Datasheet LM2651MTCX-2.5, LM2651MTCX-1.8, LM2651MTC-2.5, LM2651MTC-1.8, LM2651MTCX-ADJ Datasheet (NSC)

...Page 1

LM2651

1.5A High Efficiency Synchronous Switching Regulator

General Description

The LM2651 switching regulator provides high efficiency

power conversion over a 100:1 load range (1.5A to 15mA).

This feature makes the LM2651 an ideal fit in

battery-powered applications that demand long battery life in

both run and standby modes.

Synchronous rectification is used to achieve up to 97%efficiency.At light loads, the LM2651 enters a low power hysteretic or “sleep” mode to keep the efficiency high. In many applications, the efficiency still exceeds 80%at 15mA load. A

shutdown pin is available to disable the LM2651 and reduce

the supply current to less than 10µA.

The LM2651 containsa patented current sensing circuitry for

current mode control. This feature eliminates the external

current sensing resistor required by other current-mode

DC-DC converters.

The LM2651 has a 300 kHz fixed frequency internal oscillator.The high oscillator frequency allows the use of extremely

small, low profile components.

A programmable soft-start feature limits current surges from

the input power supply at start up and provides a simple

means of sequencing multiple power supplies.

Other protection features include input undervoltage lockout,

current limiting, and thermal shutdown.

Features

n Ultra high efficiency up to 97

%

n High efficiency over a 1.5A to milliamperes load range

n 4V to 14V input voltage range

n 1.8V, 2.5V, 3.3V, or ADJ output voltage

n Internal MOSFET switch with low R

DS(on)

of 75mΩ

n 300kHz fixed frequency internal oscillator

n 7µA shutdown current

n Patented current sensing for current mode control

n Input undervoltage lockout

n Adjustable soft-start

n Current limit and thermal shutdown

n 16-pin TSSOP package

Applications

n Personal digital assistants (PDAs)

n Computer peripherals

n Battery-powered devices

n Handheld scanners

n High efficiency 5V conversion

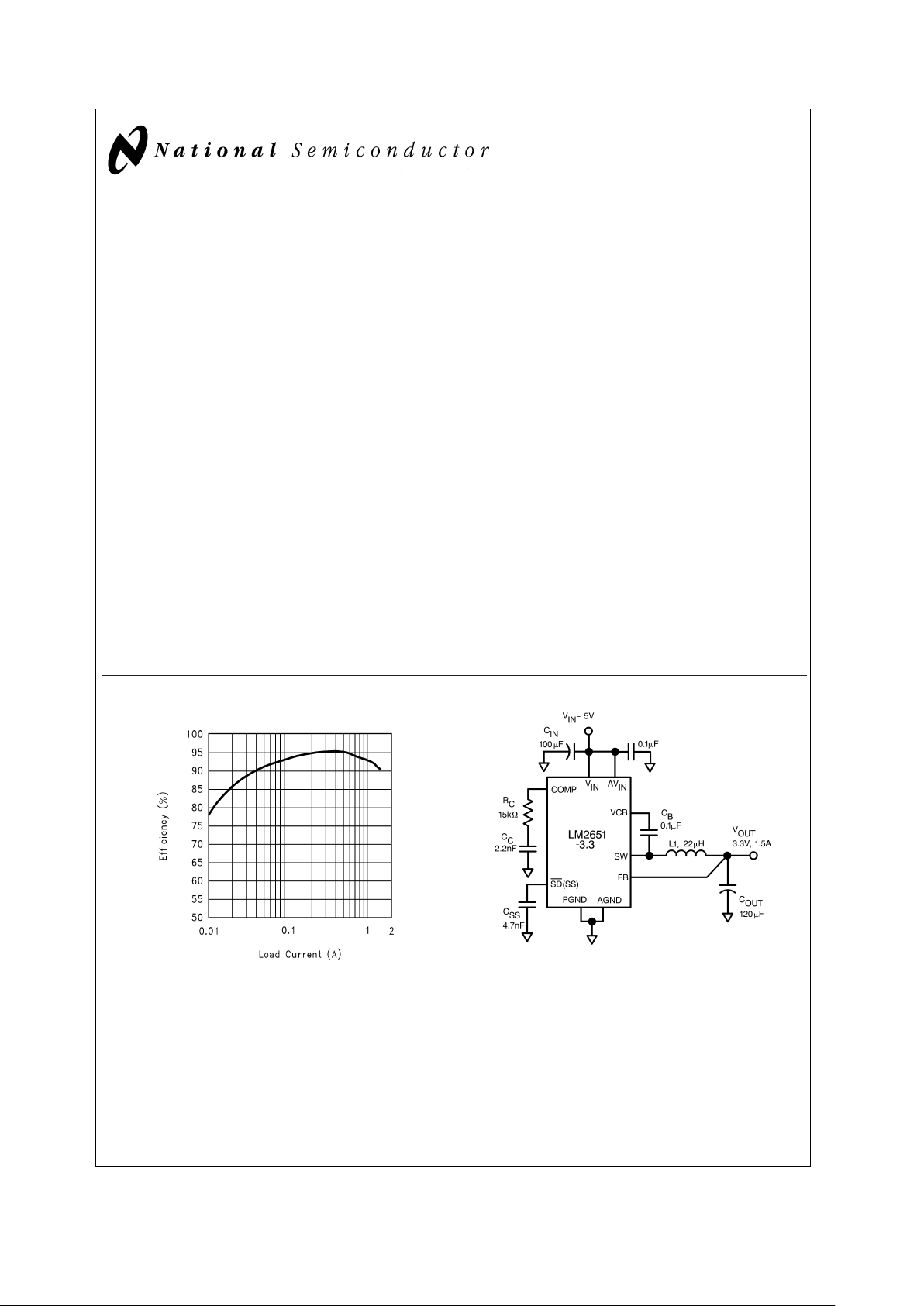

Typical Application

DS100925-15

Efficiency vs Load Current

(V

IN

=

5V, V

OUT

=

3.3V)

DS100925-1

February 2000

LM2651 1.5A High Efficiency Synchronous Switching Regulator

© 2000 National Semiconductor Corporation DS100925 www.national.com

Page 2

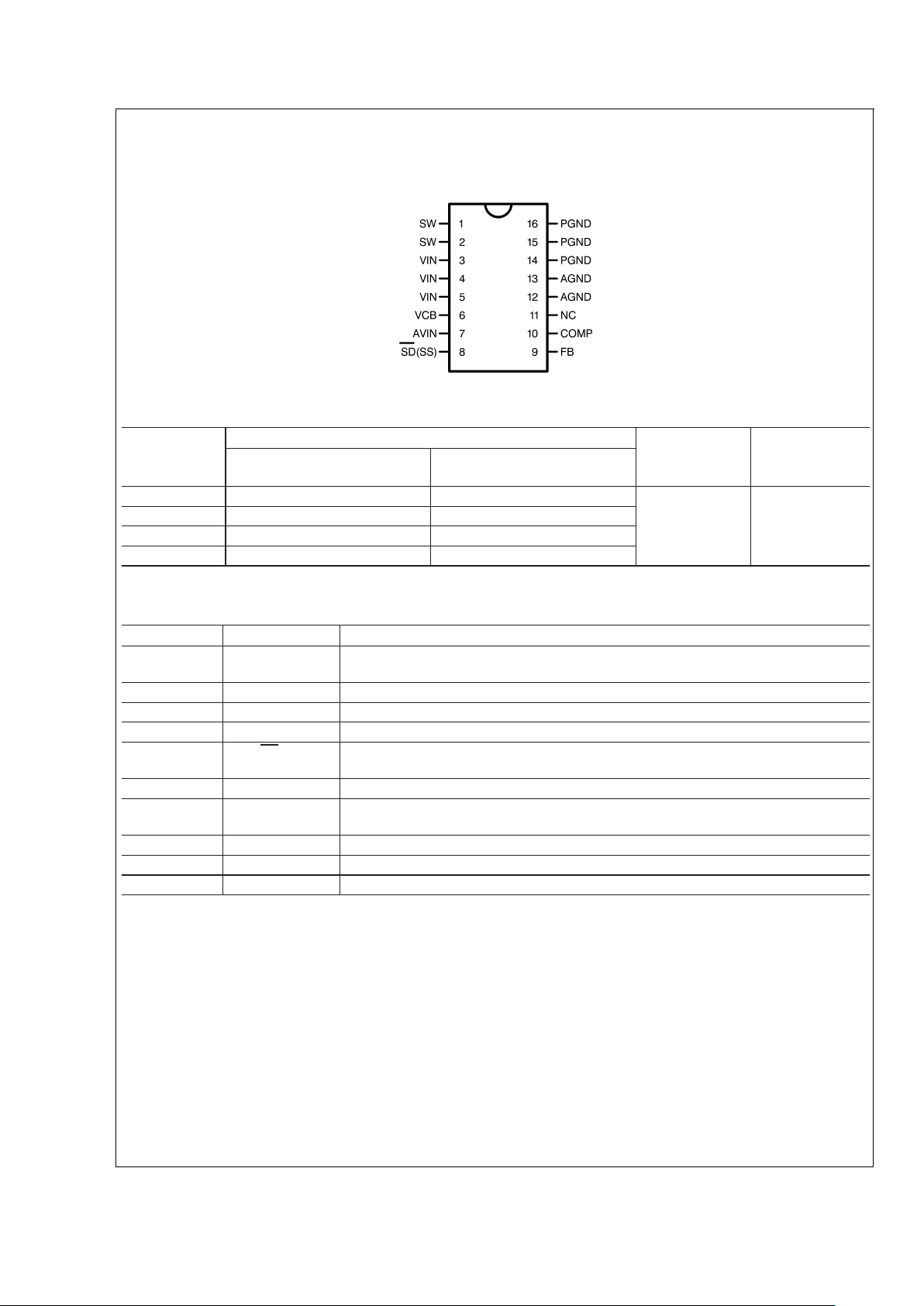

Connection Diagram

Ordering Information

V

OUT

Part Number

Package Type

NSC Package

Drawing

Supplied as 94 Units, Rail Supplied as 2.5k Units, Tape

and Reel

1.8 LM2651MTC-1.8 LM2651MTCX-1.8

TSSOP-16 MTC16

2.5 LM2651MTC-2.5 LM2651MTCX-2.5

3.3 LM2651MTC-3.3 LM2651MTCX-3.3

ADJ LM2651MTC-ADJ LM2651MTCX-ADJ

Pin Description

Pin Name Function

1, 2 SW Switched-node connection, which is connected with the source of the internal high-side

MOSFET.

3-5 VIN Main power supply pin.

6 VCB Bootstrap capacitor connection for high-side gate drive.

7 AVIN Input supply voltage for control and driver circuits.

8 SD(SS)

Shutdown control input, active low. This pin can also function as soft-start control pin. A

capacitor connected from this pin to ground sets the ramp time to full current output.

9 FB Output voltage feedback input. Connected to the output voltage.

10 COMP Compensation network connection. Connected to the output of the voltage error

amplifier.

11 NC No internal connection.

12-13 AGND Low-noise analog ground.

14-16 PGND Power ground.

16-Lead TSSOP (MTC)

DS100925-2

LM2651

www.national.com 2

Page 3

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Input Voltage 15V

Feedback Pin Voltage −0.4V ≤ V

FB

≤ 5V

Power Dissipation (T

A

=

25˚C),

(Note 2)

893 mW

Junction Temperature Range −40˚C ≤ T

J

≤ +125˚C

Storage Temperature Range −65˚C to +150˚C

ESD Susceptibility

Human Body Model (Note 3) 1kV

Operating Ratings (Note 1)

Supply Voltage 4V ≤ V

IN

≤ 14V

Electrical Characteristics Specifications in standard type face are for T

J

=

25˚C and those with boldface

type apply over full operating junction temperature range. V

IN

=

10V unless otherwise specified.

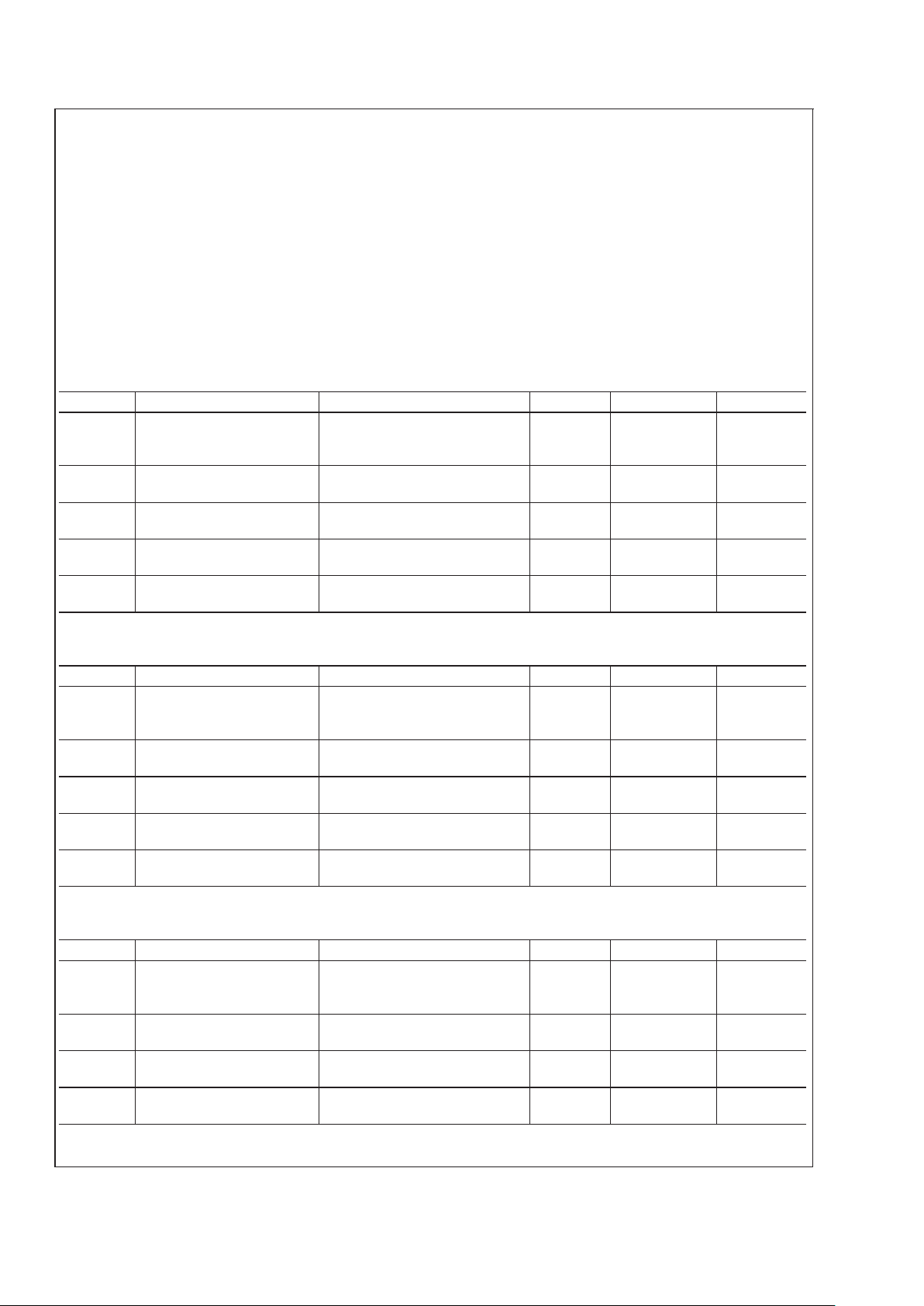

LM2651-1.8 System Parameters

Symbol Parameter Conditions Typical Limit Units

V

OUT

Output Voltage I

LOAD

=

900 mA 1.8 1.761/1.719

1.836/1.854

V

V(min)

V(max)

V

OUT

Output Voltage Line

Regulation

V

IN

=

4V to 14V

I

LOAD

=

900 mA

0.2

%

V

OUT

Output Voltage Load

Regulation

I

LOAD

=

10 mA to 1.5A

V

IN

=

5V

1.3

%

V

OUT

Output Voltage Load

Regulation

I

LOAD

=

200 mA to 1.5A

V

IN

=

5V

0.3

%

V

HYST

Sleep Mode Output Voltage

Hysteresis

35 mV

LM2651-2.5 System Parameters

Symbol Parameter Conditions Typical Limit Units

V

OUT

Output Voltage I

LOAD

=

900 mA 2.5

2.43/2.388

2.574/2.575

V

V(min)

V(max)

V

OUT

Output Voltage Line

Regulation

V

IN

=

4V to 12V

I

LOAD

=

900 mA

0.2

%

V

OUT

Output Voltage Load

Regulation

I

LOAD

=

10 mA to 1.5A

V

IN

=

5V

1.3

%

V

OUT

Output Voltage Load

Regulation

I

LOAD

=

200 mA to 1.5A

V

IN

=

5V

0.3

%

V

HYST

Sleep Mode Output Voltage

Hysteresis

48 mV

LM2651-3.3 System Parameters

Symbol Parameter Conditions Typical Limit Units

V

OUT

Output Voltage I

LOAD

=

900 mA 3.3

3.265/3.201

3.379/3.399

V

V(min)

V(max)

V

OUT

Output Voltage Line

Regulation

V

IN

=

4V to 14V

I

LOAD

=

900 mA

0.2

%

V

OUT

Output Voltage Load

Regulation

I

LOAD

=

10 mA to 1.5A

V

IN

=

5V

1.3

%

V

OUT

Output Voltage Load

Regulation

I

LOAD

=

200 mA to 1.5A

V

IN

=

5V

0.3

%

LM2651

www.national.com3

Page 4

LM2651-3.3 System Parameters (Continued)

Symbol Parameter Conditions Typical Limit Units

V

HYST

Sleep Mode Output Voltage

Hysteresis

60 mV

LM2651-ADJ System Parameters

(V

OUT

=

2.5V unless otherwise specified)

Symbol Parameter Conditions Typical Limit Units

V

FB

Feedback Voltage I

LOAD

=

900 mA 1.238

1.200

1.263

V

V(min)

V(max)

V

OUT

Output Voltage Line

Regulation

V

IN

=

4V to 14V

I

LOAD

=

900 mA

0.2

%

V

OUT

Output Voltage Load

Regulation

I

LOAD

=

10 mA to 1.5A

V

IN

=

5V

1.3

%

V

OUT

Output Voltage Load

Regulation

I

LOAD

=

200 mA to 1.5A

V

IN

=

5V

0.3

%

V

HYST

Sleep Mode Output Voltage

Hysteresis

24 mV

All Output Voltage Versions

Specifications in standard type face are for T

J

=

25˚C and those with boldface type apply over full operating junction tem-

perature range. V

IN

=

10V unless otherwise specified.

Symbol Parameter Conditions Typical Limit Units

I

Q

Quiescent Current 1.6

2.0

mA

mA(max)

I

QSD

Quiescent Current in

Shutdown Mode

Shutdown Pin Pulled Low 7

12/20

µA

µA(max)

R

SW(ON)

High-Side or Low-Side

Switch On Resistance

(MOSFET On Resistance +

Bonding Wire Resistance)

I

SWITCH

=

1A 110 mΩ

R

DS(ON)

MOSFET On Resistance

(High-Side or Low-Side)

I

SWITCH

=

1A 75

130

mΩ

mΩ(max)

I

L

Switch Leakage Current High Side

130 nA

Switch Leakage Current Low Side

130 nA

V

BOOT

Bootstrap Regulator Voltage I

BOOT

=

1 mA 6.75

6.45/6.40

6.95/7.00

V

V(min)

V(max)

G

M

Error Amplifier

Transconductance

1250 µmho

V

INUV

VINUndervoltage Lockout

Threshold Voltage

Rising Edge 3.8 3.95 V

V(max)

V

UV-HYST

Hysteresis for the

Undervoltage Lockout

210 mV

I

CL

Switch Current Limit V

IN

=

5V 2

1.55

2.60

A

A(min)

A(max)

I

SM

Sleep Mode Threshold

Current

V

IN

=

5V 100 mA

A

V

Error Amplifier Voltage Gain 100 V/V

LM2651

www.national.com 4

Page 5

All Output Voltage Versions (Continued)

Specifications in standard type face are for T

J

=

25˚C and those with boldface type apply over full operating junction tem-

perature range. V

IN

=

10V unless otherwise specified.

Symbol Parameter Conditions Typical Limit Units

I

EA_SOURCE

Error Amplifier Source

Current

40

25/15

µA

µA(min)

I

EA_SINK

Error Amplifier Sink Current 65

30

µA

µA(min)

V

EAH

Error Amplifier Output Swing

Upper Limit

2.70

2.50/2.40

V

V(min)

V

EAL

Error Amplifier Output Swing

Lower Limit

1.25

1.35/1.50

V

V(max)

V

D

Body Diode Voltage I

DIODE

=

1.5A 1 V

f

OSC

Oscillator Frequency V

IN

=

4V 300

280/255

330/345

kHz

kHz(min)

kHz(max)

D

MAX

Maximum Duty Cycle V

IN

=

4V 95

92

%

%

(min)

I

SS

Soft-Start Current Voltage at the SS pin=1.4V 11

7

14

µA

µA(min)

µA(max)

I

SHUTDOWN

Shutdown Pin Current Shutdown Pin Pulled Low 2.2

0.8/0.5

3.7/4.0

µA

µA(min)

µA(max)

v

SHUTDOWN

Shutdown Pin Threshold

Voltage

Falling Edge 0.6

0.3

0.9

V

V(min)

V(max)

T

SD

Thermal Shutdown

Temperature

165

˚C

T

SD_HYST

Thermal Shutdown

Hysteresis Temperature

25

˚C

Note 1: Absolute maximum ratings indicate limits beyond which damage to the device may occur. Operating ratings indicate conditions for which the device is intended to be functional, but device parameter specifications may not be guaranteed under these conditions. For guaranteed specifications and test conditions, see

the Electrical Characteristics.

Note 2: The maximum allowable power dissipation is calculated by using P

Dmax

=

(T

Jmax−TA

)/θJA, where T

Jmax

is the maximum junction temperature, TAis the

ambient temperature, and θ

JA

is the junction-to-ambient thermal resistance of the specified package. The 893 mW rating results from using 150˚C, 25˚C, and

140˚C/W for T

Jmax,TA

, and θJArespectively.A θJAof 140˚C/W represents the worst-case condition of no heat sinking of the 16-pin TSSOP package. Heat sinking

allows the safe dissipation of more power. The Absolute Maximum power dissipation must be derated by 7.14mW per ˚C above 25˚C ambient. The LM2651 actively

limits its junction temperature to about 165˚C.

Note 3: The human body model is a 100pF capacitor discharged through a 1.5kΩ resistor into each pin.

Note 4: Typical numbers are at 25˚C and represent the most likely norm.

Note 5: All limits are guaranteed at room temperature (standard typeface) and at temperature extremes (boldface type ). All room temperature limits are 100

%

production tested.All limits at temperature extremes are guaranteed via correlation using standard Statistical Quality Control (SQC) methods.All limits are used to

calculate Average Outgoing Quality Level (AOQL).

LM2651

www.national.com5

Page 6

Typical Performance Characteristics

Efficiency vs Load Current

(V

IN

=

12V, V

OUT

=

5V)

DS100925-16

IQvs Input Voltage

DS100925-5

I

QSD

vs Input Voltage

DS100925-6

I

QSD

vs Junction Temperature

DS100925-7

Frequency vs

Junction Temperature

DS100925-8

R

DS(ON)

vs Input Voltage

DS100925-9

R

DS(ON)

vs Junction Temperature

DS100925-10

Current Limit vs Input

Voltage (V

OUT

=

2.5V)

DS100925-11

Current Limit vs Junction

Temperature (V

OUT

=

2.5V)

DS100925-12

LM2651

www.national.com 6

Page 7

Typical Performance Characteristics (Continued)

Block Diagram

Operation

The LM2651 operates in a constant frequency (300 kHz),

current-mode PWM for moderateto heavy loads; and it automatically switches to hysteretic mode for light loads. In hysteretic mode, the switching frequency is reduced to keep the

efficiency high.

Main Operation

When the load current is higher than the sleep mode threshold, the part is always operating in PWM mode. At the beginning of each switching cycle, the high-side switch is turned

on, the current from the high-side switch is sensed and compared with the output of the error amplifier (COMP pin).

When the sensed current reaches the COMP pin voltage

level, the high-side switch is turned off; after 40 ns (dead-

Current Limit vs Junction

Temperature (V

OUT

=

3.3V)

DS100925-13

Current Limit vs Input

Voltage (V

OUT

=

3.3V)

DS100925-14

DS100925-3

FIGURE 1. LM2651 Block Diagram

LM2651

www.national.com7

Page 8

Operation (Continued)

time), the low-side switch is turned on. At the end of the

switching cycle, the low-side switch is turned off; and the

same cycle repeats.

The current ofthe top switch is sensed by apatentedinternal

circuitry.This unique technique gets rid of the external sense

resistor, saves cost and size, and improves noise immunity

of the sensedcurrent. Afeedforward from the input voltage is

added to reduce the variation of the current limit over the input voltage range.

When the load current decreases below the sleep mode

threshold, the output voltage will rise slightly, this rise is

sensed by the hysteretic mode comparator which makes the

part go into the hysteretic mode with both the high and low

side switches off.The output voltage starts to drop untilit hits

the low threshold of the hysteretic comparator, and the part

immediately goes back to the PWM operation. The output

voltage keeps increasing until it reaches the top hysteretic

threshold, then both the high and low side switches turn off

again, and the same cycle repeats.

Protections

The cycle-by-cycle current limit circuitry turns off the

high-side MOSFET whenever the current in MOSFET

reaches 2A.

Design Procedure

This section presents guidelines for selecting external components.

INPUT CAPACITOR

A low ESR aluminum, tantalum, or ceramic capacitor is

needed betwen the input pin and power ground.This capacitor prevents large voltage transients from appearing at the

input. The capacitor is selected based on the RMS current

and voltage requirements. The RMS current is given by:

The RMS current reaches its maximum (I

OUT

/2) when

V

IN

equals 2V

OUT

. For an aluminum or ceramic capacitor,

the voltage rating should be at least 25%higher than the

maximum input voltage. If a tantalum capacitor is used, the

voltage rating required is about twice the maximum input

voltage. The tantalum capacitor should be surge current

tested by the manufacturer to prevent being shorted by the

inrush current. Itis also recommended to put asmall ceramic

capacitor (0.1 µF) between the input pin and ground pin to

reduce high frequency spikes.

INDUCTOR

The most critical parameters for the inductor are the inductance, peak current and the DC resistance. The inductance

is related to the peak-to-peak inductor ripple current, the input and the output voltages:

A higher value of ripple current reduces inductance, but increases the conductance loss, core loss, current stress for

the inductor and switch devices.It also requires a bigger output capacitor for the same output voltage ripple requirement.

A reasonable value is setting the ripple current to be 30%of

the DC output current. Since the ripple current increases

with the input voltage, the maximum input voltage is always

used to determine the inductance. The DC resistance of the

inductor is a key parameter for the efficiency. Lower DC resistance is available with a bigger winding area. A good

tradeoff betweenthe efficiency and thecoresize is letting the

inductor copper loss equal 2%of the output power.

OUTPUT CAPACITOR

The selection of C

OUT

is driven by the maximum allowable

output voltage ripple. The output ripple in the constant frequency, PWM mode is approximated by:

The ESR term usuallyplays the dominant role in determining

the voltage ripple. A low ESR aluminum electrolytic or tantalum capacitor (such as Nichicon PL series, Sanyo OS-CON,

Sprague 593D, 594D, AVX TPS, and CDE polymer aluminum) is recommended. An electrolytic capacitor is not recommended for temperatures below −25˚C since its ESR

rises dramatically at cold temperature. A tantalum capacitor

has a muchbetter ESR specification at cold temperatureand

is preferred for low temperature applications.

The output voltage ripple in constant frequency mode has to

be less than the sleep mode voltage hysteresis to avoid entering the sleep mode at full load:

V

RIPPLE

<

20mV x V

OUT/VFB

BOOST CAPACITOR

A0.1 µF ceramic capacitor isrecommended for the boost capacitor. The typical voltage across the boost capacitor is

6.7V.

SOFT-START CAPACITOR

Asoft-start capacitor is used to provide the soft-start feature.

When the input voltage is first applied, or when the SD(SS)

pin is allowed to go high, the soft-start capacitor is charged

by a current source (approximately 2 µA). When the SD(SS)

pin voltage reaches 0.6V (shutdown threshold), the internal

regulator circuitry starts to operate. The current charging the

soft-start capacitor increases from 2 µA to approximately

10 µA. With the SD(SS) pin voltage between 0.6V and 1.3V,

the level of the current limit is zero, which means the output

voltage is still zero. When the SD(SS) pin voltage increases

beyond 1.3V, the current limit starts to increase. The switch

duty cycle, whichis controlled by the level of thecurrentlimit,

starts with narrow pulses and gradually gets wider. At the

same time, the output voltage of the converter increases towards the nominal value, which brings down the output voltage of the error amplifier. When the output of the erroramplifier is less than the current limit voltage, it takes over the

control of the duty cycle. The converter enters the normal

current-mode PWM operation. The SD(SS) pin voltage is

eventually charged up to about 2V.

The soft-start time can be estimated as:

T

SS

=

C

SS

x 0.6V/2 µA + CSSx (2V−0.6V)/10 µA

R

1

AND R2(Programming Output Voltage)

Use the following formula to select the appropriate resistor

values:

V

OUT

=

V

REF

(1+R1/R2)

where V

REF

=

1.238V

LM2651

www.national.com 8

Page 9

Design Procedure (Continued)

Select resistors between10kΩ and 100kΩ.(1%or higher accuracy metal film resistors for R

1

and R2.)

COMPENSATION COMPONENTS

In the controlto output transfer function, the firstpole F

p1

can

be estimated as 1/(2πR

OUTCOUT

); The ESR zero Fz1of the

output capacitor is 1/(2πESRC

OUT

); Also, there is a high fre-

quency pole F

p2

in the range of 45kHz to 150kHz:

F

p2

=

F

s

/(πn(1−D))

where D=V

OUT/VIN

,n=1+0.348L/(VIN−V

OUT

)(LisinµHs

and V

IN

and V

OUT

in volts).

The total loop gain G is approximately 500/I

OUT

where I

OUT

is in amperes.

A Gm amplifier is used inside the LM2651. The output resis-

tor R

o

of the Gm amplifier is about 80kΩ.Cc1and RCto-

gether with R

o

give a lag compensation to roll off the gain:

F

pc1

=

1/(2πC

c1(Ro+Rc

)), F

zc1

=

1/2πC

c1Rc

.

In some applications, the ESR zero F

z1

can not be cancelled

by F

p2

. Then, Cc2is needed to introduce F

pc2

to cancel the

ESR zero, F

p2

=

1/(2πC

c2Ro\Rc

).

The rule of thumb is to have more than 45˚ phase margin at

the crossover frequency (G=1).

If C

OUT

is higher than 68µF, C

c1

=

2.2nF, and R

c

=

15KΩ are

good choices for most applications. If the ESR zero is too

low to be cancelled by F

p2

, add Cc2.

If the transient response to a step load is important, choose

R

C

to be higher than 10kΩ.

EXTERNAL SCHOTTKY DIODE

A Schottky diode D

1

is recommended to prevent the intrinsic

body diode of the low-side MOSFET from conducting during

the deadtime in PWM operation and hysteretic mode when

both MOSFETs are off. If the body diode turns on, there is

extra power dissipation in the body diode because of the

reverse-recovery current and higher forward voltage; the

high-side MOSFET also has more switching loss since the

negative diode reverse-recovery current appears as the

high-side MOSFET turn-on current in addition to the load

current. These losses degrade the efficiency by 1-2%. The

improved efficiency and noise immunity with the Schottky diode become more obvious with increasing input voltage and

load current.

The breakdown voltage rating of D

1

is preferred to be 25

%

higher than the maximum input voltage. Since D

1

is only on

for a short period of time, the average current rating for D

1

only requires being higher than 30%of the maximum output

current. It is important to place D

1

very close to the drain and

source of the low-side MOSFET, extra parasitic inductance

in the parallel loop will slow the turn-on of D

1

and direct the

current through the body diode of the low-side MOSFET.

When an undervoltage situation occurs, the output voltage

can be pulled below ground as the inductor current is reversed through the synchronous FET. For applications which

need to be protected from a negative voltage, a clamping diode D2 is recommended. When used, D2 should be connected cathode to V

OUT

and anode to ground. A diode rated

for a minimum of 2A is recommended.

PCB Layout Considerations

Layout is critical to reduce noises and ensure specified performance. The important guidelines are listed as follows:

1. Minimize the parasitic inductance in the loop of input ca-

pacitors and the internalMOSFETs by connecting the input capacitors toV

IN

and PGND pinswith short and wide

traces. This is important because the rapidly switching

current, together with wiring inductance can generate

large voltage spikes that may result in noise problems.

2. Minimize the trace from the center of the output resistor

divider to the FB pin and keep it away from noise

sources to avoid noise pick up. For applications requiring tight regulation at the output, a dedicated sense

trace (separated from the power trace) is recommended

to connect the top of the resistor divider to the output.

3. If the Schottky diode D

1

is used, minimize the traces

connecting D

1

to SW and PGND pins.

DS100925-23

Schematic for the Typical Board Layout

LM2651

www.national.com9

Page 10

Physical Dimensions inches (millimeters) unless otherwise noted

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

labeling, can be reasonably expected to result in a

significant injury to the user.

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

National Semiconductor

Europe

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: ap.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

www.national.com

16-Lead TSSOP (MTC)

For ordering, refer to Ordering Information Table

See NS Package Number MTC16

LM2651 1.5A High Efficiency Synchronous Switching Regulator

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...