Page 1

LM2419

Triple 65 MHz CRT Driver

LM2419 Triple 65 MHz CRT Driver

December 1994

General Description

The LM2419 contains three wide bandwidth, large signal

amplifiers designed for large voltage swings. The amplifiers

have a gain of

CRT monitors and is a low cost solution to designs conforming to 1024 x 768 display resolution.

The device is mounted in the industry standard 11-lead

TO-220 molded power package. The heat sink is electrically

isolated and may be grounded for ease of manufacturing

and EMI/RFI shielding.

b

15. The device is intended for use in color

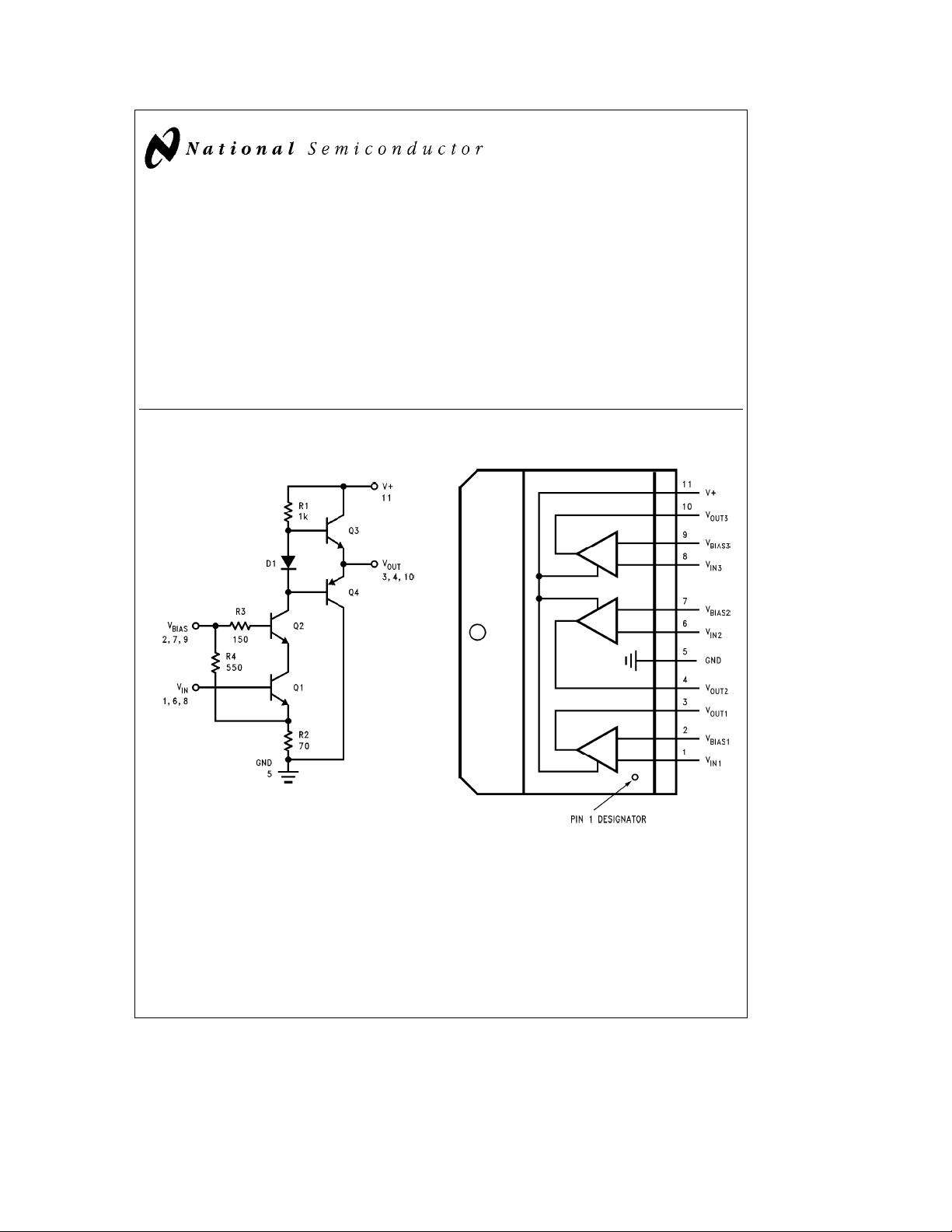

Schematic and Connection Diagrams

One Channel

Features

Y

50 VPPoutput swing at 65 MHz

Y

Rise/Fall time 5 ns with 12 pF load

Y

60 VPPoutput swing capability

Y

Pin and function compatible with LM2416

Y

No low frequency tilt compensation required

Applications

Y

CRT driver for SVGA, IBM 8514 and 1024 x 768

display resolution RGB monitors

TL/H/11442– 1

Order Number LM2419T

See NS Package Number TA11B

C

1995 National Semiconductor Corporation RRD-B30M115/Printed in U. S. A.

TL/H/11442

TL/H/11442– 2

Page 2

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales

Office/Distributors for availability and specifications.

Supply Voltage (V

Storage Temperature (T

Operating Case Temperature, T

Lead Temperature (solderingk10 sec.) 300§C

ESD Tolerance 2 kV

a

)

)

STG

Case

b

25§Ctoa100§C

b

a

85V

20§Ctoa90§C

Electrical Characteristics

Unless otherwise specified, the following specifications apply for V

swing; frequency

Symbol Parameter Conditions

I

CC

I

B

V

OUT

t

r

t

f

A

V

OS Overshoot VIN:tr,t

LE Linearlty Error V

e

1 MHz; V

Bias

e

12V; C

L

e

12 pF; T

A

Supply Current (per Amplifier) Input/Output Open Circuit 27 40 mA

Bias Current (Pins 2 or 7 or 9) 11 mA

Output Offset Voltage 40 50 60 V

Rise Time 10% to 90% 5 ns

Fall Time 90% to 10% 5 ns

Voltage Gain

k

f

e

25V to 75V 8 %

OUT

a

e

e

25§C; see test circuit,

80V, DC input bias, V

Figure 1

.

IN DC

e

3.9V; 50 VPPoutput

Min Typ Max Units

(Note 3) (Note 2) (Note 3) (Limit)

b

13

b

15

b

18 V/V

2ns 8 %

DAVmatch Gain Matching 0.3 dB

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. The guaranteed specifications apply only for the test conditions

listed. Some performance characteristics may degrade when the device is not operated under the listed test conditions.

Note 2: Typical specifications are at 25

Note 3: Min/Max limits are guaranteed to National’s AOQL (Average Outgoing Quality Level).

C and represent the most likely parametric norm.

§

Typical Performance

Characteristics

e

T

25§C, Test CircuitÐ

A

Figure 1

Frequency Response

*12 pF is the total load capacitance and includes the test fixture capacitance.

TL/H/11442– 3

FIGURE 1. Test Circuit (One Section)

TL/H/11442– 4

2

Page 3

Typical Performance

Characteristics

e

T

25§C, Test CircuitÐ

A

Pulse Response

(Continued)

Figure 1

small signal cross over distortion. Resistor R3 is used to

prevent Q2 from oscillating at high frequencies.

TL/H/11442– 5

Test Circuit

Figure 1

LM2419. The input signal is AC coupled into the input of

LM2419 and is referenced to 3.9V DC using an external

3.9V DC bias through a 390X resistor. The test circuit is

designed to allow testing of the LM2419 in a 50X environment such as a 50X oscilloscope or network analyzer. The

4950X resistor in series with the output of the LM2419

forms a 100:1 voltage divider when connected to a 50X

oscilloscope or network analyzer.

shows a typical test circuit for evaluation of the

Theory of Operation

The LM2419 is a high voltage triple CRT driver suitable for

SVGA, IBM 8514 and 1024 x 768 display resolution monitors. The device is packaged in the industry standard

11 lead TO-220 molded power package. The heat sink is

electrically isolated and may be grounded for ease of manufacturing and RFl/EMl shielding.

The schematic diagram of LM2419 is shown in

and R2 provide a conversion of the input voltage to current

while Q2 acts as a common base amplifier to drive the load

resistor, R1. Resistor R4 along with R2 sets up the DC bias

at the base of Q1. Emitter followers Q3 and Q4 isolate R1

from the capacitive load at the output, thus making the rise

and fall times relatively insensitive to the load capacitance.

The gain of the amplifier is

approximately

limited by the time constant due to R1 and the capacitances

associated with D1, Q2, Q3 and Q4. Diode D1 is used to

provide some bias voltage for Q3 and Q4 so as to reduce

b

15. The bandwidth of LM2419 is primarily

b

R1/(R2llR4) and is fixed at

Figure 2

.Q1

FIGURE 2. Schematic Diagram of

One Section of LM2419

TL/H/11442– 7

Application Hints

POWER SUPPLY BYPASS

Since the LM2419 is a wide-bandwidth amplifier with greater

than 10,000 V/ms slew rate, proper power supply bypassing

is critical for optimum performance. Improper power supply

bypassing can result in large overshoot, ringing and oscillation. A 0.01 mF ceramic capacitor should be connected as

close to the supply pin as is practical (preferably less than

(/4

from the supply pin). The lead length of the 0.01 mF

×

ceramic capacitor should be as small as is practical. In addition, 10 mF–100 mF electrolytic capacitor should be connected from the supply pin to ground. The electrolytic capacitor should be placed reasonably close to the LM2419’s

supply pin.

ARC PROTECTION

The LM2419 must be protected from arcing within the CRT.

To limit the arcover voltage, a 200V spark gap is recommended at the cathode. Clamp diodes D1 and D2 (as

shown in

output of LM2419 to a safe level. The clamp diodes used

should have high current rating, low series impedance and

low shunt capacitance. Resistor R2 in

arcover current while R1 limits the current into LM2419 and

reduces the power dissipation of the output transistors

when the output is stressed beyond the supply voltage.

Having large value resistors for R1 and R2 would be desirable but this has the effect of reducing rise and fall times.

Figure 3

) are used to clamp the voltage at the

Figure 3

limits the

3

Page 4

Application Hints (Continued)

FIGURE 3. Typical Application Circuit (One Channel)

IMPROVING RISE AND FALL TIMES

Because of an emitter follower output stage, the rise and fall

times of the LM2419 are relatively unaffected by capacitive

loading. However, the series resistors R1 and R2 (see

ure 3

) will reduce the rise and fall times when driving the

Fig-

CRT’s cathode which appears as a capacitive load. The capacitance at the cathode typically ranges from 8 pF to

12 pF.

To improve the rise and fall times at the cathode, a small

inductor is often used in series with the output of the amplifier. The inductor L1 in

Figure 3

peaks the amplifier’s frequency response at the cathode, thus improving rise and fall

times. The inductor value is empirically determined and is

dependent on the load. An inductor value of 0.1 mHisa

good starting value. Note that peaking the amplifier’s frequency response will increase the overshoot.

REDUCING OVERSHOOT

LM2419’s overshoot is a function of both the input signal

rise and fall times and the capacitive loading. The overshoot

is increased by either more capacitive loading or faster rise

and fall times of the input signal.

Table I shows the overshoot for a typical device with different capacitive loads and different input signal rise and fall

times. As can be observed from Table I, overshoot is large

for large capacitive loads and faster input signal rise and fall

times. In an actual application, the LM2419 is driven from a

preamplifier with rise and fall times of 3 ns to 7 ns. When

driven from LM1203 preamplifier (see application circuit,

Figure 6

) the overshoot is 10% with 12 pF capacitive load.

The overshoot can be reduced by including a resistor in

series with LM2419’s output as in

Figure 3

. Larger value

resistors for R1 and R2 would reduce overshoot but this

also increases the rise and fall times at the output. Frequency peaking using an inductor in series with the output may

restore the bandwidth.

TL/H/11442– 8

Table I. LM2419 Output Overshoot

vs Capacitive Loading for a Typical Device

Input Signal C

tr/t

f

5 pF 8 pF 11 pF 15 pF

L

1.2 ns 4% 6% 7% 8%

7ns 4% 5% 6% 7%

GAIN VS OUTPUT DC LEVEL

Figure 4

Figure 4

shows LM2419’s gain versus output DC level. A

100 mV

the input signal’s DC level is swept. As can be seen from

15.4 (V

and 65V. Thus the amplifier’s output response is linear for

AC signal is applied at the LM2419’s input and

PP

, the amplifier’s gain is constant at approximately

e

1.54 VPP) for output DC level between 35V

OUT

output voltage between 35V and 65V. If the output voltage

is less than 35V or more than 70V, the amplifier’s output

response becomes non-linear (note the change in gain,

ure 4

). For optimum performance, it is recommended that

Fig-

LM2419’s output low voltage be at 25V or above. For a

50 V

swing, the output high voltage is 75V. With an output

PP

signal swing from 25V to 75V, LM2419’s linearity error is

measured at 8%.

TL/H/11442– 9

FIGURE 4. Gain vs V

OUT

(DC), V

e

100 mV

IN

PP

4

Page 5

Application Hints (Continued)

THERMAL CONSIDERATIONS

LM2419’s transfer characteristic and power dissipation versus DC input voltage is shown in

current increases as the input voltage increases, consequently power dissipation increases. For the LM2419, the

worst case power dissipation occurs when a white screen is

displayed on the CRT. Considering a 20% black retrace

time in a 1024 x 768 display resolution application, the average power dissipation for continuous white screen is less

than 4W per channel with 50 V

at 75V and white level at 25V). Although the total power

dissipation is less than 12W for a continuous white screen,

the heat sink should be selected for 13W power dissipation

because of the variation in power dissipation from part to

part.

For thermal and gain linearity considerations, the output low

voltage (white level) should be maintained above 20V. If the

device is operated at an output low voltage below 20V, the

power dissipation might exceed 4.7W per channel (i.e., 14W

power dissipation for the device). Note that the device can

be operated at lower power by reducing the peak to peak

video output voltage to less than 50V and clamping the video black level close to the supply voltage.

FIGURE 5. V

and Power Dissipation vs V

OUT

Figure 5

. Power supply

output signal (black level

PP

TL/H/11442– 10

IN

The LM2419 requires that the package be properly heat

sunk under all operating conditions. Maximum ratings re-

quire that the device case temperature be limited to 90

maximum. Thus for 50

and 13W maximum power dissipation, the thermal resistance of the heat sink should be:

i

sa

SHORT CIRCUIT PROTECTION

The output of LM2419 is not short circuit protected. Shorting the output to either ground or to V

device. The minimum DC load resistance the LM2419 can

drive without damage is 1.6 kX to ground or V

driving a 1.6 kX load for an extended period of time is not

recommended because of power dissipation considerations. If the LM2419 is used to drive a resistive load then the

load should be 10 kX or greater.

C maximum ambient temperature

§

s

(90–50)§C/13We3§C/W

a

will destroy the

a

. However,

RGB Video Application

A complete video section for an RGB CRT monitor is shown

in

Figure 6

include almost all the circuitry required between the video

input connection and the CRT’s cathodes. However, an externally generated back porch clamp signal is required to

accomplish DC restoration of the video signal.

Figure 6

1024 x 768 display resolution application. With 50 V

put swing and 12 pF load, the rise/fall time for

circuit was measured at 7.5 ns. In this application, feedback

is local to the LM1203. For detailed information on the

LM1203, please refer to the LM1203 data sheet.

PC BOARD LAYOUT CONSIDERATIONS

For optimum performance, adequate ground plane, isolation

between channels, good supply bypassing and minimizing

unwanted feedback are necessary. Moreover, the length of

the signal trace from the preamplifier to the LM2419 and

from the LM2419 to the cathode should be as short as is

practical. The following book is highly recommended:

Ott, Henry W,

Systems

. The LM1203 video preamplifier and the LM2419

’s circuit is excellent choice for a non-interlaced

PP

Figure 6

out-

Noise Reduction Techniques in Electronic

, John Wiley & Sons, New York, 1976.

C

§

’s

5

Page 6

Application Hints (Continued)

FIGURE 6. Typical VGA/SVGA Application

6

TL/H/11442– 11

Page 7

Application Hints (Continued)

TL/H/11442– 12

FIGURE 7. Typical SVGA/XGA Application

Diodes FDH400

Unmarked capacitors 0.1 mF

7

Page 8

Physical Dimensions inches (millimeters) Lit.

LM2419 Triple 65 MHz CRT Driver

Order Number LM2419T

NS Package Number TA11B

Ý

107763

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL

SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or 2. A critical component is any component of a life

systems which, (a) are intended for surgical implant support device or system whose failure to perform can

into the body, or (b) support or sustain life, and whose be reasonably expected to cause the failure of the life

failure to perform, when properly used in accordance support device or system, or to affect its safety or

with instructions for use provided in the labeling, can effectiveness.

be reasonably expected to result in a significant injury

to the user.

National Semiconductor National Semiconductor National Semiconductor National Semiconductor

Corporation Europe Hong Kong Ltd. Japan Ltd.

1111 West Bardin Road Fax: (

Arlington, TX 76017 Email: cnjwge@tevm2.nsc.com Ocean Centre, 5 Canton Rd. Fax: 81-043-299-2408

Tel: 1(800) 272-9959 Deutsch Tel: (

Fax: 1(800) 737-7018 English Tel: (

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Fran3ais Tel: (

Italiano Tel: (

a

49) 0-180-530 85 86 13th Floor, Straight Block, Tel: 81-043-299-2309

a

49) 0-180-530 85 85 Tsimshatsui, Kowloon

a

49) 0-180-532 78 32 Hong Kong

a

49) 0-180-532 93 58 Tel: (852) 2737-1600

a

49) 0-180-534 16 80 Fax: (852) 2736-9960

Loading...

Loading...