Page 1

LM1949 Injector Drive Controller

LM1949 Injector Drive Controller

February 1995

General Description

The LM1949 linear integrated circuit serves as an excellent

control of fuel injector drive circuitry in modern automotive

systems. The IC is designed to control an external power

NPN Darlington transistor that drives the high current injector solenoid. The current required to open a solenoid is several times greater than the current necessary to merely hold

it open; therefore, the LM1949, by directly sensing the actual solenoid current, initially saturates the driver until the

‘‘peak’’ injector current is four times that of the idle or ‘‘holding’’ current

(Figure 3 –Figure 7).

This guarantees opening

of the injector. The current is then automatically reduced to

the sufficient holding level for the duration of the input

pulse. In this way, the total power consumed by the system

is dramatically reduced. Also, a higher degree of correlation

of fuel to the input voltage pulse (or duty cycle) is achieved,

since opening and closing delays of the solenoid will be

reduced.

Normally powered from a 5V

cally operable over the entire temperature range (

a

125§C ambient) with supplies as low as 3 volts. This is

g

10% supply, the IC is typi-

b

55§Cto

particularly useful under ‘‘cold crank’’ conditions when the

battery voltage may drop low enough to deregulate the

5-volt power supply.

The LM1949 is available in the plastic miniDIP, (contact factory for other package options).

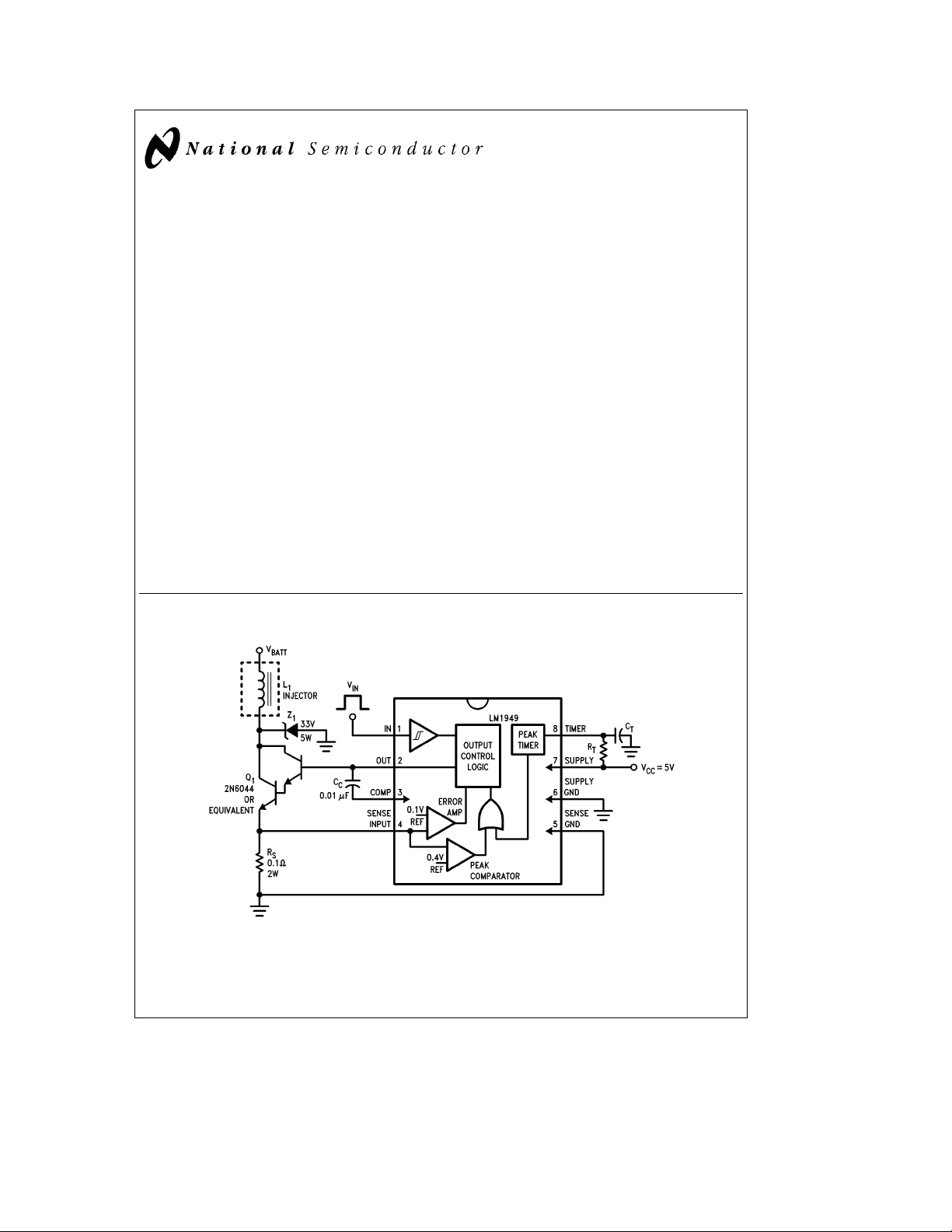

Typical Application Circuit

Features

Y

Low voltage supply (3V– 5.5V)

Y

22 mA output drive current

Y

No RFI radiation

Y

Adaptable to all injector current levels

Y

Highly accurate operation

Y

TTL/CMOS compatible input logic levels

Y

Short circuit protection

Y

High impedance input

Y

Externally set holding current, I

Y

Internally set peak current (4cIH)

Y

Externally set time-out

Y

Can be modified for full switching operation

Y

Available in plastic 8-pin miniDIP

H

Applications

Y

Fuel injection

Y

Throttle body injection

Y

Solenoid controls

Y

Air and fluid valves

Y

DC motor drives

FIGURE 1. Typical Application and Test Circuit

TL/H/5062– 1

Order Number LM1949M or LM1949N

See NS Package Number M08A or N08E

COPSTMis a trademark of National Semiconductor Corporation.

C

1995 National Semiconductor Corporation RRD-B30M115/Printed in U. S. A.

TL/H/5062

Page 2

Absolute Maximum Ratings

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales

Office/Distributors for availability and specifications.

Supply Voltage 8V

Power Dissipation (Note 1) 1235 mW

Input Voltage Range

Operating Temperature Range

Storage Temperature Range

b

0.3V to V

b

40§Ctoa125§C

b

65§Ctoa150§C

CC

Junction Temperature 150§C

Lead Temp. (Soldering 10 sec.) 260§C

Electrical Characteristics (V

CC

e

5.5V, V

IN

e

2.4V, T

j

e

25§C,

Figure 1

, unless otherwise specified.)

Symbol Parameter Conditions Min Typ Max Units

I

CC

Supply Current

Off V

Peak Pin 8

e

0V 11 23 mA

IN

e

0V 28 54 mA

Hold Pin 8 Open 16 26 mA

V

OH

V

OL

I

B

I

OP

V

S

Input On Level V

Input Off Level V

Input Current

Output Current

Output Saturation Voltage 10 mA, V

Peak Pin 8

Hold Pin 8 Open

e

5.5V 1.4 2.4 V

CC

e

V

3.0V 1.2 1.6 V

CC

e

5.5V 1.0 1.35 V

CC

e

V

3.0V 0.7 1.15 V

CC

b

25 3

e

0V

e

0V 0.2 0.4 V

IN

b

10

b

1.5

b

22 mA

b

5mA

a

25 mA

Sense Input

V

p

V

H

Peak Threshold V

Hold Reference 88 94 102 mV

t Time-out, t tdRTC

NOTE 1: For operation in ambient temperatures above 25§C, the device must be derated based on a 150§C maximum junction temperature and a thermal

resistance of 100

C/W junction to ambient.

§

e

4.75V 350 386 415 mV

CC

T

90 100 110 %

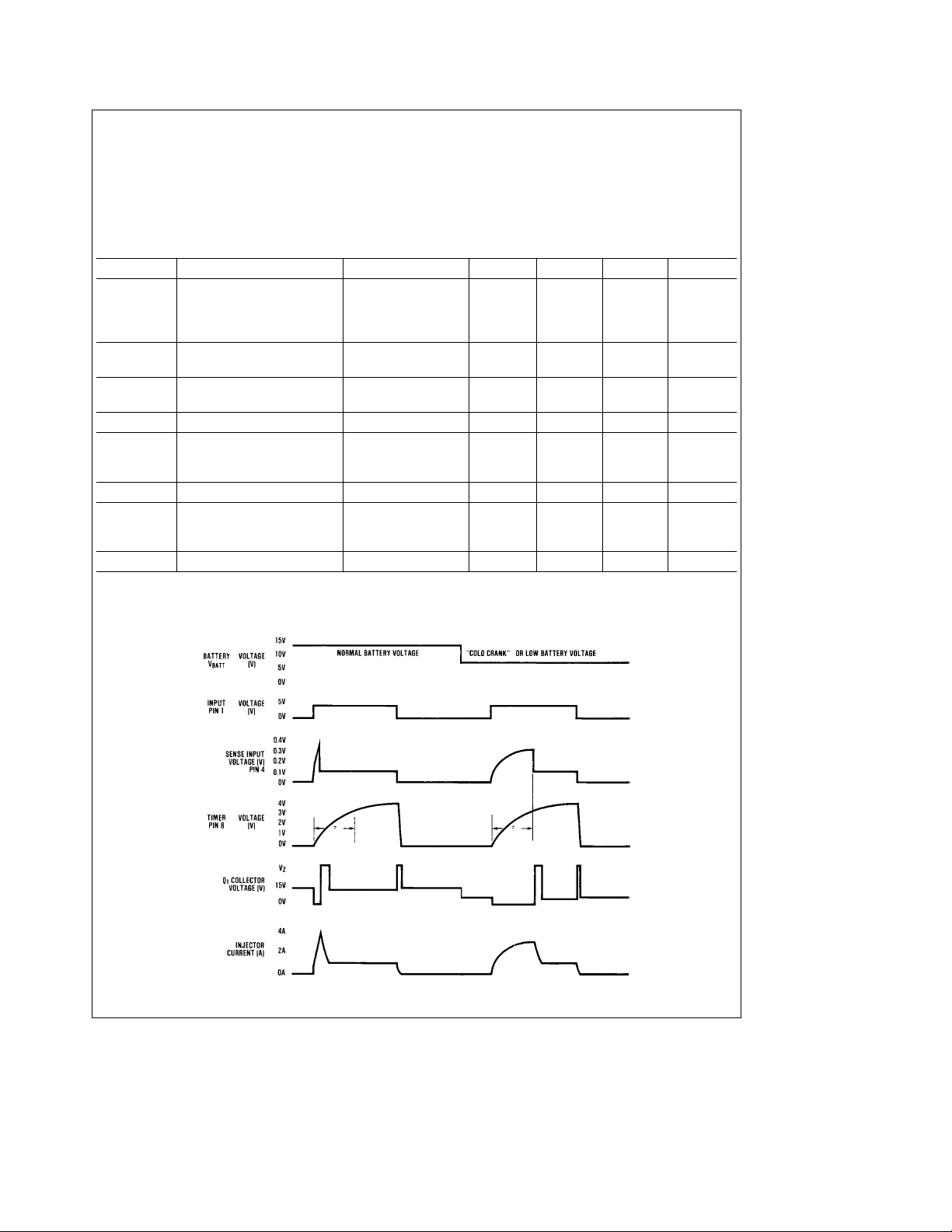

Typical Circuit Waveforms

TL/H/5062– 2

2

Page 3

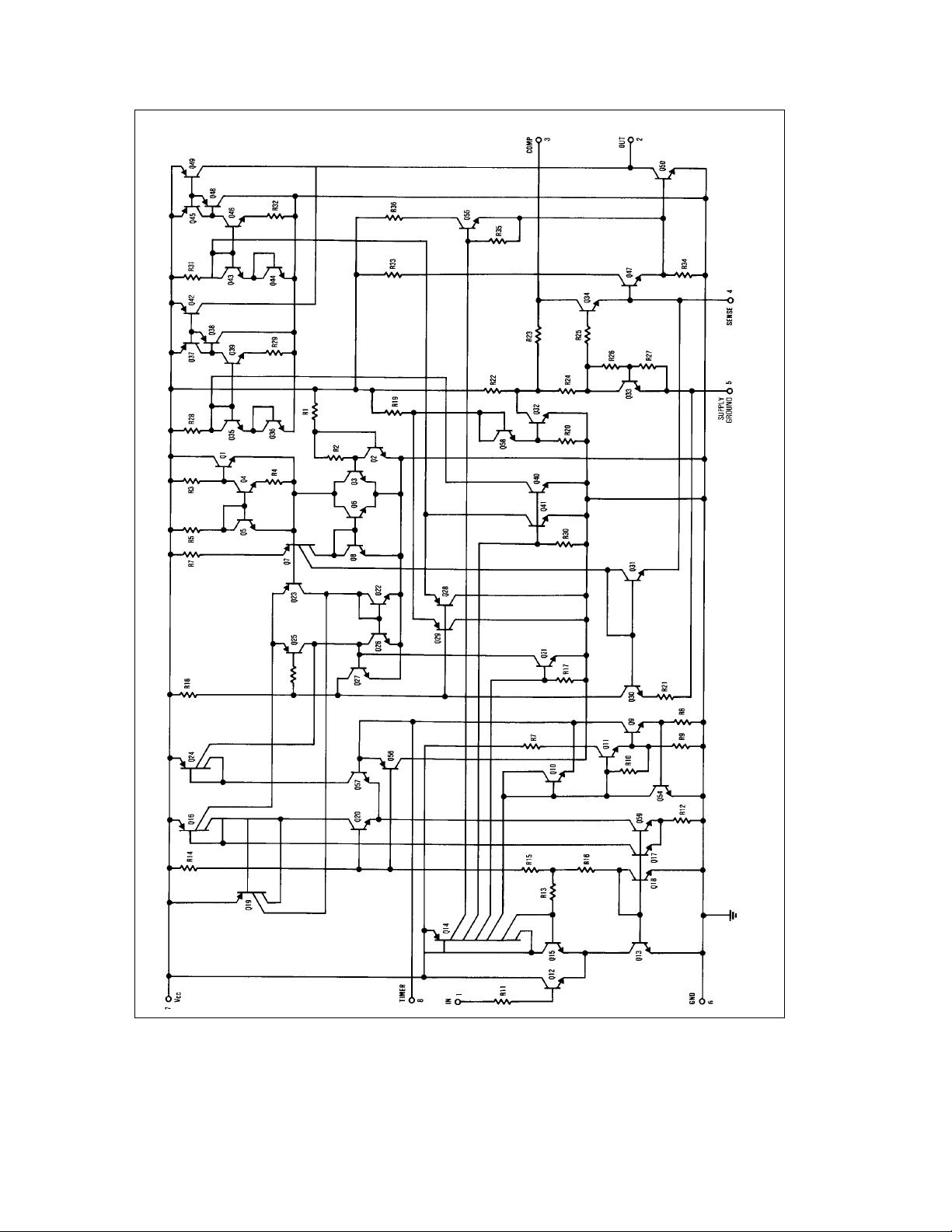

Schematic Diagram

TL/H/5062– 3

FIGURE 2. LM1949 Circuit

3

Page 4

Typical Performance Characteristics

Quiescent Current vs

Supply Voltage

Supply Current vs

Supply Voltage

Output Current vs

Supply Voltage

Input Voltage Thresholds

vs Supply Voltage

Normalized Timer Function

vs Supply Voltage

Output Current vs

Junction Temperature

Sense Input Peak Voltage

vs Supply Voltage

Quiescent Supply Current

vs Junction Temperature

Input Voltage Thresholds

vs Junction Temperature

Sense Input Hold Voltage

vs Supply Voltage

Quiescent Supply Current

vs Junction Temperature

Sense Input Peak Voltage

vs Junction Temperature

TL/H/5062– 4

4

Page 5

Typical Performance Characteristics (Continued)

Sense Input Hold Voltage

vs Junction Temperature

Normalized Timer Function

vs Junction Temperature

Application Hints

The injector driver integrated circuits were designed to be

used in conjunction with an external controller. The LM1949

derives its input signal from either a control oriented processor (COPS

TM

), microprocessor, or some other system. This

input signal, in the form of a square wave with a variable

duty cycle and/or variable frequency, is applied to Pin 1. In

a typical system, input frequency is proportional to engine

RPM. Duty cycle is proportional to the engine load. The circuits discussed are suitable for use in either open or closed

loop systems. In closed loop systems, the engine exhaust is

monitored and the air-to-fuel mixture is varied (via the duty

cycle) to maintain a perfect, or stochiometric, ratio.

INJECTORS

Injectors and solenoids are available in a vast array of sizes

and characteristics. Therefore, it is necessary to be able to

design a drive system to suit each type of solenoid. The

purpose of this section is to enable any system designer to

use and modify the LM1949 and associated circuitry to

meet the system specifications.

Fuel injectors can usually be modeled by a simple RL circuit.

Figure 3

shows such a model for a typical fuel injector. In

actual operation, the value of L

of the solenoid. In other words, L

will depend upon the status

1

will change depending

1

TL/H/5062– 6

FIGURE 3. Model of a Typical Fuel Injector

upon whether the solenoid is open or closed. This effect, if

pronounced enough, can be a valuable aid in determining

the current necessary to open a particular type of injector.

The change in inductance manifests itself as a breakpoint in

the initial rise of solenoid current. The waveforms on Page 2

at the sense input show this occurring at approximately 130

mV. Thus, the current necessary to overcome the constrictive forces of that particular injector is 1.3 amperes.

PEAK AND HOLD CURRENTS

The peak and hold currents are determined by the value of

the sense resistor R

logic 1 signal at Pin 1, initially drives Darlington transistor Q

. The driver IC, when initiated by a

S

into saturation. The injector current will rise exponentially

from zero at a rate dependent upon L

, the battery volt-

1,R1

age and the saturation voltage of Q

sense resistor is created by the solenoid current, and when

this drop reaches the peak threshold level, typically 385 mV,

the IC is tripped from the peak state into the hold state. The

IC now behaves more as an op amp and drives Q

closed loop system to maintain the hold reference voltage,

typically 94 mV, across R

from the peak level to the hold level, it remains there for the

duration of the input signal at Pin 1. This mode of operation

is preferable when working with solenoids, since the current

required to overcome kinetic and constriction forces is often

a factor of four or more times the current necessary to hold

the injector open. By holding the injector current at one

fourth of the peak current, power dissipation in the solenoids and Q

In the circuit of

tor shown opens when the current exceeds 1.3 amps and

closes when the current then falls below 0.3 amps. In order

to guarantee injector operation over the life and temperature range of the system, a peak current of approximately 4

amps was chosen. This led to a value of R

ing the peak and hold thresholds by this factor gives peak

and hold currents through the solenoid of 3.85 amps and

0.94 amps respectively.

Different types of solenoids may require different values of

current. The sense resistor R

An 8-amp peak injector would use R

Note that for large currents above one amp, IR drops within

the component leads or printed circuit board may create

substantial errors unless appropriate care is taken. The

sense input and sense ground leads (Pins 4 and 5 respectively), should be Kelvin connected to R

should not be allowed to flow through any part of these

traces or connections. An easy solution to this problem on

double-sided PC boards (without plated-through holes) is to

have the high current trace and sense trace attach to the

R

lead from opposite sides of the board.

S

TIMER FUNCTION

The purpose of the timer function is to limit the power dissipated by the injector or solenoid under certain conditions.

Specifically, when the battery voltage is low due to engine

cranking, or just undercharged, there may not be sufficient

1

voltage available for the injector to achieve the peak current. In the

tion, the injector current can be seen to be leveling out at 3

LM1949N Junction

Temperature Rise Above

Ambient vs Supply Voltage

. The drop across the

1

. Once the injector current drops

S

is reduced by at least the same factor.

1

Figure 1

, it was known that the type of injec-

S

may be changed accordingly.

S

Figure 2

waveforms under the low battery condi-

equal to .05X, etc.

S

S

TL/H/5062– 5

within a

1

of 0.1X . Divid-

. High current

5

Page 6

Timer Function (Continued)

amps, or 1 amp below the normal threshold. Since continuous operation at 3 amps may overheat the injectors, the

timer function on the IC will force the transition into the hold

state after one time constant (the time constant is equal to

R

). The timer is reset at the end of each input pulse. For

TCT

systems where the timer function is not needed, it can be

disabled by grounding Pin 8. For systems where the initial

peak state is not required, (i.e., where the solenoid current

rises immediately to the hold level), the timer can be used to

disable the peak function. This is done by setting the time

constant equal to zero, (i.e., C

recommended. The timer will then complete its time-out and

disable the peak condition before the solenoid current has

had a chance to rise above the hold level.

The actual range of the timer in injection systems will probably never vary much from the 3.9 milliseconds shown in

Figure 1

. However, the actual useful range of the timer extends from microseconds to seconds, depending on the

component values chosen. The useful range of R

proximately 1k to 240k. The capacitor C

stray capacitances for low values and by leakages for large

values.

The capacitor reset time at the end of each controller pulse

is determined by the supply voltage and the capacitor value.

The IC resets the capacitor to an initial voltage (V

discharging it with a current of approximately 15 mA. Thus,

a 0.1 mF cap is reset in approximately 25 ms.

COMPENSATION

Compensation of the error amplifier provides stability for the

circuit during the hold state. External compensation (from

Pin 2 to Pin 3) allows each design to be tailored for the

characteristics of the system and/or type of Darlington power device used. In the vast majority of designs, the value or

type of the compensation capacitor is not critical. Values of

100 pF to 0.1 mF work well with the circuit of

value shown of .01 mF (disc) provides a close optimum in

choice between economy, speed, and noise immunity. In

some systems, increased phase and gain margin may be

acquired by bypassing the collector of Q

appropriately rated 0.1 mF capacitor. This is, however, rarely

necessary.

FLYBACK ZENER

The purpose of zener Z

tive, a voltage spike is produced at the collector of Q

time the injector current is reduced. This occurs at the peakto-hold transition, (when the current is reduced to one fourth

of its peak value), and also at the end of each input pulse,

(when the current is reduced to zero). The zener provides a

current path for the inductive kickback, limiting the voltage

spike to the zener value and preventing Q

voltage levels. Thus, the rated zener voltage at the system

peak current must be less than the guaranteed minimum

breakdown of Q

majority of the injector current during the peak-to-hold transition (see

. Also, even while Z1is conducting the

1

Figure 4

), Q1is operating at the hold current

level. This fact is easily overlooked and, as described in the

following text, can be corrected if necessary. Since the error

amplifier in the IC demands 94 mV across R

biased to provide exactly that. Thus, the safe operating area

(SOA) of Q

volts. For systems where this is not desired, the zener an-

must include the hold current with a VCEof Z

1

ode may be reconnected to the top of R

ure 5

. Since the voltage across the sense resistor now ac-

curately portrays the injector current at all times, the error

e

0). Leaving RTin place is

T

T

is limited only by

T

BE

Figure 1

to ground with an

1

is twofold. Since the load is induc-

1

from damaging

1

will be

S,Q1

as shown in

S

is ap-

)by

. The

any-

1

Fig-

FIGURE 4. Circuit Waveforms

amplifier keeps Q1off until the injector current has decayed

to the proper value. The disadvantage of this particular configuration is that the ungrounded zener is more difficult to

heat sink if that becomes necessary.

The second purpose of Z

protection. Automotive systems are susceptible to a vast

is to provide system transient

1

array of voltage transients on the battery line. Though their

duration is usually only milliseconds long, Q

permanent damage unless buffered by the injector and Z

This is one reason why a zener is preferred over a clamp

diode back to the battery line, the other reason being long

decay times.

1

FIGURE 5. Alternate Configuration for Zener Z

6

TL/H/5062– 7

could suffer

1

TL/H/5062– 8

.

1

1

Page 7

POWER DISSIPATION

The power dissipation of the system shown in

Figure 1

dependent upon several external factors, including the frequency and duty cycle of the input waveform to Pin 1. Calculations are made more difficult since there are many discontinuities and breakpoints in the power waveforms of the

various components, most notably at the peak-to-hold transition. Some generalizations can be made for normal operation. For example, in a typical cycle of operation, the majority of dissipation occurs during the hold state. The hold state

is usually much longer than the peak state, and in the peak

state nearly all power is stored as energy in the magnetic

field of the injector, later to be dumped mostly through the

zener. While this assumption is less accurate in the case of

low battery voltage, it nevertheless gives an unexpectedly

accurate set of approximations for general operation.

The following nomenclature refers to

Figure 1

. Typical val-

ues are given in parentheses:

e

R

V

V

V

V

L

R

n

f

S

H

p

Z

BATT

1

1

Sense Resistor (0.1X)

e

Sense Input Hold Voltage (.094V)

e

Sense Input Peak Voltage (.385V)

e

Z1Zener Breakdown Voltage (33V)

e

Battery Voltage (14V)

e

Injector Inductance (.002H)

e

Injector Resistance (1X)

e

Duty Cycle of Input Voltage of Pin 1 (0 to 1)

e

Frequency of Input (10Hz to 200Hz)

Q1Power Dissipation:

V

BATT

H

Watts

#

R

S

&

P

V

n

#

Q

Zener Dissipation:

2

2

a

(V

V

BATT

H

)#R

)

Watts

2

)

S

&

P

Z

L

V

#

#f#

Z

1

P

((VZ-V

Injector Dissipation:

2

V

&

P

n

I

H

R

#

Watts

#

1

2

R

S

Sense Resistor:

2

V

H

&

P

R

(worst case)&n

P

R

Watts

n

2

R

S

2

V

P

Watts

2

R

S

SWITCHING INJECTOR DRIVER CIRCUIT

The power dissipation of the system, and especially of Q

can be reduced by employing a switching injector driver circuit. Since the injector load is mainly inductive, transistor Q

can be rapidly switched on and off in a manner similar to

switching regulators. The solenoid inductance will naturally

integrate the voltage to produce the required injector current, while the power consumed by Q

note of caution: The large amplitude switching voltages that

will be reduced. A

1

are present on the injector can and do generate a tremendous amount of radio frequency interference (RFI). Because

of this, switching circuits are not recommended. The extra

cost of shielding can easily exceed the savings of reduced

power. In systems where switching circuits are mandatory,

extensive field testing is required to guarantee that RFI cannot create problems with engine control or entertainment

equipment within the vicinity.

is

The LM1949 can be easily modified to function as a switcher. Accomplished with the circuit of

Figure 7

tional components required are two external resistors, R

and RB. Additionally, the zener needs to be reconnected, as

shown, to R

easily controlled by the resistor ratio of R

. The amount of ripple on the hold current is

S

small so that sense input bias current (typically 0.3 mA) has

negligible effect on V

tion during the hold state are dependent on the injector

characteristics, R

the following equations.

Hold Current

Minimum Hold Current

Ripple or DI Hold

R

R

S

A

&

f

#

o

L

R

1

B

Duty Cycle of f

. Duty cycle and frequency of oscilla-

H

, and the zener voltage as shown in

A,RB

V

H

&

R

S

&

R

B

&

R

A

V

BATT

#

#

V

#

Z

e

f

o

V

BATT

&

o

V

Z

R

B

b

V

#

H

R

#

A

R

S

1

V

#

#

Z

R

S

V

BATT

b

1

V

J

Z

Hold State Oscillation Frequency

Component Power Dissipation

&

P

n

Q

e

V

SAT

&

n

P

Z

&

P

RA

V

b

1

#

#

Q1Saturation Volt

V

#

BATT

#

R

S

V

V

#

B

Z

R

1

BATT

V

Z

V

H

V

SAT

V

#

#

H

R

J

S

@

E

1 Amp (1.5V)

As shown, the power dissipation by Q1in this manner is

substantially reduced. Measurements made with a thermocouple on the bench indicated better than a fourfold reduction in power in Q

zener (which is independent of the zener voltage chosen) is

increased over the circuit of

,

1

1

. However, the power dissipation of the

1

Figure 1

.

FIGURE 6. Switching Waveforms

, the only addi-

to RB.RBis kept

A

V

Z

J

TL/H/5062– 9

A

7

Page 8

FIGURE 7. Switching Application Circuit

TL/H/5062– 10

8

Page 9

Physical Dimensions inches (millimeters)

14-Lead (0.150×Wide) Molded Small Outline Package, JEDEC

Order Number LM1949M

NS Package Number M08A

9

Page 10

Physical Dimensions inches (millimeters) (Continued)

LM1949 Injector Drive Controller

Molded Dual-In-Line Package (N)

Order Number LM1949N

NS Package Number N08E

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL

SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or 2. A critical component is any component of a life

systems which, (a) are intended for surgical implant support device or system whose failure to perform can

into the body, or (b) support or sustain life, and whose be reasonably expected to cause the failure of the life

failure to perform, when properly used in accordance support device or system, or to affect its safety or

with instructions for use provided in the labeling, can effectiveness.

be reasonably expected to result in a significant injury

to the user.

National Semiconductor National Semiconductor National Semiconductor National Semiconductor

Corporation Europe Hong Kong Ltd. Japan Ltd.

1111 West Bardin Road Fax: (

Arlington, TX 76017 Email: cnjwge@tevm2.nsc.com Ocean Centre, 5 Canton Rd. Fax: 81-043-299-2408

Tel: 1(800) 272-9959 Deutsch Tel: (

Fax: 1(800) 737-7018 English Tel: (

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Fran3ais Tel: (

Italiano Tel: (

a

49) 0-180-530 85 86 13th Floor, Straight Block, Tel: 81-043-299-2309

a

49) 0-180-530 85 85 Tsimshatsui, Kowloon

a

49) 0-180-532 78 32 Hong Kong

a

49) 0-180-532 93 58 Tel: (852) 2737-1600

a

49) 0-180-534 16 80 Fax: (852) 2736-9960

Loading...

Loading...