Page 1

LM2645

Advanced Two-Phase Switching Controller With Two

Linear Outputs

General Description

The LM2645 is a feature-rich IC that combines two current

mode synchronous buck regulator controllers, an adjustable

linear regulator controller and a fixed 3.3V standby output

rail.

The two switching regulator controllers operate 180˚ out of

phase. This feature reduces the input ripple RMS current,

thereby significantly reducing the required input capacitance.

The two switching regulator outputs canalso be paralleled to

operate as a dual-phase regulator.

The use of synchronous rectification and pulse-skip operation at light load achieves high efficiency over a wide load

range. Fixed-frequency operation can be obtained by disabling the pulse-skip mode. The switching frequency of the

LM2645 is user selectable between 200 kHz or 300 kHz.

The first switching controller (Channel 1) features a fixed 5V

output, and the second switching controller controller (Channel 2) features a fixed 3.3V output. Both channels can also

be independently adjusted from 1.3 to 5.5V. The adjustable

linear regulator can be adjusted from 3.3V to 15V.An internal

5V rail is also available externally for driving bootstrap circuitry. This rail also serves as the input for an internal LDO

that provides the fixed 3.3V/50mA output rail.

Current-mode feedback control assures excellent line and

load regulation and a wide loop bandwidth for excellent

response to fast load transients. Current is sensed across

either the Vds of the top FET or across an external sense

resistor connected in series with the drain of the top FET.

Current limit is independently adjustable for each channel.

The analog soft-start for the switching controllers uses an

innovative new approach. It is independent of the input

voltage which makes the soft-start behavior more predictable and controllable.

Independant PGOOD signals monitor each of the switching

regulator outputs. The switching outputs have under-voltage

and over-voltage latch protection, while the output of the

external linear regulator has undervoltage latch protection.

The undervoltage latch can be disabled or adjustably delayed.

Features

GENERAL

n 4.5V to 30V input range

n Power good function

n Input under-voltage lockout

n 10 µA Shutdown/Recycle for entire chip

n Thermal shutdown

n TSSOP package

SWITCHING SECTION

n Two synchronous buck regulators for fixed 5V/3.3V or

adjustable outputs

n Outputs adjustable from 1.3V to 5.5V

n 0.04% (typical) line and load regulation error

n Selectable switching frequency 200/300 kHz

n Two channels operating 180˚ out of phase

n Separate on/off for each channel

n Separate Power Good signals

n Current mode control with or without sense resistor

n Adjustable cycle-by-cycle current limit

n Skip-mode operation available

n Negative current limit

n Separate soft start for each channel

n Output UVP and OVP

n Programmable output UVP delay

n Self discharge of output capacitors when turned off

LINEAR SECTION

n Adjustable (3.3V to 15V) linear regulator with external

PNP pass transistor

n

±

2% initial tolerance of set voltage

n Output UVP for adjustable linear regulator

n Fixed 3.3V/50mA output rail

n Fixed 5V reference rail

Applications

n Notebook and sub-notebook computers

n Embedded computer systems

n Battery-powered instruments

n High end gaming systems

n Set-top boxes

n WebPAD

April 2001

LM2645 Advanced Two-Phase Switching Controller With Two Linear Outputs

© 2001 National Semiconductor Corporation DS200159 www.national.com

Page 2

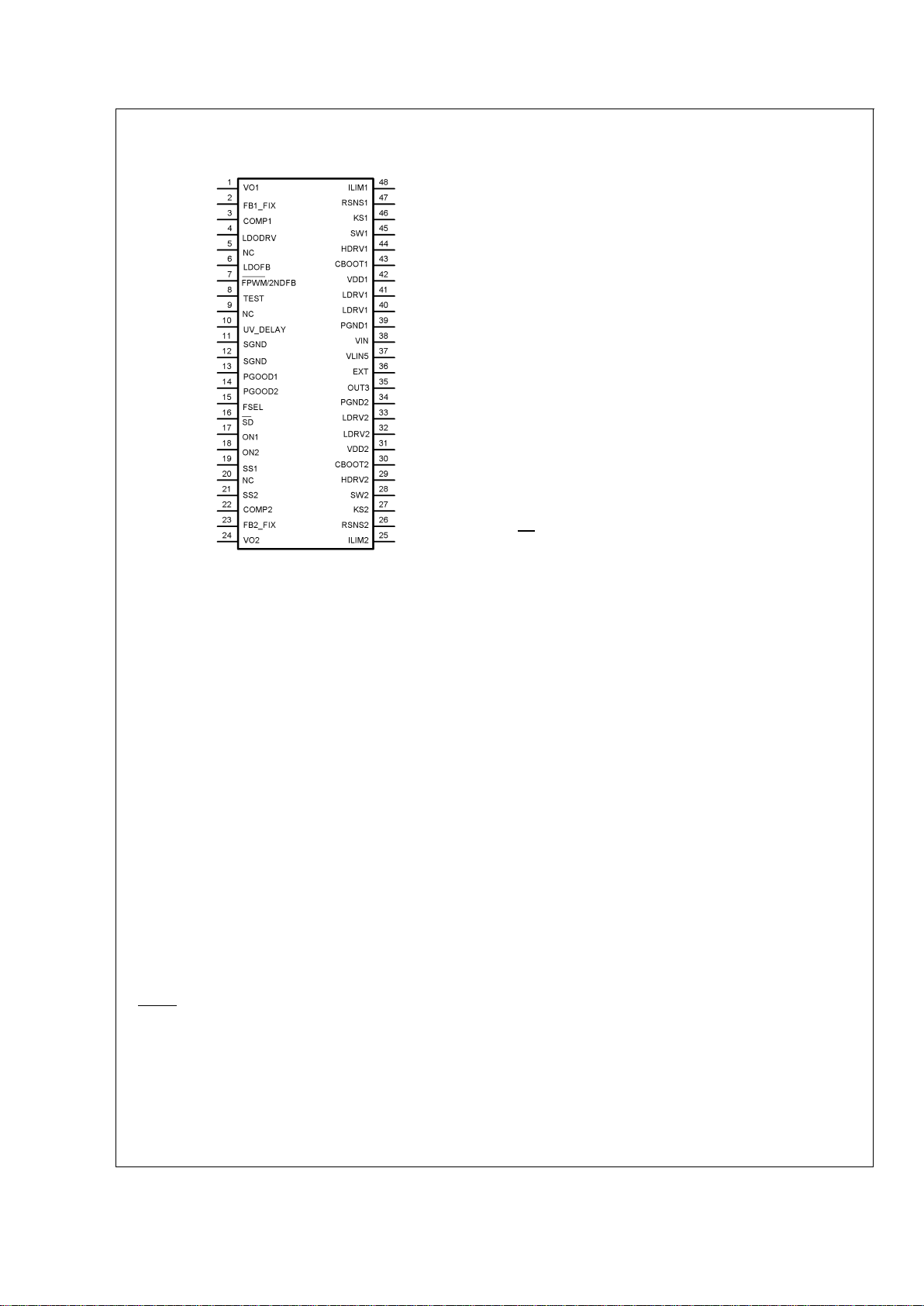

Connection Diagram

TOP VIEW

20015901

48-Lead TSSOP (MTD)

Order Number LM2645MTD

See NS Package Number MTD48

Pin Descriptions

VO1 (Pin 1):The feedback input for Channel 1. Always con-

nect directly to the output. Fixed or adjustable output voltage

is selected by FB1_FIX.

FB1_FIX (Pin 2): The feedback input for setting the output

voltage of Channel 1. Connecting this pin to VLIN5 sets the

output voltage to 5V, or to the center of a voltage divider for

an adjustable output.

COMP1 (Pin 3): Compensation pin for Channel 1. This is the

output of the internal transconductance amplifier. The compensation network should be connected between this pin

and the signal ground, SGND.

LDODRV (Pin 4): The output of the adjustable linear regulator controller. Connects to the base of a PNP Pass transistor. This pin is activated when Channel 1 is enabled.

NC (Pins 5, 9, 20): No internal connection. Connect these

pins to ground.

LDOFB (Pin 6): Dual function input pin. When connected to

the center of a resistor divider, it serves as the 1.238V

feedback input for the LDODRV. Connecting this pin to

VLIN5 disables the LDODRV.

FPWM/2NDFB (Pin 7): Multi-function input pin. When held

HIGH (>2V), pulse-skipping mode is enabled for both

switching regulators. When held LOW (

<

0.8V), both regulators will function in Fixed Frequency PWM mode. This pin

can also be connected to the center of a resistor divider for

feedback regulation of a secondary winding voltage. In this

case, Ch 1 will operate in pulse-skipping mode when the

output is lightly loaded. If the linear regulator controller output is heavy loaded, the operating frequency in

pulse-skipping will be increased accordingly to maintain the

voltage at this pin to 1.5V or higher. Thus, the secondary

winding voltage will always have the necessary overhead

voltage for the linear regulator to maintain regulation.

TEST (Pin 8): Special purpose input pin for factory use only.

This pin must be connected to ground.

UV_DELAY (Pin 10): : A capacitor from this pin to ground

adjusts the delay of the undervoltage protection for the two

switching outputs and the linear regulated output controlled

by the LDODRV. The delay time is set by charging a capacitor to 2.3V from a 5µA current source. Pulling this pin to

ground disables undervoltage protection on these outputs.

SGND (Pin 11,12): Ground connection for the signal level

circuitry. It should be connected to the ground rail of the

system.

PGOOD1 (Pin 13): An open-drain power-good output for

Channel 1. It is ’LOW’ (low impedance to ground) whenever

the output voltage travels out of the

±

10% window. It stays

latched in a ’LOW’ state if the output travels beyond the

positive limit that trips the over-volatge protection.

PGOOD2 (Pin 14): An open drain power good output for

Channel 2. It serves the same function as the PGOOD1.

FSEL (Pin 15): Selects the Switching Frequency of the two

switching controllers. The frequency is 300kHz when this pin

is pulled HIGH (

>

2V), or 200kHz when this pin is pulled

LOW (

<

0.8V).

SD (Pin 16): Shutdown control input. Pulling this pin LOW

(<0.6V) turns OFF the entire chip which then draws less

than 10 µA of supplycurrent. The chip isON if thispin is held

HIGH (

>

2V). Toggling this pin from HIGH to LOW and then

HIGH again resets the chip causing it to recover from any

protection latch.

ON1 (Pin 17): Output enable for Channel 1 and LDODRV

(Pin 4). Channel 1 and LDODRV are disabled when this pin

is pulled LOW (

<

0.8V), and are enabled when this pin is

pulled HIGH (

>

2V).

ON2 (Pin 18): Output enable for Channel 2. Channel 2 is

enabled when this pin is pulled high (

>

2V) and disabled

when this is pulled low (

<

0.8V).

SS1 (Pin 19): Soft-start input pin for Channel 1. The rise

time of the output voltage of Channel 1 is programmed by

the charge rate of a capacitor connected from this pin to

ground by an internal 2 µA current source. If the output does

not reach regulation (to within −6% of nominal voltage) by

the time this pin exceeds 2V (typical), the UV_DELAY pin

begins charging the capacitor connected from it to ground. If

the output is not within regulation after the UVP delay, the

chip latches off.

SS2 (Pin 21): Soft-start input pin for Channel 2. Serves the

same function as the SS1, Pin 19.

COMP2 (Pin 22): Compensation pin for Channel 2. This is

the output of the internal transconductance amplifier. The

compensation network should be connected between this

pin and the signal ground SGND (Pins 11, 12).

FB2_FIX (Pin 23): The feedback input for setting the output

voltage of Channel 2. Connecting this pin to VLIN5 sets the

output voltage to 3.3V,or to the center of a voltage divider for

an adjustable output.

VO2 (Pin 24): The feedback input for Channel 2. Always

connect directly to the output. Fixed or adjustable output

voltage is selected by FB2_FIX.

ILIM2 (Pin 25): Current limit threshold setting for Channel 2.

It sinks a constant current of 10 µA that is converted to a

voltage through a resistor connected from this pin to Vin. The

voltage across this resistor is compared with either the Vds

LM2645

www.national.com 2

Page 3

Pin Descriptions (Continued)

of the top MOSFET or the voltage across an external current

sense resistor to determine if an over-current condition has

occurred in Channel 2.

RSNS2 (Pin 26): The negative (−) Kelvin sense for the

internal current limit comparator of Channel 2. Always use a

separate trace to connect this pin to the current sense point.

Connect this pin to the low side of the current sense resistor

that is placed between V

IN

and the drain of thetop MOSFET.

When the Vds of the top MOSFET is used for current sensing, then connect this pin to the source of the top MOSFET.

KS2 (Pin 27): The positive (+) Kelvin sense for the internal

current limit comparator of Channel 2. Use a separate trace

to connect this pin to the current sense point. Connect to Vin

as close to the node of the current sense resistor; when no

current-sense resistor is used, connect it as close to the

Drain node of the upper MOSFET.

SW2 (Pin 28): : Switch-node connection for Channel 2,

which is connected to the source of the top MOSFET. It

serves as the negative supply rail for the topside gate driver,

HDRV2.

HDRV2 (Pin 29):Top-sidegate-drive output for Channel 2.A

floating drive output that rides on the switching-node voltage.

CBOOT2 (Pin 30): Bootstrap capacitor connection. It serves

as the positive supply rail for the Channel 2 top-side gate

drive.

VDD2 (Pin 31): The supply rail for the Channel 2 low-side

gate drive, usually ties together with VDD1. Connect to

VLIN5 through a 4.7Ω resistor and bypassed to ground with

a ceramic capacitor of at least 1µF.

LDRV2 (Pins 32, 33): Low-side gate-drive output for Channel 2. Tie these two pins together.

PGND2 (Pin 34): Power ground for Channel 2.

OUT3 (Pin 35): The fixed 3.3V linear regulated output. De-

rived from VLIN5 by an internal LDO, it is current limited at

100mA. The continuous output current is a function of the

ambient operating temperature and the total power dissipation in the chip and must be derated accordingly. See (Note

2) in Electrical Characteristics section.

EXT (Pin 36): External power input to an internal switch.

This pin is usually connected to the fixed 5V output of

Channel 1. When the voltage on this pin is higher than 4.7V,

the internal 5V LDO that provides VLIN5 from VIN is disabled, and an internal switch connects VLIN5 to this pin to

minimize dissipation in the chip. Connect this pin to ground

and VLIN5 to VIN if VIN is operating in 4.5V to 5.5V range.

VLIN5 (Pin 37): This pin is the output of an internal 5V LDO

regulator derived from VIN when no external 5V supply is

available. It supplies the internal bias for the chip, supplies

the boostrap circuitry for gate drive and serves as the input

supply of an internal LDO to generate OUT3.Bypass this pin

to power ground with a minimum of 4.7µF ceramic capacitor.

Connect this pin to the VIN pin when Vin is operating in 4.5V

to 5.5V range.

VIN (Pin 38):The input power of the chip. Connects to the

upper (+) input rail of the system.

PGND1 (Pin 39):Power ground for Channel 1.

LDRV1 (Pins 40, 41): Low-side gate-drive output for Chan-

nel 1. Tie these two pins together.

VDD1 (Pin 42): The supply rail for the low-side gate drive of

Channel 1. Same function as VDD2 (Pin 31).

CBOOT1 (Pin 43): Bootstrap capacitor connection. It serves

as the positive supply rail for the Channel 1 top-side gate

drive.

HDRV1 (Pin 44): Top-side gate-drive output for Channel 1.

See HDRV2 (Pin 29).

SW1 (Pin 45): Switch-node connection for Channel 1, See

SW2 (Pin 28).

KS1 (Pin 46): The upper (+) Kelvin sense for the internal

current limit comparator of Channel 1 (see KS2, Pin 27).

RSNS1 (Pin 47): The lower (−) Kelvin sense for the internal

current limit comparator of Channel 1 (see RSNS2, Pin 26).

ILIM1 (Pin 48): Current limit threshold setting for Channel 1

(see ILIM2, Pin 25).

LM2645

www.national.com3

Page 4

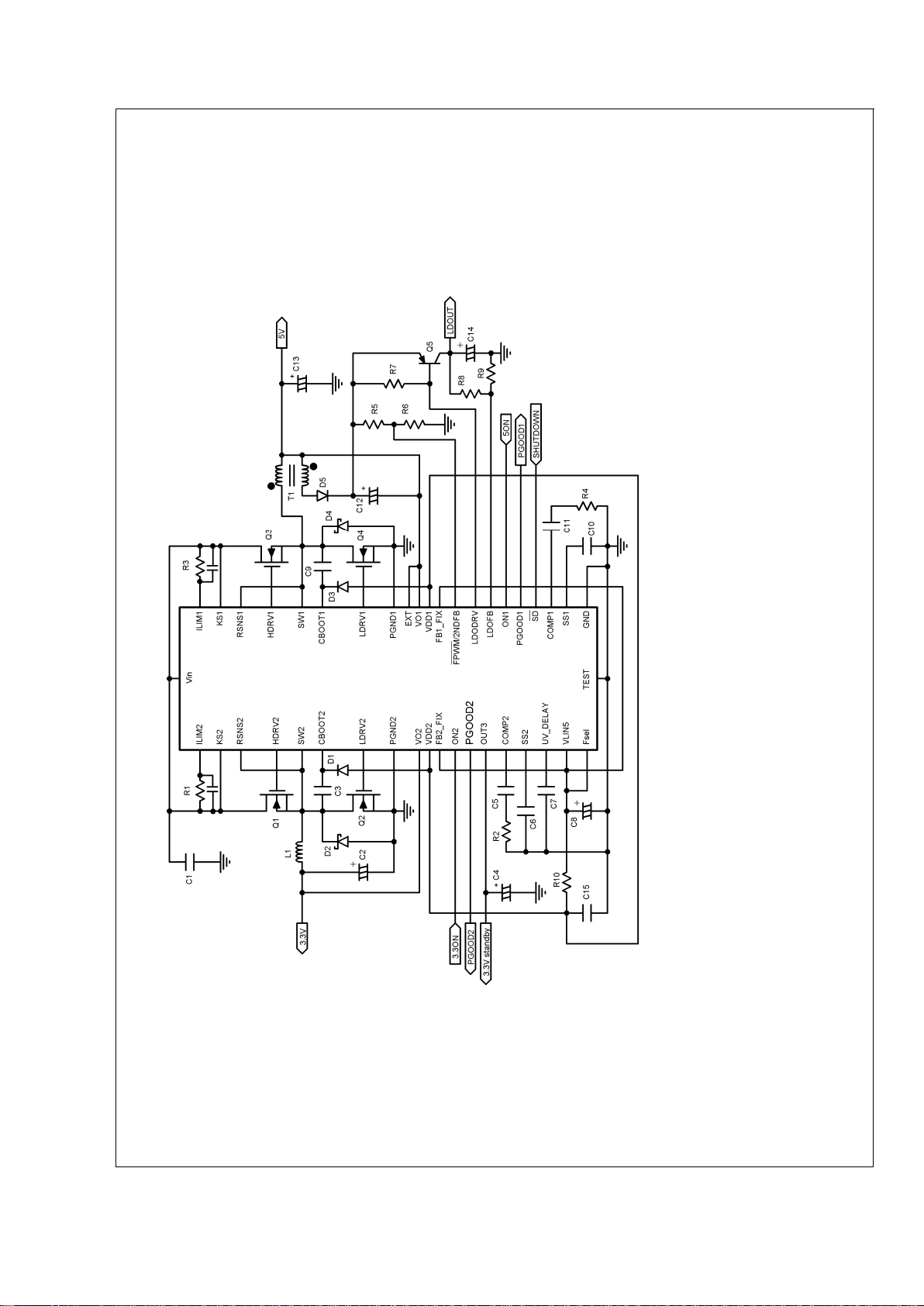

Typical Application Circuit

20015902

LM2645

www.national.com 4

Page 5

Simplified Block Diagram

20015905

LM2645

www.national.com5

Page 6

Simplified Block Diagram (Continued)

20015903

LM2645

www.national.com 6

Page 7

TABLE 1. Shut Down Latch Truth Table

Input Output

ovp1 ovp2 uvp1 uvp2 uvp4 oc3 ch1 on ch2 on fault ssto1 ssto2 uv_delay latch off

1101

1101

1 1 0 1 cap 1

1 1 0 1 cap 1

1 1 0 1 cap 1

000001 000cap 0

All other combinations 0

Notes:

1. ’fault’ is the logic OR of UVLO and thermal shutdown.

2. ’cap’ means the pin has a capacitor of appropriate value between it and ground.

3. Positive logic is used.

4. ssto1, ssto2 means soft start timeout for Ch 1 and Ch 2 respectively.

5. A blank value means ’don’t care’.

6. ″oc3″ means OUT3 output current over 100mA current.

7. ″uvp4″ means UVP of the linear regulated output controlled by LDODRV.

8. SD pin is pulled high.

TABLE 2. Power Good Truth Table

Input Output

ovp1 ovp2 uvpg1 uvpg2 uvpg4 ch1 on ch2 on fault latch

off

SD

PGOOD1 PGOOD2

1 1 1100

1 1 1100

11 10

11 10

00110011

010

010

00 10011

0 0 100 1 1

1 100

1100

000

Notes:

1. Positive logic is used.

2. A blank value means ’don’t care’.

3. The symbol uvpg1, 2, 4 means the power good undervoltage threshold of the corresponding channel.

LM2645

www.national.com7

Page 8

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Voltages from the indicated pins to SGND/PGND:

VIN, ILIM1, ILIM2, KS1, KS2,

LDODRV −0.3V to 31V

SW1, SW2, RSNS1, RSNS2 −0.3 to (V

IN

+

0.3)V

VO1, VO2, FB1_FIX, FB2_FIX,

VDD1, VDD2, EXT −0.3V to 6V

SD, ON1, SS1, ON2, SS2, LDOFB,

F

SEL

, UV_DELAY, PGOOD1, OUT3,

PGOOD2, COMP1, COMP2,

FPWM/2NDFB

−0.3V to (VLIN5

+0.3)V

CBOOT

1

to SW1, CBOOT2 to SW2 −0.3V to 7V

LDRV1, LDRV2 −0.3V to

(VDD+0.3)V

HDRV1 to SW1, HDRV2 to SW2 −0.3V

HDRV1 to CBOOT1, HDRV2 to

CBOOT2 +0.3V

Power Dissipation (T

A

= 25˚C,

(Note 2) 1.56W

Junction Temperature (T

J

)

(Note 2) +150˚C

Ambient Storage Temperature

Range −65˚C to +150˚C

Soldering Dwell Time, Temperature

(Note 3)

Wave

Infrared

Vapor Phase

4 sec, 260˚C

10sec, 240˚C

75sec, 219˚C

ESD Rating (Note 4) 2kV

Operating Ratings(Note 1)

VIN (VIN and VLIN5 separate) 5.5V to 30V

VIN (VLIN5 tied to VIN) 4.5V to 5.5V

Junction Temperature 0˚C to +125˚C

EXT 5.5V max.

Electrical Characteristics

Unless otherwise specified, VIN= 15V, SGND = PGND = 0V, VLIN5 = VDD1 = VDD2. Limits appearing in boldface type apply over the entire operating junction temperature range, 0˚C to +125˚C. Specifications appearing in plain type are measured

using low duty cycle pulse testing with T

A

= 25˚C (Note 5), (Note 6). Min/Max limits are guaranteed by design, test, or statisti-

cal analysis.

Symbol Parameter Conditions Min Typ Max Units

SYSTEM

∆V

OUT/VOUT

Load Regulation VIN=15V, V

compx

= 0.5V to 1.5V 0.04 %

∆V

OUT/VOUT

Line Regulation 5.5V ≤ VIN≤ 30V, V

compx

=1.25V 0.04 %

V

FBX_FIX

Feedback Voltage in

Adjustable Mode

5.5V ≤ VIN ≤ 30V

1.217 1.238 1.259 V

V

OUT

V

OUTx

accuracy at fixed

output mode

5.5V ≤ VIN≤ 30V, V

OUT1

= 5V, V

OUT2

= 3.3V

−2.4 +2.4 %

I

VIN

Input Supply Current ON1 = ON2 = 5V and

5.5V ≤ V

IN

≤ 30V

1.5 2.8 mA

ON1 = ON2 = 5V and

4.5V ≤ V

IN

= VLIN5 ≤ 5.5V

1.3 2.8 mA

Standby (Note 7)

ON1 = ON2 = 0V, V

SD

=5V

50 120 µA

Shutdown V

SD

=0V 5 30 µA

VLIN5 VLIN5 Output

Voltage(Note 8)

IVLIN5 = 0 to 25mA, EXT = 0V,

5.5V ≤ VIN ≤ 30V, SD = 5V

4.65 5 5.35 V

V

CLos

Current Limit

Comparator Offset

(VILIMX −VRSNSX)

VKS1−VILIM1 = VKS2-VILIM2

=140mV

±

2mV

I

CL

Current Limit Sink

Current

8 10 12 µA

I

ss_SC

Soft-Start Source

Current

V

ss1=Vss2

=1V

0.5 2 3.5 µA

I

ss_SK

Soft-Start Sink Current V

ss1=Vss2

=1V 24 µA

V

ssto

Soft-Start Timeout

Threshold

(Note 9)

2V

LM2645

www.national.com 8

Page 9

Electrical Characteristics (Continued)

Unless otherwise specified, VIN= 15V, SGND = PGND = 0V, VLIN5 = VDD1 = VDD2. Limits appearing in boldface type apply over the entire operating junction temperature range, 0˚C to +125˚C. Specifications appearing in plain type are measured

using low duty cycle pulse testing with T

A

= 25˚C (Note 5), (Note 6). Min/Max limits are guaranteed by design, test, or statisti-

cal analysis.

Symbol Parameter Conditions Min Typ Max Units

SYSTEM

V

UVP

FB1_FIX, FB2_FIX,

LDOFB Undervoltage

Protection Latch

Threshold

As a Percentage of nominal output

voltage (Falling edge)

73 80 90 %

Hysteresis 4%

V

UV_DELAY

UV_DELAY Threshold

Voltage

(Note 10)

2.3 V

I

UV_DELAY

UV_DELAY source

current

V

UV_DELAY

=2V

5µA

V

OVP

V

OUTx

Overvoltage

Protection Latch

Threshold

As a percentage measured at

FB1_FIX, FB2_FIX 106 110 119 %

TH

LREG

V

OUTx

Low Regulation

Comparator Enable

Threshold for channels 1

and 2

Falling Edge

95 %

HYS

LREG

Hysteresis of Low

Regulation Comparator

As a Percentage of output voltage

3%

V

pwrbad

Regulator Window

Detector Thresholds

(PGOOD from High to

Low) (Note 11)

As a Percentage of output voltage

86 91 94 %

V

pwrgd

Regulator Window

Detector Thresholds

(PGOOD from Low to

High)

As a Percentage of output voltage

92.5 94 96.5 %

TH

VOX_DIS

VO1, VO2 Quick

Discharge Threshold

(Note 12)

0.8 V

V

ox_R

VO1,VO2

ON-Resistance

VO1=VO2=2V

200 Ω

Gate Drive

I

CBOOT

CBOOT Leakage

Current

V

CBOOT1

=V

CBOOT2

=7V

100 nA

I

SC_DRV

HDRVx and LDRVx

Source Current

V

CBOOT1

=V

CBOOT2

= 5V, VSWx=0V,

HDRVx=LDRVx=2.5V

0.8 A

I

sk_HDRV

HDRVx Sink Current V

CBOOTx

= VDDx = 5V, V

SWx

= 0V,

HDRVX = 2.5V

1.3 A

I

sk_LDRV

LDRVx Sink Current V

CBOOTx

= VDDx = 5V, V

SWx

= 0V,

LDRVX = 2.5V

2.5 A

R

HDRV

HDRV1 & 2 Source

On-Resistance

V

CBOOT1

=V

CBOOT2

= 5V,

V

SW1=VSW2

=0V

2.2 Ω

HDRV1 & 2 Sink

On-Resistance

1.1 Ω

R

LDRV

LDRV1 & 2 Source

On-Resistance

V

CBOOT1

=V

CBOOT2

= 5V,

V

SW1=VSW2

=0V

2.2 Ω

LDRV1 & 2 Sink

On-Resistance

0.65

Ω

LM2645

www.national.com9

Page 10

Electrical Characteristics (Continued)

Unless otherwise specified, VIN= 15V, SGND = PGND = 0V, VLIN5 = VDD1 = VDD2. Limits appearing in boldface type apply over the entire operating junction temperature range, 0˚C to +125˚C. Specifications appearing in plain type are measured

using low duty cycle pulse testing with T

A

= 25˚C (Note 5), (Note 6). Min/Max limits are guaranteed by design, test, or statisti-

cal analysis.

Symbol Parameter Conditions Min Typ Max Units

SYSTEM

Oscillator

F

osc

Oscillator Frequency F

SEL

=5V 265 300 335 kHz

F

SEL

=0V 174 200 226 kHz

Don_max Maximum On-Duty Cycle V

FB1=VFB2

= 1V, Measured at pins

HDRV1 and HDRV2

96 98 %

T

on_min

Minimum On-Time 150 ns

Error Amplifier

I

FB1,IFB2

Feedback Input Bias

Current

V

FB1_FIX

= 1.5V, V

FB2_FIX

= 1.5V

90 250 nA

I

comp1_SC

,

I

comp2_SC

COMP Output Source

Current

V

FB1_FIX

=V

FB2_FIX

= 1V,

V

COMP1

=V

COMP2

=1V

27 104 µA

I

comp1_SK

,

I

comp2_SK

COMP Output Sink

Current

V

FB1_FIX

=V

FB2_FIX

= 1.5V and

V

COMP1

=V

COMP2

= 0.5V

27 99 µA

Voltage References and Linear Voltage Regulators

UVLO VLIN5 Under-voltage

Lockout Threshold

(Rising)

SS1, SS2 transition from low to high

3.6 4.0 4.4 V

R_EXT EXT pin ON-Resistance V

EXT

= 5V, IVLIN5=25mA 3 Ω

EXT_TH VLIN5-to-EXT Switch

Over Threshold

Rising edge of V

EXT

4.7 V

V

OUT3

3.3V Linear Regulator

Output Voltage

0mA<IOUT3<50mA, 5.5V ≤ VIN ≤

30V, V

EXT

=5V

3.306 3.3 3.564 V

I

OUT3

3.3V Linear regulator

Current limit threshold

ON1 = HIGH, EXT = 5V

100 mA

I

LDODRV

LDODRV pin Sink

Current

V

LDODRV

= 11V, V

LDOFB

= 1.1V

4.0 6mA

V

LDOFB

LDODRV Feedback

Voltage

3.5V ≤ V

LDODRV

≤ 12V

1.215 1.240 1.265 V

Accuracy with Load 3.5V ≤ LDO power supply voltage ≤

15V, I

LDODRV

= 500µA

1.236 V

I

LDOFB

LDOFB Leakage Current

(Sourcing)

V

LDOFB

= 1.4V

50 100 nA

V

2NDFB

Secondary winding

voltage feedback detect

threshold

Falling Edge

1.3 1.5 1.7 V

Logic Inputs

V

IH

Minimum High Level

Input Voltage (SD,

FPWM/2NDFB, ON1,

ON2, F

SEL

)

2.0 V

V

IL

Maximum Low Level

Input Voltage for

FPWM/2NDFB, ON1

ON2, F

SEL

)

0.8 V

SD

0.6 V

LM2645

www.national.com 10

Page 11

Electrical Characteristics (Continued)

Unless otherwise specified, VIN= 15V, SGND = PGND = 0V, VLIN5 = VDD1 = VDD2. Limits appearing in boldface type apply over the entire operating junction temperature range, 0˚C to +125˚C. Specifications appearing in plain type are measured

using low duty cycle pulse testing with T

A

= 25˚C (Note 5), (Note 6). Min/Max limits are guaranteed by design, test, or statisti-

cal analysis.

Symbol Parameter Conditions Min Typ Max Units

SYSTEM

I

IL

Maximum Input Leakage

Current (SD,

FPWM/2NDFB, ON1,

ON2, FSEL).

Logic Input Voltage 0 or 5V

±

0.1 µA

Logic Outputs

I

OL

PGOOD Low Sink

Current

V

PGOOD

= 0.4V

1.4 mA

I

OH

PGOOD High Leakage

Current

V

PGOOD

=5V

50 200 nA

Note 1: Absolute maximum ratings indicate limits beyond which damage to the device may occur. Operating Ratings are conditions under which operation of the

device is guaranteed. For guaranteed performance limits and associated test conditions, see the Electrical Characteristic tables.

Note 2: Maximum allowable power dissipation is calculated by using P

DMAX

=(T

JMAX-TA

)/θJA, where T

JMAX

is the maximum junction temperature, TAis the

ambient temperature and θ

JA

is the junction-to-ambient thermal resistance of the specified package. The 1.56W rating results from using 150˚C, 25˚C, and 80˚C/W

for T

JMAX,TA

, and θJArespectively. A θJAof 90˚C/W represents the worst-case condition of no heat sinking of the 48-pin TSSOP. Heat sinking allows the safe

dissipation of more power. The Absolute Maximum power dissipation should be derated by 12.5mW per ˚C above 25˚C ambient. The LM2645 actively limits its

junction temperature to about 150˚C.

Note 3: For detailed information on soldering plastic small-outline packages, refer to the Packaging Databook available from National Semiconductor Corporation.

Note 4: Except for SW1, SW2, CBOOT1 and CBOOT2 pins which are 1.5kV. For testing purposes, ESD was applied using the human-body model, a 100pF

capacitor discharged through a 1.5kΩ resistor.

Note 5: A typical is the center of characterization data measured with low duty cycle pulse tsting at T

A

= 25˚C. Typicals are not guaranteed.

Note 6: All limits are guaranteed.All electrical characteristics having room-temperature limits are tested during production with T

A=TJ

= 25˚C. All hot and cold limits

are guaranteed by correlating the electrical characteristics to process and temperature variations and applying statistical process control.

Note 7: Both switching controllers are OFF. The linear regulators VLIN5 and 3OUT remain ON.

Note 8: The output voltage at the VLIN5 pin may be as high as 6.5V in shutdown mode (SD ≤ 0.6V).

Note 9: When SS1, SS2 pins are charged above this voltage and either of the output voltage at V

OUT1

or V

OUT2

is still below the regulation limit, the under voltage

protection feature is initialized.

Note 10: Above this voltage, the under voltage protection is enabled.

Note 11: Foreach device, there is a 10% (typical) gap of the measured output voltage between the PGOOD signal transitions from high to low and the under voltage

protection is activated. The under voltage protection will not be activated while the PGOOD signal is in the logic HIGH state.

Note 12: During normal shutdown or UVP, LDRV1or LDRV2 pin goes high when VO1, VO2 detects an output voltage below this level.

LM2645

www.national.com11

Page 12

Typical Performance Characteristics

Efficiency vs Load Current

(FPWM/2NDFB = VLIN5)

Efficiency vs Load Current

(FPWM/2NDFB = VLIN5)

20015906 20015907

Efficiency vs Load Current

(FPWM/2NDFB = VLIN5)

Quiescent Current vs Supply Voltage

20015908

20015912

Reference Voltage vs Temperature

(Bandgap + Error Amplifier Offset)

Error Amplifier Gm vs Temperature

(V

IN

= 15V)

20015910

20015911

LM2645

www.national.com 12

Page 13

Typical Performance Characteristics (Continued)

Switching Frequency vs Load Current

(FPWM/2NDFB = VLIN5)

Normalized Switching Frequency vs Temperature

(F

OSC

= 300 kHz)

20015909

20015913

VLIN5 Output vs Temperature

OUT3 vs Temperature

(VIN= 15V, EXT = Vo1 = 5V, ON1 = On, ON2 = Off)

20015914 20015915

Shutdown Waveforms

(V

OUT

= 3.3V, I

OUT

= 0A)

Shutdown Waveforms

(V

OUT

= 5V, I

OUT

= 3A)

20015916

20015917

LM2645

www.national.com13

Page 14

Typical Performance Characteristics (Continued)

Load Transient Response

(V

IN

= 10V, V

OUT

= 3.3V, L = 6.0 µH, C

OUT

=

180µF/15mΩ)

Load Transient Response

(V

IN

= 10V, V

OUT

= 1.8V, L = 3.1 µH, C

OUT

=

270µF/15mΩ)

20015918

20015919

Overcurrent and Undervoltage Protection

(V

OUT1

= 5V, V

OUT2

= 3.3V)

Pulse-Skipping Operation

(VIN= 15V, V

OUT

= 5V, I

OUT

= 35mA)

20015920

20015921

Soft Start

(V

IN

= 10V to 28V, V

OUT

= 5V, I

OUT

=0Ato3A)

Start Up at Sleep Mode

(VIN= 15V, ON1 = ON2 = Off)

20015922

20015923

LM2645

www.national.com 14

Page 15

Operation Descriptions

General

The LM2645 integrates two synchronous switching controllers, one adjustable linear regulator controller and one fixed

3.3V output into a single package. It solves the need within

many portable systems for 5V, 3.3V, 3.3V stand-by and 12V

legacy power supplies.

The two switching controllers, Channel 1 and Channel 2,

operate 180˚ out of phase to reduce input capacitor size and

cost. They can be independently enabled and disabled. The

external linear regulator controller, or Channel 4,can also be

independently enabled and disabled when Channel 1 has

been enabled.

The output voltages of channel 1 and channel 2 can be set

between 1.3V to 5.5V by external voltage divider, or fixed at

5V and 3.3V respectively without the need of external voltage divider. The output voltage of Channel 4 is adjustable

from 3.3V to 15V.

Both switching channels use synchronous rectification and

employ a peak current mode control scheme. Protection

features include over-voltage protection (Ch1 and 2),

under-voltage protection (Ch1, 2 and 4), and positive and

negative peak current limit (Ch1 and 2).UVP function can be

disabled or delayed by an arbitrary amount of time. The

device operates with a wide input voltage range from 5.5V to

30V. The outputs of the two switching channels have independent power good monitoring. Channel 1 and channel 2

can be configured to operate in parallel as a dual phase

switching converter for high power applications

Soft Start

In normal operation the soft-start functions as follows.As the

input voltage rises above the 4.2V UVLO threshold, the

internal circuitry is powered on, aninternal 2µA current starts

to charge the capacitor connected between the SSx pin and

ground, and the corresponding channel is turned on. A MIN_ON_TIME comparator generates the soft start PWM

pulses. As the SSx pin voltage ramps up, the duty cycle

increases, causing the output voltage to ramp up. Duringthis

time, the error amplifier output voltage is clamped at 0.8V,

and the duty cycle generated by the PWM comparator is

ignored. When the corresponding output voltage exceeds

98.5% (typical) of the set target voltage, the regulator transitions from soft-start to operating mode. Beyond this point,

once the PWM pulses generated by the PWM comparator

are wider than those generated by the MIN_ON_TIME comparator, the PWM comparator takes over and starts to regulate the output voltage. At the same time, the high clamp at

the output of the error amplifier is switched to 2V. That is,

peak current mode control now takes place.

The rate at which the duty cycle increases depends on the

capacitance of the soft start capacitor. The higher the capacitance, the slower the output voltage ramps. A unique

feature of the LM2645 is that the rate at which the duty cycle

grows is independent of the input voltage. This is because

the ramp signal used to generate the soft start duty cycle has

a peak value proportional to the input voltage, making the

product of duty cycle and input voltage a constant. This

makes the soft start process more predictable and reliable.

During soft start, under-voltage protection istemporarily suspended, but over-voltage protection and current limit remain

in effect. When the SSx pin voltage exceeds 2V, a soft start

time out signal (sstox) will be issued. This signal sets the

under-voltage protection into ready mode. See the

Under-Voltage Protection section.

If either the SS1 or SS2 pin is short-circuited to ground

before startup, the corresponding channel will operate at

minimum duty cycle when it is enabled, and the

under-voltage protection of that channel will be disabled.

However, if the soft start has been completed and the output

voltage has been established, then short-circuiting the SSx

pin to ground does not affect the normal operation and

under-voltage protection of that channel.

Shut Down Latch State

This state is typically caused by an output under-voltage or

over-voltage event. In this state, both switching channels

have their top FETs turned off and their bottom FETs turned

on (See the Ch1 and 2 output capacitors discharge section).

The LDODRV pin will be shut down, but VLIN5 and OUT3

will remain unaffected.

There are two methods to release the system from the latch

off state. One is to cycle theinput voltage. Another method is

to pull the SD pin below 0.6V and release it HIGH again.

After the latch is released, the two switching channels will go

through the normal soft start process.

Ch 1 and 2 Output Capacitors Discharge

Each switching channel has an embedded 200Ω MOSFET

with the drain connected to the VOx pin. This MOSFET will

discharge the output capacitor of that channel if that channel

is turned off due to one of the following events:

1. Its ONx pin is pulled low to below 0.8V.

2. The IC enters shut down mode or fault state.

3. The IC enters shut down latch state causedby an output

under-voltage event.

When the output capacitor has been discharged to about

0.8V, the bottom gate-drive (LDRVx) will be turned on, driv-

ing on the bottom FET to discharge the output capacitor

through the filter inductor.

If an output over-voltage event occurs, the HDRVx will be

turned off and the LDRVx will be turned on immediately

regardless of the level of output voltage, thus discharging the

output capacitor through the filter inductor.

When that channel is released from theshutdown latchstate

or returned to the on state, it will go through the soft start

process to recover the output voltage.

Fault State

If the input voltage drops to less than 3.9V, or the IC enters

thermal shut down mode, a ″fault″ signal will be generated

internally.This signal will discharge the capacitor connected

between the SSx pin and ground with 24µA of current until

the SSx pin reaches 50mV. This will turn off both switching

channels.

Force PWM Mode

This mode applies to both switching channels simultaneously. The force-PWM mode is activated by pulling the

FPWM/2NDFB pin to logic low. In this mode, the top FET

and the bottom FET gate signals are always complementary

to each other and the NEGATIVE CURRENT LIMIT comparator is activated (see

Negative Current Limit

section). In

force-PWM mode, the regulator always operates in Continuous Conduction Mode (CCM) and its duty cycle (approximately Vout / Vin) is almost independent of load.

LM2645

www.national.com15

Page 16

Operation Descriptions (Continued)

The force-PWM mode is good for applications where fixed

switching frequency is required.

In force-PWM mode, the top FET has to be turned on for a

minimum of typically 220ns each cycle. However, when the

required duty cycle is less than the minimum value, the skip

comparator will be activated and pulses will be skipped to

maintain regulation.

Skip Comparator

Whenever the output voltage of the error amplifier (COMPx

pin) goes below a 0.5V threshold, the PWM cycles will be

″skipped″ until that voltage exceeds the threshold again.

Pulse-Skip Mode

This mode is activated by pulling the FPWM/2NDFB pin to a

TTL-compatible logic high and applies to both switching

channels simultaneously. In this mode, the 0-CROSSING /

NEGATIVECURRENT LIMIT comparator detects the bottom

FET current. Once the bottom FET current flows from drain

to source, the bottom FET will be turned off. This prevents

negative inductor current. In force-PWM operation, the inductor current is allowed to go negative, so the regulator is

always in Continuous Conduction Mode (CCM), no matter

what the load is. In CCM, duty cycle is almost independent of

the load and is roughly Vout divided by Vin. In pulse-skip

mode, the regulator enters Discontinuous Conduction Mode

(DCM) under light load. Once the regulator enters DCM, its

switching frequency droops as the load current decreases.

The regulator operates in DCM PWM mode until its on-time

falls below 85% of the CCM on-time, then the MIN_ON_TIME comparator takes over. It forces 85% of the CCM

on-time thus causing the output voltage to continuously rise

and COMPx pin voltage (error amplifier output voltage) to

continuously droop. When the COMPx pin voltage hits the

0.5V level, the CYCLE_SKIP comparator toggles, causing

the present switching cycle to be ″skipped″, i.e., both FETs

remain off during the whole cycle.As long as the COMPx pin

voltage is below 0.5V, no switching of the FETs will happen.

As a result, the output voltage will droop, and the COMPx pin

voltage will rise. When the COMPx pin goes above the 0.5V

level, the CYCLE_SKIP comparator flips and allows a 85%

CCM on-time pulse to happen. If the load current is so small

that this single pulse is enoughto bring theoutput voltage up

to such a level that the COMPx pin drops below 0.5V again,

the pulse skipping will happen again. Otherwise it may take

a number of consecutive pulses to bring the COMPx pin

voltage down to 0.5V again. As the load current increases, it

takes more and more consecutive pulses to drive the

COMPx voltage to 0.5V. When the load current is so high

that the duty cycle exceeds the 85% CCM on-time, then

pulse-skipping disappears. In pulse-skip mode, the frequency of the switching pulses decrease as the load current

decreases. Since the load is usually very light in pulse-skip

mode, conducted noise will be very low and the variable

operating frequency should cause no EMI problems in the

system.

The LM2645 pulse-skip mode helps the light load efficiency

for two reasons. First, it turns on the bottom FET only when

inductor current is in positive conduction region, this eliminates circulating energy loss. Second, the FETs are switching only when necessary, rather than every cycle, that reduces FETs switching loss and gate drive power loss.

Current Sensing and Current Limiting

The information of inductor current is extracted by the current sense pin KSx and RSNSx. As shown in

Figure 1

and

Figure 2

, current sensing is accomplished by either sensing

the Vds of the top FET, or sensing the voltage across a

current sense resistor connected from Vin to the drain of the

top FET. The advantage of sensing current across the top

FET is reduced parts count and cost. Using a current sense

resistor improves current sense accuracy. To ensure linear

operation of the current amplifier, the current sense voltage

input must not exceed 200mV. Therefore, the Rds of the top

FET or the current sense resistor must besmall enough that,

when the top FET is on, the current sense voltage does not

exceed 200mV.

There is a leading edge blanking circuit that forces the top

FET to be on for at least 150ns. Beyond this minimum on

time, the output of the PWM comparator is used to turn off

the top FET.

With an external resistor connected between the ILIMx pin

and the KSx pin, the 10µA current sink on the ILIMx pin

produces a voltage across the resistor to serve as the reference voltage for current limit. Adding a 10nF capacitor

across this resistor will filter unwanted noise that could improperly trip the current limit comparator. Current limit is

activated if the inductor current is too high causing the

voltage at the RSNSx pin to be lower than that of the ILIMx

pin, toggling the comparator thus turning off the top FET

immediately.The comparator is disabled either when the top

FET is turned off or during the leading edge blanking time.

20015928

FIGURE 1. Current Sensing by Vds of the Top FET

20015929

FIGURE 2. Current Sensing by External Sense Resistor

LM2645

www.national.com 16

Page 17

Operation Descriptions (Continued)

Negative Current Limit

The purpose of negative current limit is to ensure that the

inductor will not saturate during negative current flow causing excessive current to flow through the bottom FET. The

negative current limit is realized through sensing the bottom

FET Vds. An internally generated 100mV (typical) is used to

compare with the bottom FET Vds when it is on. Upon

sensing too high a Vds, the bottom FET will be turned off.

The negative current limit is activated in force PWM mode.

Over-Voltage Protection

This protection feature is implemented in the two switching

channels and not the linear channels.Any over voltage event

at any of the two switching channels’ output will cause the

LM2645 to enter the

shut down latch state

. The HDRVx will

be turned off, and the LDRVx will be turned on immediately

to drive the bottom FET to discharge the output capacitor

through the filter inductor.

Under-Voltage Protection

The UVP feature is implemented in channel 1, channel 2 and

the linear regulator controller (LDODRV). The under-voltage

protection feature is disabled if the UV_DELAY pin is pulled

to ground; this is useful forsystem debug work.If a capacitor

is connected between the UV_DELAY pin and ground, and

the voltage at the SSx pin is above 2V, the UVP is at ready

mode.

If a switching channel is enabled, and its soft-start time out

signal, sstox (see soft start section) is asserted, then an

under-voltage event at the output of that channel will cause

the system to enter the UVP timeout state. For the external

linear regulator controller (LDODRV), if channel 1 is on and

the soft start time out signal (ssto1) has been issued, then an

under voltage event at the linear regulator output will cause

the system to enter UVP timeout state.

When the system reacts on an under-voltage event, a 5µA

current will charge the capacitor connected to the UV_DELAYpin; when the capacitor is charged to a voltage exceeding 2.3V(typical), the system immediately enters shut down

latch state.

Power Good Function

Two power good signals are available for indicating the

general health of the two switching channels individually.

The function is realized through the internal MOSFET of

each channel tied from the PGOODx pins to ground. The

power good signal is asserted by turning off the MOSFET of

that channel. The on resistance of the power good MOSFET

is about 300Ω.

The internal power good MOSFET will not be turned on

unless at least one of the following occurs:

1. there is an output over voltage event;

2. the output voltage is below the power good lower limit;

3. system is in the shut down mode, i.e. the SD pin voltage

is below 0.6V;

4. The switching channel is in standby mode, i.e. the ONx

pin is below 0.8V;

5. system is in the

fault state

.

6. system is in the

shut down latch state

.

Power good upper limit is the same as that of the OVP

threshold.

Except in the latched off condition (cases 1 and 6) , if the

corresponding output voltage(s) recovers to within −6% of

regulation, PGOODx will be asserted again. But there is a

built-in hysteresis. See V

pwrgd

in the Electrical Characteris-

tics table. The above information is also available in

Power

Good Truth Table

.

VLIN5, VDDx and EXT

An internal 5V supply (VLIN5) is generated from the VIN

voltage through an internal linear regulator. This 5V supplyis

mainly for internal circuitry use, but can also be used externally. When used externally, it is recommended that the

VLIN5 voltage only be used for powering the gate drivers,

i.e. supplying the bias for the top drivers’ bootstrap circuit

and the bottom drivers’ VDDx pins.

When the voltage applied to the EXT pin is below 4.7V, an

internal 5V low dropout regulator supplies the power for the

VLIN5. If the EXT voltage is taken above 4.7V, the 5V

regulator is turned off and an internal switch is turned on to

connect the EXT pin to the VLIN5 pin. This allows the VLIN5

power to be derived from a high efficiency source such as

the output from either one of the switching channels, when

the channel is configured to operate in fixed 5V mode.

Irrespective of the signals on the ONx pins, the VLIN5 voltage output will come from the EXT pin whenever the voltage

applied to the EXT pin is higher than 4.7V. The externally

applied voltage is required to be less than the voltage applied to the VIN pin at all times, even when both channels are

shut down. This prevents a voltage back feed situation from

the EXT pin to the VIN pin.

In shut down mode the VLIN5 pin may go as high as 6.5V.

Connecting a 100kΩ dummy load from VLIN5 to ground will

hold the voltage to 6V maximum. Using a 200kΩ resistor to

pull up PGOOD1 and PGOOD2 to VLIN5 is an alternative

solution.

When input voltage is guaranteed to be within 4.5V to 5.5V,

tie the VLIN5 pin directly to the VIN pin and tie the EXT to

ground. In this mode, the VLIN5 current directly comes from

power stage input rail and power loss due to the internal

linear regulation is no longer an issue.

The two VDDx pins can be tied together. Always connect

them to the VLIN5 pin through a 4.7Ω resistor and connect a

ceramic capacitor of at least 1µF to bypass theVDDx pinsto

ground.

Output Capacitors For Linear Regulators

Like any linear regulator, each linear output that is either

generated or controlled by the LM2645 requires an output

capacitor to ensure stability. The output of OUT3 needs a

capacitor of 1µF minimum. The VLIN5 needs a minimum of

4.7µF. Channel 4, the linear regulated output rail that is

controlled by the LDODRV pin, requires an output capacitor

of 10µF minimum to prevent oscillation.

In applications where the OUT3 is not needed, it may be

disabled by connecting this pin to the VLIN5 as illustrated in

Figure 3

to eliminate the need of a output capacitor.

LM2645

www.national.com17

Page 18

Operation Descriptions (Continued)

Likewise, if the LDODRV pin is not used, connect the LDOFB pin to VLIN5 as shown in

Figure 4

to disable this

channel and the under voltage protection associated with it.

Switching Noise Reduction

Power MOSFETs are very fast switching devices. In synchronous rectifier converter, rapid drain current rise rate of

the top FET coupled with parasitic inductance will generate

unwanted Ldi/dt spikes noise at the source node of the FET

(SWx node). The magnitude of the spike noise will increase

as the output current increases. This parasitic spike noise

may turn into electromagnetic interference (EMI) that may

cause trouble to the system performance, therefore, mustbe

suppressed.

As shown in

Figure 5

, adding a resistor in series with the

CBOOTx pin will slowdown the gate drive (HDRVx) rise time

of the top FET to yield a desired drain current transition time.

Usually a 3.3 to 5.1 ohm resistor is sufficient to suppress the

noise. The top FET switching loss will increase with higher

resistance values.

Input Power Supply Cycling

If the input supply is removed during operation and then

re-applied before the power-on-reset signal has been reset,

the part will remain latched off.A solution for this problem is

shown in

Figure 6

, using a voltage divider of 4:5 ratio to pull

the SD pin up to VLIN5. With the voltage divider, the SD pin

always falls below the logic low level and executes the

power-on-reset after VIN drops below 3V. External shudown

control is included as an option.

Dual-Phase Parallel Outputs

In applications with high output current demand, the two

switching channels can be configured to operate as a

two-phase converter to provide a single output voltage with

current sharing between the two switching channels. This

approach greatly reduces the stress and heat on the output

stage components while lowering input ripple current.

Figure

7

shows a typical example for the two-phase operation.

Because precision current sense is the primary design criteria to ensure accurate current sharing between the two

channels, both channels must use external sense resistors

for current sensing. To minimize the error between the error

amplifiers of the two channel, tie the feedback pins FB1_FIX

and FB2_FIX together and connect to onevoltage dividerfor

output voltage sensing. Also, tie the COMP1 and COMP2

together and connect to the compensation network. Since

there is only one output involved, POOGD1 and 2, and VO1

and 2 should be connected in pairs for monitoring the single

output rail. ON1 and ON2 should be tied together to enable

and disable both channels simultaneously.

20015925

FIGURE 3. Connecting OUT3 to VLIN5 when not in use

20015924

FIGURE 4. Connecting LDOFB to VLIN5 to disable the

LDODRV and the UVP associated with it

20015926

FIGURE 5. Adding a resistor in series with the CBOOT

pin to suppress the turn-on switching noise

20015927

FIGURE 6. Voltage divider ratio for SD pin

LM2645

www.national.com 18

Page 19

Operation Descriptions (Continued)

20015904

FIGURE 7. Dual-Phase parallel operation

LM2645

www.national.com19

Page 20

Physical Dimensions inches (millimeters)

unless otherwise noted

48-Lead TSSOP Package

Order Number LM2645MTD

NS Package Number MTD48

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

labeling, can be reasonably expected to result in a

significant injury to the user.

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

National Semiconductor

Europe

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: ap.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

www.national.com

LM2645 Advanced Two-Phase Switching Controller With Two Linear Outputs

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...