Page 1

November 13, 2007

LM20154

4A, 1MHz PowerWise® Synchronous Buck Regulator with

SYNCOUT

General Description

The LM20154 is a full featured 1 MHz synchronous buck regulator capable of delivering up to 4A of continuous output

current. The current mode control loop can be compensated

to be stable with virtually any type of output capacitor. For

most cases, compensating the device only requires two external components, providing maximum flexibility and ease of

use. The device is optimized to work over the input voltage

range of 2.95V to 5.5V making it suited for a wide variety of

low voltage systems.

The device features internal over voltage protection (OVP)

and over current protection (OCP) circuits for increased system reliability. A precision enable pin and integrated UVLO

allows the turn on of the device to be tightly controlled and

sequenced. Start-up inrush currents are limited by both an

internally fixed and externally adjustable Soft-Start circuit.

Fault detection and supply sequencing is possible with the

integrated power good circuit.

The LM20154 features an open drain SYNCOUT pin which

provides an external clock that matches the switching frequency of the device but is shifted by 180 degrees.

The LM20154 is designed to work well in multi-rail power

supply architectures. The output voltage of the device can be

configured to track a higher voltage rail using the SS/TRK pin.

If the output of the LM20154 is pre-biased at startup it will not

sink current to pull the output low until the internal soft-start

ramp exceeds the voltage at the feedback pin.

The LM20154 is offered in an exposed pad 16-pin eTSSOP

package that can be soldered to the PCB, eliminating the

need for bulky heatsinks.

Features

■

Input voltage range 2.95V to 5.5V

■

Accurate current limit minimizes inductor size

■

96% peak efficiency at 1.0 MHz switching frequency

■

Frequency synchronization output

■

32 mΩ integrated FET switches

■

Starts up into pre-biased loads

■

Output voltage tracking

■

Peak current mode control

■

Adjustable output voltage down to 0.8V

■

Adjustable Soft-Start with external capacitor

■

Precision enable pin with hysteresis

■

Integrated OVP, UVLO, power good and thermal

shutdown

■

eTSSOP-16 exposed pad package

Applications

■

Simple to design, high efficiency point of load regulation

from a 5V or 3.3V bus

■

High Performance DSPs, FPGAs, ASICs and

microprocessors

■

Broadband, Networking and Optical Communications

Infrastructure

Typical Application Circuit

30030801

PowerWise® is a registered trademark of National Semiconductor Corporation.

© 2007 National Semiconductor Corporation 300308 www.national.com

LM20154 4A, 1MHz PowerWise

®

Synchronous Buck Regulator with SYNCOUT

Page 2

Connection Diagram

30030802

Top View

eTSSOP-16 Package

Ordering Information

Order Number Package Type NSC Package Drawing Package Marking Supplied As

LM20154MH eTSSOP-16 MXA16A 20154MH 92 Units of Rail

LM20154MHE 250 Units of Tape and Reel

LM20154MHX 2500 Units of Tape and Reel

Pin Descriptions

Pin # Name Description

1 SS/TRK Soft-Start or Tracking control input. An internal 5 µA current source charges an external capacitor to

set the Soft-Start ramp rate. If driven by a external source less than 800 mV, this pin overrides the

internal reference that sets the output voltage. If left open, an internal 1ms Soft-Start ramp is activated.

2 FB Feedback input to the error amplifier from the regulated output. This pin is connected to the inverting

input of the internal transconductance error amplifier. An 800 mV reference connected to the noninverting input of the error amplifier sets the closed loop regulation voltage at the FB pin.

3 PGOOD Power good output signal. Open drain output indicating the output voltage is regulating within

tolerance. A pull-up resistor of 10 to 100 kΩ is recommend for most applications.

4 COMP External compensation pin. Connect a resistor and capacitor to this pin to compensate the device.

5,16 NC These pins must be connected to GND to ensure proper operation.

6,7 PVIN Input voltage to the power switches inside the device. These pins should be connected together at the

device. A low ESR capacitor should be placed near these pins to stabilize the input voltage.

8,9 SW Switch pin. The PWM output of the internal power switches.

10,11 PGND Power ground pin for the internal power switches.

12 EN Precision enable input for the device. An external voltage divider can be used to set the device turn-

on threshold. If not used the EN pin should be connected to PVIN.

13 VCC Internal 2.7V sub-regulator. This pin should be bypassed with a 1 µF ceramic capacitor.

14 AVIN Analog input supply that generates the internal bias. Must be connected to VIN through a low pass

RC filter.

15 AGND Quiet analog ground for the internal bias circuitry.

16 SYNCOUT Frequency synchronization output. This NMOS open drain output provides a signal that has the same

frequency as the internal oscillator, but is shifted by 180 degrees.

EP Exposed Pad Exposed metal pad on the underside of the package with a weak electrical connection to ground. It is

recommended to connect this pad to the PC board ground plane in order to improve heat dissipation.

www.national.com 2

LM20154

Page 3

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Voltages from the indicated pins to GND

AVIN, PVIN, EN, PGOOD, SS/

TRK, COMP, FB, SYNCOUT

-0.3V to +6V

Storage Temperature -65°C to 150°C

Junction Temperature 150°C

Power Dissipation (Note 2) 2.6W

Lead Temperature (Soldering,

10 sec)

260°C

Minimum ESD Rating (Note 3) ±2kV

Operating Ratings

PVIN, AVIN to GND 2.95V to 5.5V

Junction Temperature −40°C to + 125°C

Electrical Characteristics Unless otherwise stated, the following conditions apply: AVIN = PVIN = VIN = 5V.

Limits in standard type are for TJ = 25°C only, limits in bold face type apply over the junction temperature (TJ) range of -40°C to

+125°C. Minimum and Maximum limits are guaranteed through test, design, or statistical correlation. Typical values represent the

most likely parametric norm at TJ = 25°C, and are provided for reference purposes only.

Symbol Parameter Conditions Min Typ Max Unit

V

FB

Feedback pin voltage VIN = 2.95V to 5.5V 0.788 0.8 0.812 V

ΔV

OUT

/ΔI

OUT

Load Regulation I

OUT

= 100 mA to 4A 0.08 %/A

I

CL

Switch Current Limit Threshold VIN = 3.3V 5.4 6.0 6.6 A

R

DS_ON

High-Side Switch On Resistance ISW = 3.5A 36 55

mΩ

R

DS_ON

Low-Side Switch On Resistance ISW = 3.5A 32 52

mΩ

I

Q

Operating Quiescent Current Non-switching, VFB = V

COMP

3.5 6 mA

I

SD

Shutdown Quiescent current VEN = 0V 90 180 µA

V

UVLO

VIN Under Voltage Lockout Rising V

IN

2.45 2.7 2.95 V

V

UVLO_HYS

VIN Under Voltage Lockout Hysteresis Falling V

IN

45 100 mV

V

VCC

VCC Voltage I

VCC

= 0 µA 2.45 2.7 2.95 V

I

SS

Soft-Start Pin Source Current V

SS/TRK

= 0V 2 4.5 7 µA

V

TRACK

SS/TRK Accuracy, VSS - V

FB

V

SS/TRK

= 0.4V -10 3 15 mV

Oscillator

F

OSC

Oscillator Frequency 850 1000 1150 kHz

T

OFF_TIME

Minimum Off Time 85 ns

T

ON_TIME

Minimum On Time 100 ns

T

CL_BLANK

Current Sense Blanking Time After Rising V

SW

80 ns

F

SYNCOUT

SYNCOUT Frequency 850 1000 1150 kHz

P

SYNCOUT

SYNCOUT Phase Shift Relative to High-Side Turn-On 180

°

I

OLSYNC

SYNCOUT Low Sink Current V

SYNCOUT

= 0.8V 1.3 1.8 2.4 mA

I

OHSYNC

SYNCOUT High Leakage Current V

SYNCOUT

= 5V 10 150 nA

Error Amplifier and Modulator

I

FB

Feedback pin bias current VFB = 0.8V 1 100 nA

I

COMP_SRC

COMP Output Source Current VFB = V

COMP

= 0.6V 80 100 µA

I

COMP_SNK

COMP Output Sink Current VFB = 1.0V, V

COMP

= 0.6V 80 100 µA

g

m

Error Amplifier Transconductance I

COMP

= ± 50 µA 450 510 600 µmho

A

VOL

Error Amplifier Voltage Gain 2000 V/V

Power Good

V

OVP

Over Voltage Protection Rising Threshold With respect to V

FB

105 108 111 %

V

OVP_HYS

Over Voltage Protection Hysteresis 2 3 %

V

PGTH

PGOOD Rising Threshold With respect to V

FB

92 94 96 %

V

PGHYS

PGOOD Falling Hysteresis 2 3 %

T

PGOOD

PGOOD deglitch time 16 µs

I

OL

PGOOD Low Sink Current V

PGOOD

= 0.4V 0.6 1 mA

I

OH

PGOOD High Leakage Current V

PGOOD

= 5V 5 100 nA

Enable

3 www.national.com

LM20154

Page 4

Symbol Parameter Conditions Min Typ Max Unit

V

IH_EN

EN Pin Turn on Threshold VEN Rising 1.08 1.18 1.28 V

V

EN_HYS

EN Pin Hysteresis 66 mV

Thermal Shutdown

T

SD

Thermal Shutdown 160 °C

T

SD_HYS

Thermal Shutdown Hysteresis 10 °C

Thermal Resistance

θ

JA

Junction to Ambient 38 °C/W

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

intended to be functional, but do not guarantee specific performance limits. For guaranteed specifications and test conditions, see the Electrical Characteristics.

Note 2: The maximum allowable power dissipation is a function of the maximum junction temperature, T

J_MAX

, the junctions-to-ambient thermal resistance, θJA,

and the ambient temperature, TA. The maximum allowable power dissipation at any ambient temperature is calculated using: P

D_MAX

= (T

J_MAX

– TA)/θJA. The

maximum power dissipations of 2.6W is determined using TA = 25°C, θJA = 38°C/W, and T

J_MAX

= 125°C.

Note 3: The human body model is a 100 pF capacitor discharged through a 1.5 kΩ resistor to each pin.

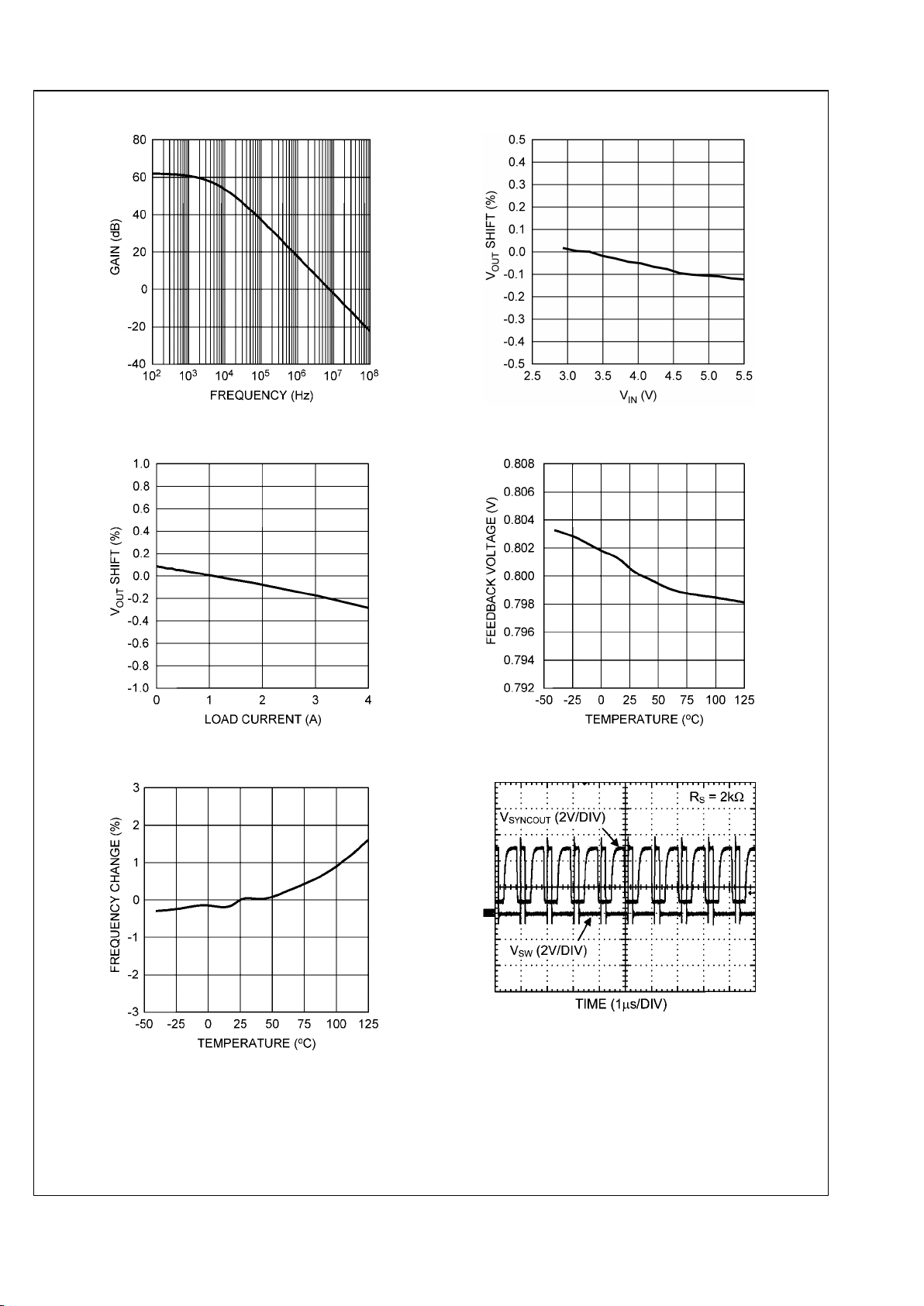

Typical Performance Characteristics Unless otherwise specified: C

IN

= C

OUT

= 100 µF, L = 1.0 µH

(Coilcraft MSS1038), VIN = 5V, V

OUT

= 1.2V, R

LOAD

= 1.2Ω, TA = 25°C for efficiency curves, loop gain plots and waveforms, and

TJ = 25°C for all others.

Efficiency vs. Load Current (VIN = 5V)

30030831

Efficiency vs. Load Current (VIN = 3.3V)

30030830

High-Side FET Resistance vs. Temperature

30030852

Low-Side FET Resistance vs. Temperature

30030853

www.national.com 4

LM20154

Page 5

Error Amplifier Gain vs. Frequency

30030836

Line Regulation

30030837

Load Regulation

30030838

Feedback Pin Voltage vs. Temperature

30030851

Switching Frequency vs. Temperature

30030839

Synchronization Output

30030861

5 www.national.com

LM20154

Page 6

Quiescent Current vs. VIN (Not Switching)

30030840

Shutdown Current vs. Temperature

30030841

Enable Threshold vs. Temperature

30030828

UVLO Threshold vs. Temperature

30030845

Peak Current Limit vs. Temperature

30030842

Peak Current Limit vs. V

OUT

30030854

www.national.com 6

LM20154

Page 7

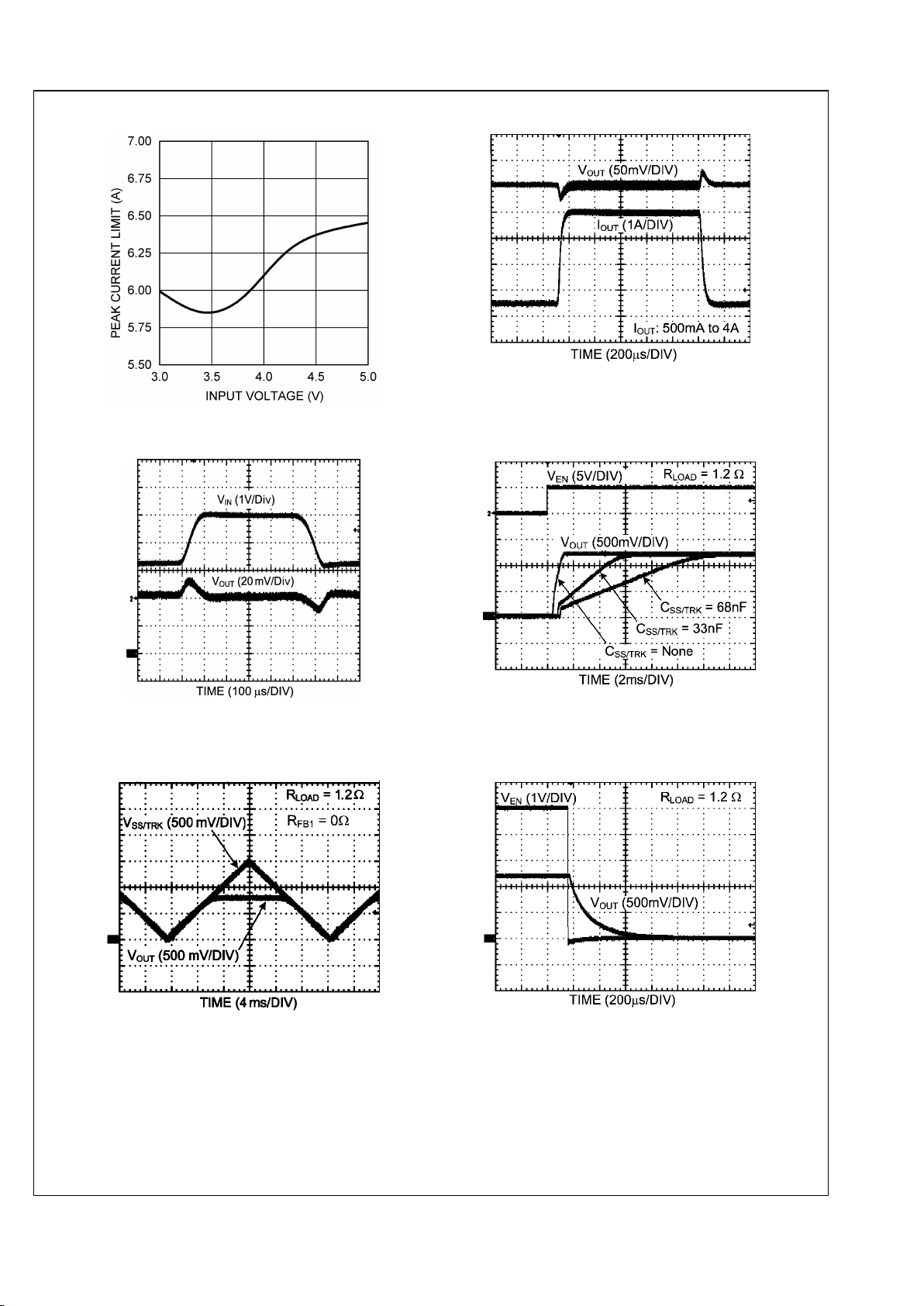

Peak Current Limit vs. V

IN

30030855

Load Transient Response

30030834

Line Transient Response

30030843

Start-Up (Soft-Start)

30030844

Start-Up (Tracking)

30030833

Power Down

30030832

7 www.national.com

LM20154

Page 8

Short Circuit Input Current vs. V

IN

30030856

P

GOOD

vs. I

PGOOD

30030827

www.national.com 8

LM20154

Page 9

Block Diagram

30030803

9 www.national.com

LM20154

Page 10

Operation Description

GENERAL

The LM20154 switching regulator features all of the functions

necessary to implement an efficient low voltage buck regulator using a minimum number of external components. This

easy to use regulator features two integrated switches and is

capable of supplying up to 4A of continuous output current.

The regulator utilizes peak current mode control with nonlinear slope compensation to optimize stability and transient

response over the entire output voltage range. Peak current

mode control also provides inherent line feed-forward, cycleby-cycle current limiting and easy loop compensation. The

fixed 1 MHz operating frequency minimizes the inductor size

while still achieving efficiencies up to 96%. The precision internal voltage reference allows the output to be set as low as

0.8V. Fault protection features include: current limiting, thermal shutdown, over voltage protection, and shutdown capability. The device is available in the eTSSOP-16 package

featuring an exposed pad to aid thermal dissipation. The

LM20154 can be used in numerous applications to efficiently

step-down from a 5V or 3.3V bus. The typical application circuit for the LM20154 is shown in Figure 2 in the design guide.

PRECISION ENABLE

The enable (EN) pin allows the output of the device to be enabled or disabled with an external control signal. This pin is a

precision analog input that enables the device when the voltage exceeds 1.18V (typical). The EN pin has 66 mV of hysteresis and will disable the output when the enable voltage

falls below 1.11V (typical). If the EN pin is not used, it should

be connected to VIN. Since the enable pin has a precise turn

on threshold it can be used along with an external resistor

divider network from VIN to configure the device to turn on at

a precise input voltage. The precision enable circuitry will remain active even when the device is disabled.

CLOCK SYNCHRONIZATION OUTPUT

The SYNCOUT pin is an open drain output that provides a

signal that is the same frequency as the internal oscillator but

is 180 degrees out of phase with the switch voltage. The

SYNCOUT pin requires an external pull-up resistor to set the

high level. For most applications a 2.94 kΩ pull-up connected

to the input voltage should be sufficient. Since the SYNCOUT

is out of phase with the switch voltage it can be used with other

devices with a synchronization input such as the LM20134 to

run multiple convertors out of phase. Running multiple converters out of phase reduces the RMS current requirements

for the input capacitor, value of the input capacitor, and conducted EMI back through the input bus.

PEAK CURRENT MODE CONTROL

In most cases, the peak current mode control architecture

used in the LM20154 only requires two external components

to achieve a stable design. The compensation can be selected to accommodate any capacitor type or value. The external

compensation also allows the user to set the crossover frequency and optimize the transient performance of the device.

For duty cycles above 50% all current mode control buck

converters require the addition of an artificial ramp to avoid

sub-harmonic oscillation. This artificial linear ramp is commonly referred to as slope compensation. What makes the

LM20154 unique is the amount of slope compensation will

change depending on the output voltage. When operating at

high output voltages the device will have more slope compensation than when operating at lower output voltages. This

is accomplished in the LM20154 by using a non-linear

parabolic ramp for the slope compensation. The parabolic

slope compensation of the LM20154 is much better than the

traditional linear slope compensation because it optimizes the

stability of the device over the entire output voltage range.

CURRENT LIMIT

The precise current limit of the LM20154 is set at the factory

to be within 10% over the entire operating temperature range.

This enables the device to operate with smaller inductors that

have lower saturation currents. When the peak inductor current reaches the current limit threshold, an over current event

is triggered and the internal high-side FET turns off and the

low-side FET turns on allowing the inductor current to ramp

down until the next switching cycle. For each sequential overcurrent event, the reference voltage is decremented and

PWM pulses are skipped resulting in a current limit that does

not aggressively fold back for brief over-current events, while

at the same time providing frequency and voltage foldback

protection during hard short circuit conditions.

SOFT-START AND VOLTAGE TRACKING

The SS/TRK pin is a dual function pin that can be used to set

the start up time or track an external voltage source. The start

up or Soft-Start time can be adjusted by connecting a capacitor from the SS/TRK pin to ground. The Soft-Start feature

allows the regulator output to gradually reach the steady state

operating point, thus reducing stresses on the input supply

and controlling start up current. If no Soft-Start capacitor is

used the device defaults to the internal Soft-Start circuitry resulting in a start up time of approximately 1 ms. For applications that require a monotonic start up or utilize the PGOOD

pin, an external Soft-Start capacitor is recommended. The

SS/TRK pin can also be set to track an external voltage

source. The tracking behavior can be adjusted by two external

resistors connected to the SS/TRK pin as shown in Figure 7

in the design guide.

PRE-BIAS START UP CAPABILITY

The LM20154 is in a pre-biased state when the device starts

up with an output voltage greater than zero. This often occurs

in many multi-rail applications such as when powering an FPGA, ASIC, or DSP. In these applications the output can be

pre-biased through parasitic conduction paths from one supply rail to another. Even though the LM20154 is a synchronous converter it will not pull the output low when a

prebias condition exists. During start up the LM20154 will not

sink current until the Soft-Start voltage exceeds the voltage

on the FB pin. Since the device can not sink current it protects

the load from damage that might otherwise occur if current is

conducted through the parasitic paths of the load.

POWER GOOD AND OVER VOLTAGE FAULT HANDLING

The LM20154 has built in under and over voltage comparators that control the power switches. Whenever there is an

excursion in output voltage above the set OVP threshold, the

part will terminate the present on-pulse, turn on the low-side

FET, and pull the PGOOD pin low. The low-side FET will remain on until either the FB voltage falls back into regulation

or the zero cross detection is triggered which in turn tri-states

the FETs. If the output reaches the UVP threshold the part will

continue switching and the PGOOD pin will be asserted and

go low. Typical values for the PGOOD resistor are on the order of 100 kΩ or less. To avoid false tripping during transient

glitches the PGOOD pin has 16 µs of built in deglitch time to

both rising and falling edges.

www.national.com 10

LM20154

Page 11

UVLO

The LM20154 has a built-in under-voltage lockout protection

circuit that keeps the device from switching until the input

voltage reaches 2.7V (typical). The UVLO threshold has 45

mV of hysteresis that keeps the device from responding to

power-on glitches during start up. If desired the turn on point

of the supply can be changed by using the precision enable

pin and a resistor divider network connected to VIN as shown

in Figure 6 in the design guide.

THERMAL PROTECTION

Internal thermal shutdown circuitry is provided to protect the

integrated circuit in the event that the maximum junction temperature is exceeded. When activated, typically at 160°C, the

LM20154 tri-states the power FETs and resets soft start. After

the junction cools to approximately 150°C, the part starts up

using the normal start up routine. This feature is provided to

prevent catastrophic failures from accidental device overheating.

LIGHT LOAD OPERATION

The LM20154 offers increased efficiency when operating at

light loads. Whenever the load current is reduced to a point

where the peak to peak inductor ripple current is greater than

two times the load current, the part will enter the diode emulation mode preventing significant negative inductor current.

The point at which this occurs is the critical conduction boundary and can be calculated by the following equation:

Several diagrams are shown in Figure 1 illustrating continuous conduction mode (CCM), discontinuous conduction

mode, and the boundary condition.

It can be seen that in diode emulation mode, whenever the

inductor current reaches zero the SW node will become high

impedance. Ringing will occur on this pin as a result of the LC

tank circuit formed by the inductor and the parasitic capacitance at the node. If this ringing is of concern an additional

RC snubber circuit can be added from the switch node to

ground.

At very light loads, usually below 100 mA, several pulses may

be skipped in between switching cycles, effectively reducing

the switching frequency and further improving light-load efficiency.

11 www.national.com

LM20154

Page 12

30030805

FIGURE 1. Modes of Operation for LM20154

www.national.com 12

LM20154

Page 13

Design Guide

This section walks the designer through the steps necessary

to select the external components to build a fully functional

power supply. As with any DC-DC converter numerous tradeoffs are possible to optimize the design for efficiency, size, or

performance. These will be taken into account and highlighted throughout this discussion. To facilitate component selection discussions the circuit shown in Figure 2 below may be

used as a reference. Unless otherwise indicated all formulas

assume units of amps (A) for current, farads (F) for capacitance, henries (H) for inductance and volts (V) for voltages.

30030823

FIGURE 2. Typical Application Circuit

The first equation to calculate for any buck converter is dutycycle. Ignoring conduction losses associated with the FETs

and parasitic resistances it can be approximated by:

INDUCTOR SELECTION (L)

The inductor value is determined based on the operating frequency, load current, ripple current, and duty cycle.

The inductor selected should have a saturation current rating

greater than the peak current limit of the device. Keep in mind

the specified current limit does not account for delay of the

current limit comparator, therefore the current limit in the application may be higher than the specified value. To optimize

the performance and prevent the device from entering current

limit at maximum load, the inductance is typically selected

such that the ripple current, ΔiL, is less than 30% of the rated

output current. Figure 3, shown below illustrates the switch

and inductor ripple current waveforms. Once the input voltage, output voltage, operating frequency, and desired ripple

current are known, the minimum value for the inductor can be

calculated by the formula shown below:

30030809

FIGURE 3. Switch and Inductor Current Waveforms

If needed, slightly smaller value inductors can be used, however, the peak inductor current, I

OUT

+ ΔiL/2, should be kept

below the peak current limit of the device. In general, the inductor ripple current, ΔiL, should be greater than 10% of the

rated output current to provide adequate current sense information for the current mode control loop. If the ripple current

in the inductor is too low, the control loop will not have sufficient current sense information and can be prone to instability.

OUTPUT CAPACITOR SELECTION (C

OUT

)

The output capacitor, C

OUT

, filters the inductor ripple current

and provides a source of charge for transient load conditions.

A wide range of output capacitors may be used with the

LM20154 that provide excellent performance. The best performance is typically obtained using ceramic, SP, or OSCON

type chemistries. Typical trade-offs are that the ceramic capacitor provides extremely low ESR to reduce the output

ripple voltage and noise spikes, while the SP and OSCON

capacitors provide a large bulk capacitance in a small volume

for transient loading conditions.

When selecting the value for the output capacitor the two performance characteristics to consider are the output voltage

ripple and transient response. The output voltage ripple can

be approximated by using the formula shown below.

Where, ΔV

OUT

(V) is the amount of peak to peak voltage ripple

at the power supply output, R

ESR

(Ω) is the series resistance

of the output capacitor, fSW(Hz) is the switching frequency,

and C

OUT

(F) is the output capacitance used in the design.

The amount of output ripple that can be tolerated is application specific; however a general recommendation is to keep

the output ripple less than 1% of the rated output voltage.

Keep in mind ceramic capacitors are sometimes preferred

because they have very low ESR; however, depending on

package and voltage rating of the capacitor the value of the

capacitance can drop significantly with applied voltage. The

output capacitor selection will also affect the output voltage

droop during a load transient. The peak droop on the output

voltage during a load transient is dependent on many factors;

however, an approximation of the transient droop ignoring

loop bandwidth can be obtained using the following equation.

13 www.national.com

LM20154

Page 14

Where, C

OUT

(F) is the minimum required output capacitance,

L (H) is the value of the inductor, V

DROOP

(V) is the output

voltage drop ignoring loop bandwidth considerations, ΔI

OUT-

STEP

(A) is the load step change, R

ESR

(Ω) is the output

capacitor ESR, VIN (V) is the input voltage, and V

OUT

(V) is

the set regulator output voltage. Both the tolerance and voltage coefficient of the capacitor needs to be examined when

designing for a specific output ripple or transient drop target.

INPUT CAPACITOR SELECTION (CIN)

Good quality input capacitors are necessary to limit the ripple

voltage at the VIN pin while supplying most of the switch current during the on-time. In general it is recommended to use

a ceramic capacitor for the input as they provide both a low

impedance and small footprint. One important note is to use

a good dielectric for the ceramic capacitor such as X5R or

X7R. These provide better over temperature performance

and also minimize the DC voltage derating that occurs on Y5V

capacitors. For most applications, a 22 µF, X5R, 6.3V input

capacitor is sufficient; however, additional capacitance may

be required if the connection to the input supply is far from the

PVIN of the device. The input capacitor should be placed as

close as possible PVIN and PGND pins of the device.

Non-ceramic input capacitors should be selected for RMS

current rating and minimum ripple voltage. A good approximation for the required ripple current rating is given by the

relationship:

As indicated by the RMS ripple current equation, highest requirement for RMS current rating occurs at 50% duty cycle.

For this case, the RMS ripple current rating of the input capacitor should be greater than half the output current. For best

performance, low ESR ceramic capacitors should be placed

in parallel with higher capacitance capacitors to provide the

best input filtering for the device.

SETTING THE OUTPUT VOLTAGE (R

FB1

, R

FB2

)

The resistors R

FB1

and R

FB2

are selected to set the output

voltage for the device. Table 1, shown below, provides suggestions for R

FB1

and R

FB2

for common output voltages.

TABLE 1. Suggested Values for R

FB1

and R

FB2

R

FB1

(kΩ) R

FB2

(kΩ)

V

OUT

short open 0.8

4.99 10 1.2

8.87 10.2 1.5

12.7 10.2 1.8

21.5 10.2 2.5

31.6 10.2 3.3

If different output voltages are required, R

FB2

should be se-

lected to be between 4.99 kΩ to 49.9 kΩ and R

FB1

can be

calculated using the equation below.

LOOP COMPENSATION (RC1, CC1)

The purpose of loop compensation is to meet static and dynamic performance requirements while maintaining adequate

stability. Optimal loop compensation depends on the output

capacitor, inductor, load, and the device itself. Table 2 below

gives values for the compensation network that will result in

a stable system when using a 100 µF, 6.3V ceramic X5R output capacitor and 1 µH inductor.

TABLE 2. Recommended Compensation for

C

OUT

= 100 µF and L = 1 µH

V

IN

V

OUTCC1

(nF)

RC1 (kΩ)

5.00 3.30 3.3 14.3

5.00 2.50 3.3 11

5.00 1.80 3.3 7.32

5.00 1.50 3.3 6.34

5.00 1.20 3.3 4.42

5.00 0.80 4.7 1.21

3.30 2.50 3.3 12.7

3.30 1.80 3.3 8.87

3.30 1.50 3.3 5.76

3.30 1.20 3.3 3.16

3.30 0.80 4.7 1.62

If the desired solution differs from the table above the loop

transfer function should be analyzed to optimize the loop

compensation. The overall loop transfer function is the product of the power stage and the feedback network transfer

functions. For stability purposes, the objective is to have a

loop gain slope that is -20db/decade from a very low frequency to beyond the crossover frequency. Figure 4, shown below,

shows the transfer functions for power stage, feedback/compensation network, and the resulting closed loop system for

the LM20154.

30030813

FIGURE 4. LM20154 Loop Compensation

The power stage transfer function is dictated by the modulator, output LC filter, and load; while the feedback transfer

www.national.com 14

LM20154

Page 15

function is set by the feedback resistor ratio, error amp gain,

and external compensation network.

To achieve a -20dB/decade slope, the error amplifier zero,

located at f

Z(EA)

, should positioned to cancel the output filter

pole (f

P(FIL)

). An additional error amp pole, located at f

P2(EA)

,

can be added to cancel the output filter zero at f

Z(FIL)

. Cancellation of the output filter zero is recommended if larger

value, non-ceramic output capacitors are used.

Compensation of the LM20154 is achieved by adding an RC

network as shown in Figure 5 below.

30030814

FIGURE 5. Compensation Network for LM20154

A good starting value for CC1 for most applications is 4.7 nF.

Once the value of CC1 is chosen the value of RC should be

calculated using the equation below to cancel the output filter

pole (f

P(FIL)

) as shown in Figure 4.

A higher crossover frequency can be obtained, usually at the

expense of phase margin, by lowering the value of CC1 and

recalculating the value of RC1. Likewise, increasing CC1 and

recalculating RC1 will provide additional phase margin at a

lower crossover frequency. As with any attempt to compensate the LM20154 the stability of the system should be verified

for desired transient droop and settling time.

If the output filter zero, f

Z(FIL)

approaches the crossover frequency (FC), an additional capacitor (CC2) should be placed

at the COMP pin to ground. This capacitor adds a pole to

cancel the output filter zero assuring the crossover frequency

will occur before the double pole at fSW/2 degrades the phase

margin. The output filter zero is set by the output capacitor

value and ESR as shown in the equation below.

If needed, the value for CC2 should be calculated using the

equation shown below.

Where R

ESR

is the output capacitor series resistance and

RC1 is the calculated compensation resistance.

AVIN FILTERING COMPONENTS (CF and RF)

To prevent high frequency noise spikes from disturbing the

sensitive analog circuitry connected to the AVIN and AGND

pins, a high frequency RC filter is required between PVIN and

AVIN. These components are shown in Figure 2 as CF and

RF. The required value for RF is 1Ω. CF must be used. Recommended value of CF is 1.0 µF. The filter capacitor, C

F

should be placed as close to the IC as possible with a direct

connection from AVIN to AGND. A good quality X5R or X7R

ceramic capacitor should be used for CF.

SUB-REGULATOR BYPASS CAPACITOR (C

VCC

)

The capacitor at the VCC pin provides noise filtering and stability for the internal sub-regulator. The recommended value

of C

VCC

should be no smaller than 1 µF and no greater than

10 µF. The capacitor should be a good quality ceramic X5R

or X7R capacitor. In general, a 1 µF ceramic capacitor is recommended for most applications.

SETTING THE START UP TIME (CSS)

The addition of a capacitor connected from the SS pin to

ground sets the time at which the output voltage will reach the

final regulated value. Larger values for CSS will result in longer

start up times. Table 3, shown below provides a list of soft

start capacitors and the corresponding typical start up times.

TABLE 3. Start Up Times for Different Soft-Start

Capacitors

Start Up Time (ms) CSS (nF)

1 none

5 33

10 68

15 100

20 120

If different start up times are needed the equation shown below can be used to calculate the start up time.

As shown above, the start up time is influenced by the value

of the Soft-Start capacitor CSS(F) and the 5 µA Soft-Start pin

current ISS(A). that may be found in the electrical characteristics table.

While the Soft-Start capacitor can be sized to meet many start

up requirements, there are limitations to its size. The SoftStart time can never be faster than 1ms due to the internal

default 1 ms start up time. When the device is enabled there

is an approximate time interval of 50 µs when the Soft-Start

capacitor will be discharged just prior to the Soft-Start ramp.

If the enable pin is rapidly pulsed or the Soft-Start capacitor

is large there may not be enough time for CSS to completely

discharge resulting in start up times less than predicted. To

aid in discharging of Soft-Start capacitor during long disable

periods an external 1 MΩ resistor from SS/TRK to ground can

be used without greatly affecting the start-up time.

SYNCOUT PULL UP RESISTANCE (RS)

In applications where timing is critical, the value of RS should

be selected to be as small as possible to avoid timing delays

due to parasitic capacitive loading. In this case, the size of the

resistor should be selected based on the desired pull down

voltage and minimum rated pull down current. The SYNCOUT

pin is specified to pull down to 0.8V while sinking at least 1.3

mA of current, which equates to an on resistance of approxi-

15 www.national.com

LM20154

Page 16

mately 615Ω. To insure a specific logic low level is met the

pull-up resistor should be selected using the formula below.

Where, V

PULLUP

is the high pull up voltage for the resistor

RS and VOL is the logic low level needed on the SYNCOUT

pin. For most applications the SYNCOUT pin will be pulled up

to the input voltage.

USING PRECISION ENABLE AND POWER GOOD

The precision enable (EN) and power good (PGOOD) pins of

the LM20154 can be used to address many sequencing requirements. The turn-on of the LM20154 can be controlled

with the precision enable pin by using two external resistors

as shown in Figure 6

30030826

FIGURE 6. Sequencing LM20154 with Precision Enable

The value for resistor RB can be selected by the user to control

the current through the divider. Typically this resistor will be

selected to be between 10 kΩ and 1 MΩ. Once the value for

RB is chosen the resistor RA can be solved using the equation

below to set the desired turn on voltage.

When designing for a specific turn-on threshold (VTO) the tolerance on the input supply, enable threshold (V

IH_EN

), and

external resistors needs to be considered to insure proper

turn on of the device.

The LM20154 features an open drain power good (PGOOD)

pin to sequence external supplies or loads and to provide fault

detection. This pin requires an external resistor (RPG) to pull

PGOOD high while when the output is within the PGOOD tolerance window. Typical values for this resistor range from 10

kΩ to 100 kΩ.

TRACKING AN EXTERNAL SUPPLY

By using a properly chosen resistor divider network connected to the SS/TRK pin, as shown in Figure 7, the output of the

LM20154 can be configured to track an external voltage

source to obtain a simultaneous or ratiometric start up.

30030820

FIGURE 7. Tracking an External Supply

Since the Soft-Start charging current ISS is always present on

the SS/TRK pin, the size of R2 should be less than 10 kΩ to

minimize the errors in the tracking output. Once a value for

R2 is selected the value for R1 can be calculated using appropriate equation in Figure 8, to give the desired start up.

Figure 8 shows two common start up sequences; the top

waveform shows a simultaneous start up while the waveform

at the bottom illustrates a ratiometric start up.

30030821

FIGURE 8. Common Start Up Sequences

A simultaneous start up is preferred when powering most FPGAs, DSPs, or other microprocessors. In these systems the

higher voltage, V

OUT1

, usually powers the I/O, and the lower

voltage, V

OUT2

, powers the core. A simultaneous start up provides a more robust power up for these applications since it

avoids turning on any parasitic conduction paths that may exist between the core and the I/O pins of the processor.

The second most common power on behavior is known as a

ratiometric start up. This start up is preferred in applications

where both supplies need to be at the final value at the same

time.

Similar to the Soft-Start function, the fastest start up possible

is 1 ms regardless of the rise time of the tracking voltage.

When using the track feature the final voltage seen by the SS/

www.national.com 16

LM20154

Page 17

TRACK pin should exceed 1V to provide sufficient overdrive

and transient immunity.

THERMAL CONSIDERATIONS

The thermal characteristics of the LM20154 are specified using the parameter θJA, which relates the junction temperature

to the ambient temperature. Although the value of θJA is dependant on many variables, it still can be used to approximate

the operating junction temperature of the device.

To obtain an estimate of the device junction temperature, one

may use the following relationship:

TJ = PDθJA + T

A

and

PD = PIN x (1 - Efficiency) - 1.1 x I

OUT

2 x DCR

Where:

TJ is the junction temperature in °C.

PIN is the input power in Watts (PIN = VIN x IIN).

θJA is the junction to ambient thermal resistance for the

LM20154.

TA is the ambient temperature in °C.

I

OUT

is the output load current.

DCR is the inductor series resistance.

It is important to always keep the operating junction temper-

ature (TJ) below 125°C for reliable operation. If the junction

temperature exceeds 160°C the device will cycle in and out

of thermal shutdown. If thermal shutdown occurs it is a sign

of inadequate heatsinking or excessive power dissipation in

the device.

Figure 9, shown below, provides a better approximation of the

θJA for a given PCB copper area. The PCB heatsink area

consists of 2oz. copper located on the bottom layer of the PCB

directly under the eTSSOP exposed pad. The bottom copper

area is connected to the eTSSOP exposed pad by means of

a 4 x 4 array of 12 mil thermal vias.

30030835

FIGURE 9. Thermal Resistance vs PCB Area

PCB LAYOUT CONSIDERATIONS

PC board layout is an important part of DC-DC converter design. Poor board layout can disrupt the performance of a DC-

DC converter and surrounding circuitry by contributing to EMI,

ground bounce, and resistive voltage loss in the traces. These

can send erroneous signals to the DC-DC converter resulting

in poor regulation or instability.

Good layout can be implemented by following a few simple

design rules.

1. Minimize area of switched current loops. In a buck regulator

there are two loops where currents are switched very fast. The

first loop starts from the input capacitor, to the regulator VIN

pin, to the regulator SW pin, to the inductor then out to the

output capacitor and load. The second loop starts from the

output capacitor ground, to the regulator PGND pins, to the

inductor and then out to the load (see Figure 10). To minimize

both loop areas the input capacitor should be placed as close

as possible to the PVIN pin. Grounding for both the input and

output capacitor should consist of a small localized top side

plane that connects to PGND and the die attach pad (DAP).

The inductor should be placed as close as possible to the SW

pin and output capacitor.

2. Minimize the copper area of the switch node. Since the

LM20154 has the SW pins on opposite sides of the package

it is recommended to via these pins down to the bottom or

internal layer with 2 to 4 vias on each SW pin. The SW pins

should be directly connected with a trace that runs across the

bottom of the package. To minimize IR losses this trace

should be no smaller that 50 mils wide, but no larger than 100

mils wide to keep the copper area to a minimum. In general

the SW pins should not be connected on the top layer since

it could block the ground return path for the power ground.

The inductor should be placed as close as possible to one of

the SW pins to further minimize the copper area of the switch

node.

3. Have a single point ground for all device analog grounds

located under the DAP. The ground connections for the compensation, feedback, and Soft-Start components should be

connected together then routed to the AGND pin of the device. The AGND pin should connect to PGND under the DAP.

This prevents any switched or load currents from flowing in

the analog ground plane. If not properly handled poor grounding can result in degraded load regulation or erratic switching

behavior.

4. Minimize trace length to the FB pin. Since the feedback

node can be high impedance the trace from the output resistor

divider to FB pin should be as short as possible. This is most

important when high value resistors are used to set the output

voltage. The feedback trace should be routed away from the

SW pin and inductor to avoid contaminating the feedback signal with switch noise.

5. Make input and output bus connections as wide as possible. This reduces any voltage drops on the input or output of

the converter and can improve efficiency. If voltage accuracy

at the load is important make sure feedback voltage sense is

made at the load. Doing so will correct for voltage drops at the

load and provide the best output accuracy.

6. Provide adequate device heatsinking. Use as many vias as

is possible to connect the DAP to the power plane heatsink.

For best results use a 4x4 via array with a minimum via diameter of 12 mils. See the Thermal Considerations section to

insure enough copper heatsinking area is used to keep the

junction temperature below 125°C.

17 www.national.com

LM20154

Page 18

30030822

FIGURE 10. Schematic of LM20154 Highlighting Layout Sensitive Nodes

www.national.com 18

LM20154

Page 19

Typical Application Circuits

This section provides several application solutions with a bill

of materials. All bill of materials reference the below figure.

The compensation for these solutions were optimized to work

over a wide range of input and output voltages; if a faster

transient response is needed reduce the value of CC1 and

calculate the new value for RC1 as outline in the design guide.

30030801

FIGURE 11.

Bill of Materials (VIN = 5V, V

OUT

= 3.3V, I

OUTMAX

= 4A)

Designator Description Part Number Manufacturer Qty

U1 Synchronous Buck Regulator LM20154 National Semiconductor 1

C

IN

100 µF, 1210, X5R, 6.3V GRM32ER60J107ME20 Murata 1

C

OUT

100 µF, 1210, X5R, 6.3V GRM32ER60J107ME20 Murata 1

L

1 µH, 6 mΩ

MSS1038-102NL Coilcraft 1

R

F

1Ω, 0603

CRCW06031R0J-e3 Vishay-Dale 1

C

F

100 nF, 0603, X7R, 16V GRM188R71C104KA01 Murata 1

C

VCC

1 µF, 0603, X5R, 6.3V GRM188R60J105KA01 Murata 1

R

C1

7.87 kΩ, 0603

CRCW06037871F-e3 Vishay-Dale 1

C

C1

2.2 nF, 0603, X7R, 25V VJ0603Y242KXXA Vishay-Vitramon 1

C

SS

33 nF, 0603, X7R, 25V VJ0603Y333KXXA Vishay-Vitramon 1

R

FB1

31.6 kΩ, 0603

CRCW06033162F-e3 Vishay-Dale 1

R

FB2

10.2 kΩ, 0603

CRCW06031022F-e3 Vishay-Dale 1

R

S

3.24 kΩ, 0603

CRCW06033241F-e3 Vishay-Dale 1

Bill of Materials (VIN = 3.3V to 5V, V

OUT

= 1.2V, I

OUTMAX

= 4A)

Designator Description Part Number Manufacturer Qty

U1 Synchronous Buck Regulator LM20154 National Semiconductor 1

C

IN

100 µF, 1210, X5R, 6.3V GRM32ER60J107ME20 Murata 1

C

OUT

100 µF, 1210, X5R, 6.3V GRM32ER60J107ME20 Murata 1

L

1 µH, 6 mΩ

MSS1038-102NL Coilcraft 1

R

F

1Ω, 0603

CRCW06031R0J-e3 Vishay-Dale 1

C

F

100 nF, 0603, X7R, 16V GRM188R71C104KA01 Murata 1

C

VCC

1 µF, 0603, X5R, 6.3V GRM188R60J105KA01 Murata 1

R

C1

3.57 kΩ, 0603

CRCW06033571F-e3 Vishay-Dale 1

C

C1

3.3 nF, 0603, X7R, 25V VJ0603Y332KXXA Vishay-Vitramon 1

C

SS

33 nF, 0603, X7R, 25V VJ0603Y333KXXA Vishay-Vitramon 1

R

FB1

4.99 kΩ, 0603

CRCW06034991F-e3 Vishay-Dale 1

R

FB2

10 kΩ, 0603

CRCW06031002F-e3 Vishay-Dale 1

R

S

3.24 kΩ, 0603

CRCW06033241F-e3 Vishay-Dale 1

19 www.national.com

LM20154

Page 20

Physical Dimensions inches (millimeters) unless otherwise noted

16-Lead eTSSOP Package

NS Package Number MXA16A

www.national.com 20

LM20154

Page 21

Notes

21 www.national.com

LM20154

Page 22

Notes

LM20154 4A, 1MHz PowerWise

®

Synchronous Buck Regulator with SYNCOUT

For more National Semiconductor product information and proven design tools, visit the following Web sites at:

Products Design Support

Amplifiers www.national.com/amplifiers WEBENCH www.national.com/webench

Audio www.national.com/audio Analog University www.national.com/AU

Clock Conditioners www.national.com/timing App Notes www.national.com/appnotes

Data Converters www.national.com/adc Distributors www.national.com/contacts

Displays www.national.com/displays Green Compliance www.national.com/quality/green

Ethernet www.national.com/ethernet Packaging www.national.com/packaging

Interface www.national.com/interface Quality and Reliability www.national.com/quality

LVDS www.national.com/lvds Reference Designs www.national.com/refdesigns

Power Management www.national.com/power Feedback www.national.com/feedback

Switching Regulators www.national.com/switchers

LDOs www.national.com/ldo

LED Lighting www.national.com/led

PowerWise www.national.com/powerwise

Serial Digital Interface (SDI) www.national.com/sdi

Temperature Sensors www.national.com/tempsensors

Wireless (PLL/VCO) www.national.com/wireless

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2007 National Semiconductor Corporation

For the most current product information visit us at www.national.com

National Semiconductor

Americas Customer

Support Center

Email:

new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Customer Support Center

Fax: +49 (0) 180-530-85-86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +49 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor Asia

Pacific Customer Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

www.national.com

Loading...

Loading...