Page 1

September 2002

LM2618

400mA Sub-miniature, High Efficiency, Synchronous

PWM & PFM Programmable DC-DC Converter

LM2618 400mA Sub-miniature, High Efficiency, Synchronous PWM & PFM Programmable DC-DC

Converter

General Description

The LM2618 step-down DC-DC converter is optimized for

powering low voltage circuits from a single Lithium-Ion cell. It

provides up to 400mA (300mA for B grade), over an input

voltage range of 2.8V to 5.5V. Pin programmable output

voltages of 1.80V, 1.83V, 1.87V or 1.92V allow adjustment

for MPU voltage options without board redesign or external

feedback resistors. Internal synchronous rectification provides high efficiency in both PWM and PFM operation.

The device has three pin-selectable modes for maximizing

battery life in mobile phones and similar portable applications. Low-noise PWM mode offers 600kHz fixed-frequency

operation to reduce interference in RF and data acquisition

applications during full-power operation. A SYNC input allows synchronizing the switching frequency in a range of

500kHz to 1MHz to avoid noise from intermodulation with

system frequencies. Low-current hysteretic PFM mode reduces quiescent current to 180 µA (typ.) during system

standby. Shutdown mode turns the device off and reduces

battery consumption to 0.02µA (typ.). Additional features

include soft start and current overload protection.

The LM2618 is available in a 10 pin micro SMD packge. This

package uses National’s wafer level chip-scale micro SMD

technology and offers the smallest possible size. Only three

small external surface-mount components, an inductor and

two ceramic capacitors are required.

Key Specifications

n Operates from a single LiION cell (2.8V to 5.5V)

n Internal synchronous rectification provides high

efficiency in both PWM and PFM

n Pin programmable output voltage (1.80V, 1.83V, 1.87V

and 1.92V)

n 400mA maximum load capability (300mA for B grade)

±

n

2% PWM mode DC output voltage precision

n 5mV typ PWM mode output voltage ripple

n 180 µA typ PFM mode quiescent current

n 0.02µA typ shutdown mode current

n Internal synchronous rectification for high efficiency

(91% at 3.0V

n 600kHz PWM mode switching frequency

n SYNC input for PWM mode frequency synchronization

from 500kHz to 1MHz

, 1.92V

IN

OUT

)

Features

n Sub-miniature 10-pin micro SMD package

n Only three tiny surface-mount external components

required

n Uses small ceramic capacitors.

n Internal soft start

n Current overload protection

n Thermal Shutdown Protection

n No external compensation required

Applications

n Mobile Phones

n Hand-Held Radios

n Battery Powered Devices

Typical Application Circuit

20036402

© 2002 National Semiconductor Corporation DS200364 www.national.com

Page 2

Connection Diagrams

micro SMD package

LM2618

TOP VIEW

20036404

BOTTOM VIEW

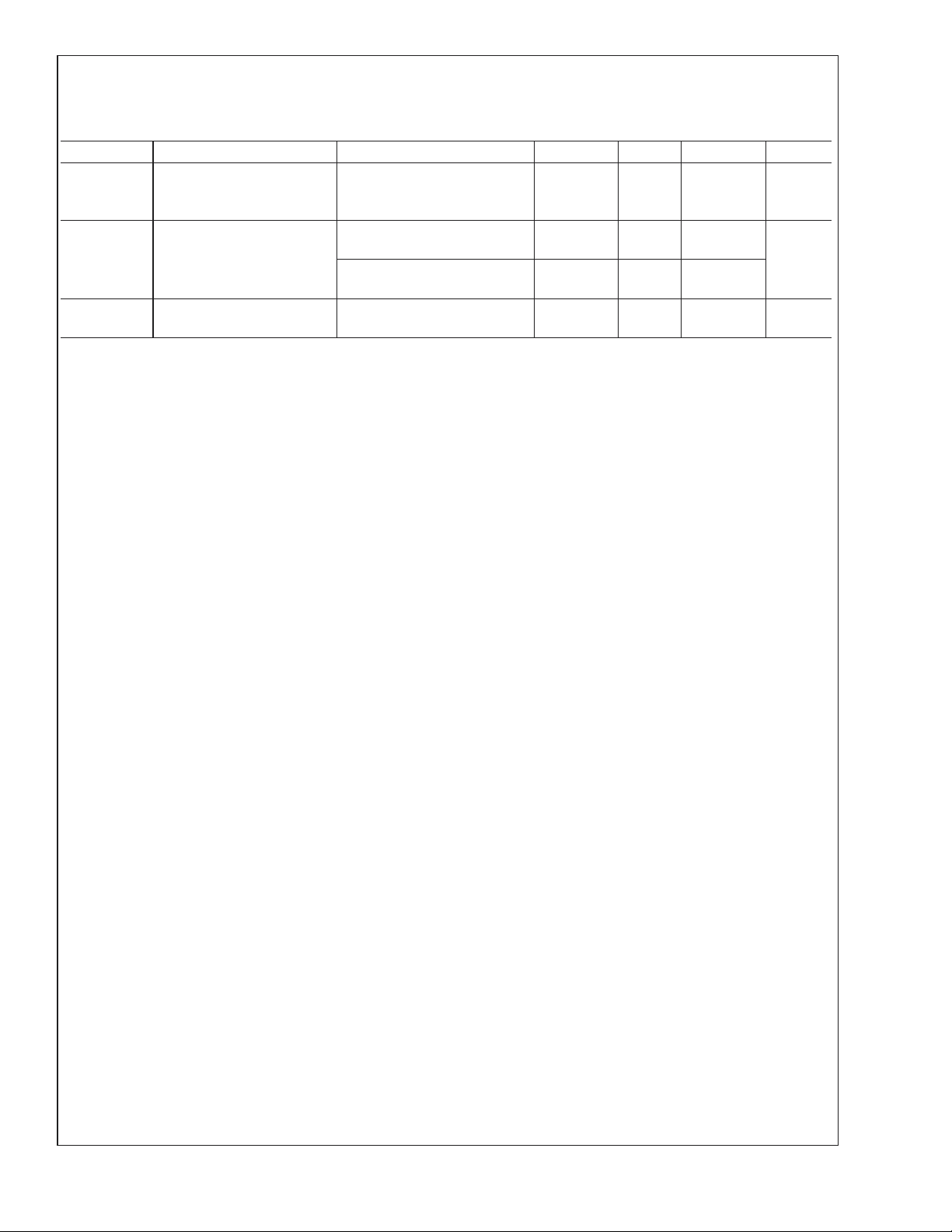

Ordering Information

Order Number Package Type NSC Package

Marking(*)

10-Pin micro SMD

LM2618ATL

LM2618BTL XYTT IS55B 250 Units, Tape and Reel

LM2618ATLX XYTT IS55A 3000 Units, Tape and Reel

10-bump Wafer Level Chip Scale

(micro SMD)

XYTT IS55A 250 Units, Tape and Reel

LM2618BTLX XYTT IS55B 3000 Units, Tape and Reel

(*) XY - denotes the date code marking (2 digit) in production

(*) TT - refers to die run/lot traceability for production

(*) I - pin one indication

(*) S - Product line designator

Note that Package Marking may change over the course of production

Supplied As

20036405

www.national.com 2

Page 3

Pin Description

Pin Number (*) Pin Name Function

A1 FB Feedback Analog Input. Connect to the output at the output filter capacitor (Figure 1)

B1 VID1 Output Voltage Control Inputs. Set the output voltage using these digital inputs (see Table

C1 VID0

D1 SYNC/MODE Synchronization Input. Use this digital input for frequency selection or modulation control.

D2 EN Enable Input. For shutdown, set low to SGND. (See Shut down Mode in the Device

D3 PGND Power Ground

C3 SW Switching Node connection to the internal PFET switch and NFET synchronous rectifier.

B3 PVIN Power Supply Input to the internal PFET switch. Connect to the input filter capacitor

A3 VDD Analog Supply Input. If board layout is not optimum, an optional 0.1µF ceramic capacitor

A2 SGND Analog and Control Ground

(*) Note that the pin numbering scheme for the microSMD package was revised in April,2002 to conform to JEDEC standard. Only the pin numbers were revised.

No changes to the physical location of the inputs/outputs were made. For reference purpose, the obsolete numbering had FB as pin 1, VID1 as pin 2, VID0 as pin

3, SYNC as pin 4, EN as pin 5, PGND as pin 6, SW as pin 7, PVIN as pin 8, VDD as pin 9 and SGND as pin 10.

1). The output defaults to 1.87V if these pins are unconnected.

Set:

SYNC/MODE = high for low-noise 600kHz PWM mode

SYNC/MODE = low for low-current PFM mode

SYNC/MODE = a 500kHz - 1MHz external clock for synchronization to an external clock

in PWM mode. See Synchronization and Operating Modes in the Device Information

section.

Information section.)

Connect to an inductor with a saturation current rating that exceeds the max Switch Peak

Current Limit specification of the LM2618 (Figure 1)

(Figure 1).

is suggested (Figure 1)

LM2618

www.national.com3

Page 4

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

LM2618

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

PVIN, VDD, to SGND −0.2V to +6V

PGND to SGND −0.2V to +0.2V

EN, SYNC/MODE, VID0, VID1 to

SGND −0.2V to +6V

Lead temperature

(Soldering, 10 sec.) 260˚C

Junction Temperature (Note 2) −25˚C to 125˚C

Minimum ESD Rating

Human body model, C = 100pF, R =

1.5 kΩ

Thermal Resistance (θ

)

JA

LM2618ATL & LM2618BTL (Note 3) 140˚C/W

FB, SW (GND −0.2V) to

(VDD +0.2V)

Storage Temperature Range −45˚C to +150˚C

Electrical Characteristics

Specifications with standard typeface are for TA=TJ= 25˚C, and those in bold face type apply over the full Operating Temperature Range (T

0V.

Symbol Parameter Conditions Min Typ Max Units

V

V

V

IN

FB

HYST

Input Voltage Range (Note4)PVIN = VDD = VID1 = VID0 =

Feedback Voltage

(Note 5)

PFM Comparator Hysteresis

Voltage

(Note 6)

I

SHDN

I

Q1

I

Q2

R

DSON (P)

Shutdown Supply Current EN = 0V 0.02 3 µA

DC Bias Current into VDD PFM mode, VFB= 2V 180 215

Pin-Pin Resistance for P

FET

R

DSON (N)

Pin-Pin Resistance for N

FET

R

DSON , TC

FET Resistance

Temperature Coefficient

I

lim

Switch Peak Current Limit

(Note 7)

V

EN_H

EN Positive Going

Threshold Voltage

V

EN_L

EN Negative Going

Threshold Voltage

V

SYNC_H

SYNC/MODE Positive

Going Threshold Voltage

V

SYNC_L

SYNC/MODE Negative

Going Threshold Voltage

V

ID_H

V

ID0,VID1

Threshold Voltage

V

ID_L

V

ID0,VID1

Threshold Voltage

I

VID

VID1, VID0 Pull Down

Current

= - 25˚C to +85˚C). Unless otherwise specified, PVIN = VDD = EN = SYNC = 3.6V, VID0 = VID1 =

A=TJ

V

IN

PVIN = VDD = VD1 = V

,

IN

2.8 5.5

3.0 5.5

VID0 = 0V

VID0 = V

VID0 = V

, VID1 = V

IN

, VID1 = 0V 1.793 1.83 1.867

IN

IN

1.764 1.80 1.836

VID0 = 0V, VID1 = 0V 1.833 1.87 1.907

VID0 = 0V, VID1 = V

IN

1.882 1.92 1.958

PFM Mode (SYNC = 0V)

25 mV

PWM mode, VFB= 2V 605 735

LM2618ATL & LM2618BTL

LM2618ATL & LM2618BTL

395 550 mΩ

330 500 mΩ

0.5 %/C

LM2618ATL 540 720 880

LM2618BTL 430 720 1020

VDD = 3.6V

VDD = 3.6V

0.4 0.80 V

0.95 1.3 V

0.95 1.3 V

0.4 0.84 V

Positive Going

Negative Going

0.4 0.83 V

VID1, VID0 = 3.6V

0.92 1.3 V

1.8 3.0 µA

±

2.0kV

V

V

µA

mA

www.national.com 4

Page 5

Electrical Characteristics (Continued)

Specifications with standard typeface are for TA=TJ= 25˚C, and those in bold face type apply over the full Operating Temperature Range (T

0V.

Symbol Parameter Conditions Min Typ Max Units

F

SYNC

SYNC/MODE Clock

Frequency Range

(Note 8)

F

OSC

Internal Oscillator

Frequency

T

min

Minimum ON-Time of P FET

Switch in PWM Mode

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings are conditions for which the device is intended

to be functional, but parameter specifications may not be guaranteed. For guaranteed specifications and associated test conditions, see the Min and Max limits and

Conditions in the Electrical Characteristics table. Electrical Characteristics table limits are guaranteed by production testing, design or correlation using standard

Statistical Quality Control methods. Typical (Typ) specifications are mean or average values from characterization at 25˚C and are not guaranteed.

Note 2: In PWM mode, Thermal shutdown will occur if the junction temperature exceeds the 150˚C maximum junction temperature of the device.

Note 3: Thermal resistance specified with 2 layer PCB(0.5/0.5 oz. cu).

Note 4: The LM2618 is designed for cell phone applications where turn-on after power-up is controlled by the system processor and internal UVLO (Under Voltage

LockOut) circuitry is unecessary. The LM2618 has no UVLO circuitry and should be kept in shutdown by holding the EN pin low until the input voltage exceeds 2.8V.

Although the LM2618 exhibits safe behavior while enabled at low input voltages, this is not guaranteed.

Note 5: The feedback voltage is trimmed at the 1.87V output setting. The other output voltages result from the pin selection of the internal DAC’s divider ratios. The

precision for the feedback voltages is

Note 6: : The hysteresis voltage is the minimum voltage swing on FB that causes the internal feedback and control circuitry to turn the internal PFET switch on and

then off during PFM mode.

Note 7: Current limit is built-in, fixed, and not adjustable. If the current limit is reached while the output is pulled below about 0.7V, the internal PFET switch turns

off for 2.5 µs to allow the inductor current to diminish.

Note 8: SYNC driven with an external clock switching between VDD and GND. When an external clock is present at SYNC, the IC is forced to PWM mode at the

external clock frequency. The LM2618 synchronizes to the rising edge of the external clock.

= - 25˚C to +85˚C). Unless otherwise specified, PVIN = VDD = EN = SYNC = 3.6V, VID0 = VID1 =

A=TJ

500 1000 kHz

LM2618ATL, PWM Mode

(SYNC = VIN)

LM2618BTL, PWM Mode

(SYNC = VIN)

468 600 732

450 600 750

200 ns

±

2%.

LM2618

kHz

www.national.com5

Page 6

Typical Operating Characteristics LM2618ATL, Circuit of Figure 1,V

µH, unless otherwise noted.

LM2618

Quiescent Supply Current vs Temperature

=1.8V) Quiescent Supply Current vs Supply Voltage

(V

OUT

20036406 20036422

Output Voltage vs Temperature

Shutdown Quiescent Current vs Temperature

IN

(V

= 1.8V, PWM Mode)

OUT

= 3.6V, TA= 25˚C, L1=10

Output Voltage vs Temperature

= 1.8V, PFM Mode)

(V

OUT

20036407

20036421 20036409

Output Voltage vs Supply Voltage

(V

= 1.8V, PWM Mode)

OUT

20036418

www.national.com 6

Page 7

LM2618

Typical Operating Characteristics LM2618ATL, Circuit of Figure 1,V

unless otherwise noted. (Continued)

Output Voltage vs Supply Voltage

(V

= 1.8V, PFM Mode)

OUT

20036419

Output Voltage vs Output Current

= 1.8V, PFM Mode)

(V

OUT

Output Voltage vs Output Current

(V

= 1.8V, PWM Mode)

OUT

Efficiency vs Output Current

(V

= 1.8V, PWM Mode)

OUT

= 3.6V, TA= 25˚C, L1= 10 µH,

IN

20036417

Efficiency vs Output Current

= 1.8V, PFM Mode)

(V

OUT

20036420 20036423

Switching Frequency vs Temperature

(PWM Mode)

20036424

20036408

www.national.com7

Page 8

Typical Operating Characteristics LM2618ATL, Circuit of Figure 1,V

unless otherwise noted. (Continued)

LM2618

PWM to PFM Response Shutdown Response (PWM Mode)

= 3.6V, TA= 25˚C, L1= 10 µH,

IN

20036413

Load Transient Response (PWM Mode) Load Transient Response (PFM Mode)

20036412

Line Transient Response (PWM Mode)

20036414

20036415

20036416

www.national.com 8

Page 9

Device Information

The LM2618 is a simple, step-down DC-DC converter optimized for powering low-voltage CPUs or DSPs in cell

phones and other miniature battery powered devices. It provides pin-selectable output voltages of 1.80V, 1.83V, 1.87V

or 1.92V from a single 2.8V to 5.5V LiION battery cell. It is

designed for a maximum load capability of 400mA (300mA

for B grade). It uses synchronous rectification in both PWM

and PFM modes for high efficiency: typically 91% for a

100mA load with 1.92V output, 3.0V input, while in PWM

mode.

The device has all three of the pin-selectable operating

modes required for cell phones and other complex portable

devices. Such applications typically spend a small portion of

their time operating at full power. During full power operation,

synchronized or fixed-frequency PWM mode offers full output current capability while minimizing interference to sensitive IF and data acquisition circuits. These applications

spend the remainder of their time in low-current standby

LM2618

operation or shutdown to conserve battery power. During

standby operation, hysteretic PFM mode reduces quiescent

current to 180µA typ to maximize battery life. Shutdown

mode turns the device off and reduces battery consumption

to 0.02µA (typ.).

The LM2618 offers good performance and a full set of features. It is based on a current-mode switching buck

architecture. The SYNC/MODE input accepts an external

clock between 500kHz and 1MHz.

The output voltage selection pins eliminate external feedback resistors. Additional features include soft-start, current

overload protection, over-voltage protection and thermal

shutdown protection.

The LM2618 is constructed using a chip-scale 10-pin micro

SMD package. The micro SMD package offers the smallest

possible size for space critical applications, such as cell

phones. Required external components are only a small

10µH inductor, and tiny 10µF and 22µF ceramic capacitors

for reduced board area.

FIGURE 1. Typical Operating Circuit

Circuit Operation

Referring to Figure 1, Figure 2, and Figure 3 the LM2618

operates as follows: During the first part of each switching

cycle, the control block in the LM2618 turns on the internal

PFET switch. This allows current to flow from the input

through the inductor to the output filter capacitor and load.

The inductor limits the current to a ramp with a slope of (V

-V

)/L, by storing energy in a magnetic field. During the

OUT

second part of each cycle, the controller turns the PFET

switch off, blocking current flow from the input, and then

turns the NFET synchronous rectifier on. In response, the

inductor’s magnetic field collapses, generating a voltage that

forces current from ground through the synchronous rectifier

to the output filter capacitor and load. As the stored energy is

20036403

transferred back into the circuit and depleted, the inductor

current ramps down with a slope of V

/L. If the inductor

OUT

current reaches zero before the next cycle, the synchronous

rectifier is turned off to prevent current reversal. The output

filter capacitor stores charge when the inductor current is

high, and releases it when low, smoothing the voltage across

the load.

IN

The output voltage is regulated by modulating the PFET

switch on-time to control the average current sent to the

load. The effect is identical to sending a duty-cycle modulated rectangular wave formed by the switch and synchronous rectifier to a low-pass filter created by the inductor and

output filter capacitor. The output voltage is equal to the

average voltage at the SW pin.

www.national.com9

Page 10

Circuit Operation (Continued)

LM2618

20036401

FIGURE 2. Simplified Functional Diagram

PWM Operation

The LM2618 can be set to current-mode PWM operation by

connecting the SYNC/MODE pin to VDD. While in PWM

(Pulse Width Modulation) mode, the output voltage is regulated by switching at a constant frequency and then modulating the energy per cycle to control power to the load.

Energy per cycle is set by modulating the PFET switch

on-time pulse-width to control the peak inductor current. This

is done by controlling the PFET switch using a flip-flop driven

by an oscillator and a comparator that compares a ramp

from the current-sense amplifier with an error signal from a

voltage-feedback error amplifier. At the beginning of each

cycle, the oscillator sets the flip-flop and turns on the PFET

switch, causing the inductor current to ramp up. When the

current sense signal ramps past the error amplifier signal,

PWM Mode Switching Waveform PFM Mode Switching Waveform

the PWM comparator resets the flip-flop and turns off the

PFET switch, ending the first part of the cycle. The NFET

synchronous rectifier turns on until the next clock pulse or

the inductor current ramps to zero. If an increase in load

pulls the output voltage down, the error amplifier output

increases, which allows the inductor current to ramp higher

before the comparator turns off the PFET switch. This increases the average current sent to the output and adjusts

for the increase in the load.

Before going to the PWM comparator, the current sense

signal is summed with a slope compensation ramp from the

oscillator for stability of the current feedback loop. During the

second part of the cycle, a zero crossing detector turns off

the NFET synchronous rectifier if the inductor current ramps

to zero.

20036410

FIGURE 3.

www.national.com 10

20036411

Page 11

PFM Operation

Connecting the SYNC/MODE pin to SGND sets the LM2618

to hysteretic PFM operation. While in PFM (Pulse Frequency

Modulation) mode, the output voltage is regulated by switching with a discrete energy per cycle and then modulating the

cycle rate, or frequency, to control power to the load. This is

done by using an error comparator to sense the output

voltage and control the PFET switch. The device waits as the

load discharges the output filter capacitor, until the output

voltage drops below the lower threshold of the PFM errorcomparator. Then the error comparator initiates a cycle by

turning on the PFET switch. This allows current to flow from

the input, through the inductor to the output, charging the

output filter capacitor. The PFET switch is turned off when

the output voltage rises above the regulation threshold of the

PFM error comparator. After the PFET switch turns off, the

output voltage rises a little higher as the inductor transfers

stored energy to the output capacitor by pushing current into

the output capacitor. Thus, the output voltage ripple in PFM

mode is proportional to the hysteresis of the error comparator and the inductor current.

In PFM mode, the device only switches as needed to service

the load. This lowers current consumption by reducing power

consumed during the switching action in the circuit due to

transition losses in the internal MOSFETs, gate drive currents, eddy current losses in the inductor, etc. It also improves light-load voltage regulation. During the second part

of the cycle, the NFET synchronous rectifier turns on until

the error comparator initiates the next cycle or the inductor

current ramps near zero. A zero crossing detector turns off

the NFET synchronous rectifier if the inductor current ramps

near zero.

Operating Mode Selection (SYNC/MODE Pin)

The SYNC/MODE digital input pin is used to select between

PWM or PFM operating modes. Set SYNC/MODE high

(above 1.3V) for 600kHz PWM operation when the system is

active and the load is above 50mA. Set SYNC/MODE low

(below 0.4V) to select PFM mode when the load is less than

50mA for precise regulation and reduced current consumption when the system is in standby. The LM2618 has an

over-voltage protection feature that activates if the device is

left in PWM mode under low-load conditions (

prevent the output voltage from rising too high. See Over-

voltage Protection, for more information.

Select modes with the SYNC/MODE pin using a signal with

a slew rate faster than 5V/100µs. Use a comparator Schmitt

trigger or logic gate to drive the SYNC/MODE pin. Do not

leave the pin floating or allow it to linger between logic levels.

These measures will prevent output voltage errors that could

otherwise occur in response to an indeterminate logic state.

Ensure a minimum load to keep the output voltage in regulation when switching modes frequently. The minimum load

requirement varies depending on the mode change frequency. A typical load of 8µA is required when modes are

changed at 100 ms intervals, 85µA for 10 ms and 800µA for

1 ms.

<

50mA) to

Frequency Synchronization (SYNC/MODE Pin)

The SYNC/MODE input can also be used for frequency

synchronization. To synchronize the LM2618 to an external

clock, supply a digital signal to the SYNC/MODE pin with a

LM2618

voltage swing exceeding 0.4V to 1.3V. During synchronization, the LM2618 initiates cycles on the rising edge of the

clock. When synchronized to an external clock, it operates in

PWM mode. The device can synchronize to an external

clock over frequencies from 500kHz to 1MHz.

Use the following waveform and duty-cycle guidelines when

applying an external clock to the SYNC/MODE pin. Each

clock cycle should have high and low periods between 1.3µs

and 200ns and a duty cycle between 30% and 70%. The

total clock period should be 2µs or less. Clock under/

overshoot should be less than 100mV below GND or above

VDD. When applying noisy clock signals, especially sharp

edged signals from a long cable during evaluation, terminate

the cable at its characteristic impedance; add an RC filter to

the SYNC pin, if necessary, to soften the slew rate and

over/undershoot. Note that sharp edged signals from a pulse

or function generator can develop under/overshoot as high

as 10V at the end of an improperly terminated cable.

Overvoltage Protection

The LM2618 has an over-voltage comparator that prevents

the output voltage from rising too high when the device is left

in PWM mode under low-load conditions. Otherwise, the

output voltage could rise out of regulation from the minimum

energy transferred per cycle due to the 200ns minimum

on-time of the PFET switch while in PWM mode. When the

output voltage rises by 50mV over its regulation threshold,

the OVP comparator inhibits PWM operation to skip pulses

until the output voltage returns to the regulation threshold. In

over voltage protection, output voltage and ripple increase

slightly.

Shutdown Mode

Setting the EN input pin to SGND places the LM2618 in a

0.02µA (typ) shutdown mode. During shutdown, the PFET

switch, NFET synchronous rectifier, reference, control and

bias of the LM2618 are turned off. Setting EN high to VDD

enables normal operation. While turning on, soft start is

activated.

EN must be set low to turn off the LM2618 during undervoltage conditions when the supply is less than the 2.8V minimum operating voltage. The LM2618 is designed for mobile

phones and similar applications where power sequencing is

determined by the system controller and internal UVLO (Under Voltage LockOut) circuitry is unnecessary. The LM2618

has no UVLO circuitry. Although the LM2618 exhibits safe

behavior while enabled at low input voltages, this is not

guaranteed.

Internal Synchronous Rectification

The LM2618 uses an internal NFET as a synchronous rectifier to improve efficiency by reducing rectifier forward voltage drop and associated power loss. In general, synchronous rectification provides a significant improvement in

efficiency whenever the output voltage is relatively low compared to the voltage drop across an ordinary rectifier diode.

Under moderate and heavy loads, the internal NFET synchronous rectifier is turned on during the inductor current

down-slope in the second part of each cycle. The synchronous rectifier is turned off prior to the next cycle, or when the

inductor current ramps near zero at light loads. The NFET is

designed to conduct through its intrinsic body diode during

transient intervals before it turns on, eliminating the need for

an external diode.

www.national.com11

Page 12

Current Limiting

A current limit feature allows the LM2618 to protect itself and

LM2618

external components during overload conditions. Current

limiting is implemented using an independent internal comparator. In PWM mode, cycle-by-cycle current limiting is

normally used. If an excessive load pulls the output voltage

down to approximately 0.7V, then the device switches to a

timed current limit mode. In timed current limit mode the

internal P-FET switch is turned off after the current comparator trips and the beginning of the next cycle is inhibited for

2.5µs to force the instantaneous inductor current to ramp

down to a safe value. PFM mode also uses timed current

limit operation. The synchronous rectifier is off in this mode.

Timed current limit prevents the loss of current control seen

in some products when the output voltage is pulled low in

serious overload conditions.

Thermal Shutdown Protection

The LM2618 has a thermal shutdown protection to protect

from short-term misuse and overload conditions. When the

junction temperature exceeds 150˚C, the device shuts down,

restarting in soft start after the temperature drops below

130˚C. Prolonged operation in thermal overload conditions

may damage the device and is considered bad practice.

Application Information

Setting The Output Voltage

The LM2618 features pin-selectable output voltage to eliminate the need for external feedback resistors. Select an

output voltage of 1.80V, 1.83V, 1.87V or 1.92V by configuring the VID0 and VID1 pins, as directed in Table 1.

Current Limiting and PWM Mode Transient Response Considerations

The LM2618 was designed for fast response to moderate

load steps. Harsh transient conditions during loads above

300mA can cause the inductor current to swing up to the

maximum current limit, resulting in PWM mode jitter or instability from activation of the current limit comparator. To avoid

this jitter or instability, do not power-up or start the LM2618

into a full load (loads near or above 400mA). Do not change

operating modes or output voltages when operating at a full

load. Avoid extremely sharp and wide-ranging load steps to

full load, such as from

<

30mA to>350mA.

Pin Selectable Output Voltage

The LM2618 features pin-selectable output voltage to eliminate the need for external feedback resistors. The output

can be set to 1.80V, 1.83V, 1.87V or 1.92V by configuring the

VID0 and VID1 pins. See Setting the Output Voltage in the

Application Information section for further details.

Soft-Start

The LM2618 has soft start to reduce current inrush during

power-up and startup. This reduces stress on the LM2618

and external components. It also reduces startup transients

on the power source.Soft start is implemented by ramping up

the internal reference in the LM2618 to gradually increase

the output voltage.

TABLE 2. Suggested Inductors and Their Suppliers

Model Vendor Phone FAX

DO1608C-103 Coilcraft 847-639-6400 847-639-1469

P1174.103T Pulse Engineering 858-674-8100 858-674-8262

P0770.103T Pulse Engineering 858-674-8100 858-674-8262

CDRH5D18-100 Sumida 847-956-0666 847-956-0702

TABLE 1. VID0 and VID1 Output Voltage Selection

Settings

V

(V) Logic Level

OUT

VID0 VID1

1.92 0 1

1.87 0 0

1.87 N.C. N.C.

1.83 1 0

1.80 1 1

VID0 and VID1 are digital inputs. They may be set high by

connecting to VDD or low by connecting to SGND. Optionally, VID0 and VID1 may be driven by digital gates that

provide over 1.3V for a high state and less than 0.4V for a

low state to ensure valid logic levels. The VID0 and VID1

inputs each have an internal 1.8 µA pull-down that pulls them

low for a default 1.87V output, when left unconnected. Leaving these pins open is acceptable, but setting the pins high or

low is recommended.

Inductor Selection

A 10µH inductor with a saturation current rating over the

maximum current limit is recommended for most applications. The inductor’s resistance should be less than 0.3Ω for

good efficiency. Table 2 lists suggested inductors and

suppliers.

For low-cost applications, an unshielded bobbin inductor is

suggested. For noise critical applications, a toroidal or

shielded-bobbin inductor should be used. A good practice is

to lay out the board with overlapping footprints of both types

for design flexibility. This allows substitution of a low-noise

toroidal inductor, in the event that noise from low-cost bobbin

models is unacceptable.

The saturation current rating is the current level beyond

which an inductor loses its inductance. Beyond this rating,

www.national.com 12

the inductor loses its ability to limit current through the PFET

switch to a ramp and allows the switch current to increase

rapidly. This can cause poor efficiency, regulation errors or

stress to DC-DC converters like the LM2618. Saturation

occurs when the magnetic flux density from current through

the windings of the inductor exceeds what the inductor’s

core material can support with energy storage in a corresponding magnetic field.

Page 13

Application Information (Continued)

TABLE 3. Suggested Capacitors and Their Suppliers

Model Size Vendor Phone FAX

22µF, X7R or X5R Ceramic Capacitor for C2 (Output Filter Capacitor)

C3225X5RIA226M 1210 TDK 847-803-6100 847-803-6296

JMK325BJ226MM 1210 Taiyo-Yuden 847-925-0888 847-925-0899

ECJ4YB0J226M 1210 Panasonic 714-373-7366 714-373-7323

GRM42-2X5R226K6.3 1210 muRata 404-436-1300 404-436-3030

10µF, 6.3V, X7R or X5R Ceramic Capacitor for C1 (Input Filter Capacitor)

C2012X5R0J106M 0805 TDK 847-803-6100 847-803-6296

JMK212BJ106MG 0805 Taiyo Yuden 847-925-0888 847-925-0899

ECJ3YB0J106K 1206 Panasonic 714-373-7366 714-373-7323

GRM40X5R106K6.3 0805 muRata 404-436-1400 404-436-3030

LM2618

Capacitor Selection

Use a 10µF, 6.3V, X7R or X5R ceramic input filter capacitor

and a 22µF, X7R or X5R ceramic output filter capacitor.

These provide an optimal balance between small size, cost,

reliability and performance. Do not use Y5V ceramic capacitors. Table 3 lists suggested capacitors and suppliers.

A 10µF ceramic capacitor can be used for the output filter

capacitor for smaller size in applications where the

worst-case transient load step is less than 200mA. Use of a

10µF output capacitor trades off smaller size for an increase

in output voltage ripple, and undershoot during line and load

transient response.

The input filter capacitor supplies current to the PFET switch

of the LM2618 in the first part of each cycle and reduces

voltage ripple imposed on the input power source. The output filter capacitor smoothes out current flow from the inductor to the load, helps maintain a steady output voltage during

transient load changes and reduces output voltage ripple.

These capacitors must be selected with sufficient capacitance and sufficiently low ESR to perform these functions.

The ESR, or equivalent series resistance, of the filter capacitors is a major factor in voltage ripple.

Micro SMD Package Assembly and Use

Use of the micro SMD package requires specialized board

layout, precision mounting and careful reflow techniques, as

detailed in National Semiconductor Application Note

AN-1112. Refer to the section Surface Mount Technology

(SMT) Assembly Considerations. For best results in assembly, alignment ordinals on the PC board should be used to

facilitate placement of the device. Since micro SMD packaging is a new technology, all layouts and assembly means

must be thoroughly tested prior to production. In particular,

proper placement, solder reflow and resistance to thermal

cycling must be verified.

The 10-Bump package used for the LM2618 has 300micron

solder balls and requires 10.82mil (0.275mm) pads for

mounting on the circuit board. The trace to each pad should

enter the pad with a 90˚ entry angle to prevent debris from

being caught in deep corners. Initially, the trace to each pad

should be 6 mil wide, for a section 6 mil long or longer, as a

thermal relief. Then each trace should neck up to its optimal

width over a span of 11 mils or more, so that the taper

extends beyond the edge of the package. The important

criterion is symmetry. This ensures the solder bumps on the

LM2618 re-flow evenly and that the device solders level to

the board. In particular, special attention must be paid to the

pads for bumps D3,C3,B3,A3, and A2. Because PVIN and

PGND are typically connected to large copper planes, inadequate thermal reliefs can result in late or inadequate reflow

of these bumps.

The pad style used with micro SMD package must be the

NSMD (non-solder mask defined) type. This means that the

solder-mask opening is larger than the pad size or 14.7mils

for the LM2618. This prevents a lip that otherwise forms if

the solder-mask and pad overlap. This lip can hold the

device off the surface of the board and interfere with mounting. See Applications Note AN-1112 for specific instructions.

Board Layout Considerations

PC board layout is an important part of DC-DC converter

design. Poor board layout can disrupt the performance of a

DC-DC converter and surrounding circuitry by contributing to

EMI, ground bounce, and resistive voltage loss in the traces.

These can send erroneous signals to the DC-DC converter

IC, resulting in poor regulation or instability. Poor layout can

also result in reflow problems leading to poor solder joints

between the micro SMD package and board pads. Poor

solder joints can result in erratic or degraded performance.

Good layout for the LM2618 can be implemented by following a few simple design rules:

1. Place the LM2618 on 10.82mil pads for micro SMD

package. As a thermal relief, connect to each pad with a

6mil wide trace (micro SMD), 6mils long or longer, then

incrementally increase each trace to its optimal width

over a span so that the taper extends beyond the edge

of the package. The important criterion is symmetry to

ensure re-flow occurs evenly (see Micro SMD Package

Assembly and Use).

2. Place the LM2618, inductor and filter capacitors close

together and make the traces short. The traces between

these components carry relatively high switching currents and act as antennas. Following this rule reduces

radiated noise. Place the capacitors and inductor within

0.2in (5mm) of the LM2618.

www.national.com13

Page 14

Application Information (Continued)

3. Arrange the components so that the switching current

LM2618

loops curl in the same direction. During the first part of

each cycle, current flows from the input filter capacitor,

through the LM2618 and inductor to the output filter

capacitor and back through ground, forming a current

loop. In the second part of each cycle, current is pulled

up from ground, through the LM2618 by the inductor, to

the output filter capacitor and then back through ground,

forming a second current loop. Routing these loops so

the current curls in the same direction prevents magnetic field reversal between the two part-cycles and

reduces radiated noise.

4. Connect the ground pins of the LM2618 and filter capacitors together using generous component-side copper fill as a pseudo-ground plane. Then, connect this to

the ground-plane (if one is used) with several vias. This

reduces ground-plane noise by preventing the switching

currents from circulating through the ground plane. It

also reduces ground bounce at the LM2618 by giving it

a low-impedance ground connection.

5. Use wide traces between the power components and for

power connections to the DC-DC converter circuit. This

reduces voltage errors caused by resistive losses across

the traces.

6. Route noise sensitive traces, such as the voltage feedback path, away from noisy traces between the power

components. The voltage feedback trace must remain

close to the LM2618 circuit and should be direct and

routed away from noisy components. This reduces EMI

radiated onto the DC-DC converter’s own voltage feedback trace.

7. Place noise sensitive circuitry, such as radio IF blocks,

away from the DC-DC converter, CMOS digital blocks

and other noisy circuitry. Interference with

noise-sensitive circuitry in the system can be reduced

through distance.

In mobile phones, for example, a common practice is to

place the DC-DC converter on one corner of the board,

arrange the CMOS digital circuitry around it (since this also

generates noise), and then place sensitive preamplifiers and

IF stages on the diagonally opposing corner. Often, the

sensitive circuitry is shielded with a metal pan and power to

it is post-regulated to reduce conducted noise, using

low-dropout linear regulators, such as the LP2966.

www.national.com 14

Page 15

Physical Dimensions inches (millimeters)

unless otherwise noted

LM2618 400mA Sub-miniature, High Efficiency, Synchronous PWM & PFM Programmable DC-DC

Converter

NOTES: UNLESS OTHERWISE SPECIFIED

1. EPOXY COATING

2. 63Sn/37Pb EUTECTIC BUMP

3. RECOMMEND NON-SOLDER MASK DEFINED LANDING PAD.

4. PIN A1 IS ESTABLISHED BY LOWER LEFT CORNER WITH RESPECT TO TEXT ORIENTATION. REMAINING PINS ARE NUMBERED COUNTER

CLOCKWISE.

5. XXX IN DRAWING NUMBER REPRESENTS PACKAGE SIZE VARIATION WHERE X1 IS PACKAGE WIDTH, X2 IS PACKAGE LENGTH AND X3 IS

PACKAGE HEIGHT.

10-Bump micro SMD Package

NS Package Number TLP106WA

The dimensions for X1, X2 and X3 are as given:

X1 = 2.250 +/− 0.030mm

X2 = 2.504 +/− 0.030mm

X3 = 0.600 +/− 0.075mm

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Corporation

Americas

Email: support@nsc.com

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: ap.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

Loading...

Loading...