Datasheet LM2586T-3.3, LM2586SX-ADJ, LM2586SX-5.0, LM2586SX-3.3, LM2586SX-12 Datasheet (NSC)

...Page 1

LM2586

SIMPLE SWITCHER

Shutdown

®

3A Flyback Regulator with

LM2586 SIMPLE SWITCHER 3A Flyback Regulator with Shutdown

May 1996

General Description

The LM2586 series of regulators are monolithic integrated

circuits specifically designed for flyback, step-up (boost), and

forward converter applications. The device is available in 4

different output voltage versions: 3.3V, 5.0V,12V,andadjustable.

Requiring a minimum number of external components,these

regulators are cost effective, and simple to use. Included in

the datasheet are typical circuits of boostandflybackregulators.Alsolistedare selector guides for diodes and capacitors

and a family of standard inductors and flyback transformers

designed to work with these switching regulators.

The power switch is a 3.0A NPN device that can stand-off

65V. Protecting the power switch are current and thermal

limiting circuits, and an undervoltage lockout circuit. This IC

contains an adjustable frequency oscillator that can be programmed up to 200kHz. The oscillator can also be synchronized with other devices, so that multiple devices can operate at the same switching frequency.

Other features includesoft start mode to reduce in-rush current during start up, and current mode control for improved

rejection of input voltage and output load transients and

cycle-by-cycle current limiting. The device also has a shutdown pin, so that it can be turned off externally. An output

voltage tolerance of

output load conditions, is guaranteed for the power supply

system.

±

4%, within specified input voltages and

Flyback Regulator

Features

n Requires few external components

n Family of standard inductors and transformers

n NPN output switches 3.0A, can stand off 65V

n Wide input voltage range: 4V to 40V

n Adjustable switching frequency: 100 kHz to 200 kHz

n External shutdown capability

n Draws less than 60 µA when shut down

n Frequency synchronization

n Current-mode operation for improved transient

response, line regulation, and current limit

n Internal soft-start function reduces in-rush current during

start-up

n Output transistor protected by current limit, under

voltage lockout, and thermal shutdown

n System output voltage tolerance of

and load conditions

±

4%max over line

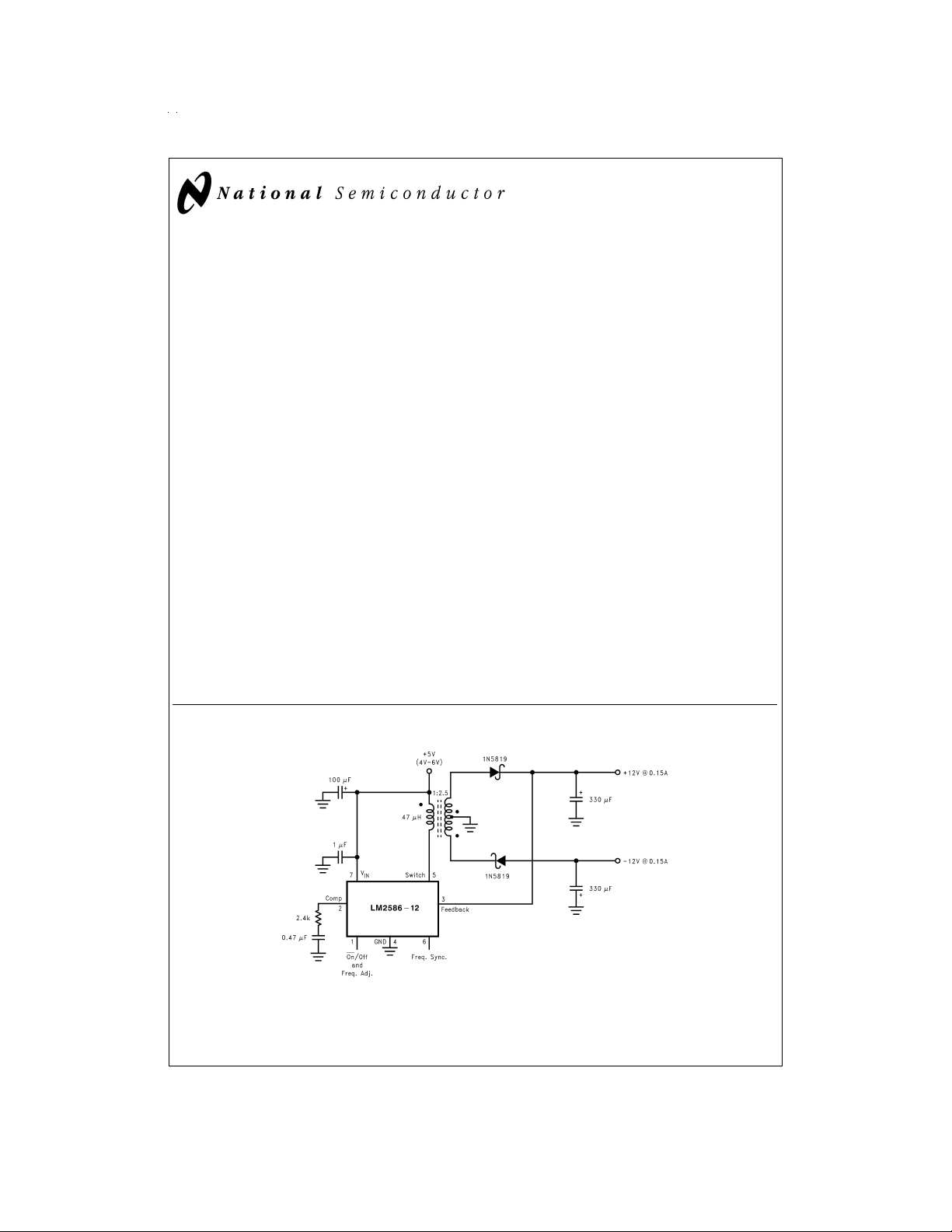

Typical Applications

n Flyback regulator

n Forward converter

n Multiple-output regulator

n Simple boost regulator

DS012516-1

SIMPLE SWITCHER®and

© 1999 National Semiconductor Corporation DS012516 www.national.com

Switchers Made Simple

®

are registered trademarks of National SemiconductorCorporation.

Page 2

Ordering Information

Package Type NSC Package Order Number

Drawing

7-Lead TO-220 Bent, Staggered Leads TA07B LM2586T-3.3, LM2586T-5.0, LM2586T-12, LM2586T-ADJ

7-Lead TO-263 TS7B LM2586S-3.3, LM2586S-5.0, LM2586S-12, LM2586S-ADJ

7-Lead TO-263 Tape and Reel TS7B LM2586SX-3.3, LM2586SX-5.0, LM2586SX-12,

LM2586SX-ADJ

www.national.com 2

Page 3

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Input Voltage −0.4V ≤ V

Switch Voltage −0.4V ≤ V

Switch Current (Note 2) Internally Limited

Compensation Pin Voltage −0.4V ≤ V

Feedback Pin Voltage −0.4V ≤ V

ON /OFF Pin Voltage −0.4V ≤ VSH≤ 6V

Sync Pin Voltage −0.4V ≤ V

Power Dissipation (Note 3) Internally Limited

COMP

FB

IN

SW

≤ 2V

SYNC

≤ 45V

≤ 65V

≤ 2.4V

OUT

≤ 2V

Lead Temperature (Soldering, 10

sec.) 260˚C

Maximum Junction Temperature

(Note 3) 150˚C

Minimum ESD Rating

(C=100 pF, R=1.5 kΩ)2kV

Operating Ratings

Supply Voltage 4V ≤ VIN≤ 40V

Output Switch Voltage 0V ≤ V

Output Switch Current I

Junction Temp. Range −40˚C ≤ T

≤ 60V

SW

≤ 3.0A

SW

≤ +125˚C

J

Storage Temperature Range −65˚C to +150˚C

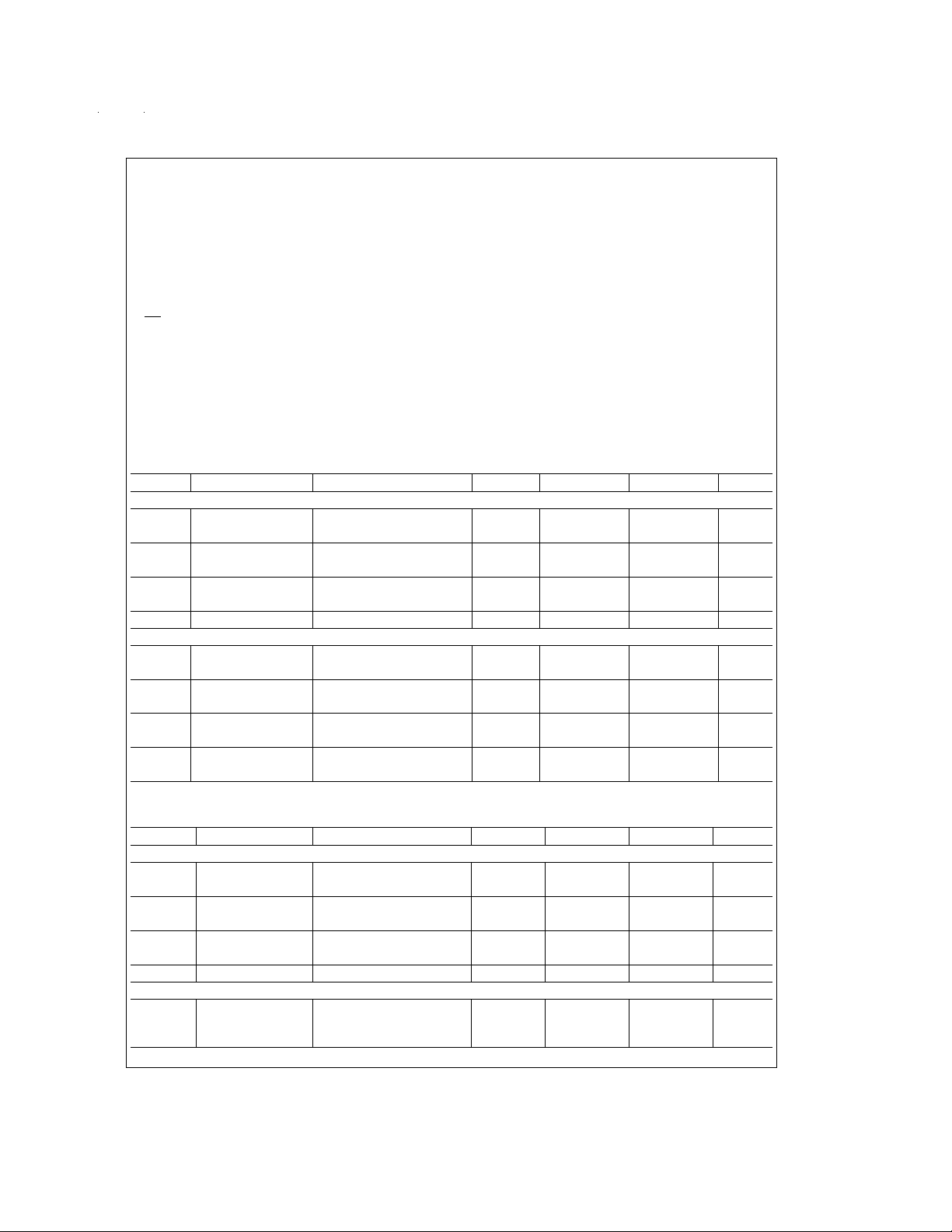

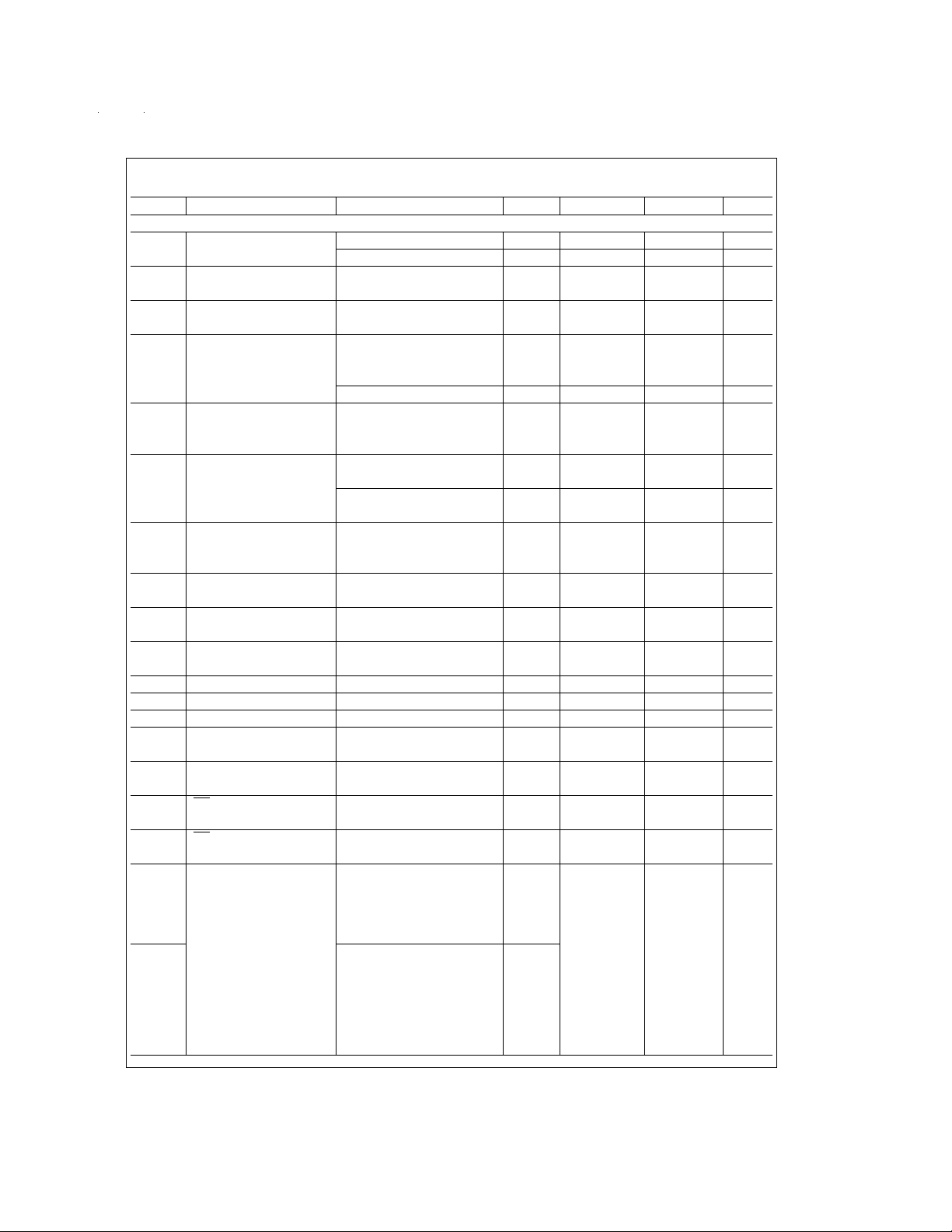

Electrical Characteristics

Specifications with standard type face are for T

Range. Unless otherwise specified, V

IN

=

25˚C, and those in bold type face apply over full Operating Temperature

J

=

5V.

LM2586-3.3

Symbol Parameters Conditions Typical Min Max Units

SYSTEM PARAMETERS Test Circuit of

V

∆V

∆V

∆V

∆I

OUT

OUT

IN

OUT

LOAD

Output Voltage V

/ Line Regulation V

/ Load Regulation V

η Efficiency V

UNIQUE DEVICE PARAMETERS (Note 5)

V

REF

Output Reference Measured at Feedback Pin 3.3 3.242/3.234 3.358/3.366 V

Voltage V

∆V

REF

Reference Voltage V

Line Regulation

G

M

Error Amp I

Transconductance V

A

VOL

Error Amp V

Voltage Gain R

Figure 1

(Note 4)

=

4V to 12V 3.3 3.17/3.14 3.43/3.46 V

IN

=

I

0.3 to 1.2A

LOAD

=

4V to 12V 20 50/100 mV

IN

=

I

0.3A

LOAD

=

12V 20 50/100 mV

IN

=

I

0.3A to 1.2A

LOAD

=

5V, I

IN

COMP

=

4V to 40V 2.0 mV

IN

=

COMP

COMP

COMP

COMP

=

0.3A 76

LOAD

=

1.0V

−30 µA to +30 µA 1.193 0.678 2.259 mmho

=

1.0V

=

0.5V to 1.6V 260 151/75 V/V

=

1.0 MΩ (Note 6)

%

LM2586-5.0

Symbol Parameters Conditions Typical Min Max Units

SYSTEM PARAMETERS Test Circuit of

V

∆V

∆V

∆V

∆I

OUT

OUT

IN

OUT

LOAD

Output Voltage V

/ Line Regulation V

/ Load Regulation V

η Efficiency V

UNIQUE DEVICE PARAMETERS (Note 5)

V

∆V

REF

REF

Output Reference

Voltage

Reference Voltage V

Figure 1

(Note 4)

=

4V to 12V 5.0 4.80/4.75 5.20/5.25 V

IN

=

I

0.3A to 1.1A

LOAD

=

4V to 12V 20 50/100 mV

IN

=

I

0.3A

LOAD

=

12V 20 50/100 mV

IN

=

I

0.3A to 1.1A

LOAD

=

12V, I

IN

Measured at Feedback Pin

=

V

COMP

=

4V to 40V 3.3 mV

IN

1.0V

=

0.6A 80

LOAD

5.0 4.913/4.900 5.088/5.100 V

www.national.com3

%

Page 4

LM2586-5.0 (Continued)

Symbol Parameters Conditions Typical Min Max Units

UNIQUE DEVICE PARAMETERS (Note 5)

Line Regulation

G

M

Error Amp I

Transconductance V

A

VOL

Error Amp V

Voltage Gain R

=

−30 µA to +30 µA 0.750 0.447 1.491 mmho

COMP

=

1.0V

COMP

=

0.5V to 1.6V 165 99/49 V/V

COMP

=

1.0 MΩ (Note 6)

COMP

LM2586-12

Symbol Parameters Conditions Typical Min Max Units

SYSTEM PARAMETERS Test Circuit of

V

∆V

∆V

∆V

∆I

OUT

OUT

IN

OUT

LOAD

Output Voltage V

/ Line Regulation V

/ Load Regulation V

η Efficiency V

UNIQUE DEVICE PARAMETERS (Note 5)

V

REF

Output Reference Measured at Feedback Pin 12.0 11.79/11.76 12.21/12.24 V

Voltage V

∆V

REF

Reference Voltage V

Line Regulation

G

M

Error Amp I

Transconductance V

A

VOL

Error Amp V

Voltage Gain R

Figure 2

(Note 4)

=

4V to 10V 12.0 11.52/11.40 12.48/12.60 V

IN

=

I

0.2A to 0.8A

LOAD

=

4V to 10V 20 100/200 mV

IN

=

I

0.2A

LOAD

=

10V 20 100/200 mV

IN

=

I

0.2A to 0.8A

LOAD

=

10V, I

IN

=

COMP

=

4V to 40V 7.8 mV

IN

=

COMP

=

COMP

=

COMP

=

COMP

=

0.6A 93

LOAD

1.0V

−30 µA to +30 µA 0.328 0.186 0.621 mmho

1.0V

0.5V to 1.6V 70 41/21 V/V

1.0 MΩ (Note 6)

%

LM2586-ADJ

Symbol Parameters Conditions Typical Min Max Units

SYSTEM PARAMETERS Test Circuit of

V

∆V

∆V

∆V

∆I

OUT

LOAD

Output Voltage V

/ Line Regulation V

OUT

IN

/ Load Regulation V

OUT

η Efficiency V

UNIQUE DEVICE PARAMETERS (Note 5)

V

REF

Output Reference Measured at Feedback Pin 1.230 1.208/1.205 1.252/1.255 V

Voltage V

∆V

Reference Voltage V

REF

Line Regulation

G

M

Error Amp I

Transconductance V

A

VOL

I

B

Error Amp Voltage Gain V

Error Amp V

Input Bias Current

www.national.com 4

Figure 2

(Note 4)

=

4V to 10V 12.0 11.52/11.40 12.48/12.60 V

IN

=

I

0.2A to 0.8A

LOAD

=

4V to 10V 20 100/200 mV

IN

=

I

0.2A

LOAD

=

10V 20 100/200 mV

IN

=

I

0.2A to 0.8A

LOAD

=

10V, I

IN

=

COMP

=

4V to 40V 1.5 mV

IN

=

COMP

=

COMP

=

COMP

=

R

COMP

=

COMP

=

0.6A 93

LOAD

1.0V

−30 µA to +30 µA 3.200 1.800 6.000 mmho

1.0V

0.5V to 1.6V,

1.0 MΩ (Note 6)

670 400/200 V/V

1.0V 125 425/600 nA

%

Page 5

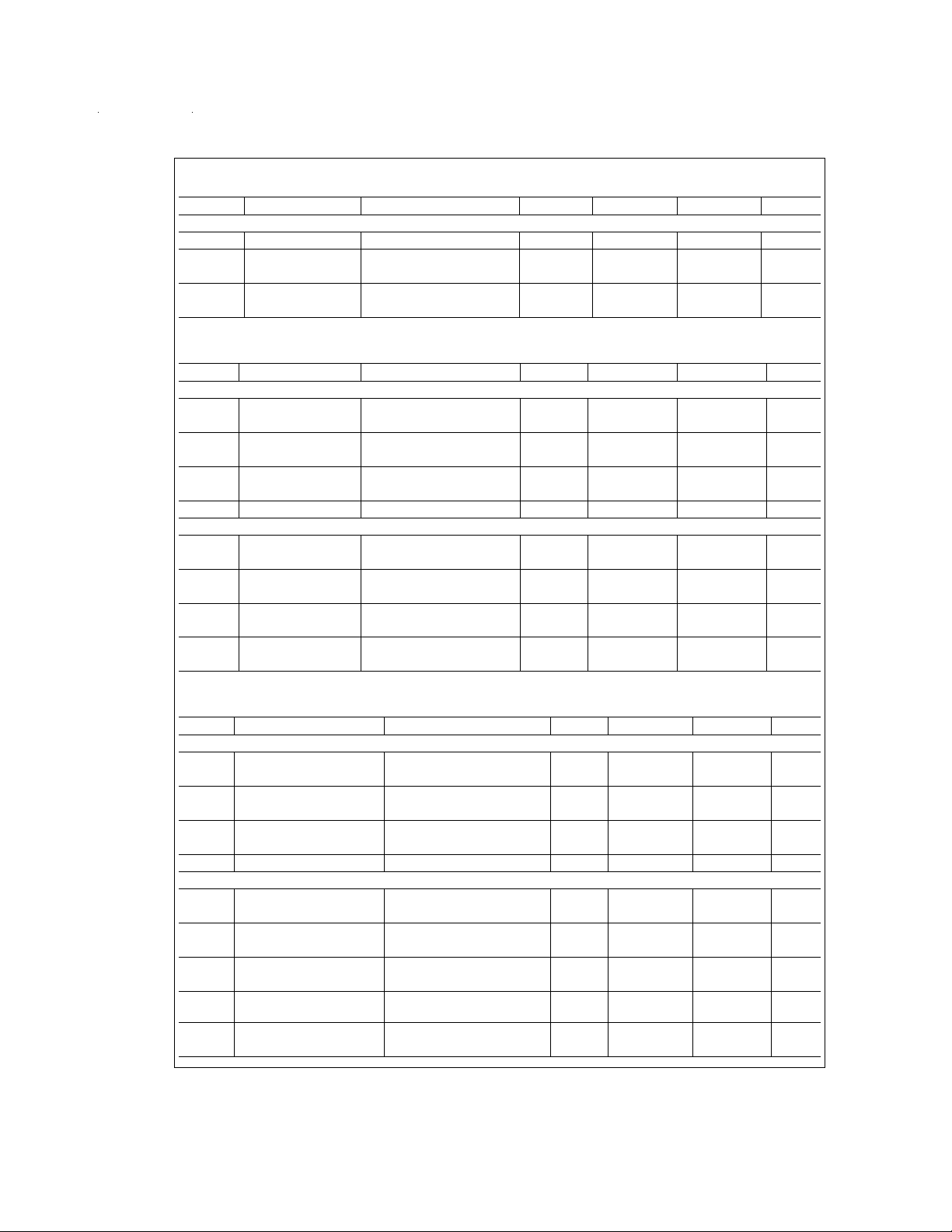

LM2586-ADJ (Continued)

Symbol Parameters Conditions Typical Min Max Units

COMMON DEVICE PARAMETERS for all versions (Note 5)

I

S

I

S/D

V

f

O

f

SC

V

I

EAO

I

SS

D

I

L

V

V

I

CL

V

I

SYNC

V

I

SH

θ

θ

θ

θ

θ

θ

θ

UV

EAO

MAX

SUS

SAT

STH

SHTH

JA

JA

JC

JA

JA

JA

JC

Input Supply Current Switch Off (Note 8) 11 15.5/16.5 mA

=

Shutdown Input V

I

SWITCH

1.8A 50 100/115 mA

=

3V 16 100/300 µA

SH

Supply Current

Input Supply R

=

100Ω 3.30 3.05 3.75 V

LOAD

Undervoltage Lockout

Oscillator Frequency Measured at Switch Pin

=

R

LOAD

100Ω,V

=

1.0V 100 85/75 115/125 kHz

COMP

Freq. Adj. Pin Open (Pin 1)

=

R

22 kΩ 200 kHz

SET

Short-Circuit Measured at Switch Pin

Frequency R

LOAD

V

FEEDBACK

=

100Ω 25 kHz

=

1.15V

Error Amplifier Upper Limit 2.8 2.6/2.4 V

Output Swing (Note 7)

Lower Limit 0.25 0.40/0.55 V

(Note 8)

Error Amp (Note 9)

Output Current 165 110/70 260/320 µA

(Source or Sink)

Soft Start Current V

Maximum Duty Cycle R

FEEDBACK

V

COMP

LOAD

=

0.92V 11.0 8.0/7.0 17.0/19.0 µA

=

1.0V

=

100Ω 98 93/90

(Note 7)

Switch Leakage Switch Off 15 300/600 µA

Current V

SWITCH

=

60V

Switch Sustaining Voltage dV/dT=1.5V/ns 65 V

Switch Saturation Voltage I

SWITCH

=

3.0A 0.45 0.65/0.9 V

NPN Switch Current Limit 4.0 3.0 7.0 A

Synchronization F

Threshold Voltage V

Synchronization V

Pin Current V

ON/OFF Pin (Pin 1) V

=

200 kHz 0.75 0.625/0.40 0.875/1.00 V

SYNC

=

COMP

=

5V 100 200 µA

IN

=

COMP

=

COMP

=

1V, V

1V, V

IN

SYNC

5V

=

V

STH

1V 1.6 1.0/0.8 2.2/2.4 V

Threshold Voltage (Note 10)

ON/OFF Pin (Pin 1) V

Current V

Thermal Resistance T Package, Junction to

=

1V 40 15/10 65/75 µA

COMP

=

V

SH

SHTH

65

Ambient (Note 11)

T Package, Junction to

45

Ambient (Note 12)

T Package, Junction to Case 2

S Package, Junction to

Ambient (Note 13)

S Package, Junction to

56

˚C/W

35

Ambient (Note 14)

S Package, Junction to

26

Ambient (Note 15)

S Package, Junction to Case 2

%

www.national.com5

Page 6

LM2586-ADJ (Continued)

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur.These ratings apply when the current is limited to less than 1.2 mA

for pins 1, 2, 3, and 6. Operating ratings indicateconditions for which the device isintended to be functional, but deviceparameter specifications may not be guaranteed under these conditions. For guaranteed specifications and test conditions, see the Electrical Characteristics.

Note 2: Note that switch current and output current are not identical in a step-up regulator. Output current cannot be internally limited when the LM2586 is used as

a step-up regulator. To prevent damage to the switch, the output current must be externally limited to 3A. However, output current is internally limited when the

LM2586 is used as a flyback regulator (see the Application Hints section for more information).

Note 3: The junction temperature of the device (T

dissipation of the device (P

. For a safe thermal design, check that the maximum power dissipated by the device is less than: PD≤ [T

(MAX)

allowable power dissipation, derate the maximum junction temperature — this ensures a margin of safety in the thermal design.

Note 4: External components such as the diode, inductor, input and output capacitors can affect switching regulator performance. When the LM2586 is used as

Figures 1, 2

shown in

Note 5: All room temperature limits are 100%production tested, and all limits at temperature extremes are guaranteed via correlation using standard Statistical Qual-

ity Control (SQC) methods.

Note 6: A 1.0 MΩ resistor is connected to the compensation pin (which is the error amplifier output) to ensure accuracy in measuringA

Note 7: Tomeasure this parameter, the feedback voltage is set to a low value, depending on the output version of the device, to force the error amplifier output high

and the switch on.

Note 8: Tomeasure this parameter, the feedback voltage is set to a high value, depending on the output version of the device, to force the error amplifier output low

and the switch off.

Note 9: Tomeasure the worst-case error amplifier output current, the LM2586 is tested with the feedback voltageset to its low value (Note 7) and at its high value

(Note 8).

Note 10: When testing the minimum value, do not sink current from this pin — isolate it with a diode. If current is drawn from this pin, the frequency adjust circuit will

begin operation (see

Note 11: Junction to ambient thermal resistance (no external heat sink) for the 7 lead TO-220 package mounted vertically, with

board with minimum copper area.

Note 12: Junction to ambient thermal resistance (no external heat sink) for the 7 lead TO-220 package mounted vertically,with

containing approximately 4 square inches of (1 oz.) copper area surrounding the leads.

Note 13: Junction to ambient thermal resistance for the 7 lead TO-263 mounted horizontally against a PC board area of 0.136 square inches (the same size as the

TO-263 package) of 1 oz. (0.0014 in. thick) copper.

Note 14: Junction to ambient thermal resistance for the 7 leadTO-263 mounted horizontally against a PC board areaof 0.4896 square inches (3.6 times the area

of the TO-263 package) of 1 oz. (0.0014 in. thick) copper.

Note 15: Junction to ambient thermal resistance for the 7 lead TO-263 mounted horizontally against a PC board copper area of 1.0064 square inches (7.4 times the

area of the TO-263 package) of 1 oz. (0.0014 in. thick) copper. Additional copper area will reduce thermal resistance further. See the thermal model in

Made Simple

®

software.

). A thermal shutdown will occur if the temperature exceedsthe maximum junction temperature of the device: PDx θJA+T

D

, system performance will be as specified by the system parameters.

Figure 41

).

) is a function of the ambient temperature (TA), the junction-to-ambient thermal resistance (θJA), and the power

J

J(MAX)−TA(MAX)

]/θJA. When calculating the maximum

VOL

1

⁄2inch leads in a socket, or on a PC

1

⁄2inch leads soldered to a PC board

A(MAX)

.

Switchers

≥ T

-

J

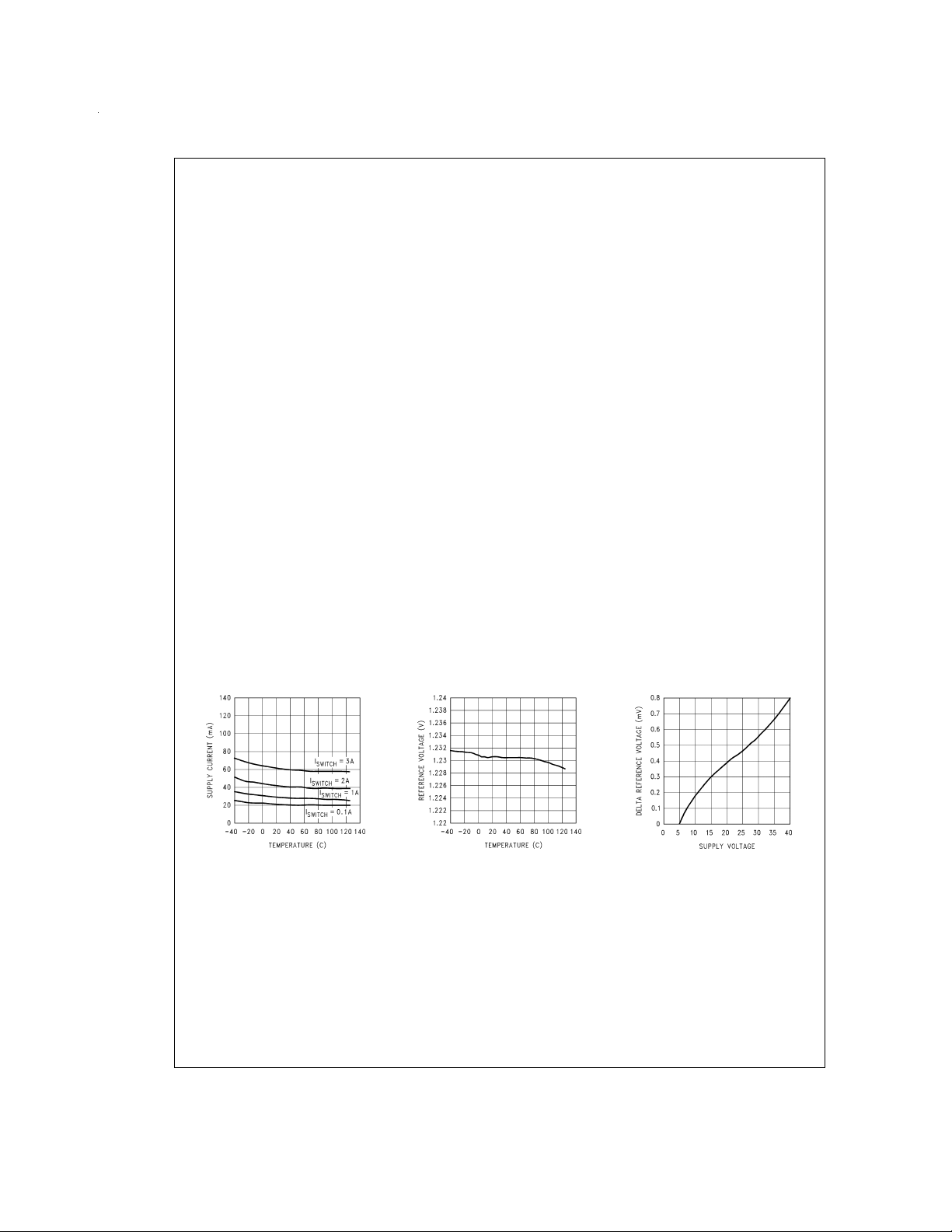

Typical Performance Characteristics

Supply Current

vs Temperature

DS012516-2

www.national.com 6

Reference Voltage

vs Temperature

DS012516-3

∆Reference Voltage

vs Supply Voltage

DS012516-4

Page 7

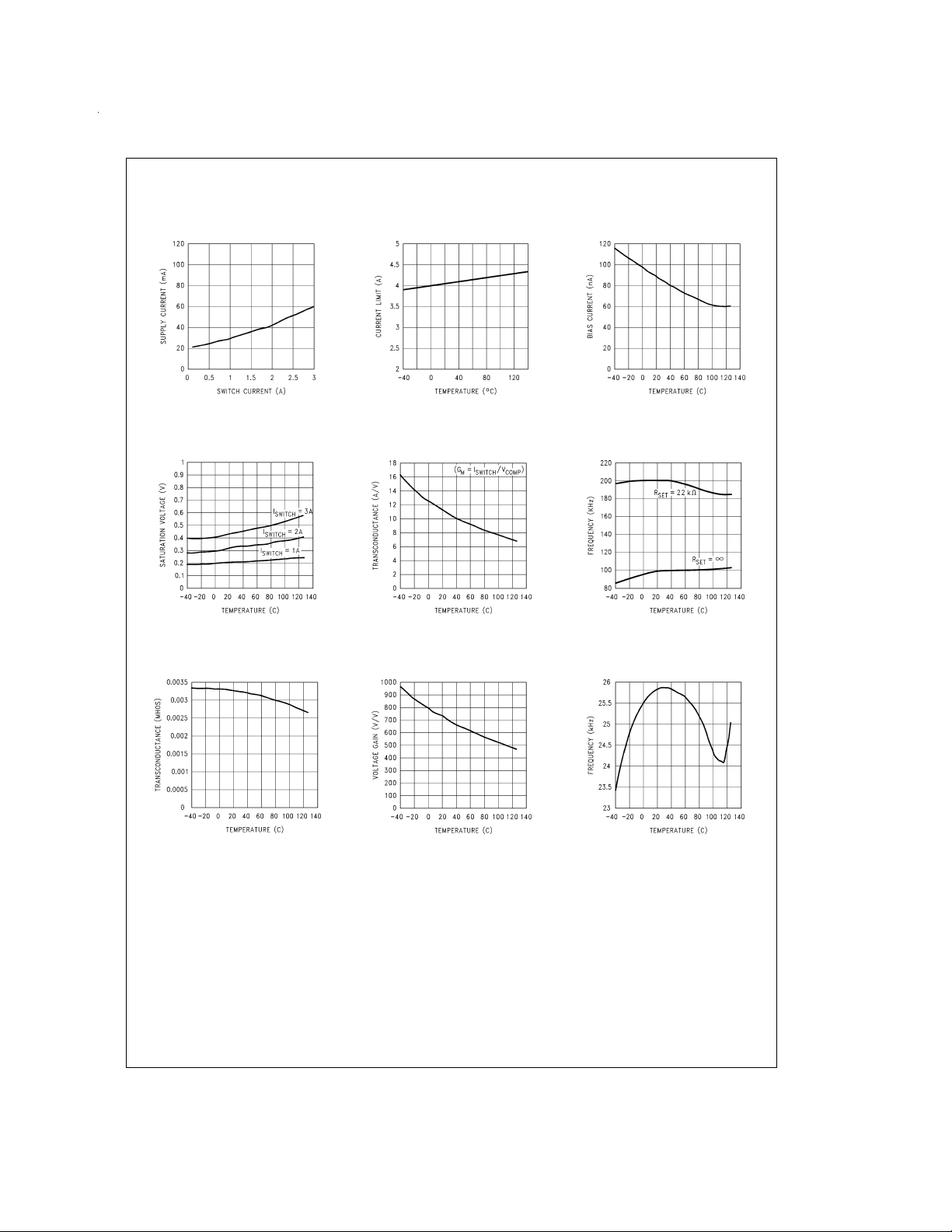

Typical Performance Characteristics (Continued)

Supply Current

vs Switch Current

DS012516-5

Switch Saturation

Voltage vs Temperature

DS012516-8

Error Amp Transconductance

vs Temperature

Current Limit

vs Temperature

Switch Transconductance

vs Temperature

Error Amp Voltage

Gain vs Temperature

DS012516-6

DS012516-9

Feedback Pin Bias

Current vs Temperature

DS012516-7

Oscillator Frequency

vs Temperature

DS012516-10

Short Circuit Frequency

vs Temperature

DS012516-11

DS012516-12

DS012516-13

www.national.com7

Page 8

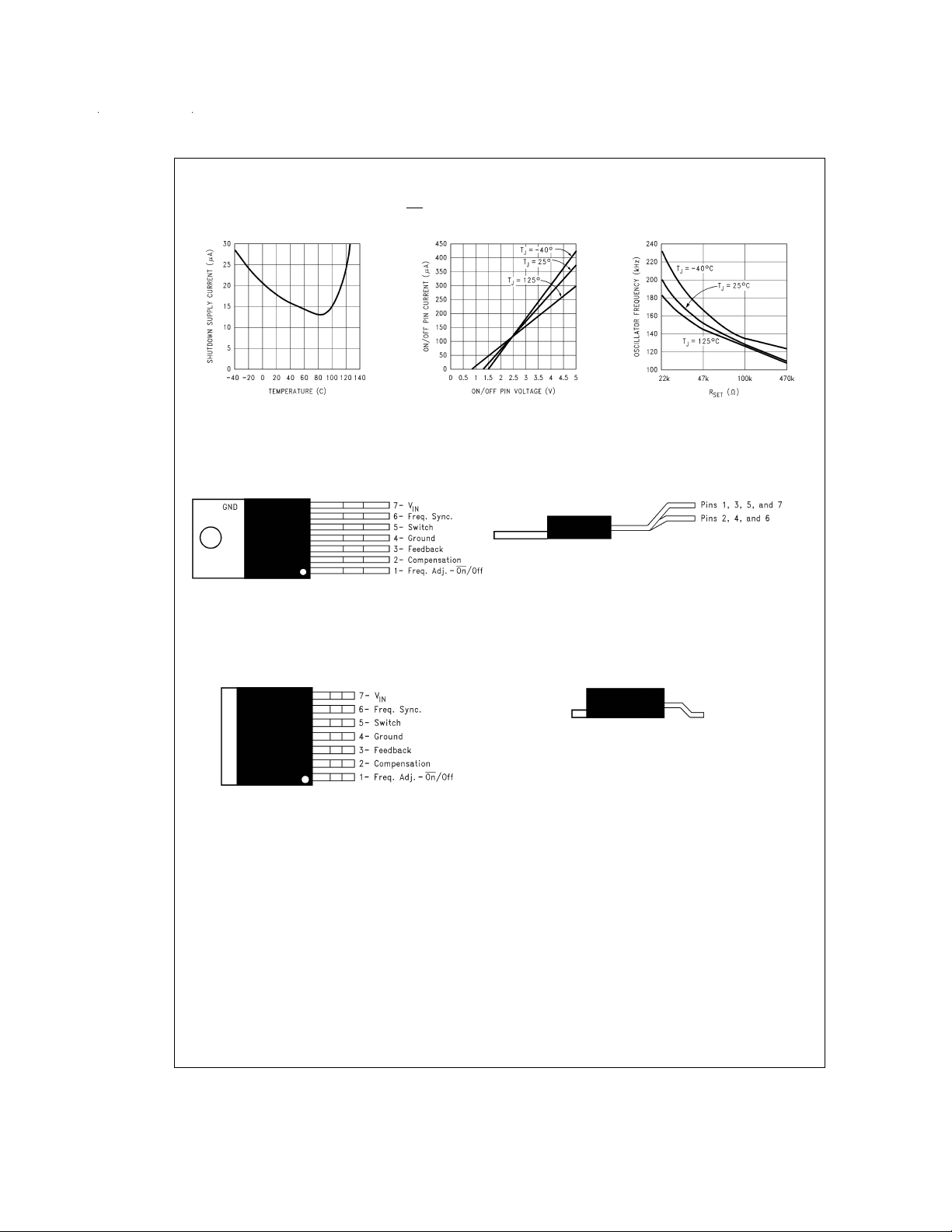

Typical Performance Characteristics (Continued)

Shutdown Supply Current

vs Temperature

DS012516-14

Connection Diagrams

Bent, Staggered Leads

7-Lead TO-220 (T)

Top View

7-Lead TO-263 (S)

Top View

ON/OFF Pin Current

vs Voltage

DS012516-15

Bent, Staggered Leads

7-Lead TO-220 (T)

DS012516-17

Order Number LM2586T3.3, LM2586T-5.0,

LM2586T-12 or LM2586T-ADJ

See NS Package Number TA07B

7-Lead TO-263 (S)

Oscillator Frequency

vs Resistance

DS012516-16

Side View

DS012516-18

Side View

DS012516-19

Order number LM2586S-3.3, LM2586S-5.0,

LM2586S-12 or LM2586S-ADJ

Tape and Reel Order Number LM2586SX-3.3,

LM2586SX-5.0, LM2586SX-12 or LM2586SX-ADJ

See NS Package Number TS7B

www.national.com 8

DS012516-20

Page 9

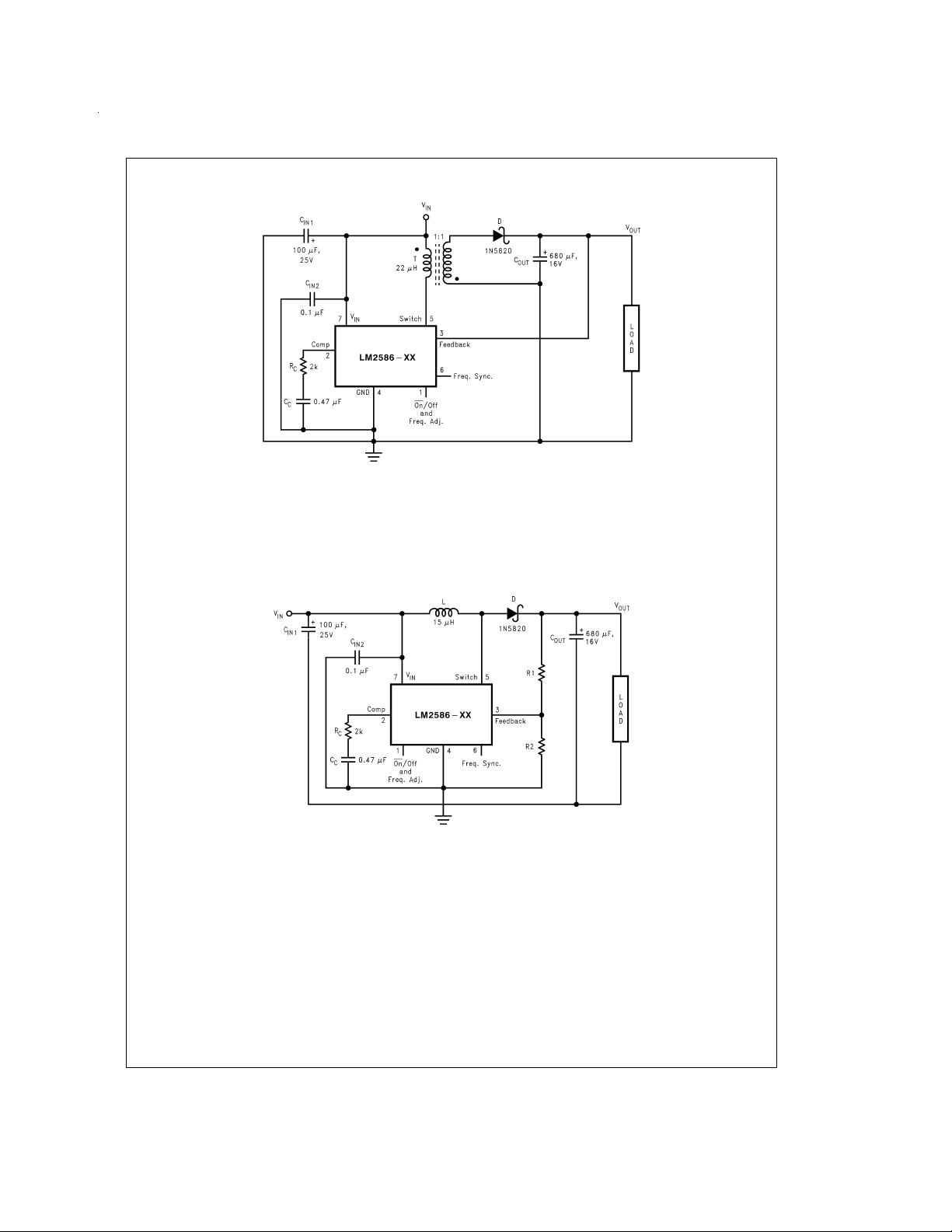

Test Circuits

C

— 100 µF, 25V Aluminum Electrolytic

IN1

— 0.1 µF Ceramic

C

IN2

T— 22 µH, 1:1 Schott

D— 1N5820

— 680 µF, 16V Aluminum Electrolytic

C

OUT

— 0.47 µF Ceramic

C

C

—2k

R

C

C

— 100 µF, 25V Aluminum Electrolytic

IN1

— 0.1 µF Ceramic

C

IN2

L— 15 µH, Renco

D— 1N5820

— 680 µF, 16V Aluminum Electrolytic

C

OUT

— 0.47 µF Ceramic

C

C

—2k

R

C

For 12V Devices: R1=Short (0Ω) and 2=Open

For ADJ Devices: R1=48.75k,

#

67141450

#

RL-5472-5

±

0.1%and 2=5.62k,±0.1

DS012516-21

FIGURE 1. LM2586-3.3 and LM2586-5.0

DS012516-22

%

FIGURE 2. LM2586-12 and LM2586-ADJ

www.national.com9

Page 10

Block Diagram

For Fixed Versions

3.3V, R1=3.4k, R2=2k

5.0V, R1=6.15k, R2=2k

12V, R1=8.73k, R2=1k

For Adj. Version

R1=Short (0Ω), R2=Open

Flyback Regulator Operation

The LM2586 is ideally suited for use in the flyback regulator

topology. The flyback regulator can produce a single output

voltage, such as the one shown in

put voltages. In

Figure 4

, the flyback regulator generates an

output voltage that is inside the range of the input voltage.

This feature is unique to flyback regulators and cannot be

duplicated with buck or boost regulators.

The operation of a flyback regulator is as follows (refer to

Figure 4

): when the switch is on, current flows through the

primary winding of the transformer, T1, storing energy in the

magnetic field of the transformer. Note that the primary and

secondary windings are out of phase, so no current flows

through the secondary when current flows through the primary. When the switch turns off, the magnetic field col-

Figure 4

, or multiple out-

DS012516-23

FIGURE 3.

lapses, reversing the voltage polarityof theprimary and secondary windings. Now rectifier D1 is forward biased and

current flows through it, releasing the energy stored in the

transformer. This produces voltage at the output.

The output voltage is controlled by modulating the peak

switch current. This is done by feeding back a portion of the

output voltage to the error amp, which amplifies the difference between the feedback voltageand a 1.230Vreference.

The error amp output voltage is compared to a rampvoltage

proportional to the switch current (i.e., inductor current during the switch on time). The comparator terminates the

switch on time when the two voltages are equal, thereby

controlling the peak switch current to maintain a constant

output voltage.

www.national.com 10

Page 11

Flyback Regulator Operation (Continued)

As shown in

regulator are shown in

Figure 4

, the LM2586 can be used as a flyback regulator by using a minimum number of external components. The switching waveforms of this

Figure 5

. Typical Performance Characteristics observed during the operation of this circuit are shown in

FIGURE 4. 12V Flyback Regulator Design Example

Typical Performance Characteristics

A: Switch Voltage, 20V/div

B: Switch Current, 2A/div

C: Output Rectifier Current, 2A/div

D: Output Ripple Voltage, 50 mV/divAC-Coupled

FIGURE 5. Switching Waveforms

DS012516-65

Figure 6

DS012516-24

.

www.national.com11

Page 12

Typical Performance Characteristics (Continued)

FIGURE 6. V

Response to Load Current Step

OUT

Typical Flyback Regulator Applications

Figure 7

through

tions, varying from single output to triple output. Each draw-

Figure 12

ing contains the part number(s) and manufacturer(s) for every component except the transformer. For the transformer

part numbers and manufacturers’ names, see the table in

show six typical flyback applica-

Figure 13

voltages— requiring the LM2586-ADJ —or different output

configurations that do not match the standard configurations,

refer to the

DS012516-66

. For applications with different output

Switchers Made Simple

software.

FIGURE 7. Single-Output Flyback Regulator

www.national.com 12

DS012516-27

Page 13

Typical Flyback Regulator Applications (Continued)

FIGURE 8. Single-Output Flyback Regulator

DS012516-28

FIGURE 9. Single-Output Flyback Regulator

DS012516-29

www.national.com13

Page 14

Typical Flyback Regulator Applications (Continued)

FIGURE 10. Dual-Output Flyback Regulator

DS012516-30

FIGURE 11. Dual-Output Flyback Regulator

www.national.com 14

DS012516-31

Page 15

Typical Flyback Regulator Applications (Continued)

DS012516-32

FIGURE 12. Triple-Output Flyback Regulator

Transformer Selection (T)

Figure 13

each transformer, as well as the output voltages, input voltage ranges, and the maximum load currents for each circuit.

lists the standard transformers available forflyback regulator applications.Included in thetable are theturns ratio(s) for

Applications

Figure 7 Figure 8 Figure 9 Figure 10 Figure 11 Figure 12

Transformers T7 T7 T7 T6 T6 T5

V

IN

V

OUT1

I

(Max) 1.4A 1A 0.8A 0.15A 0.6A 1.8A

OUT1

N

1

V

OUT2

I

(Max) 0.15A 0.6A 0.25A

OUT2

N

2

V

OUT3

I

(Max) 0.25A

OUT3

N

3

4V–6V 4V–6V 8V–16V 4V–6V 18V–36V 18V–36V

3.3V 5V 12V 12V 12V 5V

1 1 1 1.2 1.2 0.5

−12V −12V 12V

1.2 1.2 1.15

−12V

1.15

FIGURE 13. Transformer Selection Table

www.national.com15

Page 16

Typical Flyback Regulator Applications (Continued)

Transformer

Type

Coilcraft

(Note 16)

Coilcraft (Note

16) Surface

Mount

Manufacturers’ Part Numbers

Pulse (Note 17)

Surface Mount

Pulse (Note

17)

Renco (Note

18)

T5 Q4338-B Q4437-B PE-68413 — RL-5532 67140890

T6 Q4339-B Q4438-B PE-68414 — RL-5533 67140900

T7 S6000-A S6057-A — PE-68482 RL-5751 26606

Note 16: Coilcraft Inc., Phone: (800) 322-2645

1102 Silver Lake Road, Cary, IL 60013 Fax: (708) 639-1469

European Headquarters, 21 Napier Place Phone: +44 1236 730 595

Wardpark North, Cumbernauld, Scotland G68 0LL Fax: +44 1236 730 627

Note 17: Pulse Engineering Inc., Phone: (619) 674-8100

12220 World Trade Drive, San Diego, CA92128 Fax: (619) 674-8262

European Headquarters, Dunmore Road Phone: +353 93 24 107

Tuam, Co. Galway, Ireland Fax: +353 93 24 459

Note 18: Renco Electronics Inc., Phone: (800) 645-5828

60 Jeffryn Blvd. East, Deer Park, NY 11729 Fax: (516) 586-5562

Note 19: Schott Corp., Phone: (612) 475-1173

1000 Parkers Lane Road, Wayzata, MN 55391 Fax: (612) 475-1786

FIGURE 14. Transformer Manufacturer Guide

Transformer Footprints

Figure 15

through

Figure 29

show the footprints of each transformer, listed in

T7

DS012516-33

Figure 14

.

T5

Top View

FIGURE 15. Coilcraft S6000-A

Schott (Note

19)

T6

DS012516-34

Top View

FIGURE 16. Coilcraft Q4339-B

www.national.com 16

DS012516-35

FIGURE 17. Coilcraft Q4437-B (Surface Mount)

T5

DS012516-36

Top View

FIGURE 18. Coilcraft Q4338-B

Page 17

Typical Flyback Regulator

Applications

(Continued)

T7

T5

Top View

FIGURE 19. Coilcraft S6057-A

(Surface Mount)

T6

Top View

FIGURE 20. Coilcraft Q4438-B

(Surface Mount)

T7

Top View

FIGURE 21. Pulse PE-68482

T6

DS012516-37

DS012516-38

DS012516-39

DS012516-42

Top View

FIGURE 23. Pulse PE-68413

(Surface Mount)

T7

DS012516-43

Top View

FIGURE 24. Renco RL-5751

T6

DS012516-45

Top View

FIGURE 25. Renco RL-5533

T5

Top View

FIGURE 22. Pulse PE-68414

(Surface Mount)

DS012516-40

DS012516-46

Top View

FIGURE 26. Renco RL-5532

www.national.com17

Page 18

Typical Flyback Regulator Applications (Continued)

T7

Top View

FIGURE 27. Schott 26606

DS012516-47

T6

DS012516-49

Top View

FIGURE 28. Schott 67140900

Step-Up (Boost) Regulator Operation

Figure 30

regulator. This is a switching regulator that produces an output voltage greater than the input supply voltage.

A brief explanation of how the LM2586 Boost Regulator

works is as follows (refer to

switch turns on, the inductor current ramps up at the rate of

V

shows the LM2586 used as a step-up (boost)

Figure 30

/L, storing energy in the inductor. When the switch turns

IN

). When the NPN

T5

DS012516-50

Top View

FIGURE 29. Schott 67140890

off, the lower end ofthe inductorflies above V

its current through diode (D)into theoutput capacitor (C

at a rate of (V

tor during theswitch on time is transferred to the output dur-

)/L. Thus, energy storedin theinduc-

OUT−VIN

, discharging

IN

OUT

ing the switch off time. The output voltage is controlled by

adjusting the peak switch current, as described in the flyback

regulator section.

)

DS012516-51

FIGURE 30. 12V Boost Regulator

Figure 30

By adding a smallnumber ofexternal components(as shownin

), the LM2586 canbe usedto producea regulatedoutput voltage that is greater than the applied input voltage. The switching waveforms observed during the operation of this circuit

are shown in

www.national.com 18

Figure 31

. Typical performance of this regulator is shown in

Figure 32

.

Page 19

Typical Performance Characteristics

A: Switch Voltage,10V/div

B: Switch Current, 2A/div

C: Inductor Current, 2A/div

D: Output Ripple Voltage,100 mV/div, AC-Coupled

FIGURE 31. Switching Waveforms

FIGURE 32. V

Response to Load Current Step

OUT

Typical Boost Regulator Applications

Figures 33, 35

applications— one fixed and three using the adjustable version of the LM2586. Each drawing contains the part number(s) and manufacturer(s) for every component. For the

through

Figure 37

show four typical boost

DS012516-67

DS012516-68

fixed 12V output application, the part numbersand manufacturers’ names for the inductor are listed in a table in

34

. For applications with different output voltages, refer to

the

Switchers Made Simple

software.

Figure

FIGURE 33. +5V to +12V Boost Regulator

DS012516-54

www.national.com19

Page 20

Typical Boost Regulator Applications (Continued)

Figure 34

of

contains a table of standard inductors, by part number and corresponding manufacturer, for the fixed output regulator

Figure 33

.

Coilcraft

(Note 20)

Pulse

(Note 21)

DO3316-153 PE-53898 RL-5471-7 67146510 67146540

Note 20: Coilcraft Inc., Phone: (800) 322-2645

1102 Silver Lake Road, Cary, IL 60013 Fax: (708) 639-1469

European Headquarters, 21 Napier Place Phone: +44 1236 730 595

Wardpark North, Cumbernauld, Scotland G68 0LL Fax: +44 1236 730 627

Note 21: Pulse Engineering Inc., Phone: (619) 674-8100

12220 World Trade Drive, San Diego, CA92128 Fax: (619) 674-8262

European Headquarters, Dunmore Road Phone: +353 93 24 107

Tuam, Co. Galway, Ireland Fax: +353 93 24 459

Note 22: Renco Electronics Inc., Phone: (800) 645-5828

60 Jeffryn Blvd. East, Deer Park, NY 11729 Fax: (516) 586-5562

Note 23: Schott Corp., Phone: (612) 475-1173

1000 Parkers Lane Road, Wayzata, MN 55391 Fax: (612) 475-1786

FIGURE 34. Inductor Selection Table

Renco

(Note 22)

Schott

(Note 23)

Schott

(Note 23)

(Surface Mount)

FIGURE 35. +12V to +24V Boost Regulator

FIGURE 36. +24V to +36V Boost Regulator

www.national.com 20

DS012516-55

DS012516-56

Page 21

Typical Boost Regulator Applications (Continued)

DS012516-57

FIGURE 37. +24V to +48V Boost Regulator

Note 24: The LM2586 will require a heat sink in these applications.The size of the heat sink will depend on the maximum ambient temperature. To calculate the

thermal resistance of the IC and the size of the heat sink needed, see the “Heat Sink/Thermal Considerations” section in the Application Hints.

Application Hints

LM2586 SPECIAL FEATURES

FIGURE 38. Shutdown Operation

SHUTDOWN CONTROL

A feature of the LM2586 is its ability to be shut down using

the ON /OFFpin (pin 1). This feature conservesinput power

by turning off thedevice when it is not inuse. For proper operation, an isolation diode is required (as shown in

38

).

Figure

The device will shut down when 3V or greater is applied on

the ON /OFF pin, sourcing current into pin 1. In shut down

mode, the device will draw typically 56 µA of supply current

(16 µA to V

vice back on, leave pin 1 floating, using an (isolation) diode,

as shown in

and 40 µA to the ON /OFF pin). Toturn the de-

IN

Figure 38

(for normal operation, do not source

or sink current to or from this pin— see the next section).

FREQUENCY ADJUSTMENT

The switching frequency of the LM2586 canbe adjusted with

the use of an external resistor.This featureallows the user to

optimize the size of the magnetics and the output capacitor(s) by tailoring the operating frequency. A resistor connected from pin 1 (the Freq. Adj. pin) to ground will set the

DS012516-58

switching frequency from 100 kHz to 200 kHz (maximum).

As shown in

Figure 38

, the pin canbe usedto adjustthe frequency while still providing the shut down function.A curve in

the Performance Characteristics Section graphs the resistor

value to thecorresponding switching frequency.The table in

Figure 39

shows resistor values correspondingto commonly

used frequencies.

However, changing the LM2586’s operating frequency from

its nominal value of 100 kHz will change the magnetics selection and compensation component values.

R

(kΩ) Frequency (kHz)

SET

Open 100

200 125

47 150

33 175

22 200

FIGURE 39. Frequency Setting Resistor Guide

www.national.com21

Page 22

Application Hints (Continued)

DS012516-59

FIGURE 40. Frequency Synchronization

FREQUENCY SYNCHRONIZATION

Another feature of the LM2586 is the ability to synchronize

the switching frequency to an external source, using the

sync pin (pin 6). This feature allows the user to parallel multiple devices to deliver more output power.

A negative falling pulse applied to the sync pin will synchronize the LM2586 to an external oscillator (see

41

).

Use of this feature enables the LM2586 to be synchronized

to an external oscillator, such as a system clock. This opera-

Figures 40,

tion allows multiple power supplies to operate at the same

frequency, thus eliminating frequency-related noise

problems.

DS012516-69

FIGURE 41. Waveforms of a Synchronized

12V Boost Regulator

The scope photo in

Figure 41

shows a LM2586 12V Boost

Regulator synchronized to a 200 kHz signal. There is a 700

ns delay between the falling edgeof the sync signal and the

turning on of the switch.

FIGURE 42. Boost Regulator

PROGRAMMING OUTPUT VOLTAGE

(SELECTING R1 AND R2)

Figure 42

Referring to theadjustable regulator in

, the output

voltage is programmed by the resistors R1 and R2 bythe following formula:

=

V

OUT

(1 + R1/R2) where V

V

REF

REF

=

1.23V

Resistors R1 and R2 divide the output voltage down so that

it can be compared with the 1.23V internal reference. With

R2 between 1k and 5k, R1 is:

R1=R2 (V

OUT/VREF

− 1) where V

REF

=

1.23V

For best temperature coefficient and stability with time, use

1%metal film resistors.

SHORT CIRCUIT CONDITION

Due to the inherent natureof boost regulators,when the output is shorted (see

Figure 42

), current flows directlyfrom the

input, through the inductor and the diode, to the output, bypassing the switch. The current limit of the switch

does not

limit the output current for the entire circuit. To protect the

load and prevent damage to the switch, the current must be

www.national.com 22

DS012516-61

externally limited, either by the input supply or at the output

with an external current limitcircuit. Theexternal limit should

be set to the maximum switch current of the device,which is

3A.

In a flyback regulator application (

Figure 43

), using the standard transformers, the LM2586 will survive a short circuit to

the main output. When the outputvoltage drops to80%of its

nominal value, the frequency will drop to 25 kHz. With a

lower frequency, off times are larger. With the longer off

times, the transformer can release all of its stored energy before the switch turnsback on.Hence, theswitch turnson initially with zero current at its collector. In this condition, the

switch current limit will limit the peak current, saving the device.

FLYBACK REGULATOR INPUT CAPACITORS

A flyback regulator draws discontinuous pulses of current

from the input supply.Therefore, there are twoinput capacitors needed in a flyback regulator — one for energy storage

and one for filtering (see

Figure 43

). Both are required due to

the inherent operation of a flyback regulator. To keep a

Page 23

Application Hints (Continued)

stable or constant voltage supply to the LM2586, a storage

capacitor (≥100 µF) is required. Ifthe input source is a rectified DC supply and/or the application has a wide temperature range, the required rms current rating of the capacitor

FIGURE 43. Flyback Regulator

might be very large. This means a larger value of capacitance or a higher voltage rating will be needed for the input

capacitor. The storage capacitor will also attenuate noise

which may interfere with other circuits connected to the

same input supply voltage.

DS012516-62

In addition, a small bypass capacitor is required due to the

noise generated by the inputcurrent pulses.Toeliminate the

noise, insert a 1.0 µF ceramic capacitor between V

ground as close as possible to the device.

and

IN

SWITCH VOLTAGE LIMITS

In a flyback regulator, the maximum steady-statevoltage appearing at theswitch, when it is off, isset by the transformer

turns ratio, N, the output voltage, V

put voltage, V

where V

and is typically 0.5V for Schottky diodes and 0.8V for

(Max):

IN

=

V

SW(OFF)

is the forward biased voltage of the output diode,

F

V

IN

(Max) + (V

, and the maximum in-

OUT

)/N

OUT+VF

ultra-fast recovery diodes. In certain circuits, there exists a

voltage spike, V

voltage (see

, superimposed on top of the steady-state

LL

Figure 5

, waveform A). Usually, this voltage

spike is caused by the transformer leakage inductance

and/or the output rectifier recovery time. To “clamp” the voltage at the switch from exceeding its maximum value, atransient suppressor in serieswith adiode isinserted acrossthe

transformer primary (as shown in the circuit in

Figure 4

and

other flyback regulator circuits throughout the datasheet).

The schematic in

Figure 43

shows another method of clamping the switch voltage. A single voltage transient suppressor

(the SA51A) is inserted at the switch pin. This method

clamps the total voltage across the switch, not just the voltage across the primary.

If poor circuit layout techniques are used (see the “Circuit

Layout Guideline” section), negative voltage transients may

appear on the Switch pin (pin 5).Applying a negative voltage

(with respect to the IC’s ground) to any monolithic IC pin

causes erratic and unpredictable operation of that IC. This

holds true for the LM2586 IC aswell. When usedin a flyback

regulator, the voltage at the Switch pin (pin 5) can go negative when the switch turns on. The “ringing” voltage at the

switch pin is caused by the output diode capacitanceand the

transformer leakage inductance forminga resonant circuit at

the secondary(ies). The resonant circuit generates the“ringing” voltage, which gets reflected back through the transformer to the switch pin. There are two common methods to

avoid this problem. Oneis toadd anRC snubberaround the

output rectifier(s), as in

Figure 43

. The values of the resistor

and the capacitor must be chosen so that the voltage at the

Switch pin does not drop below −0.4V. The resistor may

range in value between10Ω and1kΩ, and the capacitorwill

vary from 0.001µF to 0.1 µF.Adding a snubber will (slightly)

reduce the efficiency of the overall circuit.

The other method to reduce or eliminatethe “ringing” is to insert a Schottky diode clamp between pins 5 and 4 (ground),

also shown in

Figure 43

. This prevents the voltage at pin 5

from dropping below −0.4V.The reversevoltage rating of the

diode must be greater than the switch off voltage.

www.national.com23

Page 24

Application Hints (Continued)

FIGURE 44. Input Line Filter

DS012516-63

OUTPUT VOLTAGE LIMITATIONS

The maximum output voltage of a boost regulator is the

maximum switch voltage minus a diode drop. In a flyback

regulator, the maximum output voltage is determined by the

turns ratio, N, and the duty cycle, D, by the equation:

V

≈ NxVINxD/(1−D)

OUT

The duty cycle of a flyback regulator is determined bythe following equation:

Theoretically, the maximum output voltage can be as large

as desired— just keep increasing the turnsratio of thetransformer. However, there exists some physical limitations that

prevent the turns ratio, and thus the output voltage, from increasing to infinity. The physical limitations are capacitances

and inductances in the LM2586 switch, the output diode(s),

and the transformer— such as reverse recovery time of the

output diode (mentioned above).

NOISY INPUT LINE CONDITION

A small, low-pass RC filtershould be used at the inputpin of

the LM2586 if the input voltage has an unusually large

amount of transient noise, such as with an input switch that

bounces. The circuit in

Figure 44

demonstrates the layoutof

the filter, with the capacitor placed from the input pin to

ground and the resistor placed betweenthe input supplyand

the input pin. Note that the values of R

the schematic are good enough for most applications, but

and CINshown in

IN

some readjusting might be required for a particular application. If efficiency is amajor concern,replace theresistor with

a small inductor (say 10 µH and rated at 200 mA).

STABILITY

All current-mode controlled regulators can suffer from an instability, known as subharmonic oscillation, if they operate

with a duty cycle above 50%. To eliminate subharmonic oscillations, a minimum value of inductance is required to ensure stability for all boost and flyback regulators. The minimum inductance is given by:

FIGURE 45. Circuit Board Layout

www.national.com 24

where V

found in the Characteristic Curves.

is the switch saturation voltage and can be

SAT

DS012516-64

Page 25

Application Hints (Continued)

CIRCUIT LAYOUT GUIDELINES

As in any switching regulator, layout is very important. Rapidly switching currents associated with wiring inductance

generate voltage transients which can cause problems. For

minimal inductance and ground loops,keep thelength of the

leads and traces as short as possible. Use single point

grounding or ground plane construction for best results.

Separate the signal grounds from the power grounds (as indicated in

physically locate the programming resistors as near the

regulator IC as possible, to keep the sensitive feedback wiring short.

HEAT SINK/THERMAL CONSIDERATIONS

In many cases, a heat sink is not required to keep the

LM2586 junction temperature within the allowed operating

temperature range. For each application, to determine

whether or not a heat sink will be required, the following must

be identified:

1) Maximum ambient temperature (in the application).

2) Maximum regulator power dissipation (in the application).

3) Maximum allowed junction temperature (125˚C for the

LM2586). For a safe, conservative design, a temperature approximately 15˚C cooler than the maximum junction temperature should be selected (110˚C).

4) LM2586 package thermal resistances θ

in the Electrical Characteristics).

Total power dissipated (P

as follows:

VINis the minimum input voltage,V

N is the transformer turns ratio, D is the duty cycle, and I

is the maximum load current (and∑I

maximum load currents for multiple-output flyback regulators). The duty cycle is given by:

Figure 45

). When using the Adjustable version,

and θJC(given

JA

) by the LM2586 can be estimated

D

is the output voltage,

OUT

LOAD

is the sum of the

LOAD

where VFis the forward biased voltage of the diode and is

typically 0.5V for Schottky diodes and 0.8V for fast recovery

diodes. V

found in the Characteristic Curves.

is the switch saturation voltage and can be

SAT

When no heat sink is used, the junction temperature rise is:

=

∆T

θJA.

P

•

J

D

Adding the junction temperature rise to the maximum ambient temperature gives the actualoperating junction temperature:

=

T

J

∆T

J+TA

.

If the operating junction temperature exceeds the maximum

junction temperatue in item 3 above, then a heat sink is required. When using a heat sink, the junction temperature rise

can be determined by the following:

=

∆T

(θJC+ θ

P

•

J

D

Interface

+ θ

Heat Sink

)

Again, the operating junction temperature will be:

=

T

∆T

J

J+TA

As before, if the maximum junction temperature is exceeded,

a larger heat sink is required (one that has a lower thermal

resistance).

Included in the

Switchers Made Simple

®

design software is

a more precise (non-linear) thermal model that can be used

to determine junction temperature with different input-output

parameters or different component values.It can also calculate the heat sink thermal resistancerequired to maintainthe

regulator junction temperature below the maximum operating temperature.

To further simplify the flyback regulator design procedure,

National Semiconductor is making available computer design software to be used with the Simple Switcher

switching regulators. Switchers Made Simple is available

1

ona3

⁄2" diskette for IBM compatible computers from a Na-

®

line of

tional Semiconductor sales office in your area or the National

Semiconductor Customer Response Center

(1-800-272-9959).

www.national.com25

Page 26

26

Page 27

Physical Dimensions inches (millimeters) unless otherwise noted

Order Number LM2586T-3.3, LM2586T-5.0,

LM2586T-12 or LM2586T-ADJ

NS Package Number TA07B

www.national.com27

Page 28

Physical Dimensions inches (millimeters) unless otherwise noted (Continued)

Order Number LM2586S-3.3, LM2586S-5.0,

LM2586S-12 or LM2586S-ADJ

Tape and Reel Order Number LM2586SX-3.3,

LM2586SX-5.0, LM2586SX-12 or LM2586SX-ADJ

NS Package Number TS7B

LM2586 SIMPLE SWITCHER 3A Flyback Regulator with Shutdown

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or systems which, (a) are intended for surgical implant into

the body, or (b) support orsustain life, and whosefailure to perform when properly used in accordance

with instructions for use provided in the labeling, can

be reasonably expected to result ina significant injury

to the user.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right atany time without notice to change said circuitry and specifications.

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80-532 78 32

Français Tel: +49 (0) 1 80-532 93 58

Italiano Tel: +49 (0) 1 80-534 16 80

2. A critical component is any component of a life support

device or system whose failure to perform can be reasonably expected to causethe failureof thelife support

device or system, or to affectits safety oreffectiveness.

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

Loading...

Loading...