Page 1

April 2005

LM2655

2.5A High Efficiency Synchronous Switching Regulator

LM2655 2.5A High Efficiency Synchronous Switching Regulator

General Description

The LM2655 is a current-mode controlled PWM step-down

switching regulator. It has the unique ability to operate in

synchronous or asynchronous mode. This gives the designer flexibility to choose between the high efficiency of

synchronous operation, or the low solution cost of asynchronous operation. Along with flexibility, the LM2655 offers high

power density with the small footprint of a TSSOP-16 package.

>

High efficiency (

internal low ON-resistance (33mΩ) MOSFET, and an external N-Channel MOSFET. This feature, together with its low

quiescent current, makes the LM2655 an ideal fit in portable

applications.

Integrated in the LM2655 are all the power, control, and drive

functions for asynchronous operation. In addition, a low-side

driver output allows easy synchronous operation. The IC

uses patented current sensing circuitry that eliminates the

external current sensing resistor required by other currentmode DC-DC converters. A programmable soft-start feature

limits start up current surges and provides a means of sequencing multiple power supplies.

90%) is obtained through the use of an

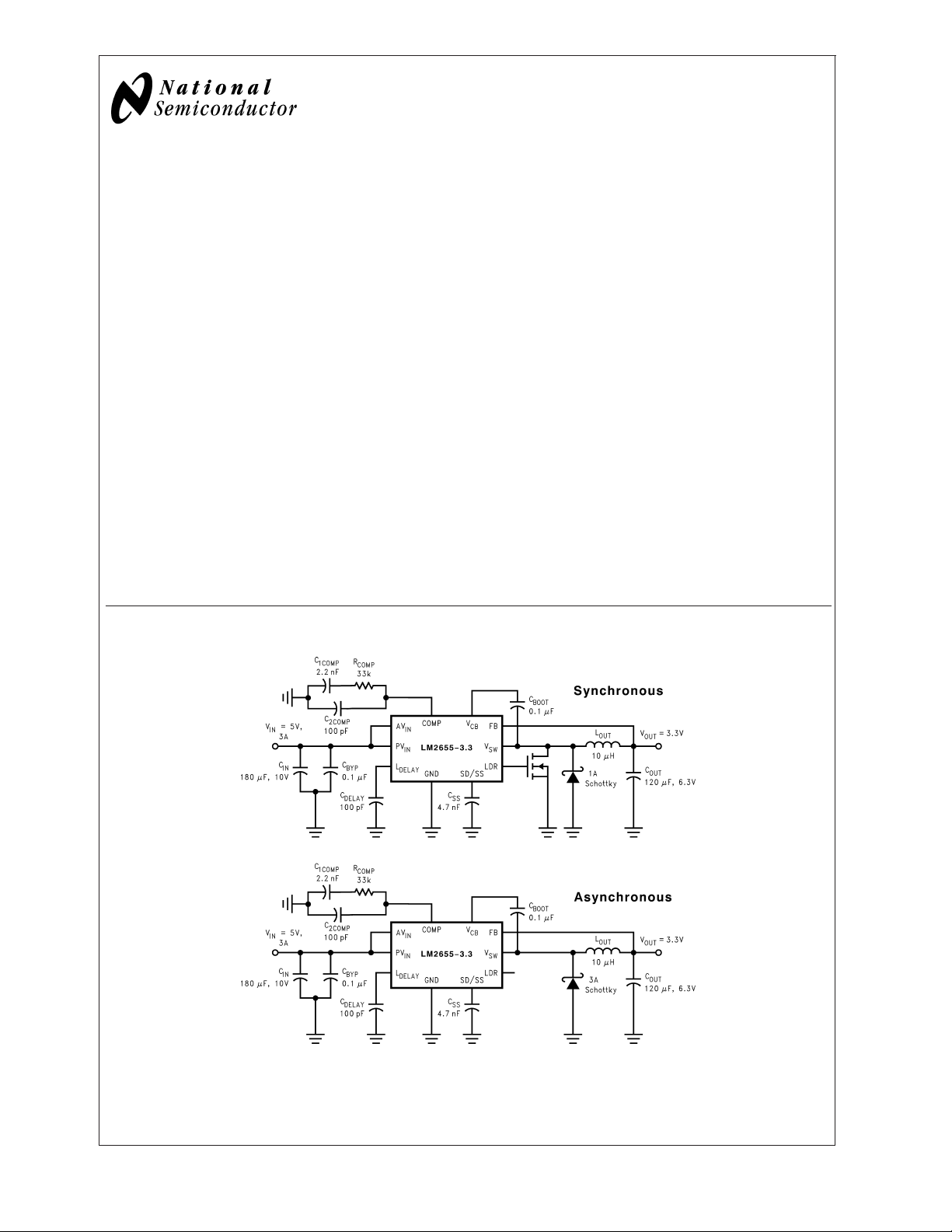

Typical Application

Features

n Ultra-high efficiency up to 96%

n 4V to 14V input voltage range

n Internal high-side MOSFET with low R

n 300 kHz fixed frequency internal oscillator

n Low-side drive for synchronous operation

n Guaranteed less than 12 µA shutdown current

n Patented current sensing for current mode control

n Programmable soft-start

n Input undervoltage lockout

n Output overvoltage shutdown protection

n Output undervoltage shutdown protection

n Thermal Shutdown

n 16-pin TSSOP package

DS(ON)

= 0.033Ω

Applications

n Hard disk drives

n Internet appliances

n TFT monitors

n Computer peripherals

n Battery powered devices

10128429

© 2005 National Semiconductor Corporation DS101284 www.national.com

Page 2

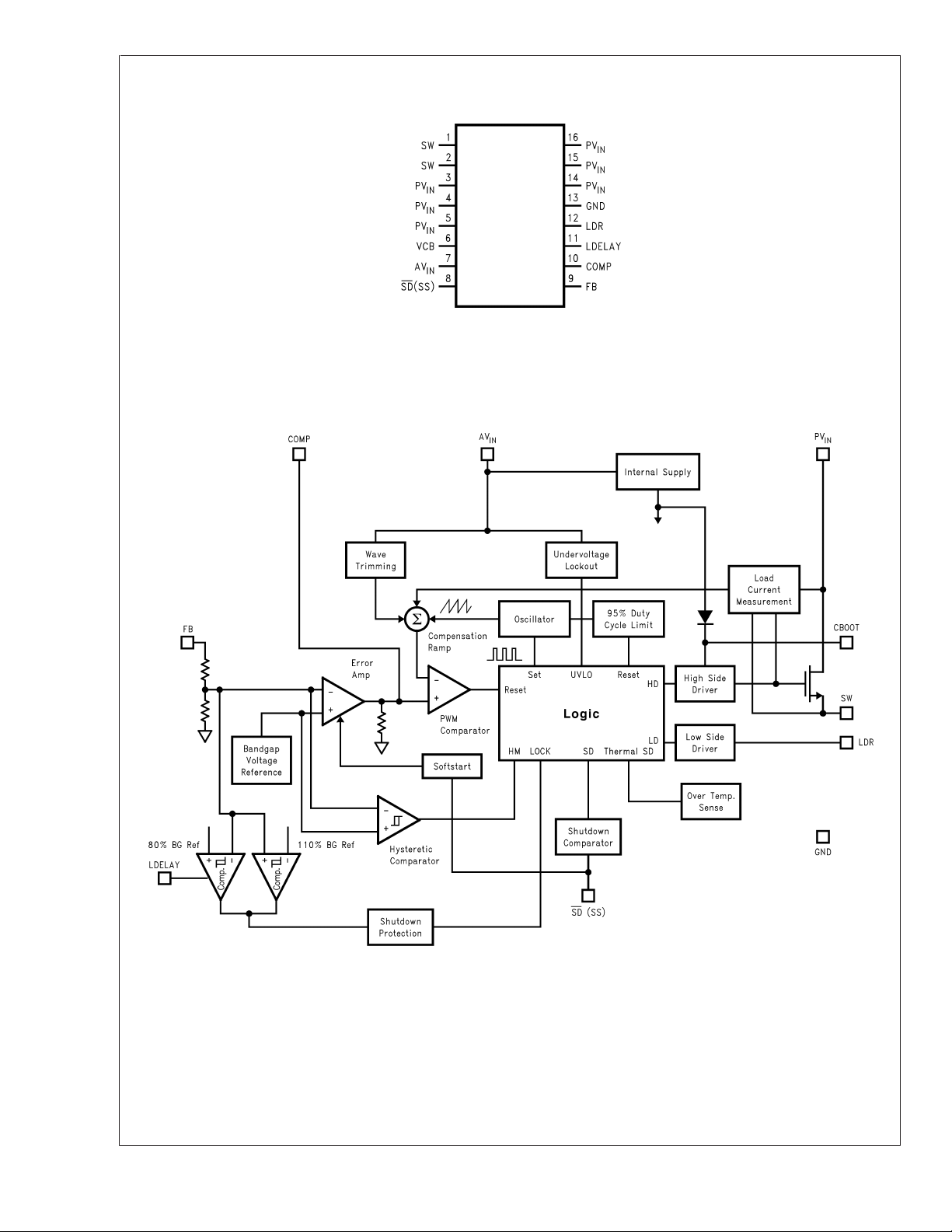

Connection Diagram

LM2655

16-Lead TSSOP (MTC)

Block Diagram

Top View

10128403

Order Number LM2655MTC-ADJ

See NS Package Number MTC16

www.national.com 2

10128404

Page 3

Pin Description

Pin Name Function

1-2 SW Switched-node connection, which is connected to the source of the internal high-side

MOSFET.

3-5 PV

6V

7AV

IN

CB

IN

8 SD(SS)

Main power supply input pin. Connected to the drain of the internal high-side MOSFET.

Bootstrap capacitor connection for high-side gate drive.

Input voltage for control and drive circuits.

Shutdown and Soft-start control pin. Pulling this pin below 0.3V shuts off the regulator. A

capacitor connected from this pin to ground provides a control ramp of the input current.

Do not drive this pin with an external source or erroneous operation may result.

9 FB Output voltage feedback input. Connected to the output voltage.

10 COMP Compensation network connection. Connected to the output of the voltage error amplifier.

11 L

DELAY

A capacitor between this pin to ground sets the delay from when the output voltage

reaches 80% of its nominal to when the undervoltage latch protection is enabled.

12 LDR Low-side FET gate drive pin.

13 GND Power ground.

14-16 PV

IN

Main power supply input pin. Connected to the drain of the internal high-side MOSFET.

Ordering Information

LM2655

Supplied as 1000 units

Tape and Reel

Supplied as 3000 units,

Tape and Reel

LM2655MTC-3.3 LM2655MTCX-3.3

LM2655MTC-ADJ LM2655MTCX-ADJ

www.national.com3

Page 4

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

LM2655

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage (PV

Supply Voltage (AV

Feedback Pin Voltage -0.4V ≤ V

V

Voltage, (Note 7) 7V

CB

C

Voltage 2.5V

SS

Comp Voltage 2.5V

L

Voltage 2.5V

DELAY

LDR Voltage 5V

V

, (Note 8) 14V

SW

Power Dissipation (T

) 3.8V ≤ VIN≤ 14V

IN

) 4.0V ≤ VIN≤ 14V

IN

=25˚C),

A

≤ 5V

FB

TSSOP-16 Package θ

JA

Power Dissapation 893mW

Lead Temperature

Vapor Phase (60 sec.) 215˚C

Infrared (15 sec.) 220˚C

ESD Susceptibility(Note 3)

Human Body Model(Note 4) 1kV

Machine Model 200V

Operating Ratings (Note 1)

Storage Temperature Range −65˚C ≤ T

Junction Temperature Range −40˚C ≤ T

(Note 2)

LM2655-3.3 Electrical Characteristics

Specifications with standard typeface are for TJ= 25˚C, and those in boldface type apply over full Operating Temperature

Range.V

Symbol Parameter Conditions

V

OUT

V

OUT

V

INUV

V

UV_HYST

ICL(Note 9) Average Output Current

= 10V unless otherwise specified.

IN

Output Voltage I

Output Voltage Line

Regulation

Output Voltage Load

Regulation

VINUndervoltage Lockout

Threshold Voltage

Hysteresis for the Input

Undervoltage Lockout

Limit

Typical

(Note 5)

= 1.5 A 3.3

LOAD

VIN=5Vto14V

= 1.5 A

I

LOAD

I

= 100 mA to 2.5A

LOAD

=10V

V

IN

0.5

0.6

Rising Edge 3.8

210 mV

VIN=5V

= 3.3V

V

OUT

3.3

Limit

(Note 6)

3.235/3.185

3.392/3.416

0.7

1.7

3.95

140˚C/W

≤ +150˚C

J

≤ +125˚C

J

Units

V

V(min)

V(max)

%

%(max)

%

%(max)

V

V(max)

LM2655-ADJ Electrical Characteristics

Specifications with standard typeface are for TJ= 25˚C, and those in boldface type apply over full Operating Temperature

Range.V

Symbol Parameter Conditions

V

FB

V

OUT

V

INUV

V

UV_HYST

(Note 9) Average Output Current

I

CL

www.national.com 4

= 10V unless otherwise specified.

IN

Feedback Voltage I

Output Voltage Line

Regulation

Output Voltage Load

Regulation

VINUndervoltage Lockout

Threshold Voltage

Hysteresis for the Input

Undervoltage Lockout

Limit

Typical

(Note 5)

= 1.5 A 1.238

LOAD

VIN=5Vto14V

= 1.5 A

I

LOAD

I

= 100 mA to 2.5A

LOAD

=10V

V

IN

0.5

0.6

Rising Edge 3.8

210 mV

VIN=5V

= 3.3V

V

OUT

3.3 A

Limit

(Note 6)

1.208/1.181

1.260/1.267

0.7

1.7

3.95

Units

V

V(min)

V(max)

%

%(max)

%

%(max)

V

V(max)

Page 5

All Output Voltage Versions Electrical Characteristics

Specifications with standard typeface are for TJ= 25˚C, and those in boldface type apply over full Operating Temperature

Range.V

Symbol Parameter Conditions

I

Q

I

QSD

R

DS(ON)

R

SW(ON)

I

L

V

BOOT

G

M

A

V

I

EA_SOURCE

I

EA_SINK

V

EAH

V

EAL

F

OSC

D

MAX

I

SS

V

OUTUV

V

OUTOV

I

LDELAY__

SOURCE

I

SHUTDOWN

V

SHUTDOWN

T

SD

= 10V unless otherwise specified.

IN

Quiescent Current Shutdown Pin Floating (Device

Typical

(Note 6)

1.7

Limit

(Note 5)

On)

Quiescent Current in

Shutdown Mode

Switch ON Resistance I

Device Not Switching

Shutdown Pin Pulled Low 7

= 1.5A 33

SWITCH

3

12/20

80

Switch On Resistance

I

= 1.5A 72 mΩ

SWITCH

(MOSFET ON Resistance +

Bonding Wire Resistance)

Switch Leakage Current 5 nA

Bootstrap Regulator Voltage I

BOOT

C

BOOT

=1mA

=tbd

6.7

6.4

7.0

Error Amplifier

1250 µmho

Transconductance

Error Amplifier Voltage Gain 100

Error Amplifier Source

Current

VIN= 4V, VFB= .9*V

=2V

OUT,VCOMP

Error Amplifier Sink Current VIN= 4V, VFB= 1.1*V

=2V

Error Amplifier Output Swing

Upper Limit

Error Amplifier Output Swing

Lower Limit

VIN= 4V, VFB= .9*V

=2V

VIN= 4V, VFB= .9*V

=2V

OUT,VCOMP

OUT,VCOMP

Oscillator Frequency Measured at Switch Pin

=4V

V

IN

OUT,VCOMP

40

32/10

80

53/30

2.70

2.50/2.40

1.25

1.35/1.50

300

280/255

330/345

Maximum Duty Cycle VIN=4V 95

92

Soft-Start Current Voltage at the SS Pin = 1.4V 11

14

V

Undervoltage Lockout

OUT

Threshold Voltage

81

76

84

Hysteresis for V

V

Overvoltage Lockout

OUT

OUTUV

Threshold Voltage

5%V

108

106

114

Hysteresis for V

OUTOV

5%V

LDELAY Pin Source Current 5 µA

Shutdown Pin Current Shutdown Pin Pulled Low 2.2

3.7/4.0

Shutdown Pin Threshold

Voltage

Rising Edge 0.6

0.25

0.9

Thermal Shutdown

165 ˚C

Temperature

Units

mA(max)

µA(max)

mΩ(max)

V(min)

V(max)

µA(min)

µA(min)

V(min)

V(max)

kHz

kHz(min)

kHz(max)

%(min)

µA(max)

%V

%V

OUT

%V

OUT

%V

%V

OUT

%V

OUT

µA(max)

V(min)

V(max)

LM2655

mA

µA

mΩ

V

µA

µA

V

V

%

µA

OUT

(min)

(max)

OUT

OUT

(min)

(max)

OUT

µA

V

www.national.com5

Page 6

All Output Voltage Versions Electrical Characteristics (Continued)

Specifications with standard typeface are for TJ= 25˚C, and those in boldface type apply over full Operating Temperature

LM2655

Range.V

Symbol Parameter Conditions

T

SD_HYST

= 10V unless otherwise specified.

IN

Thermal Shutdown

Typical

(Note 6)

Limit

(Note 5)

25 ˚C

Hysteresis Temperature

Low-side Driver (LDR) Parameters

Specifications with standard typeface are for TJ= 25˚C, and those in boldface type apply over full Operating Temperature

Range.V

Symbol Parameter Conditions

V

OH

V

OL

I

SINK

I

SOURCE

T

RR

T

F

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

intended to be functional, but device parameter specifications may not be guaranteed under these conditions. For guaranteed specifications and test conditions, see

the Electrical Characteristics.

Note 2: The maximum allowable power dissipation is calculated by using P

ambient temperature, and θ

140˚C/W for T

allows the safe dissipation of more power. The Absolute Maximum power dissipation must be derated by 7.14 mW per ˚C above 25˚C ambient. The LM2655 actively

limits its junction temperatures to about 165˚C.

Note 3: The human body model is a 100 pF capacitor discharged through a 1.5 kΩ resistor into each pin. The machine model is a 200pF capacitor discharged

directly into each pin.

Note 4: ESD susceptibility using the human body model is 500V for V

Note 5: Typical numbers are at 25˚C and represent the most likely norm.

Note 6: All limits guaranteed at room temperature (standard typeface) and at temperature extremes (bold typeface). All room temperature limits are 100%

production tested. All limits at temperature extremes are guaranteed via correlation using standard Statistical Quality Control (SQC) methods. All limits are used

to calculate Average Outgoing Quality Level (AOQL).

Note 7: Measured with respect to V

Note 8: Measured while switching in closed loop with Vin = 15V.

Note 9: Average output current limit obtained using typical application circuit. This figure is dependant on the the inductor used.

Note 10: Bond wire resistance accounts for approximately 40mΩ of R

= 10V unless otherwise specified.

IN

Typical

(Note 5)

Limit

(Note 6)

Logic High Level VIN= 10V 6.8

6.6

= 6.0V 6

V

IN

5.8

Logic Low Level 0

0.05

LDR Sink Current LDR Voltage = 1V 500 mA

LDR Source Current LDR Voltage = 2V 180 mA

Rise Time CGS=1000pF 18 ns

Fall Time CGS=1000pF 7 ns

=(T

is the junction-to-ambient thermal resistance of the specified package. The 893 mW rating results from using 150˚C, 25˚C, and

JA

, and θJArespectively. A θJAof 140˚C/W represents the worst-case condition of no heat sinking of the 16-pin TSSOP package. Heat sinking

JMAX,TA

.

SW

DMAX

CB,VSW

SW(ON)

, LDR, and L

.

JMAX−TA

DELAY

)/θJA, where T

.

is the maximum junction temperature, TAis the

JMAX

Units

Units

V

V(min)

V

V(min)

V

V(max)

www.national.com 6

Page 7

Typical Performance Characteristics

LM2655

Efficiency vs Load Current

(V

= 5V, V

IN

lQvs V

OUT

= 3.3V)

IN

10128405

Efficiency vs V

(I

= 0.5A) (Synchronous)

LOAD

I

QSD

vs V

IN

10128406

IN

10128407 10128408

I

vs Junction Temperature Frequency vs Junction Temperature

QSD

10128409 10128410

www.national.com7

Page 8

Typical Performance Characteristics (Continued)

LM2655

R

Input Voltage (Note 10) (I

+ Bond Wire Resistance vs

SW(ON)

LOAD

Current Limit vs Input Voltage

(Synchronous)

= 1.5A)

10128411

R

+ Bond Wire Resistance vs

SW(ON)

Junction Temperature (Note 10) (I

Current Limit vs Input Voltage

(Asynchronous)

= 1.5A, VIN=5V)

LOAD

10128412

10128413

Current Limit vs Junction Temperature

(V

= 5V, V

IN

= 3.3V) Reference Voltage vs Junction Temperature

OUT

10128415

10128414

10128416

www.national.com 8

Page 9

Operation

The LM2655 is a constant frequency (300kHz), currentmode PWM switcher that can be operated synchronously or

asynchronously.

SYNCHRONOUS OPERATION

A converter is said to be in synchronous operation when a

MOSFET is used in place of the catch diode. In the case of

the buck converter, this MOSFET is known as the low-side

MOSFET (the MOSFET connected between the input

source and the low-side MOSFET is the high-side MOSFET). Converters in synchronous operation exhibit higher

efficiencies compared to asynchronous operation because

2

R losses are reduced with the use of a MOSFET .

the I

Operation of the LM2655 in synchronous mode is identical to

its operation in asynchronous mode, except that internal

logic drives the low-side MOSFET. At the beginning of a

switching cycle, the high-side MOSFET is on and current

from the input source flows through the inductor and to the

load. The current from the high-side MOSFET is sensed and

compared with the output of the error amplifier (COMP pin).

When the sensed current reaches the COMP pin voltage

level, the high-side switch is turned off. After a 30ns delay

(deadtime), the low-side driver goes high and turns the

low-side MOSFET on. The current now flows through the

low-side MOSFET, through the inductor and on to the load. A

30ns delay is necessary to insure that the MOSFETs are

never on at the same time. During the 30ns deadtime, the

current is forced to flow through the low-side MOSFET’s

body diode. It is recommended that a low forward drop

schottky diode be placed in parallel to the low-side MOSFET

so that current will be more efficiently conducted during this

30ns deadtime. This Schottky diode should be placed within

5mm of the switch pin so that current limit is not effected (see

External Schottky Diode section). At the end of the switching

cycle, the low-side switch is turned off and after another

30ns delay, the cycle is repeated.

Current through the high-side MOSFET is sensed by patented circuitry that does not require an external sense resistor. As a result, system cost and size are reduced, efficiency

is increased, and noise immunity of the sensed current is

improved. A feedforward from the input voltage is added to

reduce the variation of the current limit over the input voltage

range.

ASYNCHRONOUS OPERATION

A unique feature of the LM2655 is that it can be operated in

either synchronous or asynchronous mode. When operating

in asynchronous mode, a small amount of efficiency is sacrificed for a less expensive solution. Any diode may be used,

but it is recommended that a low forward drop schottky diode

be use to maximize efficiency. When operating the LM2655

in asynchronous mode, the LDR pin should be terminated

with a large resistor (

asynchronous mode is similar to that of synchronous mode,

except the internal low-side MOSFET logic is not used. At

the beginning of a switching cycle, the high-side MOSFET is

on and current from the input source flows through the

inductor and to the load. The current from the high-side

MOSFET is sensed and compared with the output of the

error amplifier (COMP pin). When the sensed current

reaches the COMP pin voltage level, the high-side switch is

turned off. At this instant, the load current is commutated

through the catch diode. The current now flows through the

diode and the inductor and on to the load. At the end of the

switching cycle, the high-side switch is turned on and the

cycle is repeated.

PROTECTIONS

The peak current in the system is monitored by cycle-bycycle current limit circuitry. This circuitry will turn the highside MOSFET off whenever the current through the highside MOSFET reaches a preset limit (see plots). A second

level current limit is accomplished by the undervoltage protection: if the load pulls the output voltage down below 80%

of its nominal value, the undervoltage latch protection will

wait for a period of time (set by the capacitor at the LDELAY

pin, see LDELAY CAPACITOR section for more information).

If the output voltage is still below 80% of its nominal after the

waiting period, the latch protection will be enabled. In the

latch protection mode, the low-side MOSFET is on and the

high-side MOSFET is off. The latch protection will also be

enabled immediately whenever the output voltage exceeds

the overvoltage threshold (110% of its nominal). Both protections are disabled during start-up.(See SOFT-START CAPACITOR section and LDELAY CAPACITOR section for

more information.) Toggling the input supply voltage or the

shutdown pin can reset the device from the latched protection mode.

>

1 MegΩ), or left floating. Operation in

LM2655

Design Procedure

This section presents guidelines for selecting external components.

INPUT CAPACITOR

A low ESR aluminum, tantalum, ceramic, or any other type of

capacitor is needed between the input pin and power

ground. This capacitor prevents large voltage transients from

appearing at the input. The capacitor is selected based on

the RMS current and voltage requirements. The RMS current is given by:

The RMS current reaches its maximum (I

equals 2V

V

IN

the voltage rating should be at least 25% higher than the

maximum input voltage. If a tantalum capacitor is used, the

voltage rating required is about twice the maximum input

. For an aluminum or ceramic capacitor,

OUT

OUT

/2) when

voltage. The tantalum capacitor should be surge current

tested by the manufacturer to prevent damage by the inrush

current. It is also recommended to put a small ceramic

capacitor (0.1 µF) between the input pin and ground pin to

reduce high frequency noise.

INDUCTOR

The most critical parameters for the inductor are the inductance, peak current and the DC resistance. The inductance

is related to the peak-to-peak inductor ripple current, the

input and the output voltages:

A higher value of ripple current reduces inductance, but

increases the conductance loss, core loss, current stress for

the inductor and switch devices. It also requires a bigger

output capacitor for the same output voltage ripple require-

www.national.com9

Page 10

Design Procedure (Continued)

ment. A reasonable value is setting the ripple current to be

LM2655

30% of the DC output current. Since the ripple current increases with the input voltage, the maximum input voltage is

always used to determine the inductance. The DC resistance

of the inductor is a key parameter for the efficiency. Lower

DC resistance is available with a bigger winding area. A good

tradeoff between the efficiency and the core size is letting the

inductor copper loss equal 2% of the output power.

OUTPUT CAPACITOR

The selection of C

mum allowable output voltage ripple. The output ripple in the

constant frequency, PWM mode is approximated by:

The ESR term usually plays the dominant role in determining

the voltage ripple. A low ESR aluminum electrolytic or tantalum capacitor (such as Nichicon PL series, Sanyo OS-CON,

is primarily determined by the maxi-

OUT

Sprague 593D, 594D, AVX TPS, and CDE polymer aluminum) is recommended. An electrolytic capacitor is not recommended for temperatures below −25˚C since its ESR

rises dramatically at cold temperature. A tantalum capacitor

has a much better ESR specification at cold temperature and

is preferred for low temperature applications.

The output voltage ripple in constant frequency mode has to

be less than the sleep mode voltage hysteresis to avoid

entering the sleep mode at full load:

<

V

RIPPLE

20mV * V

OUT/VFB

10128421

FIGURE 1. Low-side/high-side driver timing diagram.

TABLE 1. MOSFET Manufacturers

Manufacturer Model Number Package Type www Address Phone Fax

Fairchild

FDC653N SuperSOT-6 www.fairchildsemi.com 888-522-5372 207-761-6020

Semiconductor

General

GF4420 SO-8 www.gensemi.com 631-847-3000 631-847-3236

Semiconductor

International

IRF7807 SO-8 www.irf.com 310-322-3331 310-322-3332

Rectifier

Vishay Siliconix Si4812DY SO-8 www.vishay.com 800-554-5565 408-567-8995

Si4874DY SO-8

Zetex ZXM64N03X SO-8 www.zetex.com (44) 161-622-4422 (44) 161-622-4420

LOW-SIDE MOSFET SELECTION

When operating in synchronous mode, special attention

should be given to the selection of the low-side MOSFET.

Besides choosing a MOSFET with minimal size and on

resistance, it is critical that the MOSFET meet certain rise

and fall time specifications. A 30ns deadtime between the

low-side and high-side MOSFET switching transitions is programmed into the LM2655, as shown in Figure 1. The prevent shoot-through current, the low-side MOSFET must turn

off before the high-side MOSFET turns on. Hence, the low-

side MOSFET has 30ns to turn off from the time the low-side

driver goes low. The fall time of the low-side MOSFET is

governed by the equation:

C=CIN

*dVC/dt.

is the LDR sink current capability, CINis the equiva-

C

is limited by the low-side

C

is fixed by the MOSFET.

IN

is the gate-to-

C

I

where I

lent capacitance seen at the LDR pin, and V

source voltage of the MOSFET. I

driver of the LM2655, but C

Therefore, it is important that the chosen MOSFET has a

suitable C

so that the LM2655 will be able to turn it off

IN

www.national.com 10

Page 11

Design Procedure (Continued)

within 30ns. An input capacitance of less than 1000pF is

recommended. Several suitable MOSFETs are shown in

Table 1.

EXTERNAL SCHOTTKY DIODE (Syncronous)

A Schottky diode is recommended to prevent the intrinsic

body diode of the low-side MOSFET from conducting during

the deadtime in PWM operation. If the body diode turns on,

there is extra power dissipation in the body diode because of

the reverse-recovery current and higher forward voltage

drop. In addition, the high-side MOSFET has more switching

loss because the diode reverse-recovery current adds to the

high-side MOSFET turn-on current. These losses degrade

the efficiency by 1-2%. The improved efficiency and noise

immunity with the Schottky diode become more obvious with

increasing input voltage and load current.

It is important to place the diode very close to the switch pin

of the LM2655. Extra parasitic impedance due to the trace

between the switch pin and the cathode of the diode will

cause the current limit to decrease. The breakdown voltage

rating of the diode is preferred to be 25% higher than the

maximum input voltage. Since it is on for a short period of

time, the diode’s average current rating need only be 30% of

the maximum output current.

EXTERNAL SCHOTTKY DIODE (Asyncronous)

In asyncronous mode, the output current commutates

throught the schottky diode when the high-side MOSFET is

turned off. Using a schottky diode with low forward voltage

drop will minimize the effeciency loss in the diode. However,

to achieve the greatest efficiency, the LM2655 should be

operated in syncronous mode using a low-side MOSFET.

Since the Schottky diode conducts for the entire second half

of the duty cycle in asyncronous mode, it should be rated

higher than the full load current.

T

SS=CSS

* 0.6V/2 µA + CSS* (2V−0.6V)/10 µA

During start-up, the internal circuit is monitoring the soft-start

voltage. When the softstart voltage reaches 2V, the undervoltage and overvoltage protections are enabled.

If the output voltage doesn’t rise above 80% of the normal

value before the soft-start reaches 2V, undervoltage protection shut down the device. You can avoid this by either

increasing the value of the soft-start capacitor, or using a

LDELAY capacitor.

LDELAY CAPACITOR

The LDELAY capacitor (CDELAY) provides a means to control undervoltage latch protection. By changing CDELAY, the

user can adjust the time delay between the output voltage

dropping below 80% of its nominal value and the part shutting off due to undervoltage latch protection. The LDELAY

circuit consists ofa5µAcurrent source in series with a user

defined capacitor, CDELAY. The 5 µA current source is

turned on whenever the output voltage is below 80% of its

nominal value, otherwise this current source is off. With the

output voltage below 80% of its nominal value, the 5 µA

current source begins to charge CDELAY, as shown in Fig-

ure 2. If the potential across CDELAY reaches 2V, undervoltage latch protection will be enabled and the part will shutdown. If the output voltage recovers to above 80% of its

nominal value before the potential across CDELAY reaches

2V, undervoltage latch protection will remain disabled.

Hence, CDELAY sets a time delay by the following equation:

T

DELAY

(ms) = C

DELAY

(nF) * 2V/5A

Undervoltage latch protection can be disabled by tying the

LDELAY pin to the ground.

LM2655

BOOST CAPACITOR

The boost capacitor provides the extra votage needed to

turn the high-side, n-channel MOSFET on. A 0.1 µF ceramic

capacitor is recommended for the boost capacitor. The typical voltage across the boost capacitor is 6.7V.

SOFT-START CAPACITOR

A soft-start capacitor is used to provide the soft-start feature.

When the input voltage is first applied, or when the SD(SS)

pin is allowed to go high, the soft-start capacitor is charged

by a current source (approximately 2 µA). When the SD(SS)

pin voltage reaches 0.6V (shutdown threshold), the internal

regulator circuitry starts to operate. The current charging the

soft-start capacitor increases from 2 µA to approximately

10 µA. With the SD(SS) pin voltage between 0.6V and 1.3V,

the level of the current limit is zero, which means the output

voltage is still zero. When the SD(SS) pin voltage increases

beyond 1.3V, the current limit starts to increase. The switch

duty cycle, which is controlled by the level of the current limit,

starts with narrow pulses and gradually gets wider. At the

same time, the output voltage of the converter increases

towards the nominal value, which brings down the output

voltage of the error amplifier. When the output of the error

amplifier is less than the current limit voltage, it takes over

the control of the duty cycle. The converter enters the normal

current-mode PWM operation. The SD(SS) pin voltage is

eventually charged up to about 2V.

The soft-start time can be estimated as:

10128422

FIGURE 2. Undervoltage latch protection.

COMPENSATION COMPONENTS

In the control to output transfer function, the first pole F

be estimated as 1/(2πR

OUTCOUT

output capacitor is 1/(2πESRC

frequency pole F

whereD=V

IN

and V

and V

in the range of 45kHz to 150kHz:

p2

F

p2=Fs

, n = 1+0.348L/(VIN−V

OUT/VIN

in volts).

OUT

The total loop gain G is approximately 1000/I

); The ESR zero Fz1of the

); Also, there is a high

OUT

/(πn(1−D))

)(LisinµHs

OUT

OUT

p1

where I

can

OUT

is in amperes.

A Gm amplifier is used inside the LM2655. The output resis-

of the Gm amplifier is about 80kΩ.Cc1and R

tor R

o

together with Rogive a lag compensation to roll off the gain:

= 1/(2πCc1(Ro+Rc)), F

F

pc1

= 1/2πCc1Rc.

zc1

C

www.national.com11

Page 12

Design Procedure (Continued)

In some applications, the ESR zero F

LM2655

. Then, Cc2is needed to introduce F

by F

p2

ESR zero, F

= 1/(2πCc2Ro\Rc).

p2

The rule of thumb is to have more than 45˚ phase margin at

the crossover frequency (G=1).

is higher than 68µF, Cc1= 2.2nF, and Rc= 15KΩ are

If C

OUT

good choices for most applications. If the ESR zero is too

low to be cancelled by F

, add Cc2.

p2

If the transient response to a step load is important, choose

to be higher than 10kΩ.

R

C

can not be cancelled

z1

pc2

to cancel the

Application Circuits

PROGRAMMABLE OUTPUT VOLTAGE

Using the adjustable output version of the LM2655 as shown

in Figure 3, output voltages between 1.24V and 13V can be

achieved. Use the following formula to select the appropriate

resistor values:

*(V

OUT-VREF

where V

REF

R

FB1=RFB2

= 1.238V.

Select resistors between 10kΩ and 100kΩ. (1% or higher

accuracy metal film resistors for R

FB1

)/V

and R

REF

FB2

.)

10128425

FIGURE 3. Programmable output voltage.

EXTENDING INPUT VOLTAGE RANGE

Figure 4 shows a way to configure the LM2655 so that input

voltages of less than 4V can be converted. This circuit

makes use of the separate analog and power V

pins. All

IN

the supervisory circuits of the LM2655 are powered through

the AV

is input to the PV

has an operating range of 4V

within this range must be applied to AV

pin, while the source voltage that is to be converted

IN

pins. The internal circuitry of the LM2655

IN

<

<

V

14V, so a voltage

CC

. This source may

IN

be low power because it only needs to supply 5mA. An input

capacitor should be connected across this source, and a

small bypass capacitor should be placed physically close to

the AV

pin to ground. With all the internal circuitry being

IN

powered by a separate source, the only requirement of the

voltage at PV

desired output voltage. The source connected to PV

is that it be slightly higher (∼500mV) than the

IN

will

IN

also need an input capacitor and bypass capacitor, but the

input capacitor must be selected following the guidelines

explained in the INPUT CAPACITOR section.

10128423

FIGURE 4. Extended input voltage range.

www.national.com 12

Page 13

Application Circuits (Continued)

OBTAINING OUTPUT VOLTAGES OF LESS THAN 1.25V

Some applications require output voltages less than 1.25V.

The circuit shown in Figure 5 will allow the LM2655 to do

such a conversion. By referencing the two feedback resistors to V

to V

ADJ(VADJ

by the equation:

ADJ

>

1.24V), V

can be adjusted from 0V

OUT

V

=(V

OUT

where V

V

REF

= 1.24V. V

REF

(1.24V). In Figure 5,V

REF-VADJ

)*(R

FB1+RFB2

can be any voltage higher than

ADJ

ADJ

)/R

is produced by an LMV431

adjustable reference following the equation:

V

ADJ

= 1.24*(R

ADJ1/RADJ2

+ 1).

LM2655

FB2+VADJ

10128424

FIGURE 5. Obtaining output voltages of less than 1.25V

Pcb Layout Considerations

Layout is critical to reduce noise and ensure specified performance. The important guidelines are listed as follows:

1. Minimize the parasitic inductance in the loop of input

capacitors and the internal MOSFETs by connecting the

input capacitors to V

wide traces. The high frequency ceramic bypass capacitor, in particular, should be placed as close to and no

more than 5mm from the V

because the rapidly switching current, together with wiring inductance can generate large voltage spikes that

may result in noise problems.

2. Minimize the trace from the center of the output resistor

divider to the FB pin and keep it away from noise

and PGND pins with short and

IN

pin. This is important

IN

sources to avoid noise pick up. For applications that

require tight regulation at the output, a dedicated sense

trace (separated from the power trace) is recommended

to connect the top of the resistor divider to the output.

3. If the Schottky diode D is used, minimize the traces

connecting D to SW and PGND pins. Use short and wide

traces.

4. If the low-side MOSFET is used, minimize the trace

connecting the LDR pin to the gate of the MOSFET, and

the traces to SW and PGND pins. Use short and wide

traces for the power traces going from the MOSFET to

SW and PGND pins.

www.national.com13

Page 14

LM2655

Schematic for the Typical Board Layout

Typical PC Board Layout: (2X Size)

Component Placement Guide

10128425

10128426

Component Side PC Board Layout

www.national.com 14

10128427

Page 15

Typical PC Board Layout: (2X Size) (Continued)

LM2655

Solder Side PC Board Layout

10128428

www.national.com15

Page 16

Physical Dimensions inches (millimeters)

unless otherwise noted

16-Lead TSSOP (MTC)

NS Package Number MTC16

Order Number LM2655MTC-ADJ

LM2655MTCX-ADJ

LM2655MTC-3.3

LM2655MTCX-3.3

See Ordering Information Table For Order Quantities

LM2655 2.5A High Efficiency Synchronous Switching Regulator

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves

the right at any time without notice to change said circuitry and specifications.

For the most current product information visit us at www.national.com.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL COUNSEL OF NATIONAL SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body, or

(b) support or sustain life, and whose failure to perform when

properly used in accordance with instructions for use

2. A critical component is any component of a life support

device or system whose failure to perform can be reasonably

expected to cause the failure of the life support device or

system, or to affect its safety or effectiveness.

provided in the labeling, can be reasonably expected to result

in a significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor manufactures products and uses packing materials that meet the provisions of the Customer Products

Stewardship Specification (CSP-9-111C2) and the Banned Substances and Materials of Interest Specification (CSP-9-111S2) and contain

no ‘‘Banned Substances’’ as defined in CSP-9-111S2.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...