Page 1

LM2405

Monolithic Triple 7 ns CRT Driver

General Description

The LM2405 is an integrated high voltage CRT driver circuit

designed for use in color monitor applications. The IC contains three high input impedance, wide band amplifiers

which directly drivethe RGB cathodes of a CRT. Each channel has its gain internally set at −14 and can drive CRT capacitive loads as well as resistive loads presented by other

applications, limited only by the package’s power dissipation.

The IC is packaged in an industry standard 11 lead TO-220

molded plastic power package. See thermal considerations

on page 5.

Features

n Rise/fall times typically 7 ns with 8 pF load

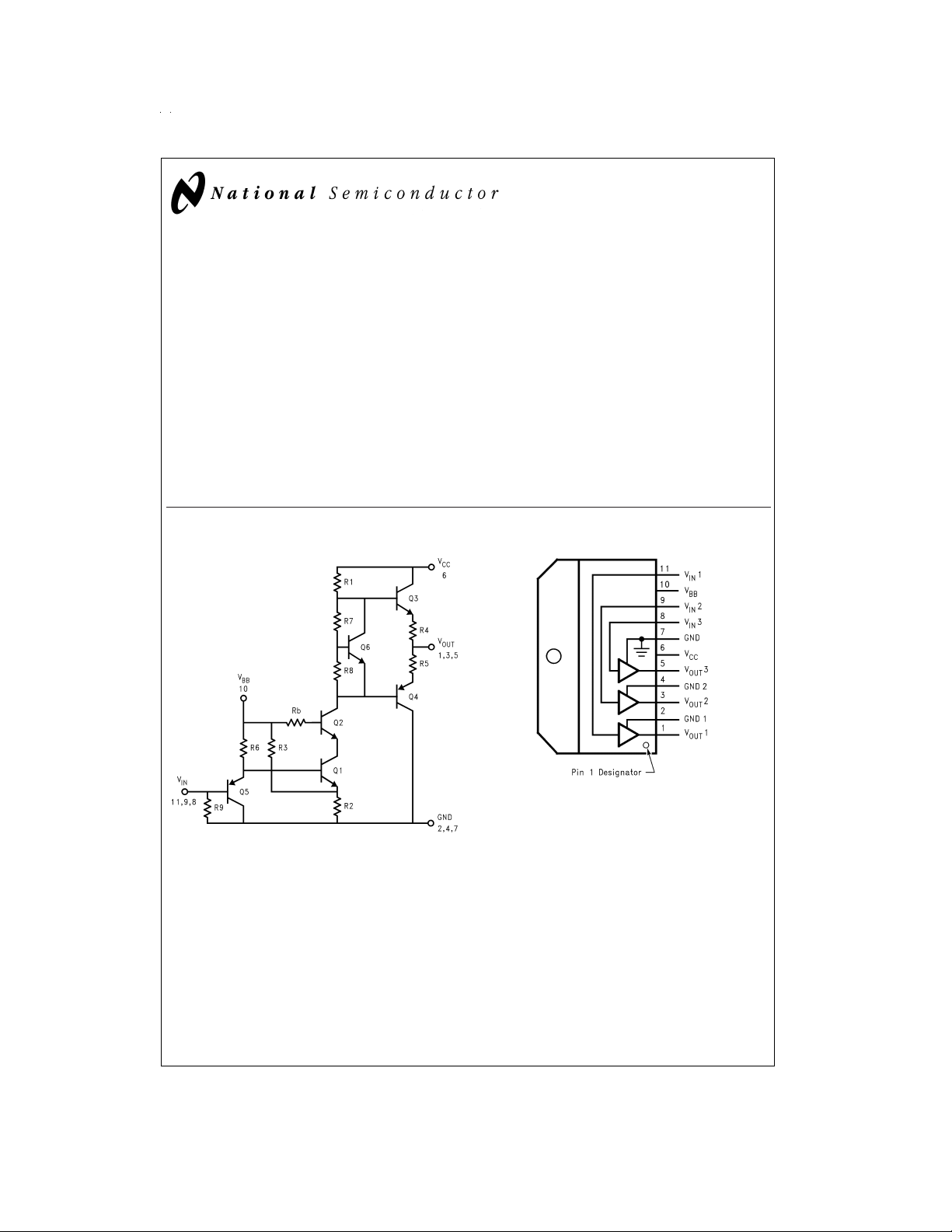

Schematic and Connection Diagram

n Output swing capability:

50 V

40 V

30 V

n Pinout designed for easy PCB layout

n 0V to 6V input range

n Stable with 0 pF–20 pF capactive loads

n Convenient TO-220 staggered lead package style

Applications

n CRT driver for 1280 x 1024 (Non-interlaced) and XGA

display resolution color monitors

n Pixel clock frequency up to 130 MHz

n Monitors using video blanking

LM2405 Monolithic Triple 7 ns CRT Driver

August 1999

=

for V

PP

for V

PP

for V

PP

80

CC

=

70

CC

=

60

CC

TabisatGND

Top View

DS012682-1

FIGURE 1. Simplified Schematic Diagram (One

Channel)

© 1999 National Semiconductor Corporation DS012682 www.national.com

Order Number LM2405T

DS012682-2

Page 2

Absolute Maximum Ratings (Notes 1, 3)

Supply Voltage (V

Bias Voltage (V

Input Voltage (V

Storage Temperature Range

) −65˚C to +150˚C

(T

STG

Lead Temperature

(Soldering,

) +90V

CC

) +16V

BB

) −0.5V to V

IN

<

10 sec.) 300˚C

BIAS

+ 0.5V

Operating Ranges (Note 2)

V

CC

V

BB

V

IN

Case Temperature (T

Do not operate the part without a heat sink.

) −20˚C to +100˚C

CASE

+60V to +85V

+8V to +15V

0V to +6V

ESD Tolerance 2 kV

Electrical Characteristics

Unless otherwise noted: V

=

T

25˚C.

A

CC

=

+80V, V

Symbol Parameter Conditions

I

I

V

A

∆A

CC

BB

OUT

V

V

Supply Current Per Channel, No Output Load 18 30 mA

Bias Current 38 mA

DC Output Voltage No Input Signal 47 50 53 V

DC Voltage Gain No Input Signal −12 −14 −16

Gain Matching No Input Signal (Note 4) 1.0 dB

LE Linearity Error No Input Signal (Notes 4, 5) 8

t

R

t

F

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur.

Note 2: Operating ratings indicate conditions for which the device is functional, but do not guarantee specific performance limits. For guaranteed specifications and

test conditions, see the Electrical Characteristics. The guaranteed specifications apply only for the test conditions listed. Some performance characteristics may

change when the device is not operated under the listed test conditions.

Note 3: All voltages are measured with respect to GND, unless otherwise specified.

Note 4: Calculated value from Voltage Gain test on each channel.

Note 5: Linearity Error is the variation in DC gain from V

Note 6: Input from signal generator: t

Rise Time 10%to 90

Fall Time 90%to 10

R,tF

=

+12V, V

BB

1 ns.

IN

<

%

%

=

+ 1.3V to V

=

+2.6V (at LM2405 input pins), C

IN

Min Typical Max

=

+3.9V.

IN

=

8 pF, Output=40 V

L

LM2405

at 1 MHz,

PP

Units

7ns

5.5 ns

DC

%

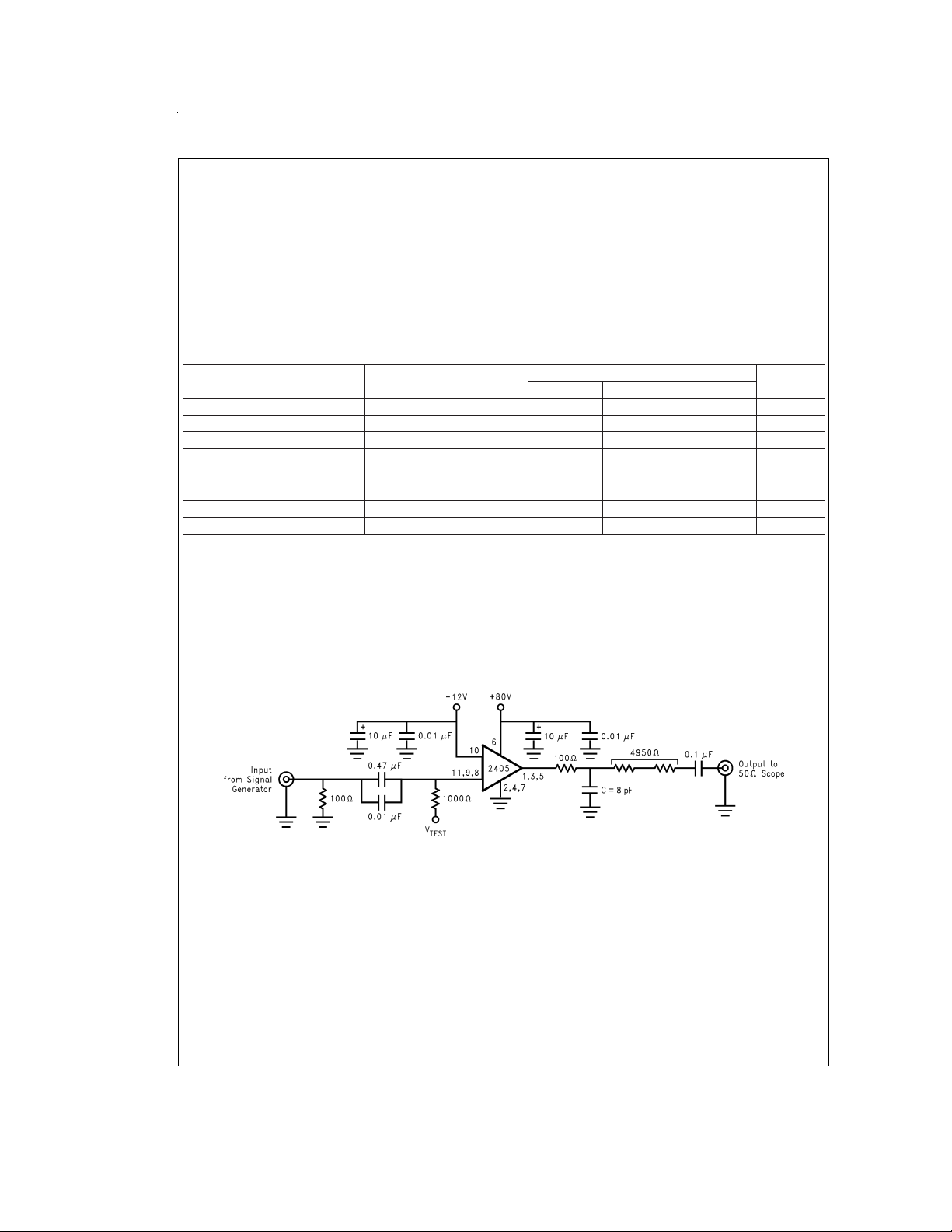

AC Test Circuit

Note: 8 pF is total load plus parasitic capacitance.

Note: Adjust Vtest for +2.6V DC at LM2405 input pins. See “Input Resistance” section of Application Hints.

FIGURE 2. Test Circuit (One Channel)

Figure 2

LM2405. This circuit is designed to allow testing of the

LM2405 in a 50Ω environment, such as a pulse generator,

oscilloscope or network analyzer. The 4950Ω resistor at the

output forms a 100:1 voltage divider when connected to a

50Ω load.

www.national.com 2

shows a typical test circuit for evaluation of the

DS012682-3

Page 3

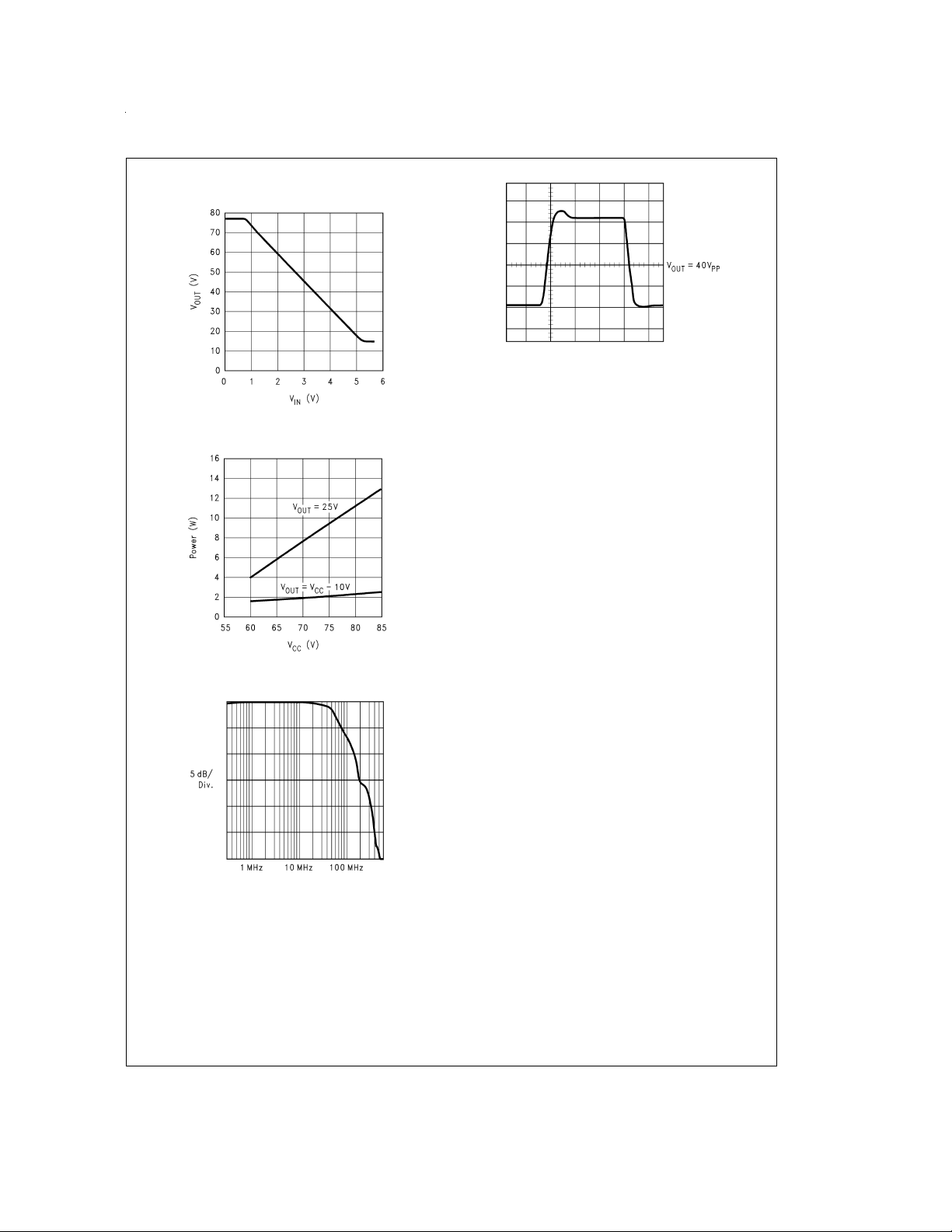

AC Test Circuit (Continued)

DS012682-7

FIGURE 6. Pulse Response

DS012682-4

FIGURE 3. V

FIGURE 4. Power Dissipation vs V

OUT

vs V

IN

DS012682-5

CC

DS012682-6

FIGURE 5. Large Signal Frequency Response

Theory of Operation

The LM2405 is a high voltage monolithic triple CRT driver

suitable for SVGA and XGA display applications. The

LM2405 features +80V operation and low power dissipation.

The part is housed in the industry standard 11-lead TO-220

molded plastic power package.

The circuit diagram of the LM2405 is shown in

Figure 1

.A

PNP emitter follower, Q5, provides input buffering. Q1 and

Q2 form a fixed gain cascode amplifier, with a gain of −14.

Emitter followers Q3 and Q4 isolate the high output impedance of the amplifier from the capacitance of the CRT cathode, and make the circuit relative insensitive to load capacitance. Q6 provides biasing to the output emitter follower

stage to reduce crossover distortion at low signal levels.

Figure 2

shows a typical test circuit for evaluation of the

LM2405. This circuit is designed to allow testing of the

LM2405 in a 50Ω environment, such as a pulse generator

and a scope, or a network analyzer. In this test circuit, two

low inductance resistors in series totaling 4.95 kΩ form a

100:1 wideband low capacitance probe when connected to a

50Ω cable and load. The input signal from the generator is

AC coupled to the base of Q5.

Application Hints

INTRODUCTION

National Semiconductor is committed to providing application information that assists our customers in obtaining the

best performance possible from our products. The following

information is provided in order to support this commitment.

The reader should be aware that the optimization of performance was done using a specific printed circuit board designed at National. Variations in performance can be realized

due to physical changes in the printed circuit board and the

application. Therefore, the designer should be aware that

component value changes may be required in order to optimize performance in a given application. The values shown

in this document can be used as a starting point for evaluation purposes. When working with high bandwidth circuits,

good layout practices are also critical to achieving maximum

performance.

POWER SUPPLY BYPASS

Since the LM2405 is a wide bandwidth amplifier, proper

power supply bypassing is critical for optimum performance.

Improper power supply bypassing can result in large overshoot, ringing and oscillation. A 0.01 µF capacitor should be

connected from the supply pin, V

, to ground, as close to

CC

www.national.com3

Page 4

Application Hints (Continued)

the supply pin as is practical (preferably less than

the supply pin). Additionally, a 10 µF to 100 µF electrolytic

capacitor should be connected from the supply pin to

ground. The electrolytic capacitor should also be placed reasonably close to the LM2405’s supply pin. A 0.1 µF capacitor

should be connected from the bias pin, V

close as is practical to the part.

ARC PROTECTION

During normal CRT operation, internal arcing may occasionally occur. Spark gaps of 200V to 300V at the cathodes will

limit the maximum voltage, but to a value that is much higher

than allowable on the LM2405. This fast, high voltage, high

energy pulse can damage the LM2405 output stage. The addition of clamp diodes D1 and D2 (as shown in

help clamp the voltage at the output of the LM2405 to a safe

level. The clamp diodes should have a fast transient response, high peak current rating, low series impedance and

low shunt capacitance. FDH400 or equivalent diodes are

recommended. Resistor R2 in

Figure 7

current while R1 limits the current into the LM2405 and reduces the power dissipation of the output transistors when

the output is stressed beyond the supply voltage. (Peaking

inductor Lp also helps protect the CRT driver from arc over.)

Having large value resistors for R1 and R2 would be desirable, but this has the effect of increasing rise and fall times.

For proper arc protection, it is important to not omit any of the

arc protection components shown in

Figure 7

FIGURE 7. One Section of the LM2405 with Arc

Protection and Peaking Inductor L

There are also ESD protection diodes built into the part. To

avoid damaging these diodes, do not apply an input voltage

from a low impedance source when the V

are held at ground potential.

IMPROVING RISE AND FALL TIMES

Because of an emitter follower output stage, the rise and fall

times of the LM2405 are relatively insensitive to capactive

loading. However, the series resistors R1 and R2 (see

ure 7

) will increase the rise and fall times when driving the

CRT’s cathode which appears as a capacitive load. The capacitance at the cathode typically ranges from 8 pF to 12 pF.

To improve the rise and fall times at the cathode, a small inductor is often used in series with the output of the amplifier.

The inductor L

response at the cathode, thus improving rise and fall times.

P

in

Figure 7

peaks the amplifier’s frequency

It also acts with the output load capacitance to form a low

pass filter, which reduces the amplitudes of high frequency

harmonics of the video signal, to lower radiated electromagnetic interference. The inductor value is empirically determined and is dependent on the load. An inductor value of

0.22 µH is a good starting value. Note that excessive peak-

1

⁄4" from

, to ground, as

BB

Figure 7

) will

limits the arcover

.

DS012682-8

P

and VCCpins

BB

Fig-

ing of the amplifier’s frequency response will increase the

overshoot. (Increasing the value of resistor R1 or R2 will reduce ringing and overshoot.)

EFFECT OF LOAD CAPACITANCE

The output rise and fall times will be slower than specified if

the load capacitance at the output is more than 8 pF, as

shown in

Figure 8

.

DS012682-9

FIGURE 8. Effect of Load Capacitance on

Rise/Fall Time

The monitor designer should ensure that stray capacitance

applied to the LM2405 is as low as possible.

THERMAL CONSIDERATIONS

Power supply current increases as the input signal increases

and consequently power dissipation also increases.

The LM2405 cannot be used without heat sinking. Typical

“average” power dissipation with the device output voltage at

one half the supply voltage is 2.4W per channel for a total

dissipation of 7.2W package dissipation. Under white screen

conditions, i.e., 25V output, dissipation increases to 3.5W

per channel or 10.5W total. The LM2405 case temperature

must be maintained below 100˚C. If the maximum expected

ambient temperature is 50˚C, then a maximum heat sink

thermal resistance can be calculated:

This example assumes a typical CRT capacitive load and is

without a resistive load. Note that this thermal resistance

must be achieved when the heat sink is operating in the

monitor.

INPUT RESISTANCE

The LM2405 has a fixed resistor of 3000Ω connected from

each signal input pin to ground. In the

Figure 2

Test Circuit,

the input DC voltage level, Vtest, must be adjusted, (to about

+3.5V) to allow for the voltage drop across the 1000Ω resistor, to set the actual voltage at the input pins to +2.6V. In actual use in a monitor, the 1000Ω resistor is not used and the

video preamp supplies the 2.6V offset.

PC BOARD LAYOUT CONSIDERATIONS

For optimum performance, an adequate ground plane, isolation between channels, good supply bypassing and minimizing unwanted feedback are necessary.Also,the length of the

www.national.com 4

Page 5

Application Hints (Continued)

signal traces from the preamplifier to the LM2405 and from

the LM2405 to the CRT cathode should be as short as possible. The following references are recommended:

Ott, Henry W., “Noise Reduction Techniques in Electronic

Systems”, John Wiley and Sons, New York, 1976.

“Guide to CRT Video Design”, National Semiconductor Application Note 861.

“Video Amplifier Design for Computer Monitors”, National

Semiconductor Application Note 1013.

Because of its high small signal bandwidth, the part may oscillate when it is used in a typical application with a preamp

in a monitor, if feedback occurs around the video amplifier

through the chassis wiring. To prevent this, leads to the input

circuit should be shielded, and input circuit wiring should be

spaced as far as possible from output circuit wiring. Power

should be removed as quickly as possible from an amplifier

that is oscillating, since power dissipation in the part is very

high in this mode and the part may be damaged if oscillations continue and the power supply can supply more than

250 mA.

TYPICAL APPLICATION

A typical application of the LM2405 is shown in

Used in conjunction with an LM1205, a complete video channel from monitor input to CRTcathode can be achieved. Performance is satisfactory for all applications up to 1280x1024

non-interlaced, and pixel clock frequencies up to 130 MHz.

Figure 9

.

www.national.com5

Page 6

Application Hints (Continued)

DS012682-10

www.national.com 6

Diodes FDH400

PNP Transistors MPSA92

NPN Transistors 2N2369

Unmarked Capacitors 0.1 µF

FIGURE 9. Typical Application

Page 7

Physical Dimensions inches (millimeters) unless otherwise noted

LM2405

11-Lead Molded TO-220

NS Package Number TA11B

Order Number LM2405T

LM2405 Monolithic Triple 7 ns CRT Driver

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80-532 78 32

Français Tel: +49 (0) 1 80-532 93 58

Italiano Tel: +49 (0) 1 80-534 16 80

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

Loading...

Loading...