Page 1

LM2750

Low Noise Switched Capacitor Boost Regulator

LM2750 Low Noise Switched Capacitor Boost Regulator

December 2005

General Description

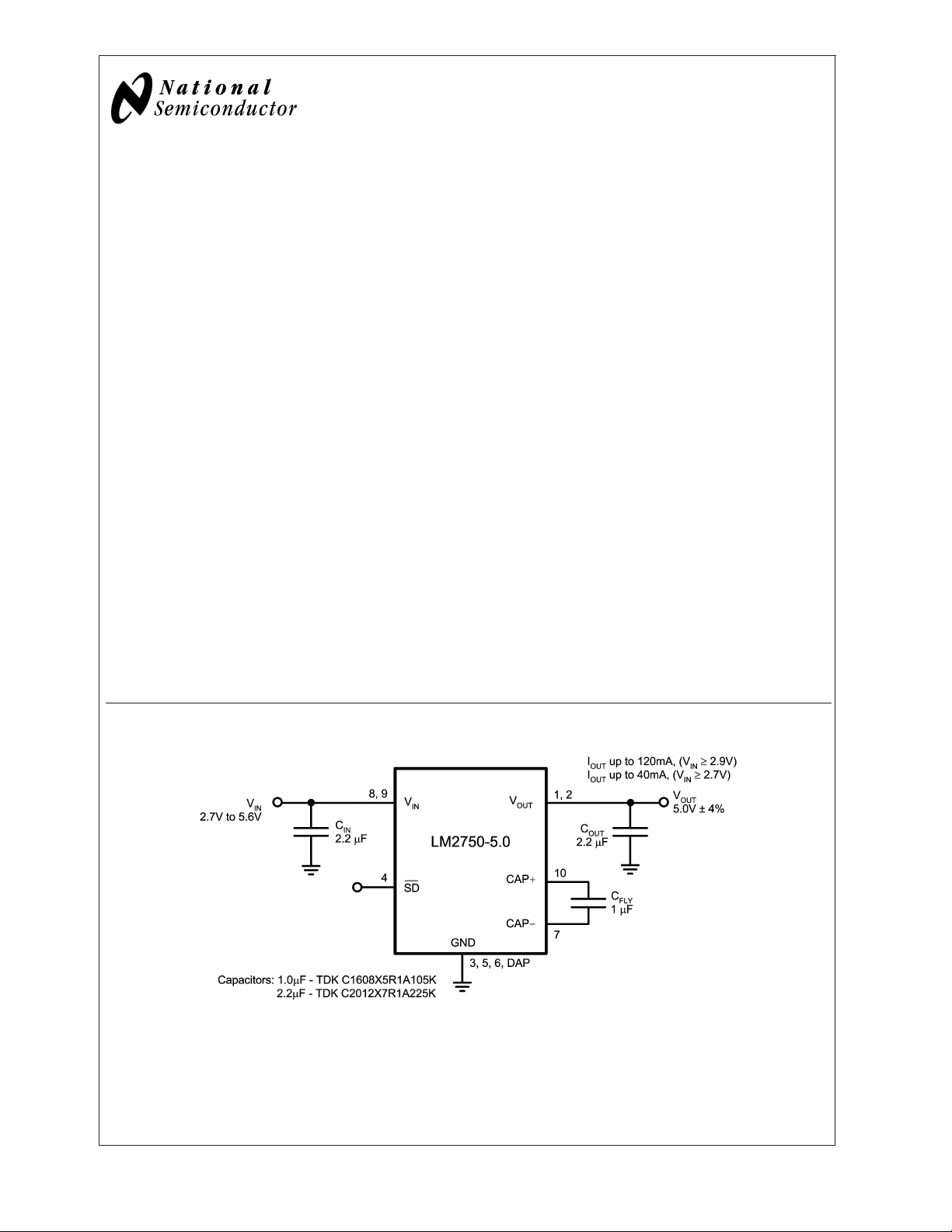

The LM2750 is a regulated switched-capacitor doubler that

produces a low-noise output voltage. The 5.0V output voltage option (LM2750-5.0) can supply up to 120mA of output

current over a 2.9V to 5.6V input range, as well as up to

40mA of output current when the input voltage is as low as

2.7V. An adjustable output voltage option with similar output

current capabilities is also available (LM2750-ADJ). The

LM2750 has been placed in National’s 10-pin LLP, a package with excellent thermal properties that keeps the part

from overheating under almost all rated operating conditions

A perfect fit for space-constrained, battery-powered applications, the LM2750 requires only 3 external components: one

input capacitor, one output capacitor, and one flying capacitor. Small, inexpensive ceramic capacitors are recommended for use. These capacitors, in conjunction with the

1.7MHz fixed switching frequency of the LM2750, yield low

output voltage ripple, beneficial for systems requiring a lownoise supply. Pre-regulation minimizes input current ripple,

reducing input noise to negligible levels.

A tightly controlled soft-start feature limits inrush currents

during part activation. Shutdown completely disconnects the

load from the input. Output current limiting and thermal

shutdown circuitry protect both the LM2750 and connected

devices in the event of output shorts or excessive current

loads.

Features

n Inductorless solution: Application requires only 3 small

ceramic capacitors

n Fixed 5.0V output and adjustable output voltage options

available

n 85% Peak Efficiency

70% Average Efficiency over Li-Ion Input Range

(2.9V-to-4.2V)

n Output Current up to 120mA with 2.9V ≤ V

Output Current up to 40mA with 2.7V ≤ V

n Wide Input Voltage Range: 2.7V to 5.6V

n Fixed 1.7MHz switching frequency for a low-noise,

low-ripple output signal

n Pre-regulation minimizes input current ripple, keeping

the battery line (V

n Tiny LLP package with outstanding power dissipation:

Usually no derating required.

n Shutdown Supply Current less than 2µA

) virtually noise-free

IN

IN

IN

≤ 5.6V

≤ 2.9V

Applications

n White and Colored LED-based Display Lighting

n Cellular Phone SIM cards

n Audio Amplifier Power Supplies

n General Purpose Li-Ion-to-5V Conversion

Typical Application Circuit

20035101

© 2005 National Semiconductor Corporation DS200351 www.national.com

Page 2

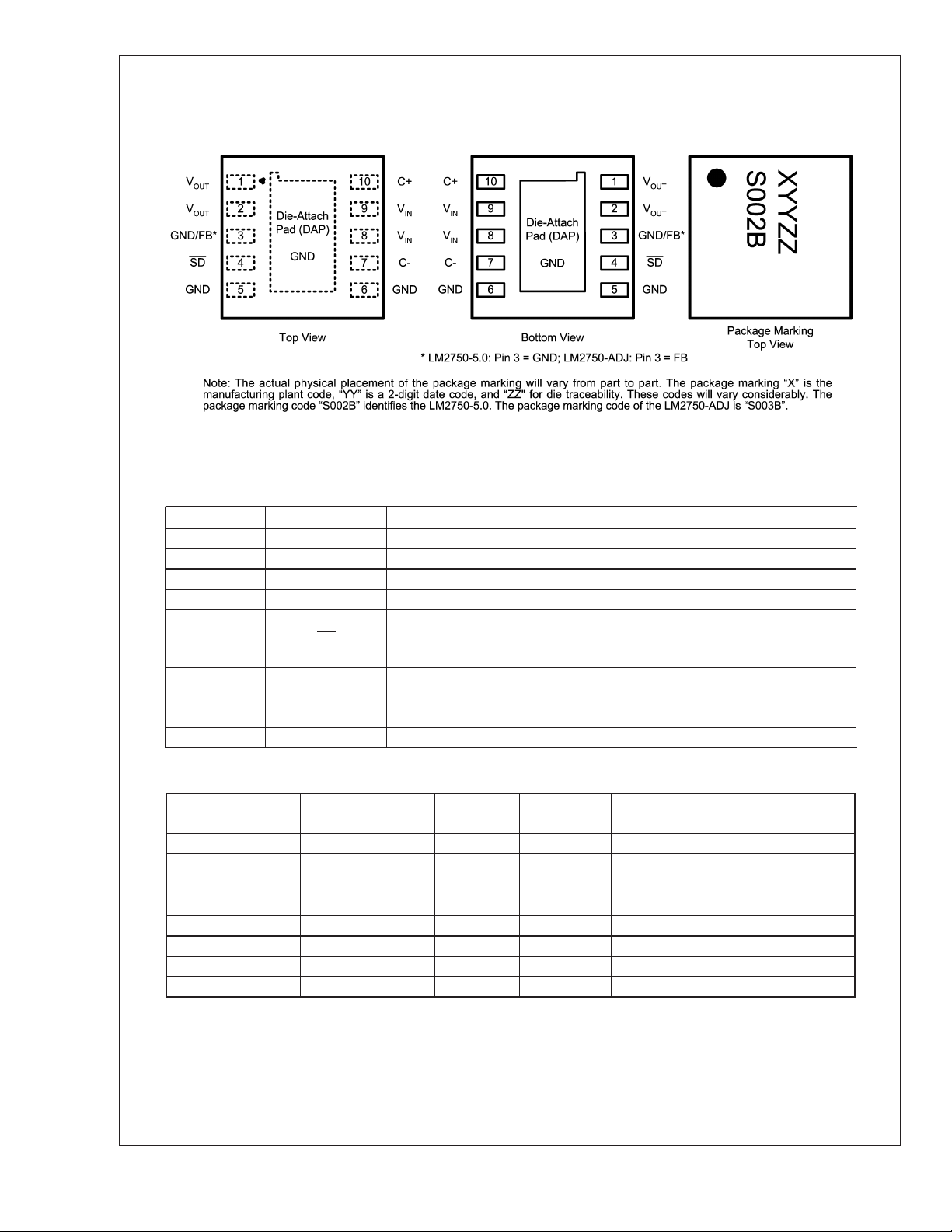

Connection Diagram

LM2750

LM2750

10-Pin Leadless Leadframe Package (LLP) - 3mm X 3mm

NS Package Number LDA10A (Shown below), and SDA10A

Pin Names and Numbers apply to both SDA10A and LDA10A packages.

20035102

Pin Descriptions

Pin #(s) Pin Name Description

8, 9 V

1, 2 V

10 CAP+ Flying Capacitor Positive Terminal

7 CAP- Flying Capacitor Negative Terminal

4SD

3

5, 6, DAP GND Ground - These pins must be connected externally.

LM2750-5.0: GND

LM2750-ADJ: FB Feedback Pin

IN

OUT

Input Voltage - The pins must be connected externally.

Output Voltage - These pins must be connected externally.

Active-Low Shutdown Input. A 200kΩ resistor is connected internally between

this pin and GND to pull the voltage on this pin to 0V, and shut down the part,

when the pin is left floating.

This pin must be connected exernally to the ground pins (pins 5, 6, and the

DAP).

Ordering Information

Output Voltage

Option

5.0 LM2750LD-5.0 LDA10A S002B 1000 Units, Tape and Reel

5.0 LM2750LDX-5.0 LDA10A S002B 4500 Units, Tape and Reel

Adjustable LM2750LD-ADJ LDA10A S003B 1000 Units, Tape and Reel

Adjustable LM2750LDX-ADJ LDA10A S003B 4500 Units, Tape and Reel

5.0 LM2750SD-5.0 SDA10A S005B 1000 Units, Tape and Reel

5.0 LM2750SDX-5.0 SDA10A S005B 4500 Units, Tape and Reel

Adjustable LM2750SD-ADJ SDA10A S004B 1000 Units, Tape and Reel

Adjustable LM2750SDX-ADJ SDA10A S004B 4500 Units, Tape and Reel

Note 1: LDA10A Package: 10 pad pullback LLP. SDA10A Package: 10 pad non-pullback LLP. For more details, refer to the package drawings in the Physical

Dimensions section at the end of this datasheet.

Ordering

Information

Package

(Note 1)

Package

Marking

Supplied as

www.national.com 2

Page 3

LM2750

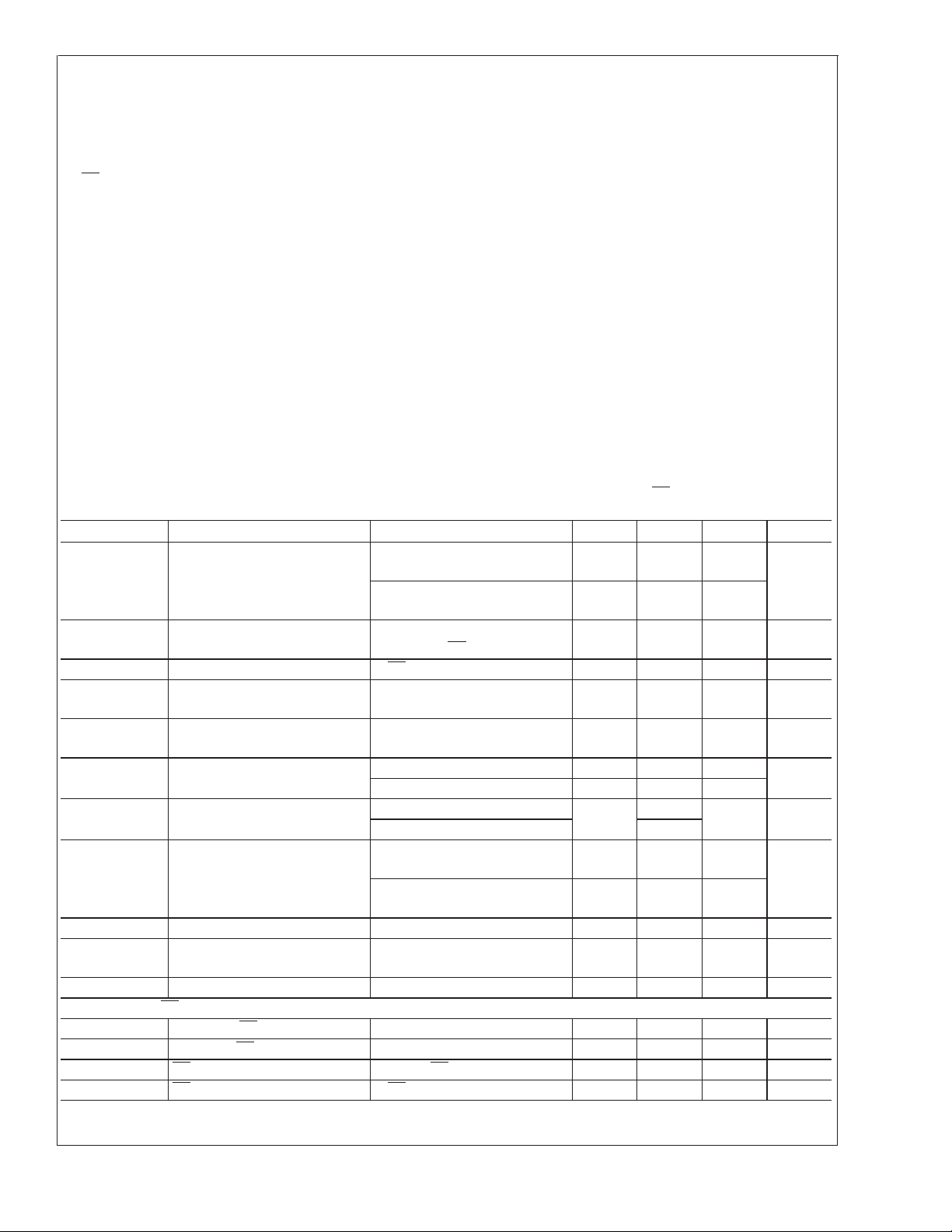

Absolute Maximum Ratings (Notes 2, 3)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Pin: Voltage to Ground −0.3V to 6V

V

IN

SD Pin: Voltage to GND

Junction Temperature (T

J-MAX-ABS

) 150˚C

Continuous Power Dissipation Internally Limited

(Note 4)

Maximum Output Current (Note 5) 175mA

Storage Temperature Range −65˚C to 150˚C

Maximum Lead Temperature 260˚C

−0.3V to

+0.3V)

(V

IN

Operating Ratings (Notes 2, 3)

LM2750-5.0 Input Voltage Range 2.7V to 5.6V

LM2750-ADJ Input Voltage Range

3.8V ≤ V

4.9V ≤ V

LM2750-ADJ Output Voltage Range 3.8V to 5.2V

Recommended Output Current

2.9V ≤ V

2.7V ≤ V

Junction Temperature (T

Ambient Temperature (T

(Note 7)

≤ 4.9V: 2.7V to (V

OUT

≤ 5.2V: 2.7V to 5.6V

OUT

≤ 5.6V 0 to 120mA

IN

≤ 2.9V 0 to 40mA

IN

) Range -40˚C to 125˚C

J

) Range -40˚C to 85˚C

A

OUT

(Soldering, 5 sec.)

ESD Rating (Note 6)

Human-body model:

Machine model

2kV

100V

Thermal Information

Junction-to-Ambient Thermal

Resistance, LLP-10 55˚C/W

Package (θJA) (Note 8)

Electrical Characteristics (Notes 3, 9)

Typical values and limits in standard typeface apply for TJ=25oC. Limits in boldface type apply over the operating junction

temperature range. Unless otherwise specified: 2.9V ≤ V

= 2 x 1µF, C

= 2 x 1µF (Note 10).

OUT

≤ 5.6V, V

IN

Symbol Parameter Conditions Min Typ Max Units

2.9V ≤ V

V

OUT

I

Q

I

SD

V

FB

Output Voltage

(LM2750-5.0)

Operating Supply Current I

Shutdown Supply Current V(SD) = 0V 2 µA

Feedback Pin Voltage

I

OUT

2.7V ≤ V

I

OUT

OUT

V

IH(MIN)

VIN= 3.1V 1.170 1.232 1.294 V

≤ 5.6V,

IN

≤ 120mA

≤ 2.9V,

IN

≤ 40mA

= 0mA,

≤ V(SD) ≤V

(LM2750-ADJ)

I

FB

Feedback Pin Input Current

VFB= 1.4V 1 nA

(LM2750-ADJ)

V

E

E

f

t

R

PEAK

AVG

SW

ON

Output Ripple C

Peak Efficiency

(LM2750-5.0)

Average Efficiency over Li-Ion

Input Range

(LM2750-5.0)

(Note 12)

= 10µF, I

OUT

C

= 2.2µF, I

OUT

VIN= 2.7V, I

V

= 2.9V, I

IN

Range: 2.9V - 4.2V,

V

IN

I

OUT

V

Range: 2.9V - 4.2V,

IN

I

OUT

OUT

OUT

= 120mA

= 40mA

Switching Frequency 1.0 1.7 MHz

V

Turn-On Time VIN= 3.0V, I

OUT

OUT

(Note 11)

I

LIM

Current Limit V

shorted to GND 300 mA

OUT

Shutdown Pin (SD) Characteristics

V

IH

V

IL

I

IH

I

IL

Logic-High SD Input 1.3 V

Logic-Low SD Input 0 0.4 V

SD Input Current (Note 13) 1.3V ≤ V(SD) ≤ V

SD Input Current V(SD) = 0V −1 1 µA

= 5.0V (LM2750-ADJ), V(SD) = VIN,C

OUT

4.80

5.0 5.20

(-4%)

4.80

5.0 5.20

(-4%)

FLY

(+4%)

(+4%)

= 1µF, C

51012mA

IN

= 100mA 4

OUT

= 100mA 15

OUT

= 40mA 87 %

= 120mA 85

70 %

67

= 100mA,

IN

0.5 ms

IN

15 50 µA

+0.7V)

IN

V

(%)

mVp-p

V

www.national.com3

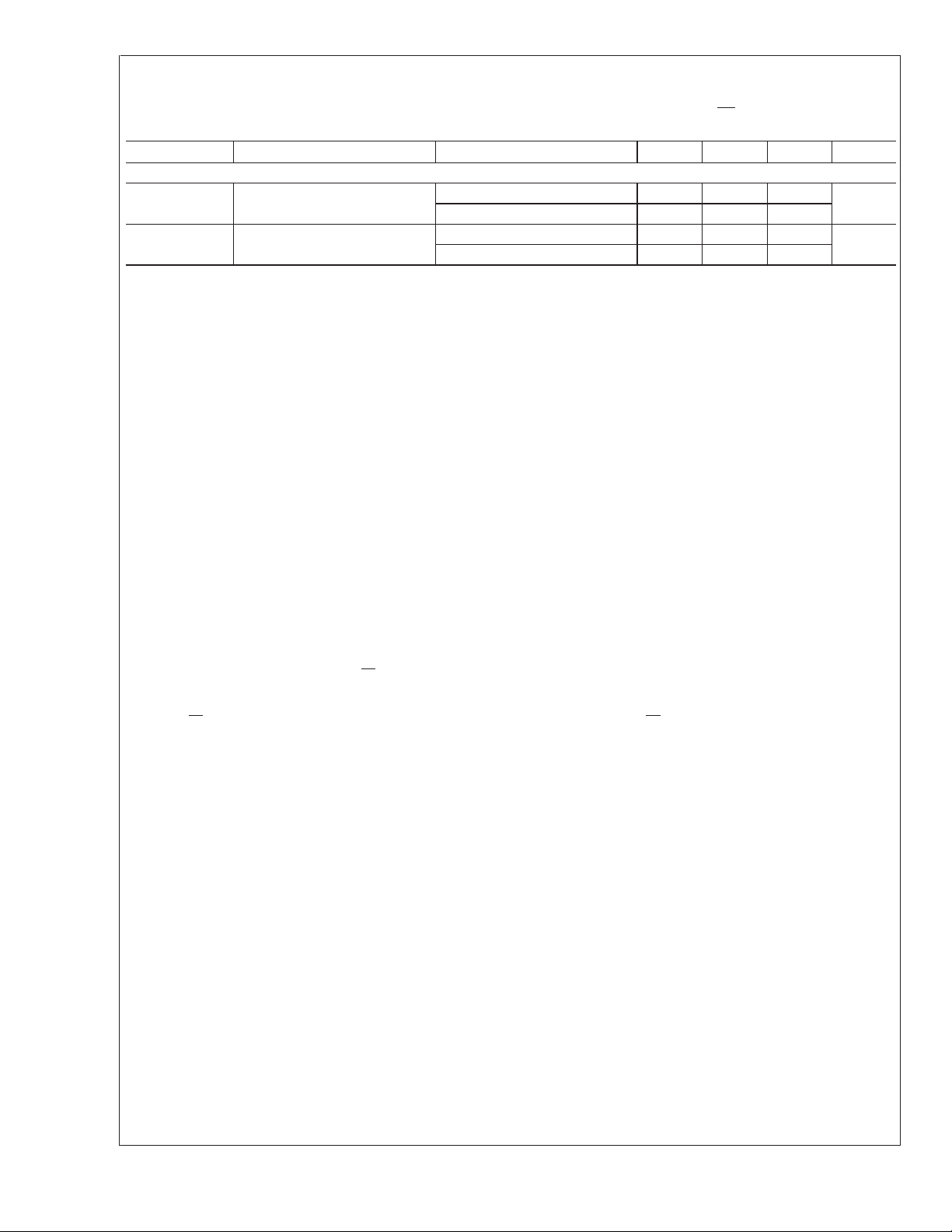

Page 4

Electrical Characteristics (Notes 3, 9) (Continued)

Typical values and limits in standard typeface apply for TJ=25oC. Limits in boldface type apply over the operating junction

LM2750

temperature range. Unless otherwise specified: 2.9V ≤ V

= 2 x 1µF, C

= 2 x 1µF (Note 10).

OUT

Symbol Parameter Conditions Min Typ Max Units

Capacitor Requirements

C

IN

C

OUT

Required Input

Capacitance(Note 14)

Required Output

Capacitance(Note 14)

Note 2: Absolute Maximum Ratings indicate limits beyond which damage to the component may occur. Operating Ratings are conditions under which operation of

the device is guaranteed. Operating Ratings do not imply guaranteed performance limits. For guaranteed performance limits and associated test conditions, see the

Electrical Characteristics tables.

Note 3: All voltages are with respect to the potential at the GND pin.

Note 4: Thermal shutdown circuitry protects the device from permanent damage. Thermal shutdown engages at T

Note 5: Absiolute Maximum Output Current guaranteed by design. Recommended input voltage range for output currents in excess of 120mA: 3.1V to 4.4V.

Note 6: The Human body model is a 100 pF capacitor discharged through a 1.5 kΩ resistor into each pin. MIL-STD-883 3015.7. The machine model is a 200pF

capacitor discharged directly into each pin.

Note 7: Maximum ambient temperature (T

dissipation of the device in the application (P

following equation: T

equation: P

I

are the maximum voltage/current of the specific application, and not necessarily the maximum rating of the LM2750.

OUT-MAX

The maximum ambient temperature rating of 85

V

= 5.5V and I

IN-MAX

20mW above 727mW (again assuming that θ

Leadframe Package (LLP) and the Power Efficiency and Power Dissipation section of this datasheet.

Note 8: Junction-to-ambient thermal resistance (θ

standard JESD51-7. The test board is a 4 layer FR-4 board measuring 102mm x 76mm x 1.6mm witha2x1array of thermal vias. The ground plane on the board

is 50mm x 50mm. Thickness of copper layers are 36µm/18µm /18µm/36µm (1.5oz/1oz/1oz/1.5oz). Ambient temperature in simulation is 22˚C, still air. Power

dissipation is 1W.

The value of θ

conditions. In applications where high maximum power dissipation exists (high V

information on these topics, please refer to Application Note 1187: Leadless Leadframe Package (LLP) and the Layout Recommendations section of this

datasheet.

Note 9: Min and Max limits are guaranteed by design, test, or statistical analysis. Typical numbers are not guaranteed, but do represent the most likely norm.

Note 10: C

Note 11: Turn-on time is measured from when SD signal is pulled high until the output voltage crosses 90% of its final value.

Note 12: Efficiency is measured versus VIN, with VINbeing swept in small increments from 3.0V to 4.2V. The average is calculated from these measurements

results. Weighting to account for battery voltage discharge characteristics (V

Note 13: SD Input Current (I

Note 14: Limit is the minimum required output capacitance to ensure proper operation. This electrical specification is guaranteed by design.

A-MAX=TJ-MAX-OP

=(V

D-MAX

FLY,CIN

IN-MAXxIIN-MAX

OUT-MAX

of the LM2750 in LLP-10 could fall in a range as wide as 50oC/W to 150oC/W (if not wider), depending on PCB material, layout, and environmental

JA

, and C

OUT

)-(V

= 115mA, for example). Maximum ambient temperature must be derated by 1.1oC for every increase in internal power dissipation of

: Low-ESR Surface-Mount Ceramic Capacitors (MLCCs) used in setting electrical characteristics

) is due to a 200kΩ (typ.) pull-down resistor connected internally between the SD pin and GND.

IH

) is dependent on the maximum operating junction temperature (T

A-MAX

), and the junction-to ambient thermal resistance of the part/package in the application (θJA), as given by the

D-MAX

-(θJAxP

JA

). Maximum power dissipation of the LM2750 in a given application can be approximated using the following

D-MAX

OUTxIOUT-MAX

o

C is determined under the following application conditions: θJA=55oC/W, P

=55oC/W in the application). For more information on these topics, please refer to Application Note 1187: Leadless

) is taken from a thermal modeling result, performed under the conditions and guidelines set forth in the JEDEC

JA

I

60mA ≤ I

I

60mA ≤ I

)=[V

≤ 5.6V, V

IN

≤ 60mA 1.0 µF

OUT

≤ 120mA 2.0

OUT

≤ 60mA 1.0 µF

OUT

≤ 120mA 2.0

OUT

x((2xI

IN-MAX

OUT-MAX

, high I

IN

vs. Time) is not done in computing the average.

BAT

= 5.0V (LM2750-ADJ), V(SD) = VIN,C

OUT

=150˚C (typ.) and disengages at TJ=135˚C (typ.).

J

= 125oC), the maximum power

J-MAX-OP

) + 5mA)] - (V

), special care must be paid to thermal dissipation issues. For more

OUT

OUTxIOUT-MAX

). In this equation, V

D-MAX

FLY

IN-MAX,IIN-MAX

= 727mW (achieved when

= 1µF, C

IN

, and

www.national.com 4

Page 5

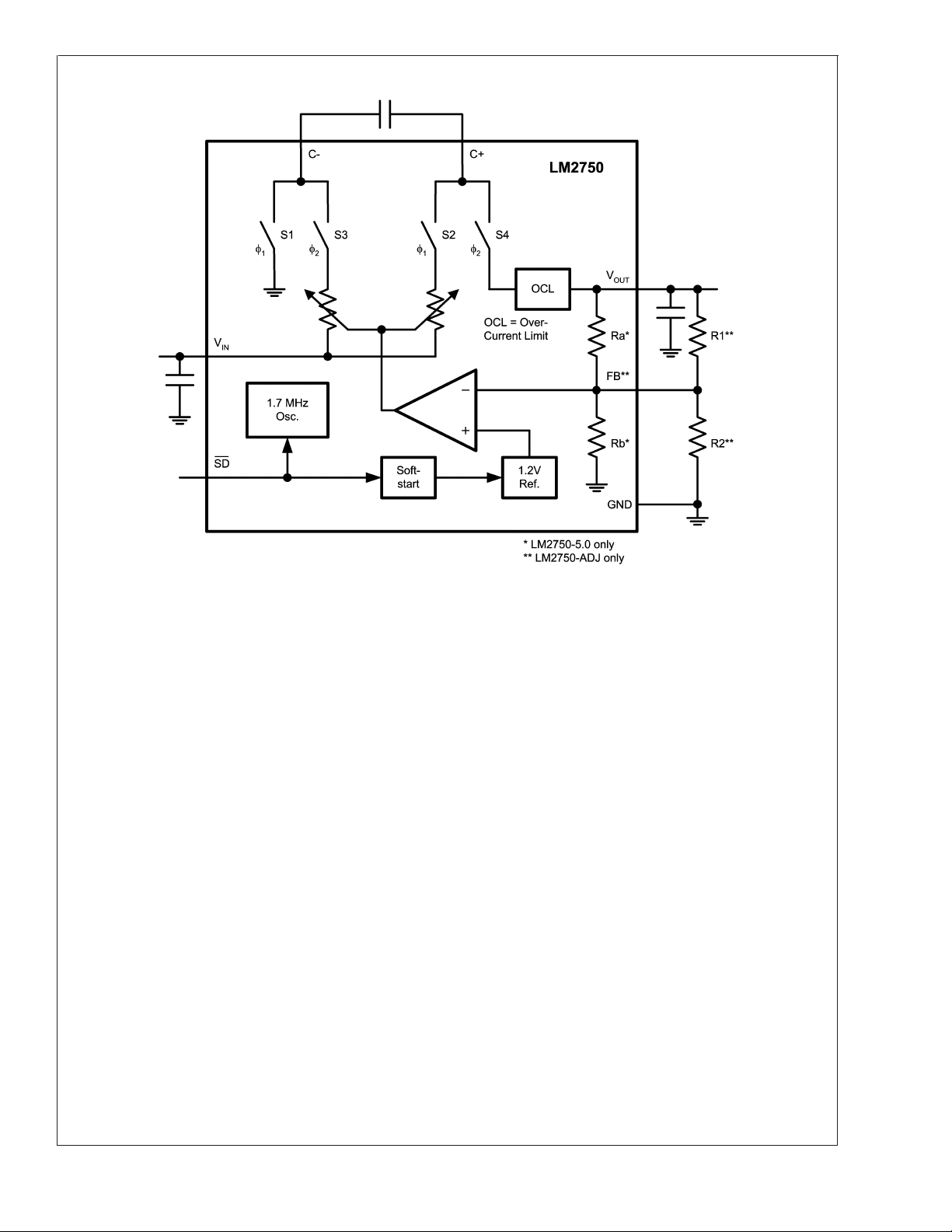

Block Diagram

LM2750

20035103

www.national.com5

Page 6

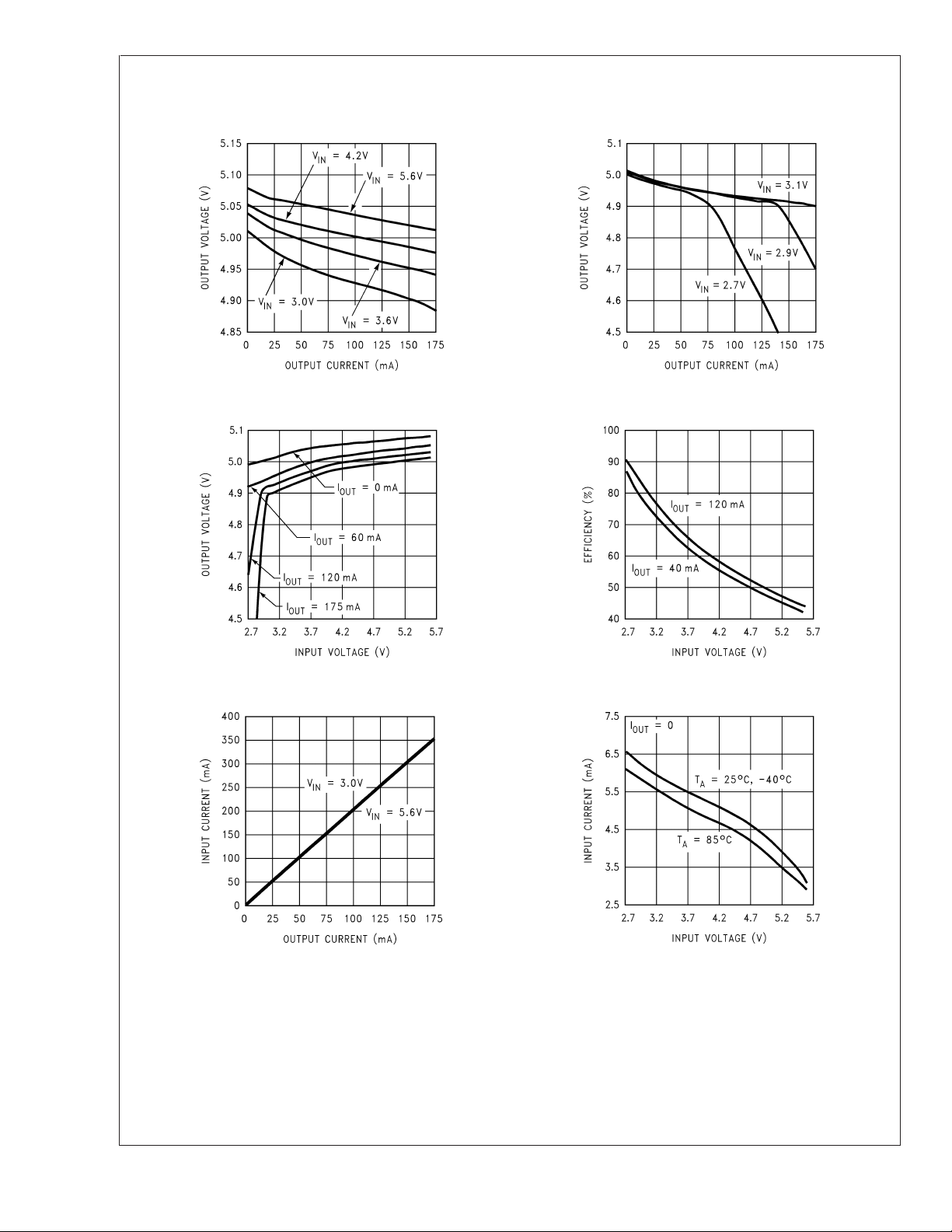

Typical Performance Characteristics Unless otherwise specified: V

2.2µF, C

LM2750

= 1.0µF, C

FLY

Output Voltage vs. Output Current Output Voltage vs. Output Current

Output Voltage vs. Input Voltage Power Efficiency

= 2.2µF. Capacitors are low-ESR multi-layer ceramic capacitors (MLCC’s).

OUT

20035115 20035116

= 3.6V, TA=25oC, CIN=

IN

20035117 20035118

Input Current vs. Output Current Quiescent Supply Current

20035119

20035120

www.national.com 6

Page 7

LM2750

Typical Performance Characteristics Unless otherwise specified: V

2.2µF, C

= 1.0µF, C

FLY

Current Limit Behavior Switching Frequency

Output Voltage Ripple Output Voltage Ripple, I

= 2.2µF. Capacitors are low-ESR multi-layer ceramic capacitors (MLCC’s). (Continued)

OUT

20035121

= 3.6V, TA=25oC, CIN=

IN

20035122

= 120mA

OUT

Turn-on Behavior

20035113

20035112

20035114

www.national.com7

Page 8

Operation Description

LM2750

OVERVIEW

The LM2750 is a regulated switched capacitor doubler that,

by combining the principles of switched-capacitor voltage

boost and linear regulation, generates a regulated output

from an extended Li-Ion input voltage range. A two-phase

non-overlapping clock generated internally controls the operation of the doubler. During the charge phase (φ1), the

flying capacitor (C

ground through internal pass-transistor switches and is

charged to the input voltage. In the pump phase that follows

(φ2), the flying capacitor is connected between the input and

output through similar switches. Stacked atop the input, the

charge of the flying capacitor boosts the output voltage and

supplies the load current.

A traditional switched capacitor doubler operating in this

manner will use switches with very low on-resistance to

generate an output voltage that is 2x the input voltage. The

LM2750 regulates the output voltage by controlling the resistance of the two input-connected pass-transistor switches

in the doubler.

PRE-REGULATION

The very low input current ripple of the LM2750, resulting

from internal pre-regulation, adds very little noise to the input

line. The core of the LM2750 is very similar to that of a basic

switched capacitor doubler: it is composed of four switches

and a flying capacitor (external). Regulation is achieved by

modulating the on-resistance of the two switches connected

to the input pin (one switch in each phase). The regulation is

done before the voltage doubling, giving rise to the term

"pre-regulation". It is pre-regulation that eliminates most of

the input current ripple that is a typical and undesirable

characteristic of a many switched capacitor converters.

INPUT, OUTPUT, AND GROUND CONNECTIONS

Making good input, output, and ground connections is essential to achieve optimal LM2750 performance. The two

input pads, pads 8 and 9, must be connected externally. It is

strongly recommended that the input capacitor (C

placed as close as possible to the LM2750, so that the traces

from the input pads are as short and straight as possible. To

minimize the effect of input noise on LM2750 performance, it

is best to bring two traces out from the LM2750 all the way to

the input capacitor pad, so that they are connected at the

capacitor pad. Connecting the two input traces between the

input capacitor and the LM2750 input pads could make the

LM2750 more susceptible to noise-related performance degradation. It is also recommended that the input capacitor be

on the same side of the PCB as the LM2750, and that traces

remain on this side of the board as well (vias to traces on

other PCB layers are not recommended between the input

capacitor and LM2750 input pads).

The two output pads, pads 1 and 2, must also be connected

externally. It is recommended that the output capacitor

) be placed as close to the LM2750 output pads as

(C

OUT

possible. It is best if routing of output pad traces follow

guidelines similar to those presented for the input pads and

capacitor. The flying capacitor (C

as close to the LM2750 as possible to minimize PCB trace

length between the capacitor and the IC. Due to the padlayout of the part, it is likely that the trace from one of the

flying capacitor pads (C+ or C-) will need to be routed to an

internal or opposite-side layer using vias. This is acceptable,

) is connected between the input and

FLY

) should also be placed

FLY

IN

)be

and it is much more advantageous to route a flying capacitor

trace in this fashion than it is to place input traces on other

layers.

The GND pads of the LM2750 are ground connections and

must be connected externally. These include pads 3

(LM2750-5.0 only), 5, 6 and the die-attach pad (DAP). Large,

low impedance copper fills and via connections to an internal

ground plane are the preferred way of connecting together

the ground pads of the LM2750, the input capacitor, and the

output capacitor, as well as connecting this circuit ground to

the system ground of the PCB.

SHUTDOWN

When the voltage on the active-low-logic shutdown pin is

low, the LM2750 will be in shutdown mode. In shutdown, the

LM2750 draws virtually no supply current. There is a 200kΩ

pull-down resistor tied between the SD pin and GND that

pulls the SD pin voltage low if the pin is not driven by a

voltage source. When pulling the part out of shutdown, the

voltage source connected to the SD pin must be able to drive

the current required by the 200kΩ resistor. For voltage management purposes required upon startup, internal switches

connect the output of the LM2750 to an internal pull-down

resistor (1kΩ typ) when the part is shutdown. Driving the

output of the LM2750 by another supply when the LM2750 is

shutdown is not recommended, as the pull-down resistor

was not sized to sink continuous current.

SOFT START

The LM2750 employs soft start circuitry to prevent excessive

input inrush currents during startup. The output voltage is

programmed to rise from 0V to the nominal output voltage

(5.0V) in 500µs (typ.). Soft-start is engaged when a part, with

input voltage established, is taken out of shutdown mode by

pulling the SD pin voltage high. Soft-start will also engage

when voltage is established simultaneously to the input and

SD pins.

OUTPUT CURRENT CAPABILITY

The LM2750-5.0 is guaranteed to provide 120mA of output

current when the input voltage is within 2.9V-to-5.6V. Using

the LM2750 to drive loads in excess of 120mA is possible.

IMPORTANT NOTE: Understanding relevant application issues is recommended and a thorough analysis of the application circuit should be performed when using the part outside operating ratings and/or specifications to ensure

satisfactory circuit performance in the application. Special

care should be paid to power dissipation and thermal effects.

These parameters can have a dramatic impact on highcurrent applications, especially when the input voltage is

high. (see "Power Efficiency and Power Dissipation" section,

to come).

The schematic of Figure 1 is a simplified model of the

LM2750 that is useful for evaluating output current capability.

The model shows a linear pre-regulation block (Reg), a

voltage doubler (2x), and an output resistance (R

OUT

). Output resistance models the output voltage droop that is inherent to switched capacitor converters. The output resistance

of the LM2750 is 5Ω (typ.), and is approximately equal to

twice the resistance of the four LM2750 switches. When the

output voltage is in regulation, the regulator in the model

controls the voltage V’ to keep the output voltage equal to

±

4%. With increased output current, the voltage drop

5.0V

across R

increases. To prevent droop in output voltage,

OUT

the voltage drop across the regulator is reduced, V’ increases, and V

remains at 5V. When the output current

OUT

www.national.com 8

Page 9

Operation Description (Continued)

increases to the point that there is zero voltage drop across

the regulator, V’ equals the input voltage, and the output

voltage is "on the edge" of regulation. Additional output

current causes the output voltage to fall out of regulation,

and the LM2750 operation is similar to a basic open-loop

doubler. As in a voltage doubler, increase in output current

results in output voltage drop proportional to the output

resistance of the doubler. The out-of-regulation LM2750 output voltage can be approximated by:

= 2xVIN-I

V

OUT

Again, this equation only applies at low input voltage and

high output current where the LM2750 is not regulating. See

Output Current vs. Output Voltage curves in the Typical

Performance Characteristics section for more details.

OUTxROUT

switches into shutdown mode. The LM2750 releases thermal

shutdown when the junction temperature of the part is reduced to 130

o

C (typ.).

Thermal shutdown is most-often triggered by self-heating,

which occurs when there is excessive power dissipation in

the device and/or insufficient thermal dissipation. LM2750

power dissipation increases with increased output current

and input voltage (see Power Efficiency and Power Dissi-

pation section). When self-heating brings on thermal shutdown, thermal cycling is the typical result. Thermal cycling is

the repeating process where the part self-heats, enters thermal shutdown (where internal power dissipation is practically

zero), cools, turns-on, and then heats up again to the thermal shutdown threshold. Thermal cycling is recognized by a

pulsing output voltage and can be stopped be reducing the

internal power dissipation (reduce input voltage and/or output current) or the ambient temperature. If thermal cycling

occurs under desired operating conditions, thermal dissipation performance must be improved to accommodate the

power dissipation of the LM2750. Fortunately, the LLP package has excellent thermal properties that, when soldered to

a PCB designed to aid thermal dissipation, allows the

LM2750 to operate under very demanding power dissipation

conditions.

LM2750

20035109

FIGURE 1. LM2750 Output Resistance Model

A more complete calculation of output resistance takes into

account the effects of switching frequency, flying capacitance, and capacitor equivalent series resistance (ESR).

This equation is shown below:

Switch resistance (5Ω typ.) dominates the output resistance

equation of the LM2750. With a 1.7MHz typical switching

frequency, the 1/(FxC) component of the output resistance

contributes only 0.6Ω to the total output resistance. Increasing the flying capacitance will only provide minimal improvement to the total output current capability of the LM2750. In

some applications it may be desirable to reduce the value of

the flying capacitor below 1µF to reduce solution size and/or

cost, but this should be done with care so that output resistance does not increase to the point that undesired output

voltage droop results. If ceramic capacitors are used, ESR

will be a negligible factor in the total output resistance, as the

ESR of quality ceramic capacitors is typically much less than

100mΩ.

THERMAL SHUTDOWN

The LM2750 implements a thermal shutdown mechanism to

protect the device from damage due to overheating. When

the junction temperature rises to 150

o

C (typ.), the part

OUTPUT CURRENT LIMITING

The LM2750 contains current limit circuitry that protects the

device in the event of excessive output current and/or output

shorts to ground. Current is limited to 300mA (typ.) when the

output is shorted directly to ground. When the LM2750 is

current limiting, power dissipation in the device is likely to be

quite high. In this event, thermal cycling should be expected

(see Thermal Shutdown section).

PROGRAMMING THE OUTPUT VOLTAGE OF THE LM2750-ADJ

As shown in the application circuit of Figure 2, the output

voltage of the LM2750-ADJ can be programmed with a

simple resistor divider (see resistors R1 and R2). The values

of the feedback resistors set the output voltage, as determined by the following equation:

= 1.23V x (1 + R1/ R2)

V

OUT

In the equation above, the "1.23V" term is the nominal

voltage of the feedback pin when the feedback loop is correctly established and the part is operating normally. The

sum of the resistance of the two feedback resistors should

be between 15kΩ and 20kΩ:

<

15kΩ

(R1 + R2)<20kΩ

If larger feedback resistors are desired, a 10pF capacitor

should be placed in parallel with resistor R1.

www.national.com9

Page 10

Operation Description (Continued)

LM2750

FIGURE 2. LM2750-ADJ Typical Application Circuit

20035123

Application Information

OUTPUT VOLTAGE RIPPLE

The amount of voltage ripple on the output of the LM2750 is

highly dependent on the application conditions: output current and the output capacitor, specifically. A simple approximation of output ripple is determined by calculating the

amount of voltage droop that occurs when the output of the

LM2750 is not being driven. This occurs during the charge

phase (φ1). During this time, the load is driven solely by the

charge on the output capacitor. The magnitude of the ripple

thus follows the basic discharge equation for a capacitor (I =

C x dV/dt), where discharge time is one-half the switching

period, or 0.5/F

A more thorough and accurate examination of factors that

affect ripple requires including effects of phase non-overlap

times and output capacitor equivalent series resistance

(ESR). In order for the LM2750 to operate properly, the two

phases of operation must never coincide. (If this were to

happen all switches would be closed simultaneously, shorting input, output, and ground). Thus, non-overlap time is built

into the clocks that control the phases. Since the output is

not being driven during the non-overlap time, this time

should be accounted for in calculating ripple. Actual output

capacitor discharge time is approximately 60% of a switching period, or 0.6/F

The ESR of the output capacitor also contributes to the

output voltage ripple, as there is effectively an AC voltage

drop across the ESR due to current switching in and out of

the capacitor. The following equation is a more complete

calculation of output ripple than presented previously, taking

into account phase non-overlap time and capacitor ESR.

. Put simply,

SW

.

SW

A low-ESR ceramic capacitor is recommended on the output

to keep output voltage ripple low. Placing multiple capacitors

in parallel can reduce ripple significantly, both by increasing

capacitance and reducing ESR. When capacitors are in

parallel, ESR is in parallel as well. The effective net ESR is

determined according to the properties of parallel resistance.

Two identical capacitors in parallel have twice the capacitance and half the ESR as compared to a single capacitor of

the same make. On a similar note, if a large-value, high-ESR

capacitor (tantalum, for example) is to be used as the primary output capacitor, the net output ESR can be significantly reduced by placing a low-ESR ceramic capacitor in

parallel with this primary output capacitor.

CAPACITORS

The LM2750 requires 3 external capacitors for proper operation. Surface-mount multi-layer ceramic capacitors are recommended. These capacitors are small, inexpensive and

have very low equivalent series resistance (≤10mΩ typ.).

Tantalum capacitors, OS-CON capacitors, and aluminum

electrolytic capacitors generally are not recommended for

use with the LM2750 due to their high ESR, as compared to

ceramic capacitors.

For most applications, ceramic capacitors with X7R or X5R

temperature characteristic are preferred for use with the

LM2750. These capacitors have tight capacitance tolerance

±

(as good as

±

15% over -55oCto125oC; X5R:±15% over -55oCto85oC),

10%), hold their value over temperature (X7R:

and typically have little voltage coefficient. Capacitors with

Y5V and/or Z5U temperature characteristic are generally not

recommended. These types of capacitors typically have

wide capacitance tolerance (+80%, -20%), vary significantly

over temperature (Y5V: +22%, -82% over -30

range; Z5U: +22%, -56% over +10

o

Cto+85oC range), and

o

Cto+85oC

have poor voltage coefficients. Under some conditions, a

nominal 1µF Y5V or Z5U capacitor could have a capacitance

of only 0.1µF. Such detrimental deviation is likely to cause

these Y5V and Z5U of capacitors to fail to meet the minimum

capacitance requirements of the LM2750.

The table below lists some leading ceramic capacitor manufacturers.

www.national.com 10

Page 11

Application Information (Continued)

Manufacturer Contact Information

TDK www.component.tdk.com

AVX www.avx.com

Murata www.murata.com

Taiyo-Yuden www.t-yuden.com

Vishay-Vitramon www.vishay.com

INPUT CAPACITOR

The input capacitor (C

helping to quickly transfer charge to the flying capacitor

during the charge phase (φ1) of operation. The input capacitor helps to keep the input voltage from drooping at the start

of the charge phase, when the flying capacitor is first connected to the input, and helps to filter noise on the input pin

that could adversely affect sensitive internal analog circuitry

biased off the input line. As mentioned above, an X7R/X5R

ceramic capacitor is recommended for use. For applications

where the maximum load current required is between 60mA

and 120mA, a minimum input capacitance of 2.0µF is required. For applications where the maximum load current is

60mA or less, 1.0µF of input capacitance is sufficient. Failure

to provide enough capacitance on the LM2750 input can

result in poor part performance, often consisting of output

voltage droop, excessive output voltage ripple and/or excessive input voltage ripple.

A minimum voltage rating of 10V is recommended for the

input capacitor. This is to account for DC bias properties of

ceramic capacitors. Capacitance of ceramic capacitors reduces with increased DC bias. This degradation can be quite

>

significant (

50%) when the DC bias approaches the volt-

age rating of the capacitor.

FLYING CAPACITOR

The flying capacitor (C

the output, providing the voltage boost of the doubler. A

polarized capacitor (tantalum, aluminum electrolytic, etc.)

must not be used here, as the capacitor will be reversebiased upon start-up of the LM2750. The size of the flying

capacitor and its ESR affect output current capability when

the input voltage of the LM2750 is low, most notable for input

voltages below 3.0V. These issues were discussed previously in the Output Current Capability section. For most

applications, a 1µF X7R/X5R ceramic capacitor is recommended for the flying capacitor.

OUTPUT CAPACITOR

The output capacitor of the LM2750 plays an important part

in determining the characteristics of the output signal of the

LM2750, many of which have already been discussed. The

ESR of the output capacitor affects charge pump output

resistance, which plays a role in determining output current

capability. Both output capacitance and ESR affect output

voltage ripple. For these reasons, a low-ESR X7R/X5R ceramic capacitor is the capacitor of choice for the LM2750

output.

In addition to these issues previously discussed, the output

capacitor of the LM2750 also affects control-loop stability of

the part. Instability typically results in the switching frequency effectively reducing by a factor of two, giving excessive output voltage droop and/or increased voltage ripple on

the output and the input. With output currents of 60mA or

less, a minimum capacitance of 1.0µF is required at the

) is used as a reservoir of charge,

IN

) transfers charge from the input to

FLY

output to ensure stability. For output currents between 60mA

and 120mA, a minimum output capacitance of 2.0µF is

required.

A minimum voltage rating of 10V is recommended for the

output capacitor. This is to account for DC bias properties of

ceramic capacitors. Capacitance of ceramic capacitors reduces with increased DC bias. This degradation can be quite

>

significant (

50%) when the DC bias approaches the volt-

age rating of the capacitor.

POWER EFFICIENCY AND POWER DISSIPATION

Efficiency of the LM2750 mirrors that of an unregulated

switched capacitor converter followed by a linear regulator.

The simplified power model of the LM2750, in Figure 3, will

be used to discuss power efficiency and power dissipation.

In calculating power efficiency, output power (P

OUT

) is easily

determined as the product of the output current and the 5.0V

output voltage. Like output current, input voltage is an

application-dependent variable. The input current can be

calculated using the principles of linear regulation and

switched capacitor conversion. In an ideal linear regulator,

the current into the circuit is equal to the current out of the

circuit. The principles of power conservation mandate the

ideal input current of a voltage doubler must be twice the

output current. Adding a correction factor for operating quiescent current (I

, 5mA typ.) gives an approximation for total

Q

input current which, when combined with the other input and

output parameter(s), yields the following equation for efficiency:

Comparisons of LM2750 efficiency measurements to calculations using the above equation have shown the equation to

be a quite accurate approximation of actual efficiency. Because efficiency is inversely proportional to input voltage, it

is highest when the input voltage is low. In fact, for an input

voltage of 2.9V, efficiency of the LM2750 is greater than 80%

≥ 40mA) and peak efficiency is 85% (I

(I

OUT

OUT

= 120mA).

The average efficiency for an input voltage range spanning

the Li-Ion range (2.9V-to-4.2V) is 70% (I

= 120mA). At

OUT

higher input voltages, efficiency drops dramatically. In Li-Ionpowered applications, this is typically not a major concern,

as the circuit will be powered off a charger in these circumstances. Low efficiency equates to high power dissipation,

however, which could become an issue worthy of attention.

LM2750 power dissipation (P

) is calculated simply by sub-

D

tracting output power from input power:

P

D=PIN-POUT

=[VINx (2·I

OUT+IQ

)]-[V

OUTxIOUT

]

Power dissipation increases with increased input voltage

and output current, up to 772mW at the ends of the operating

ratings (V

= 5.6V, I

IN

= 120mA). Internal power dissipa-

OUT

tion self-heats the device. Dissipating this amount power/

heat so the LM2750 does not overheat is a demanding

thermal requirement for a small surface-mount package.

When soldered to a PCB with layout conducive to power

dissipation, the excellent thermal properties of the LLP package enable this power to be dissipated from the LM2750 with

little or no derating, even when the circuit is placed in elevated ambient temperatures.

LM2750

www.national.com11

Page 12

Application Information (Continued)

LM2750

FIGURE 3. LM2750 Model for Power Efficiency and

Power Dissipation Calculations

LAYOUT RECOMMENDATIONS

A good board layout of the LM2750 circuit is required to

achieve optimal assembly, electical, and thermal dissipation

perfromance. Figure 4 is an example of a board layout

20035110

implementing recommended techniques. For more information related to layout for the LLP package, refer to National

Semiconductor’s Application Note 1187: Leadless Lead-

frame Package (LLP). Below are some general guidelines

for board layout:

Place capacitors as close to the as possible to the

•

LM2750, and on the same side of the board. V

connections are most critical: run short traces from

V

OUT

and

IN

the LM2750 pads directly to these capacitor pads.

Connect the ground pins of the LM2750 and the capaci-

•

tors to a good ground plane. The ground plane is essential for both electrical and thermal disspation performance.

For optimal thermal performance, make the ground

•

plane(s) as large as possible. Connect the die-attach pad

(DAP) of the LM2750 to the ground plane(s) with wide

traces and/or multiple vias. Top-layer ground planes are

most effective in increasing the thermal dissipation capability of the LLP package. Large internal ground planes

are also very effective in keeping the die temperature of

the LM2750 within operating ratings.

20035126

FIGURE 4. LM2750-5.0 Recommended Layout

www.national.com 12

Page 13

LM2750 LED Drive Application

FIGURE 5. LM2750-5.0 LED Drive Application Circuit

LM2750

20035124

FIGURE 6. LM2750-ADJ LED Drive Application Circuit

The LM2750 is an excellent part for driving white and blue

LEDs for display backlighting and other general-purpose

lighting functions. The circuits of Figure 5 and Figure 6 show

LED driver circuits for the LM2750-5.0 and the LM2750-ADJ,

respectively. Simply placing a resistor (R) in series with each

LED sets the current through the LEDs:

=(V

I

LED

OUT-VLED

In the equation above, I

a particular LED, and V

)/R

is the current that flows through

LED

is the forward voltage of the LED

LED

at the given current. As can be seen in the equation above,

LED current will vary with changes in LED forward voltage

). Mismatch of LED currents will result in brightness

(V

LED

mismatch from one LED to the next.

The feedback pin of the LM2750-ADJ can be utilized to help

better control brightness levels and negate the effects of

LED forward voltage variation. As shown in Figure 6, connecting the feedback pin to the primary LED-resistor junction

(LED1-R1) regulates the current through that LED. The voltage across the primary resistor (R1) is the feedback pin

20035125

voltage (1.23V typ.), and the current through the LED is the

current through that resistor. Current through all other LEDs

(LEDx) will not be regulated, however, and will vary with LED

forward voltage variations. When using the LM2750-ADJ in

current-mode, LED currents can be calculated with the

equations below:

= 1.23V / R1

I

LED1

I

LEDx

= (1.23V + V

LED1-VLEDx

)/Rx

The current-mode configuration does not improve brightness

matching from one LED to another in a single circuit, but will

keep currents similar from one circuit to the next. For example: if there is forward voltage mismatch from LED1 to

LED2 on a single board, the current-mode LM2750-ADJ

solution provides no benefit. But if the forward voltage of

LED1 on one board is different than the forward voltage of

LED1 on another board, the currents through LED1 in both

phones will match. THis helps keep LED currents fairly

consistent from one product to the next, adn helps to offset

lot-to-lot variation of LED forward voltage characteristics.

www.national.com13

Page 14

LM2750 LED Drive Application

(Continued)

LM2750

PWM BRIGHTNESS/DIMMING CONTROL

Brightness of the LEDs can be adjusted in an application by

driving the SD pin of the LM2750 with a PWM signal. When

the PWM signal is high, the LM2750 is ON, and current flows

through the LEDs, as described in the previous section. A

low PWM signal turns the part and the LEDs OFF. The

perceived brightness of the LEDs is proportional to ON

current of the LEDs and the duty cycle (D) of the PWM signal

(the percentage of time the LEDs are ON).

To achieve good brightness/dimming control with this circuit,

proper selection of the PWM frequency is required. The

PWM frequency (F

avoid visible flickering of the LED light. An upper bound on

this frequency is also needed to accomodate the turn-on

time of the LM2750 (T

recommended PWM frequency is similarly dependent on the

minimum duty cycle (D

equation puts bounds on the reommended PWM frequency

range:

100Hz

Choosing a PWM frequency within these limits will result in

fairly linear control of the time-averaged LED current over

the full duty-cycle adjustment range. For most applications, a

PWM frequency between 100Hz and 500Hz is recommended. A PWM frequency up to 1kHz may be acceptable in

some designs.

LED DRIVER POWER EFFICIENCY

Efficiency of an LED driver (E

power consumed by the LEDs (P

consumed at the input of the circuit. Input power consumption of the LM2750 was explained and defined in the previous section titled: Power Efficiency and Power Dissipa-

tion. Assuming LED forward voltages and currents match

reasonably well, LED power consumption is the product of

the number of LEDs in the circuit (N), the LED forward

voltage (V

P

LED

E

LED=PLED/PIN

), and the LED forward current (I

LED

=NxV

LEDxILED

Figure 7 is an efficiency curve for a typical LM2750 LEDdrive application.

) should be set higher than 100Hz to

PWM

= 0.5ms typ.). This maximum

ON

) of the application. The following

MIN

<

= (NxV

F

PWM

LED

LEDxILED

<

D

MIN÷TON

) is typically defined as the

) divided by the power

LED

)/{VINx [(2xI

LED

OUT

):

) + 5mA]}

LED DRIVER POWER CONSUMPTION

For battery-powered LED-drive applications, it is strongly

recommended that power consumption, rather than power

efficiency, be used as the metric of choice when evaluating

power conversion performance. Power consumed (P

simply the product of input voltage (V

):

(I

IN

P

IN=VINxIIN

) and input current

IN

IN

)is

LM2750 input current is equal to twice the output current

), plus the supply current of the part (nominally 5mA):

(I

OUT

I

IN

= (2xI

OUT

) + 5mA

Output voltage and LED voltage do not impact the amount of

current consumed by the LM2750 circuit. Thus, neither factor

affects the current draw on a battery. Since output voltage

does not impact input current, there is no power savings with

either the LM2750-5.0 or the LM2750-ADJ: both options

consume the same amount of power.

In the previous section, LED Driver Efficiency was defined

as:

E

LED=PLED/PIN

= (NxV

LEDxILED

)/{VINx [(2xI

OUT

) + 5mA]}

The equation above can be simplified by recognizing the

following:

>>

2xI

NxI

OUT

LED=IOUT

5mA (high output current applications)

Simplification yields:

E

LED=VLED/VIN

This is in direct contrast to the previous assertion that

showed that power consumption was completely independent of LED voltage. As is the case here with the LM2750,

efficiency is often not a good measure of power conversion

effectiveness of LED driver topologies. This is why it is

strongly recommended that power consumption be studied

or measured when comparing the power conversion effictiveness of LED drivers.

One final note: efficiency of an LED drive solution should not

be confused with an efficiency calculation for a standard

power converter (E

E

P=POUT/PIN

).

P

=(V

OUTxIOUT

)/(VINxIIN)

The equation above neglects power losses in the external

resistors that set LED currents and is a very poor metric of

LED-drive power conversion performance.

20035127

FIGURE 7. LM2750 LED Drive Efficiency. 6 LEDs, I

20mA each, V

www.national.com 14

LED

= 4.0V

LED

=

Page 15

Datasheet Revision History

REV. # DATE COMMENTS

1.0 Production Release of LM2750 Datasheet

1.1 09/24/2004 Preliminary version with the following additions:

SDA10A Non-pullback package Added (pgs 2, 16)

•

Absolute Maximum Output Current Rating Added (pgs 3, 4)

•

1.2 09/28/2005 Production Release of new LM2750 Datasheet

Ordering information for SDA10A package added

•

Reference to SDA10A package option added to the Connection Diagram

•

section

1.3 12/21/2005 Production release of new Datasheet for ADJ voltage option in the

No-Pullback Package

Physical Dimensions inches (millimeters) unless otherwise noted

LM2750

10-Pin Pullback LLP

NS Package Number LDA10A

www.national.com15

Page 16

Physical Dimensions inches (millimeters) unless otherwise noted (Continued)

10-Pin Non-Pullback LLP

NS Package Number SDA10A

LM2750 Low Noise Switched Capacitor Boost Regulator

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves

the right at any time without notice to change said circuitry and specifications.

For the most current product information visit us at www.national.com.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL COUNSEL OF NATIONAL SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body, or

(b) support or sustain life, and whose failure to perform when

properly used in accordance with instructions for use

provided in the labeling, can be reasonably expected to result

in a significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor manufactures products and uses packing materials that meet the provisions of the Customer Products

Stewardship Specification (CSP-9-111C2) and the Banned Substances and Materials of Interest Specification (CSP-9-111S2) and contain

no ‘‘Banned Substances’’ as defined in CSP-9-111S2.

Leadfree products are RoHS compliant.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

2. A critical component is any component of a life support

device or system whose failure to perform can be reasonably

expected to cause the failure of the life support device or

system, or to affect its safety or effectiveness.

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Page 17

Loading...

Loading...