similar to the LM3151/2/3

require a certain amount of ripple that is generated across the

ESR of the output capacitor and fed back to the error comparator. Emulated Ripple Mode control built into the

LM3151/2/3 will recreate a similar ripple signal and thus the

requirement for output capacitor ESR will decrease compared

to a typical Hysteretic COT converter. The emulated ripple is

generated by sensing the voltage signal across the low-side

FET and is then compared to the FB voltage at the error comparator input to determine when to initiate the next on-time

period.

2

C

Omin

= 70 / (f

s

x L)

The maximum ESR allowed to prevent over-voltage protection during normal operation is:

ESR

= (80 mV x L) / ET

ET

is calculated using V

min

max

IN-MIN

min

The minimum ESR must meet both of the following criteria:

ESR

≥ (15 mV x L) / ET

ESR

ET

is calculated using V

max

min

min

≥ [ET

/ (VIN - V

max

IN-MAX

.

OUT

max

)]/ C

O

Any additional parallel capacitors should be chosen so that

their effective impedance will not negatively attenuate the

output ripple voltage.

5. MOSFET Selection

The high-side and low-side FETs must have a drain to source

(VDS) rating of at least 1.2 x VIN.

The gate drive current from VCC must not exceed the minimum current limit of VCC. The drive current from VCC can be

calculated with:

I

VCCdrive

Where, Q

side and low-side FETs.

is the combined total gate charge of the high-

gtotal

= Q

gtotal

x f

S

Use the following equations to calculate the current limit, ICL,

as shown in Figure 1.

Tj is the junction temperature of the LM3151/2/3.

The plateau voltage of the FET VGS vs Qg curve, as shown in

Figure 3 must be less than VCC - 750 mV.

30053281

FIGURE 3. Typical MOSFET Gate Charge Curve

See following design example for estimated power dissipation

calculation.

6. Calculate Input Capacitance

The main parameters for the input capacitor are the voltage

rating, which must be greater than or equal to the maximum

DC input voltage of the power supply, and its rms current rating. The maximum rms current is approximately 50% of the

maximum load current.

Where, ΔV

age. A good starting point for the input ripple voltage is 5% of

is the maximum allowable input ripple volt-

IN-MAX

VIN.

When using low ESR ceramic capacitors on the input of the

LM3151/2/3 a resonant circuit can be formed with the

impedance of the input power supply and parasitic impedance

of long leads/PCB traces to the LM3151/2/3 input capacitors.

It is recommended to use a damping capacitor under these

circumstances, such as aluminum electrolytic that will prevent

ringing on the input. The damping capacitor should be chosen

to be approximately 5 times greater than the parallel ceramic

capacitors combination. The total input capacitance should

be greater than 10 times the input inductance of the power

supply leads/pcb trace. The damping capacitor should also

be chosen to handle its share of the rms input current which

is shared proportionately with the parallel impedance of the

ceramic capacitors and aluminum electrolytic at the

LM3151/2/3 switching frequency.

The C

The recommended value is 0.1 µF.

capacitor should be placed directly at the VIN pin.

BYP

7. Calculate Soft-Start Capacitor

LM3151/LM3152/LM3153

Where tSS is the soft-start time in seconds and V

13 www.national.com

= 0.6V.

ref

Page 14

8. C

, and C

VCC

C

should be placed directly at the VCC pin with a recom-

VCC

mended value of 1 µF to 2.2 µF. For input voltage ranges that

BST

and C

EN

include voltages below 8V a 1 µF capacitor must be used for

C

. C

VCC

creates a voltage used to drive the gate of the

BST

Design Example

LM3151/LM3152/LM3153

high-side FET. It is charged during the SW off-time. The recommended value for C

itor, CEN, recommended value is 1000 pF when driving the EN

is 0.47 µF. The EN bypass capac-

BST

pin from open drain type of signal.

30053261

FIGURE 4. Design Example Schematic

1. Define Power Supply Operating Conditions

a. V

= 3.3V

OUT

b. V

IN-MIN

= 6V, V

IN-TYP

= 12V, V

IN-MAX

= 24V

c. Typical Load Current = 12A, Max Load Current = 15A

d. Soft-Start time tSS = 5 ms

2. Determine which IC Controller to Use

The LM3151 and LM3152 allow for the full input voltage

range. However, from buck converter basic theory, the higher

switching frequency will allow for a smaller inductor. Therefore, the LM3152-3.3 500 kHz part is chosen so that a smaller

inductor can be used.

3. Determine Inductor Required

a. ET = (24-3.3) x (3.3/24) x (1000/500) = 5.7 V µs

b. From the inductor nomograph a 12A load and 5.7 V µs calculation corresponds to a L44 type of inductor.

c. Using the inductor designator L44 in Table 1 the Coilcraft

HA3778-AL 1.65 µH inductor is chosen.

4. Determine Output Capacitance

The voltage rating on the output capacitor should be greater

than or equal to the output voltage. As a rule of thumb most

capacitor manufacturers suggests not to exceed 90% of the

capacitor rated voltage. In the case of multilayer ceramics the

capacitance will tend to decrease dramatically as the applied

voltage is increased towards the capacitor rated voltage. The

capacitance can decrease by as much as 50% when the applied voltage is only 30% of the rated voltage. The chosen

capacitor should also be able to handle the rms current which

is equal to:

For this design the chosen ripple current ratio, r = 0.3, represents the ratio of inductor peak-to-peak current to load current

Iout. A good starting point for ripple ratio is 0.3 but it is acceptable to choose r between 0.25 to 0.5. The nomographs

in this datasheet all use 0.3 as the ripple current ratio.

I

= 1A

rmsco

tON = (3.3V/12V) / 500 kHz = 550 ns

Minimum output capacitance is:

2

C

= 70 / (f

Omin

C

= 70 / (500 kHz2 x 1.65 µH) = 169 µF

Omin

S

x L)

The maximum ESR allowed to prevent over-voltage protection during normal operation is:

ESR

= (80 mV x L) / ET

max

ESR

= (80 mV x 1.65 µH) / 5.7 V µs

max

ESR

= 23 mΩ

max

The minimum ESR must meet both of the following criteria:

ESR

≥ (15 mV x L) / ET

min

www.national.com 14

Page 15

LM3151/LM3152/LM3153

ESR

≥ [ET / (VIN - V

min

ESR

≥ (15 mV x 1.65 µH) / 5.7 V µs = 4.3 mΩ

min

ESR

≥ [5.7 V µs / (12 - 3.3)] / 169 µF = 3.9 mΩ

min

OUT

)] / C

O

Based on the above criteria two 150 µF polymer aluminum

capacitors with a ESR = 12 mΩ each for a effective ESR in

parallel of 6 mΩ was chosen from Panasonic. The part number is EEF-UE0J151P.

5. MOSFET Selection

The LM3151/2/3 are designed to drive N-channel MOSFETs.

For a maximum input voltage of 24V we should choose Nchannel MOSFETs with a maximum drain-source voltage,

VDS, greater than 1.2 x 24V = 28.8V. FETs with maximum

VDS of 30V will be the first option. The combined total gate

charge Q

the following:

Where I

temperature range, specified in the electrical characteristics

of the high-side and low-side FET should satisfy

gtotal

Q

≤ I

gtotal

Q

≤ 65 mA / 500 kHz

gtotal

Q

gtotal

is the minimum current limit of VCC, over the

VCCL

/ f

VCCL

≤ 130 nC

s

table. The MOSFET gate charge Qg is gathered from reading

the VGS vs Qg curve of the MOSFET datasheet at the VGS =

5V for the high-side, M1, MOSFET and VGS = 6V for the lowside, M2, MOSFET.

The Renesas MOSFET RJK0305DPB has a gate charge of

10 nC at VGS = 5V, and 12 nC at VGS = 6V. This combined

gate charge for a high-side, M1, and low-side, M2, MOSFET

12 nC + 10 nC = 22 nC is less than 130 nC calculated

Q

.

gtotal

The calculated MOSFET power dissipation must be less than

the max allowed power dissipation, Pdmax, as specified in the

MOSFET datasheet. An approximate calculation of the FET

power dissipated Pd, of the high-side and low-side FET is

given by:

High-Side MOSFET

tion temperature rise above ambient temperature and θJA =

30°C/W, can be estimated by:

Pdmax = 125°C / 30°C/W = 4.1W

The system calculated Pdh of 0.674W is much less than the

FET Pdmax of 4.1W and therefore the RJK0305DPB max allowable power dissipation criteria is met.

Low-Side MOSFET

Primary loss is conduction loss given by:

Pdl = Iout2 x R

x (1-D) = 122 x 0.01 x (1-0.275) = 1W

DS(ON)

Pdl is also less than the Pdmax specified on the RJK0305DPB

MOSFET datasheet.

However, it is not always necessary to use the same MOSFET for both the high-side and low-side. For most applications

it is necessary to choose the high-side MOSFET with the lowest gate charge and the low-side MOSFET is chosen for the

lowest allowed R

vs Qg curve must be less than VCC - 750 mV.

The current limit, I

of the low-side FET at the maximum junction temperature

(ON)

of 100°C. Then the following calculation of I

. The plateau voltage of the FET V

DS(ON)

, is calculated by estimating the R

OCL

OCL

I

= ICL + ΔIL / 2

OCL

GS

DS

is:

ICL = 200 mV / 0.014 = 14.2A

I

= 14.2A + 3.6 / 2 = 16A

OCL

6. Calculate Input Capacitance

The input capacitor should be chosen so that the voltage rating is greater than the maximum input voltage which for this

example is 24V. Similar to the output capacitor, the voltage

rating needed will depend on the type of capacitor chosen.

The input capacitor should also be able to handle the input

rms current which is approximately 0.5 x I

ple the rms input current is approximately 0.5 x 12A = 6A.

. For this exam-

OUT

The minimum capacitance with a maximum 5% input ripple

ΔV

= (0.05 x 12) = 0.6V:

IN-MAX

CIN = [12 x 0.275 x (1-0.275)] / [500 kHz x 0.6] = 8 µF

To handle the large input rms current 2 ceramic capacitors

are chosen at 10 µF each with a voltage rating of 50V and

case size of 1210, that can handle 3A of rms current each. A

100 µF aluminum electrolytic is chosen to help dampen input

ringing.

C

= 0.1 µF ceramic with a voltage rating greater than max-

BYP

imum V

IN

7. Calculate Soft-Start Capacitor

The soft start-time should be greater than the input voltage

rise time and also satisfy the following equality to maintain a

smooth transition of the output voltage to the programmed

regulation voltage during startup.

The max power dissipation of the RJK0305DPB is rated as

45W for a junction temperature that is 125°C higher than the

case temperature and a thermal resistance from the FET

junction to case, θJC, of 2.78°C/W. When the FET is mounted

onto the PCB, the PCB will have some additional thermal resistance such that the total system thermal resistance of the

FET package and the PCB, θJA, is typically in the range of 30°

C/W for this type of FET package. The max power dissipation,

Pdmax, with the FET mounted onto a PCB with a 125°C junc-

tSS ≥ (V

OUT

x C

OUT

) / (I

OCL

- I

OUT

)

5 ms > (3.3V x 300 µF) / (1.2 x 12A - 12A)

5 ms > 0.412 ms

The desired soft-start time, tSS, of 5 ms satisfies the equality

as shown above. Therefore, the soft-start capacitor, CSS, is

calculated as:

CSS = (7.7 µA x 5 ms) / 0.6V = 0.064 µF

15 www.national.com

Page 16

Let CSS = 0.068 µF, which is the next closest standard value.

This should be a ceramic cap with a voltage rating greater

than 10V.

Bill of Materials

Designator Value Parameters Manufacturer Part Number

C

C

C

IN2

OUT1

BST

C

BYP

C

EN

C

IN1

, C

IN3

, C

OUT2

C

SS

C

VCC

LM3151/LM3152/LM3153

L1 1.65 µH

M1, M2 30V

U1 National Semiconductor LM3152MH-3.3

0.47 µF Ceramic, X7R, 16V, 10% TDK C2012X7R1C474K

0.1 µF Ceramic, X7R, 50V, 10% TDK C2012X7R1H104K

1000 pF Ceramic, X7R, 50V, 10% TDK C1608X7R1H102K

100 µF AL, EEV-FK, 63V, 20% Panasonic EEV-FK1J101P

10 µF Ceramic, X5R, 35V, 10% Taiyo Yuden GMK325BJ106KN-T

150 µF AL, UE, 6.3V, 20% Panasonic EEF-UE0J151R

0.068 µF Ceramic, 16V, 10% 0603YC683KAT2A

1 µF Ceramic, X7R, 16V, 10% Kemet C0805C105K4RACTU

Shielded Drum Core, A, 2.53 mΩ

8 nC, R

@4.5V = 10 mΩ

DS(ON)

8. C

, CEN, and C

VCC

C

= 1µF ceramic with a voltage rating greater than 10V

VCC

BST

CEN = 1000 pF ceramic with a voltage rating greater than 10V

C

= 0.47 µF ceramic with a voltage rating greater than 10V

BST

Coilcraft Inc. HA3778-AL

Renesas RJK0305DB

www.national.com 16

Page 17

PCB Layout Considerations

It is good practice to layout the power components first, such

as the input and output capacitors, FETs, and inductor. The

first priority is to make the loop between the input capacitors

and the source of the low side FET to be very small and tie

the grounds of each directly to each other and then to the

ground plane through vias. As shown in the figure below,

when the input cap ground is tied directly to the source of the

low side FET, parasitic inductance in the power path, along

with noise coupled into the ground plane, are reduced.

The switch node is the next item of importance. The switch

node should be made only as large as required to handle the

load current. There are fast voltage transitions occurring in

the switch node at a high frequency, and if the switch node is

made too large it may act as an antennae and couple switching noise into other parts of the circuit. For high power designs

it is recommended to use a multi-layer board. The FET’s are

going to be the largest heat generating devices in the design,

and as such, care should be taken to remove the heat. On

multi layer boards using exposed-pad packages for the FET’s

such as the power-pak SO-8, vias should be used under the

FETs to the same plane on the interior layers to help dissipate

the heat and cool the FETs. For the typical single FET PowerPak type FETs the high-side FET DAP is Vin. The Vin plane

should be copied to the other interior layers to the bottom layer

for maximum heat dissipation. Likewise, the DAP of the lowside FET is connected to the SW node and it’s shape should

be duplicated to the interior layers down to the bottom layer

for maximum heat dissipation.

See the Evaluation Board application note AN-1900 for an

example of a typical multilayer board layout, and the Demonstration Board Reference Design App Note for a typical 2 layer

board layout. Each design allows for single sided component

mounting.

LM3151/LM3152/LM3153

30053258

FIGURE 5. Schematic of Parasitics

30053280

FIGURE 6. PCB Placement of Power Stage

17 www.national.com

Page 18

Physical Dimensions inches (millimeters) unless otherwise noted

LM3151/LM3152/LM3153

14-Lead eTSSOP Package

NS Package Number MXA14A

www.national.com 18

Page 19

Notes

LM3151/LM3152/LM3153

19 www.national.com

Page 20

Notes

For more National Semiconductor product information and proven design tools, visit the following Web sites at:

Products Design Support

Amplifiers www.national.com/amplifiers WEBENCH www.national.com/webench

Audio www.national.com/audio Analog University www.national.com/AU

Clock Conditioners www.national.com/timing App Notes www.national.com/appnotes

Data Converters www.national.com/adc Distributors www.national.com/contacts

Displays www.national.com/displays Green Compliance www.national.com/quality/green

Ethernet www.national.com/ethernet Packaging www.national.com/packaging

Interface www.national.com/interface Quality and Reliability www.national.com/quality

LVDS www.national.com/lvds Reference Designs www.national.com/refdesigns

Power Management www.national.com/power Feedback www.national.com/feedback

Switching Regulators www.national.com/switchers

LDOs www.national.com/ldo

LED Lighting www.national.com/led

PowerWise www.national.com/powerwise

Serial Digital Interface (SDI) www.national.com/sdi

Temperature Sensors www.national.com/tempsensors

Wireless (PLL/VCO) www.national.com/wireless

CONTROLLER, 42V Synchronous Step-Down

®

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2008 National Semiconductor Corporation

For the most current product information visit us at www.national.com

National Semiconductor

LM3151/LM3152/LM3153 SIMPLE SWITCHER

www.national.com

Americas Technical

Support Center

Email: support@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Technical Support Center

Email: europe.support@nsc.com

German Tel: +49 (0) 180 5010 771

English Tel: +44 (0) 870 850 4288

National Semiconductor Asia

Pacific Technical Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Technical Support Center

Email: jpn.feedback@nsc.com

Loading...

Loading...