Page 1

LM2853

3A 550 kHz Synchronous SIMPLE SWITCHER

Regulator

®

Buck

LM2853 3A 550 kHz Synchronous SIMPLE SWITCHER

October 2006

General Description

The LM2853 synchronous SIMPLE SWITCHER®buck regulator is a 550 kHz step-down switching voltage regulator

capable of driving up to a 3A load with excellent line and load

regulation. The LM2853 accepts an input voltage between

3.0V and 5.5V and delivers a customizable output voltage

that is factory programmable from 0.8V to 3.3V in 100mV

increments. Internal type-three compensation enables a low

component count solution and greatly simplifies external

component selection. The exposed-pad TSSOP-14 package

enhances the thermal performance of the LM2853.

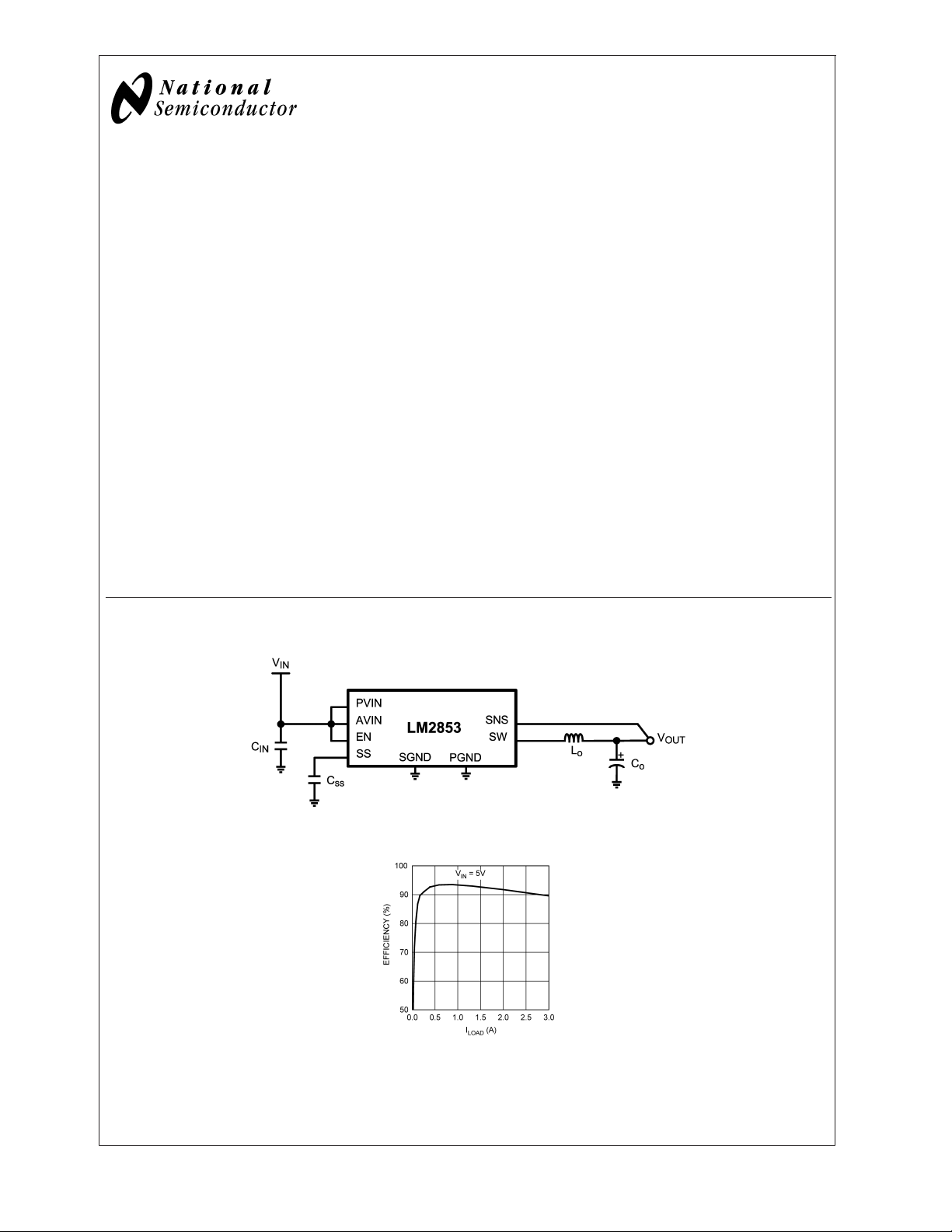

Typical Application Circuit

Features

n Input voltage range of 3.0V to 5.5V

n Factory EEPROM set output voltages from 0.8V to 3.3V

in 100 mV increments

n Maximum load current of 3A

n Voltage Mode Control

n Internal type-three compensation

n Switching frequency of 550 kHz

n Low standby current of 12 µA

n Internal 40 mΩ MOSFET switches

n Standard voltage options

0.8/1.0/1.2/1.5/1.8/2.5/3.0/3.3 volts

n Exposed pad TSSOP-14 package

Applications

n Low voltage point of load regulation

n Local solution for FPGA/DSP/ASIC core power

n Broadband networking and communications

infrastructure

®

Buck Regulator

20201502

Efficiency vs Load Current (V

SIMPLE SWITCHER®is a Registered Trademark of National Semiconductor Corporation.

© 2006 National Semiconductor Corporation DS202015 www.national.com

OUT

20201501

= 3.3V)

Page 2

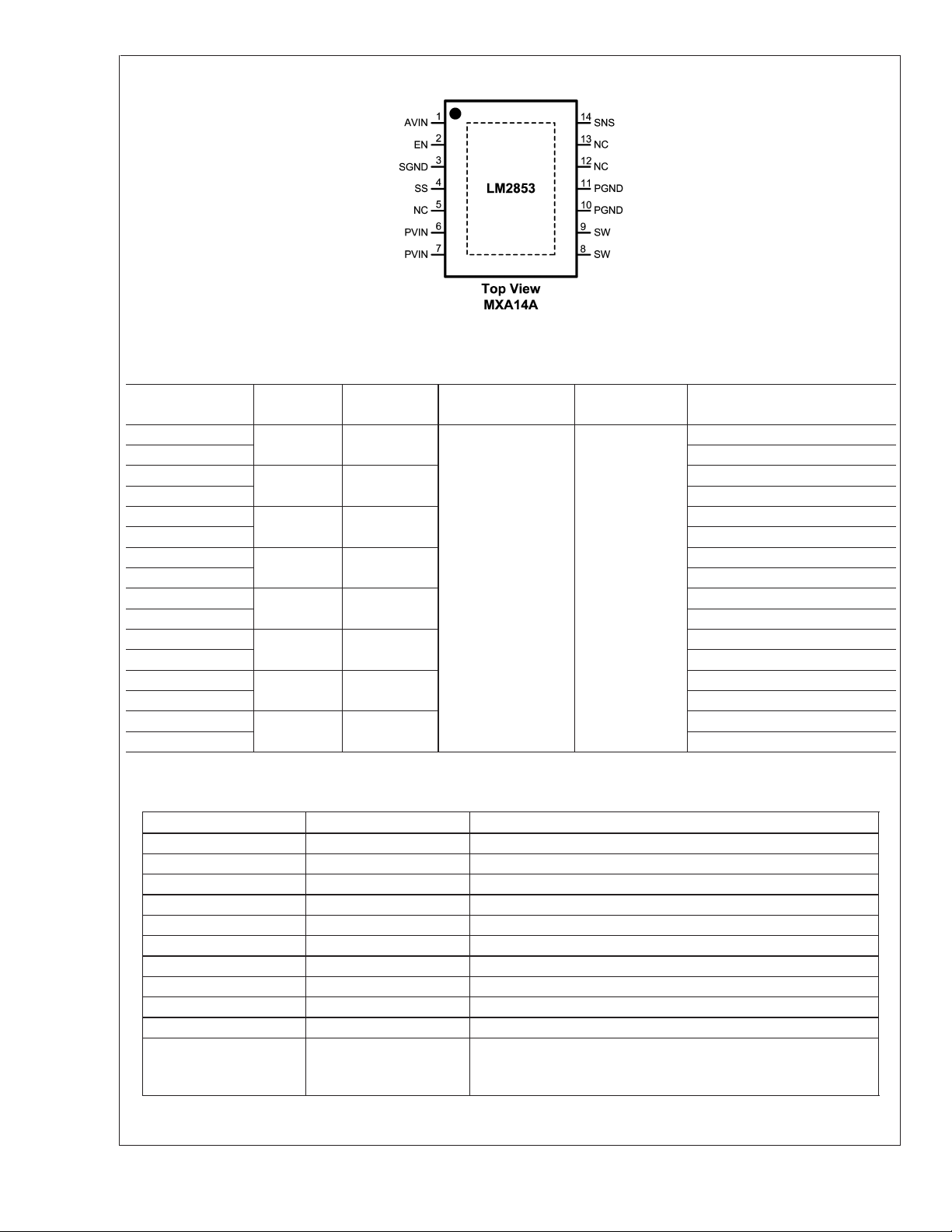

Connection Diagram

LM2853

Ordering Information

20201503

Voltage

Order Number

LM2853MH-0.8

LM2853MHX-0.8 2500 Units, Tape and Reel

LM2853MH-1.0

LM2853MHX-1.0 2500 Units, Tape and Reel

LM2853MH-1.2

LM2853MHX-1.2 2500 Units, Tape and Reel

LM2853MH-1.5

LM2853MHX-1.5 2500 Units, Tape and Reel

LM2853MH-1.8

LM2853MHX-1.8 2500 Units, Tape and Reel

LM2853MH-2.5

LM2853MHX-2.5 2500 Units, Tape and Reel

LM2853MH-3.0

LM2853MHX-3.0 2500 Units, Tape and Reel

LM2853MH-3.3

LM2853MHX-3.3 2500 Units, Tape and Reel

Note: Contact factory for other voltage options.

Option

0.8 LM2853-0.8

1.0 LM2853-1.0

1.2 LM2853-1.2

1.5 LM2853-1.5

1.8 LM2853-1.8

2.5 LM2853-2.5

3.0 LM2853-3.0

3.3 LM2853-3.3

Package

Marking Package Type

TSSOP-14 exposed

pad

Package

Drawing Supplied As

94 Units, Rail

94 Units, Rail

94 Units, Rail

94 Units, Rail

MXA14A

94 Units, Rail

94 Units, Rail

94 Units, Rail

94 Units, Rail

Pin Descriptions

Pin # Name Function

1 AVIN Input Voltage for Control Circuitry.

2 EN Enable.

3 SGND Low noise ground.

4 SS Soft-Start Pin.

5 NC No Connect. This pin must be tied to ground.

6,7 PVIN Input Voltage for Power Circuitry.

8,9 SW Switch Pin.

10,11 PGND Power Ground.

12,13 NC No-Connect. These pins must be tied to ground.

14 SNS Output Voltage Sense Pin.

Exposed Pad EP The exposed pad is internally connected to GND, but it cannot be

used as the primary GND connection. The exposed pad should be

soldered to an external GND plane.

www.national.com 2

Page 3

LM2853

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

14-Pin Exposed Pad TSSOP Package

Infrared (15 sec) 220˚C

Vapor Phase (60 sec) 215˚C

Soldering (10 sec) 260˚C

AVIN, PVIN, EN, SNS, SW, SS −0.3V to 6.0V

ESD Susceptibility (Note 2) 2kV

Operating Ratings (Note 1)

Power Dissipation Internally Limited

Storage Temperature Range −65˚C to +150˚C

Maximum Junction Temp. 150˚C

PVIN to GND 1.5V to 5.5V

AVIN to GND 3.0V to 5.5V

Junction Temperature −40˚C to +125˚C

Electrical Characteristics Specifications with standard typeface are for T

= 25˚C, and those in bold face

J

type apply over the full Junction Temperature Range (−40˚C to 125˚C). Minimum and Maximum limits are guaranteed through

test, design or statistical correlation. Typical values represent the most likely parametric norm at T

= 25˚C and are provided

J

for reference purposes only. Unless otherwise specified AVIN = PVIN = 5V.

Symbol Parameter Conditions Min Typ Max Units

SYSTEM PARAMETERS

V

OUT

∆V

/∆AVIN Line Regulation (Note 3) V

OUT

Voltage Tolerance (Note 3) V

= 0.8V option 0.782 0.8 0.818

OUT

V

= 1.0V option 0.9775 1.0 1.0225

OUT

V

= 1.2V option 1.1730 1.2 1.227

OUT

V

= 1.5V option 1.4663 1.5 1.5337

OUT

V

= 1.8V option 1.7595 1.8 1.8405

OUT

V

= 2.5V option 2.4437 2.5 2.5563

OUT

V

= 3.0V option 2.9325 3.0 3.0675

OUT

V

= 3.3V option 3.2257 3.3 3.3743

OUT

= 0.8V, 1.0V, 1.2V, 1.5V,

OUT

0.2 1.1 %

1.8V or 2.5V

3.0V ≤ AVIN ≤ 5.5V

= 3.0V or 3.3V

V

OUT

0.2 1.1 %

3.5V ≤ AVIN ≤ 5.5V

∆V

V

ON

OUT

/∆I

Load Regulation Normal operation 2 mV/A

O

UVLO Threshold (AVIN) Rising 2.47 3.0 V

Falling Hysteresis 50 155 260 mV

R

DS(ON)-P

R

DS(ON)-N

R

SS

I

CL

I

Q

I

SD

R

SNS

PFET On Resistance Isw = 3A 40 120 mΩ

NFET On Resistance Isw = 3A 32 100 mΩ

Soft-Start Resistance 450 kΩ

Peak Current Limit Threshold 3.6 5A

Operating Current Non-switching 0.85 2 mA

Shutdown Quiescent Current EN = 0V 12 50 µA

Sense Pin Resistance 432 kΩ

PWM

f

D

osc

range

Switching Frequency . 325 550 725 kHz

Duty Cycle Range 0 100 %

ENABLE CONTROL (Note 4)

V

IH

V

IL

I

EN

EN Pin Minimum High Input 75 %of

EN Pin Maximum Low Input 25 %of

EN Pin Pullup Current EN = 0V 1.5 µA

V

AVIN

AVIN

www.national.com3

Page 4

Electrical Characteristics Specifications with standard typeface are for T

apply over the full Junction Temperature Range (−40˚C to 125˚C). Minimum and Maximum limits are guaranteed through test,

LM2853

design or statistical correlation. Typical values represent the most likely parametric norm at T

= 25˚C, and those in bold face type

J

= 25˚C and are provided for

J

reference purposes only. Unless otherwise specified AVIN = PVIN = 5V. (Continued)

Symbol Parameter Conditions Min Typ Max Units

THERMAL CONTROLS

T

SD

T

SD-HYS

Thermal Shutdown Threshold 165 ˚C

Hysteresis for Thermal

10 ˚C

Shutdown

THERMAL RESISTANCE

θ

JA

Note 1: Absolute maximum ratings indicate limits beyond which damage to the device may occur. Operating Range indicates conditions for which the device is

intended to be functional, but does not guarantee specific performance limits. For guaranteed specifications and test conditions, see the Electrical Characteristics.

Note 2: The human body model is a 100 pF capacitor discharged through a 1.5 kΩ resistor into each pin. Test Method is per JESD22-AI14.

Note 3: V

Note 4: The enable pin is internally pulled up, so the LM2853 is automatically enabled unless an external enable voltage is applied.

Junction to Ambient MXA14A 38 ˚C/W

measured in a non-switching, closed-loop configuration at the SNS pin.

OUT

www.national.com 4

Page 5

LM2853

Typical Performance Characteristics Unless otherwise specified, the following conditions apply: V

= AVIN = PVIN = 5V, TJ= 25˚C.

Efficiency vs. I

V

OUT

Efficiency vs. I

V

OUT

LOAD

= 1.8V NFET R

20201507 20201505

LOAD

= 2.5V PFET R

vs. Temperature

DS(ON)

vs. Temperature

DS(ON)

IN

Efficiency vs. I

V

= 3.3V Switching Frequency vs. Temperature

OUT

20201509 20201504

LOAD

20201508 20201506

www.national.com5

Page 6

Typical Performance Characteristics Unless otherwise specified, the following conditions apply: V

= AVIN = PVIN = 5V, TJ= 25˚C. (Continued)

LM2853

I

vs. VINand Temperature ISDvs. VINand Temperature

Q

20201510 20201511

IN

www.national.com 6

Page 7

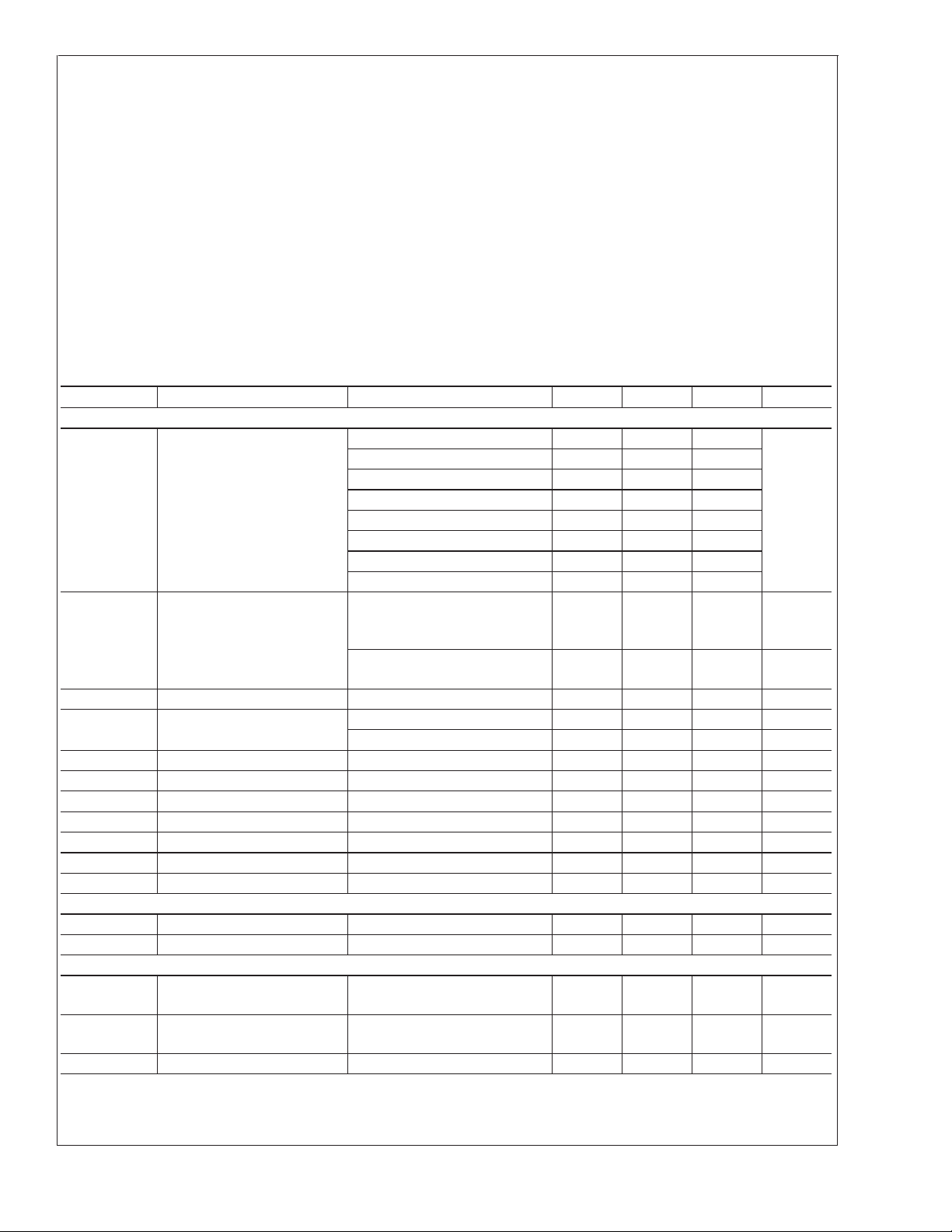

Block Diagram

LM2853

Applications Information

The LM2853 is a DC-DC buck regulator belonging to National Semiconductor’s synchronous SIMPLE SWITCHER

family. Integration of the PWM controller, power switches

and compensation network greatly reduces the component

count required to implement a switching power supply. A

typical application requires only four components: an input

capacitor, a soft-start capacitor, an output filter capacitor and

an output filter inductor.

INPUT CAPACITOR (C

Fast switching of large currents in the buck converter places

a heavy demand on the voltage source supplying PVIN. The

input capacitor, C

IN

needs to draw a burst of current from the supply. The RMS

current rating and the voltage rating of the C

therefore important in the selection of C

specification can be approximated by:

where D is the duty cycle, V

filtering of the supply. Trace resistance and inductance degrade the benefits of the input capacitor, so C

placed very close to PVIN in the layout. A 22 µF or 47 µF

ceramic capacitor is typically sufficient for C

with the large input capacitance a smaller capacitor should

be added such asa1µFceramic for higher frequency

filtering. Ceramic capacitors with high quality dielectrics such

as X5R or X7R should be used to provide a constant capacitance across temperature and line variations. For improved

)

IN

, supplies extra charge when the switcher

capacitor are

IN

. The RMS current

IN

OUT/VIN.CIN

also provides

should be

IN

. In parallel

IN

20201512

load regulation and transient performance, the use of a small

®

1 µF ceramic capacitor is also recommended as a local

bypass for the AVIN pin.

SOFT-START CAPACITOR (C

)

SS

The DAC that sets the reference voltage of the error amplifier sources a current through a resistor to set the reference

voltage. The reference voltage is one half of the output

voltage of the switcher due to the 200 kΩ divider connected

to the SNS pin. Upon start-up, the output voltage of the

switcher tracks the reference voltage with a two to one ratio

as the DAC current charges the capacitance connected to

the reference voltage node. Internal capacitance of 20 pF is

permanently attached to the reference voltage node which is

also connected to the soft start pin, SS. Adding a soft-start

capacitor externally increases the time it takes for the output

voltage to reach its final level. The charging time required for

the reference voltage can be estimated using the RC time

constant of the DAC resistor and the capacitance connected

to the SS pin. Three RC time constant periods are needed

for the reference voltage to reach 95% of its final value. The

actual start up time will vary with differences in the DAC

resistance and higher-order effects.

If little or no soft-start capacitance is connected, then the

start up time may be determined by the time required for the

current limit current to charge the output filter capacitance.

The capacitor charging equationI=C∆V/∆t can be used to

estimate the start-up time in this case. For example, a part

with a 3V output, a 100 µF output capacitance and a 5A

current limit threshold would require a time of 60 µs:

www.national.com7

Page 8

Applications Information (Continued)

LM2853

Since it is undesirable for the power supply to start up in

current limit, a soft-start capacitor must be chosen to force

the LM2853 to start up in a more controlled fashion based on

the charging of the soft-start capacitance. In this example,

supposea3msstart time is desired. Three time constants

are required for charging the soft-start capacitor to 95% of

the final reference voltage. So in this case RC = 1 ms. The

DAC resistor, R, is 450 kΩ so C can be calculated to be 2.2

nF. A 2.2 nF ceramic capacitor can be chosen to yield

approximatelya3msstart-up time.

SOFT-START CAPACITOR (C

CONDITIONS

Various fault conditions such as short circuit and UVLO of

the LM2853 activate internal circuitry designed to control the

voltage on the soft-start capacitor. For example, during a

short circuit current limit event, the output voltage typically

falls to a low voltage. During this time, the soft-start voltage

is forced to track the output so that once the short is removed, the LM2853 can restart gracefully from whatever

V

(V) VIN (V)

OUT

0.8 5 4.7 6.8 120 220 70 100

0.8 3.3 4.7 4.7 150 220 50 100

) AND FAULT

SS

TABLE 1. Recommended L

Min Max Min Max Min Max

voltage the output reached during the short circuit event. The

range of soft-start capacitors is therefore restricted to values

1nFto50nF.

COMPENSATION

The LM2853 provides a highly integrated solution to power

supply design. The compensation of the LM2853, which is

type-three, is included on-chip. The benefit of integrated

compensation is straight-forward, simple power supply design. Since the output filter capacitor and inductor values

impact the compensation of the control loop, the range of L

C

O

and C

values is restricted in order to ensure stability.

ESR

OUTPUT FILTER VALUES

Table 1 details the recommended inductor and capacitor

ranges for the LM2853 that are suggested for various typical

output voltages. Values slightly different than those recommended may be used, however the phase margin of the

power supply may be degraded. For best performance when

output voltage ripple is a concern, ESR values near the

minimum of the recommended range should be paired with

capacitance values near the maximum. If a minimum output

voltage ripple solution from a 5V input voltage is desired, a

6.8 µH inductor can be paired with a 220 µF (50 mΩ)

capacitor without degraded phase margin.

and COValues

O

(µH) CO(µF) C

L

O

ESR

(mΩ)

,

O

1 5 4.7 6.8 120 220 70 100

1 3.3 4.7 4.7 150 220 50 100

1.2 5 4.7 6.8 120 220 70 100

1.2 3.3 4.7 4.7 120 220 60 100

1.5 5 4.7 6.8 120 220 70 100

1.5 3.3 4.7 4.7 120 220 60 100

1.8 5 4.7 6.8 120 220 70 120

1.8 3.3 4.7 4.7 100 220 70 120

2.5 5 4.7 6.8 120 220 70 150

2.5 3.3 4.7 4.7 100 220 80 150

3.0 5 4.7 6.8 120 220 70 150

3.0 3.3 4.7 4.7 100 220 80 150

3.3 5 4.7 6.8 120 220 70 150

www.national.com 8

Page 9

Applications Information (Continued)

CHOOSING AN INDUCTANCE VALUE

The current ripple present in the output filter inductor is

determined by the input voltage, output voltage, switching

frequency and inductance according to the following equation:

where ∆ILis the peak to peak current ripple, D is the duty

cycle V

OUT/VIN,VIN

stage, V

OUT

switching frequency and L

filter inductor. Knowing the current ripple is important for

inductor selection since the peak current through the inductor is the load current plus one half the ripple current. Care

must be taken to ensure the peak inductor current does not

reach a level high enough to trip the current limit circuitry of

the LM2853. As an example, consider a 5V to 1.2V conversion and a 550 kHz switching frequency. According to Table

1, a 4.7 µH inductor may be used. Calculating the expected

peak-to-peak ripple,

Inductance Part Number Vendor

is the input voltage applied to the output

is the output voltage of the switcher, f is the

is the inductance of the output

O

TABLE 2. Recommended Inductors

4.7 µF DO3308P-472ML Coilcraft

4.7 µF DO3316P-472ML Coilcraft

4.7 µF MSS1260-472ML Coilcraft

5.2 µF MSS1038-522NL Coilcraft

5.6 µF MSS1260-562ML Coilcraft

6.8 µF DO3316P-682ML Coilcraft

6.8 µF MSS1260-682ML Coilcraft

The maximum inductor current for a 3A load would therefore

be 3A plus 177 mA, 3.177A. As shown in the ripple equation,

the current ripple is inversely proportional to inductance.

OUTPUT FILTER INDUCTORS

Once the inductance value is chosen, the key parameter for

selecting the output filter inductor is its saturation current

) specification. Typically I

(I

SAT

is given by the manufac-

SAT

turer as the current at which the inductance of the coil falls to

a certain percentage of the nominal inductance. The I

SAT

an inductor used in an application should be greater than the

maximum expected inductor current to avoid saturation. Below is a table of inductors that are suitable in LM2853

applications.

LM2853

of

OUTPUT FILTER CAPACITORS

The recommended capacitors that may be used in the output

Below are some examples of capacitors that can typically be

used in an LM2853 application.

filter with the LM2853 are limited in value and ESR range

according to Table 1.

TABLE 3. Recommended Capacitors

Capacitance (µF) Part Number Chemistry Vendor

100 594D107X_010C2T Tantalum Vishay-Sprague

100 593D107X_010D2_E3 Tantalum Vishay-Sprague

100 TPSC107M006#0075 Tantalum AVX

100 NOSD107M006#0080 Niobium Oxide AVX

100 NOSC107M004#0070 Niobium Oxide AVX

120 594D127X_6R3C2T Tantalum Vishay-Sprague

150 594D157X_010C2T Tantalum Vishay-Sprague

150 595D157X_010D2T Tantalum Vishay-Sprague

150 591D157X_6R3C2_20H Tantalum Vishay-Sprague

150 TPSD157M006#0050 Tantalum AVX

150 TPSC157M004#0070 Tantalum AVX

150 NOSD157M006#0070 Niobium Oxide AVX

220 594D227X_6R3D2T Tantalum Vishay-Sprague

220 591D227X_6R3D2_20H Tantalum Vishay-Sprague

220 591D227X_010D2_20H Tantalum Vishay-Sprague

220 593D227X_6R3D2_E3 Tantalum Vishay-Sprague

www.national.com9

Page 10

Applications Information (Continued)

LM2853

Capacitance (µF) Part Number Chemistry Vendor

220 TPSD227M006#0050 Tantalum AVX

220 NOSD227M0040060 Niobium Oxide AVX

TABLE 3. Recommended Capacitors (Continued)

SPLIT-RAIL OPERATION

The LM2853 can be powered using two separate voltages

for AVIN and PVIN. AVIN is the supply for the control logic;

PVIN is the supply for the power FETs. The output filter

SWITCH NODE PROTECTION

The LM2853 includes protection circuitry that monitors the

voltage on the switch pin. Under certain fault conditions,

switching is disabled in order to protect the switching devices. One side effect of the protection circuitry may be

observed when power to the LM2853 is applied with no or

light load on the output. The output will regulate to the rated

voltage, but no switching may be observed. As soon as the

output is loaded, the LM2853 will begin normal switching

operation.

LAYOUT GUIDELINES

These are several guidelines to follow while designing the

PCB layout for an LM2853 application.

1. The input bulk capacitor, C

, should be placed very

IN

close to the PVIN pin to keep the resistance as low as

possible between the capacitor and the pin. High current

levels will be present in this connection.

2. All ground connections must be tied together. Use a

broad ground plane, for example a completely filled back

plane, to establish the lowest resistance possible be-

components need to be chosen based on the value of PVIN.

For PVIN levels lower than 3.3V, use output filter component

values recommended for 3.3V. PVIN must always be equal

to or less than AVIN.

20201513

tween all ground connections.

3. The sense pin connection should be made as close to

the load as possible so that the voltage at the load is the

expected regulated value. The sense line should not run

too close to nodes with high dV/dt or dl/dt (such as the

switch node) to minimize interference.

4. The switch node connections should be low resistance

to reduce power losses. Low resistance means the trace

between the switch pin and the inductor should be wide.

However, the area of the switch node should not be too

large since EMI increases with greater area. So connect

the inductor to the switch pin with a short, but wide trace.

Other high current connections in the application such

as PVIN and V

assume the same trade off between

OUT

low resistance and EMI.

5. Allow area under the chip to solder the entire exposed

die attach pad to ground for improved thermal performance. Lab measurements also show improved regulation performance when the exposed pad is well

grounded.

LM2853 Example Circuit Schematic

FIGURE 1.

www.national.com 10

20201514

Page 11

LM2853 Example Circuit Schematic (Continued)

Bill of Materials for 5V to 3.3V Conversion

ID Part Number Type Size Parameters Qty Vendor

U

1

C

IN

C

BYP

C

SS

L

O

C

O

ID Part Number Type Size Parameters Qty Vendor

U

1

C

IN

C

BYP

CSS VJ0805Y222KXXA Capacitor 0603 2.2 nF 1 Vishay-Vitramon

L

O

C

O

LM2853MH-3.3 3A Buck ETSSOP-14 3.3V 1 NSC

GRM31CR60J476ME19 Capacitor 1206 47 µF 1 Murata

GRM21BR71C105KA01 Capacitor 0805 1 µF 1 Murata

VJ0805Y222KXXA Capacitor 0603 2.2 nF 1 Vishay-Vitramon

DO3316P-682 Inductor DO3316P 6.8 µH 1 Coilcraft

594D127X06R3C2T Capacitor C Case 120µF

1 Vishay-Sprague

(85mΩ)

Bill of Materials for 3.3V to 1.2V Conversion

LM2853MH-1.2 3A Buck ETSSOP-14 1.2V 1 NSC

GRM31CR60J476ME19 Capacitor 1206 47 µF 1 Murata

GRM21BR71C105KA01 Capacitor 0805 1 µF 1 Murata

DO3316P-472 Inductor DO3316P 4.7 µH 1 Coilcraft

NOSD157M006R0070 Capacitor D Case 150 µF

1AVX

(70 mΩ)

LM2853

www.national.com11

Page 12

Physical Dimensions inches (millimeters) unless otherwise noted

Buck Regulator

®

14-Lead ETSSOP Package

NS Package Number MXA14A

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves

the right at any time without notice to change said circuitry and specifications.

For the most current product information visit us at www.national.com.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL COUNSEL OF NATIONAL SEMICONDUCTOR

LM2853 3A 550 kHz Synchronous SIMPLE SWITCHER

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body, or

(b) support or sustain life, and whose failure to perform when

properly used in accordance with instructions for use

2. A critical component is any component of a life support

device or system whose failure to perform can be reasonably

expected to cause the failure of the life support device or

system, or to affect its safety or effectiveness.

provided in the labeling, can be reasonably expected to result

in a significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor follows the provisions of the Product Stewardship Guide for Customers (CSP-9-111C2) and Banned Substances

and Materials of Interest Specification (CSP-9-111S2) for regulatory environmental compliance. Details may be found at:

www.national.com/quality/green.

Lead free products are RoHS compliant.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...