Page 1

LM2636

5-Bit Programmable Synchronous Buck Regulator

Controller

General Description

The LM2636 is a high speed controller designed specifically

for use in synchronous DC/DC buck converters for advance

d microprocessors. A 5-bit DAC accepts the VID code directly fromthe CPU and adjusts the output voltage from 1.3V

to 3.5V.It provides the power good, over-voltage protection,

and output enable features as required by Intel VRM specifications. Current limiting is achieved by monitoring the voltage drop across the r

DS_ON

of the high side MOSFET, which

eliminates an expensive current sense resistor.

The LM2636 employs a fixed-frequency voltage mode PWM

architecture. To provide a faster response to a large and fast

load transient, two ultra-fast comparators are built in to monitor the output voltage and override the primary control loop

when necessary. The PWM frequency is adjustable from 50

kHz to 1 MHz through an external resistor. The wide range of

PWM frequency gives the power supply designer the flexibility to make trade-offs between load transient response performance, MOSFET cost and the overall efficiency. The

adaptive non-overlapping MOSFET gate drivers help avoid

any potential shoot-through problem while maintaining high

efficiency.BiCMOS gate drivers with rail-to-rail swing ensure

that no spurious turn-on occur. When only 5V is available, a

bootstrap structure can be employed to accommodate an

NMOS high side switch. The precision reference trimmed to

2.5%over temperature is available externally for use by

other regulators. Dynamic positioning of load voltage, which

helps cut the number of output capacitors, can also be implemented easily.

Features

n 1.3V to 3.5V 5-bit programmable output voltage

n Synchronous rectification

n Power Good flag and output enable

n Over-voltage protection

n Initial Output Accuracy: 1.5%over temperature

n Current limit without external sense resistor

n Adaptive non-overlapping MOSFET gate drives

n Adjustable switching frequency: 50 kHz to 1 MHz

n Dynamic output voltage positioning

n 1.256V reference voltage available externally

n Plastic SO-20 package and TSSOP-20 package

Applications

n Motherboard power supply/VRM for Cyrix Gxm, Cyrix

Gxi, Cyrix MII, Pentium

™

II, Pentium Pro, 6x86 and K6

processors

n 5V to 1.3V–3.5V high current power supplies

Typical Application

Pentium™is a trademark of Intel Corporation.

DS100834-1

FIGURE 1. 5V to 1.3V–3.5V, 14A Power Supply

October 1999

LM2636 5-Bit Programmable Synchronous Buck Regulator Controller

© 1999 National Semiconductor Corporation DS100834 www.national.com

Page 2

Connection Diagrams

Pin Descriptions

LSGATE (Pin 1): Gate drive for the low-side N-channel

MOSFET. This signal is interlocked with HSGATE (Pin 20) to

avoid a shoot-through problem.

BOOTV (Pin 2): Power supply for high-side N-channel

MOSFET gate drive. The voltage should be at least one gate

threshold above the converter input voltage to properly operate the high-side N-FET.

PGND (Pin 3): Ground for high current circuitry. It should be

connected to system ground.

SGND (Pin 4): Ground for signal level circuitry. It should be

connected to system ground.

V

CC

(Pin 5): Power supply for the controller.

SENSE (Pin 6): Converter output voltage sensing. It pro-

vides input for power good, fast dual comparator control

loop, and over-voltage protection circuitry. It is recommended that a 0.1 µF capacitor be connected between this

pin and ground to avoid potential noise problems.

IMAX (Pin 7): Current limit threshold setting. It sinks a fixed

180 µA current. By connecting a resistor between the high

side MOSFET drain and this pin, a fixed voltage drop can be

built across the resistor. This voltage drop is compared with

the V

DS

of the high-side N-MOSFET to determine if an over-

current condition has occurred.

IFB (Pin 8): High-side N-MOSFET source voltage sensing.

This pin is one V

DS

below drain voltage. When this voltage is

lower than that of IMAX pin during the time the high-side FET

is on, it means V

DS

is higher than the preset voltage across

the IMAX resistor, which can be interpreted as an overcurrent condition.

V

REF

(Pin 9): Bandgap reference voltage. This voltage is

mainly for use by other power supplies on the motherboard

which need a reference.

EA_OUT (Pin 10): Output of the error amplifier. The voltage

level on this pin is compared with an internally generated

ramp signal to determine the duty cycle. This pin is necessary for compensating the primary control loop.

FB (Pin 11): Inverting input of the error amplifier.A pin necessary for compensating the control loop.

FREQ_ADJ (Pin 12): Switching frequency adjustment.

Switching frequency can be adjusted by changing the

grounding resistance on this pin.

PWRGD (Pin 13): Power Good. There are two windows

around the DAC output voltage that are associated with

PWRGD pin, the

±

10%window and the±8%window. If

PWRGD is initially high (open drain state) and output voltage

travels out of

±

10%window, PWRGD goes to low (low impedance to ground). If PWRGD is initially low and output

voltage travels into the

±

8%window and has stayed within

the window for at least 10 ms, PWRGD goes to high. A

PWRGD high means the output voltage is at least within the

±

10%window whereas a PWRGD low indicates the output

voltage is definitely outside the

±

8%window.

VID4:0 (Pins 14, 15, 16, 17, 18): Voltage Identification

Code. The five pins accept an open-ground pattern 5-bit binary code from outside the chip (typically from the CPU) for

generating the desired output voltage. Each VID pin is internally pulled up to V

CC

via a 90 µA current source.

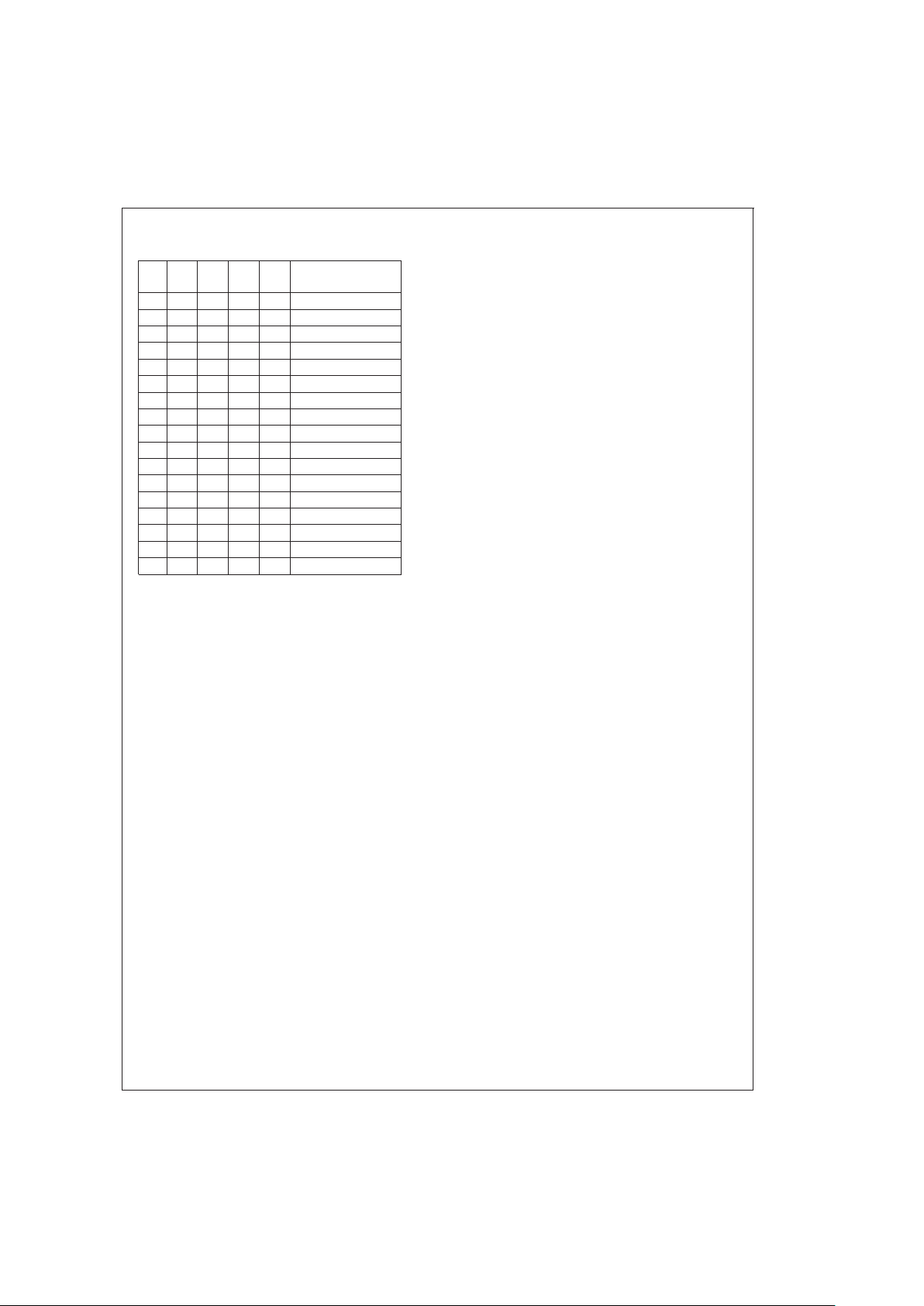

Table 1

shows the code table.

OUTEN (Pin 19): Output Enable. The output voltage is dis-

abled when this pin is pulled low. It is internally pulled up to

V

CC

via a 90 µA current source.

HSGATE (Pin 20): Gate drive for the high-side N-channel

MOSFET. This signal is interlocked with LSGATE (Pin 1) to

avoid a shoot-through problem.

TABLE 1. VID Code and DAC Output

V

ID4VID3VID2VID1VID0

Rated Output

Voltage (V)

01111 1.30

01110 1.35

01101 1.40

01100 1.45

01011 1.50

01010 1.55

01001 1.60

01000 1.65

00111 1.70

00110 1.75

00101 1.80

00100 1.85

00011 1.90

00010 1.95

00001 2.00

TOP VIEW

DS100834-3

Plastic SO-20

Order Number LM2636M

See NS Package Number M20B

TOP VIEW

DS100834-3

Plastic TSSOP-20

Order Number LM2636MTC

See NS Package Number MTC20

LM2636

www.national.com 2

Page 3

Pin Descriptions (Continued)

TABLE 1. VID Code and DAC Output (Continued)

V

ID4VID3VID2VID1VID0

Rated Output

Voltage (V)

00000 2.05

11111 (shutdown)

11110 2.1

11101 2.2

11100 2.3

11011 2.4

11010 2.5

11001 2.6

11000 2.7

10111 2.8

10110 2.9

10101 3.0

10100 3.1

10011 3.2

10010 3.3

10001 3.4

10000 3.5

LM2636

www.national.com3

Page 4

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

(All voltages are referenced to the PGND and SGND pins.)

V

CC

7V

BOOTV 18V

Junction Temperature 150˚C

DC Power Dissipation (Note 2) 1.42W

Storage Temperature −65˚C to +150˚C

Soldering Time, Temperature

Wave (4 seconds)

Infrared (10 seconds)

Vapor Phase (75 seconds)

260˚C

240˚C

219˚C

ESD Susceptibility (Note 3) 2 kV

Recommended Operating

Conditions

(Note 1)

Supply Voltage Range (V

CC

) 4.5V to 5.5V

Junction Temperature Range 0˚C to +125˚C

Electrical Characteristics

VCC= 5V unless otherwise indicated under the Conditions column. Typicals and limits appearing in plain type apply for TA=

T

J

= +25˚C. Limits appearing in boldface type apply over 0˚C to +70˚C.

Symbol Parameter Conditions Min Typ Max Units

V

BOOTV

FET Driver Supply

Voltage

18 V

V

DACOUT

5-Bit DAC Output

Voltage

VID4:0=01111 1.284 1.304 1.324

V

VID4:0=01101 1.385 1.406 1.427

VID4:0=01011 1.483 1.506 1.529

VID4:0=01001 1.585 1.609 1.633

VID4:0=00111 1.683 1.709 1.735

VID4:0=00101 1.784 1.811 1.838

VID4:0=00001 1.983 2.013 2.043

VID4:0=11101 2.173 2.206 2.239

VID4:0=11010 2.471 2.509 2.547

VID4:0=10111 2.768 2.81 2.852

∆V

OUT

DC Load Regulation I

OUT

=0 to 14A

Figure 2

−5

mV

DC Line Regulation V

IN

=4.75V to 5.25V

Figure 2

1

G

EA

Error Amplifier DC Gain 85 dB

SR

EA

Error Amplifier Slew

Rate

6 V/µs

BW

EA

Error Amplifier Unity

Gain Bandwidth

5 MHz

I

Q_V

CC

Operating VCCCurrent OUTEN=VCC=5V, VID=10111 1.5 2.5 4

mA

Shutdown V

CC

Current OUTEN Floating, VID0:4 Floating 1 1.5 3

I

Q_BOOTV

BOOTV Pin Quiescent

Current

BOOTV=12V, OUTEN=0, VID0:4

Floating

4µA

D

MAX

Maximum Duty Cycle 90

%

D

MIN

Minimum Duty Cycle 0

%

R

SENSE

SENSE Pin Resistance

to Ground

7 11.5 16 kΩ

R

DS_SRC

FET Driver

Drain-Source ON

Resistance when

Sourcing Current

BOOTV=5V

7 Ω

R

DS_SINK

FET Driver

Drain-Source ON

Resistance when

Sinking Current

(Independent of BOOTV Voltage)

1.7 Ω

f

OSC

Oscillator Frequency RFA=84kΩ 250 300 350

kHzR

FA

=22kΩ 1000

R

FA

= 10.5 kΩ 2000

I

MAX

IMAX Pin Sink Current V

IMAX

= 5V, V

IFB

= 6V, VCC=5V 130 180 230 µA

LM2636

www.national.com 4

Page 5

Electrical Characteristics (Continued)

VCC= 5V unless otherwise indicated under the Conditions column. Typicals and limits appearing in plain type apply for TA=

TJ= +25˚C. Limits appearing in boldface type apply over 0˚C to +70˚C.

Symbol Parameter Conditions Min Typ Max Units

V

OUTEN_IH

OUTEN Pin Input Logic

Low to Logic High Trip

Point

OUTEN Voltage

↑

3.5 3.0 V

V

OUTEN_IL

OUTEN Pin Input Logic

High to Logic Low Trip

Point

OUTEN Voltage

↓

1.8 1.5 V

V

REF

Band Gap Reference I

VREF

=0mA 1.225 1.256 1.287 V

V

REF_LOAD

Reference Voltage at

Full Load

I

VREF

= 0.5 mA, Sourcing

1.223 1.254 1.285 V

V

REF_525

Reference Voltage at

High Line

I

VREF

= 0 mA, VCC= 5.25V

1.226 1.257 1.288 V

V

REF_475

Reference Voltage at

Low Line

I

VREF

= 0 mA, VCC= 4.75V

1.224 1.255 1.286 V

∆V

REF_LOAD

Reference Voltage

Load Regulation

I

VREF

= 0.5 mA, Sourcing

−2 mV

∆V

REF_LINE

Reference Voltage Line

Regulation

I

VREF

= 0 mA, VCCChanges from

5.25V to 4.75V

−0.5 mV

V

SAWL

Ramp Signal Valley

Voltage

1.25 V

V

SAWH

Ramp Signal Peak

Voltage

3.25 V

V

PWRBAD_GD

PWRGD Pin↓Trip

Points (see Pin

Description for Pin 13)

%

above DAC Output Voltage, when

Output Voltage

↑

10

%

%

below DAC Output Voltage, when

Output Voltage

↓

−10

V

PWRGD_BAD

PWRGD Pin↑Trip

Points (see Pin

Description for Pin 13)

%

above DAC Output Voltage, when

Output Voltage

↓

8

%

%

below DAC Output Voltage, when

Output Voltage

↑

−8

V

OVP

Over-voltage Protection

Trip Point

%

above DAC Output Voltage

15

%

t

PWRGD

Power Good Response

Time

V

SENSE

Rises from 0V to Rated

V

OUT

2 6 15 µs

t

PWRBAD

Power Not Good

Response Time

V

SENSE

Falls from Rated V

OUT

to 0V

2 6 15 µs

I

OUTEN

OUTEN Pin Internal

Pull-Up Current

60 90 130 µA

V

VID_IH

VID Pins Logic High

Trip Point

3.5 3.0 V

V

VID_IL

VID Pins Logic Low

Trip Point

1.8 1.3 V

I

VID

VID0:4 Internal Pull-Up

Current

60 90 130 µA

t

SS

Soft Start Duration

2048

clock

cycles

Note 1: Absolute Maximum Ratings are limits beyond which damage to the device may occur.Recommended Operating Conditions are conditions under which

the device operates correctly. Recommended Operating Conditions do not imply guaranteed performance limits.

Note 2: Maximum allowable DC power dissipation is a function of the maximum junction temperature, T

JMAX

, the junction-to-ambient thermal resistance, θJA, and

the ambient temperature, T

A

. The maximum allowable power dissipation at any ambient temperature is calculated using:

The junction-to-ambient thermal resistance, θJA, for LM2636 in the M20B package is 88˚C/W, and 120˚C/W for the MTC20 package.

LM2636

www.national.com5

Page 6

Electrical Characteristics (Continued)

Note 3: All pins are rated for 2 kV, except for the I

MAX

pin (Pin 7) which is rated for 1.5 kV.

Block Diagram

Test Circuit

DS100834-2

DS100834-4

FIGURE 2.

LM2636

www.national.com 6

Page 7

Applications Information

OVERVIEW

The LM2636 is a high speed synchronous PWM buck regulator controller designed for VRM vendors or motherboard

manufacturers who need to build on-board power supplies

for Cyrix MII, Pentium II or Deschutes microprocessors. It

has a built-in 5-bit DAC to decode the 5-bit word provided by

the CPU and supply the corresponding voltage. It also has

the power good (PWRGD) and output enable (OUTEN) functions required by the VRM specification. It employs a voltage

mode control scheme plus two fast responding comparators

to quickly respond to large load transients. It has two fast

FET drivers to drive the high-side and low-side NMOS

switches of a synchronous buck regulator. The PWM frequency is adjustable from 50 kHz to 1 MHz through an external resistor. Over-voltage protection is achieved by shutting

off the high-side driver and turning on the low-side driver

100%of the time. Current limiting is implemented by sensing

V

DS

of the high-side NMOS switch and shutting it off for the

present switching cycle when an over current condition is detected. Soft start functionality is realized through an internal

digital counter and an internal DAC.

THEORY OF OPERATION

Start Up

When V

CC

voltage exceeds 4.2V,OUTEN pin is a logic high

and the VID code is valid, the soft start circuitry starts to

work. The duration of the soft start is determined by an internal digital counter and the switching frequency. During soft

start, the output of the error amplifier is allowed to increase

gradually.When the counter has counted 2,048 clock cycles,

the soft start session ends and the output voltage level of the

error amplifier is released and allowed to go to a value that is

determined by the feedback loop. PWRGD pin is forced low

during soft start and is turned over to output voltage monitoring circuitry after that. Before V

CC

reaches 4.2V, all internal

logic is in a power on reset state and the two FET drivers are

disabled.

During normal operation, if V

CC

voltage drops below 3.8V,

the internal circuitry will go into power on reset again. The

hysteresis helps decrease the noise sensitivity on the V

CC

pin. After soft starts ends and during normal operation, if the

converter output voltage exceeds 115%of the DAC output

voltage, the LM2636 will lock into over voltage protection

mode. The high side drive will be disabled, and the low side

drive will be high. There are two ways to clear the mode. One

is to cycle V

CC

voltage once. The other is to toggle the

OUTEN level. After the over voltage protection mode is

cleared, the LM2636 will enter the soft start session and start

over.

Normal Operation

During the normal operation mode, the LM2636 regulates

the converter output voltage by adjusting the duty ratio. The

output voltage is determined by the 5-bit VID code set by the

user/load.

The PWM frequency is set by the external resistor between

FREQ_ADJ pin and ground. The resistance needed for a desired switching frequency is:

For example, if the desired switching frequency is 300 kHz,

the resistance should be around 84 kΩ.

The minimum allowable PWM frequency is 5 kHz.

MOSFET Gate Drive

The LM2636 has two gate drives that are suitable for driving

external N-MOSFETs in a synchronous buck topology. The

power for the two FET drivers is supplied by the BOOTV pin.

This BOOTV voltage needs to be at least one V

GS(th)

higher

than the converter input voltage for the high side FET to be

fully turned on. The voltage can be either supplied from

a separate source other than the input voltage or can be

generated locally by utilizing a charge pump structure. In a

typical desktop microprocessor application, if 5V is chosen

to be the input voltage, then 12V can be used for the

BOOTV. If 12V is not available, a simple charge pump circuitry consisting of a diode and a small capacitor can be

used, as shown in

Figure 3

.

When the low side FET is on, the charge pump capacitor is

charged to near the input voltage through the diode. When

low side FET is turned off, the high side FET driver is enabled, and the charge pump capacitor starts to charge the

high side FET gate until it is fully on. By this time the high

side FET source node will fly to close to input voltage level

and the upper node of the capacitor will also fly to one input

voltage higher than the input voltage, enabling the high side

FET driver to continue working.

For a BOOTV of 12V, the initial gate charging current is typically 2A, and the initial gate discharging current is typically

6A, good for high speed switching.

The LM2636 gate drives are of BiCMOS design. Unlike

some other bipolar VRM control ICs, the gate drive has railto-rail swing that ensures no spurious turn-on due to capacitive coupling.

Another feature of the FET gate drives is the adaptive nonoverlapping mechanism. A gate driver is not turned on until

the other is fully off. The dead time in between is typically 20

ns. This avoids the potential shoot-through problem and

helps improve efficiency.

Load Transient Response

In a typical modern MPU application such as the Pentium II

core voltage power supply, load transient response is a critical issue. The LM2636 utilizes the conventional voltage

feedback technology as the primary feedback control

method. When the load transient happens, the error in the

output voltage level is fed to the error amplifier. The output of

DS100834-6

FIGURE 3. BOOTV Voltage Supplied by a Charge Pump

LM2636

www.national.com7

Page 8

Applications Information (Continued)

the error amplifier is then compared with an

internally generated PWM ramp signal and the result of the

comparison is a series of pulses with certain duty ratios.

These pulses are used to control the turn-on and turn-off of

the MOSFET gate drivers. In this way, the error in the output

voltage gets “compensated” or cancelled by the change in

the duty ratio of the FET switches. During a large load transient, depending on the compensation design, the change in

duty ratio can be as fast as less than one switching cycle.

Refer to Design Considerations section for more details.

Besides the usual voltage mode feedback control loop, the

LM2636 also has a pair of fast comparators (the MIN and

MAX comparators) to help maintain the output voltage during a large and fast load transient. The trip points of the comparators are set to

±

5%of the DAC output voltage. When

the load transient is so large that the output voltage goes

outside the

±

5%window, the MIN or MAX comparator will

bypass the primary voltage control loop and immediately set

the duty ratio to either maximum value or to zero. This provides the fastest possible way to react to such a large load

transient in a classical buck converter.

Power Good Signal

The power good signal is used to indicate that the output

voltage is within specified range. In the LM2636, the range is

set to a

±

10%window of the DAC output voltage. During soft

start, the power good signal is always low.At the end of the

soft start session,the output voltage is checked and the

PWRGD pin will be asserted if the voltage is within specified

range.

Over Voltage Protection

When the output voltage exceeds 115%of the DAC output

voltage after the end of soft start, the LM2636 will enter over

voltage protection mode in which it shuts itself down. The upper gate driver is held low while the lower gate driver is held

high. PWRGD will be low. For LM2636 to recover from OVP

mode, either OUTEN or V

CC

voltage has to be toggled. Another more subtle way to recover is to float all the VID pins

and reapply the correct code.

Current Limit

Current limit is realized by sensing the V

DS

voltage of the

high side MOSFET when it is on. Since the r

DS_ON

of a

MOSFET is a known value, current through the MOSFET

can be known by monitoring V

DS

. The relationship between

the three parameters is:

To implement the current limit function, an external resistor

R

IMAX

is need. The resistor should be connected between

the drain of the high side MOSFET and the IMAX pin. A constant current of around 180 µA is forced into the IMAX pin

and causes a fixed voltage drop across the R

IMAX

resistor.

This voltage drop is then compared with the V

DS

of the high

side MOSFET and if the latter is higher, over current is

reached. So the appropriate value of R

IMAX

for a predetermined current limit level I

LIM

can be calculated by the

following equation:

For example, if we know that the r

DS_ON

of the MOSFET is

20 mΩ, and the current limit we want to set is 20A, then we

should choose the value of R

IMAX

to be 2.2 kΩ.

To provide the greatest protection over the high side MOSFET, cycle by cycle protection is implemented. The sampling

of the V

DS

starts as early as about 300 ns after the switch is

turned on. Whenever an over current condition is detected,

the high side switch is immediately turned off and the low

side switch turned on, until the next switching cycle comes.

The delay of 300 ns is to circumvent switching noise when

the MOSFET is first turned on.

DESIGN CONSIDERATIONS

Control Loop Compensation

A switching regulator should be properly compensated to

achieve a stable condition. For a synchronous buck regulator that needs to meet stringent load transient requirement

such as a Pentium II MPU core voltage supply, a simple

2-pole-1-zero compensation network should suffice, such as

the one shown in

Figure 4

(C1,C2,R1and R2). This is because the ESR zero of the typical output capacitors is low

enough to make the control-to-output transfer function a

single-pole-roll-off.

As an example, let us figure out the values of the compensation network components in

Figure 4

. Assume the following

parameters:R=20Ω,R

L

=20mΩ,RC=9mΩ,L=2µH,

C = 7.5 mF, V

IN

=5V,Vm= 2V and switching frequency

= 300 kHz. These parameters are based on the typical application in

Figure 1

. Notice RLis the sum of the inductor DC re-

sistance and the on resistance of the MOSFETs.

DS100834-9

FIGURE 4. Buck Converter from a Control Point of

View

LM2636

www.national.com 8

Page 9

Applications Information (Continued)

The control-to-output transfer function is

The ESR zero frequency is:

The power stage double pole frequency is:

The corresponding Bode plots are shown in

Figure 5

.

Since the ESR zero frequency is so low,it effectively cancels

the phase shift from one of the power stage poles. This limits

the total phase shift to 90%.

Although this regulator design is stable (phase shift is

<

90˚

when gain=0dB), it needs compensation to improve the DC

gain and cut off frequency (0dB frequency). Otherwise, the

low DC gain may cause a poor line regulation, and the low

cutoff frequency will hurt transient response performance.

The transfer function for the 2-pole-1-zero compensation

network shown in

Figure 4

is:

where

One of the poles is located at origin to help achieve the highest DC gain. So there are three parameters to determine, the

position of the zero, the position of the second pole, and the

constant A. To determine the cutoff frequency and phase

margin, the loop bode plots need to be generated. The loop

transfer function is:

TF = −TF1 x TF2

By choosing the zero close to the double pole position and

the second pole to half of the switching frequency,the closed

loop transfer function turns out to be very good.

That is, if f

Z

= 1.32 kHz, fP= 153 kHz, and A = 4.8 x 10−6ΩF,

then the cutoff frequency will be 50 kHz, the phase margin

will be 72˚, and the DC gain will be that of the error amplifier.

See

Figure 6

below.

The compensation network component values can be determined by the following equations:

Notice there are three equations but four variables. So one

of the variables can be chosen arbitrarily. Since the current

driving capability of the error amplifier is limited to around

3 mA, it is a good idea to have a high impedance path from

the output of the error amplifier to the output of the converter.

From the above equations it can be told that a larger R

2

will

DS100834-13

FIGURE 5. Control-to-Output Bode Plots

DS100834-17

FIGURE 6. Loop Bode Plots

LM2636

www.national.com9

Page 10

Applications Information (Continued)

result in a smaller C

1,C2

and a larger R1. However, too large

an R

1

can also bring error due to the bias current required by

the inverting input pin of the error amplifier. Calculations

show that the following combination is a good one: R

2

=51Ω,

C

1

= 0.022 µF, R1= 5.6 kΩ,C2= 820 pF.

For a different application or different type of output capacitors, a different compensation scheme may be necessary.

The user can either follow the steps above to figure the appropriate component values or contact the factory for help.

MOSFET SELECTION

The selection of MOSFET switches affects both the efficiency of the whole converter and the current limit setting.

From an efficiency point of view it is suggested that for the

high-side switch, only logic level MOSFETs be used. Standard MOSFETs can be used for the low side switch when

12V is used to power the BOOTV pin. The lower loss associated with the MOSFETs is two-fold—Ohmic loss and

switching loss. The Ohmic loss is easy to calculate whereas

the switching loss is much more difficult to estimate. In general the switching loss is directly proportional to the switching

frequency. As the power MOSFET technology advances,

lower and lower gate charge devices will be available. That

should allow the user to go to higher switching frequencies

without the penalty of losing too much efficiency.

As an example, let us select the MOSFETs for a converter

with a target efficiency of 80%at a load of 2.8V, 14A. Assume the inductors lose 1W, the capacitors lose 0.75W and

the total switching loss at 300 kHz is 3.2W. The total allowed

power loss is 9.8W, so the MOSFET Ohmic loss should not

exceed 4.9W. Assume the two switches have the same conduction loss, i.e., 2.5W each, then the ON resistance for the

two switches is:

The low side switch ON resistance is much higher than the

high side because at 2.8V the duty cycle is higher than 50

%

and becomes even larger at full load. For the high side

switch, an IRL3202 (TO-220 package) or IRL3202S (D

2

PAK)

should be sufficient. For the low side switch, an IRL3303

(TO-220 package) or IRL3303S (D

2

PAK) should be sufficient. Since each FET is dissipating 3.2W/2 + 2.5W = 4.1W,

it is suggested that appropriate heat sinks be used in the

case of TO-220 package or large enough copper area be

connected to the drain in the case of surface mount package.

CAPACITOR SELECTION

The selection of capacitors is an extremely important step

when designing a converter for a load such as the

Pentium II. Since the typical slew rate of the load current during a large load transient is around 20A/µs to 30A/µs, the

switching converter has to rely on the output capacitors to

take care of the first few microseconds. Under such a current

slew rate, ESR of the output capacitors is more of a concern

than the ESL. Depending on the kind of capacitors being

used, capacitance of the output capacitors may or may not

be an important factor. When the output capacitance is too

low, the converter may have to have a small output inductor

to quickly supply current to the output capacitors when the

load suddenly kicks in and to quickly stop supplying current

when the load is suddenly removed.

Multilayer ceramic (MLC) capacitors can have very low ESR

but also a low capacitance value compared to other kinds of

capacitors. Low ESR aluminum electrolytic capacitors tend

to have large sizes and capacitances. Tantalum electrolytic

capacitors can have a fairly low ESR with a much smaller

size and capacitance than the aluminum capacitors. Certain

OSCON capacitors present ultra low ESR and long life span.

By the time the total ESR of the output capacitor bank

reaches around 9 mΩ, the capacitance of the aluminum/

tantalum/OSCON capacitors is usually already in the millifarad range. For those capacitors, ESR is the only factor to

consider.MLCs can have the same amount of total ESR with

much less capacitance, most probably under 100 µF.A very

small inductor, ultra fast control loop and a high switching

frequency become necessary in such a case to deal with the

fast charging/discharging rate of the output capacitor bank.

From a cost savings point of view, aluminum electrolytic capacitors are the most popular choice for output capacitors.

They have reasonably long life span and they tend to have

huge capacitance to withstand the charging or discharging

process during a load transient for a fairly long period. Sanyo

MV-GX series gives good performance when enough of the

capacitors are paralleled. The 6MV1500GX capacitor has a

typical ESR of 44 mΩ. Five of these capacitors should be

sufficient in the case of on-board power supply for a Pentium

II motherboard.

The challenge for input capacitors is the ripple current. The

large ripple current drawn by the high side switch tends to

generate quite some heat due to the capacitor ESR. The

ripple current ratings in the capacitor catalogs are usually

specified under the highest allowable temperature. In the

case of desktop applications, those ratings seem too conservative.Agood way to ensure enough number of capacitors is

through lab evaluation. The input current RMS ripple value

can be determined by the following equation:

and the power loss in each input capacitor is:

In the case of Pentium II power supply, the maximum output

current is around 14A. Under the worst case when duty cycle

is 50%, the maximum input capacitor RMS ripple current is

half of output current, i.e., 7A. It is found that three Sanyo

16MV820GX capacitors are enough under room temperature. The typical ESR of those capacitors is 44 mΩ.Sothe

power loss in each of them is around (7A)

2

x44mΩ/32=

0.24W. Note that the power loss in each capacitor is inversely proportional to the square of the total number of capacitors, which means the power loss in each capacitor

quickly drops when the number of capacitors increases.

INDUCTOR SELECTION

The size of the output is determined by a number of parameters. Basically the larger the inductor, the smaller the output

ripple voltage, but the slower the converter’s response

speed during a load transient. On the other hand, a smaller

inductor requires higher switching frequency to maintain the

same level of output ripple, and probably results in a more

lossy converter, but has less inertia responding to load tran-

LM2636

www.national.com 10

Page 11

Applications Information (Continued)

sient. In the case of Pentium II power supply, fast recovery of

the load voltage from transient window back to the steady

state window is considered important. This limits the highest

inductance value that can be used. The lowest inductance

value is limited by the highest switching frequency that can

be practically employed. As the switching frequency increases, the switching loss in the MOSFETs tends to increase, resulting in less converter efficiency and larger heat

sinks. A good switching frequency is probably a frequency

under which the MOSFET conduction loss is higher than the

switching loss because the cost of the MOSFET is directly

related to its R

DSON

. The inductor size can be determined by

the following equation:

where V

O_RIP

is the peak-to-peak output ripple voltage, f is

the switching frequency. For commonly used low R

DSON

MOSFETs, a reasonable switching frequency is 300 kHz. Assume an output peak-peak ripple voltage of 18 mV is to be

guaranteed, the total output capacitor ESR is 9 mΩ, the input

voltage is 5V, and output voltage is 2.8V. The inductance

value according to the above equation will then be 2 µH. The

highest slew rate of the inductor current when the load

changes from no load to full load can be determined as follows:

where D

MAX

is the maximum allowed duty cycle, which is

around 0.9 for LM2636. For a load transient from 0A to 14A,

the highest current slew rate of the inductor, according to the

above equation, is 0.85A/µs, and therefore the shortest possible total recovery time is 14A/(0.85A/µs) = 16.5 µs. Notice

that the output voltage starts to recover whenever the inductor starts to supply current.

The highest slew rate of the inductor current when the load

changes from full load to no load can be determined from the

same equation, but use D

MIN

instead of D

MAX

.

Since the D

MIN

of LM2636 at 300 kHz is 0%, the slew rate is

therefore −1.4A/µs. So the approximate total recovery time

will be 14A/(1.4A/µs) = 10 µs.

The input inductor is for limiting the input current slew rate

during a load transient. In the case that low ESR aluminum

electrolytic capacitors are used for the input capacitor bank,

voltage change due to capacitor charging/discharging is usually negligible for the first 20 µs. ESR is by far the dominant

factor in determining the amount of capacitor voltage

undershoot/overshoot due to load transient. So the worst

case is when the load changes between no load and full

load, under which condition the input inductor sees the highest voltage change across the input capacitors. Assume the

input capacitor bank is made up of three 16MV820GX, i.e.,

the total ESR is 15 mΩ. Whenever there is a sudden load

current change, it has to initially be supported by the input

capacitor bank instead of the input inductor.So for a full load

swing between 0A and 14A, the voltage seen by the input inductor is ∆V=14Ax15mΩ= 210 mV. Use the following

equation to determine the minimum inductance value:

where (di/dt)

MAX

is the maximum allowable input current

slew rate, which is 0.1A/µs in the case of the Pentium II

power supply. So the input inductor size, according to the

above equation, should be 2.1 µH.

DYNAMIC POSITIONING OF LOAD VOLTAGE

Since the Intel VRM specifications have defined two operating windows for the MPU core voltage, one being the steady

state window and the other the transient window, it is a good

idea to dynamically position the steady state output voltage

in the steady state window with respect to load current level

so that the output voltage has more headroom for load transient response. This requires information about the load current. There are at least two simple ways to implement this

idea with LM2636. One is to utilize the output inductor DC resistance, see

Figure 7

. The average voltage across the output inductor is actually that across its DC resistance. That

average voltage is proportional to load current.

Since the switching node voltage V

A

bounces between the

input voltage and ground at the switching frequency, it is impossible to choose point A as the feedback point, otherwise

the dynamic performance will suffer and the system may

have some noise problems. Using a low pass filter network

around the inductor, such as the one shown in the figure,

seems to be a good idea. The feedback point is C.

Since at the switching frequency the impedance of the 0.1

µF is much less than 5 kΩ, the bouncing voltage at point A

will be mainly applied across the resistor 5 kΩ, and point C

will be much quieter thanA. However, V

CB

average is still the

majority of V

AB

average, because of the resistor divider. So

in steady state V

C=IOxrL+VCORE

, where rLis the inductor

DC resistance. So at no load, output voltage is equal to V

C

,

and at full load, output voltage is I

OxrL

lower than VC. Tofurther utilize the steady state window, a resistor can be connected between the FB pin and ground to increase the no

load output voltage to close to the upper limit of the window.

DS100834-26

FIGURE 7. Dynamic Voltage Positioning by Utilizing

Output Inductor DC Resistance

LM2636

www.national.com11

Page 12

Applications Information (Continued)

A possible drawback of the scheme in

Figure 7

is slow transient recovery speed. Since the 5 kΩresistor and the 0.1 µF

capacitor have a large time constant, the settling of point C

to its steady state value during a load transient may take a

few milliseconds. Depending on the interaction between the

compensation network and the 0.1 µF capacitor, V

core

may

take different routes to reach its steady state value. This is

undesired when the load transients happens more than 1000

times per second. Reducing the time constant will result in a

more fluctuating V

C

due to a less effective low pass filter.

Fine tuning the parameters may balance the tradeoffs.

Another way to implement the dynamic voltage positioning is

through the use of a stand-alone resistor, such as the 4 mΩ

resistor in

Figure 8

above. The advantage of this implemen-

tation over the previous one is a much faster speed of V

CORE

from transient level to steady state level. The disadvantage

is less efficiency. The total power loss can be 0.78W at 14A

of load current. The cost of the resistor can be minimized by

implementing it through a PCB trace.

REFERENCE VOLTAGE

The V

REF

pin can have many uses, such as in the watchdog

circuitry and in an LDO controller.

Figure 9

shows an applica-

tion where V

REF

is used to build a N-FET LDO controller.An

appropriate compensation network is necessary to tailor the

dynamic performance of the whole power supply.

PCB LAYOUT CONSIDERATIONS

There are several points to consider.

1. Try to use 2 oz. copper for the ground plane if tight load

regulation is desired. In the case of dynamic voltage positioning, this may not be a concern because the loose

load regulation is desired anyway. However, do not forget to take into consideration the voltage drop caused by

the ground plane when calculating dynamic voltage positioning parameters.

2. Try to keep gate traces short. However, do not make

them too short or else the LM2636 may stay too close to

the MOSFETs and get heated up by them. For the same

reason, do not use wide traces, 10 mil traces should be

enough.

3. When not employing dynamic voltage positioning, place

the feedback point at the VRM connector pins to have a

tight load regulation. If it is an on-board power supply,

place the feedback point at Slot I connector or wherever

is closest to the MPU.

4. Start component placement with the power devices such

as MOSFETs and inductors.

5. Do not place the LM2636 directly underneath the MOS-

FETs when when surface mount MOSFETs are used.

6. If possible, keep the capacitors some distance away

from the inductors so that the capacitors will have a

lower temperature environment.

7. When implementing dynamic voltage positioning

through a PCB trace, be aware that the PCB trace is a

heat source and try to avoid placing the trace directly underneath the LM2636.

DS100834-27

FIGURE 8. Dynamic Voltage Positioning by Using A

Stand-Alone Resistor

DS100834-28

FIGURE 9. V

REF

Used in an N-FET LDO Supply

LM2636

www.national.com 12

Page 13

Physical Dimensions inches (millimeters) unless otherwise noted

20-Lead Plastic SO Package

Order Number LM2636M

NS Package Number M20B

LM2636

www.national.com13

Page 14

Physical Dimensions inches (millimeters) unless otherwise noted (Continued)

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

labeling, can be reasonably expected to result in a

significant injury to the user.

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80-532 78 32

Français Tel: +49 (0) 1 80-532 93 58

Italiano Tel: +49 (0) 1 80-534 16 80

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

www.national.com

20-Lead Plastic TSSOP (MTC)

Order Number LM2636MTC

NS Package Number MTC20

LM2636 5-Bit Programmable Synchronous Buck Regulator Controller

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...