Page 1

LM2630

Synchronous Step-Down Power Supply Controller

General Description

The LM2630 controller provides all the active functions for

step-down (buck)switching converters. These dc-to-dc converters provide core CPU power in battery-operated systems.

High efficiency is achieved by using synchronous rectification and pulse-skipping mode operation at light load. Inexpensive N-channel MOSFETs are used to reduce system

cost. Bootstrap circuit is used to drive the high-side

N-channel MOSFET.

Current mode control schemeis used to improve line regulation and transient response, also provides cycle-by-cycle

current limiting.

The operating frequency is adjustable between 200 kHz and

400 kHz. An external shutdown pin can be used to disable

the device and reducethe quiescent current to 0.1µA. In low

noise applications, bringing theFPWMpin high can force the

device to operate in constant frequency mode. Other features include the external synchronization pin, and the

PGOOD pin to indicate the state of the output voltage.

Protection circuitry includesthermal shutdown, undervoltage

shut down, soft-startcapability,and two levelsof current limits: The first levelsimply limits the load currentdirectly; at the

second level, if the load pulls the output voltage down below

80%of the regulated value, the chip willshut down. This

latched operation is disabled during startup, but an internal

timer will enable it if the outputdoes not come up in the preset time.

Features

n 4.5V to 30V input range

n Adjustable output (1.8V to 6V)

n 200 kHz to 400 kHz adjustable operating frequency

n Externally synchronizable

n On-board power good function

n Precision 1.24V reference output

n 0.8 mA typical quiescent current

n 0.1 µA shutdown current

n Thermal shutdown

n Direct current limit protection

n Input undervoltage lockout

n Output Undervoltage shutdown protection

n Programmable soft-start function

n Tiny TSSOP package

Applications

n Notebook and subnotebook computers

n Cellular phones

n Portable instruments

n Battery-powered digital devices

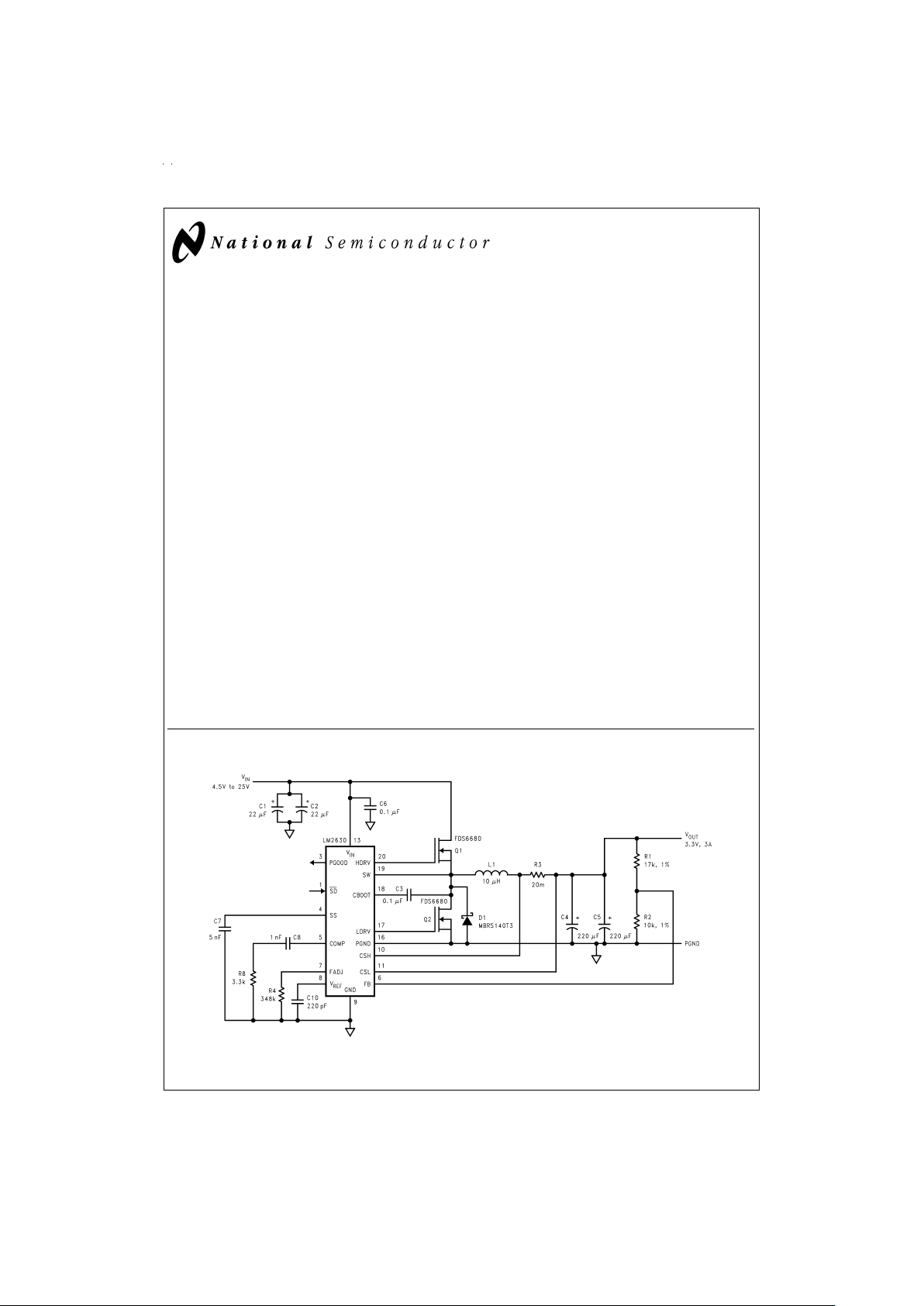

Typical Application Circuit

DS100120-1

February 1999

LM2630 Synchronous Step-Down Power Supply Controller

© 1999 National Semiconductor Corporation DS100120 www.national.com

Page 2

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the NationalSemiconductorSales Office/

Distributors for availability and specifications.

Voltages from the indicated

pins to GND and PGND:

V

IN

−0.3V to 31V

CBOOT −0.3V to 36V

SD

−0.3V to 31V

SW −0.3V to 31V

CSH, CSL −0.3V to 7V

FPWM, SYNC −0.3V to 10V

Power Dissipation (T

A

=

70˚C), (Note 2)

720mW

Storage Temperature Range −65˚C to +150˚C

Soldering Dwell Time,

Temperature (Note 3)

Wave 4 sec, 260˚C

Infrared 10 sec, 240˚C

Vapor Phase 75 sec, 219˚C

ESD Rating (Note 4) 1.5 kV

Operating Ratings

V

IN

4.5V to 30V

Junction Temperature −40˚C to +125˚C

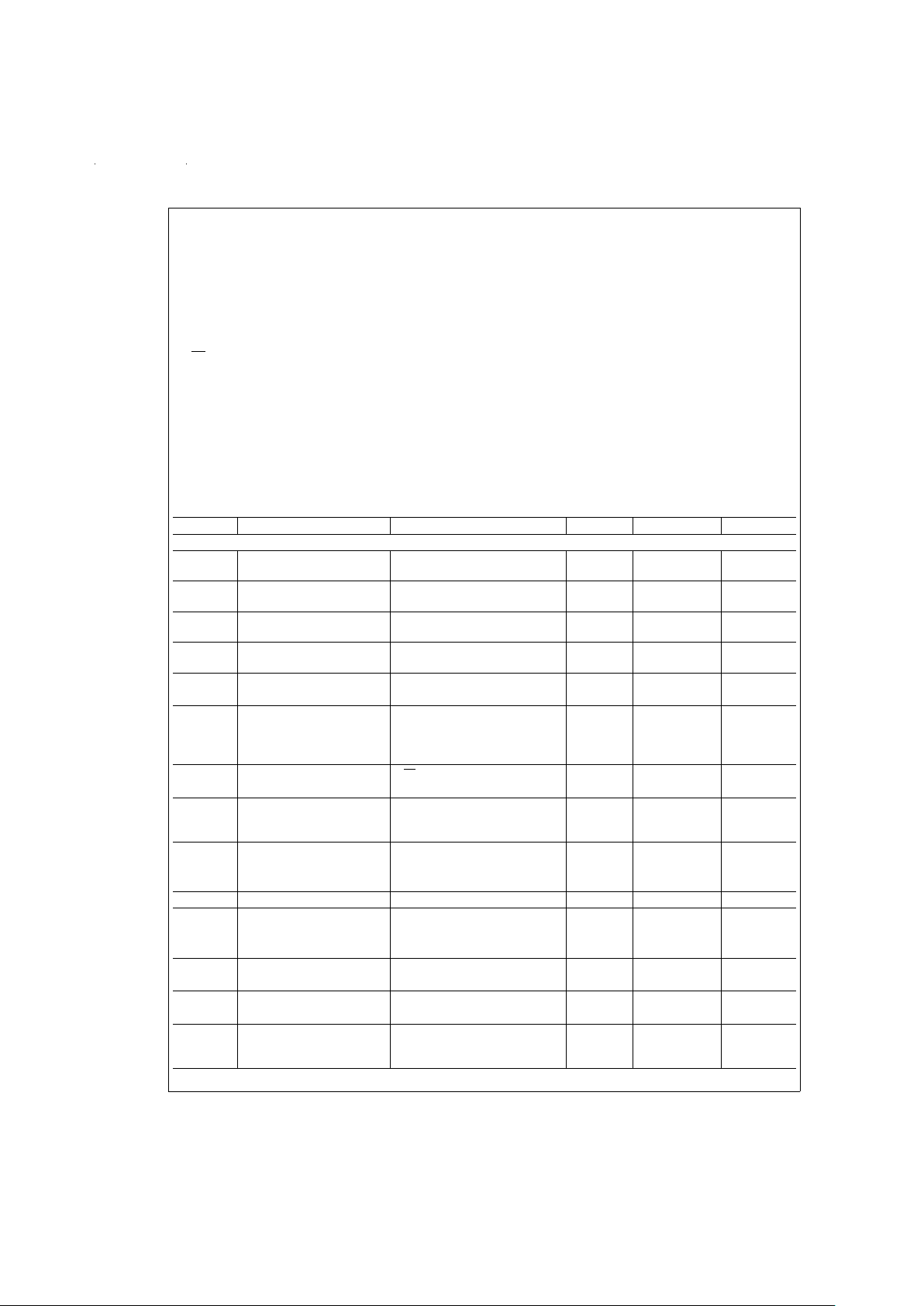

Electrical Characteristics

Specifications in standard type face are for T

j

=

25˚C and those with boldface type apply over full operating junction tem-

perature range. V

IN

=

10V, GND=PGND=0V,unless otherwise stated. (Notes 5, 6)

Symbol Parameter Conditions Typical Limit Units

System

V

IN

Input Supply Voltage 4.5

30

V(min)

V(max)

V

OUT

Output Voltage Adjustment

Range

1.8

6.0

V(min)

V(max)

∆V

OUT

/

V

OUT

Load Regulation 0 mV ≤ (CSH-CSL) ≤ 75 mV

0.3

%

∆V

OUT

/

V

OUT

Line Regulation 4.5 ≤ VIN≤ 30V

0.002

%

/V

I

IN

Input Supply Current with the

Switching Controller ON

V

FB

=

1V, V

CSH

=

2.15V, V

CSL

=

2.1V

0.8 mA

1.2/1.4 mA(max)

Input Supply Current with the

Switching Controller ON

(Internal Rail is Supplied

from CSL Pin)

V

FB

=

1V, V

CSH

=

5.15V, V

CSL

=

5V

0.15 mA

Input Supply Current with the

IC Shut Down

V

SD

=

0V, V

IN

=

30V

0.1 µA

3 (Note 7) µA(max)

Minimum Output Voltage for

CSL Providing the Internal

Rail

3V

I

SS

Soft Start Source Current V

SS

=

1.5V 10 µA

5 µA(min)

13 µA(max)

Soft Start Sink Current V

SS

=

1.5V 20 µA

V

CL

Current Limit Voltage

(Voltage from CSH to CSL)

V

FB

=

1V, V

CSL

=

1.8V 110 mV

90/80 mV(min)

130/140 mV(max)

V

IN

Undervoltage Shutdown

Latch Threshold

Rising Edge 3.5 V

2.8 V(min)

V

OUT

Undervoltage

Shutdown Latch Threshold

80

%

V

OUT

65

%

V

OUT

(min)

V

OUT

Low Regulation

Comparator Enable

Threshold

97

%

V

OUT

www.national.com 2

Page 3

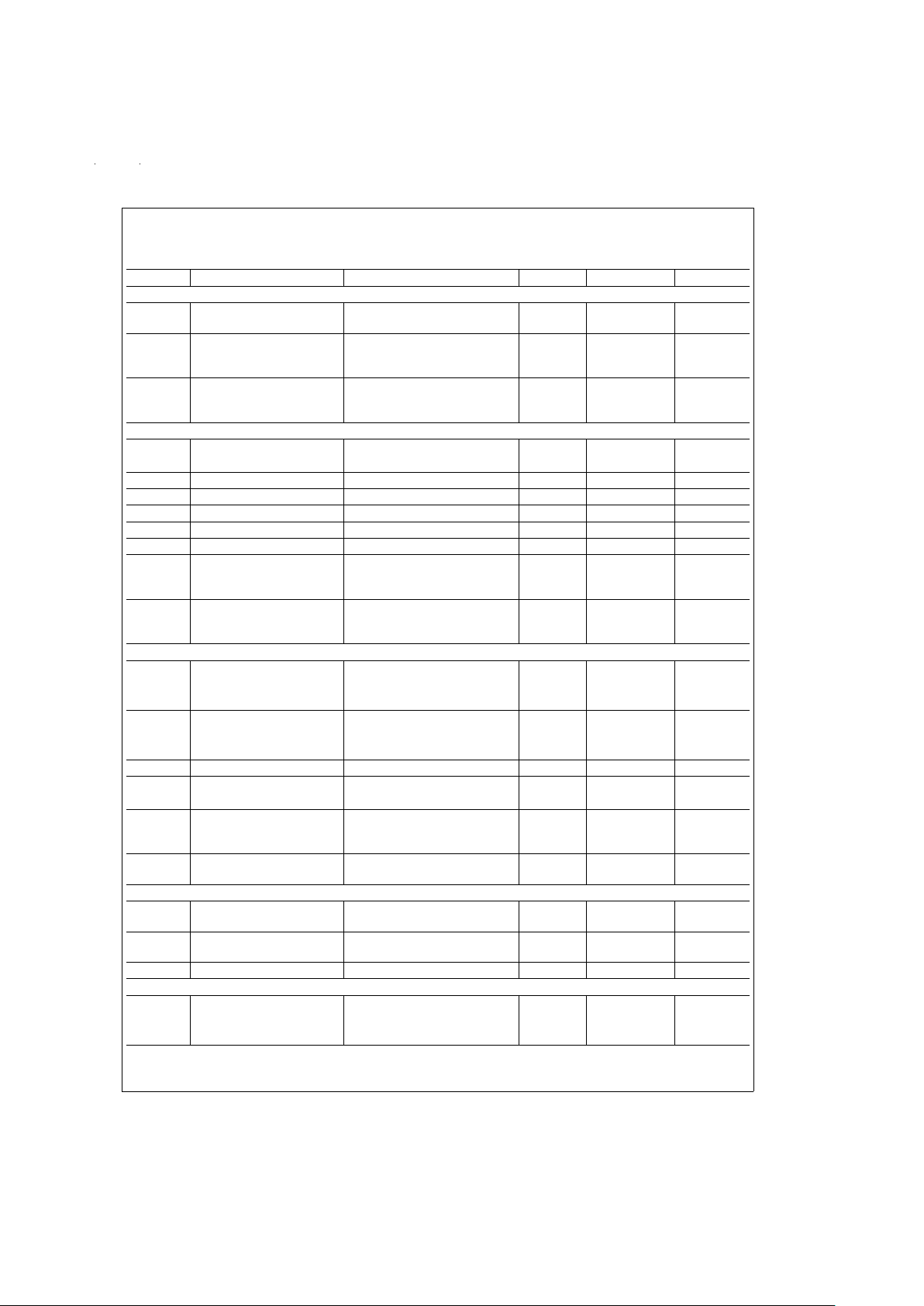

Electrical Characteristics (Continued)

Specifications in standard type face are for T

j

=

25˚C and those with boldface type apply over full operating junction tem-

perature range. V

IN

=

10V, GND=PGND=0V,unless otherwise stated. (Notes 5, 6)

Symbol Parameter Conditions Typical Limit Units

System

Hysteresis of Low Regulation

Comparator

2

%

V

OUT

Regulator Window Detector

Thresholds (PGOOD from

High to Low)

91 or 109

%

V

OUT

Regulator Window Detector

Thresholds (PGOOD from

Low to High)

97 or 103

%

V

OUT

Gate Drive

V

BOOT

Bootstrap Voltage (Voltage

from CBOOT to SW)

CBOOT Sourcing 100 µA 4.5 V

4.0 V(min)

I

BOOT

CBOOT Leakage Current V

CBOOT

=

7V 100 nA

High Drive Source Current V

HDRV

=

0V, V

CBOOT

=

5V 0.3 A

High Drive Sink Current HDRV Forced to 5V 0.45 A

Low Drive Source Current LDRV Forced to 0V 0.35 A

Low Drive Sink Current LDRV Forced to 5V 0.55 A

High-Side FET

On-Resistance HDRV or

LDRV

8 Ω

Low-Side FET

On-Resistance HDRV or

LDRV

4 Ω

Oscillator

F

OSC

Oscillator Frequency FADJ Open 200 kHz

172/162 kHz(min)

228/230 kHz(max)

Oscillator Frequency FADJ Sourcing 2.94 µA (Note 8) 300 kHz

255 kHz(min)

345 kHz(max)

V

FADJ

Voltage at FADJ pin 1.03 V

D

MAX

Maximum Duty Cycle FADJ Open 96

%

92

%

(min)

Maximum Frequency of

Synchronization

Low-Going 200 ns Wide

Rectangular Pulses Applied at

400 kHz at the SYNC Input

400 kHz(min)

Minimum Pulse Width of the

SYNC Signal

SYNC Pulses are Low-Going

200 ns(min)

Error Amplifier

I

FB

Feedback Input Bias Current V

FB

=

1.3V, V

CSH

=

5.15V, V

CSL

=

5V

100 nA

I

COMP

COMP Output Source

Current

V

COMP

=

0.2V, V

FB

=

1V

50 µA

COMP Output Sink Current V

COMP

=

1.2V, V

FB

=

1.4V 50 µA

Voltage Reference

V

REF

Reference Voltage

(Nominal))

I

REF

=

0µA 1.238 V

1.213/1.208 V(min)

1.263/1.268 V(max)

www.national.com3

Page 4

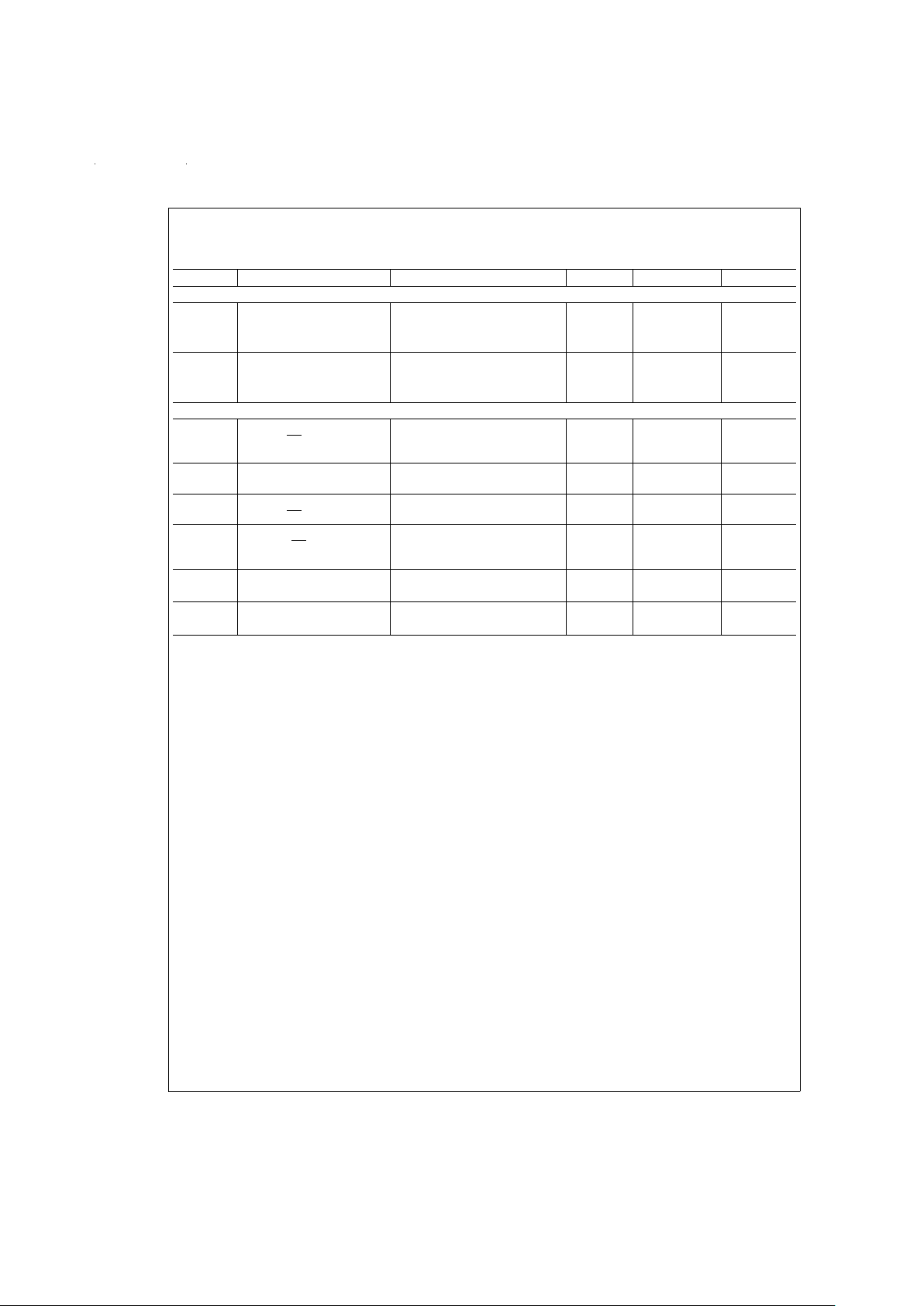

Electrical Characteristics (Continued)

Specifications in standard type face are for T

j

=

25˚C and those with boldface type apply over full operating junction tem-

perature range. V

IN

=

10V, GND=PGND=0V,unless otherwise stated. (Notes 5, 6)

Symbol Parameter Conditions Typical Limit Units

Voltage Reference

V

REF

Reference Voltage (Line

Regulation)

4.5V<V

IN

<

30V 1.238 V

1.213/1.208 V(min)

1.263/1.268 V(max)

Reference Voltage (Load

Regulation)

0µA

<

I

REF

<

50 µA 1.238 V

1.213/1.208 V(min)

1.263/1.268 V(max)

Logic Inputs and Outputs

V

IH

Minimum High Level Input

Voltage (SD, FPWM and

SYNC)

2.4 V(min)

V

IL

Maximum Low Level Input

Voltage (FPWM and SYNC)

0.8 V(max)

Maximum Low Level Input

Voltage (SD)

0.5

V(max)

Maximum Input Leakage

Curren1t (SD , FPWM and

SYNC)

Logic Input Voltage 0V or 5V

±

0.1 µA

V

OH

PGOOD High Level Output

Voltage

PGOOD Sourcing 50 µA 2.7 V

2.4 V(min)

V

OL

PGOOD Low Level Output

Voltage

PGOOD Sinking 50 µA 0 V

0.5 V(max)

Note 1: Absolute maximum ratings indicate limits beyond which damage to the device may occur. Electrical specifications do not apply when operating the device

outside of its rated operating conditions.

Note 2: The maximum allowable power dissipation is calculated by using P

Dmax

=

(T

Jmax-TA

)/θJA, where T

Jmax

is the maximum junction temperature, TAis the

ambient temperature, and θ

JA

is the junction-to-ambient thermal resistance of the specified package. The 720 mW rating results from using 160˚C, 70˚C, and

125˚C/W for T

Jmax,TA

, and θJArespectively.AθJAof 125˚C/W represents the worst-casecondition of no heat sinking of the 20-pinTSSOP. Heat sinking allows the

safe dissipation of more power. TheAbsoluteMaximumpowerdissipationmustbederatedby8 mW per ˚C above 70˚C ambient. The LM2630 actively limits its junction temperature to about 160˚C.

Note 3: For detailed information on soldering plastic small-outline packages, refer to the Packaging Databook available from National Semiconductor Corporation.

Note 4: For testing purposes, ESD was applied using the human-body model, a 100 pF capacitor discharged through a 1.5 kΩ resistor.

Note 5: A typical is the center of characterization data taken withT

A

=

T

J

=

25˚C. Typicals are not guaranteed.

Note 6: All limits are guaranteed. All electricalcharacteristicshavingroom-temperaturelimitsaretestedduringproduction with T

A

=

T

J

=

25˚C.All hot and cold limits

are guaranteed by correlating the electrical characteristics to process and temperature variations and applying statistical process control.

Note 7: This limit is guaranteed by design.

Note 8: Pulling 2.94 µA out of FADJ pin simulates adjusting the oscillator frequency with a 350 kΩ resistor connected from FADJ to GND.

www.national.com 4

Page 5

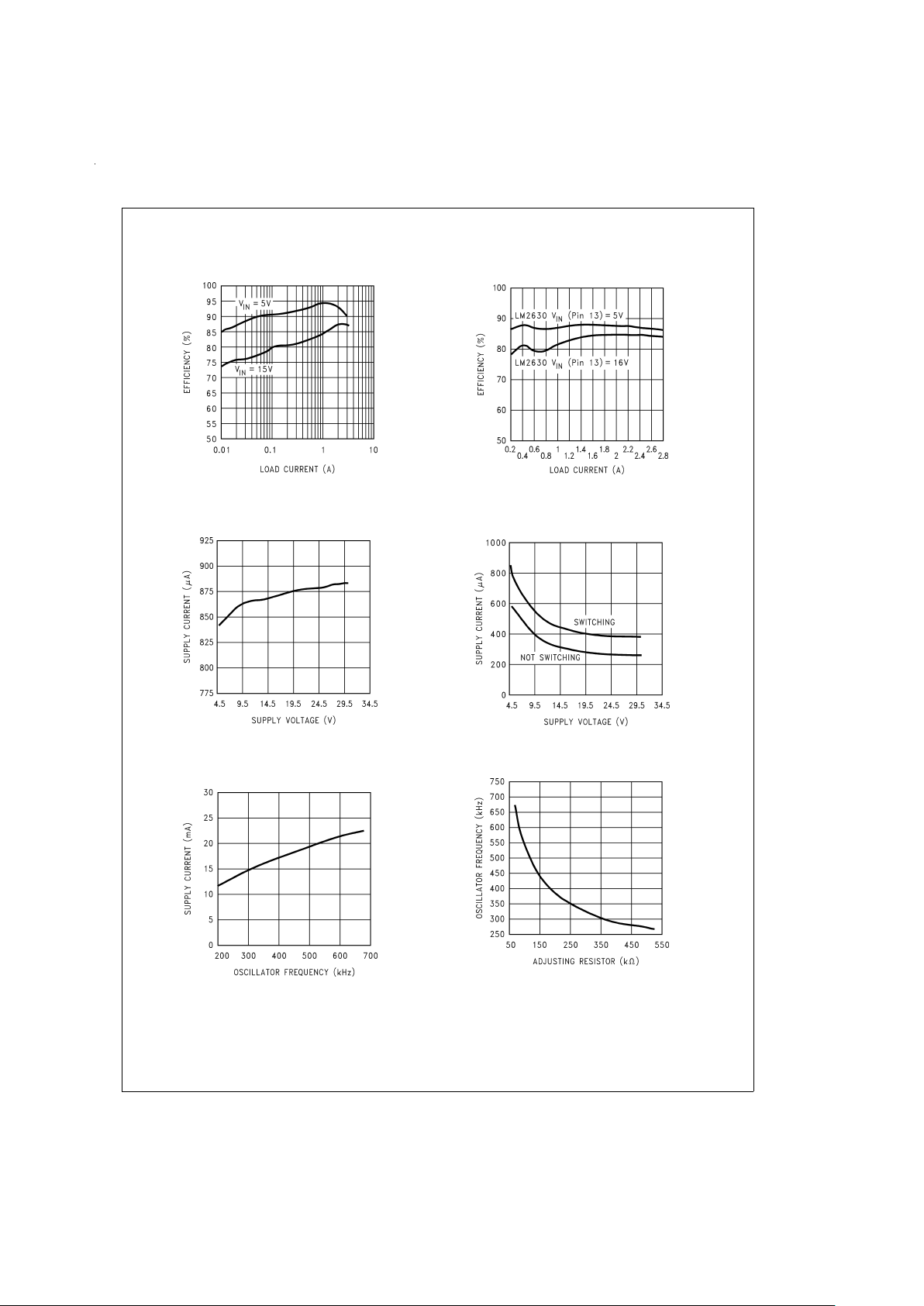

Typical Performance Characteristics

Efficiency vs Load Current

(FPWM=Low, V

OUT

=

3.3V)

DS100120-11

Efficiency (FPWM=High, Input Voltage=16V,

V

OUT

=

2.9V)

DS100120-12

Quiscent Supply Current vs Supply Voltage

(Not Switching, FPWM=Low, V

OUT

=

2.0V)

DS100120-15

Quiscent Supply Current vs Supply Voltage

(FPWM=Low, V

OUT

=

3.3V)

DS100120-16

Supply Current vs Oscillator Frequency

(FPWM=High)

DS100120-17

Oscillator Frequency vs Adjusting Resistor

DS100120-18

www.national.com5

Page 6

Typical Performance Characteristics (Continued)

Connection Diagram and Ordering Information

Pin Description

Pin Name Function

1SD

Shutdown control input, active low.

2 SYNC Oscillator synchronization input. Connect this pin to ground if not used.

3 PGOOD A constant monitor on the output voltage. PGOOD will go low if the output voltage

exceeds

±

9%of its nominal value. Once PGOOD goes low, it will go high if the output

moves within

±

3%of its nominal value.

4 SS The soft-start control pin. A capacitor connected from this pin to ground sets the ramp

time to full current output.

5 COMP Compensation network connection (connected to the output of the voltage error

amplifier).

6 FB Output voltage feedback input (connected to the center of the external resistor divider).

7 FADJ Frequency adjustment input.

8 VREF The output of the precision reference.

9 GND Low-noise analog ground.

10 CSH Current-sense positive input.

11 CSL Current-sense negative input.

12 NC No internal connection.

Oscillator Frequency vs Junction Temperature

DS100120-13

Reference Voltage vs Junction Temperature

DS100120-14

20-Lead TSSOP (MTC)

DS100120-2

Top View

Order Number LM2630MTC-ADJ

See NS Package Number MTC20

www.national.com 6

Page 7

Pin Description (Continued)

Pin Name Function

13 V

IN

Main power supply pin.

14 NC No internal connection.

15 FPWM When FPWM is high, pulse-skipping mode operation at light load is disabled. The

converter is forced to operate in constant frequency mode.

16 PGND Power ground.

17 LDRV Low-side gate-drive output.

18 CBOOT Bootstrap capacitor connection for high-side gate drive.

19 SW Switched-node connection, which is connected with the source of the high-side

MOSFET.

20 HDRV High-side gate-drive output. HDRV is a floating drive output that rides on SW voltage.

www.national.com7

Page 8

Block Diagram

Operation

Basic Operation of the Current Mode Controlled

Switching Regulator

The main control loop includesthe error amplifier, the current

amplifier and PWM comparator (as shown in

Figure 1

). During heavy load or any load with FPWM mode enabled, the

controller is in constant frequency current mode operation:

the high-side switch is turned on at the beginning of each

clock cycle, andthe outputof the erroramplifier iscompared

with the sensed inductor current ramp; once the ramp

reaches the control level set by the error amplifier, the PWM

comparator reset the driver logic to turn off the high-side

switch; the low-side switch is turned on after certain delay

(the voltage at the SW pin is sensed and the low-side switch

is turned on once the SW pin voltagereaches zero. A preset

maximum delay is 100 ns).The low-side switchstays on until

the end of the cycle or until the inductor current reaches

zero; when this occurs, the zero cross detector will disable

the low-side driver to turn off the low-side switch. The zero

cross detector is disabled in FPWM mode.

For any peak current mode step-down converter, a compensation ramp is needed to avoid subharmonic oscillations

DS100120-3

FIGURE 1. LM2630 Block Diagram

www.national.com 8

Page 9

Operation (Continued)

when the duty cycle ishigher than 50%. For the LM2630, this

compensation ramp is internally set to equal the maximum

down slope of the current amplifier output:

Where n=5 is the gain of the current sense amplifier. The

maximum output voltage equals 6V. Also, a 10 µH inductor

and a 0.025Ω sense resistor are assumed to determine the

internal compensation ramp.Different valuesof inductorand

sense resistor can be used as long as the resulted M

DOWN

(=nxR

SENxVOUT

/L) is less than MC.

Pulse-Skipping Mode at Light Load

Pulse-skipping mode can be enabled by pulling PFWM pin

low. This mode decreases switching frequency at light loads

to reduce the switchingfrequency related losses. IfPFWM is

set at low, the controller goes into the pulse-skipping mode

when the sensed inductor current goes below the 25 mV

threshold set by the pulse-skipping comparator. In the

pulse-skipping mode, the high-side switch only turns on at

the beginning of a clock cycle when the voltage at the feedback pin falls below thereference voltage. Oncethe switch is

on, it stays on until the sensed current rises to the 25 mV

threshold

Fast Transient Response

When the output voltage fails to exceed 97%of the nominal

level, the low voltage regulation(LREG) comparator will set

the PWM logic to turn the high-side switch on at maximum

duty cycle. This improves transient response since it bypasses the error amplifier and PWM comparator. During

start-up, the LREG is disabled.

Boost High-Side Gate Drive

A flying capacitor is used to bootstrap the power supply for

the high-side driver as illustrated in

Figure 1

. The boost capacitor is charged from an internal voltage rail (about 5.5V)

through an internal diode when the synchronous rectifier

(low-side MOSFET) is on, and then boosts up the high-side

gate voltage to turn high-side MOSFET on at the beginning

of next cycle. The internaldiode connectingbetween theVIN

pin and the CBOOT pin reduces the count of external components. For low input voltage application (Vin

<

5V), some

external charge pump circuitrycan beused toboost thegate

voltage in order to reduce conduction loss. Details will be

discussed in the Application Circuits Section.

Supply Voltage for the LM2630

When 5V is available,it isrecommended toconnect LM2630

V

IN

(pin13) to 5V. This can improve efficiency (see the second figure in Typical PerformanceCharacteristics), and also

reduce power dissipation inside the IC. Since the 5V supply

is only usedto powerthe LM2630 (includingthe gatecharge

for the external MOSFETs), it only requires a small amount

of current.

Reference

The 1.238V reference is of

±

2.4%accuracy over tempera-

ture. A 220 pF capacitor isrecommended between the V

REF

pin and ground. The load at the V

REF

pin should not exceed

100µA.

Frequency Control Pin (FADJ) and SYNC Pin

With the FADJ pin open, the switching frequencyis 200 kHz.

The frequency can beincreased byconnecting aresistor between FADJ and ground. The device can also be synchronized with an external CMOS or TTL logic clock in the range

from 200 kHz to 400 kHz. It is recommended to connect the

SYNC pin to ground if not used.

Protections

The current limit comparatorprovides thecycle-by-cycle current limit function by turning off the high-side MOSFET

whenever the sensed current reaches 110 mV. A second

level of current limit is accomplished by the 80%low voltage

detector: if the loadpulls theoutput voltage downbelow 80

%

of the nominal value, the device will turn off the high-side

MOSFET and turn on the low-side MOSFET in a latched

condition. This protection feature is disabled during startup.

The latched condition can be reset by shutting the device

down and then powering it up. Built-in input undervoltage

lockout circuit will keep most of the internal function blocks

off until the input voltage rises to about 3.5V.

Soft Start

A capacitor at the SS pin provides the soft start feature.

When the regulator is first powered up, or when the SD pin

goes high, a10µA currentsource chargesup the SScapacitor from the 0.6V clamping voltage. The switch duty cycle

starts with narrow pulses and gradually get wider as the SS

pin voltage ramps up to about 1.3V, above which the duty

cycle will becontrolled bythe maximumcurrent limituntil the

output voltage rises to the nominal value and the regulator

starts to operate in the normal current mode PWM control.

The LM2630 use a digital counter, referenced to the oscillator frequency, to setthe soft start timeout. The timeout is dependent on the switching frequency (timeout=4096/F

S

). If

the output voltage doesn’t move within the

±

3%window of

the nominal value during this period, the device will latch itself off.

Power Good

The LM2630 provides apower goodsignal bymonitoring the

voltage at the FB pin and compared the feedback voltage

with the V

REF

voltage. Once the output voltage exceeds the

±

9%window of the nominal value,the PGOOD pingoes low,

and stays low until the output voltage returns to the

±

3

%

window of the nominal value.

Design Procedure

Guidelines for selecting external components are discussed

in this section.

Inductor Selection

The most critical parameters for the inductor are the inductance, peak currentand thedc resistance. The inductance is

related to the switching frequency and the ripple current:

Higher switching frequency allows smaller inductor, but reduces the efficiency. A higher value of ripple current reduces

inductance, but increase the conductance loss, core loss,

current stress for the inductor and switch devices, and requires a bigger output capacitor for the same output voltage

ripple requirement. A reasonable value is setting the ripple

www.national.com9

Page 10

Design Procedure (Continued)

current to be 30%of the dc output current. Since the ripple

current increase with the input voltage, the maximum input

voltage is always used to determine the inductance. The dc

resistance of the inductor is a key parameter for the efficiency. Lower dc resistance is available with a bigger winding area. A good tradeoff between theefficiency and thecore

size is letting theinductor copperloss equalto 2%of the output power.

Input Capacitor

A low ESR aluminum or tantalum capacitor is needed between the drain ofthe high-sideMOSFET and groundto prevent large voltage transients from appearing at the input.

The capacitor is selected based on the RMS current and

voltage requirements. The RMS current is given by:

The RMS current reaches its maximum (I

OUT

/2) when V

IN

equals 2V

OUT

. A parallel of several capacitors may be required to meet the RMS current rating. For an aluminum capacitor,the voltagerating shouldbe atleast 25%higher than

the maximum input voltage. If a tantalum capacitor is used,

the voltage rating should be about twice the maximum input

voltage. The tantalum capacitorshould also besurge current

tested by the manufacturer. It is also recommended to put a

small ceramic capacitor (0.1 µF) between the V

IN

pin and

ground.

Output Capacitor

The selection of C

OUT

is driven by the maximum allowable

output voltage ripple. The outputripple inFPWM mode isapproximated by:

The ESR term plays the dominant role in determining the

voltage ripple. Low ESR aluminum electrolytic or tantalum

capacitors (such as Nichicon PL series, Sanyo OS-CON,

Sprague 593D, 594D, and AVX TPS) are recommended.

Electrolytic capacitors are not recommendedfor temperature

below −25˚C since their ESR rises dramatically at cold temperature. Tantalum capacitors have a much better ESR

specification at cold temperatures and are preferred for low

temperature applications.

Power MOSFETs

TwoN-channel logic-levelMOSFETsare requiredfor this application. MOSFETs with low on-resistance and total gate

charge are recommended to achieve high efficiency. The

drain-source breakdown voltage ratings are recommended

to be 1.2 times the maximum input voltage.

Schottky Diode D

1

The Schottky diode D1is used to prevent the intrinsic body

diode of the low-side MOSFET Q

2

from conducting during

the dead time when both MOSFETs are off. Since the forward voltage of D

1

is less than thebody diode,efficiency can

be improved. The breakdown voltage rating of D

1

is preferred to be 25%higher than the maximum input voltage.

Since D

1

is only on for a short period of time (about 200 ns

each cycle), the average current rating for D

1

only requires

to be higher than 30%of the maximum output current. It is

important to place D

1

very close to the drain and source of

Q

2

, extra parasitic inductance in the parallel loop will slow

the turn-on of D

1

and direct the current through the body di-

ode of Q

2

.

R

1

and R2(Programming Output Voltage)

Use the following formula to select the appropriate resistor

values:

V

OUT

=

V

REF

(1+R1/R2)

where V

REF

=

1.238V

Select a value for R

2

between 10kΩ and 100kΩ. (Use 1%or

higher accuracy metal film resistors).

Current sense resistor

The value of the sense resistor is determined by the minimum current limit voltage and the maximum peak current. It

can be calculated as follows:

where TF is the tolerance factor of the sense resistor.

PCB Layout Considerations

Layout is critical to reduce noises and ensure specified performance. The important guidelines are listed as follows:

1. Minimize the parasiticinductance in the loop of input ca-

pacitors and MOSFETS: Q1, Q2by using wideand short

traces. This is important because the rapidly switching

current, together with wiring inductance can generate

large voltage spikes which can cause noise problems.

2. Always minimize the high-current groundtraces: such as

the traces from PGND pin to the source of Q2, then to

the negative terminals of the output capacitors.

3. Use dedicated (Kelvin sense) and short traces from

CSH, CSL pins to the sense resistor, R3. Keep these

traces away from noise traces (such as SW trace, and

gate traces).

4. Minimize the traces connecting Q2 and the Schottky di-

ode. Any parasitic inductance in the loop can delay the

turn-on of the Schottky diode, which diminishes the efficiency gain from adding D1.

5. Minimize the traces from drivers (HDRV pin and LDRV

pin) to the MOSFETs gates.

6. Minimize the trace from the center of the output resistor

divider to the FB pin and keep it away from noise

sources to avoid noise pickup. A dedicated sense trace

(separated from the power trace) can be used to connect the top of the resistor divider to the output. The

sense trace ensures tight regulation at the output.

Application Circuits

Atypical applicationcircuit is shownin

Figure 2

, with some of

the components values shown in

Table 1

.

www.national.com 10

Page 11

Design Procedure (Continued)

TABLE 1. Components for Typical 2.5V, 300kHz Application Circuits

Input Voltage 4.75V to 24V 4.5V to 6V

Output Current 4A 10A

Application Notebook Desktop

Q1 and Q2 Fairchild FDS6680; Siliconix

Si4410DY; or International Rectifier

IRF7805

Fairchild FDB7030L; or Motorola

MTB75N03HDL

Inductor L1 Sumida CDRH127-7R6: 7.6µH, 5.9A Pulse PE-53681: 2.5 µH, 11.4A

Input Capacitors 2 x 22µF, 35V Sprague 593D or TPS 2 x 220 µF, 10V Sanyo OS-CON SA

Output Capacitors 2 x 220µF, 10V Sprague 593D or TPS 3 x 330 µF, 6.3V Sanyo OS-CON SA

Rectifier D1 Motorola MBRS140T3 Motorola MBRS340T3

Sensing Resistor R3 15 mΩ IRC 3x20mΩIRC

Compensation components C8 and

R8

R8=3.3 KΩ,C8=1nF R8=4KΩ,C8=1nF

When the input voltage is low (less than 5V), the bootstrap

function cannot deliver enough gate voltage to fully drive the

high-side MOSFET on, which increases Rdson, and consequently reduces efficiency.An externalcharge-pump doubler

can be added to double the CBOOT pin voltage (see

Figure

3

). It can also be added to the VIN pin to increase the gate

drive voltage at both high-side and low-side MOSFETs.

DS100120-4

FIGURE 2. The Typical 2.5V Application Circuit

www.national.com11

Page 12

Design Procedure (Continued)

DS100120-5

FIGURE 3. High Efficiency, 300 kHz, 5V to 2.5V Converter.

Efficiency is 94%(typ) at 1A load.

www.national.com 12

Page 13

13

Page 14

Physical Dimensions inches (millimeters) unless otherwise noted

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTSARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or systems which, (a) are intended for surgical implant into

the body, or (b)support orsustain life,and whose failure to perform when properly used in accordance

with instructions for use provided in the labeling, can

be reasonably expected toresult in asignificant injury

to the user.

2. A critical component is any component of a life support

device or system whose failure to perform can be reasonably expected tocause the failureof the life support

device or system, orto affect itssafety oreffectiveness.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

www.national.com

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0)1 80-530 85 85

English Tel: +49 (0) 1 80-532 78 32

Français Tel: +49 (0) 1 80-532 93 58

Italiano Tel: +49 (0) 1 80-534 16 80

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

20-Lead TSSOP (MTC)

Order Number LM2630MTC-ADJ

NS Package Number MTC20

LM2630 Synchronous Step-Down Power Supply Controller

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change saidcircuitry and specifications.

Loading...

Loading...