Datasheet LM2577T-12, LM2577SX-ADJ, LM2577SX-12, LM2577S-ADJ, LM2577S-15 Datasheet (NSC)

...Page 1

LM1577/LM2577 Series

SIMPLE SWITCHER

®

Step-Up Voltage Regulator

General Description

The LM1577/LM2577 are monolithic integrated circuits that

provide all of the power and control functions for step-up

(boost), flyback, and forward converter switching regulators.

The device is available in three different output voltage versions: 12V, 15V, and adjustable.

Requiring a minimum number of external components, these

regulators are cost effective, and simple to use. Listed in this

data sheet are a family of standard inductors and flyback

transformers designed to work with these switching regulators.

Included on the chip is a 3.0A NPN switch and its associated

protection circuitry,consisting of current and thermal limiting,

and undervoltage lockout. Other features include a 52 kHz

fixed-frequency oscillator that requires no external components, a soft start mode to reduce in-rush current during

start-up, and current mode control for improved rejection of

input voltage and output load transients.

Features

n Requires few external components

n NPN output switches 3.0A, can stand off 65V

n Wide input voltage range: 3.5V to 40V

n Current-mode operation for improved transient

response, line regulation, and current limit

n 52 kHz internal oscillator

n Soft-start function reduces in-rush current during start-up

n Output switch protected by current limit, under-voltage

lockout, and thermal shutdown

Typical Applications

n Simple boost regulator

n Flyback and forward regulators

n Multiple-output regulator

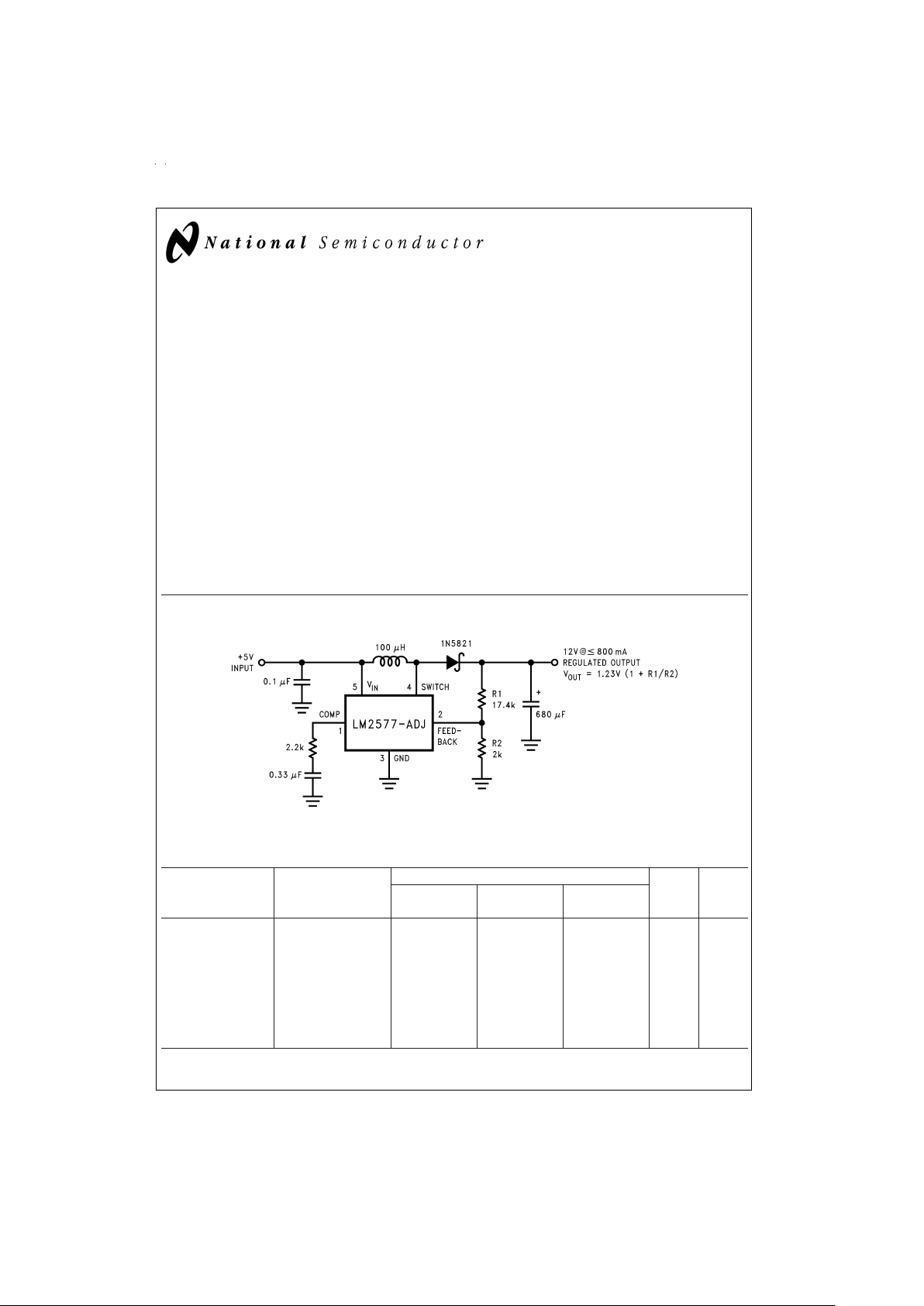

Typical Application

Ordering Information

Temperature

Range

Package

Type

Output Voltage NSC

12V 15V ADJ Package Package

Drawing

−40˚C ≤ T

A

≤ +125˚C 24-Pin Surface Mount LM2577M-12 LM2577M-15 LM2577M-ADJ M24B SO

16-Pin Molded DIP LM2577N-12 LM2577N-15 LM2577N-ADJ N16A N

5-Lead Surface Mount LM2577S-12 LM2577S-15 LM2577S-ADJ TS5B TO-263

5-Straight Leads LM2577T-12 LM2577T-15 LM2577T-ADJ T05A TO-220

5-Bent Staggered LM2577T-12 LM2577T-15 LM2577T-ADJ T05D TO-220

Leads Flow LB03 Flow LB03 Flow LB03

−55˚C ≤ T

A

≤ +150˚C 4-Pin TO-3 LM1577K-12/883 LM1577K-15/883 LM1577K-

ADJ/883

K04A TO-3

SIMPLE SWITCHER®is a registered trademark ofNational Semiconductor Corporation.

DS011468-1

Note: Pin numbers shown are for TO-220 (T) package.

June 1999

LM1577/LM2577 Series SIMPLE SWITCHER Step-Up Voltage Regulator

© 1999 National Semiconductor Corporation DS011468 www.national.com

Page 2

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage 45V

Output Switch Voltage 65V

Output Switch Current (Note 2) 6.0A

Power Dissipation Internally Limited

Storage Temperature Range −65˚C to +150˚C

Lead Temperature

(Soldering, 10 sec.) 260˚C

Maximum Junction Temperature 150˚C

Minimum ESD Rating

(C=100 pF, R=1.5 kΩ)2kV

Operating Ratings

Supply Voltage 3.5V ≤ VIN≤ 40V

Output Switch Voltage 0V ≤ V

SWITCH

≤ 60V

Output Switch Current I

SWITCH

≤ 3.0A

Junction Temperature Range

LM1577 −55˚C ≤ T

J

≤ +150˚C

LM2577 −40˚C ≤ T

J

≤ +125˚C

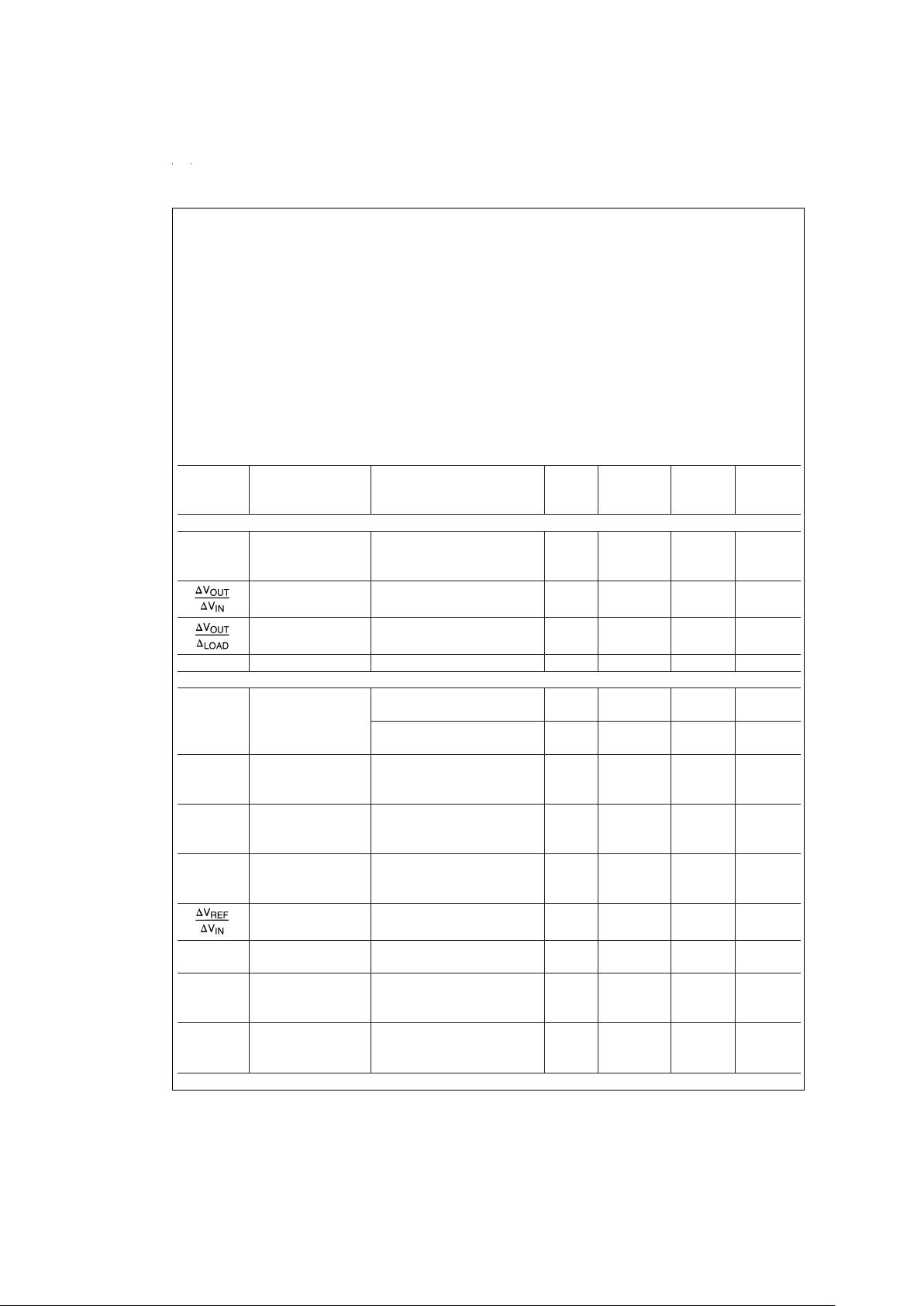

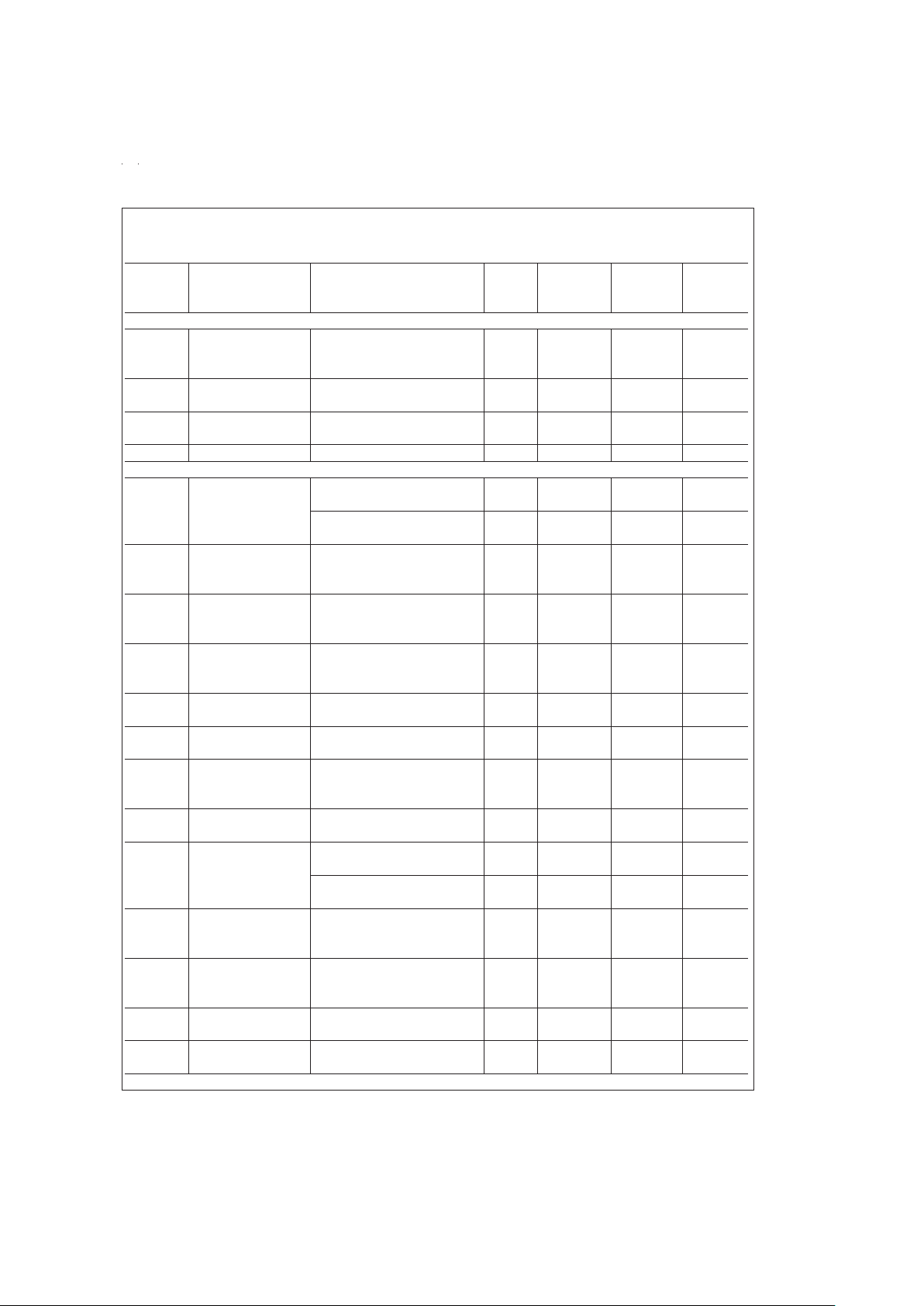

Electrical Characteristics—LM1577-12, LM2577-12

Specifications with standard type face are for T

J

=

25˚C, and those in bold type face apply over full Operating Temperature

Range. Unless otherwise specified, V

IN

=

5V, and I

SWITCH

=

0.

LM1577-12 LM2577-12 Units

Symbol Parameter Conditions Typical Limit Limit (Limits)

(Notes 3, 4) (Note 5)

SYSTEM PARAMETERS Circuit of

Figure 1

(Note 6)

V

OUT

Output Voltage V

IN

=

5V to 10V 12.0 V

I

LOAD

=

100 mA to 800 mA 11.60/11.40 11.60/11.40 V(min)

(Note 3) 12.40/12.60 12.40/12.60 V(max)

Line Regulation V

IN

=

3.5V to 10V 20 mV

I

LOAD

=

300 mA 50/100 50/100 mV(max)

Load Regulation V

IN

=

5V 20 mV

I

LOAD

=

100 mA to 800 mA 50/100 50/100 mV(max)

η Efficiency V

IN

=

5V, I

LOAD

=

800 mA 80

%

DEVICE PARAMETERS

I

S

Input Supply Current V

FEEDBACK

=

14V (Switch Off) 7.5 mA

10.0/14.0 10.0/14.0 mA(max)

I

SWITCH

=

2.0A 25 mA

V

COMP

=

2.0V (Max Duty Cycle) 50/85 50/85 mA(max)

V

UV

Input Supply I

SWITCH

=

100 mA 2.90 V

Undervoltage Lockout 2.70/2.65 2.70/2.65 V(min)

3.10/3.15 3.10/3.15 V(max)

f

O

Oscillator Frequency Measured at Switch Pin 52 kHz

I

SWITCH

=

100 mA 48/42 48/42 kHz(min)

56/62 56/62 kHz(max)

V

REF

Output Reference Measured at Feedback Pin V

Voltage V

IN

=

3.5V to 40V 12 11.76/11.64 11.76/11.64 V(min)

V

COMP

=

1.0V 12.24/12.36 12.24/12.36 V(max)

Output Reference V

IN

=

3.5V to 40V

7mV

Voltage Line Regulator

R

FB

Feedback Pin Input 9.7 kΩ

Resistance

G

M

Error Amp I

COMP

=

−30 µA to +30 µA 370 µmho

Transconductance V

COMP

=

1.0V 225/145 225/145 µmho(min)

515/615 515/615 µmho(max)

A

VOL

Error Amp V

COMP

=

1.1V to 1.9V 80 V/V

Voltage Gain R

COMP

=

1.0 MΩ 50/25 50/25 V/V(min)

(Note 7)

www.national.com 2

Page 3

Electrical Characteristics—LM1577-12, LM2577-12 (Continued)

Specifications with standard type face are for T

J

=

25˚C, and those in bold type face apply over full Operating Temperature

Range. Unless otherwise specified, V

IN

=

5V, and I

SWITCH

=

0.

LM1577-12 LM2577-12 Units

Symbol Parameter Conditions Typical Limit Limit (Limits)

(Notes 3, 4) (Note 5)

DEVICE PARAMETERS

Error Amplifier Upper Limit 2.4 V

Output Swing V

FEEDBACK

=

10.0V 2.2/2.0 2.2/2.0 V(min)

Lower Limit 0.3 V

V

FEEDBACK

=

15.0V 0.40/0.55 0.40/0.55 V(max)

Error Amplifier V

FEEDBACK

=

10.0V to 15.0V

±

200 µA

Output Current V

COMP

=

1.0V

±

130/±90±130/±90 µA(min)

±

300/±400±300/±400 µA(max)

I

SS

Soft Start Current V

FEEDBACK

=

10.0V 5.0 µA

V

COMP

=

0V 2.5/1.5 2.5/1.5 µA(min)

7.5/9.5 7.5/9.5 µA(max)

D Maximum Duty Cycle V

COMP

=

1.5V 95

%

I

SWITCH

=

100 mA 93/90 93/90

%

(min)

Switch

Transconductance

12.5 A/V

I

L

Switch Leakage V

SWITCH

=

65V 10 µA

Current V

FEEDBACK

=

15V (Switch Off) 300/600 300/600 µA(max)

V

SAT

Switch Saturation I

SWITCH

=

2.0A 0.5 V

Voltage V

COMP

=

2.0V (Max Duty Cycle) 0.7/0.9 0.7/0.9 V(max)

NPN Switch 4.5 A

Current Limit 3.7/3.0 3.7/3.0 A(min)

5.3/6.0 5.3/6.0 A(max)

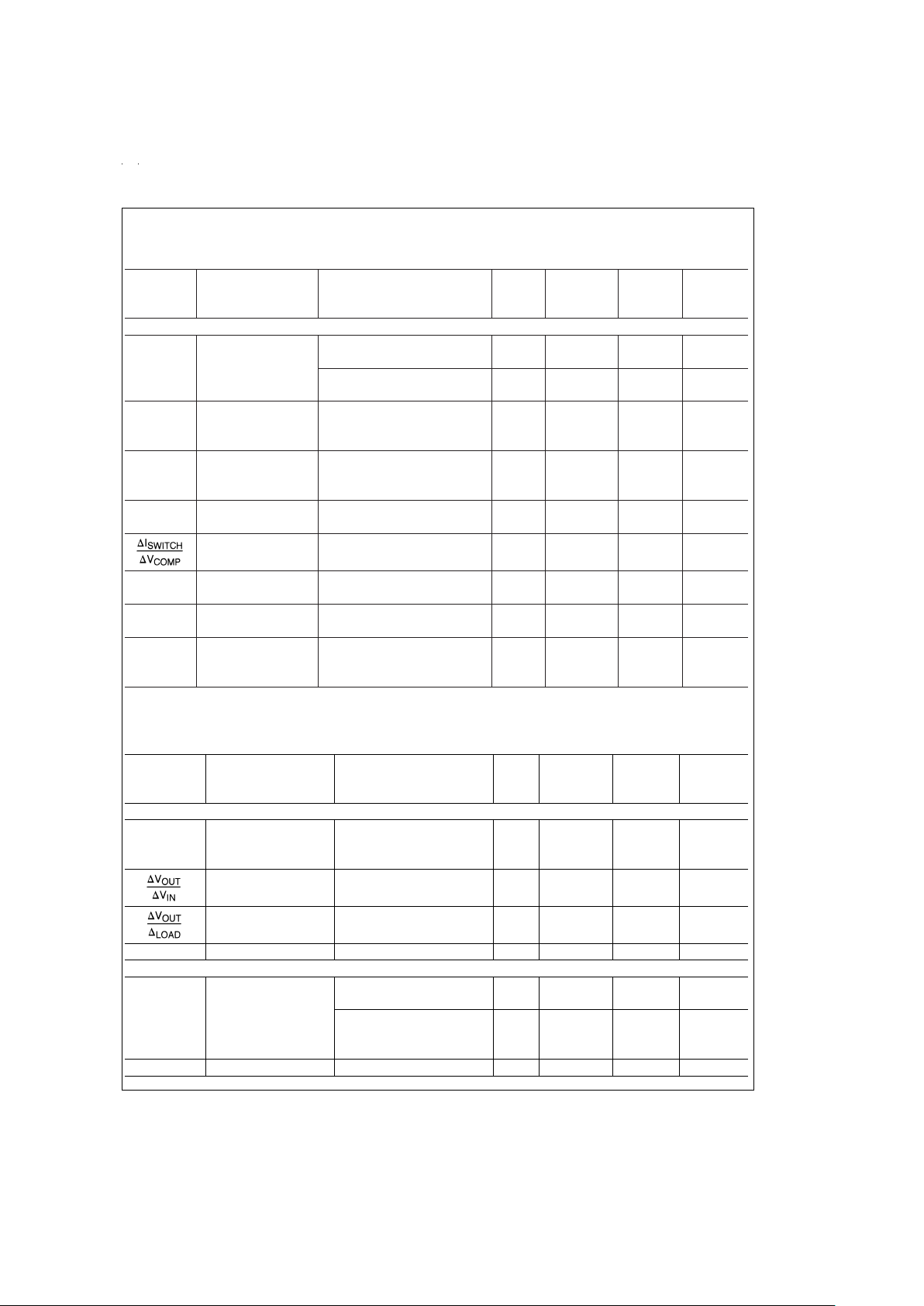

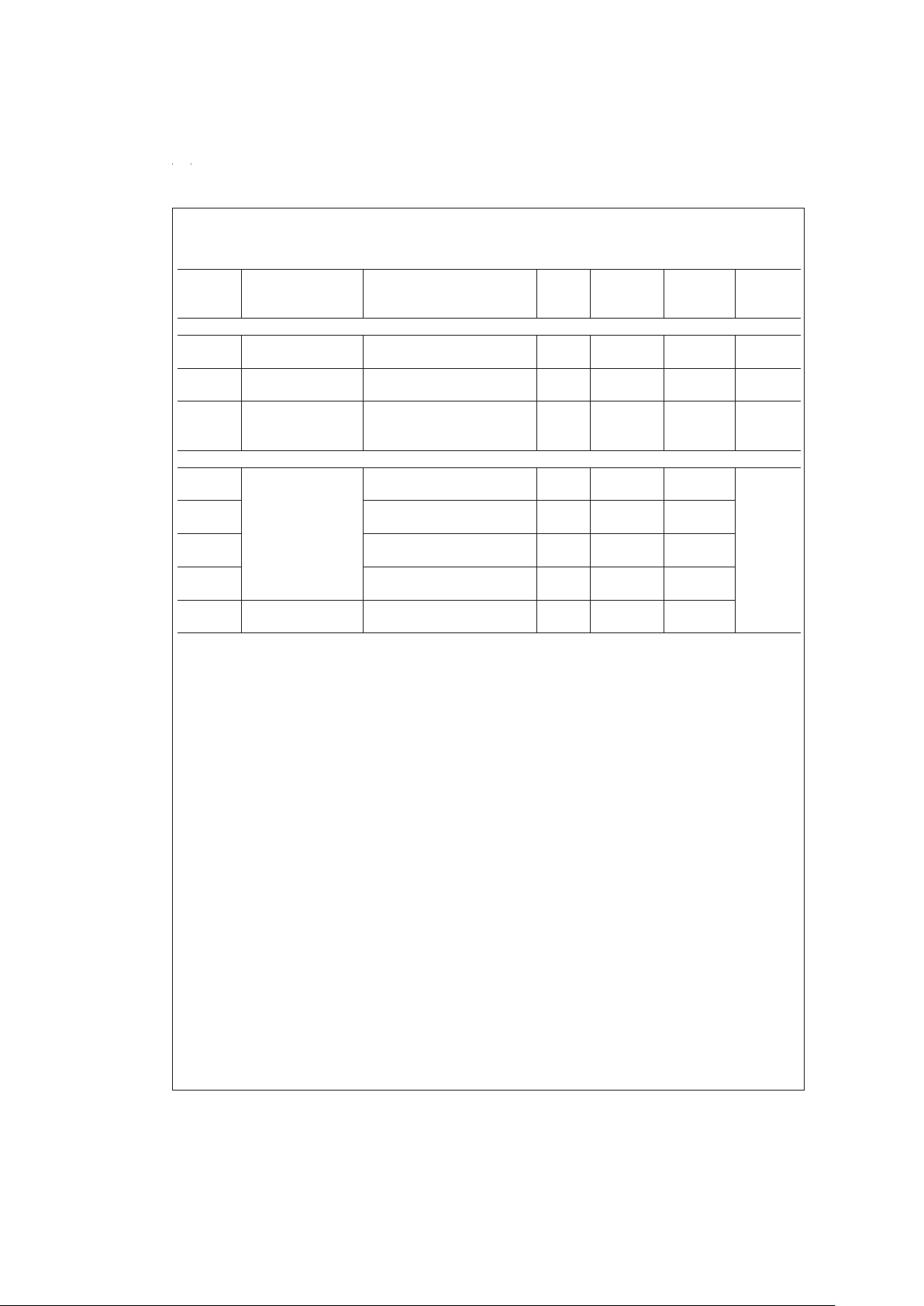

Electrical Characteristics—LM1577-15, LM2577-15

Specifications with standard type face are for T

J

=

25˚C, and those in bold type face apply over full Operating Temperature

Range. Unless otherwise specified, V

IN

=

5V, and I

SWITCH

=

0.

LM1577-15 LM2577-15 Units

Symbol Parameter Conditions Typical Limit Limit (Limits)

(Notes 3, 4) (Note 5)

SYSTEM PARAMETERS Circuit of

Figure 2

(Note 6)

V

OUT

Output Voltage V

IN

=

5V to 12V 15.0 V

I

LOAD

=

100 mA to 600 mA 14.50/14.25 14.50/14.25 V(min)

(Note 3) 15.50/15.75 15.50/15.75 V(max)

Line Regulation V

IN

=

3.5V to 12V 20

50/100 50/100

mV

I

LOAD

=

300 mA mV(max)

Load Regulation V

IN

=

5V 20

50/100 50/100

mV

I

LOAD

=

100 mA to 600 mA mV(max)

η Efficiency V

IN

=

5V, I

LOAD

=

600 mA 80

%

DEVICE PARAMETERS

I

S

Input Supply Current V

FEEDBACK

=

18.0V 7.5 mA

(Switch Off) 10.0/14.0 10.0/14.0 mA(max)

I

SWITCH

=

2.0A 25 mA

V

COMP

=

2.0V 50/85 50/85 mA(max)

(Max Duty Cycle)

V

UV

Input Supply I

SWITCH

=

100 mA 2.90 V

www.national.com3

Page 4

Electrical Characteristics—LM1577-15, LM2577-15 (Continued)

Specifications with standard type face are for T

J

=

25˚C, and those in bold type face apply over full Operating Temperature

Range. Unless otherwise specified, V

IN

=

5V, and I

SWITCH

=

0.

LM1577-15 LM2577-15 Units

Symbol Parameter Conditions Typical Limit Limit (Limits)

(Notes 3, 4) (Note 5)

DEVICE PARAMETERS

Undervoltage 2.70/2.65 2.70/2.65 V(min)

Lockout 3.10/3.15 3.10/3.15 V(max)

f

O

Oscillator Frequency Measured at Switch Pin 52 kHz

I

SWITCH

=

100 mA 48/42 48/42 kHz(min)

56/62 56/62 kHz(max)

V

REF

Output Reference Measured at Feedback Pin V

Voltage V

IN

=

3.5V to 40V 15 14.70/14.55 14.70/14.55 V(min)

V

COMP

=

1.0V 15.30/15.45 15.30/15.45 V(max)

Output Reference V

IN

=

3.5V to 40V 10 mV

Voltage Line Regulation

R

FB

Feedback Pin Input 12.2 kΩ

Voltage Line Regulator

G

M

Error Amp I

COMP

=

−30 µA to +30 µA 300 µmho

Transconductance V

COMP

=

1.0V 170/110 170/110 µmho(min)

420/500 420/500 µmho(max)

A

VOL

Error Amp V

COMP

=

1.1V to 1.9V 65 V/V

Voltage Gain R

COMP

=

1.0 MΩ 40/20 40/20 V/V(min)

(Note 7)

Error Amplifier Upper Limit 2.4 V

Output Swing V

FEEDBACK

=

12.0V 2.2/2.0 2.2/2.0 V(min)

Lower Limit 0.3 V

V

FEEDBACK

=

18.0V 0.4/0.55 0.40/0.55 V(max)

Error Amp V

FEEDBACK

=

12.0V to 18.0V

±

200 µA

Output Current V

COMP

=

1.0V

±

130/±90±130/±90 µA(min)

±

300/±400±300/±400 µA(max)

I

SS

Soft Start Current V

FEEDBACK

=

12.0V 5.0 µA

V

COMP

=

0V 2.5/1.5 2.5/1.5 µA(min)

7.5/9.5 7.5/9.5 µA(max)

D Maximum Duty V

COMP

=

1.5V 95

%

Cycle I

SWITCH

=

100 mA 93/90 93/90

%

(min)

Switch

Transconductance

12.5 A/V

I

L

Switch Leakage V

SWITCH

=

65V 10 µA

Current V

FEEDBACK

=

18.0V 300/600 300/600 µA(max)

(Switch Off)

V

SAT

Switch Saturation I

SWITCH

=

2.0A 0.5 V

Voltage V

COMP

=

2.0V 0.7/0.9 0.7/0.9 V(max)

(Max Duty Cycle)

NPN Switch V

COMP

=

2.0V 4.3 A

Current Limit 3.7/3.0 3.7/3.0 A(min)

5.3/6.0 5.3/6.0 A(max)

www.national.com 4

Page 5

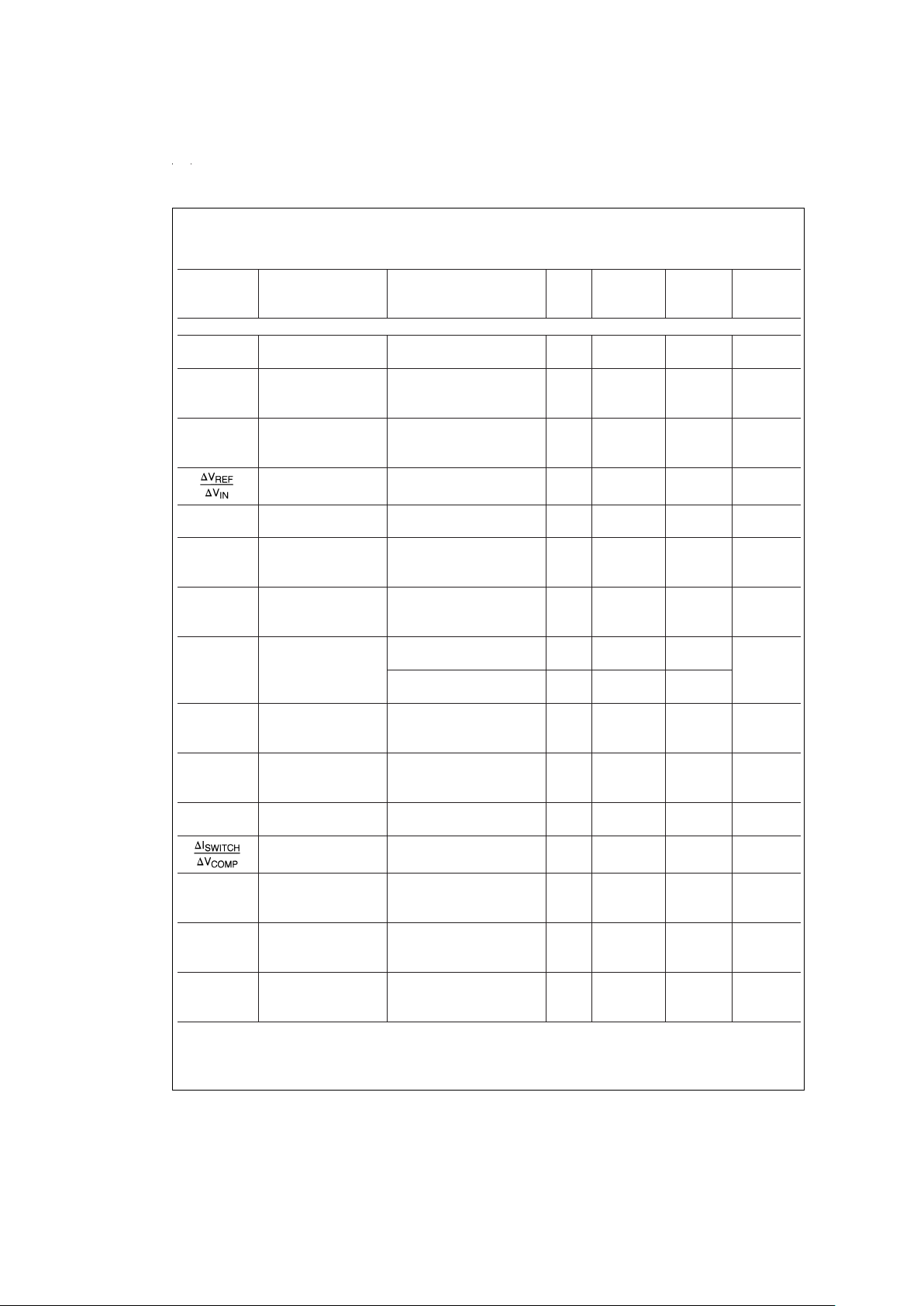

Electrical Characteristics—LM1577-ADJ, LM2577-ADJ

Specifications with standard type face are for T

J

=

25˚C, and those in bold type face apply over full Operating Temperature

Range. Unless otherwise specified, V

IN

=

5V, V

FEEDBACK

=

V

REF

, and I

SWITCH

=

0.

LM1577-ADJ LM2577-ADJ Units

Symbol Parameter Conditions Typical Limit Limit (Limits)

(Notes 3, 4) (Note 5)

SYSTEM PARAMETERS Circuit of

Figure 3

(Note 6)

V

OUT

Output Voltage V

IN

=

5V to 10V 12.0 V

I

LOAD

=

100 mA to 800 mA 11.60/11.40 11.60/11.40 V(min)

(Note 3) 12.40/12.60 12.40/12.60 V(max)

∆V

OUT

/ Line Regulation V

IN

=

3.5V to 10V 20 mV

∆V

IN

I

LOAD

=

300 mA 50/100 50/100 mV(max)

∆V

OUT

/ Load Regulation V

IN

=

5V 20 mV

∆I

LOAD

I

LOAD

=

100 mA to 800 mA 50/100 50/100 mV(max)

η Efficiency V

IN

=

5V, I

LOAD

=

800 mA 80

%

DEVICE PARAMETERS

I

S

Input Supply Current V

FEEDBACK

=

1.5V (Switch Off) 7.5 mA

10.0/14.0 10.0/14.0 mA(max)

I

SWITCH

=

2.0A 25 mA

V

COMP

=

2.0V (Max Duty Cycle) 50/85 50/85 mA(max)

V

UV

Input Supply I

SWITCH

=

100 mA 2.90 V

Undervoltage Lockout 2.70/2.65 2.70/2.65 V(min)

3.10/3.15 3.10/3.15 V(max)

f

O

Oscillator Frequency Measured at Switch Pin 52 kHz

I

SWITCH

=

100 mA 48/42 48/42 kHz(min)

56/62 56/62 kHz(max)

V

REF

Reference Measured at Feedback Pin V

Voltage V

IN

=

3.5V to 40V 1.230 1.214/1.206 1.214/1.206 V(min)

V

COMP

=

1.0V 1.246/1.254 1.246/1.254 V(max)

∆V

REF

/ Reference Voltage V

IN

=

3.5V to 40V 0.5 mV

∆V

IN

Line Regulation

I

B

Error Amp V

COMP

=

1.0V 100 nA

Input Bias Current 300/800 300/800 nA(max)

G

M

Error Amp I

COMP

=

−30 µA to +30 µA 3700 µmho

Transconductance V

COMP

=

1.0V 2400/1600 2400/1600 µmho(min)

4800/5800 4800/5800 µmho(max)

A

VOL

Error Amp V

COMP

=

1.1V to 1.9V 800 V/V

Voltage Gain R

COMP

=

1.0 MΩ (Note 7) 500/250 500/250 V/V(min)

Error Amplifier Upper Limit 2.4 V

Output Swing V

FEEDBACK

=

1.0V 2.2/2.0 2.2/2.0 V(min)

Lower Limit 0.3 V

V

FEEDBACK

=

1.5V 0.40/0.55 0.40/0.55 V(max)

Error Amp V

FEEDBACK

=

1.0V to 1.5V

±

200 µA

Output Current V

COMP

=

1.0V

±

130/±90

±

130/±90 µA(min)

±

300/±400±300/±400 µA(max)

I

SS

Soft Start Current V

FEEDBACK

=

1.0V 5.0 µA

V

COMP

=

0V 2.5/1.5 2.5/1.5 µA(min)

7.5/9.5 7.5/9.5 µA(max)

D Maximum Duty Cycle V

COMP

=

1.5V 95

%

I

SWITCH

=

100 mA 93/90 93/90

%

(min)

∆I

SWITCH

/ Switch 12.5 A/V

∆V

COMP

Transconductance

www.national.com5

Page 6

Electrical Characteristics—LM1577-ADJ, LM2577-ADJ (Continued)

Specifications with standard type face are for T

J

=

25˚C, and those in bold type face apply over full Operating Temperature

Range. Unless otherwise specified, V

IN

=

5V, V

FEEDBACK

=

V

REF

, and I

SWITCH

=

0.

LM1577-ADJ LM2577-ADJ Units

Symbol Parameter Conditions Typical Limit Limit (Limits)

(Notes 3, 4) (Note 5)

DEVICE PARAMETERS

I

L

Switch Leakage V

SWITCH

=

65V 10 µA

Current V

FEEDBACK

=

1.5V (Switch Off) 300/600 300/600 µA(max)

V

SAT

Switch Saturation I

SWITCH

=

2.0A 0.5 V

Voltage V

COMP

=

2.0V (Max Duty Cycle) 0.7/0.9 0.7/0.9 V(max)

NPN Switch V

COMP

=

2.0V 4.3 A

Current Limit 3.7/3.0 3.7/3.0 A(min)

5.3/6.0 5.3/6.0 A(max)

THERMAL PARAMETERS (All Versions)

θ

JA

Thermal Resistance K Package, Junction to Ambient 35

˚C/W

θ

JC

K Package, Junction to Case 1.5

θ

JA

T Package, Junction to Ambient 65

θ

JC

T Package, Junction to Case 2

θ

JA

N Package, Junction to 85

Ambient (Note 8)

θ

JA

M Package, Junction 100

to Ambient (Note 8)

θ

JA

S Package, Junction to 37

Ambient (Note 9)

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating ratings indicate conditions the device is intended to

be functional, but device parameter specifications may not be guaranteed under these conditions. For guaranteed specifications and test conditions, see the Electrical

Characteristics.

Note 2: Due to timing considerations of the LM1577/LM2577 current limit circuit, output current cannot be internally limited when the LM1577/LM2577 is used as a

step-up regulator. To prevent damage to the switch, its current must be externally limited to 6.0A. However, output current is internally limited when the LM1577/

LM2577 is used as a flyback or forward converter regulator in accordance to the Application Hints.

Note 3: All limits guaranteed at room temperature (standard type face) and at temperature extremes (boldface type). All limits are used to calculate Outgoing Quality

Level, and are 100%production tested.

Note 4: A military RETS electrical test specification is available on request. At the time of printing, the LM1577K-12/883, LM1577K-15/883, and LM1577K-ADJ/883

RETS specifications complied fully with the boldface limits in these columns. The LM1577K-12/883, LM1577K-15/883, and LM1577K-ADJ/883 may also be procured

to Standard Military Drawing specifications.

Note 5: All limits guaranteed at room temperature (standard type face) and at temperature extremes (boldface type). All room temperature limits are 100%produc-

tion tested. All limits at temperature extremes are guaranteed via correlation using standard Statistical Quality Control (SQC) methods.

Note 6: External components such as the diode, inductor,input and output capacitors can affect switching regulator performance. When the LM1577/LM2577 is used

as shown in the Test Circuit, system performance will be as specified by the system parameters.

Note 7: A 1.0 MΩ resistor is connected to the compensation pin (which is the error amplifier’s output) to ensure accuracy in measuring A

VOL

. In actual applications,

this pin’s load resistance should be ≥10 MΩ, resulting in A

VOL

that is typically twice the guaranteed minimum limit.

Note 8: Junction to ambient thermal resistance with approximately 1 square inch of pc board copper surrounding the leads.Additional copper area will lower thermal

resistance further. See thermal model in “Switchers Made Simple” software.

Note 9: If the TO-263 package is used, the thermal resistance can be reduced by increasing the PC board copper area thermally connected to the package. Using

0.5 square inches of copper area, θ

JA

is 50˚C/W; with 1 square inch of copper area, θJAis 37˚C/W; and with 1.6 or more square inches of copper area, θJAis 32˚C/W.

www.national.com 6

Page 7

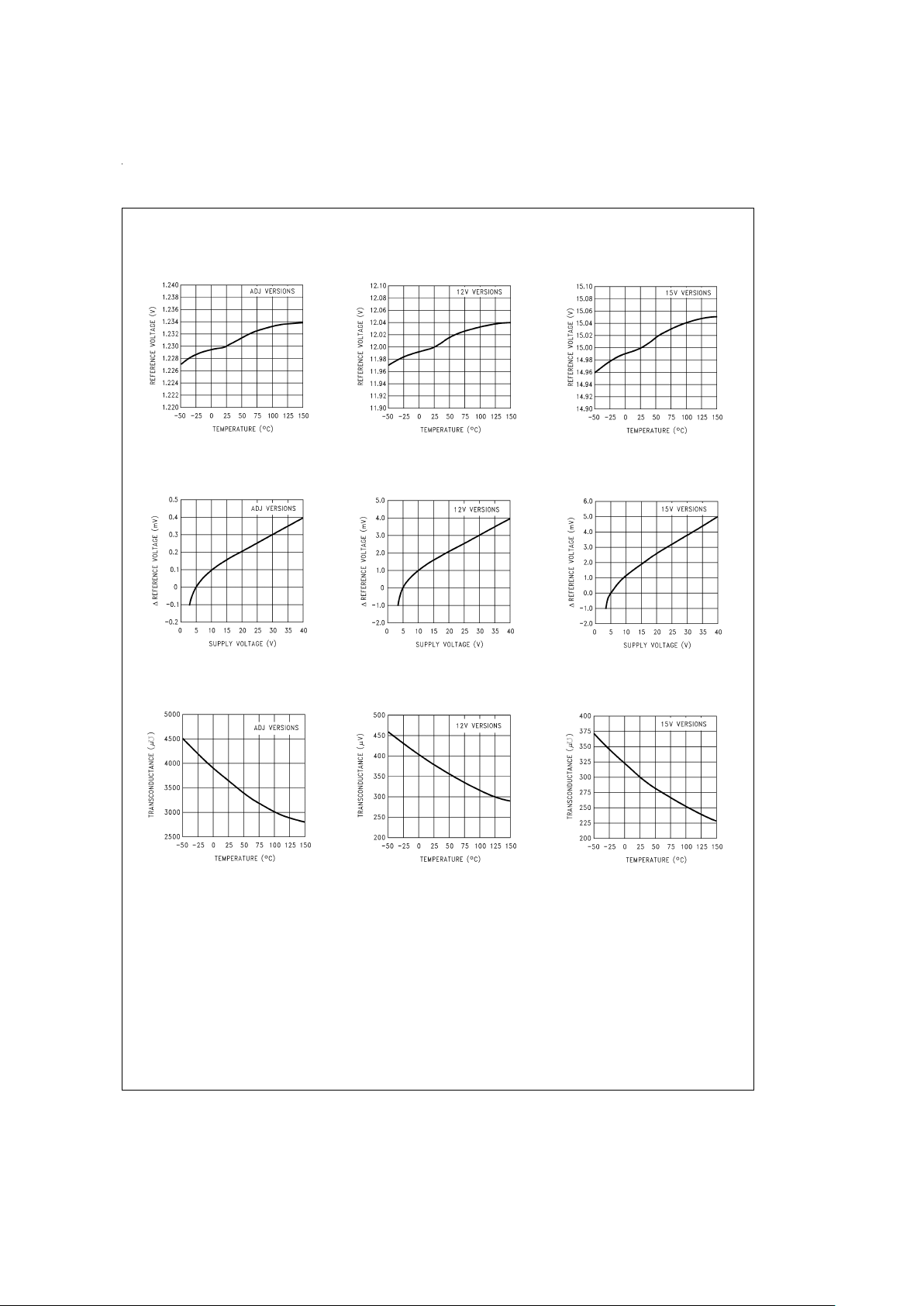

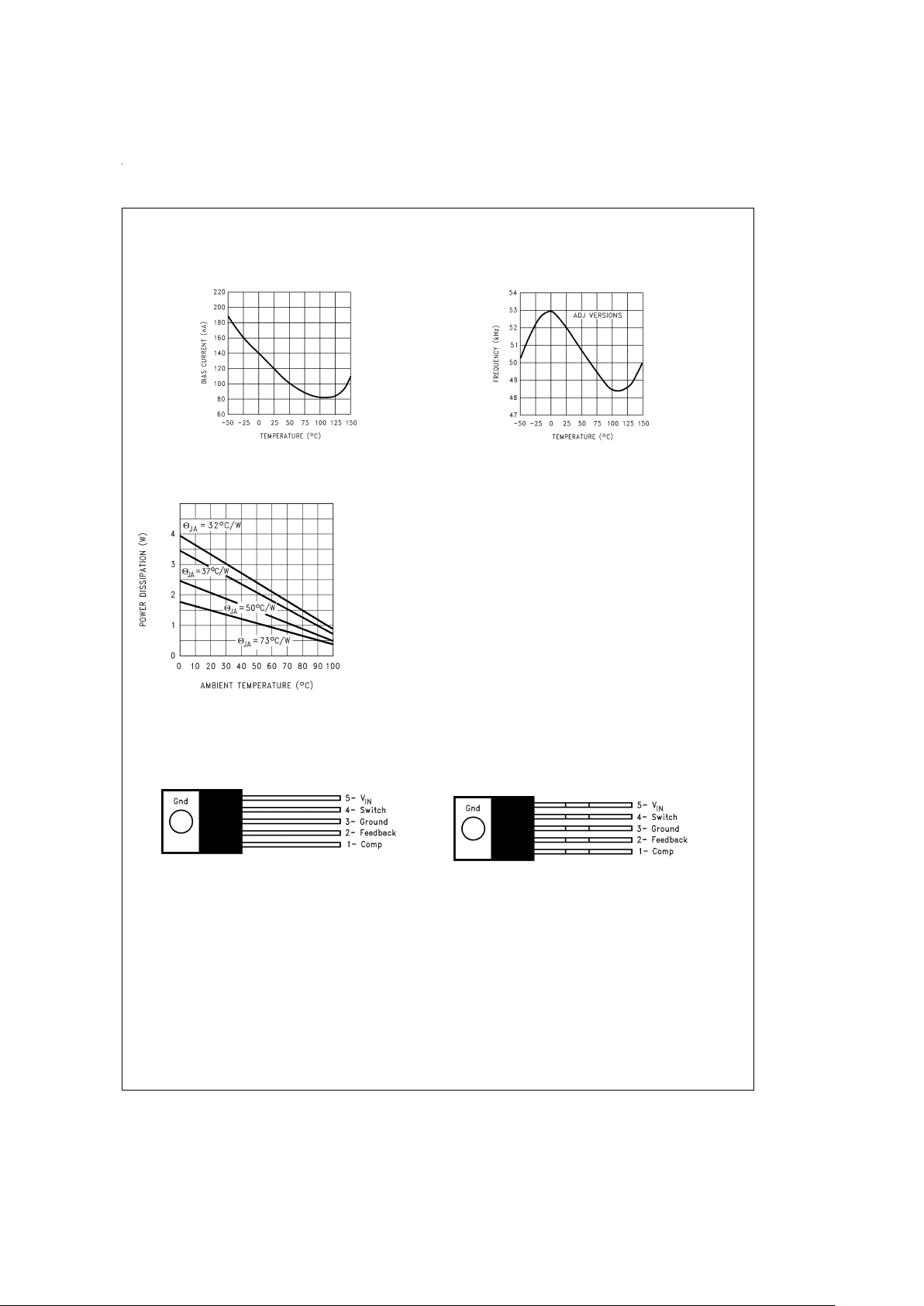

Typical Performance Characteristics

Reference Voltage

vs Temperature

DS011468-34

Reference Voltage

vs Temperature

DS011468-35

Reference Voltage

vs Temperature

DS011468-36

∆ Reference Voltage

vs Supply Voltage

DS011468-37

∆ Reference Voltage

vs Supply Voltage

DS011468-38

∆ Reference Voltage

vs Supply Voltage

DS011468-39

Error Amp Transconductance

vs Temperature

DS011468-40

Error Amp Transconductance

vs Temperature

DS011468-41

Error Amp Transconductance

vs Temperature

DS011468-42

www.national.com7

Page 8

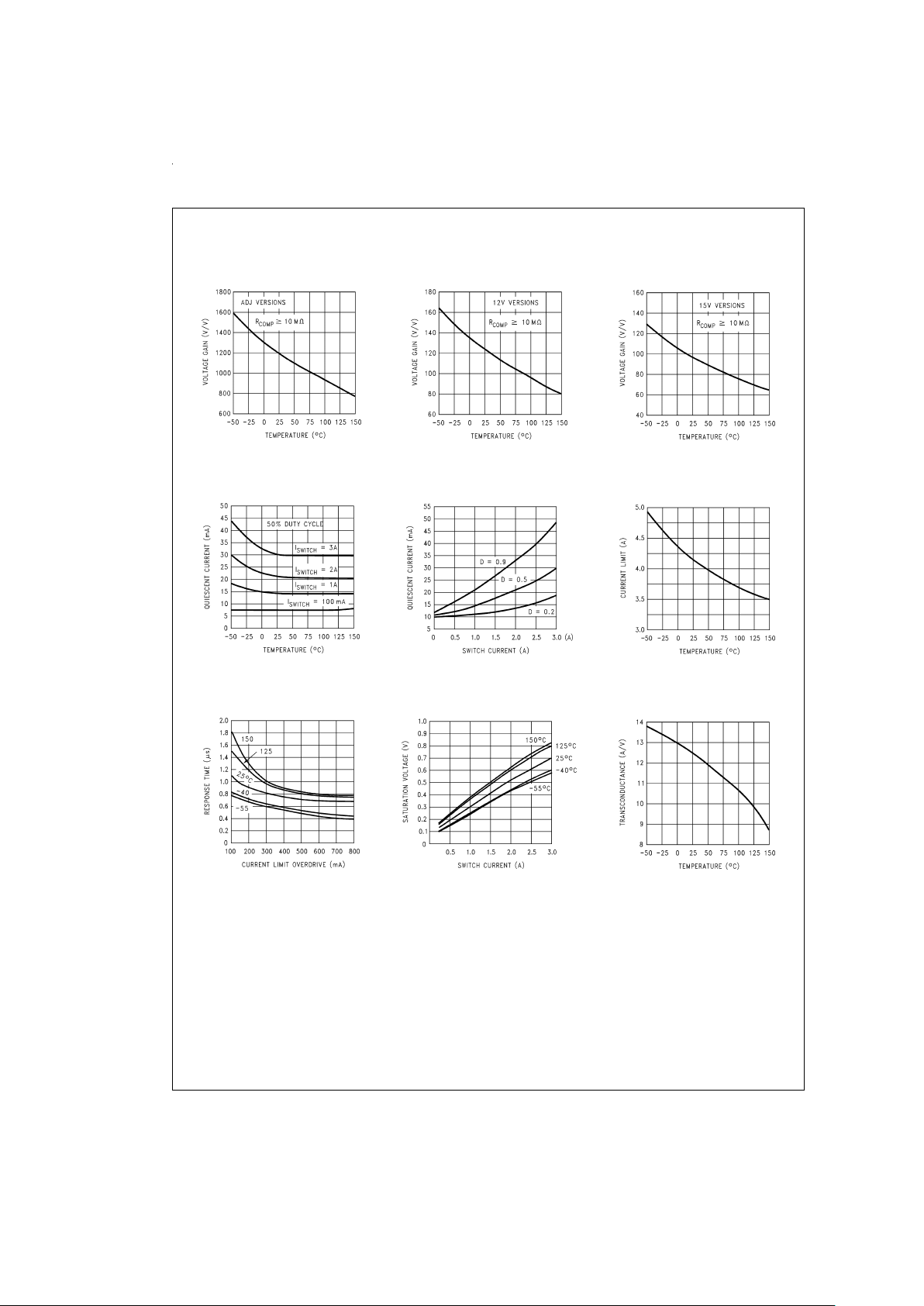

Typical Performance Characteristics (Continued)

Error Amp Voltage

Gain vs Temperature

DS011468-43

Error Amp Voltage

Gain vs Temperature

DS011468-44

Error Amp Voltage

Gain vs Temperature

DS011468-45

Quiescent Current

vs Temperature

DS011468-46

Quiescent Current

vs Switch Current

DS011468-47

Current Limit

vs Temperature

DS011468-48

Current Limit Response

Time vs Overdrive

DS011468-49

Switch Saturation Voltage

vs Switch Current

DS011468-50

Switch Transconductance

vs Temperature

DS011468-51

www.national.com 8

Page 9

Typical Performance Characteristics (Continued)

Connection Diagrams

Feedback Pin Bias

Current vs Temperature

DS011468-52

Oscillator Frequency

vs Temperature

DS011468-53

Maximum Power Dissipation

(TO-263) (Note 9)

DS011468-31

Straight Leads

5-Lead TO-220 (T)

DS011468-4

Top View

Order Number LM2577T-12, LM2577T-15,

or LM2577T-ADJ

See NS Package Number T05A

Bent, Staggered Leads

5-Lead TO-220 (T)

DS011468-5

Top View

Order Number LM2577T-12 Flow LB03, LM2577T-15

Flow LB03, or LM2577T-ADJ Flow LB03

See NS Package Number T05D

www.national.com9

Page 10

Connection Diagrams (Continued)

16-Lead DIP (N)

DS011468-6

*

No internal Connection

Top View

Order Number LM2577N-12, LM2577N-15,

or LM2577N-ADJ

See NS Package Number N16A

24-Lead Surface Mount (M)

DS011468-7

*

No internal Connection

Top View

Order Number LM2577M-12, LM2577M-15,

or LM2577M-ADJ

See NS Package Number M24B

TO-263 (S)

5-Lead Surface-Mount Package

DS011468-32

Top View

DS011468-33

Side View

Order Number LM2577S-12, LM2577S-15,

or LM2577S-ADJ

See NS Package Number TS5B

4-Lead TO-3 (K)

DS011468-8

Bottom View

Order Number LM1577K-12/883, LM1577K-15/883,

or LM1577K-ADJ/883

See NS Package Number K04A

www.national.com 10

Page 11

LM1577-12, LM2577-12 Test Circuit

LM1577-15, LM2577-15 Test Circuit

LM1577-ADJ, LM2577-ADJ Test Circuit

DS011468-30

L=415-0930 (AIE)

D=any manufacturer

C

OUT

=

Sprague Type 673D

Electrolytic 680 µF, 20V

Note: Pin numbers shown are for TO-220 (T) package

FIGURE 1. Circuit Used to Specify System Parameters for 12V Versions

DS011468-26

L=415-0930 (AIE)

D=any manufacturer

C

OUT

=

Sprague Type 673D

Electrolytic 680 µF, 20V

Note: Pin numbers shown are for TO-220 (T) package

FIGURE 2. Circuit Used to Specify System Parameters for 15V Versions

DS011468-9

L=415-0930 (AIE)

D=any manufacturer

C

OUT

=

Sprague Type 673D

Electrolytic 680 µF, 20V

R1=48.7k in series with 511Ω (1%)

R2=5.62k (1%)

Note: Pin numbers shown are for TO-220 (T) package

FIGURE 3. Circuit Used to Specify System Parameters for ADJ Versions

www.national.com11

Page 12

Application Hints

DS011468-10

Note: Pin numbers shown are for TO-220 (T) package

*

Resistors are internal to LM1577/LM2577 for 12V and 15V versions.

FIGURE 4. LM1577/LM2577 Block Diagram and Boost Regulator Application

www.national.com 12

Page 13

Application Hints (Continued)

STEP-UP (BOOST) REGULATOR

Figure 4

shows the LM1577-ADJ/LM2577-ADJ used as a

Step-Up Regulator. This is a switching regulator used for

producing an output voltage greater than the input supply

voltage. The LM1577-12/LM2577-12 and LM1577-15/

LM2577-15 can also be used for step-up regulators with 12V

or 15V outputs (respectively), by tying the feedback pin directly to the regulator output.

A basic explanation of how it works is as follows. The

LM1577/LM2577 turns its output switch on and off at a frequency of 52 kHz, and this creates energy in the inductor (L).

When the NPN switch turns on, the inductor current charges

up at a rate of V

IN

/L, storing current in the inductor. When the

switch turns off, the lower end of the inductor flies above V

IN

,

discharging its current through diode (D) into the output capacitor (C

OUT

) at a rate of (V

OUT−VIN

)/L. Thus, energy

stored in the inductor during the switch on time is transferred

to the output during the switch off time. The output voltage is

controlled by the amount of energy transferred which, in turn,

is controlled by modulating the peak inductor current. This is

done by feeding back a portion of the output voltage to the

error amp, which amplifies the difference between the feedback voltage and a 1.230V reference. The error amp output

voltage is compared to a voltage proportional to the switch

current (i.e., inductor current during the switch on time).

The comparator terminates the switch on time when the two

voltages are equal, thereby controlling the peak switch current to maintain a constant output voltage.

Voltage and current waveforms for this circuit are shown in

Figure 5

, and formulas for calculating them are given in

Fig-

ure 6

.

STEP-UP REGULATOR DESIGN PROCEDURE

The following design procedure can be used to select the appropriate external components for the circuit in

Figure 4

,

based on these system requirements.

Given:

V

IN (min)

=

Minimum input supply voltage

V

OUT

=

Regulated output voltage

I

LOAD(max)

=

Maximum output load current

Before proceeding any further, determine if the LM1577/

LM2577 can provide these values of V

OUT

and I

LOAD(max)

when operating with the minimum value of VIN. The upper

limits for V

OUT

and I

LOAD(max)

are given by the following

equations.

V

OUT

≤ 60V

and V

OUT

≤ 10xV

IN(min)

These limits must be greater than or equal to the values

specified in this application.

1. Inductor Selection (L)

A.

Voltage Options:

1. For 12V or 15V output

DS011468-11

FIGURE 5. Step-Up Regulator Waveforms

Duty Cycle D

Average

Inductor

Current

I

IND(AVE)

Inductor

Current

Ripple

∆I

IND

Peak

Inductor

Current

I

IND(PK)

Peak Switch

Current

I

SW(PK)

Switch

Voltage

When Off

V

SW(OFF)

V

OUT+VF

Diode

Reverse

Voltage

V

R

V

OUT−VSAT

Average

Diode

Current

I

D(AVE)

I

LOAD

Peak Diode

Current

I

D(PK)

Power

Dissipation

of

LM1577/2577

P

D

V

F

=

Forward Biased Diode Voltage

I

LOAD

=

Output Load Current

FIGURE 6. Step-Up Regulator Formulas

www.national.com13

Page 14

Application Hints (Continued)

From

Figure 7

(for 12V output) or

Figure 8

(for 15V

output), identify inductor code for region indicated by

V

IN (min)

and I

LOAD (max)

. The shaded region indicates

conditions for which the LM1577/LM2577 output switch

would be operating beyond its switch current rating. The

minimum operating voltage for the LM1577/LM2577 is

3.5V.

From here,

proceed to step C

.

2. For Adjustable version

Preliminary calculations:

The inductor selection is based on the calculation of the

following three parameters:

D

(max)

, the maximum switch duty cycle (0 ≤ D ≤ 0.9):

where V

F

=

0.5V for Schottky diodes and 0.8V for fast recov-

ery diodes (typically);

E•T

, the product of volts x time that charges the inductor:

I

IND,DC

, the average inductor current under full load;

B.

Identify Inductor Value:

1. From

Figure 9

, identify the inductor code for the re-

gion indicated by the intersection of E

•

T and I

IND,DC

.

This code gives the inductor value in microhenries. The

L or H prefix signifies whether the inductor is rated for a

maximum E

•

Tof90V•µs (L) or 250 V•µs (H).

2. If D

<

0.85, go on to step C. If D ≥ 0.85, then calculate the minimum inductance needed to ensure the

switching regulator’s stability:

If L

MIN

is smaller than the inductor value found in step B1, go

on to step C. Otherwise, the inductor value found in step B1

is too low; an appropriate inductor code should be obtained

from the graph as follows:

1. Find the lowest value inductor that is greater than L

MIN

.

2. Find where E

•

T intersects this inductor value to determine

if it has an L or H prefix. If E

•

T intersects both the L and H re-

gions, select the inductor with an H prefix.

DS011468-27

FIGURE 7. LM2577-12 Inductor Selection Guide

DS011468-28

FIGURE 8. LM2577-15 Inductor Selection Guide

www.national.com 14

Page 15

Application Hints (Continued)

C.

Select an inductor

from the table of

Figure 10

which

cross-references the inductor codes to the part numbers

of three different manufacturers. Complete specifications for these inductors are available from the respective manufacturers. The inductors listed in this table

have the following characteristics:

AIE:

ferrite, pot-core inductors; Benefits of this type are

low electro-magnetic interference (EMI), small physical

size, and very low power dissipation (core loss). Be

careful not to operate these inductors too far beyond

their maximum ratings for E

•

T and peak current, as this

will saturate the core.

Pulse:

powdered iron, toroid core inductors; Benefits are

low EMI and ability to withstand E

•

T and peak current

above rated value better than ferrite cores.

Renco:

ferrite, bobbin-core inductors; Benefits are low

cost and best ability to withstand E

•

T and peak current

above rated value. Be aware that these inductors generate more EMI than the other types, and this may interfere with signals sensitive to noise.

DS011468-12

Note: These charts assume that the inductor ripple current inductor is approximately 20%to 30%of the average inductor current (when the regulator is under

full load). Greater ripple current causes higher peak switch currents and greater output ripple voltage; lower ripple current is achieved with larger-value

inductors. The factor of 20 to 30%is chosen as a convenient balance between the two extremes.

FIGURE 9. LM1577-ADJ/LM2577-ADJ Inductor Selection Graph

www.national.com15

Page 16

Application Hints (Continued)

2. Compensation Network (R

C,CC

) and Output Capacitor

(C

OUT

) Selection

R

C

and CCform a pole-zero compensation network that sta-

bilizes the regulator. The values of R

C

and CCare mainly de-

pendant on the regulator voltage gain, I

LOAD(max)

, L and

C

OUT

. The following procedure calculates values for RC,CC,

and C

OUT

that ensure regulator stability. Be aware that this

procedure doesn’t necessarily result in R

C

and CCthat provide optimum compensation. In order to guarantee optimum

compensation, one of the standard procedures for testing

loop stability must be used, such as measuring V

OUT

tran-

sient response when pulsing I

LOAD

(see

Figure 15

).

A.

First, calculate the maximum value for RC.

Select a resistor less than or equal to this value, and it

should also be no greater than 3 kΩ.

B.

Calculate the minimum value for

C

OUT

using the following

two equations.

The larger of these two values is the minimum value that ensures stability.

C.

Calculate the minimum value of C

C

.

The compensation capacitor is also part of the soft start circuitry. When power to the regulator is turned on, the switch

duty cycle is allowed to rise at a rate controlled by this capacitor (with no control on the duty cycle, it would immediately rise to 90%, drawing huge currents from the input

power supply). In order to operate properly, the soft start circuit requires C

C

≥ 0.22 µF.

The value of the output filter capacitor is normally large

enough to require the use of aluminum electrolytic capacitors.

Figure 11

lists several different types that are recommended for switching regulators, and the following parameters are used to select the proper capacitor.

Working Voltage (WVDC):

Choose a capacitor with a working voltage at least 20%higher than the regulator output voltage.

Ripple Current:

This is the maximum RMS value of current

that charges the capacitor during each switching cycle. For

step-up and flyback regulators, the formula for ripple current

is

Choose a capacitor that is rated at least 50%higher than this

value at 52 kHz.

Equivalent Series Resistance (ESR)

: This is the primary

cause of output ripple voltage, and it also affects the values

of R

C

and CCneeded to stabilize the regulator. As a result,

the preceding calculations for C

C

and RCare only valid if

ESR doesn’t exceed the maximum value specified by the following equations.

Select a capacitor with ESR, at 52 kHz, that is less than or

equal to the lower value calculated. Most electrolytic capacitors specify ESR at 120 Hz which is 15%to 30%higher than

at 52 kHz. Also, be aware that ESR increases by a factor of

2 when operating at −20˚C.

In general, low values of ESR are achieved by using large

value capacitors (C ≥ 470 µF), and capacitors with high

WVDC, or by paralleling smaller-value capacitors.

Inductor Manufacturer’s Part Number

Code Schott Pulse Renco

L47 67126980 PE - 53112 RL2442

L68 67126990 PE - 92114 RL2443

L100 67127000 PE - 92108 RL2444

L150 67127010 PE - 53113 RL1954

L220 67127020 PE - 52626 RL1953

L330 67127030 PE - 52627 RL1952

L470 67127040 PE - 53114 RL1951

L680 67127050 PE - 52629 RL1950

H150 67127060 PE - 53115 RL2445

H220 67127070 PE - 53116 RL2446

H330 67127080 PE - 53117 RL2447

H470 67127090 PE - 53118 RL1961

H680 67127100 PE - 53119 RL1960

H1000 67127110 PE - 53120 RL1959

H1500 67127120 PE - 53121 RL1958

H2200 67127130 PE - 53122 RL2448

Schott Corp., (612) 475-1173

1000 Parkers Lake Rd., Wayzata, MN 55391

Pulse Engineering, (619) 268-2400

P.O. Box 12235, San Diego, CA 92112

Renco Electronics Inc., (516) 586-5566

60 Jeffryn Blvd. East, Deer Park, NY 11729

FIGURE 10. Table of Standardized Inductors and

Manufacturer’s Part Numbers

www.national.com 16

Page 17

Application Hints (Continued)

3. Output Voltage Selection (R1 and R2)

This section is for applications using the LM1577-ADJ/

LM2577-ADJ. Skip this section if the LM1577-12/LM2577-12

or LM1577-15/LM2577-15 is being used.

With the LM1577-ADJ/LM2577-ADJ, the output voltage is

given by

V

OUT

=

1.23V (1 + R1/R2)

Resistors R1 and R2 divide the output down so it can be

compared with the LM1577-ADJ/LM2577-ADJ internal

1.23V reference. For a given desired output voltage V

OUT

,

select R1 and R2 so that

4. Input Capacitor Selection (CIN)

The switching action in the step-up regulator causes a triangular ripple current to be drawn from the supply source. This

in turn causes noise to appear on the supply voltage. For

proper operation of the LM1577, the input voltage should be

decoupled. Bypassing the Input Voltage pin directly to

ground with a good quality,low ESR, 0.1 µF capacitor (leads

as short as possible) is normally sufficient.

If the LM1577 is located far from the supply source filter capacitors, an additional large electrolytic capacitor (e.g.

47 µF) is often required.

5. Diode Selection (D)

The switching diode used in the boost regulator must withstand a reverse voltage equal to the circuit output voltage,

and must conduct the peak output current of the LM2577. A

suitable diode must have a minimum reverse breakdown

voltage greater than the circuit output voltage, and should be

rated for average and peak current greater than I

LOAD(max)

and I

D(PK)

. Schottky barrier diodes are often favored for use

in switching regulators. Their low forward voltage drop allows

higher regulator efficiency than if a (less expensive) fast recovery diode was used. See

Figure 12

for recommended

part numbers and voltage ratings of 1A and 3A diodes.

BOOST REGULATOR CIRCUIT EXAMPLE

By adding a few external components (as shown in

Figure

13

), the LM2577 can be used to produce a regulated output

voltage that is greater than the applied input voltage. Typical

performance of this regulator is shown in

Figure 14

and

Fig-

ure 15

. The switchingwaveforms observed during the opera-

tion of this circuit are shown in

Figure 16

.

Cornell Dublier — Types 239, 250, 251, UFT,

300, or 350

P.O. Box 128, Pickens, SC 29671

(803) 878-6311

Nichicon —Types PF, PX, or PZ

927 East Parkway,

Schaumburg, IL 60173

(708) 843-7500

Sprague —Types 672D, 673D, or 674D

Box 1, Sprague Road,

Lansing, NC 28643

(919) 384-2551

United Chemi-Con — Types LX, SXF, or SXJ

9801 West Higgins Road,

Rosemont, IL 60018

(708) 696-2000

FIGURE 11. Aluminum Electrolytic Capacitors

Recommended for Switching Regulators

V

OUT

Schottky Fast Recovery

(max) 1A 3A 1A 3A

20V 1N5817 1N5820

MBR120P MBR320P

1N5818 1N5821

30V MBR130P MBR330P

11DQ03 31DQ03

1N5819 1N5822

40V MBR140P MBR340P

11DQ04 31DQ04

MBR150 MBR350 1N4933

50V 11DQ05 31DQ05 MUR105

1N4934 MR851

100V HER102 30DL1

MUR110 MR831

10DL1 HER302

FIGURE 12. Diode Selection Chart

www.national.com17

Page 18

Application Hints (Continued)

DS011468-13

Note: Pin numbers shown are for TO-220 (T) package.

FIGURE 13. Step-up Regulator Delivers 12V from a 5V Input

DS011468-14

FIGURE 14. Line Regulation (Typical) of Step-Up Regulator of

Figure 13

DS011468-15

A: Output Voltage Change, 100 mV/div. (AC-coupled)

B: Load current, 0.2 A/div

Horizontal: 5 ms/div

FIGURE 15. Load Transient Response of Step-Up

Regulator of

Figure 13

DS011468-16

A: Switch pin voltage, 10 V/div

B: Switch pin current, 2 A/div

C: Inductor current, 2 A/div

D: Output ripple voltage, 100 mV/div (AC-coupled)

Horizontal: 5 µs/div

FIGURE 16. Switching Waveforms of Step-Up

Regulator of

Figure 13

www.national.com 18

Page 19

Application Hints (Continued)

FLYBACK REGULATOR

A Flyback regulator can produce single or multiple output

voltages that are lower or greater than the input supply voltage.

Figure 18

shows the LM1577/LM2577 used as a flyback regulator with positive and negative regulated outputs.

Its operation is similar to a step-up regulator, except the output switch contols the primary current of a flyback transformer. Note that the primary and secondary windings are

out of phase, so no current flows through secondary when

current flows through the primary.This allows the primary to

charge up the transformer core when the switch is on. When

the switch turns off, the core discharges by sending current

through the secondary, and this produces voltage at the outputs. The output voltages are controlled by adjusting the

peak primary current, as described in the step-up regulator

section.

Voltage and current waveforms for this circuit are shown in

Figure 17

, and formulas for calculating them are given in

Fig-

ure 19

.

FLYBACK REGULATOR DESIGN PROCEDURE

1. Transformer Selection

A family of standardized flyback transformers is available for

creating flyback regulators that produce dual output voltages, from

±

10V to±15V, as shown in

Figure 18.Figure

20

lists these transformers with the input voltage, output volt-

ages and maximum load current they are designed for.

2. Compensation Network (C

C,RC

) and

Output Capacitor (C

OUT

) Selection

As explained in the Step-Up Regulator Design Procedure,

C

C,RC

and C

OUT

must be selected as a group. The following

procedure is for a dual output flyback regulator with equal

turns ratios for each secondary (i.e., both output voltages

have the same magnitude). The equations can be used for a

single output regulator by changing

∑

I

LOAD(max)

to I

LOAD(max)

in the following equations.

A. First, calculate the maximum value for R

C

.

Where∑I

LOAD(max)

is the sum of the load current (magnitude) required from both outputs. Select a resistor less than

or equal to this value, and no greater than 3 kΩ.

B. Calculate the minimum value for

∑

C

OUT

(sum of C

OUT

at both outputs) using the following two equations.

The larger of these two values must be used to ensure regulator stability.

DS011468-17

FIGURE 17. Flyback Regulator Waveforms

DS011468-18

T1=Pulse Engineering, PE-65300

D1, D2=1N5821

FIGURE 18. LM1577-ADJ/LM2577-ADJ Flyback Regulator with±Outputs

www.national.com19

Page 20

Application Hints (Continued)

C.

Calculate the minimum value of C

C

D.

Calculate the maximum ESR

of the +V

OUT

and −V

OUT

output capacitors in parallel.

This formula can also be used to calculate the maximum

ESR of a single output regulator.

At this point, refer to this same section in the Step-Up Regu-

lator Design Procedurefor more information regarding the

selection of C

OUT

.

3. Output Voltage Selection

This section is for applications using the LM1577-ADJ/

LM2577-ADJ. Skip this section if the LM1577-12/LM2577-12

or LM1577-15/LM2577-15 is being used.

With the LM1577-ADJ/LM2577-ADJ, the output voltage is

given by

V

OUT

=

1.23V (1 + R1/R2)

Resistors R1 and R2 divide the output voltage down so it can

be compared with the LM1577-ADJ/LM2577-ADJ internal

1.23V reference. For a desired output voltage V

OUT

, select

R1 and R2 so that

4. Diode Selection

The switching diode in a flyback converter must withstand

the reverse voltage specified by the following equation.

A suitable diode must have a reverse voltage rating greater

than this. In addition it must be rated for more than the average and peak diode currents listed in

Figure 19

.

5. Input Capacitor Selection

The primary of a flyback transformer draws discontinuous

pulses of current from the input supply.As a result, a flyback

regulator generates more noise at the input supply than a

step-up regulator,and this requires a larger bypass capacitor

to decouple the LM1577/LM2577 V

IN

pin from this noise. For

most applications, a low ESR, 1.0 µF cap will be sufficient, if

it is connected very close to the V

IN

and Ground pins.

Duty Cycle D

Primary Current Variation

∆I

P

Peak Primary Current

I

P(PK)

Switch Voltage when Off

V

SW(OFF)

Diode Reverse Voltage V

R

V

OUT

+

N(V

IN

−

V

SAT

)

Average Diode Current I

D(AVE)

I

LOAD

Peak Diode Current

I

D(PK)

Short Circuit Diode Current

Power Dissipation of

LM1577/LM2577

P

D

DS011468-78

FIGURE 19. Flyback Regulator Formulas

www.national.com 20

Page 21

Application Hints (Continued)

Transformer Input

Dual Maxi-

mum

Type Voltage Output Output

Voltage Current

L

P

=

100 µH 5V

±

10V 325 mA

1N

=

15V

±

12V 275 mA

5V

±

15V 225 mA

10V

±

10V 700 mA

10V

±

12V 575 mA

2L

P

=

200 µH 10V

±

15V 500 mA

N=0.5 12V

±

10V 800 mA

12V

±

12V 700 mA

12V

±

15V 575 mA

3L

P

=

250 µH 15V

±

10V 900 mA

N=0.5 15V

±

12V 825 mA

15V

±

15V 700 mA

In addition to this bypass cap, a larger capacitor (≥ 47 µF)

should be used where the flyback transformer connects to

the input supply. This will attenuate noise which may interfere with other circuits connected to the same input supply

voltage.

6. Snubber Circuit

A “snubber” circuit is required when operating from input

voltages greater than 10V, or when using a transformer with

L

P

≥ 200 µH. This circuit clamps a voltage spike from the

transformer primary that occurs immediately after the output

switch turns off. Without it, the switch voltage may exceed

the 65V maximum rating. As shown in

Figure 21

, the snub-

ber consists of a fast recovery diode, and a parallel RC. The

RC values are selected for switch clamp voltage (V

CLAMP

)

that is 5V to 10V greater than V

SW(OFF)

. Use the following

equations to calculate R and C;

Power dissipation (and power rating) of the resistor is;

The fast recovery diode must have a reverse voltage rating

greater than V

CLAMP

.

FLYBACK REGULATOR CIRCUIT EXAMPLE

The circuit of

Figure 22

produces±15V (at 225 mA each)

from a single 5V input. The output regulation of this circuit is

shown in

Figure 23

and

Figure 25

, while the load transient

response is shown in

Figure 24

and

Figure 26

. Switching

waveforms seen in this circuit are shown in

Figure 27

.

Transformer Manufacturers’ Part Numbers

Type AIE Pulse Renco

1 326-0637 PE-65300 RL-2580

2 330-0202 PE-65301 RL-2581

3 330-0203 PE-65302 RL-2582

FIGURE 20. Flyback Transformer Selection Guide

DS011468-19

FIGURE 21. Snubber Circuit

www.national.com21

Page 22

Application Hints (Continued)

DS011468-20

T1=Pulse Engineering, PE-65300

D1, D2=1N5821

FIGURE 22. Flyback Regulator Easily Provides Dual Outputs

DS011468-21

FIGURE 23. Line Regulation (Typical) of Flyback

Regulator of

Figure 22

, +15V Output

DS011468-23

A: Output Voltage Change, 100 mV/div

B: Output Current, 100 mA/div

Horizontal: 10 ms/div

FIGURE 24. Load Transient Response of Flyback

Regulator of

Figure 22

, +15V Output

DS011468-22

FIGURE 25. Line Regulation (Typical) of Flyback

Regulator of

Figure 22

, −15V Output

DS011468-24

A: Output Voltage Change, 100 mV/div

B: Output Current, 100 mA/div

Horizontal: 10 ms/div

FIGURE 26. Load Transient Response of Flyback

Regulator of

Figure 22

, −15V Output

www.national.com 22

Page 23

Application Hints (Continued)

DS011468-25

A: Switch pin voltage, 20 V/div

B: Primary current, 2 A/div

C: +15V Secondary current, 1 A/div

D: +15V Output ripple voltage, 100 mV/div

Horizontal: 5 µs/div

FIGURE 27. Switching Waveforms of Flyback Regulator of

Figure 22

, Each Output Loaded with 60Ω

www.national.com23

Page 24

Physical Dimensions inches (millimeters) unless otherwise noted

TO-3 Metal Can Package (K)

Order Number LM1577K-12/883, LM1577K-15/883, or LM1577K-ADJ/883

NS Package Number K04A

0.300 Wide SO Package (M)

Order Number LM2577M-12, LM2577M-15 or LM2577M-ADJ

NS Package Number M24B

www.national.com 24

Page 25

Physical Dimensions inches (millimeters) unless otherwise noted (Continued)

Molded Dual-In-Line Package (N)

Order Number LM2577N-12, LM2577N-15, or LM2577N-ADJ

NS Package Number N16A

TO-220, Straight Leads (T)

Order Number LM2577T-12, LM2577T-15, or LM2577T-ADJ

NS Package Number TO5A

www.national.com25

Page 26

Physical Dimensions inches (millimeters) unless otherwise noted (Continued)

TO-220, Bent Staggered Leads (T)

Order Number LM2577T-12 Flow LB03, LM2577T-15 Flow LB03, or LM2577T-ADJ Flow LB03

NS Package Number T05D

www.national.com 26

Page 27

Physical Dimensions inches (millimeters) unless otherwise noted (Continued)

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

labeling, can be reasonably expected to result in a

significant injury to the user.

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80-532 78 32

Français Tel: +49 (0) 1 80-532 93 58

Italiano Tel: +49 (0) 1 80-534 16 80

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

www.national.com

5-Lead TO-263 (S)

Order Number LM2577S-12, LM2577S-15 or LM2577S-ADJ

NS Package Number TS5B

LM1577/LM2577 Series SIMPLE SWITCHER Step-Up Voltage Regulator

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...