Page 1

LM2641

Dual Adjustable Step-Down Switching Power Supply

Controller

General Description

The LM2641 is a dual step-down power supply controller intended for application in notebook personal computers and

other battery-powered equipment.

Fixed-frequency synchronous drive of logic-level N-channel

power MOSFETs is combined with an optional

pulse-skipping mode to achieve ultra efficient powerconversion over a 1000:1 load current range. The pulse-skipping

mode can be disabled in favor of fixed-frequency operation

regardless of the load current level.

High DC gain and current-mode feedback control assure excellent line and load regulation and a wide loop bandwidth

for fast response to dynamic loads.

An internal oscillator fixes the switching frequency at

300 kHz. Optionally, switching can be synchronized to an external clock running as fast as 400 kHz.

An optional soft-start feature limits current surges from the

input power supply at start up and provides a simple means

of start-up sequencing.

Logic-level inputs allow the controllers to be turned ON and

OFF separately.

Key Specifications

n 96%efficient

n 5.5 to 30V input range

n Dual outputs adjustable from 2.2 to 8V

n 0.5%typical load regulation error

n 0.002%/V typical line regulation error

Features

n 300 kHz fixed-frequency switching

n Switching synchronization with an external signal up to

400 kHz

n Optional pulse-skipping mode

n Adjustable secondary feedback

n Input undervoltage lockout

n Output undervoltage shutdown protection

n Output overvoltage shutdown protection

n Programmable soft-start (each controller)

n 5V, 50 mA linear regulator output

n Precision 2.5V reference output

n 28-pin TSSOP

Applications

n Notebook and subnotebook computers

n Wireless data terminals

n Battery-powered instruments

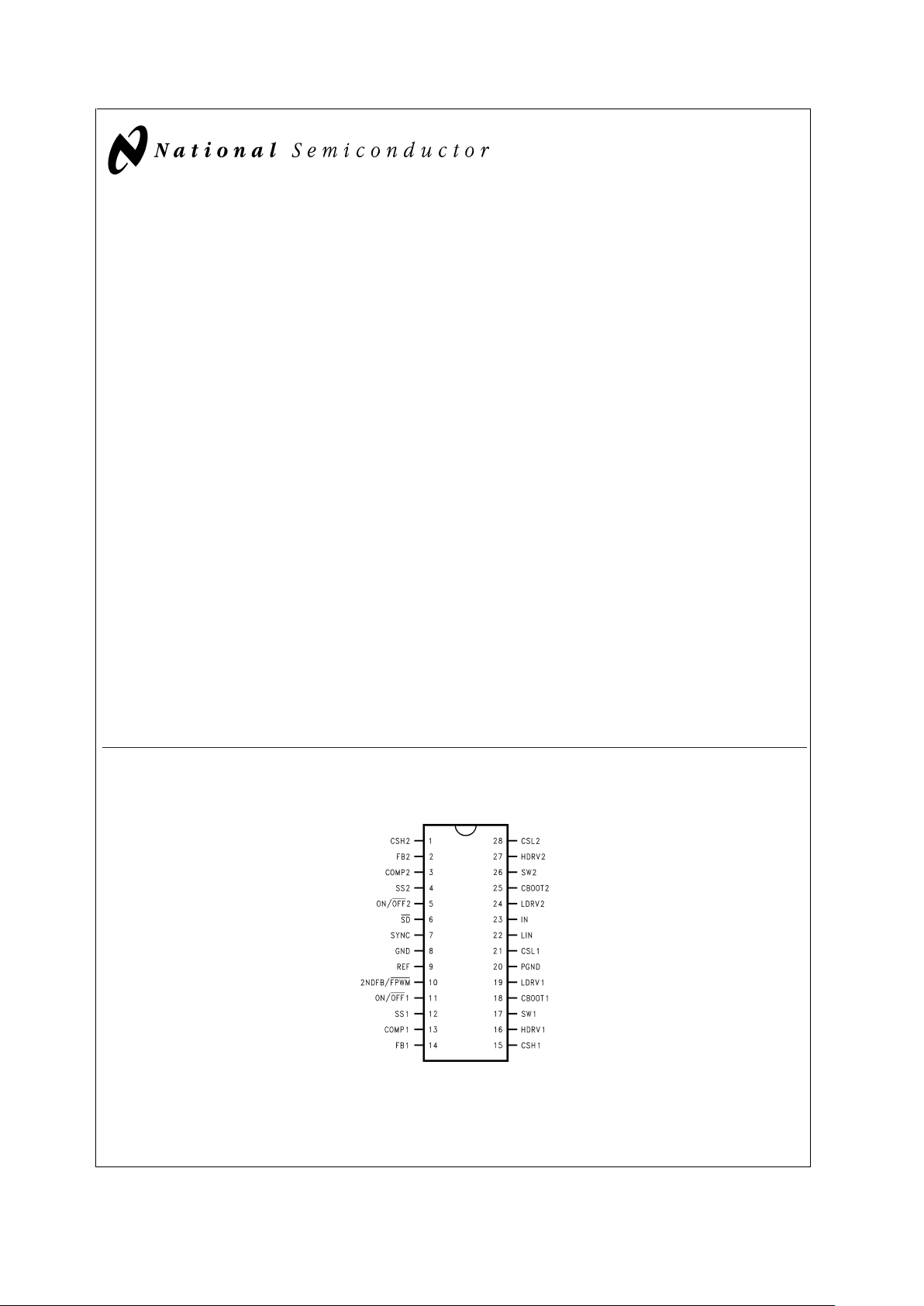

Connection Diagram and Ordering Information

28-Lead TSSOP (MTC)

DS100949-1

Top View

Order Number LM2641MTC-ADJ

See NS Package Number MTC28

January 2000

LM2641 Dual Adjustable Step-Down Switching Power Supply Controller

© 2000 National Semiconductor Corporation DS100949 www.national.com

Page 2

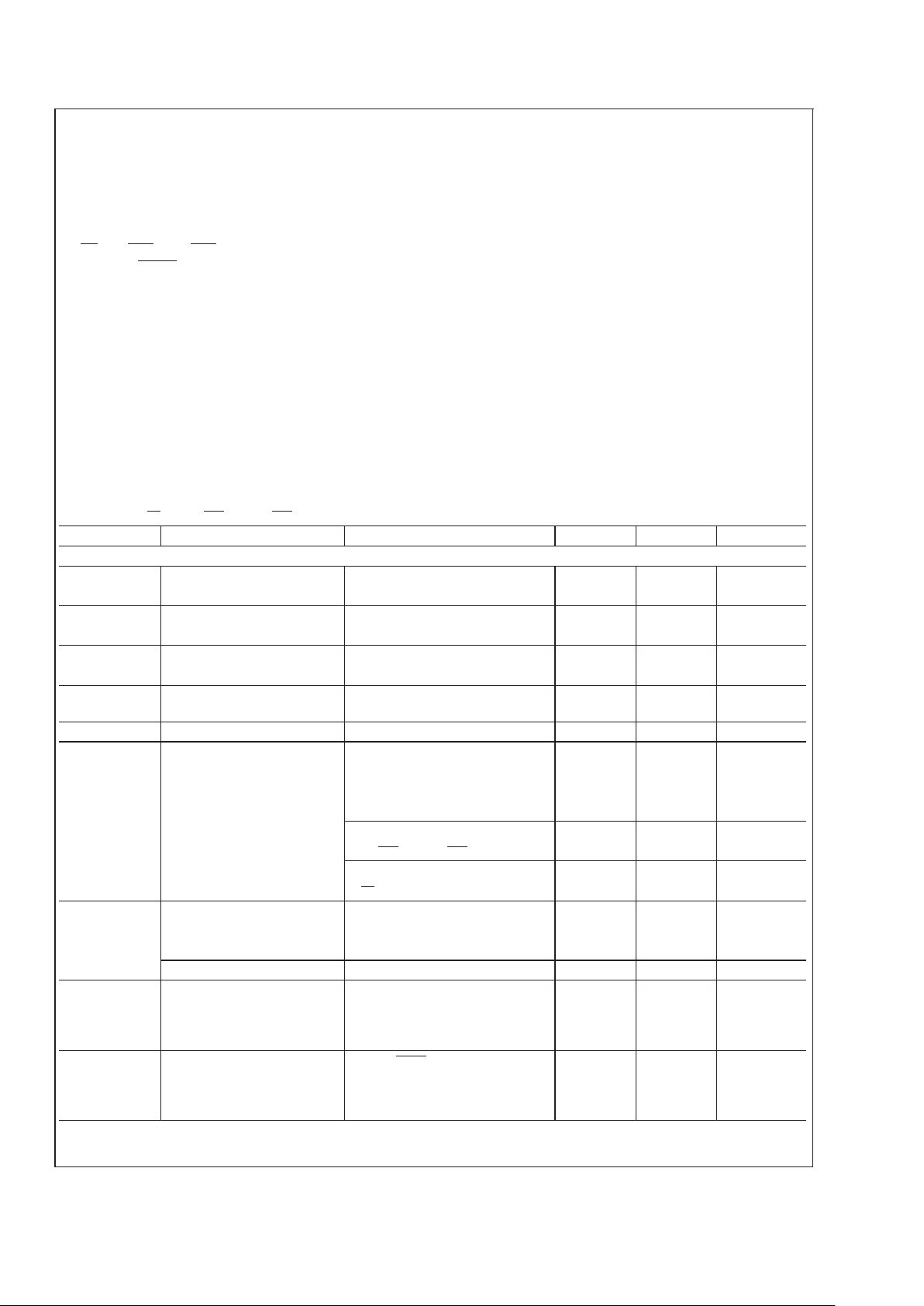

Pin Description (Refer to Typical Application Circuits)

Pin

#

Name Function

1 CSH2 The sense point for the positive side of the voltage across the current sense resistor (R13)

placed in series with output

#

2.

2 FB2 The regulated output voltage appearing at output

#

2 is sensed using this pin by connecting it to

the center of the output resistive divider (R15 and R16).

3 COMP2 An R-C network made up of R11, C10, and C12 is connected to this pin which provides loop

compensation for regulated output

#

2.

4 SS2 This provides programmable soft-start for the

#

2 output along with capacitor C15.

5 ON/OFF2

This pin turns off only output#2.

6SD

The part can be put into “sleep” mode using this pin, where both outputs are off and the internal

chip functions are shut down.

7 SYNC The internal oscillator may be synchronized to an external clock via this pin.

8 GND Connect this pin to circuit Signal Ground.

9 REF Internal 2.5V reference voltage. This voltage is turned off by the SD pin, but remains on if either

or both ON/OFF pins are pulled low, which turns off the regulated output(s).

10 2NDFB/FPWM A 12V supply can be generated using an auxiliary winding on the 5V output inductor. Feedback

to control this 12V output is brought in through this pin. If the 12V supply is not required, this

pin can also force the chip to operate at fixed frequency at light loads by pulling the pin low

(this is the “forced-PWM” mode of operation). This will prevent the converter from operating in

pulse-skipping mode.

11 ON/OFF1

This pin turns off only output#1.

12 SS1 This provides programmable soft-start for the

#

1 output along with capacitor C3.

13 COMP1 An R-C network made up of R6, C5, and C7 is connected to this pin which provides loop

compensation for regulated output

#

1.

14 FB1 The regulated output voltage appearing at output

#

1 is sensed using this pin by connecting it to

the center of the output resistive divider (R1 and R2).

15 CSH1 The sense point for the positive side of the voltage across the current sense resistor (R4)

placed in series with output

#

1.

16 HDRV1 The drive for the gate of the high-side switching FET used for output

#

1.

17 SW1 This is the switching output drive point of the two power FETs which produce output

#

1.

18 CBOOT1 The bootstrap capacitor (C8) for output

#

1 is returned to this point.

19 LDRV1 The drive for the gate of the low-side switching FET (synchronous rectifier) used for output

#

1.

20 PGND Connect this pin to circuit Power Ground.

21 CSL1 The sense point for the negative side of the voltage across the current sense resistor (R4)

placed in series with output

#

1.

22 LIN This pin provides a low-current (50 mA max) 5V output. This output is always on, and can not

be turned off by either the SD or ON/OFF pins.

23 IN This is the connection for the main input power.

24 LDRV2 The drive for the gate of the low-side switching FET (synchronous rectifier) used for output

#

2.

25 CBOOT2 The bootstrap capacitor (C9) for output

#

2 is returned to this point.

26 SW2 This is the switching output drive point of the two power FETs which produce output

#

2.

27 HDRV2 The drive for the gate of the high-side switching FET used for output

#

2.

28 CSL2 The sense point for the negative side of the voltage across the current sense resistor (R13)

placed in series with output

#

2.

LM2641

www.national.com 2

Page 3

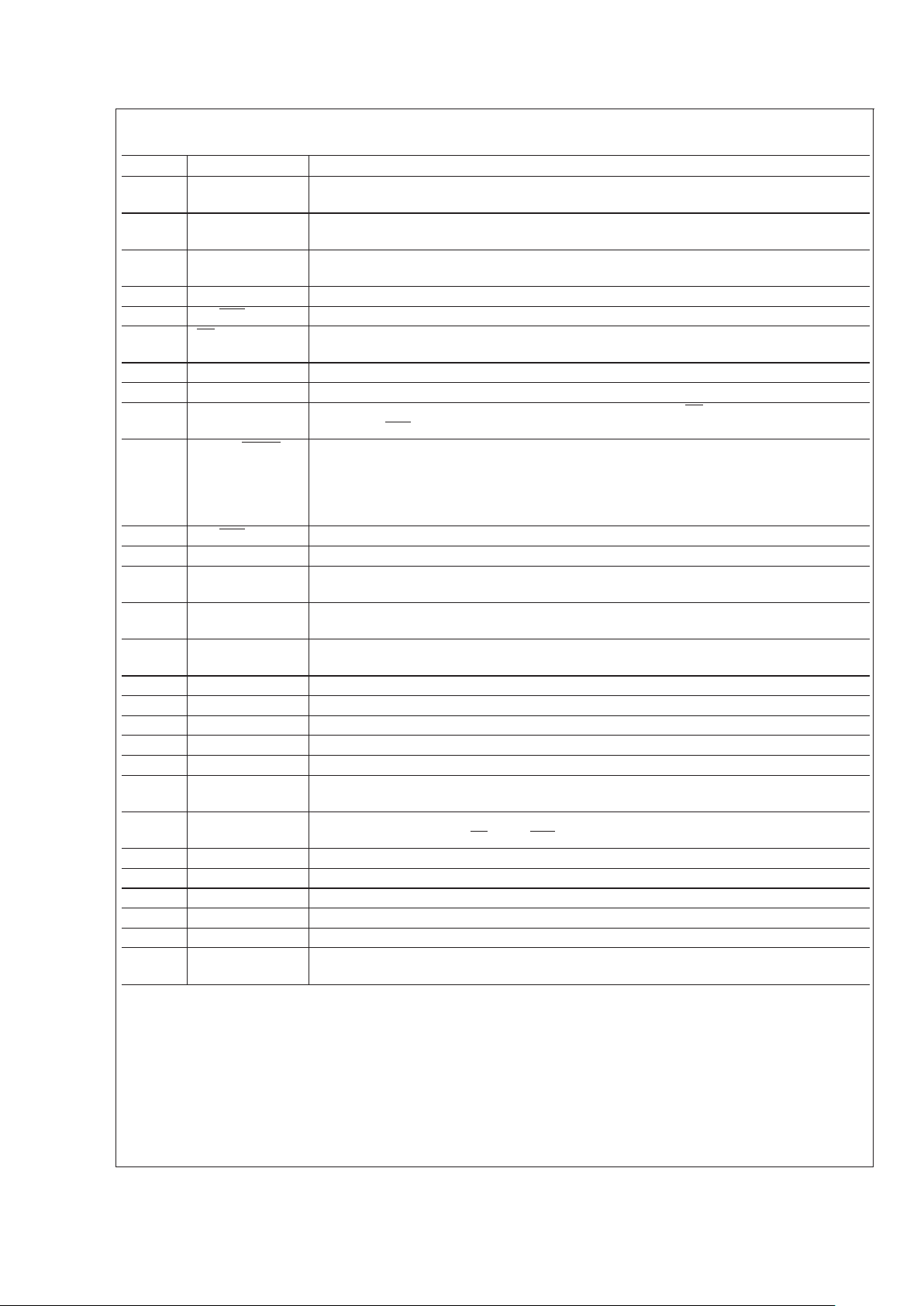

Typical Application Circuits

DS100949-3

FIGURE 1. Application With 5V/3A and 3.3V/4A Outputs

LM2641

www.national.com3

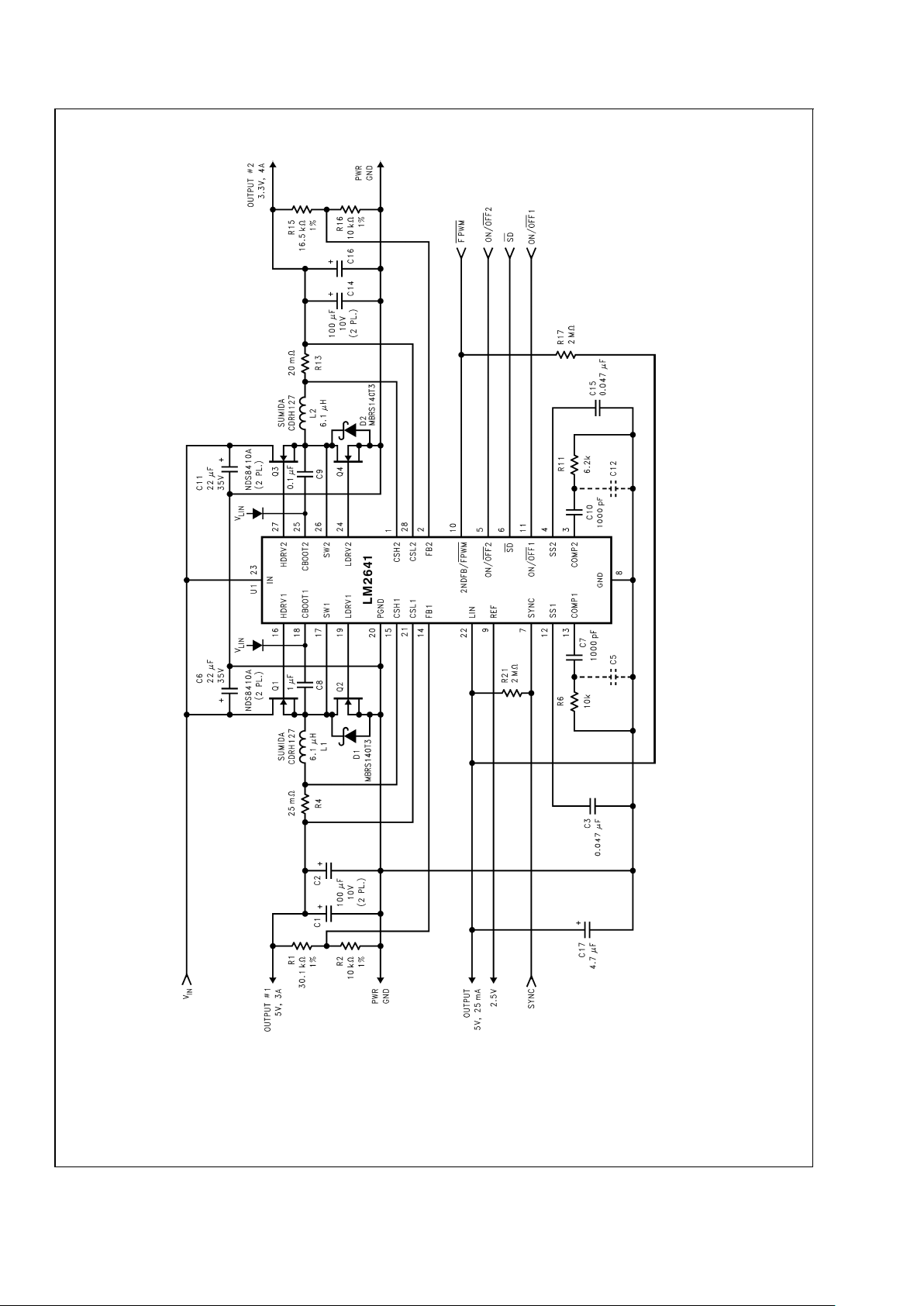

Page 4

Typical Application Circuits (Continued)

DS100949-4

FIGURE 2. Application With 5V/3A, 3.3V/4A, and 12V/0.3A Outputs

LM2641

www.national.com 4

Page 5

Absolute Maximum Ratings (Notes 2, 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

IN, SW1, and SW2 −0.3 to 31V

FB1 and FB2 −0.3 to 3V

SD, ON/OFF1, ON/OFF2,

2NDFB/FPWM, SYNC, REF,

SS1, SS2, COMP1,

COMP2 and CSL1

−0.3 to (V

LIN

+0.3)V

LIN −0.3 to 6V

CSH1, CSH2, and CSL2 (Note

12)

−0.3 to 9V

Voltage from CBOOT1 to SW1

and from CBOOT2 to SW2

−0.3 to 5V

Voltage from HDRV1 to SW1

and from HDRV2 to SW2

−0.3V

Voltage from CBOOT1 to

HDRV1 and from CBOOT2

HDRV2

−0.3V

Junction Temp. +150˚C

Power Dissipation (Note 3) 883 mW

Ambient Storage Temp. (T

J

) −65 to +150˚C

Soldering Dwell Time, Temp. (Note 4)

Wave 4 sec, 260˚C

Infrared 10 sec, 240˚C

Vapor Phase 75 sec, 219˚C

ESD Rating (Note 5) 2 kV

Operating Ratings (Notes 1, 2)

V

IN

5.5 to 30V

Junction Temp. (T

J

) 0 to +125˚C

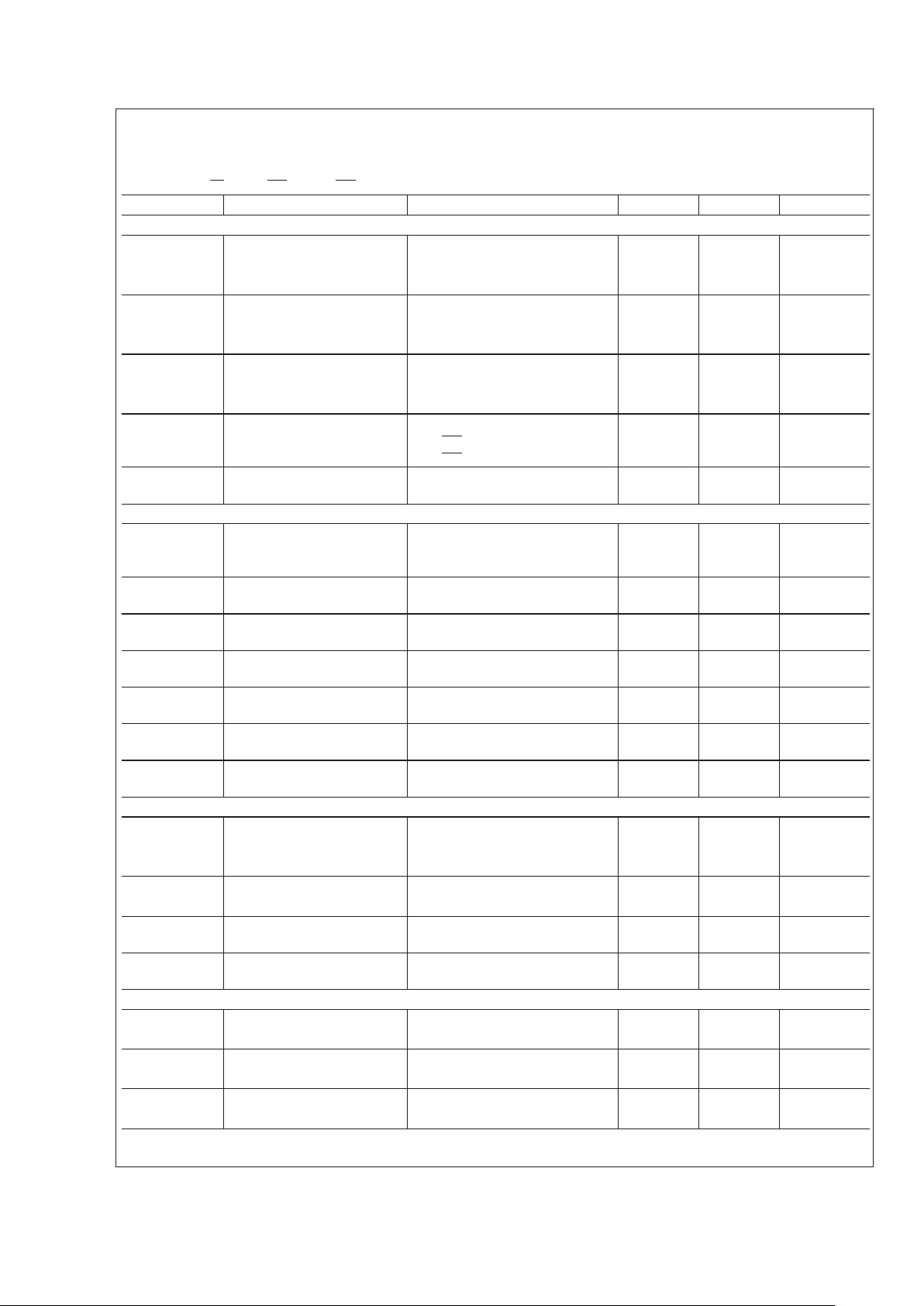

Electrical Characteristics

Typicals and limits appearing in regular type apply for T

J

=

25˚C. Limits appearing in boldface type apply over the entire junc-

tion temperature range for operation, 0 to +125˚C. Unless otherwise specified under the Parameter or Conditions columns, V

IN

=

10V, and V

SD

=

V

ON/OFF1

=

V

ON/OFF2

=

5V. (Notes 2, 6, 7)

Symbol Parameter Conditions Typical Limit Units

System

V

IN

Input Supply Voltage Range 5.5 V(min)

30 V(max)

V

OUT1

Output Voltage Adjustment

Range

2.2 V(min)

6.0 V(max)

V

OUT2

Output Voltage Adjustment

Range

2.2 V(min)

8.0 V(max)

∆V

OUT/VOUT

Load Regulation 0 mV ≤ (CSH1-CSL1) ≤ 80 mV,

0mV≤(CSH2-CSL2) ≤ 80 mV

0.5

%

∆V

OUT

/∆V

IN

Line Regulation 5.5V ≤ VIN≤ 30V 0.002

%

/V

I

IN

Input Supply Current ON (Note 8) 0.6 mA

V

FB1

=

V

FB2

=

1.4V, 1 mA(max)

V

CSH1

=

5.2V, V

CSL1

=

5V,

V

CSH2

=

3.5V, V

CSL2

=

3.3V

Standing By (Note 9) 80 µA

V

ON/OFF1

=

V

ON/OFF2

=

0V

150 µA(max)

Shut Down (Note 10) 25 µA

V

SD

=

0V

60 µA(max)

I

SS1,ISS2

Soft-Start Source Current V

SS1

=

V

SS2

=

1V 4.75 µA

2.0 µA(min)

7.0 µA(max)

Soft-Start Sink Current 10 µA

V

PCL

Positive Current Limit

Voltage (Voltage from CSH1

to CSL1 and from CSH2 to

CSL2)

100 mV

80

mV(min)

140 mV(max)

V

NCL

Negative Current Limit

Voltage (Voltage from CSH1

to CSL1 and from CSH2 to

CSL2)

V

2NDFB/FPWM

=

0.8V

−100 mV

−80 mV(min)

−140 mV(max)

LM2641

www.national.com5

Page 6

Electrical Characteristics (Continued)

Typicals and limits appearing in regular type apply for T

J

=

25˚C. Limits appearing in boldface type apply over the entire junc-

tion temperature range for operation, 0 to +125˚C. Unless otherwise specified under the Parameter or Conditions columns, V

IN

=

10V, and V

SD

=

V

ON/OFF1

=

V

ON/OFF2

=

5V. (Notes 2, 6, 7)

Symbol Parameter Conditions Typical Limit Units

System

V

OUT

Undervoltage

Shutdown Latch Threshold

70

%

60

%

(min)

80

%

(max)

V

OUT

Overvoltage Shutdown

Latch Threshold

150

%

135

%

(min)

165

%

(max)

Secondary Feedback

Threshold Voltage

(2NDFB/FPWM)

2.5 V

2.4 V(min)

2.6 V(max)

(2NDFB/FPWM) Pin

Pull-Up Current

V

SFB

=

2.4V

V

ON/OFF1

=

0V

V

ON/OFF2

=

5V

40 80 µA(max)

(2NDFB/FPWM) Pin

Input Leakage Current

±

0.1 µA

Gate Drive

V

BOOT

Bootstrap Voltage (Voltage

from CBOOT1 to SW1 and

from CBOOT2 to SW2)

CBOOT1 and CBOOT2 Source

1µA Each

4.5 V

4.3 V(min)

HDRV1 and HDRV2 Sink

and Source Current

0.35 A

LDRV1 and LDRV2 Sink and

Source Current

0.35 A

HDRV1 and HDRV2

High-Side On-Resistance

V

CBOOT1

=

V

CBOOT2

=

5V, V

SW1

=

V

SW2

=

0V

6 Ω

HDRV1 and HDRV2

Low-Side On-Resistance

V

CBOOT1

=

V

CBOOT2

=

5V, V

SW1

=

V

SW2

=

0V

4 Ω

LDRV1 and LDRV2

High-Side On-Resistance

V

LIN

=

5V 8 Ω

LDRV1 and LDRV2 Low-Side

On-Resistance

V

LIN

=

5V 4 Ω

Oscillator

F

OSC

Oscillator Frequency 300 kHz

255 kHz(min)

345 kHz(max)

Minimum OFF-Time V

FB1

=

1V, Measured at HDRV1 250 ns

350 ns(max)

Maximum Frequency of

Synchronization

400 kHz(min)

Minimum Width of

Synchronization Pulses

SYNC Pulses are Low-Going 200 ns(min)

Error Amplifier

I

FB1,IFB2

Feedback Input Bias Current V

FB1

=

V

FB2

=

1.4V 100 nA

250 nA(max)

I

COMP1,ICOMP2

COMP Output Source

Current

V

FB1

=

V

FB2

=

1V, V

COMP1

=

V

COMP2

=

1V

90 µA

40 µA(min)

I

COMP1,ICOMP2

COMP Output Sink Current V

FB1

=

V

FB2

=

1.4V, V

COMP1

=

V

COMP2

=

0.2V

60 µA

40 µA(min)

LM2641

www.national.com 6

Page 7

Electrical Characteristics (Continued)

Typicals and limits appearing in regular type apply for T

J

=

25˚C. Limits appearing in boldface type apply over the entire junc-

tion temperature range for operation, 0 to +125˚C. Unless otherwise specified under the Parameter or Conditions columns, V

IN

=

10V, and V

SD

=

V

ON/OFF1

=

V

ON/OFF2

=

5V. (Notes 2, 6, 7)

Symbol Parameter Conditions Typical Limit Units

Voltage References and Linear Voltage Regulator

V

BG

Bandgap Voltage 1.238 V

V

REF

Reference Voltage 0.01 mA ≤ I

REF

≤ 5 mA Source,

V

LIN

≤ 6V

2.5 V

2.45 V(min)

2.55 V(max)

V

LIN

Output Voltage of the Linear

Voltage Regulator

6V ≤ VIN≤ 30V,

0mA≤I

LIN

≤ 25 mA

5V

4.6 V(min)

5.4 V(max)

V

UVLO

Undervoltage Lockout

Threshold

(Note 11) 4.0 V

3.6 V(min)

4.4 V(max)

LIN-to-V

OUT

Switch-Over

Threshold

V

OUT

taken at CSL1 4.8 V

Logic Inputs

V

IH

Minimum High Level Input

Voltage (SD, ON/OFF1,

ON/OFF2, and SYNC)

2.4 V(min)

V

IH

Minimum High Level Input

Voltage (2NDFB/FPWM)

2.6 V(min)

V

IL

Maximum Low Level Input

Voltage (SD, ON/OFF1,

ON/OFF2, SYNC, and

2NDFB/FPWM)

0.8 V(max)

Maximum Input Leakage

Current (SD, ON/OFF1,

ON/OFF2, and SYNC)

Logic Input Voltage 0 or 5V

±

0.1 µA

Note 1: Unless otherwise specified, all voltages are with respect to the voltage at the GND and PGND pins.

Note 2: Absolute Maximum Ratings are limits beyond which damage to the device may occur. Operating Ratings are conditions under which operation of the device

is guaranteed. Operating Ratings do not imply guaranteed performance limits. For guaranteed performance limits and associated test conditions, see the Electrical

Characteristics tables.

Note 3: The Absolute Maximum power dissipation depends on the ambient temperature. The 883 mW rating results from substituting 150˚C, 70˚C, and 90.6˚C/W

for T

Jmax,TA

, and θJArespectively into the formula P

max

=

(T

Jmax-TA

)/θJA, where P

max

is theAbsoluteMaximumpowerdissipation,T

Jmax

is theAbsoluteMaximum

junction temperature, T

A

is the ambient temperature, and θJAis the junction-to-ambient thermal resistance of the package. A θJAof 90.6˚C/W represents the

worst-case condition of no heat sinking of the 28-pin TSSOP.Heat sinking allows the safe dissipation of more power. TheAbsoluteMaximumpowerdissipationmust

be derated by 11.04 mW per ˚C above 70˚C ambient. The LM2641 actively limits its junction temperature to about 150˚C.

Note 4: For detailed information on soldering plastic small-outline packages, refer to the Packaging Databook available from National Semiconductor Corporation.

Note 5: For testing purposes, ESD was applied using the human-body model, a 100 pF capacitor discharged through a 1.5 kΩ resistor.

Note 6: A typical is the center of characterization data taken with T

A

=

T

J

=

25˚C. Typicals are not guaranteed.

Note 7: All limits are guaranteed. All electrical characteristics having room-temperature limits are tested during production with T

A

=

25˚C. All hot and cold limits are

guaranteed by correlating the electrical characteristics to process and temperature variations and applying statistical process control.

Note 8: Both controllers are ON but not switching. Currents entering the IC at IN, CSL1, CSH1, CSL2, and CSH2 are measured. Those entering at CSL1 and CSH1

are multiplied by 0.50 to emulate the effect of a switching conversion from 10V down to 5V.Those entering at CSL2 and CSH2 are multiplied by 0.33 to emulate the

effect of a switching conversion from 10V down to 3.3V. After multiplication, all five currents are added. Because the voltage at the CSL1 input is greater than the

LIN-to-V

OUT

switchover threshold, most of the input supply current enters the IC via the CSL1 input.

Note 9: Both switching controllers are OFF. The 5V, 50 mA linear regulator (output at LIN) and the precision 2.5V reference (output at REF) remain ON.

Note 10: Both switching controllers and the 2.5V precision reference are OFF.The 5V, 50 mA linear regulator remains ON.

Note 11: The controllers remain OFF until the voltage of the 5V, 50 mA linear regulator (output at LIN) reaches this threshold.

Note 12: In applications where the output voltage can exceed the absolute maximum rating, a 100Ω resistor must be placed in series with the CSH and CSL inputs.

LM2641

www.national.com7

Page 8

Block Diagram

DS100949-2

FIGURE 3. LM2641 Block Diagram

LM2641

www.national.com 8

Page 9

Typical Performance Charateristics

Efficiency vs Load Current

DS100949-14

Efficiency vs Load Current

DS100949-15

Efficiency vs Load Current

DS100949-16

Efficiency vs Load Current

DS100949-17

Efficiency vs Load Current

DS100949-18

Efficiency vs Load Current

DS100949-19

Efficiency vs Load Current

DS100949-20

Efficiency vs Load Current

DS100949-21

Efficiency vs Load Current

DS100949-22

Ref Output Voltage

DS100949-23

Ref Output Voltage

DS100949-24

Normalized Switching Output

Voltage vs

Junction Temperature

DS100949-25

LM2641

www.national.com9

Page 10

Typical Performance Charateristics (Continued)

Theory of Operation

Basic Operation of the Current-Mode Controller

The output voltage is held at a constant value by the main

control loop, which is made up of the

error amplifier

, the

cur-

rent sense amplifier

, and the

PWM comparator

(refer to the

Block Diagram,

Figure 3

).

The LM2641 controller has two primary modes of operation:

Forced Pulse-Width Modulation (FPWM)

where the control-

ler always operates at a fixed frequency, and

Pulse-Skipping

mode where the controller frequency decreases at reduced

output loads to improve light-load efficiency.

FPWM Mode of Operation

Pulling the FPWM pin low initiates a mode of operation

called Forced Pulse-Width Modulation (FPWM). This means

that the LM2641 will

always

operate at a fixed frequency, re-

gardless of output load. The cycle of operation is:

The high-side FET switch turns ON at the beginning of every

clock cycle, causing current to flow through the inductor. The

inductor current ramps up, causing a voltage drop across the

sense resistor, and this voltage is amplified by the current

sense amplifier.

The voltage signal from the current sense amplifier is applied

to the input of the PWM comparator, where it is compared to

the control level set by the error amplifier. Once the current

sense signal reaches this control voltage, the PWM comparator resets the driver logic which turns OFF the high-side

FET switch.

The low-side FET switch turns on after a delay time which is

the lesser of either:

(a) The time it takes the SW pin voltage to reach zero (this

voltage is sensed by the shoot-through protection circuitry).

(b) 100 ns, which is the pre-set value for maximum delay.

When operating at very light loads (in FPWM mode), the inductor current must flow in a negative direction through the

low-side FET switch in order to maintain the fixed-frequency

mode of operation. For this reason, the built-in zero cross

detector is disabled when ever FPWM mode is activated

(that is, when ever the FPWM pin is pulled to a low state).

It should be noted that if the FPWM pin is high (operation described in next section), the zero cross detector will turn OFF

the low-side FET switch anytime the inductor current drops

to zero (which prevents negative inductor current).

Pulse-Skipping Mode of Operation

Pulling the FPWM pin high allows the LM2641 to operate in

pulse-skipping mode at light loads, where the switching frequency decreases as the output load is reduced. The controller will operate in fixed-frequency mode, as described in

the previous section, if the output load current is sufficiently

high.

Pulse-skipping results in higher efficiency at light loads, as

decreasing the switching frequency reduces switching

Normalized Error Amplifier Voltage

vs

Junction Temperature

DS100949-26

Error Amplifier Gm vs

Junction Temperature

DS100949-27

Normalized Oscillator Frequency

vs

Junction Temperature

DS100949-28

Shutdown Quiescent Current

And Standby Quiescent Current vs

Supply Voltage

DS100949-29

LM2641

www.national.com 10

Page 11

Theory of Operation (Continued)

losses. The load current value where the transition from

fixed-frequency to pulse-skipping operation occurs is the

point where the inductor current goes low enough to cause

the voltage measured across the current sense resistor (R4

or R13) to drop below 25 mV.

In pulse-skipping mode, the high-side FET switch will turn

ON at the beginning of the first clock cycle which occurs after

the voltage at the feedback pin falls below the reference voltage. The high-side FET switch remains ON until the voltage

across the current sense resistor rises to 25 mV (and then it

turns OFF).

Ramp Compensation

All current-mode controllers require the use of ramp compensation to prevent subharmonic oscillations, and this compensation is built into the LM2641. The internal compensation assumes an R

SENSE

value of 25 mΩ, inductor value of

6.8µH, and a maximum output voltage of 6V.

To prevent oscillations, the slope M of the compensation

ramp must be equal to the maximum downward slope of the

voltage waveform at the output of the current sense amplifier. The relationship of the slope M to the external components is given by:

M

COMP

=

M

CS AMP

(max)=NXR

SENSE

XV

OUT

(max) / L

Where:

M

COMP

is the slope of the compensation ramp.

M

CS AMP

(max) is the maximum downward slope of the volt-

age at the output of the current sense amplifier.

N is the gain of the current sense amplifier.

R

SENSE

is the value of the current sense resistor.

V

OUT

(max) is the maximum output voltage.

L is the inductance of the output inductor.

It is important to note that since the value R

SENSE

appears in

the numerator and L is in the denominator, these two values

may be increased or decreased at the same ratio without

changing the slope.

At higher values of load current, a lower value R

SENSE

will be

selected. The inductance value for the output inductor

should be decreased by the same percentage to maintain

correct ramp compensation.

Application Information

Improved Transient Response

If the output voltage falls below 97%of the nominal value,

the low-voltage regulation (LREG) comparator will activate

logic which turns ON the high-side FET switch continuously

until the output returns to nominal. The low-side FET switch

is held OFF during this time.

This action will improve transient response since it bypasses

the error amplifier and PWM comparator, forcing the

high-side switch ON until the output returns to nominal. This

feature is disabled during start-up.

Boost High-Side Gate Drive

A “flying” bootstrap capacitor is used to generate the gate

drive voltage used for the high-side FET switch. This bootstrap capacitor is charged up to about 5V using an internal

supply rail and diode when ever the low-side FET switch is

ON. When the high-side FET switch turns ON, the Source is

pulled up near the input voltage. The voltage across the

bootstrap capacitor boosts up the gate drive voltage, ensuring that the Gate is driven at least 4.3V higher than the

Source.

Reference

The internal bandgap reference is used to generate a 2.5V

reference voltage which is connected to the REF pin. The

guaranteed tolerance of the REF voltage is

±

2%over the full

operating temperature range, as long as the current drawn is

≤ 5 mA.

A bypass capacitor on the REF pin is not required, but may

be used to reduce noise.

5V LIN Output

The LM2641 contains a built-in 5V/50 mA LDO regulator

whose output is connected to the LIN pin. Since this is an

LDO regulator, it does require an external capacitor to maintain stability. A good quality Tantalum capacitor ≥ 4.7µF is

recommended.

Since the current limit for this LDO regulator is set at about

85 mA, it can be used at load currents up to about 50 mA

(assuming total IC power dissipation does not exceed the

maximum value).

Guaranteed specifications are provided for worst-case values of V

LIN

over the full operating temperature range for load

currents up to 25mA (see Electrical Characteristics). To estimate how the V

LIN

output voltage changes when going from

I

LIN

=

25mA to I

LIN

=

50mA, a change in V

LIN

of about

−30mV should be expected due to loading (typical value

only,not guaranteed). This decrease in V

LIN

is linear with in-

creasing load current.

It must be understood that the maximum allowable current of

50mA must include the current drawn by the gate drive circuitry. This means that the maximum current available for

use at the LIN pin is 50 mA minus whatever is being used internally for gate drive.

The amount of current used for gate drive by each switching

output can be calculated using the formula:

I

GD

=2XQXF

OSC

Where:

I

GD

is the gate drive current supplied by V

LIN

.

Q is the gate charge required by the selected FET (see FET

data sheet: Gate Charge Characteristics).

F

OSC

is the switching frequency.

Example: As shown in the typical application, if the FET

NDS8410 is used with the LM2641, the turn-on gate voltage

(V

GS

)is5V−V

DIODE

=

4.3V. Referring to the NDS8410 data

sheet, the curve Gate Charge Characteristics shows that the

gate charge for this value of V

GS

is about 24 nC.

Assuming 300 kHz switching frequency, the gate drive current used by each switching output is:

I

GD

=

2XQXF

OSC

=

2X(24X10

−9

)X(3X105)

=

14.4 mA

If both outputs are switching, the total gate drive current

drawn would be twice (28.8 mA).

Note that in cases where the voltage at switching output

#

1

is 4.8V or higher, the internal gate drive current is obtained

from that output (which means the full 50 mA is available for

external use at the LIN pin).

LM2641

www.national.com11

Page 12

Application Information (Continued)

SYNC Pin

The basic operating frequency of 300kHz can be increased

to up to 400kHz by using the SYNC pin and an external

CMOS or TTL clock. The synchronizing pulses must have a

minimum pulse width of 200 ns.

If the sync function is not used, the SYNC pin must be connected to the LIN pin or to ground to prevent false triggering.

Current Limit Circuitry

The LM2641 is protected from damage due to excessive output current by an internal current limit comparator, which

monitors output current on a cycle-by-cycle basis. The current limiter activates when ever the absolute magnitude of

the voltage developed across the output sense resistor exceeds 100 mV (positive or negative value).

If the sensed voltage exceeds 100 mV, the high-side FET

switch is turned OFF. If the sensed voltage goes below -100

mV, the low-side FET switch is turned OFF. It should be

noted that drawing sufficient output current to activate the

current limit circuits can cause the output voltage to drop,

which could result in a under-voltage latch-OFF condition

(see next section).

Under-voltage/Over-voltage Protection

The LM2641 contains protection circuitry which activates if

the output voltage is too low (UV) or too high (OV). In the

event of either a UV or OV fault, the LM2641 is latched off

and the high-side FET is turned off, while the low-side FET is

turned on.

If the output voltage drops below 70%of nominal value, the

under-voltage comparator will latch OFF the LM2641. To restore operation, power to the device must be shut off and

then restored.

It should be noted that the UV latch provides protection in

cases where excessive output current forces the output voltage down. The UV latch circuitry is disabled during start-up.

If the output voltage exceeds 150%of nominal, the

over-voltage comparator latches off the LM2641. As stated

before, power must be cycled OFF and then ON to restore

operation.

It must be noted that the OV latch can not protect the load

from damage in the event of a high-side FET switch failure

(where the FET shorts out and connects the input voltage to

the load).

Protection for the load in the event of such a failure can be

implemented using a fuse in the power lead. Since the

low-side FET switch turns ON whenever the OV latch activates, this would blow a series fuse if the FET and fuse are

correctly sized.

Soft-Start

An internal 5 µA current source connected to the soft-start

pins allows the user to program the turn-on time of the

LM2641. If a capacitor is connected to the SS pin, the voltage at that pin will ramp up linearly at turn ON. This voltage

is used to control the pulse widths of the FET switches.

The pulse widths start at a very narrow value and linearly increase up to the point where the SS pin voltage is about

1.3V. At that time, the pulse-to-pulse current limiter controls

the pulse widths until the output reaches its nominal value

(and the PWM current-mode control loop takes over).

The LM2641 contains a digital counter (referenced to the oscillator frequency) that times the soft-start interval. The maximum allotted SS time period is 4096 counts of the oscillator

clock, which means the time period varies with oscillator frequency:

max. allowable SS interval=4096 / F

OSC

If the output voltage does not move to within −1%of nominal

in the period of 4096 counts, the device will latch OFF.To restore operation, the power must be cycled OFF to ON.

Minimum Pulse Width

As the input voltage is increased, the pulse widths of the

switching FET’s decreases. If the pulse widths become narrower than 350ns, pulse jitter may occur as the pulses alternate with slightly different pulse widths. This is does not affect regulator stability or output voltage accuracy.

Loop Compensation

The LM2641 must be properly compensated to assure

stable operation and good transient response. As with any

control loop, best performance is achieved when the compensation is optimized so that maximum bandwidth is obtained while still maintaining sufficient phase margin for good

stability.

Best performance for the LM2641 is typically obtained when

the loop bandwidth (defined as the frequency where the loop

gain equals unity) is in the range of F

OSC

/10 to F

OSC

/5.

In the discussion of loop stability, it should be noted that

there is a high-frequency pole f

p

(HF), whose frequency can

be approximated by:

f

p

(HF) ∼ F

OSC

/2XQS(Assumes Q

S

<

0.5)

Where:

As can be seen in the approximation for QS, the highest frequency for f

p

(HF) occurs at the maximum value of VIN. The

lowest frequency for f

p

(HF) is about F

OSC

/10 (when V

IN

=

4.5V and V

OUT

=

1.8V).

As noted above, the location of the pole f

p

(HF) is typically in

the range of about F

OSC

/10 to F

OSC

/4. This pole will often be

near the unity-gain crossover frequency, and it can significantly reduce phase margin if left uncompensated. Fortunately,the ESR of the output capacitor(s) forms a zero which

is usually very near the frequency of f

p

(HF), and provides

cancellation of the negative phase shift it would otherwise

cause. For this reason, the output capacitor must be carefully selected.

Most of the loop compensation for the LM2641 is set by an

R-C network from the output of the error amplifier to ground

(see

Figure 4

). Since this is a transconductance amplifier, it

has a very high output impedance (160 kΩ).

LM2641

www.national.com 12

Page 13

Application Information (Continued)

The components shown will add poles and zeros to the loop

gain as given by the following equations:

C10 adds a pole whose frequency is given by:

f

p

(C10)=1/[2πX C10 (R11 + 160k) ]

C12 adds a pole whose frequency is given by:

f

p

(C12)=1/[2πX C12 (R11 || 160k) ]

R11 adds a zero whose frequency is given by:

f

z

(R11)=1/[2πX R11 (C10 + C12) ]

The output capacitor adds both a pole and a zero to the loop:

f

p(COUT

)=1/[2πXRLXC

OUT

]

f

z

(ESR)=1/[2πXESRXC

OUT

]

Where R

L

is the load resistance, and ESR is the equivalent

series resistance of the output capacitor(s).

The function of the compensation components will be ex-

plained in a qualitative discussion of a typical loop gain plot

for an LM2641 application, as illustrated in

Figure 5

.

C10 and R11 form a pole and a zero. Changing the value of

C10 moves the frequency of both the pole and the zero.

Changing R11 moves the zero without significantly affecting

the pole.

The C10 pole is typically referred to as the dominant pole,

and its primary function is to roll off loop gain and reduce the

bandwidth.

The R11 zero is required to add some positive phase shift to

offset some of the negative phase shift from the two

low-frequency poles. Without this zero, these two poles

would cause −180˚ of phase shift at the unity-gain crossover,

which is clearly unstable. Best results are typically obtained

if R11 is selected such that the frequency of f

z

(R11) is in the

range of f

c

/4 to fcwhere fcis the unity-gain crossover fre-

quency.

The output capacitor (along with the load resistance R

L

)

forms a pole shown as f

p(COUT

). Although the frequency of

this pole varies with R

L

, the loop gain also varies proportionally which means the unity-gain crossover frequency stays

essentially constant regardless of R

L

value.

C12 can be used to create an additional pole most often

used for bypassing high-frequency switching noise on the

COMP pin. In many applications, this capacitor is unnecessary.

If C12 is used, best results are obtained if the frequency of

the pole is set in the range F

OSC

/2 to 2F

OSC

. This will provide

bypassing for the high-frequency noise caused by switching

transitions, but add only a small amount of negative phase

shift at the unity-gain crossover frequency.

The ESR of C

OUT

(as well as the capacitance of C

OUT

) form

the zero f

z

(ESR), which typically falls somewhere between

10kHz and 50kHz. This zero is very important, as it cancels

phase shift caused by the high-frequency pole f

p

(HF). It is

important to select C

OUT

with the correct value of capaci-

tance and ESR to place this zero near f

c

(typical range fc/2 to

f

c

).

As an example, we will present an analysis of the loop gain

plot for a 3.3V design. Values used for calculations are:

V

IN

=

12V

V

OUT

=

3.3V

@

4A

C

OUT

=

C14 + C16=200 µF

ESR=60 mΩ(each)=30mΩ total

F

OSC

=

300kHz

f

p

(HF) ∼ 40kHz

R13=20mΩ

L2=6.8 µH

R

L

=

0.825Ω

DC gain=55dB

The values of compensation components will be: C10

=

2200 pF, R11=8.2k, and C12 will not be used. Using this

data, the poles and zeros are calculated:

f

p

(C10)=1/[2πX C10 (R11 + 160k) ]=430Hz

f

z

(R11)=1/[2πX R11 (C10 + C12) ]=8.8kHz

f

p(COUT

)=1/[2πXRLXC

OUT

]=960Hz

f

z

(ESR)=1/[2πXESRXC

OUT

]=27kHz

f

p

(HF) ∼ 40kHz

Using these values, the calculated gain plot is shown in

Fig-

ure 6

.

DS100949-5

FIGURE 4. Typical Compensation Network

DS100949-6

FIGURE 5. Typical Loop Gain Plot

LM2641

www.national.com13

Page 14

Application Information (Continued)

Looking at the plot, it can be seen that the unity-gain crossover frequency f

c

is expected to be about 25kHz. Using this

value, the phase margin at the point is calculated to be about

84˚.

To verify the accuracy of these calculations, the circuit was

bench tested using a network analyzer. The measured gain

and phase are shown plotted in

Figure 7

.

The measured gain plot agrees very closely to the predicted

values. The phase margin at 0dB is slightly less than predicted (71˚ vs. 84˚), which is to be expected due to the negative phase shift contributions of high frequency poles not included in this simplified analysis.

It should be noted that 70˚ phase margin with 25kHz bandwidth is excellent, and represents the optimal compensation

for this set of values for V

IN,VOUT

, inductor and RL.

Optimizing Stability

The best tool for measuring both bandwidth and phase margin is a network analyzer. If this is not available, a simple

method which gives a good measure of loop stability is to apply a minimum to maximum step of output load current and

observe the resulting output voltage transient. A design

which has good phase margin (

>

50˚) will typically show no

ringing after the output voltage transient returns to its nominal value.

It should be noted that the stability (phase margin) does not

have to be optimal for the regulator to be stable. The design

analyzed in the previous section was re-compensated by

changing R11 and C10 to intentionally reduce the phase

margin to about 35˚ and re-tested for step response. The

output waveform displayed slight ringing after the initial return to nominal, but was completely stable otherwise.

In most cases, the compensation components shown in the

Typical Application Circuits will give good performance. To

assist in optimizing phase margin, the following guidelines

show the effects of changing various components.

C

OUT

: Increasing the capacitance of C

OUT

moves the fre-

quency of the pole f

p(COUT

) to a lower value and reduces

loop bandwidth. Increasing C

OUT

can be beneficial (increasing the phase margin) if the loop bandwidth is too wide

(

>

F

OSC

/5) which places the high-frequency poles too close

to the unity-gain crossover frequency.

ESR of C

OUT

: The ESR forms a zero fz(ESR), which is

needed to cancel negative phase shift near the unity-gain

frequency. High-ESR capacitors can not be used, since the

zero will be too low in frequency which will make the loop

bandwidth too wide.

R11/C10:These form a pole and a zero. Changing the value

of C10 changes the frequency of both the pole and zero.

Note that since this causes the frequency of both the pole

and zero to move up or down together, adjusting the value of

C10 does not significantly affect loop bandwidth.

Changing the value of R11 moves the frequency location of

the zero f

z

(R11),but does not significantly shift the C10 pole

(since the value of R11 is much less than the 160kΩ output

impedance of the Gm amplifier). Since only the zero is

moved, this affects both bandwidth and phase margin. This

means adjusting R11 is an easy way to maximize the positive phase shift provided by the zero. Best results are typically obtained if f

z

(R11) is in the frequency range of fc/4 to f

c

(where fcis the unity-gain crossover frequency).

Design Procedure

This section presents guidelines for selecting external components.

INDUCTOR SELECTION

In selecting an inductor, the parameters which are most important are inductance, current rating, and DC resistance.

Inductance

It is important to understand that all inductors are not created

equal, as the method of specifying inductance varies widely.

It must also be noted that the inductance of every inductor

decreases with current. The core material, size, and construction type all contribute the the inductor’s dependence

on current loading. Some inductors exhibit inductance

curves which are relatively flat, while others may vary more

than 2:1 from minimum to maximum current. In the latter

case, the manufacturer’s specified inductance value is usually the maximum value, which means the actual inductance

in your application will be much less.

An inductor with a flatter inductance curve is preferable,

since the loop characteristics of any switching converter are

affected somewhat by inductance value. An inductor which

has a more constant inductance value will give more consistent loop bandwidth when the load current is varied.

DS100949-7

FIGURE 6. Calculated Gain Plot for 3.3V/4A Application

DS100949-8

FIGURE 7. Measured Gain/Phase Plot for 3.3V/4A

Application

LM2641

www.national.com 14

Page 15

Design Procedure (Continued)

The data sheet for the inductor must be reviewed carefully to

verify that the selected component will have the desired inductance at the frequency and current for the application.

Current Rating

This specification may be the most confusing of all when

picking an inductor, as manufacturers use different methods

for specifying an inductor’s current rating.

The current rating specified for an inductor is typically given

in RMS current, although in some cases a peak current rating will also be given (usually as a multiple of the RMS rating) which gives the user some indication of how well the inductance operates in the saturation region.

Other things being equal, a higher peak current rating is preferred, as this allows the inductor to tolerate high values of

ripple current without significant loss of inductance.

In the some cases where the inductance vs. current curve is

relatively flat, the given current rating is the point where the

inductance drops 10%below the nominal value. If the inductance varies a lot with current, the current rating listed by the

manufacturer may be the “center point” of the curve. This

means if that value of current is used in your application, the

amount of inductance will be less than the specified value.

DC Resistance

The DC resistance of the wire used in an inductor dissipates

power which reduces overall efficiency. Thicker wire decreases resistance, but increases size, weight, and cost. A

good tradeoff is achieved when the inductor’s copper wire

losses are about 2%of the maximum output power.

Selecting An Inductor

Determining the amount of inductance required for an application can be done using the formula:

Where:

V

IN

is the maximum input voltage.

V

OUT

is the output voltage.

F is the switching frequency, F

OSC

I

RIPPLE

is the inductor ripple current. In general, a good value

for this is about 30%of the DC output current.

It can be seen from the above equation, that increasing the

switching frequency reduces the amount of required inductance proportionally. Of course, higher frequency operation

is typically less efficient because switching losses become

more predominant as a percentage of total power losses.

It should also be noted that reducing the inductance will increase inductor ripple current (other terms held constant).

This is a good point to remember when selecting an inductor:

increased ripple current increases the FET conduction

losses, inductor core losses, and requires a larger output capacitor to maintain a given amount of output ripple voltage.

This means that a cheaper inductor (with less inductance at

the operating current of the application) will cost money in

other places.

INPUT CAPACITORS

The switching action of the high-side FET requires that high

peak currents be available to the switch or large voltage transients will appear on the V

IN

line. To supply these peak currents, a low ESR capacitor must be connected between the

drain of the high-side FET and ground. The capacitor must

be located as close as possible to the FET (maximum distance=0.5 cm).

A solid Tantalum or low ESR aluminum electrolytic can be

used for this capacitor. If a Tantalum is used, it must be able

to withstand the turn-ON surge current when the input power

is applied. To assure this, the capacitor must be surge tested

by the manufacturer and guaranteed to work in such applications.

Caution: If a typical off-the-shelf Tantalum is used that has

not been surge tested, it can be blown during power-up and

will then be a dead short. This can cause the capacitor to

catch fire if the input source continues to supply current.

Voltage Rating

For an aluminum electrolytic, the voltage rating must be at

least 25%higher than the maximum input voltage for the application.

Tantalum capacitors require more derating, so it is recommended that the selected capacitor be rated to work at a

voltage that is about twice the maximum input voltage.

Current Rating

Capacitors are specified with an RMS current rating. To determine the requirement for an application, the following formula can be used:

LM2641

www.national.com15

Page 16

Design Procedure (Continued)

It is also recommended that a 0.1µF ceramic capacitor be

placed from V

IN

to ground for high frequency bypassing, lo-

cated as close as possible to the V

IN

pin.

OUTPUT CAPACITORS

The output capacitor(s) are critical in loop stability (covered

in a previous section) and also output voltage ripple.

The types best suited for use as output capacitors are aluminum electrolytics and solid Tantalum.

Aluminum Electrolytics

The primary advantage of aluminum electrolytics is that they

typically give the maximum capacitance-to-size ratio, and

they are reasonably priced. However, it must be noted that

aluminum electrolytics used in high-performance switching

regulator designs must be high frequency, low ESR types

such as Sanyo OSCON or Panasonic HFQ which are specifically designed for switching applications. Capacitors such

as these with good high frequency (≥ 100kHz) specifications

are not cheap.

Aluminum electrolytic capacitors should generally not be

used in switching regulator applications where the ambient

temperature goes below 0˚C. A typical low-voltage aluminum

electrolytic has an ESR vs. Temperature curve that is fairly

flat from 25˚C to 125˚C. However, a temperature change

from 25˚C to 0˚C will approximately double the ESR, and it

will double again going from 0˚C down to −20˚C.

Tantalum

Solid Tantalum capacitors are best in applications which

must operate over a wide temperature range. A good quality

Tantalum will typically exhibit less than 2:1 change in ESR

over the temperature range of +125˚C to −40˚C. Recommended types are Sprague 593D, Sprague 594D, and AVX

TPS series.

Selecting An Output Capacitor

The required value of output capacitance is directly related

to the specification for the maximum amount of output voltage ripple allowed in the application. Since ESR effects the

ripple voltage, it is important to have a guideline for ESR.

The maximum allowed ESR can be calculated as follows.

V

RIPPLE

=

I

RIPPLE

*

ESR(max)

Using V=Ldi/dt

V

OUT

=

L

*

I

RIPPLE

/{(1−D)TS}=L*I

RIPPLE

*

FS/(1−D)

I

RIPPLE

=

V

OUT

*

(1−D)/)L*FS)

ESR(max)=V

RIPPLE/IRIPPLE

A reasonable value for C

OUT

can be obtained by choosing

capacitors with net ESR less than

1

⁄2of ESR(max).

Hence,

ESR(max)=V

RIPPLE

*L*

FS/{V

OUT

(1−D)}

The value of C

OUT

necessary to meet the voltage ripple

specification can be found using the approximation:

Where:

I

RIPPLE

is the inductor ripple current.

V

RIPPLE

is the output ripple voltage.

ESR is the equivalent series resistance of the output capacitor.

F is the switching frequency, F

S

.

T

S

=

1/F

S

.

The ESR term predominates in determining output ripple

voltage. Good quality Tantalum capacitors have guaranteed

maximum specifications for ESR, but the typical values for

ESR are usually considerably lower than the maximum limit.

LM2641

www.national.com 16

Page 17

Design Procedure (Continued)

POWER MOSFETs

Two N-channel logic-level MOSFETs are required for each

output. The voltage rating should be at least 1.2 times the

maximum input voltage.

Maximizing efficiency for a design requires selecting the right

FET. The ON-resistance of the FET determines the ON-state

(conduction) losses, while gate charge defines the losses

during switch transitions. These two parameters require a

trade-off, since reducing ON-resistance typically requires increasing gate capacitance (which increases the charge required to switch the FET). Improved FETs are currently being

released which are designed specifically for optimized

ON-resistance and gate charge characteristics.

The V

IN

and V

OUT

for a specific application determines the

ON time of each switch. In some cases where one FET is on

most of the time, efficiency may be improved slightly by selecting a low ON-resistance FET for one of the FET switches

and a different type with lower gate charge requirement for

the other FET switch. However, for most applications this

would give no measurable improvement.

CURRENT SENSE RESISTOR

A sense resistor is placed between the inductor and the output capacitor to measure the inductor current. The value of

this resistor is set by the current limit voltage of the LM2641

(see Electrical Characteristics) and the maximum (peak) inductor current. The value of the sense resistor can be calculated from:

Where:

V

CL

(MIN) is the minimum specified current limit voltage (see

Electrical Characteristics).

I

MAX

is the maximum output current for the application.

I

RIPPLE

is the inductor ripple current for the application.

TOL is the tolerance (in%) of the sense resistor.

The physical placement of the sense resistors should be as

close as possible to the LM2641 to minimize the lead length

of the connections to the CSH and CSL pins. Keeping short

leads on these connections reduces the amount of switching

noise conducted into the current sense circuitry of the

LM2641.

EXTERNAL DIODES

FET Diodes

Both of the low-side MOSFET switches have an external

Schottky diode connected from drain to source. These diodes are electrically in parallel with the intrinsic body diode

present inside the FET. These diodes conduct during the

dead time when both FETs are off and the inductor current

must be supplied by the catch diode (which is either the body

diode or the Schottky diode).

Converter efficiency is improved by using external Schottky

diodes. Since they have much faster turn-off recovery than

the FET body diodes, switching losses are reduced.

The voltage rating of the Schottky must be at least 25

%

higher than the maximum input voltage. The average current

rating of the diode needs to be only about 30%of the output

current, because the duty cycle is low.

The physical placement of the Schottky diode must be as

close as possible to the FET, since any parasitic (lead) inductance in series with the Schottky will slow its turn-ON and

cause current to flow through the FET body diode.

Bootstrap Diodes

As shown in the block diagram for the LM2641, the CBOOT

pin has an internal diode which is connected to the 5V internal rail (which is also connected to the LIN pin). This diode

charges up the bootstrap capacitor to about 5V when the

low-side FET switch turns ON and pulls its drain down to

ground. The internal diode works well until the pulse widths

get extremely narrow, and then the charge applied to the

bootstrap capacitor can become insufficient to fully turn ON

the gate of the FET.

For this reason, an external diode should be used which connects directly between the bootstrap capacitor and the external capacitor connected to the LIN pin (C17). A fast-recovery

silicon diode should be used which has an average current

rating ≥ 50 mA, with voltage rating

>

30V.

Output Diodes

It is recommended that diodes be placed between the regulated outputs and ground to prevent the outputs from swinging below ground. The diode used may be a Schottky or silicon type, and should have a current rating of 1A or more. If

the outputs are allowed to swing below ground more than a

Vbe, the substrate of the LM2641 will become forward biased which will cause the part to operate incorrectly.Another

potential problem which could be caused by negative output

transients is damage to the output capacitors, since tantalum

capacitors can be damaged if a reverse voltage is forced

across them

The operating conditions where this can occur are not typical: it can happen if one or both of the outputs are very lightly

loaded, and an undervoltage (or overvoltage) condition is

detected. When this happens, the LM2641 turns off the

switching oscillator and turns on both of the low-side FET’s

which abruptly grounds one end of the inductor. When this

happens, the other end of the inductor (which is connected

to the regulated output) will experience a transient ringing

voltage as the energy stored in the inductor is discharged.

The amplitude and duration of the ringing is a function of the

R-L-C tank circuit made up the output capacitance, inductor,

and resistance of the inductor windings.

Because of this, the choice of inductor influences how large

in amplitude the ringing will be. In tests performed on the

TypicalApplication Circuit, the Sumida inductor showed less

ringing than the Pulse inductor, but both showed a voltage

transient that would go slightly below ground. For this reason, the output diodes are recommended.

LM2641

www.national.com17

Page 18

Physical Dimensions inches (millimeters) unless otherwise noted

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

labeling, can be reasonably expected to result in a

significant injury to the user.

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80-532 78 32

Français Tel: +49 (0) 1 80-532 93 58

Italiano Tel: +49 (0) 1 80-534 16 80

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

www.national.com

28-Lead TSSOP (MTC)

Order Number LM2641MTC-ADJ

NS Package Number MTC28

LM2641 Dual Adjustable Step-Down Switching Power Supply Controller

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...