Page 1

LM2853 Evaluation Board

Introduction

The LM2853 synchronous SIMPLE SWITCHER®buck regulator is a synchronous switching regulator capable of delivering up to 3A of current into a load. The LM2853 represents

the ultimate in ease of use, as internal type-3 compensation

minimizes the necessary external components and eases

the selection of those components. The LM2853 is capable

of accepting an input voltage between 3.0V and 5.5V and

delivering an output voltage that is factory programmable

from 0.8V to 3.3V in 100mV increments. The nominal switching frequency of the LM2853 is 550 kHz.

The LM2853 Evaluation Board was designed to accommodate three standard output voltage options (1.2V/1.8V/3.3V)

using the same layout and external components. Just five

external components are included on the board, and the

entire 3A power supply occupies a minimum amount of

space (1.2” by 0.82”) on a two layer PCB without sacrificing

efficiency or performance. The input voltage can be varied

over the entire operating range of the LM2853 (3.0V to 5.5V)

for testing purposes. Also, the board is designed to be stable

with all standard LM2853 voltage options, so if another

voltage option needs to be tested, the LM2853 IC can be

removed and replaced with the desired option.

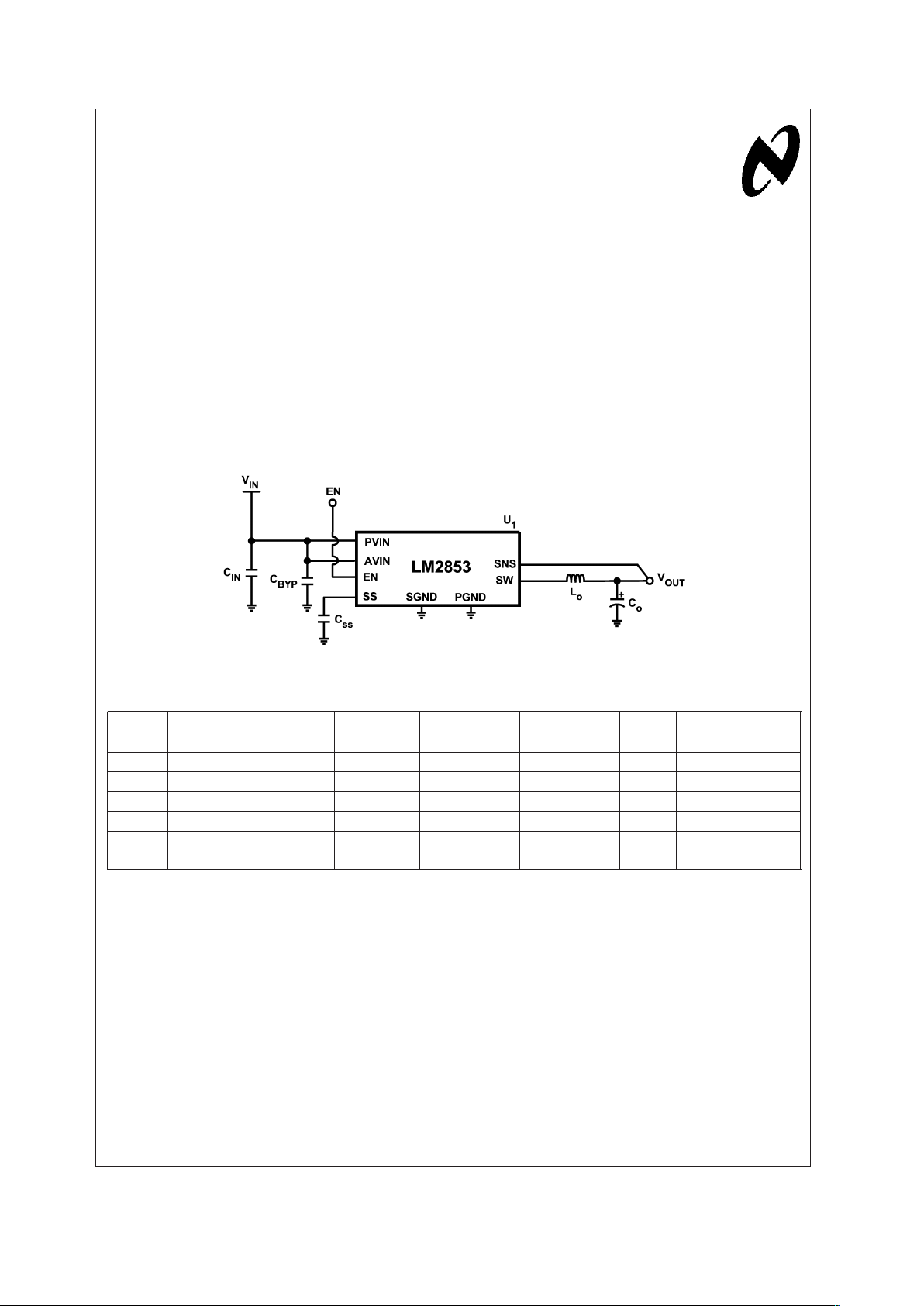

Schematic

20201803

Bill Of Material

ID Part Number Type Size Parameters QTY Vendor

U1 LM2853MH-x.x/NOPB 3A Buck ETSSOP-14 x.xV 1 NSC

C

IN

GRM31CR60J476ME19 Capacitor 1206 47 µF 1 Murata

C

BYP

GRM21BR71C105KA01 Capacitor 0805 1 µF 1 Murata

C

SS

VJ0805Y222KXXA Capacitor 0603 2.2 nF 1 Vishay-Vitramon

L

O

DO3316P-472 Inductor DO3316P 4.7 µH 1 Coilcraft

C

O

TPSD227X06R0050 Capacitor D Case 220 µF

(50 mΩ)

1 Vishay-Sprague

National Semiconductor

Application Note 1513

Jeff Kissinger

October 2006

LM2853 Evaluation Board AN-1513

© 2006 National Semiconductor Corporation AN202018 www.national.com

Page 2

Performance

Efficiency vs. I

LOAD(VIN

= 5V)

20201802

0.5A to 3A Load Step Response (VIN= 5V, V

OUT

= 1.8V)

20201805

Horizontal Resolution: 200 µs/Div.

Trace 1: V

OUT

(100 mV/Div.)

Trace 2: I

LOAD

(1 A /Div.)

Component Selection

CINand C

BYP

The necessary RMS current rating of the input capacitor can

be estimated by the following equation:

where the variable D refers to the duty cycle, and can be

approximated by:

From this equation, it follows that the maximum I

RMS

will

occur at a full 3A load current with the system operating at

50% duty cycle. Under this condition, the maximum I

RMS

is

given by:

Ceramic capacitors feature a very large I

RMS

rating in a small

footprint, making a ceramic capacitor ideal for this application. A 47 µF ceramic capacitor from Murata with a 4.9A I

RMS

rating provides the necessary input capacitance for the

evaluation board. For improved load regulation and transient

performance, an extra 1 µF ceramic capacitor is placed near

to the AVIN pin from V

IN

to GND. This small capacitor helps

to filter high frequency noise pulses on the supply, and

prevent those pulses from disturbing the analog control circuitry of the chip.

C

SS

The soft-start capacitor has been chosen to provide a softstart time of roughly 3 ms. Using the internal soft-start resistance of 450 kΩ and the external soft-start capacitor value of

2.2 nF, the approximate soft-start time can be calculated as

follows:

T

SS

=3xCSSxRSS=

3 x 2.2 nF x 450 kΩ = 2.97 ms ≈ 3ms

A 3 ms soft-start time will allow the LM2853 to start up

gracefully without triggering over-current protection, regardless of the operating conditions.

AN-1513

www.national.com 2

Page 3

Component Selection (Continued)

L

O

and C

O

The selection of the output filter components LOand CO, are

intrinsically linked, as both of these parameters affect the

stability of the system, and various characteristics of the

output voltage. First, a 4.7 µH inductor is chosen to allow

stable operation over the entire input voltage range (as per

the datasheet recommendations) from 3.0V to 5.5V. The size

of the inductor also directly affects the amplitude of the

inductor current ripple. This amplitude can be calculated

from the following equation:

From this, it follows that the maximum inductor current ripple

using standard operating conditions of the LM2853 and a 4.7

µH inductor will occur at V

IN

= 5.5V, and V

OUT

= 2.5V. Under

these conditions the inductor current ripple is given as:

This means an inductor must be selected with a saturation

current higher than 3.264A to ensure that the inductor will

never saturate during normal operating conditions. A Coilcraft DO3316P, 4.7 µH inductor provides the necessary current handling capabilities (I

SAT

= 5.4A) in a relatively small

footprint.

The ESR of the output capacitor affects both the ripple

voltage at the output and the overall stability of the loop. In

order to keep the output voltage ripple manageable under all

operating conditions, an ESR value of 50 mΩ is selected. As

per the datasheet recommendations, a capacitance of 220

µF will guarantee stability regardless of V

IN

and V

OUT

when

coupled with 4.7 µH inductor and 50 mΩ ESR. An AVX

low-ESR 6.3V tantalum capacitor provides the necessary

ESR and capacitance to stabilize the loop and control the

output voltage ripple, with suitable voltage derating for up to

a 3.3V output.

PCB Layout

The PCB layout of the LM2853 demo board was designed to

occupy as little board space as possible, while still following

sound layout guidelines and techniques. The input capacitor,

C

IN

is placed as close as possible to the PVIN pins and the

PGND pins, to minimize stray resistance and inductance

between C

IN

and the LM2853. Likewise, the AVIN bypass

capacitor is placed as close as possible to the AVIN and

SGND pins. PGND and SGND are connected to each other

and the ground plane at a single point, the exposed pad of

the LM2853. Also, in order to help conduct heat to the

ground plane and away from the LM2853, an array of vias is

used to connect the exposed pad to the ground plane,

instead of a single via. Finally, the sense pin trace is intentionally routed away from the SW node to minimize any EMI

pickup.

Top Layer (not to scale) Bottom Layer (not to scale)

20201804

20201801

AN-1513

www.national.com3

Page 4

Notes

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(″NATIONAL″) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY OR

COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS, IMPLIED,

ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR APPLICATIONS

ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND APPLICATIONS USING

NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE NATIONAL COMPONENTS,

BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE AND/OR

USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR PURPOSE,

MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL COUNSEL

OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and whose

failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected to result in

a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform can be

reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are trademarks or registered trademarks of National Semiconductor

Corporation. All other brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright © 2006 National Semiconductor Corporation.

For the most current product information visit us at www.national.com.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

www.national.com

AN-1513 LM2853 Evaluation Board

Loading...

Loading...