Page 1

LM2591HV

SIMPLE SWITCHER

®

Power Converter 150 kHz 1A

Step-Down Voltage Regulator

General Description

The LM2591HV series of regulators are monolithic integrated circuits that provide all the active functions for a

step-down (buck) switching regulator, capable of driving a

1A load with excellent line and load regulation. These devices are available in fixed output voltages of 3.3V, 5V, and

an adjustable output version.

This series of switching regulators is similar to the

LM2590HV, but without some of the supervisory and performance features of the latter.

Requiring a minimum number of external components, these

regulators are simple to use and include internal frequency

compensation

fixed-frequency oscillator.

The LM2591HV operates at a switching frequency of 150

kHz thus allowing smaller sized filter components than what

would be needed with lower frequency switching regulators.

Available in a standard 5-lead TO-220 package with several

different lead bend options, and a 5-lead TO-263 Surface

mount package.

Other features include a guaranteed

put voltage under all conditions of input voltage and output

load conditions, and

ternal shutdown is included, featuring typically 90 µA

standby current. Self protection features include a two stage

†

, improved line and load specifications and a

±

4% tolerance on out-

±

15% on the oscillator frequency. Ex-

July 2003

current limit for the output switch and an over temperature

shutdown for complete protection under fault conditions.

Features

n 3.3V, 5V, and adjustable output versions

n Adjustable version output voltage range, 1.2V to 57V

±

4% max over line and load conditions

n Guaranteed 1A output load current

n Available in 5-pin TO-220 and TO-263 (surface mount)

Package

n Input voltage range up to 60V

n 150 kHz fixed frequency internal oscillator

n On/Off control

n Low power standby mode, I

n High Efficiency

n Thermal shutdown and current limit protection

typically 90 µA

Q

Applications

n Simple high-efficiency step-down (buck) regulator

n Efficient pre-regulator for linear regulators

n On-card switching regulators

n Positive to Negative converter

Note:†Patent Number 5,382,918.

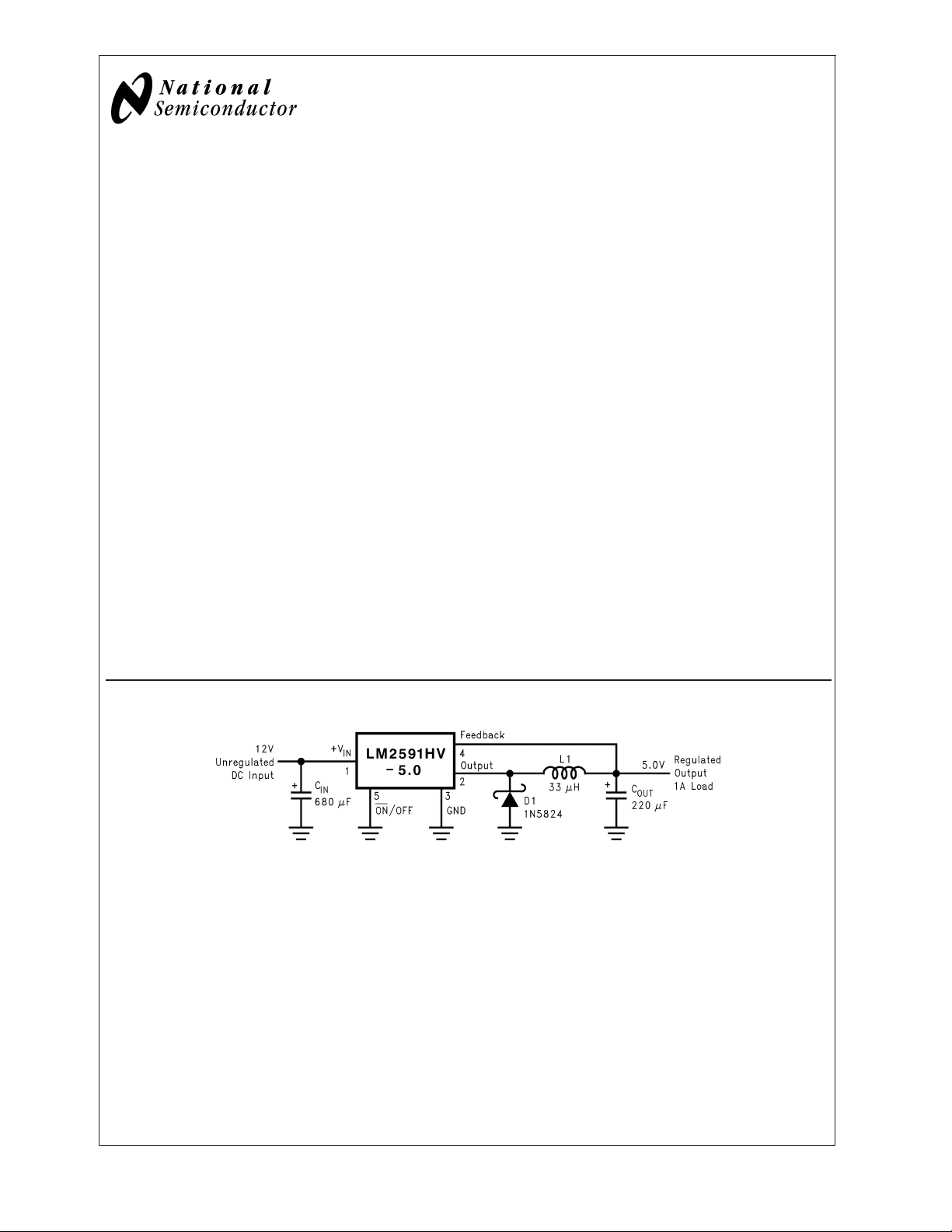

LM2591HV SIMPLE SWITCHER Power Converter 150 kHz 1A Step-Down Voltage Regulator

Typical Application (Fixed Output Voltage Versions)

10129301

SIMPLE SWITCHER®and Switchers Made Simple®are registered trademarks of National Semiconductor Corporation.

© 2003 National Semiconductor Corporation DS101293 www.national.com

Page 2

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

LM2591HV

Distributors for availability and specifications.

Maximum Supply Voltage (V

ON/OFF Pin Voltage

Feedback Pin Voltage −0.3 ≤ V ≤ +25V

) 63V

IN

−0.3 ≤ V ≤ +25V

Human Body Model (Note 2) 2 kV

Lead Temperature

S Package

Vapor Phase (60 sec.) +215˚C

Infrared (10 sec.) +245˚C

T Package (Soldering, 10 sec.) +260˚C

Maximum Junction Temperature +150˚C

Output Voltage to Ground

(Steady State) −1V

Operating Conditions

Power Dissipation Internally limited

Storage Temperature Range −65˚C to +150˚C

ESD Susceptibility

Temperature Range −40˚C ≤ TJ≤ +125˚C

Supply Voltage 4.5V to 60V

LM2591HV-3.3 Electrical Characteristics

Specifications with standard type face are for TJ= 25˚C, and those with boldface type apply over full Operating Temperature Range.

Symbol Parameter Conditions LM2591HV-3.3 Units

Typ Limit

(Note 3) (Note 4)

SYSTEM PARAMETERS (Note 5) Test Circuit Figure 1

V

OUT

Output Voltage 4.75V ≤ VIN≤ 60V, 0.2A ≤ I

η Efficiency V

= 12V, I

IN

=1A 77

LOAD

≤ 1A 3.3 V

LOAD

3.168/3.135 V(min)

3.432/3.465 V(max)

(Limits)

LM2591HV-5.0 Electrical Characteristics

Specifications with standard type face are for TJ= 25˚C, and those with boldface type apply over full Operating Temperature Range.

Symbol Parameter Conditions LM2591HV-5.0 Units

Typ Limit

(Limits)

(Note 3) (Note 4)

SYSTEM PARAMETERS (Note 5) Test Circuit Figure 1

V

OUT

Output Voltage 7V ≤ VIN≤ 60V, 0.2A ≤ I

≤ 1A 5 V

LOAD

4.800/4.750 V(min)

5.200/5.250 V(max)

η Efficiency V

= 12V, I

IN

=1A 82 %

LOAD

LM2591HV-ADJ Electrical Characteristics

Specifications with standard type face are for TJ= 25˚C, and those with boldface type apply over full Operating Temperature Range.

Symbol Parameter Conditions LM2591HV-ADJ Units

(Limits)

SYSTEM PARAMETERS (Note 5) Test Circuit Figure 1

V

FB

η Efficiency V

Feedback Voltage 4.5V ≤ VIN≤ 60V, 0.2A ≤ I

V

programmed for 3V. Circuit of Figure 1. 1.193/1.180 V(min)

OUT

= 12V, V

IN

OUT

= 3V, I

Typ Limit

(Note 3) (Note 4)

≤ 1A 1.230 V

LOAD

1.267/1.280 V(max)

=1A 76 %

LOAD

www.national.com 2

Page 3

All Output Voltage Versions Electrical Characteristics

Specifications with standard type face are for TJ= 25˚C, and those with boldface type apply over full Operating Temperature Range. Unless otherwise specified, V

= 12V for the 3.3V, 5V, and Adjustable version. I

IN

Symbol Parameter Conditions LM2591HV-XX Units

DEVICE PARAMETERS

I

b

f

O

V

SAT

Feedback Bias Current Adjustable Version Only, VFB= 1.3V 10 nA

Oscillator Frequency (Note 6) 150 kHz

Saturation Voltage I

= 1A (Note 7) (Note 8) 0.95 V

OUT

DC Max Duty Cycle (ON) (Note 8) 100 %

Min Duty Cycle (OFF) (Note 9) 0

I

I

CLIM

L

Switch current Limit Peak Current, (Note 7) (Note 8) 1.9 A

Output Leakage Current (Note 7) (Note 9) (Note 10) Output = 0V 50 µA(max)

Output = −1V 5 mA

I

Q

Operating Quiescent SD /SS Pin Open (Note 9) 5mA

Current 10 mA(max)

I

STBY

Standby Quiescent SD /SS pin = 0V (Note 10) 90 µA

Current 200/250 µA(max)

θ

JC

θ

JA

θ

JA

θ

JA

θ

JA

Thermal Resistance TO220 or TO263 Package, Junction to Case 2 ˚C/W

TO220 Package, Juncton to Ambient (Note 11) 50 ˚C/W

TO263 Package, Juncton to Ambient (Note 12) 50 ˚C/W

TO263 Package, Juncton to Ambient (Note 13) 30 ˚C/W

TO263 Package, Juncton to Ambient (Note 14) 20 ˚C/W

ON/OFF CONTROL Test Circuit Figure 1

ON /OFF Pin Logic Input

V

IH

V

IL

I

H

I

L

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

intended to be functional, but do not guarantee specific performance limits. For guaranteed specifications and test conditions, see the Electrical Characteristics.

Note 2: The human body model is a 100 pF capacitor discharged through a 1.5k resistor into each pin.

Note 3: Typical numbers are at 25˚C and represent the most likely norm.

Note 4: All limits guaranteed at room temperature (standard type face) and at temperature extremes (bold type face). All room temperature limits are 100%

production tested. All limits at temperature extremes are guaranteed via correlation using standard Statistical Quality Control (SQC) methods. All limits are used

to calculate Average Outgoing Quality Level (AOQL).

Note 5: External components such as the catch diode, inductor, input and output capacitors can affect switching regulator system performance. When the

LM2591HV is used as shown in the Figure 1 test circuit, system performance will be as shown in system parameters section of Electrical Characteristics.

Note 6: The switching frequency is reduced when the second stage current limit is activated. The amount of reduction is determined by the severity of current

overload.

Note 7: No diode, inductor or capacitor connected to output pin.

Note 8: Feedback pin removed from output and connected to 0V to force the output transistor switch ON.

Note 9: Feedback pin removed from output and connected to 12V for the 3.3V, 5V, and the ADJ. version to force the output transistor switch OFF.

Note 10: V

Threshold Voltage Low (Regulator ON) 0.6 V(max)

High (Regulator OFF) 2.0 V(min)

ON /OFF Pin Input Current V

= 60V.

IN

= 2.5V (Regulator OFF) 5 µA

LOGIC

V

= 0.5V (Regulator ON) 0.02 µA

LOGIC

= 500 mA

LOAD

Typ Limit

(Note 3) (Note 4)

50/100 nA (max)

127/110 kHz(min)

173/173 kHz(max)

1.2/1.3 V(max)

1.3/1.2 A(min)

2.8/3.0 A(max)

30 mA(max)

1.3 V

15 µA(max)

5 µA(max)

(Limits)

LM2591HV

www.national.com3

Page 4

All Output Voltage Versions

Electrical Characteristics

Note 11: Junction to ambient thermal resistance (no external heat sink) for the package mounted TO-220 package mounted vertically, with the leads soldered to

LM2591HV

a printed circuit board with (1 oz.) copper area of approximately 1 in

Note 12: Junction to ambient thermal resistance with the TO-263 package tab soldered to a single sided printed circuit board with 0.5 in

Note 13: Junction to ambient thermal resistance with the TO-263 package tab soldered to a single sided printed circuit board with 2.5 in

Note 14: Junction to ambient thermal resistance with the TO-263 package tab soldered to a double sided printed circuit board with 3 in

the LM2591HVS side of the board, and approximately 16 in

model in Switchers Made Simple available at http://power.national.com.

(Continued)

2

.

2

of copper on the other side of the p-c board. See application hints in this data sheet and the thermal

2

of (1 oz.) copper area.

2

of (1 oz.) copper area.

2

of (1 oz.) copper area on

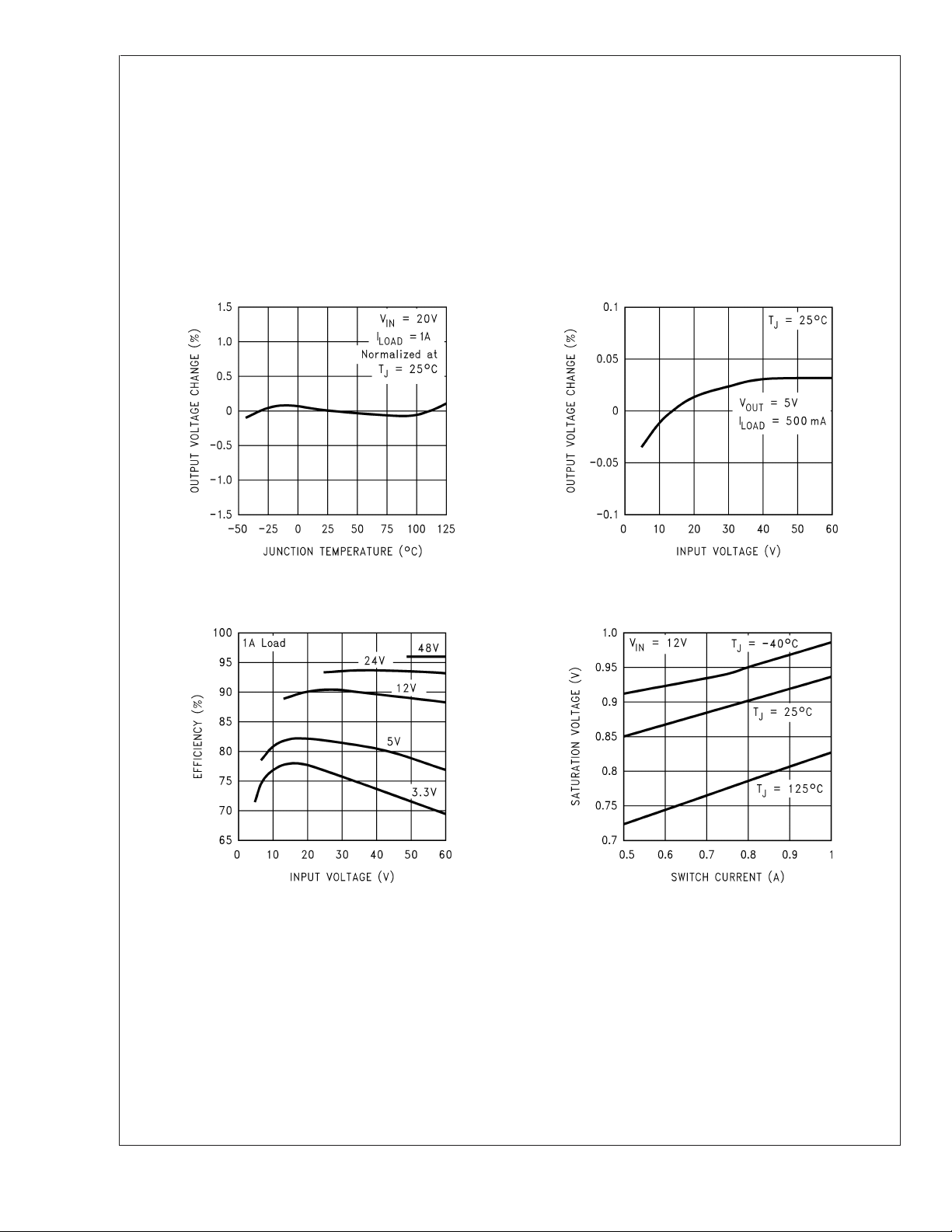

Typical Performance Characteristics (Circuit of Figure 1)

Normalized

Output Voltage Line Regulation

Efficiency

10129302

10129304

10129303

Switch Saturation

Voltage

10129305

www.national.com 4

Page 5

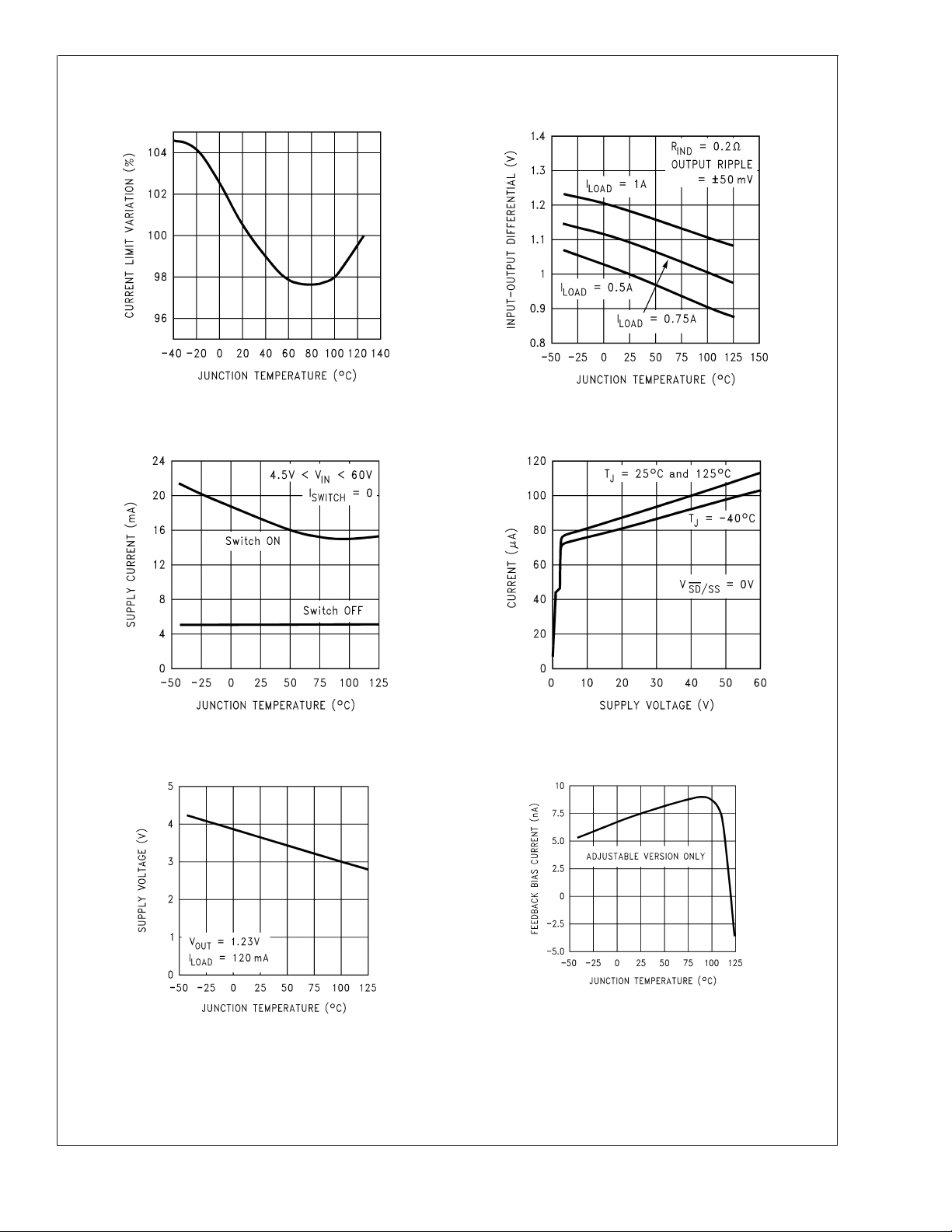

Typical Performance Characteristics (Circuit of Figure 1) (Continued)

Switch Current Limit Dropout Voltage

LM2591HV

Operating

Quiescent Current

Minimum Operating

Supply Voltage

10129306

10129307

Shutdown

Quiescent Current

10129308 10129309

Feedback Pin

Bias Current

10129310

10129311

www.national.com5

Page 6

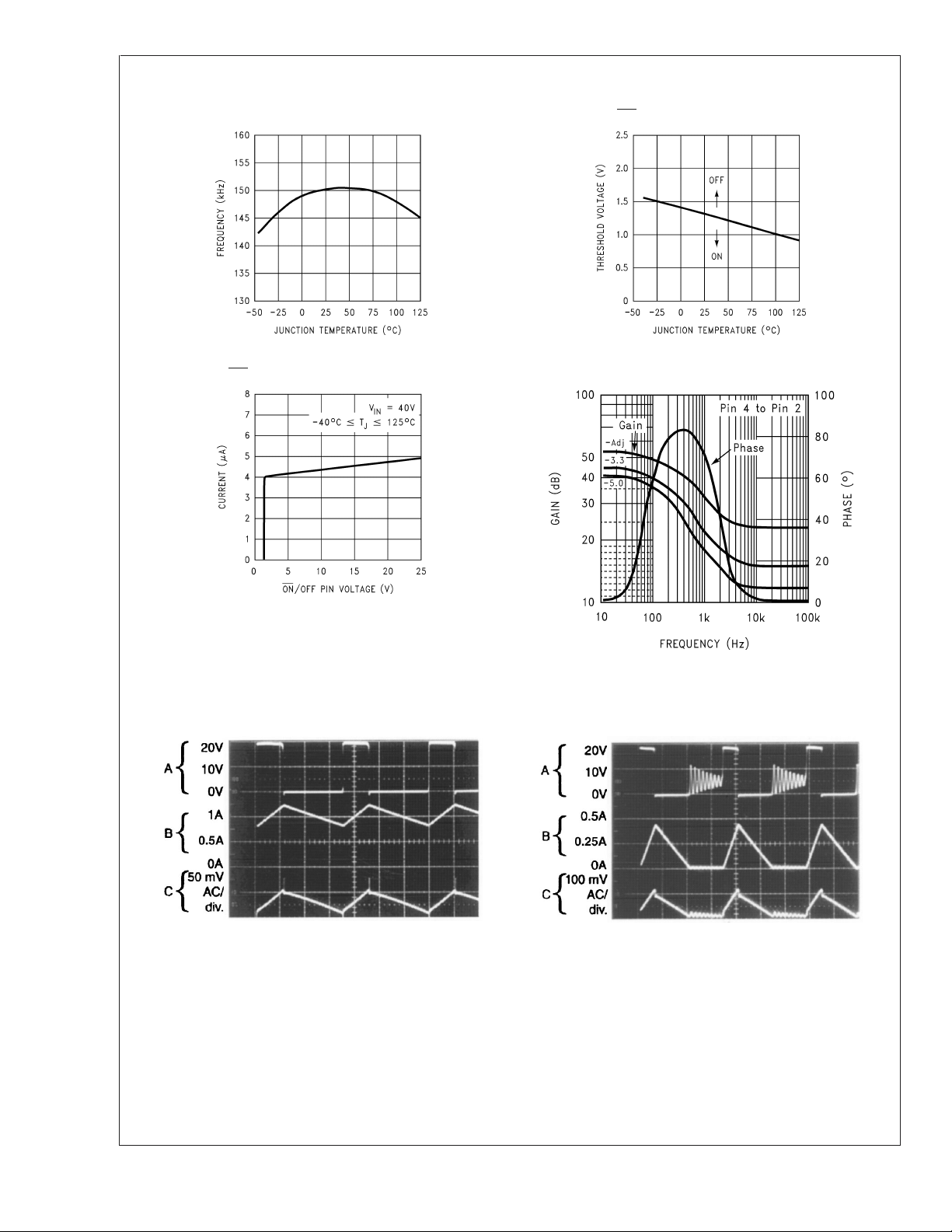

Typical Performance Characteristics (Circuit of Figure 1) (Continued)

LM2591HV

Switching Frequency ON/OFF Threshold Voltage

10129313

10129379

ON/OFF Pin Current (Sinking) Internal Gain-Phase Characteristics

Continuous Mode Switching Waveforms

= 20V, V

V

L = 52 µH, C

IN

A: Output Pin Voltage, 10V/div.

B: Inductor Current 0.5A/div.

C: Output Ripple Voltage, 50 mV/div.

= 100 µF, C

OUT

OUT

Horizontal Time Base: 2 µs/div.

= 5V, I

10129380

=1A

LOAD

ESR = 100 mΩ

OUT

10129320

Discontinuous Mode Switching Waveforms

V

= 20V, V

IN

L = 15 µH, C

A: Output Pin Voltage, 10V/div.

B: Inductor Current 0.25A/div.

C: Output Ripple Voltage, 100 mV/div.

OUT

= 5V, I

OUT

= 150 µF, C

LOAD

OUT

Horizontal Time Base: 2 µs/div.

10129378

= 250 mA

ESR=90mΩ

10129319

www.national.com 6

Page 7

Typical Performance Characteristics (Circuit of Figure 1) (Continued)

LM2591HV

Load Transient Response for Continuous Mode

V

= 20V, V

IN

L = 52 µH, C

A: Output Voltage, 100 mV/div. (AC)

B: 250 mA to 1A Load Pulse

OUT

= 100 µF, C

OUT

= 5V, I

= 250 mA to 1A

LOAD

ESR = 100 mΩ

OUT

10129321

Load Transient Response for Discontinuous Mode

V

L = 15 µH, C

A: Output Voltage, 100 mV/div. (AC)

B: 250 mA to 1A Load Pulse

Horizontal Time Base: 50 µs/div.

Connection Diagrams and Order Information

Bent and Staggered Leads, Through Hole Package

5-Lead TO-220 (T)

= 20V, V

IN

= 5V, I

OUT

= 150 µF, C

OUT

= 250 mA to 1A

LOAD

OUT

Horizontal Time Base: 200 µs/div.

Surface Mount Package

5-Lead TO-263 (S)

ESR=90mΩ

10129322

Order Number LM2591HVT-3.3, LM2591HVT-5.0,

10129381

or LM2591HVT-ADJ

See NS Package Number T05D

Order Number LM2591HVS-3.3, LM2591HVS-5.0,

10129382

or LM2591HVS-ADJ

See NS Package Number TS5B

www.national.com7

Page 8

Test Circuit and Layout Guidelines

LM2591HV

Fixed Output Voltage Versions

Component Values shown are for VIN= 15V,

10129324

= 5V, I

V

OUT

— 470 µF, 50V, Aluminum Electrolytic Nichicon “PM Series”

C

IN

— 220 µF, 25V Aluminum Electrolytic, Nichicon “PM Series”

C

OUT

LOAD

= 1A.

D1 — 2A, 60V Schottky Rectifier, 21DQ06 (International Rectifier)

L1 — 68 µH, See Inductor Selection Procedure

Adjustable Output Voltage Versions

Select R1to be approximately 1 kΩ, use a 1% resistor for best stability.

Component Values shown are for V

= 10V, I

V

OUT

: — 470 µF, 35V, Aluminum Electrolytic Nichicon “PM Series”

C

IN

: — 220 µF, 35V Aluminum Electrolytic, Nichicon “PM Series”

C

OUT

LOAD

= 1A.

IN

= 20V,

D1 — 2A, 60V Schottky Rectifier, 21DQ06 (International Rectifier)

L1 — 100 µH, See Inductor Selection Procedure

—1kΩ,1%

R

1

— 7.15k, 1%

R

2

— 3.3 nF

C

FF

Typical Values

— 0.1 µF

C

SS

— 0.1 µF

C

DELAY

R

†

— 4.7k (use 22k if V

PULL UP

Small signal Schottky diode to prevent damage to feedback pin by negative spike when output is shorted (CFFnot being able to discharge immediately will

drag feedback pin below ground). Required if V

OUT

is ≥ 45V)

>

40V

IN

10129325

FIGURE 1. Standard Test Circuits and Layout Guides

www.national.com 8

Page 9

Block Diagram

LM2591HV

10129383

Pin Functions

+VIN(Pin 1) —This is the positive input supply for the IC

switching regulator. A suitable input bypass capacitor must

be present at this pin to minimize voltage transients and to

supply the switching currents needed by the regulator.

Output (Pin 2) — Internal switch. The voltage at this pin

switches between approximately (+V

mately −0.5V, with a duty cycle of V

Ground (Pin 3)— Circuit ground.

Feedback (Pin 4) —Senses the regulated output voltage to

complete the feedback loop. This pin is directly connected to

the Output for the fixed voltage versions, but is set to 1.23V

by means of a resistive divider from the output for the

Adjustable version. If a feedforward capacitor is used (Adjustable version), then a negative voltage spike is generated

IN−VSAT

OUT/VIN

) and approxi-

.

on this pin whenever the output is shorted. This happens

because the feedforward capacitor cannot discharge fast

enough, and since one end of it is dragged to Ground, the

other end goes momentarily negative. To prevent the energy

rating of this pin from being exceeded, a small-signal Schottky diode to Ground is recommended for DC input voltages

above 40V whenever a feedforward capacitor is present

(See Figure 1). Feedforward capacitor values larger than 0.1

µF are not recommended for the same reason, whatever be

the DC input voltage.

ON /OFF (Pin 5) — The regulator is in shutdown mode,

drawing about 90 µA, when this pin is driven to a high level

(≥ 2.0V), and is in normal operation when this Pin is left

floating or driven to a low level (≤ 0.6V). The typical value of

the threshold is 1.3V and the voltage on this pin must not

exceed 25V.

www.national.com9

Page 10

Inductor Value Selection Guides

(For Continuous Mode Operation)

LM2591HV

FIGURE 2. LM2591HV-3.3

10129365

FIGURE 3. LM2591HV-5.0

www.national.com 10

10129366

Page 11

Inductor Value Selection Guides (For Continuous Mode Operation) (Continued)

LM2591HV

FIGURE 4. LM2591HV-ADJ

FIGURE 5. Current Ripple Ratio

10129367

10129368

www.national.com11

Page 12

Inductor Value Selection Guides (For Continuous Mode Operation) (Continued)

LM2591HV

Coilcraft Inc. Phone (USA): 1-800-322-2645

Web Address http://www.coilcraft.com

Coilcraft Inc., Europe Phone (UK): 1-236-730595

Web Address http://www.coilcraft-europe.com

Pulse Engineering Inc. Phone (USA): 1-858-674-8100

Web Address http://www.pulseeng.com

Pulse Engineering Inc., Phone (UK): 1-483-401700

Europe Web Address http://www.pulseeng.com

Renco Electronics Inc. Phone (USA): 1-321-637-1000

Web Address http://www.rencousa.com

Schott Corp. Phone (USA): 1-952-475-1173

Web Address http://www.shottcorp.com

Cooper Electronic Tech.

(Coiltronics)

TDK Phone (USA): 1-847-803-6100

FIGURE 6. Contact Information for Suggested Inductor Manufacturers

Phone (USA): 1-888-414-2645

Web Address http://www.cooperet.com

Web Address http://www.componet.tdk.com

www.national.com 12

Page 13

Application Information

INDUCTOR SELECTION PROCEDURE

Application Note AN-1197 titled "Selecting Inductors for Buck

Converters" provides detailed information on this topic. For a

quick-start the designer may refer to the nomographs provided in Figure 2 to Figure 4. To widen the choice of the

Designer to a more general selection of available inductors,

the nomographs provide the required inductance and also

the energy in the core expressed in microjoules (µJ), as an

alternative to just prescribing custom parts. The following

points need to be highlighted:

1. The Energy values shown on the nomographs apply to

steady operation at the corresponding x-coordinate

(rated maximum load current). However under start-up,

without soft-start, or a short-circuit on the output, the

current in the inductor will momentarily/repetitively hit

the current limit I

could be much higher than the rated load, I

represents an overload situation, and can cause the

Inductor to saturate (if it has been designed only to

handle the energy of steady operation). However most

types of core structures used for such applications have

a large inherent air gap (for example powdered iron

types or ferrite rod inductors), and so the inductance

does not fall off too sharply under an overload. The

device is usually able to protect itself by not allowing the

current to ever exceed I

to the regulator is over 40V, the current can slew up so

fast under core saturation, that the device may not be

able to act fast enough to restrict the current. The current can then rise without limit till destruction of the

device takes place. Therefore to ensure reliability, it is

recommended, that if the DC Input Voltage exceeds

40V, the inductor must ALWAYS be sized to handle an

instantaneous current equal to I

irrespective of the type of core structure/material.

2. The Energy under steady operation is

of the device, and this current

CLIM

. But if the DC input voltage

CLIM

without saturating,

CLIM

LOAD

. This

consider the rather wide tolerance on the nominal inductance of commercial inductors.

5. Figure 4 shows the inductor selection curves for the

Adjustable version. The y-axis is ’Et’, in Vµsecs. It is the

applied volts across the inductor during the ON time of

the switch (V

IN-VSAT-VOUT

) multiplied by the time for

which the switch is on in µsecs. See Example 3 below.

Example 1: (V

@

0.8A

5V

≤ 40V) LM2591HV-5.0, VIN= 24V, Output

IN

1. A first pass inductor selection is based upon Inductance

and rated max load current. We choose an inductor with the

Inductance value indicated by the nomograph (Figure 3) and

a current rating equal to the maximum load current. We

therefore quick-select a 100µH/0.8A inductor (designed for

150 kHz operation) for this application.

2. We should confirm that it is rated to handle 50 µJ (see

Figure 3) by either estimating the peak current or by a

detailed calculation as shown in AN-1197, and also that the

losses are acceptable.

>

Example 2: (V

@

1A

5V

40V) LM2591HV-5.0, VIN= 48V, Output

IN

1. A first pass inductor selection is based upon Inductance

and the switch currrent limit. We choose an inductor with the

Inductance value indicated by the nomograph (Figure 3) and

a current rating equal to I

. We therefore quick-select a

CLIM

100µH/3A inductor (designed for 150 kHz operation) for this

application.

2. We should confirm that it is rated to handle e

CLIM

by the

procedure shown in AN-1197 and that the losses are acceptable. Here e

CLIM

is:

LM2591HV

where L is in µH and I

current waveform with the regulator delivering I

is the peak of the inductor

PEAK

LOAD

These are the energy values shown in the nomographs.

See Example 1 below.

3. The Energy under overload is

>

If V

e

CLIM

case I

40V, the inductor should be sized to handle

IN

instead of the steady energy values. The worst

for the LM2591HV is 3A. The Energy rating

CLIM

depends on the Inductance. See Example 2 below.

4. The nomographs were generated by allowing a greater

amount of percentage current ripple in the Inductor as

the maximum rated load decreases (see Figure 5). This

was done to permit the use of smaller inductors at light

loads. Figure 5 however shows only the ’median’ value

of the current ripple. In reality there may be a great

spread around this because the nomographs approximate the exact calculated inductance to standard available values. It is a good idea to refer to AN-1197 for

detailed calculations if a certain maximum inductor current ripple is required for various possible reasons. Also

Example 3: (VIN≤ 40V) LM2591HV-ADJ, VIN= 20V, Output

@

1A

10V

1. Since input voltage is less than 40V, a first pass inductor

selection is based upon Inductance and rated max load

.

current. We choose an inductor with the Inductance value

indicated by the nomograph Figure 4 and a current rating

equal to the maximum load. But we first need to calculate Et

for the given application. The Duty cycle is

where VDis the drop across the Catch Diode () 0.5V for a

Schottky) and V

the drop across the switch ()1.5V). So

SAT

And the switch ON time is

where f is the switching frequency in Hz. So

www.national.com13

Page 14

Application Information (Continued)

LM2591HV

Therefore, looking at Figure 2 we quick-select a 100µH/1A

inductor (designed for 150 kHz operation) for this application.

2. We should confirm that it is rated to handle 100 µJ (see

Figure 4) by the procedure shown in AN-1197 and that the

losses are acceptable. (If the DC Input voltage had been

greater than 40V we would need to consider e

Example 2 above).

Note that we have taken V

estimated resistive drop across the inductor.

This completes the simplified inductor selection procedure.

For more general applications and better optimization, the

designer should refer to AN-1197. Figure 6 provides helpful

contact information on suggested Inductor manufacturers

who may be able to recommend suitable parts, if the requirements are known.

FEEDFORWARD CAPACITOR

(Adjustable Output Voltage Version)

- A Feedforward Capacitor CFF, shown across R2 in

C

FF

Figure 1 is used when the output voltage is greater than 10V

or when C

has a very low ESR. This capacitor adds lead

OUT

compensation to the feedback loop and increases the phase

margin for better loop stability.

If the output voltage ripple is large (

output voltage), this ripple can be coupled to the feedback

pin through the feedforward capacitor and cause the error

comparator to trigger the error flag. In this situation, adding a

resistor, R

, in series with the feedforward capacitor, ap-

FF

proximately 3 times R1, will attenuate the ripple voltage at

the feedback pin.

INPUT CAPACITOR

C

— A low ESR aluminum or tantalum bypass capacitor is

IN

needed between the input pin and ground pin. It must be

located near the regulator using short leads. This capacitor

prevents large voltage transients from appearing at the input, and provides the instantaneous current needed each

time the switch turns on.

The important parameters for the Input capacitor are the

voltage rating and the RMS current rating. Because of the

relatively high RMS currents flowing in a buck regulator’s

input capacitor, this capacitor should be chosen for its RMS

current rating rather than its capacitance or voltage ratings,

although the capacitance value and voltage rating are directly related to the RMS current rating. The voltage rating of

the capacitor and its RMS ripple current capability must

never be exceeded.

as 1.5V which includes an

SAT

>

5% of the nominal

CLIM

as in

OUTPUT CAPACITOR

— An output capacitor is required to filter the output

C

OUT

and provide regulator loop stability. Low impedance or low

ESR Electrolytic or solid tantalum capacitors designed for

switching regulator applications must be used. When selecting an output capacitor, the important capacitor parameters

are; the 100 kHz Equivalent Series Resistance (ESR), the

RMS ripple current rating, voltage rating, and capacitance

value. For the output capacitor, the ESR value is the most

important parameter. The ESR should generally not be less

than 100 mΩ or there will be loop instability. If the ESR is too

large, efficiency and output voltage ripple are effected. So

ESR must be chosen carefully.

CATCH DIODE

Buck regulators require a diode to provide a return path for

the inductor current when the switch turns off. This must be

a fast diode and must be located close to the LM2591HV

using short leads and short printed circuit traces.

Because of their very fast switching speed and low forward

voltage drop, Schottky diodes provide the best performance,

especially in low output voltage applications (5V and lower).

Ultra-fast recovery, or High-Efficiency rectifiers are also a

good choice, but some types with an abrupt turnoff characteristic may cause instability or EMI problems. Ultra-fast

recovery diodes typically have reverse recovery times of 50

ns or less. The diode must be chosen for its average/RMS

current rating and maximum voltage rating. The voltage

rating of the diode must be greater than the DC input voltage

(not the output voltage).

DELAYED STARTUP

The circuit in Figure 7 uses the the ON /OFF pin to provide

a time delay between the time the input voltage is applied

and the time the output voltage comes up (only the circuitry

pertaining to the delayed start up is shown). As the input

voltage rises, the charging of capacitor C1 pulls the ON /OFF

pin high, keeping the regulator off. Once the input voltage

reaches its final value and the capacitor stops charging, and

resistor R

pulls the ON /OFF pin low, thus allowing the

2

circuit to start switching. Resistor R1is included to limit the

maximum voltage applied to the ON /OFF pin (maximum of

25V), reduces power supply noise sensitivity, and also limits

the capacitor, C1, discharge current. When high input ripple

voltage exists, avoid long delay time, because this ripple can

be coupled into the ON /OFF pin and cause problems.

This delayed startup feature is useful in situations where the

input power source is limited in the amount of current it can

deliver. It allows the input voltage to rise to a higher voltage

before the regulator starts operating. Buck regulators require

less input current at higher input voltages.

www.national.com 14

Page 15

Application Information (Continued)

FIGURE 7. Delayed Startup

LM2591HV

10129336

UNDERVOLTAGE LOCKOUT

Some applications require the regulator to remain off until

the input voltage reaches a predetermined voltage. An undervoltage lockout feature applied to a buck regulator is

shown in Figure 8, while Figure 9 and Figure 10 applies the

same feature to an inverting circuit. The circuit in Figure 9

features a constant threshold voltage for turn on and turn off

(zener voltage plus approximately one volt). If hysteresis is

FIGURE 8. Undervoltage Lockout for Buck Regulator

needed, the circuit in Figure 10 has a turn ON voltage which

is different than the turn OFF voltage. The amount of hysteresis is approximately equal to the value of the output voltage. If zener voltages greater than 25V are used, an additional 47 kΩ resistor is needed from the ON /OFF pin to the

ground pin to stay within the 25V maximum limit of the ON

/OFF pin.

10129337

www.national.com15

Page 16

Application Information (Continued)

LM2591HV

This circuit has an ON/OFF threshold of approximately 13V.

FIGURE 9. Undervoltage Lockout for Inverting Regulator

10129384

lNVERTING REGULATOR

The circuit in Figure 11 converts a positive input voltage to a

negative output voltage with a common ground. The circuit

operates by bootstrapping the regulator’s ground pin to the

negative output voltage, then grounding the feedback pin,

the regulator senses the inverted output voltage and regulates it.

This example uses the LM2591HV-5.0 to generate a −5V

output, but other output voltages are possible by selecting

other output voltage versions, including the adjustable version. Since this regulator topology can produce an output

voltage that is either greater than or less than the input

voltage, the maximum output current greatly depends on

both the input and output voltage.

To determine how much load current is possible before the

internal device current limit is reached (and power limiting

occurs), the system must be evaluated as a buck-boost

configuration rather than as a buck. The peak switch current

in Amperes, for such a configuration is given as:

where L is in µH and f is in Hz. The maximum possible load

current I

is limited by the requirement that I

LOAD

While checking for this, take I

to be the lowest possible

CLIM

PEAK

≤ I

CLIM

current limit value (min across tolerance and temperature is

1.2A for the LM2591HV). Also to account for inductor toler-

ances, we should take the min value of Inductance for L in

the equation above (typically 20% less than the nominal

value). Further, the above equation disregards the drop

across the Switch and the diode. This is equivalent to assuming 100% efficiency, which is never so. Therefore expect

to be an additional 10-20% higher than calculated from

I

PEAK

the above equation.

The reader is also referred to Application Note AN-1157 for

examples based on positive to negative configuration.

The maximum voltage appearing across the regulator is the

absolute sum of the input and output voltage, and this must

be limited to a maximum of 60V. For example, when converting +20V to −12V, the regulator would see 32V between the

input pin and ground pin. The LM2591HV has a maximum

input voltage spec of 60V.

Additional diodes are required in this regulator configuration.

Diode D1 is used to isolate input voltage ripple or noise from

coupling through the C

capacitor to the output, under light

IN

or no load conditions. Also, this diode isolation changes the

topology to closley resemble a buck configuration thus providing good closed loop stability. A Schottky diode is recommended for low input voltages, (because of its lower voltage

drop) but for higher input voltages, a fast recovery diode

could be used.

.

Without diode D3, when the input voltage is first applied, the

charging current of C

can pull the output positive by sev-

IN

eral volts for a short period of time. Adding D3 prevents the

output from going positive by more than a diode voltage.

www.national.com 16

Page 17

Application Information (Continued)

This circuit has hysteresis

Regulator starts switching at V

Regulator stops switching at V

FIGURE 10. Undervoltage Lockout with Hysteresis for Inverting Regulator

= 13V

IN

=8V

IN

LM2591HV

10129339

CIN— 68 µF/25V Tant. Sprague 595D

470 µF/50V Elec. Panasonic HFQ

— 47 µF/20V Tant. Sprague 595D

C

OUT

220 µF/25V Elec. Panasonic HFQ

FIGURE 11. Inverting −5V Regulator with Delayed Startup

Because of differences in the operation of the inverting

regulator, the standard design procedure is not used to

select the inductor value. In the majority of designs, a 33 µH,

3A inductor is the best choice. Capacitor selection can also

be narrowed down to just a few values.

This type of inverting regulator can require relatively large

amounts of input current when starting up, even with light

loads. Input currents as high as the LM2591HV current limit

(approx 4A) are needed for at least 2 ms or more, until the

output reaches its nominal output voltage. The actual time

depends on the output voltage and the size of the output

capacitor. Input power sources that are current limited or

sources that can not deliver these currents without getting

loaded down, may not work correctly. Because of the relatively high startup currents required by the inverting topology,

the delayed startup feature (C1, R

and R2) shown in Figure

1

10129340

11 is recommended. By delaying the regulator startup, the

input capacitor is allowed to charge up to a higher voltage

before the switcher begins operating. A portion of the high

input current needed for startup is now supplied by the input

capacitor (C

). For severe start up conditions, the input

IN

capacitor can be made much larger than normal.

lNVERTING REGULATOR SHUTDOWN METHODS

To use the ON /OFF pin in a standard buck configuration is

simple, pull it below 1.3V (@25˚C, referenced to ground) to

turn regulator ON, pull it above 1.3V to shut the regulator

OFF. With the inverting configuration, some level shifting is

required, because the ground pin of the regulator is no

longer at ground, but is now setting at the negative output

voltage level. Two different shutdown methods for inverting

regulators are shown in Figure 12 and Figure 13

www.national.com17

Page 18

Application Information (Continued)

LM2591HV

FIGURE 12. Inverting Regulator Ground Referenced Shutdown

10129342

FIGURE 13. Inverting Regulator Ground Referenced Shutdown using Opto Device

LAYOUT SUGGESTIONS

As in any switching regulator, layout is very important. Rapidly switching currents associated with wiring inductance can

generate voltage transients which can cause problems. For

minimal inductance and ground loops, with reference to

Figure 1, the wires indicated by heavy lines should be wide

printed circuit traces and should be kept as short as

possible. For best results, external components should be

located as close to the switcher lC as possible using ground

plane construction or single point grounding.

10129386

If open core inductors are used, special care must be

taken as to the location and positioning of this type of inductor. Allowing the inductor flux to intersect sensitive feedback,

lC groundpath and C

wiring can cause problems.

OUT

When using the adjustable version, special care must be

taken as to the location of the feedback resistors and the

associated wiring. Physically locate both resistors near the

IC, and route the wiring away from the inductor, especially an

open core type of inductor.

www.national.com 18

Page 19

Physical Dimensions inches (millimeters)

unless otherwise noted

LM2591HV

5-Lead TO-220 Bent and Staggered Package

Order Number LM2591HVT-3.3, LM2591HVT-5.0

or LM2591HVT-ADJ

NS Package Number T05D

www.national.com19

Page 20

Physical Dimensions inches (millimeters) unless otherwise noted (Continued)

5-Lead TO-263 Bent and Formed Package

Order Number LM2591HVS-3.3, LM2591HVS-5.0 or LM2591HVS-ADJ

NS Package Number TS5B

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

LM2591HV SIMPLE SWITCHER Power Converter 150 kHz 1A Step-Down Voltage Regulator

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...