Page 1

LM2650

Synchronous Step-Down DC/DC Converter

LM2650 Synchronous Step-Down DC/DC Converter

June 1999

General Description

The LM2650 is a step-down DC/DC converter featuring high

efficiency over a 3A to milliamperes load range. This feature

makes the LM2650 an ideal fit in battery-powered applications that demand long battery life in both run and standby

modes.

The LM2650 alsofeatures a logic-controlled shutdown mode

in which it draws at most 25µA from the input power supply.

The LM2650 employs a fixed-frequency pulse-width modulation (PWM) and synchronous rectification to achieve very

high efficiencies. In many applications, efficiencies reach

95%+ for loads around 1A and exceed 90%for moderate to

heavy loads from 0.2A to 2A.

A low-power hysteretic or ″sleep″ mode keeps efficiencies

high at light loads. The LM2650 enters and exits sleep mode

automatically as the load crosses ″sleep in″ and ″sleep out″

thresholds. The LM2650 provides nodes for programming

both thresholds via external resistors. A logic input allows the

user to override the automatic sleep feature and keep the

LM2650 in PWM mode regardless of the load level.

An optional soft-start feature limits current surges from the

input power supply at start up and provides a simple means

of sequencing multiple power supplies.

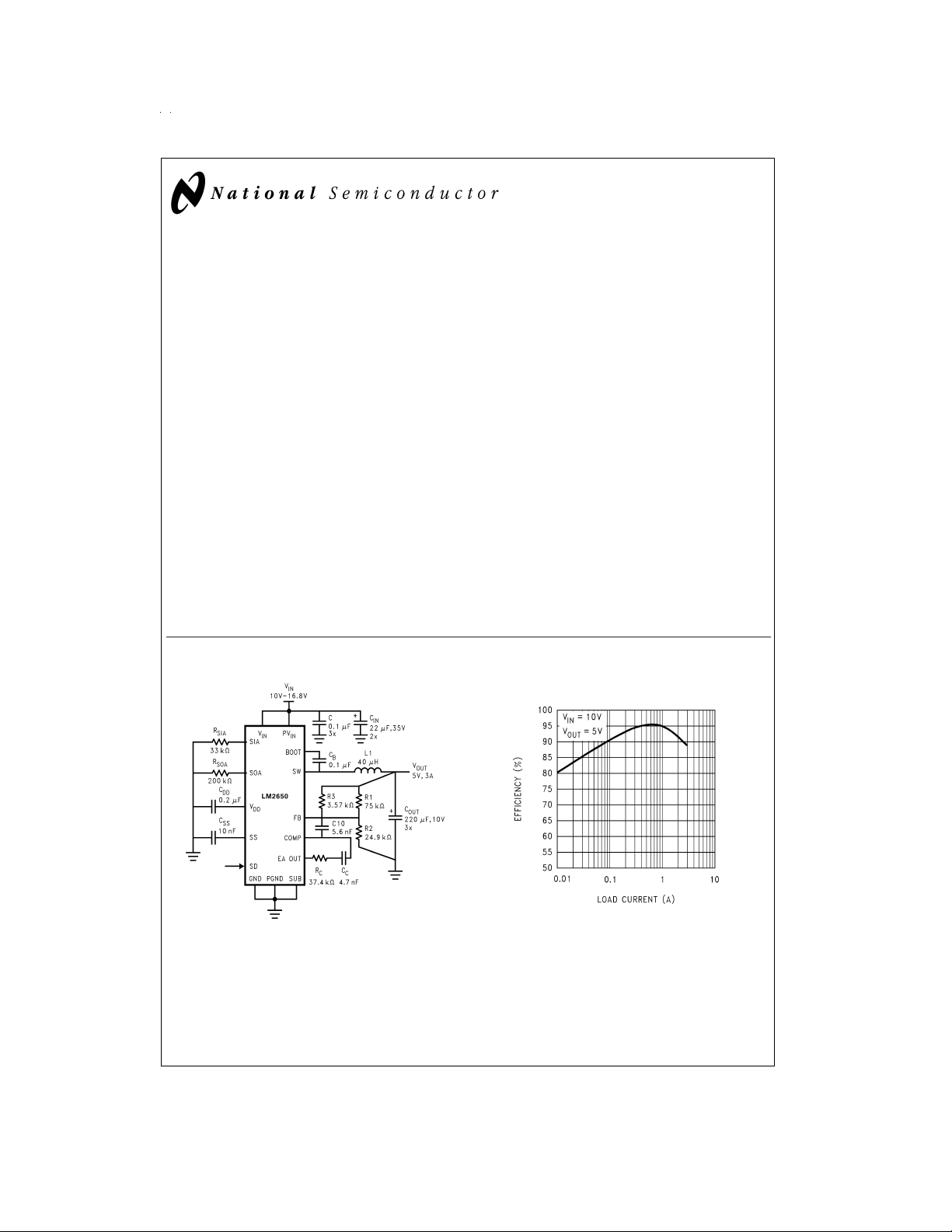

Typical Application

Features

n Ultra high efficiencies (95%possible)

n High efficiency over a 3A to milliamperes load range

n Synchronous switching of internal NMOS power FETs

n Wide input voltage range (4.5V to 18V)

n Output voltage adjustable from 1.5V to 16V

n Automatic low-power sleep mode

n Logic-controlled micropower shutdown (I

n Frequency adjustable up to 300 kHz

n Frequency synchronization with external signal

n Programmable soft-start

n Short-circuit current limiting

n Thermal shutdown

n Available in 24-lead Small-Outline package

QSD

≤ 25 µA)

Applications

n Notebook and palmtop personal computers

n Portable data terminals

n Modems

n Portable Instruments

n Global positioning devices (GPSs)

n Battery-powered digital devices

LM2650-ADJ Efficiency

DS012848-1

Converting a Four-Cell Li Ion Battery to 5V

© 1999 National Semiconductor Corporation DS012848 www.national.com

DS012848-2

Page 2

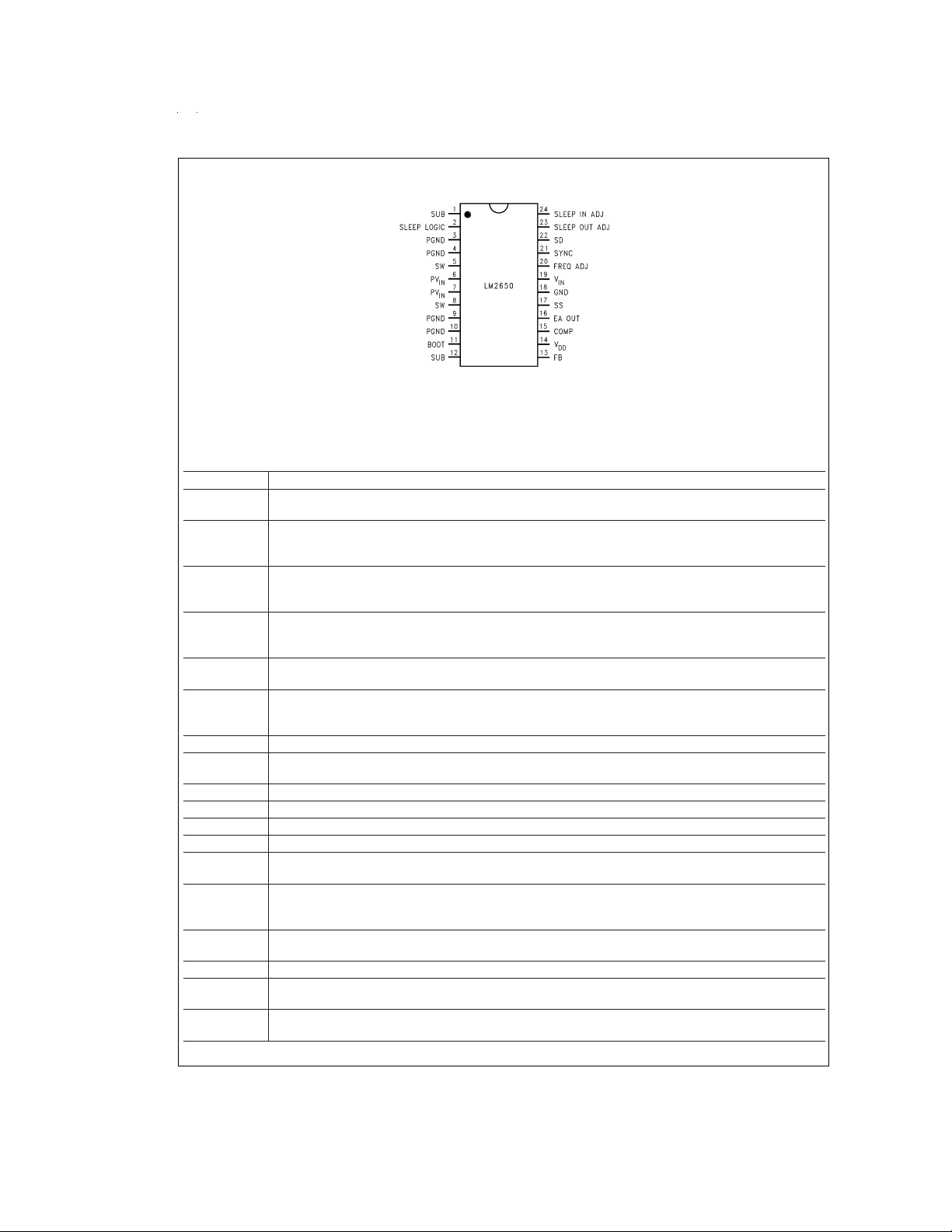

Connection Diagram

DS012848-14

24-Lead Small Outline Package (M)

Order Number LM2650M-ADJ

See Package Number M24B

Pin Descriptions

(Refer to the Block Diagrams)

Pins Description

1, 12 SUB: These pins make electrical contact with the substrate of the die. Ground them. For best thermal

performance, ground them to the same large, uninterrupted copper plane as the PGND pins.

2 SLEEP LOGIC: Use this logic input to select the conversion mode; low selects PWM, high selects sleep, and

high impedance (open) permits the LM2650 to move freely and automatically between the modes, using PWM

for moderate to heavy loads and sleep for light loads.

3, 4, 9, 10 PGND: The ground return of the power stage. The power stage consists of the two power switches Q1 and

Q2, the gate drivers DH and DL, and the linear voltage regulators VRegH and VRegL. For best electrical and

thermal performance, ground these pins to a large, uninterrupted copper plane.

5, 8 SW: The output node of the power stage. It swings from slightly below ground to slightly below the voltage to

. To minimize the effects of switching noise on nearby circuitry, keep all traces originating from SW short

PV

IN

and to the point. Route all traces carrying signals well away from the SW traces.

6, 7 PV

: The positive supply rail of the power stage. Bypass each PVINpin to PGND with a 0.1 µF capacitor. Use

IN

capacitors having low ESL and low ESR, and locate them close to the IC.

11 BOOT: The positive supply rail of the high-side gate driver DH. Connect a 0.1 µF capacitor from this node to

SW. Bootstrapping action creates a supply rail about 9V above that at PV

the gate of the NMOS power FET Q1. Overriding ensures low R

13 FB: The feedback input.

14 V

: An internal regulator steps the input voltage down to a 4V rail used by the signal-level circuitry. VDDis the

DD

output node of this regulator. Bypass V

15 COMP: The inverting input of the error amplifier EA.

16 EA OUT: The output node of the error amplifier EA.

17 SS: The soft start node. Connect a capacitor from SS to GND.

18 GND: The ground return of the signal-level circuitry.

19 V

: The positive supply rail of the internal 4V regulator. Bypass VINto GND close to the IC with a 0.1 µF

IN

capacitor.

20 FREQ ADJ: The LM2650 switches at a nominal 90 kHz. Connect a resistor between FREQ ADJ and GND to

adjust the frequency up from the nominal. Use the graph under Typical performance Characteristics to select

the resistor.

21 SYNC: The synchronization input. If the switching frequency is to be synchronized with an external clock

signal, apply the clock signal here.

22 SD: Use this logic input to control shutdown; pull low for operation, high for shutdown.

23 SLEEP OUT ADJ (SOA): The value of the resistor connected between SIA and ground programs the sleep-in

threshold. Higher values program lower thresholds.

24 SLEEP IN ADJ (SIA): The value of the resistor connected between SIA and ground programs the sleep-in

threshold. Higher values program lower thresholds.

Top View

, and DH uses this rail to override

IN

.

DS(on)

to GND close to the IC with a 0.2 µF capacitor.

DD

www.national.com 2

Page 3

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

(All voltages are referenced to the PGND and GND pins.)

DC Voltage at PV

DC Voltage at SD, SLEEP LOGIC

and SYNC 15V

DC current into SW

Junction Temperature Limited by the IC

DC Power Dissipation (Note 2) 1.28W

Storage Temperature −65˚C to +150˚C

IN

and V

±

20V

7.5A

IN

Soldering Time, Temperature (Note

3)

Wave (4 seconds)

Infrared (10 seconds)

Vapor Phase (75 seconds)

260˚C

240˚C

219˚C

ESD Susceptibility (Note 4) 1.3 kV

Operating Ratings (Note 1)

Supply Voltage Range (PV

) 4.5V to 18V

V

IN

Junction Temperature Range −40˚C to +125˚C

and

IN

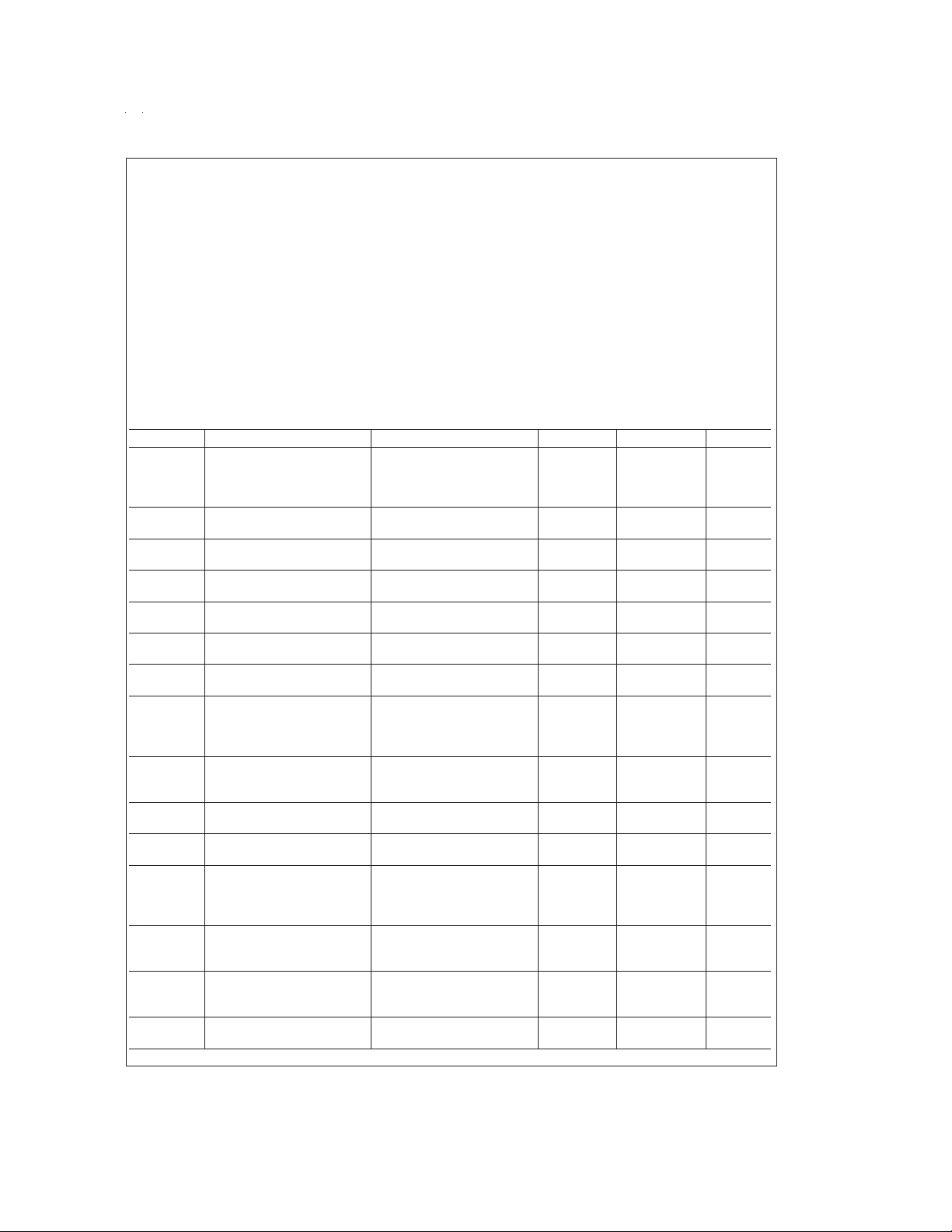

Electrical Characteristics

V

= 15V, V

PVIN

type apply for T

Operating Ratings.

SLEEP LOGIC

A=TJ

=

0V and V

= +25˚C. Limits appearing in boldface type apply over the full junction temperature range shown under

Symbol Parameter Conditions Typ (Note 5) Limit (Note 6) Units

V

OUT

Output Voltage R1=75 kΩ,1%,

η1 System Efficiency I

η2 System Efficiency I

V

I

I

I

R

REF

Q

QS

QSD

DS(on)

Reference Voltage V

Quiescent Current in PWM

mode

Quiescent Current in Sleep

mode

Quiescent Current in Shutdown

mode

HS DC On-Resistance

Drain-to-Source of the

High-Side Power Switch

LS DC On-Resistance

R

DS(on)

Drain-to-Source of the

Low-Side Power Switch

I

LHS

I

LLS

I

LIMIT

F

F

D

OSC

MAX

MAX

Leakage current of the

High-Side Power Switch

Leakage current of the

Low-Side Power Switch

Active Current Limit of the

High-Side Power Switch

Oscillator Frequency V

Maximum Oscillator Frequency I

Maximum Duty Cycle V

=

0V unless superseded under Conditions. Typicals and limits appearing in plain

SD

5.00

R2=25 kΩ,1%,

7.5V ≤ V

0.12A ≤ I

LOAD

F

OSC

LOAD

F

OSC

SLEEPLOGIC

V

FB

−20mV (Note 8)

IV

FB

V

SLEEPLOGIC

≤ 18V

PVIN

LOAD

=

1A, T

Not Adjusted

=

3A, T

Not Adjusted

=

=

V

REF

=

−20mV,

V

REF

=

≤ 3A

A

A

VSD=3V

(Note 8)

=

1A,

I

DS

V

SLEEPLOGIC

V

FB

V

BOOT

=

I

DS

V

FB

V

PVIN

V

SD

V

PVIN

V

SD

V

PVIN

V

BOOT

V

FB

V

SLEEPLOGIC

FB

=

=

3V,

=

24V

1A,

=

3V

=

18V, V

=

3V

=

18V, V

=

3V

=

15V,

=

24V,

=

3V,

=

=

−20 mV 90

V

REF

=

25˚C,

=

25˚C,

3V (Note 7)

3V (Note 8)

3V,

=

0V,

SW

=

18V,

SW

3V,

94

89

1.25

4.0

850

9

130

125

100

95

5.5

4.80/4.75

5.20/5.25

1.281/1.294

1.219/1.206

6.50/7.0

1.35/1.60

20/25

170/245

175/245

10

210

3.5

7.5

80/75

100/105

FREQ ADJ

=

V

FB

=

FB

F

OSC

=

100µA,(Note 9)

−20 mV

V

REF

−20 mV,

V

REF

Not Adjusted

315

270/260

360/370

97

94/93

V

V(min)

V(max)

%

%

V(min)

V(max)

mA

mA(max)

µA

mA(max)

µA

µA(max)

mΩ

mΩ(max)

mΩ

mΩ(max)

nA

µA(max)

µA

µA(max)

A

A(min)

A(max)

kHz

kHz(min)

kHz(max)

kHz

kHz(min)

kHz(max)

%

%

(min)

www.national.com3

Page 4

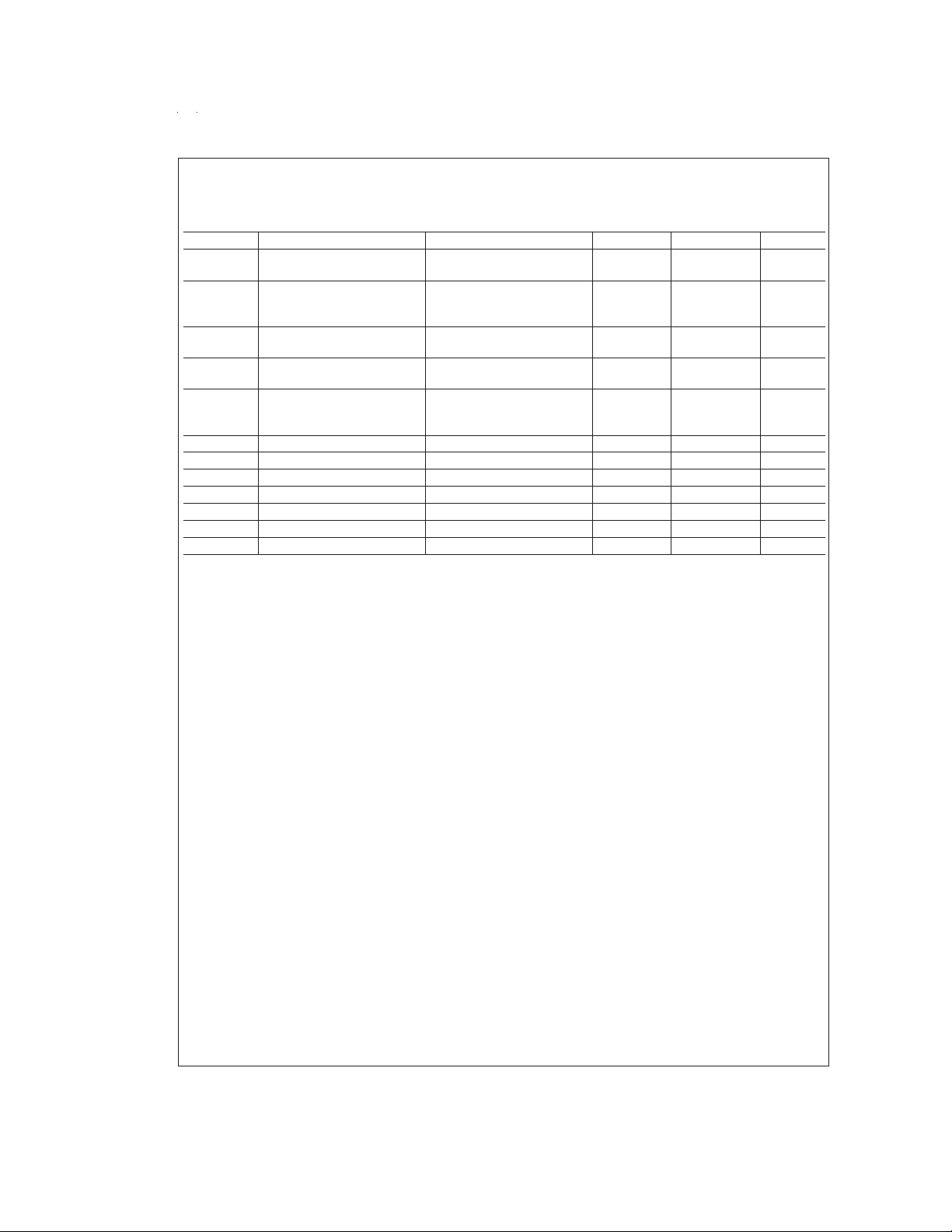

Electrical Characteristics (Continued)

V

= 15V, V

PVIN

type apply for T

Operating Ratings.

SLEEP LOGIC

A=TJ

=

0V and V

= +25˚C. Limits appearing in boldface type apply over the full junction temperature range shown under

Symbol Parameter Conditions Typ (Note 5) Limit (Note 6) Units

D

MIN

V

DD

V

BOOT

I

SS

V

HYST

T

SD

Note 1: Absolute Maximum Ratings are limits beyond which damage to the device may occur. Operating Ratings are conditions under which the device operates

correctly. Operating ratings do not imply guaranteed performance limits. For guaranteed performance limits and associated test conditions, see the Electrical Characteristics.

Note 2: This rating is calculated using the formula P

junction temperature, and θ

78˚C/W for T

the safe dissipation of more power. See Application Notes on thermal management. The LM2650 actively limits its junction temperature to about 170˚C.

Note 3: For detailed information on soldering plastic small-outline packages, refer to the Packaging Databook published by National Semiconductor Corporation.

Note 4: ESD is applied using the human-body model, a 100pF capacitor discharged through a 1.5kΩ resistor.

Note 5: A typical is the center of characterization data taken at T

Note 6: All limits are guaranteed. The guarantee is backed with 100%testing at T

Note 7: V

Note 8: Quiescent current is the total current flowing into the P

nominal switching frequency. I

Note 9: Pulling 100µA out of FREQ ADJ simulates adjusting the oscillator frequency with a 12.5 kΩ resistor connected from FREQ ADJ to GND. The sleep mode

cannot be used at switching frequencies above 250 kHz.

Minimum Duty Cycle V

Internal Rail Voltage I

Bootstrap Regulator Voltage

(VRegH)

Soft Start Current 10

Hysteresis of the Sleep

Comparator (C2

of SD 0.95 V(max)

V

IL

V

of SD 2.10 V(min)

IH

V

of SLEEP LOGIC 0.9 V(max)

IL

V

of SLEEP LOGIC 2.0 V(min)

IH

V

of SYNC 0.50 V(max)

IL

V

of SYNC 1.45 V(min)

IH

Figure 2

TJfor Thermal Shutdown 170 ˚C

is the junction ot ambient thermal resistance of the package. The P

JA

and θJArespectively.A θJAof 78˚C represents the worst condition of no heat sinking of the M24B small-outline package. Heat sinking allows

Jmax,TA

is measured at SLEEP OUT ADJ.

REF

includes no such current.

QS

=

0V unless superseded under Conditions. Typicals and limits appearing in plain

SD

=

+50 mV,

V

FB

REF

Not Adjusted

F

OSC

=1mA 4.0

VDD

2.8

5

3.6/3.4

4.2/4.3

I

=1mA 7.5

BOOT

6.5/6.0

13.5/20.0

V

)

SLEEPLOGIC

=

3V 30

10

50

DCmax

=

)/θJA, where P

(T

Jmax−TA

= 25˚C.

A=TJ

and VINpins. IQincludes the current used to drive the gates of the two NMOS power FETsat the

VIN

A=TJ

is the absolute maximum power dissipation, T

DCmax

= 125˚C and statistical correlation for room temperature and cold limits.

rating of 1.28W results from substituting 170˚C, 70˚C and

DCmax

is the maximum

Jmax

%

V(min)

V(max)

V(min)

µA(max)

mV(min)

mV(max)

%

(min)

V

V

µA

mV

www.national.com 4

Page 5

Typical Performance Characteristics

I

vs Input Voltage

QSD

IQSvs Input Voltage

IQvs Input Voltage

IQvs Oscillator Frequency

R

Low-Side vs Junction

DS(on)

Temperature

DS012848-3

DS012848-6

DS012848-9

R

Low-Side vs Input Voltage

DS(on)

R

High-Side vs Junction

DS(on)

Temperature

DS012848-4

DS012848-7

DS012848-10

DS012848-5

R

High-Side vs Input Voltage

DS(on)

DS012848-8

Oscillator Frequency vs Junction

Temperature

DS012848-11

Oscillator Frequency vs Adjusting Resistor

DS012848-12

Current Limit vs Junction Temperature

DS012848-13

www.national.com5

Page 6

Block Diagrams

FIGURE 1. The PWM Circuit with External Components in a Closed Control Loop

DS012848-15

DS012848-16

FIGURE 2. The Hysteretic or ″Sleep″ Circuit with External Components in a Closed Control Loop

DS012848-21

FIGURE 3. The Internal Voltage Regulator and Voltage Reference used by Both the PWM and Hysteretic Circuits

www.national.com 6

Page 7

Operation

OVERVIEW

The LM2650 uses two step-down conversion modes:

fixed-frquency pulse-width modulation (PWM) and hysteretic. It moves freely and automatically between them, using

PWM for moderate to heavy loads and hysteretic for light

loads.

For clarity, separate block diagrams for each conversion

mode have been included. See

Blocks used in both modes appear in both diagrams with the

same label. For example, both modes use the input buffer B.

To keep the diagrams simple, most power supply rails have

been omitted. R3, C10, R

are outside the IC.

THE PWM CIRCUIT (

Figure 1

The PWM is a fixed-frequency, voltage-mode pulse-width

modulator. It consists of four functional blocks: an input

buffer, an error amplifier, a modulator, and a power stage.

1. The input buffer B: B is a voltage follower. A fraction of

the output voltage is fed back to its noninverting input

FB. Circumventing B by using the COMP input as the

feedback input will cause the IC to malfunction.

2. The error amplifier EA: EA is a voltage amplifier. It subtracts the feedback voltage from the 1.25V reference

and amplifies the difference to produce an error voltage

for the control loop. For the purpose of loop compensation, EA is typically configured as an integrator. In this

configuration, a capacitor C

nected in series between the inverting input COMP and

the output terminal EA OUT.The capacitor and the internal 6.5kΩ resistor create a pole, while the capacitor and

series resistor create a zero.

3. The modulator: The modulator is the heart of the PWM

circuit. It consists of the 90 kHz oscillator, the voltage

comparator C1, and output logic represented here as a

simple SR latch.

The modulator generates a continuous stream of rectangular, signal-level. It generates the pulses at a fixed frequency, and it modulates or varies their widths in response to variations in the error voltage. The pulses

appear at Q, the output of the SR latch. An increase in

the error voltage results in a proportional increase in the

pulse widths, and, conversely, a decrease in the error

voltage results in a proportional decrease in the pulse

widths.

The oscillator produces a 90 kHz sawtooth that ramps

between 1V and 2V. At the beginning of each ramp, the

oscillator sets the SR latch sending Q high. As the ramp

voltage surpasses the error voltage, C1 resets the SR

latch sending Q low. An increase in the error voltage increases the time between the setting and the resetting of

the SR latch which , in turn, results in an equal increase

in pulse widths: that is, an equal increase in the time Q

spends high in each cycle. A decrease in the error voltage has the opposite effect on the pulse widths as it decreases the time between the setting and resetting of the

SR latch.

4. The power stage: The power stage puts some punch between the output of the modulator by translating the

stream of signal-level pulses generated by the modulator into a stream of power pulses that swing from ground

up to the input voltage while sinking and sourcing as

much as 3.5A. The power stage consists of two gate

Figure 1

C,CC,CB

, L1, R1, R2, and C

)

and a resistor RCare con-

C

and

Figure 2

OUT

drivers DH and DL, two linear voltage regulators VRegH

and VRegL, and two NMOS power FETs Q1 and Q2.

The power pulses appear at the SW mode. When Q

goes high, DL drives the gate of Q2 low turning Q23 off.

While Q2 turns off, the SW potential may remain at just

below ground as the body diode of Q2 conducts what

was previously reverse current (source-to-drain) in Q2,

or the SW potential may swing up to just above the input

voltage as the body diode of Q1 conducts what was pre-

.

viously forward current (drain-to-source) in Q2. About 50

ns after Q goes high, DH drives the gate of Q1 high turning Q1 on. If the task remains, Q1 pulls the SW potential

up, if not, Q1 simply takes over the conduction responsibility from its own body diode. When Q goes low, the inverse action occurs resulting in the SW potential swinging from the input voltage to the ground. The 50 ns delay

between one switch beginning to turn off and the other

switch beginning to turn on prevents the switches from

″shooting through″ directly from the input supply to the

ground.

The PWM circuit drives the pulse stream into the

low-pass filter made up of L1 and C

passed the DC component of the stream and attenuates

the AC components. The output of the filter is the DC

voltage V

Since the DC component of any periodic waveforms the

average value of the waveform, V

ing:

superimposed with a small ripple voltage.

OUT

OUT

Here T is the switching period in seconds V(t) is the pulse

stream. Under DC steady-state conditions, (1) yields

Here V

is the input voltage, and therefore the height of the

IN

pulses, in volts, is the width of the pulses in seconds, and D

is the ratio of t

The output voltage is programmed using the resistive divider

to T, the duty or the duty cycle.

ON

made up for R1 and R2,

As Q1 turns on, its source voltage swings up to just below

the input voltage. The LM2650 uses a simple technique

called ″bootstrapping″ to pull the positive supply rail of DH

(at BOOT) up along with the source voltage of Q1, but to a

voltage above the input voltage. Because the source of Q1

and the positive supply rail of DH make the same voltage

swing together, DH maintains the positive gate-to-source

voltage required to turn Q1 on. Q12 plays an active role in

pulling the supply rail of DH up and is therefore said to pull itself up by its ″bootstraps″, thus the name of the technique

and of the BOOT pin.

In the typical application, a capacitor CB is connected outside the IC between the BOOT and SW pins. When Q2 is on,

the input supply charges CB through VRegH and the internal

diode D.

THE HYSTERETIC CIRCUIT AND LOOP (

Except for C2, the hysteretic circuit borrows all its circuit

blocks from the PWM circuit.

The hysteretic comparator C2 is a voltage comparator with

built-in hysteresis V

1.25V.

of typically 30mV centered at

HYST

. The filter

OUT

can be found us-

(1)

(2)

(3)

Figure 2

)

www.national.com7

Page 8

Operation (Continued)

The diode D2 is the body diode of Q2. The hysteretic circuit

uses D2 as a rectifier instead of switching Q2 as a synchronous rectifier.

When the load current drops below the prescribed sleep-in

threshold, the LM2650 shuts down the PWM loop and starts

up the hysteretic loop. The hysteretic loop supports light

loads more efficiently because it uses less power to support

its own operation; it uses less bias power because it’s a simpler loop having less circuit blocks to bias, and it switches

slower, so it incurs lower switching losses.

The hysteretic control loop does not switch at a constant frequency. Instead, it monitors V

V

reaches either side of a narrow window centered on

OUT

the desired output voltage. C2 directs the switching based

on its reading of the feedback voltage. Switching in this manner yields a regulated voltage consisting of the desired output voltage and an AC ripple voltage. The magnitude of the

AC component can be approximated using

and switches only when

OUT

back voltage just surpasses the lower hysteretic threshold of

C2, the output of C2 changes states from low to high, and

DH responds by pulling the gate of Q1 up turning Q1 on and

starting the hysteretic cycle over.

Note that as the load current decreases, it takes increasingly

longer periods for the load current to discharge C

through the hysteretic window, and as the load current in-

OUT

creases, the periods become even shorter. It can be seen

from the above observation that the switching frequency of

the hysteretic loop varies as the load varies. The switching

frequency can be approximated using

(6)

Here f is the switching frequency in hertz, I is the load current

in amperes, C

V

OUT_PP

Typical switching frequencies range anywhere from a few

is the value of the capacitor in farads, and

OUT

is the magnitude of the AC ripple voltage in volts.

hertz for very light loads to a few thousand hertz for light

loads bordering on the moderate level.

(4)

For example, with V

120mV,

OUT

set to 5V,V

OUT_PP

is approximately

(5)

When it starts up, the hysteretic loop turns Q1 on. While Q1

is on, the input power supply charges C

current to the load. Current from the supply reaches C and

and supplies

OUT

the load via the series path provided by Q1 and L1. As the

feedback voltage just surpasses the upper hysteretic threshold of C2, the output of C2 changes from high to low, and HD

responds by pulling the gate of Q1 down turning Q1 off. As

Q1 turns off, L1 generates a negative-going voltage transient

that D2 clamps at just below ground. D2 remains on only

briefly as the current in L1 runs out. While both Q1 and D2

are off, C

alone supplies current to the load. As the feed-

OUT

Application Circuits

Figure 4

is a schematic of the typical application circuit. use

the component values shown in the figure and those contained in

Table 1

DC/DC converter. As with the design of any DC/DC converter, the design of these circuits involved tradeoffs between efficiency, size, and cost. Here more weight was given

to efficiency than to size as evidenced by the low switching

frequency which keeps switching losses low but pushes the

value and size of the inductor up.

From a smaller circuit, use the component values shown in

Figure 4

slightly higher switching losses for a much smaller inductor.

Note,

Figure 4

adjust the switching frequency from 90 kHz up to 200 kHz.

Connect R

to build a 5V, 3A, or 3.3V, 3A step-down

and those contained in

Table3

. These circuits trade

does not show RFA, the resistor required to

between the FREQ ADJ pin and ground.

FA

FIGURE 4. The Typical 90 kHz Application Circuit

www.national.com 8

DS012848-19

Page 9

Application Circuits (Continued)

TABLE 1. Components for the Typical 90 kHz Application Circuit

Input Voltage 7V to 18V IN

Applicable Cell Stacks 8 to 12 Cell NiCd or NiMh, 3 to 4 Cell Li Ion, 8 to 11 Cell Alkaline, 6 Cell

Output 5V, 3A Out 3.3V, 3A out

Input Capacitor C

IN

Inductor L1 40µH (See

Output Capacitor C

OUT

Feedback Resistors R1

and R2

Compensation

Components R

and C

Sleep Resistors R

and R

10

SOA

C,CC,R3

SIA

,

2 x 22 µF, 35V AVX TPS

Series or Sprague 593D Series

Table 2

3x220 µF, 10V AVX TPS

Series or Sprague 593D Series

R1=75kΩ,1%,

R2=24.9kΩ,1%,

=

R

37.4 kΩ,

C

=

4.7 nF,

C

C

=

3.57 kΩ,

R

3

=

5.6 nF

C

10

=

R

33 kΩ,

SIA

=

200 kΩ

R

SOA

TABLE 2. Toroidal Inductors Using Cores from MICROMETALS, INC.

Lead Acid

2 x 22 µF, 35V AVX TPS

Series or Sprague 593D Series

) 33µH (See

3x220 µF, 10V AVX TPS

Series or Sprague 593D Series

R1=41.2kΩ,1%,

R2=24.9kΩ,1%,

=

R

C

=

C

C

=

R

3

C

10

R

SIA

R

SOA

23.2 kΩ,

8.2 nF,

2.0 kΩ,

=

=

=

Table 2

10 nF

39 kΩ,

130 kΩ

)

Core

Number

15µH T38 −52 AWG

20µH T38 −52 AWG

33µH T50 −52 AWG

40µH T50 (B) −18 AWG

MICROMETALS

5615 E. La Palma Ave. Anaheim, CA 92807 USA (800) 356-5977

Core

Material

Wire

Gauge

#

23 1 21

#

23 1 25

#

21 1 41

#

21 1 41

Number of

Strands

TABLE 3. Components for Typical 200 kHz Applications

Input Voltage 7V to 18V IN

Applicable Cell Stacks 8 to 12 Cell NiCd or NiMh, 3 to 4 Cell Li Ion, 8 to 11 Cell Alkaline, 6 Cell

Lead Acid

Output 5V, 3A Out 3.3V, 3A out

Input Capacitor C

IN

Inductor L1 20µH (See

Output Capacitor C

OUT

Feedback Resistors R1

and R2

Compensation

Components R

and C

Sleep Resistors R

and R

10

SOA

C,CC,R3

SIA

,

Frequency Adjusting

Resistor R

FA

2 x 22 µF, 35V AVX TPS

Series or Sprague 593D Series

Table 2

) 15µH (See

3x220 µF, 10V AVX TPS

Series or Sprague 593D Series

R1=75kΩ,1%,

R2=24.9kΩ,1%,

=

R

53.6 kΩ,

C

=

2.7 nF,

C

C

=

4.02 kΩ,

R

3

=

4.7 nF

C

10

=

R

33 kΩ,

SIA

=

200 kΩ

R

SOA

=

R

24.9 kΩ R

FA

2 x 22 µF, 35V AVX TPS

Series or Sprague 593D Series

3x220 µF, 10V AVX TPS

Series or Sprague 593D Series

R1=41.2kΩ,1%,

R2=24.9kΩ,1%,

=

R

33.2 kΩ,

C

=

C

C

=

3.01 kΩ,

R

3

=

C

10

=

R

SIA

=

R

SOA

=

FA

Table 2

3.9 nF,

6.8 nF

47 kΩ,

91 kΩ

24.9 kΩ

Number of

Turns

)

www.national.com9

Page 10

Application Circuits (Continued)

FIGURE 5. An Efficient, 2%Accurate 5V to 3.3V Converter

DS012848-20

www.national.com 10

Page 11

Physical Dimensions inches (millimeters) unless otherwise noted

24-Lead Small-Outline Package (M)

Order Number LM2650M-ADJ

NS Package Number M24B

LM2650 Synchronous Step-Down DC/DC Converter

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80-532 78 32

Français Tel: +49 (0) 1 80-532 93 58

Italiano Tel: +49 (0) 1 80-534 16 80

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

Loading...

Loading...