Page 1

October 2002

LM2788

120mA High Efficiency Step-Down Switched Capacitor

Voltage Converter

LM2788 120mA High Efficiency Step-Down Switched Capacitor Voltage Converter

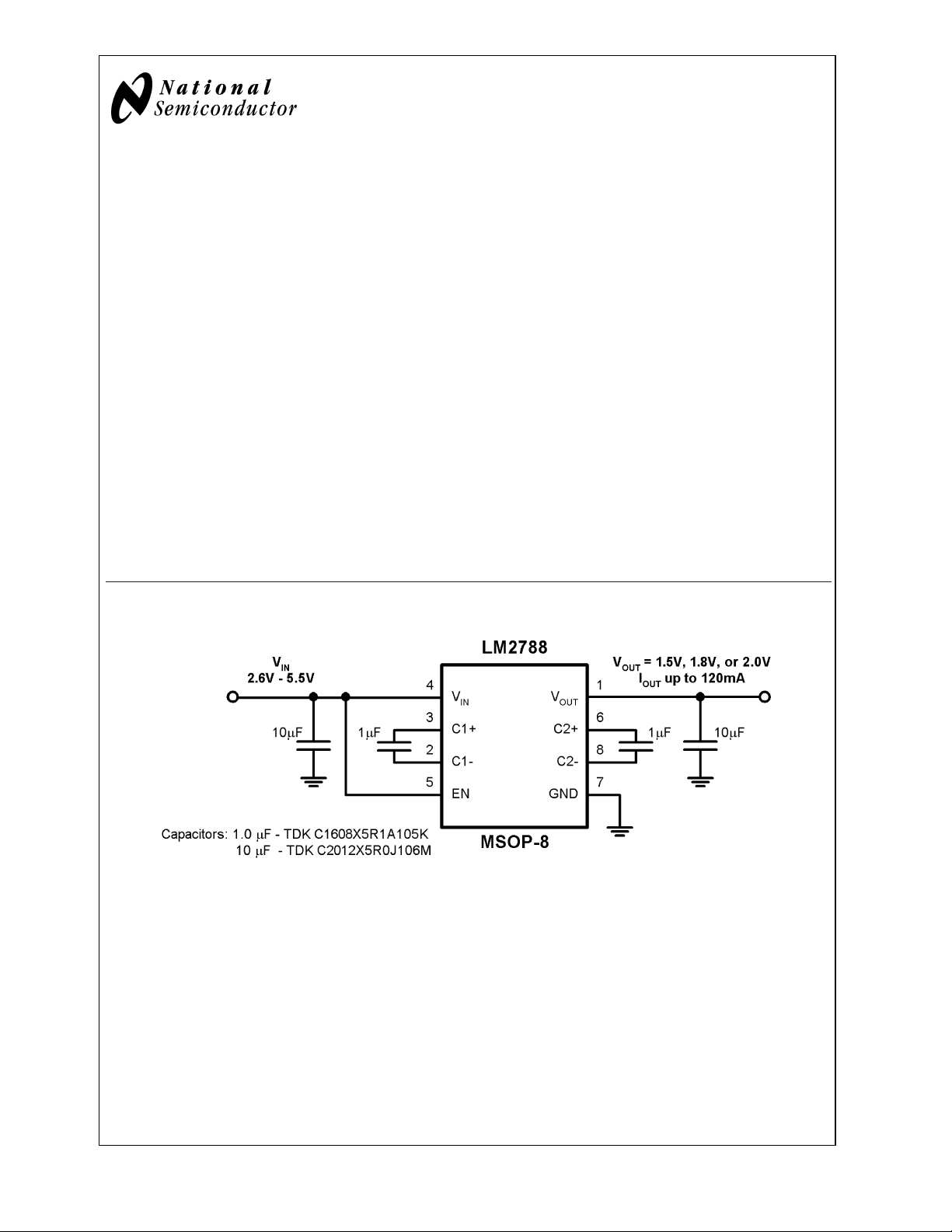

General Description

The LM2788 switched capacitor step-down DC/DC converter efficiently produces a 120mA regulated low-voltage

rail from a 2.6V to 5.5V input. Fixed output voltage options of

1.5V, 1.8V, and 2.0V are available. The LM2788 uses multiple fractional gain configurations to maximize conversion

efficiency over the entire input voltage and output current

ranges. Also contributing to high overall efficiency is the

extremely low supply current of the LM2788: 32µA operating

unloaded and 0.1µA in shutdown.

The optimal external component requirements of the

LM2788 solution minimize size and cost, making the part

ideal for Li-Ion and other battery powered designs. Two 1µF

flying capacitors and two 10µF bypass capacitors are all that

are required, and no inductors are needed.

The LM2788 also features noise-reducing soft-start circuitry,

short-circuit protection and over-temperature protection.

Typical Application Circuit

Features

n Output voltage options:

n 120mA output current capability

n Multi-Gain and Gain Hopping for Highest Possible

n 2.6V to 5.5V input range

n Low operating supply current: 32µA

n Shutdown supply current: 0.1µA

n Thermal and short circuit protection

n Available in an 8-Pin MSOP Package

±

5%, 1.8V±5%, 1.5V±6%

2.0V

Efficiency - up to 90% Efficient

Applications

n Cellular Phones

n Pagers

n H/PC and P/PC Devices

n Portable Electronic Equipment

n Handheld Instrumentation

20044401

© 2002 National Semiconductor Corporation DS200444 www.national.com

Page 2

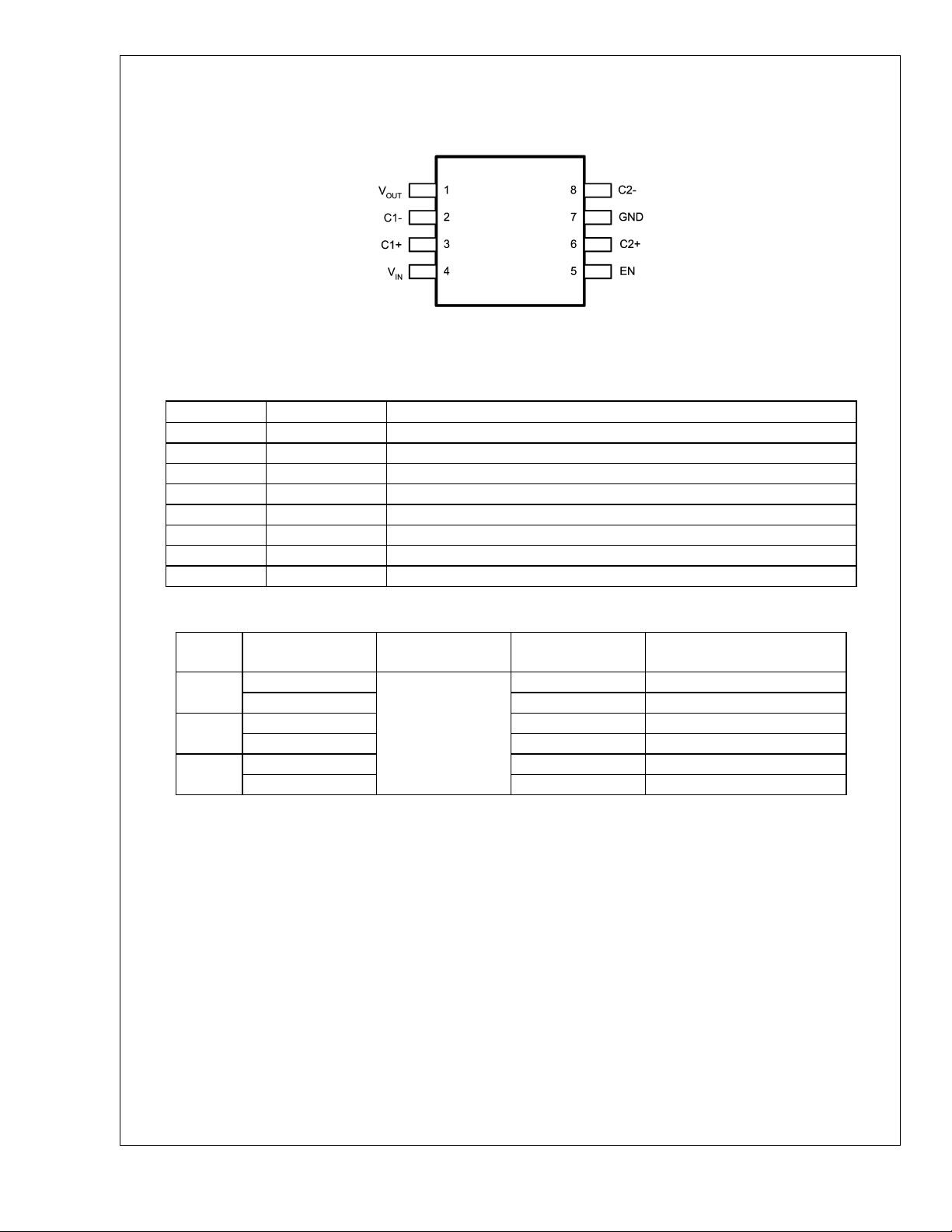

Connection Diagram

LM2788

LM2788

Mini SO-8 (MSOP-8) Package

NS Package #: MUA08A

Pin Description

Pin Name Description

1V

2 C1- First Flying Capacitor: Negative Terminal

3 C1+ First Flying Capicitor: Positive terminal

4V

5 EN Enable. Logic Input. High voltage = ON, Low voltage = SHUTDOWN

6 C2+ Second Flying-Capacitor: Positive Terminal

7 GND Ground Connection

8 C2- Second Flying Capacitor: Negative Terminal

OUT

IN

Ordering Information

Output

Voltage

1.50V LM2788MM-1.5

1.80V LM2788MM-1.8 S23B 1000 units on Tape-and Reel

2.00V LM2788MM-2.0 S24B 1000 units on Tape-and Reel

Ordering

Information

LM2788MMX-1.5 S30B 3500 units onTape-and-Reel

LM2788MMX-1.8 S23B 3500 units on Tape-and Reel

LM2788MMX-2.0 S24B 3500 units on Tape-and Reel

Top View

20044402

Regulated Output Voltage

Input voltage. Recommended VINRange: 2.6V to 5.5V

Package Type Package Marking Supplied as

S30B 1000 units on Tape-and Reel

MSOP-8

www.national.com 2

Page 3

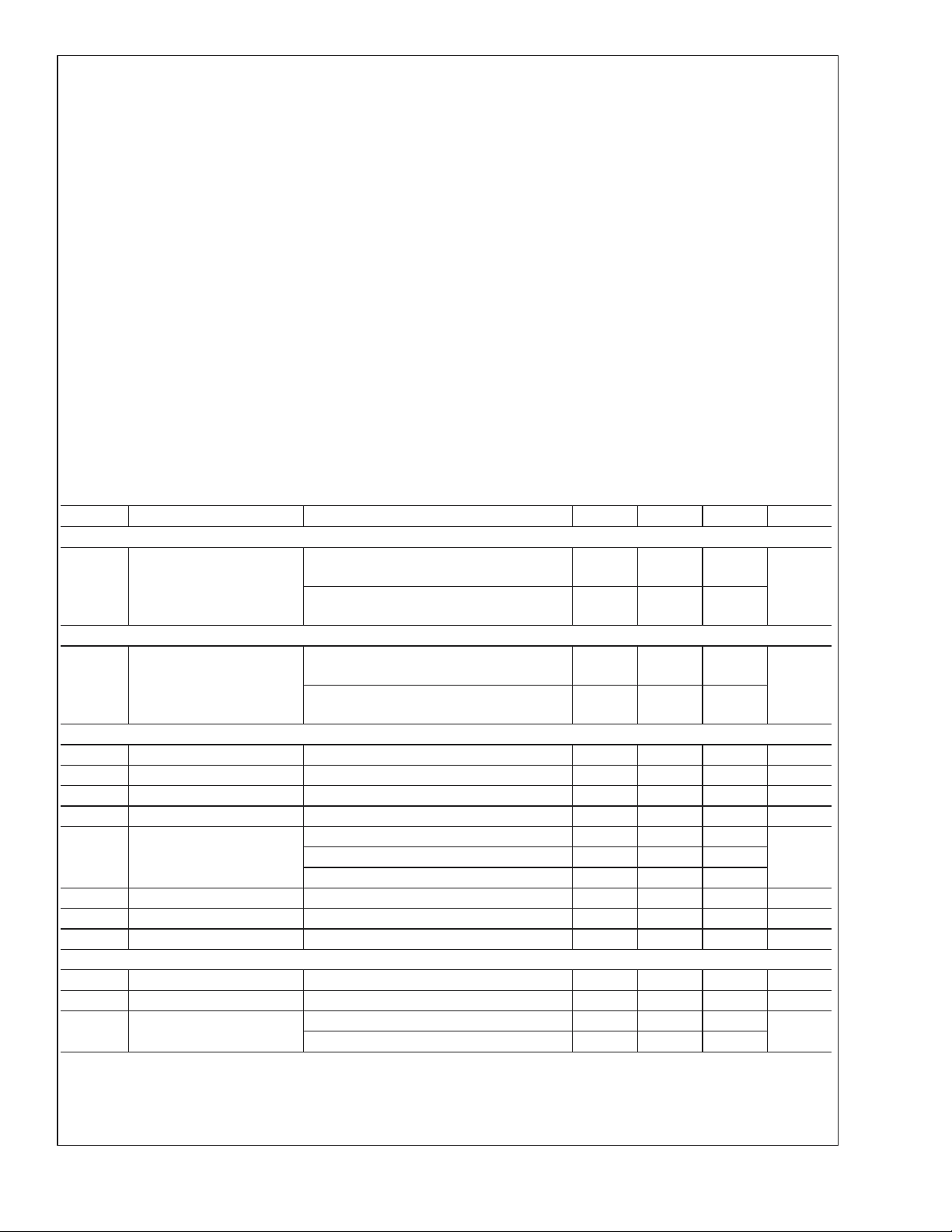

Absolute Maximum Ratings (Notes 1,

2)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

, EN pins: Voltage to Ground

V

IN

(Note 3) −0.3V to 5.6V

Junction Temperature (T

J-MAX-ABS

Continuous Power Dissipation

(Note 4) Internally Limited

V

Short-Circuit to GND Duration

OUT

(Note 4) Unlimited

Storage Temperature Range −65˚C to 150˚C

Lead Temperature

(Soldering, 5 Sec.) 260˚C

ESD Rating (Note 5)

Human-body model:

Machine model

) 150˚C

2kV

200V

Operating Ratings (Notes 1, 2)

Input Voltage Range 2.6V to 5.5V

Recommended Output Current

Range 0mA to 120mA

Junction Temperature Range -40˚C to 125˚C

Ambient Temperature Range

-40˚C to 85˚C

(Note 6)

Thermal Information

Junction-to-Ambient Thermal 220˚C/W

Resistance, MSOP-8 Package

(θJA) (Note 7)

LM2788

Electrical Characteristics (Notes 2, 8) Limits in standard typeface and typical values apply for T

o

C. Limits in boldface type apply over the operating junction temperature range. Unless otherwise specified: 2.6 ≤ VIN≤

25

5.5V, V(EN) = V

IN,C1=C2

= 1µF, CIN=C

= 10µF. (Note 9)

OUT

=

J

Symbol Parameter Conditions Min Typ Max Units

LM2788-1.8, LM2788-2.0

2.8V ≤ V

V

OUT

Output Voltage Tolerance

0mA ≤ I

4.2V ≤ VIN≤ 5.5V

0mA ≤ I

IN

OUT

OUT

≤ 4.2V

≤ 120mA

≤ 120 mA

-5 +5

-6 +6

%of

V

OUT (nom)

(Note 10)

LM2788-1.5

2.8V ≤ V

V

OUT

Output Voltage Tolerance

0mA ≤ I

4.2V ≤ VIN≤ 5.5V

0mA ≤ I

IN

OUT

OUT

≤ 4.2V

≤ 120 mA

≤ 120mA

-6 +6

-6 +6

%of

V

OUT (nom)

(Note 10)

All Output Voltage Options

I

I

V

E

E

t

f

I

Q

SD

R

PEAK

AVG

ON

SW

SC

Operating Supply Current I

= 0mA 32 50 µA

OUT

Shutdown Supply Current V(EN) = 0V 0.1 2 µA

Output Voltage Ripple LM2788-1.8: VIN= 3.6V, I

Peak Efficiency LM2788-1.8: VIN= 3.0V, I

Average Efficiency over

Li-Ion Input Voltage Range

(Note 11)

Turn-On Time VIN= 3.6V, I

LM2788-1.5: 3.0 ≤ V

LM2788-2.0: 3.0 ≤ V

= 120mA (Note 12) 0.4 ms

OUT

IN

IN

IN

= 120mA 20 mV

OUT

= 60mA 90 %

OUT

≤ 4.2V, I

≤ 4.2V, I

≤ 4.2V, I

= 60mA 76

OUT

= 60mA 82

OUT

= 60mA 75

OUT

Switching Frequency 500 kHz

Short-Circuit Current VIN= 3.6, V

=0V 25 mA

OUT

Enable Pin (EN) Characteristics

V

IH

V

IL

I

EN

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the component may occur. Operating Ratings are conditions under which operation of

the device is guaranteed. Operating Ratings do not imply guaranteed performance limits. For guaranteed performance limits and associated test conditions, see the

Electrical Characteristics tables.

Note 2: All voltages are with respect to the potential at the GND pin.

Note 3: Voltage on the EN pin must not be brought above V

EN pin Logic-High Input 0.9 V

IN

EN pin Logic-Low Input 0 0.4 V

=0V 0 nA

V

EN pin input current

EN

V

= 5.5V 30

EN

+ 0.3V.

IN

p-p

%LM2788-1.8: 3.0 ≤ V

V

www.national.com3

Page 4

Electrical Characteristics (Notes 2, 8) Limits in standard typeface and typical values apply for T

Limits in boldface type apply over the operating junction temperature range. Unless otherwise specified: 2.6 ≤ V

LM2788

V(EN) = V

Note 4: Thermal shutdown circuitry protects the device from permanent damage.

Note 5: The Human body model is a 100 pF capacitor discharged through a 1.5 kΩ resistor into each pin. The machine model is a 200pF capacitor discharged

directly into each pin.

Note 6: Maximum ambient temperature (T

dissipation of the device in the application (P

following equation: T

outside the listed T

Note 7: Junction-to-ambient thermal resistance is a highly application and board-layout dependent. In applications where high maximum power dissipation exists,

special care must be paid to thermal dissipation issues. Fore more information on these topics, please refer to the Power Dissipation section of this datasheet.

Note 8: All room temperature limits are 100% tested or guaranteed through statistical analysis. All limits at temperature extremes are guaranteed by correlation

using standard Statistical Quality Control methods (SQC). All limits are used to calculate Average Outgoing Quality Level (AOQL). Typical numbers are not

guaranteed, but do represent the most likely norm.

Note 9: C

Note 10: Nominal output voltage (V

table for available options.

Note 11: Efficiency is measured versus V

results. Weighting to account for battery voltage discharge characteristics (V

Note 12: Turn-on time is measured from when the EN signal is pulled high until the output voltage crosses 90% of its final value.

IN,C1=C2

FLY,CIN

= 1µF, CIN=C

A-MAX=TJ-MAX-OP

rating, so long as the junction temperature of the device does not exceed the maximum operating rating of 125oC.

A

, and C

OUT

-(θJAxP

: Low-ESR Surface-Mount Ceramic Capacitors (MLCCs) used in setting electrical characteristics

(nom) ) is the target output voltage of the part, as given by the output-voltage-option identifier. See Ordering Information

OUT

= 10µF. (Note 9) (Continued)

OUT

) is dependent on the maximum operating junction temperature (T

A-MAX

), and the junction-to ambient thermal resistance of the part/package in the application (θJA), as given by the

D-MAX

). The ambient temperature operating rating is provided merely for convenience. This part may be operated

D-MAX

, with VINbeing swept in small increments from 3.0V to 4.2V. The average is calculated from these measurements

IN

vs. Time) is not done in computing the average.

BAT

J-MAX-OP

= 125oC), the maximum power

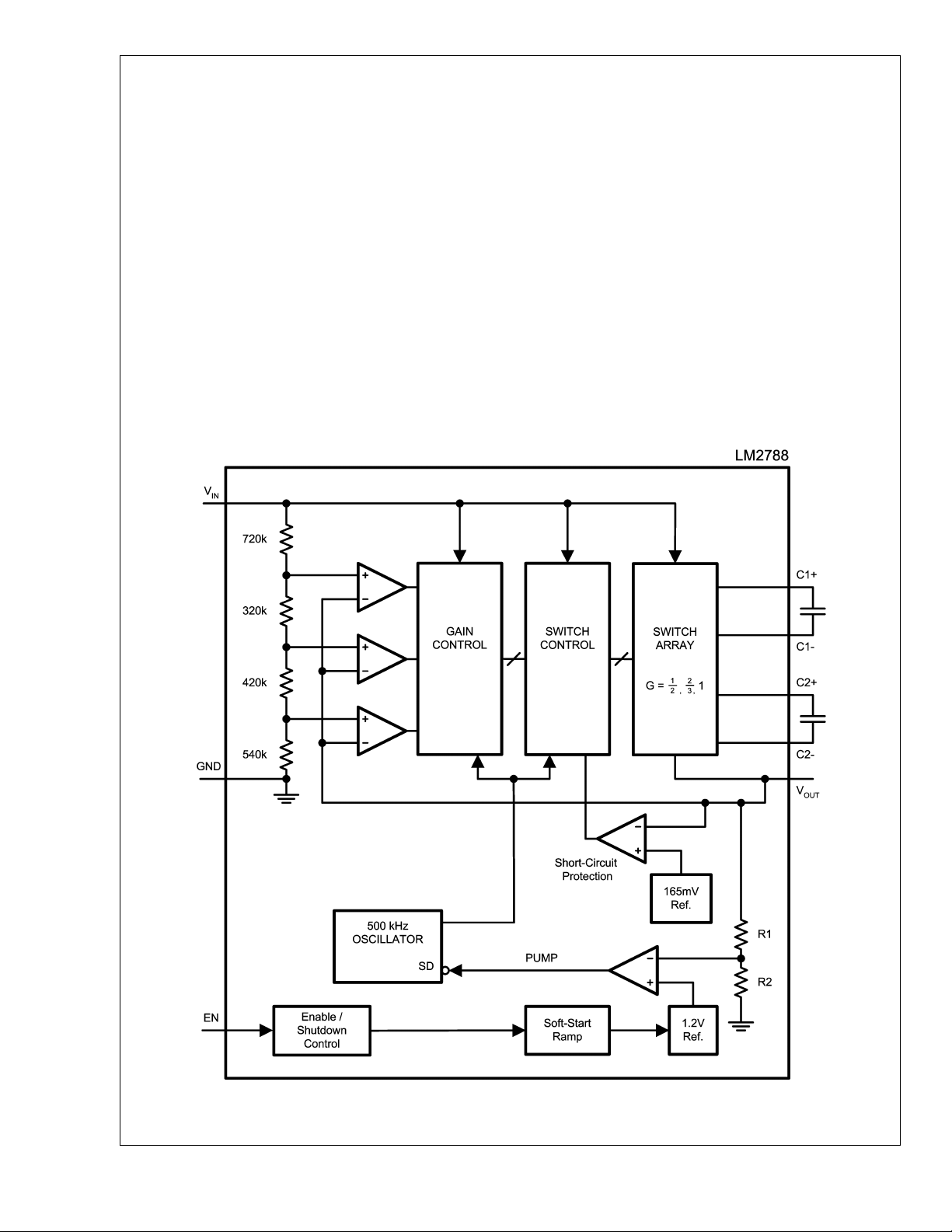

Block Diagram

IN

=25oC.

J

≤ 5.5V,

www.national.com 4

20044403

Page 5

Typical Performance Characteristics

Unless otherwise specified: CIN= 10µF, C1 = 1.0µF, C2 = 1.0µF C

ceramic capacitors (MLCC’s).

Output Voltage vs. Input Voltage:

LM2788-1.5 (1mA)

20044407 20044408

= 10µF, TA=25oC. Capacitors are low-ESR multi-layer

OUT

Output Voltage vs. Input Voltage:

LM2788-1.5 (120mA)

LM2788

Output Voltage vs. Input Voltage:

LM2788-1.8 (1mA)

Output Voltage vs. Input Voltage:

LM2788-2.0 (1mA)

Output Voltage vs. Input Voltage:

LM2788-1.8 (120mA)

20044409 20044410

Output Voltage vs. Input Voltage:

LM2788-2.0 (120mA)

20044411 20044412

www.national.com5

Page 6

Typical Performance Characteristics (Continued)

LM2788

Efficiency vs. Input Voltage: LM2788-1.5 Efficiency vs. Output Current: LM2788-1.5

20044413

20044414

Efficiency vs. Input Voltage: Lm2788-1.8 Efficiency vs. Output Current: LM2788-1.8

20044415

20044416

Efficiency vs. Input Voltage: LM2788-2.0 Effiency vs. Output Current: LM2788-2.0

20044417

20044418

www.national.com 6

Page 7

Typical Performance Characteristics (Continued)

Output Voltage Ripple vs. Output Current Output Voltage Ripple vs. Input Voltage

20044421 20044419

Output Voltage Ripple Short Circuit Current

LM2788

20044406

Start Up Waveform Transient Load Response

20044404 20044405

20044420

www.national.com7

Page 8

Operation Description

LM2788

OVERVIEW

The LM2788 is a switched capacitor converter that produces

a regulated low-voltage output. The core of the part is the

highly efficient charge pump that utilizes multiple fractional

gains and pulse-frequency modulated (PFM) switching to

minimize power losses over wide input voltage and output

current ranges. A description of the principal operational

characteristics of the LM2788 is broken up into the following

sections: PFM Regulation, Fractional Multi-Gain Charge

Pump, and Gain Selection for Optimal Efficiency. Each of

these sections refers to the block diagram presented on the

previous page.

PFM REGULATION

The LM2788 achieves tightly regulated output voltages with

pulse-frequency modulated (PFM) regulation. PFM simply

means the part only pumps when it needs to. When the

output voltage is above the target regulation voltage, the part

idles and consumes minimal supply-current. In this state, the

load current is supplied solely by the charge stored on the

output capacitor. As this capacitor discharges and the output

voltage falls below the target regulation voltage, the charge

pump activates. Charge/current is delivered to the output

(supplying the load and boosting the voltage on the output

capacitor).

The primary benefit of PFM regulation is when output currents are light and the part is predominantly in the lowsupply-current idle state. Net supply current is minimal because the part only occasionally needs to refresh the output

capacitor by activating the charge pump, and the supply

current it consumes.

FRACTIONAL MULTI-GAIN CHARGE PUMP

The core of the LM2788 is a two-phase charge pump controlled by an internally generated non-overlapping clock. The

charge pump operates by using the external flying capacitors, C1 and C2, to transfer charge from the input to the

output. During the charge phase, which doubles as the PFM

’idle state’, the flying capacitors are charged by the input

supply. The charge pump will be in this state until the output

voltage drops below the target regulation voltage, triggering

the charge pump to activate so that it can deliver charge to

the output. Charge transfer is achieved in the pump phase,

where the fully charged flying capacitors are connected to

the output so that the charge they hold can supply the load

and recharge the output capacitor.

Input, output, and intermediary connections of the flying

capacitors are made with internal MOS switches. The

LM2788 utilizes two flying capacitors and a versatile switch

network to achieve several fractional voltage gains:

and 1. With this gain-switching ability, it is as if the LM2788

is three-charge-pumps-in-one. The ’active’ charge pump at

any given time is the one that will yield the highest efficiency

given the input and output conditions present.

1

⁄2,2⁄3,

E=(V

OUTxIOUT

)÷(VINxIIN)=V

÷(GXVIN)

OUT

In the equations, G represents the charge pump gain. Efficiency is optimal as GxV

approaches V

IN

. Optimal effi-

OUT

ciency is achieved when gain is able to adjust depending on

input and output voltage conditions. Due to the nature of

charge pumps, G cannot adjust continuously, which would

be ideal from an efficiency standpoint. But G can be a set of

simple quantized ratios, allowing for a good degree of efficiency optimization.

2

The gain set of the LM2788 consists of the gains 1/2,

⁄3, and

1. An internal input voltage range detector, along with the

nominal output voltage of the given LM2788 option, determines what is to be referred to as the ’base gain’ of the part,

. The base gain is the default gain configuration of the part

G

B

at a given V

. Table 1 lists GBof the LM2788-1.8 over the

IN

input voltage range. (For the remainder of this discussion,

the 1.8V option of the LM2788 will be used as an example.

The other voltage options operate under the same principles

as the 1.8V version, the gain-transitions merely occur at

different voltage levels.)

TABLE 1. LM2788-1.8 Base Gain (G

) vs. V

B

IN

Input Voltage Base Gain (GB)

2.6V - 2.9V 1

2.9V - 3.8V

3.8V - 5.5V

2

⁄

3

1

⁄

2

Table 1 shows the efficiency of the LM2788-1.8 versus input

voltage, with output currents of 10mA and 120mA. The base

gain regions (G

set of ideal efficiency gradients, E

) are separated and labeled. There is also a

B

IDEAL(G=xx)

, showing the

ideal efficiency of a charge pumps with gains of 1/2, 2/3, and

1. These curves were generated using the ideal efficiency

equation presented above.

20044422

GAIN SELECTION AND GAIN HOPPING FOR OPTIMAL EFFICIENCY

The ability to switch gains based on input and output conditions results in optimal LM2788 efficiency throughout the

operating ranges of the part. Charge-pump efficiency is derived in the following two ideal equations (supply current and

other losses are neglected for simplicity):

=GxI

I

IN

www.national.com 8

OUT

FIGURE 1. Efficiency of LM2788-1.8 with 10mA and

120mA output currents Base-gain (G

) regions are

B

separated and labeled Ideal efficiency curves of

charge pumps with G =1/2, 2/3, and 1 are included

(E

IDEAL(G=1),EIDEAL(G=2/3),EIDEAL(G=1/2)

)

The 10mA-load efficiency curve in Figure 1 closely resembles the ideal Efficiency-vs.-Input- Voltage curves that

correspond to each of the base-gain regions. The same

Page 9

Operation Description (Continued)

holds true for the other base-gain regions. At the base-gain

transitions (V

transition as the part switches base-gains. The 10mA load

curve gives a clear picture of how base-gain affects overall

converter efficiency. With a 10mA output current, the gain of

the LM2788-1.8 is equal to the base-gain over the entire

operating input voltage range. Additionally, with a 10mA load,

internal supply current has a minimal impact on efficiency

(Supply current does have a small affect: it is why the 10mA

load curve is slightly below the ideal efficiency gradients in

each of the base-gain regions).

The 120mA-load curve in Figure 1 illustrates the effect of

gain hopping on converter efficiency. Gain hopping is implemented to overcome output voltage droop that results from

charge-pump non-idealities. In an ideal charge pump, the

output voltage is equal to the product of the gain and the

input voltage. Non-idealities such as finite switch resistance,

capacitor ESR, and other factors result in the output of

practical charge pumps being below the ideal value, however. This output droop is typically modeled as an output

resistance, R

creases linearly with load current.

Real Charge Pump: V

The LM2788 compensates for output voltage droop under

high load conditions by gain hopping: when the base-gain is

not sufficient to keep the output voltage in regulation, the

part will temporarily switch up to the next highest gain setting

to provide an intermittent boost in output voltage. When the

output voltage is sufficiently boosted, the gain configuration

reverts back to the base-gain setting. If the load remains

high, the part will continue to hop back and forth between the

base-gain and the next highest gain setting, and the output

voltage will remain in regulation. In contrast to the base-gain

decision, which is made based on the input voltage, the

decision to gain hop is made by monitoring the voltage at the

output of the part.

The efficiency curve of the LM2788-1.8 with a 120mA output

current, also contained in Figure 1, shows the effect that gain

hopping has on efficiency. Comparing the 120mA load curve

to the 10mA load curve, it is plain to see that to the right of

the base-gain transitions, the efficiency of the 120mA curve

increases gradually whereas the 10mA curve makes a sharp

transition. The base-gain of both curves is the same for both

loads. The difference comes in gain hopping. With the

120mA load, the part will spend a percentage of time in the

base-gain setting and the rest of the time in the next-highest

gain setting. The percentage of time gain hopping decreases

as the input voltage rises, as less gain-hopping boost is

required with increased input voltage. When the input voltage in a given base-gain region is large enough so that no

extra boost from gain hopping is required, the 120mA-load

efficiency curve mirrors the 10mA efficiency curve.

TABLE 2. LM2788-1.8 Gain Hopping Regions

Input Voltage Base Gain

Gain hopping contributes to the overall high efficiency of the

LM2788. Gain hopping only occurs when required for keeping the output voltage in regulation. This allows the LM2788

= 2.9V, 3.8V), the 10mA curve makes sharps

IN

, because the magnitude of the droop in-

OUT

Ideal Charge Pump: V

=(GxVIN)-(I

OUT

OUT

=GxV

Gain Hop

)

(G

B

3.0V - 3.3V

3.8V - 4.4V

2

⁄

3

1

⁄

2

IN

OUTxROUT

Setting

1

2

⁄

3

)

to operate in the higher efficiency base-gain setting as much

as possible. Gain hopping also allows the base-gain transitions to be placed at input voltages that are as low as

practically possible. This maximizes the peaks, and minimizes the valleys, of the efficiency ’saw-tooth’ curves, again

maximizing total solution efficiency.

SHUTDOWN

The LM2788 is in shutdown mode when the voltage on the

active-low logic enable pin (EN) is low. In shutdown, the

LM2788 draws virtually no supply current. When in shutdown, the output of the LM2788 is completely disconnected

from the input, and will be 0V unless driven by an outside

source.

In some applications, it may be desired to disable the

LM2788 and drive the output pin with another voltage

source. This can be done, but the voltage on the output pin

of the LM2788 must not be brought above the input voltage.

The output pin will draw a small amount when driven externally due the internal feedback resistor divider connected

between V

OUT

and GND.

SOFT START

The LM2788 employs soft start circuitry to prevent excessive

input inrush currents during startup. The output voltage is

programmed to rise from 0V to the nominal output voltage in

approximately 400µs (typ.). With the input voltage established, soft-start is engaged when a part is enabled by

pulling the voltage on the EN pin high. Soft-start also engages when voltage is established simultaneously to the V

and EN pins

THERMAL SHUTDOWN

Protection from overheating-related damage is achieved

with a thermal shutdown feature. When the junction temperature rises to 150

o

C (typ.), the part switches into shutdown mode. The LM2788 disengages thermal shutdown

when the junction temperature of the part is reduced to

o

C (typ.). Due to its high efficiency, the LM2788 should

130

not activate thermal shutdown (or exhibit related thermal

cycling) when the part is operated within specified input

voltage, output current, and ambient temperature operating

ratings.

SHORT-CIRCUIT PROTECTION

The LM2788 short-circuit protection circuitry that protects the

device in the event of excessive output current and/or output

shorts to ground. A graph of ’Short-Circuit Current vs. Input

Voltage’ is provided in the Performance Characteristics

section.

Application Information

OUTPUT VOLTAGE RIPPLE

The voltage ripple on the output of the LM2788 is highly

dependent on the application conditions. The output capacitor, the input voltage, and the output current each play a

significant part in determining the output voltage ripple. Due

to the complexity of LM2788 operation, providing equations

or models to approximate the magnitude of the ripple cannot

be easily accomplished. The following general statements

can be made however

The output capacitor will have a significant effect on output

voltage ripple magnitude. Ripple magnitude will typically be

linearly proportional to the output capacitance present. A

LM2788

IN

www.national.com9

Page 10

Application Information (Continued)

low-ESR ceramic capacitor is recommended on the output to

LM2788

keep output voltage ripple low. Placing multiple capacitors in

parallel can reduce ripple significantly, both by increasing

capacitance and reducing ESR. When capacitors are in

parallel, ESR is in parallel as well. The effective net ESR is

determined according to the properties of parallel resistance.

Two identical capacitors in parallel have twice the capacitance and half the ESR as compared to a single capacitor of

the same make. On a similar note, if a large-value, high-ESR

capacitor (tantalum, for example) is to be used as the primary output capacitor, the net output ESR can be significantly reduced by placing a low-ESR ceramic capacitor in

parallel with this primary output capacitor.

Ripple is increased when the LM2788 is gain hopping. Thus,

in the presence of high currents, ripple is likely to vary

significantly over the input voltage, depending on wether or

not the part is gain hopping.

CAPACITORS

The LM2788 requires 4 external capacitors for proper operation. Surface-mount multi-layer ceramic capacitors are recommended. These capacitors are small, inexpensive and

have very low equivalent series resistance (ESR, ≤15mΩ

typ.). Tantalum capacitors, OS-CON capacitors, and aluminum electrolytic capacitors generally are not recommended

for use with the LM2788 due to their high ESR, as compared

to ceramic capacitors.

For most applications, ceramic capacitors with X7R or X5R

temperature characteristic are preferred for use with the

LM2788. These capacitors have tight capacitance tolerance

(as good as

±

15% over -55oCto125oC; X5R:±15% over -55oCto85oC),

and typically have little voltage coefficient.

Capacitors with Y5V and/or Z5U temperature characteristic

are generally not recommended for use with the LM2788.

These types of capacitors typically have wide capacitance

tolerance (+80%, -20%), vary significantly over temperature

(Y5V: +22%, -82% over -30

-56% over +10

coefficients. Under some conditions, a nominal 1µF Y5V or

Z5U capacitor could have a capacitance of only 0.1µF. Such

detrimental deviation is likely to cause these Y5V and Z5U of

capacitors to fail to meet the minimum capacitance requirements of the LM2788.

The table below lists some leading ceramic capacitor manufacturers.

Vishay-Vitramon www.vishay.com

OUTPUT CAPACITOR

The output capacitor of the LM2788 plays an important part

in LM2788 performance. In typical high-current applications,

a 10µF low-ESR (ESR = equivalent series resistance) ceramic capacitor is recommended for use. For lighter loads,

the output capacitance may be reduced (capacitance as low

as 1µF for output currents ≤ 60mA is usually acceptable).

The performance of the part should be evaluated with spe-

±

10%), hold their value over temperature (X7R:

o

o

C to +85oC range), and have poor voltage

Cto+85oC range; Z5U: +22%,

Manufacturer Contact Information

AVX www.avx.com

Murata www.murata.com

Taiyo-Yuden www.t-yuden.com

TDK www.component.tdk.com

cial attention paid to efficiency and output ripple to ensure

the capacitance chosen on the output yields performance

suitable for the application. In extreme cases, excessive

ripple could cause control loop instability, severely affecting

the performance of the part. If excessive ripple is present,

the output capacitance should be increased.

The ESR of the output capacitor affects charge pump output

resistance, which plays a role in determining output current

capability. Both output capacitance and ESR affect output

voltage ripple (See Output Voltage Ripple section, above).

For these reasons, a low-ESR X7R/X5R ceramic capacitor is

the capacitor of choice for the LM2788 output.

FLYING CAPACITORS

The flying capacitors (C

and C2) transfer charge from the

1

input to the output, and thus are like the engine of the charge

pump. Low-ESR ceramic capacitors with X7R or X5R temperature characteristic are strongly recommended for use

here. The flying capacitors C1 and C2 should be identical. As

a general rule, the capacitance value of each flying capacitor

should be 1/10th that of the output capacitor. Polarized

capacitor (tantalum, aluminum electrolytic, etc.) must not be

used for the flying capacitors, as they could become reversebiased upon start-up of the LM2788.

The flying capacitance determines the strength of the charge

pump-the larger the capacitance, the bigger the engine. ESR

in the flying capacitors negatively affects the strength of the

charge pump and should be minimized, as ESR contributes

to undesired output resistance. If capacitors are too small

the LM2788 could spend excessive amount of time gain

hopping: decreasing efficiency, increasing output voltage

ripple, and possibly impeding the ability of the part to regulate. On the other hand, if the flying capacitors are too large

they could potentially overwhelm the output capacitor, resulting in increased output voltage ripple.

INPUT CAPACITOR

If the flying capacitors are the charge pump engine, the input

capacitor (CIN) is the fuel tank: a reservoir of charge that

aids a quick transfer of charge from the supply to the flying

capacitors during the charge phase of operation. The input

capacitor helps to keep the input voltage from drooping at

the start of the charge phase, when the flying capacitor is

first connected to the input, and helps to filter noise on the

input pin that could adversely affect sensitive internal analog

circuitry biased off the input line. As mentioned above, an

X7R/X5R ceramic capacitor is recommended for use. As a

general recommendation, the input capacitor should be chosen to match the output capacitor.

POWER DISSIPATION

LM2788 power dissipation will, typically, not be much of a

concern in most applications. Derating to accommodate selfheating will rarely be required due to the high efficiency of

the part. When operating within specified operating ratings,

the peak power dissipation (PD) of all LM2788 voltage options occurs with the LM2788-1.5 operating at the maximum

rated operating output current of 120mA. With an input voltage of 5.5V, the power efficiency (E) of the LM2788-1.5

bottoms out at 54%. Assuming a typical junction-to-ambient

thermal resistance (θJA) for the MSOP package of 220˚C/

Watt, the junction temperature (T

) of the part is calculated

J

below for a part operating at the maximum rated ambient

temperature (T

) of 85˚C.

A

www.national.com 10

Page 11

Application Information (Continued)

Even under these peak power dissipation and ambient temperature conditions, the junction temperature of the LM2788

is below the maximum operating rating of 125˚C.

As an additional note, the ambient temperature operating

rating range listed in the specifications is provided merely for

convenience. The LM2788 may be operated outside this

rating, so long as the junction temperature of the device

does not exceed the maximum operating rating of 125˚C.

Use short, wide traces to connect the external capacitors

•

to the LM2788 to minimize trace resistance and inductance.

Use a low resistance connection between ground and the

•

GND pin of the LM2788. Using wide traces and/or multiple vias to connect GND to a ground plane on the board

is most advantageous.

Figure 2 is a sample single-layer board layout that accommodates the LM2788 typical application circuit, as pictured

on the cover of this datasheet

20044424

LM2788

Layout Guidelines

Proper board layout to accommodate the LM2788 circuit will

help to ensure optimal performance. The following guidelines are recommended:

Place capacitors as close to the LM2788 as possible, and

•

preferably on the same side of the board as the IC.

FIGURE 2. Sample single-layer board layout of the

LM2788 Typical Application Circuit (Vias to a ground

plane, assumed to be present, are located in the

center of the LM2788 footprint.)

www.national.com11

Page 12

Physical Dimensions inches (millimeters)

unless otherwise noted

Mini SO-8 (MSOP-8)

MUA08A

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

LM2788 120mA High Efficiency Step-Down Switched Capacitor Voltage Converter

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Fax: 65-6250 4466

Email: ap.support@nsc.com

Tel: 65-6254 4466

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: nsj.crc@jksmtp.nsc.com

Tel: 81-3-5639-7560

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Page 13

Loading...

Loading...