Page 1

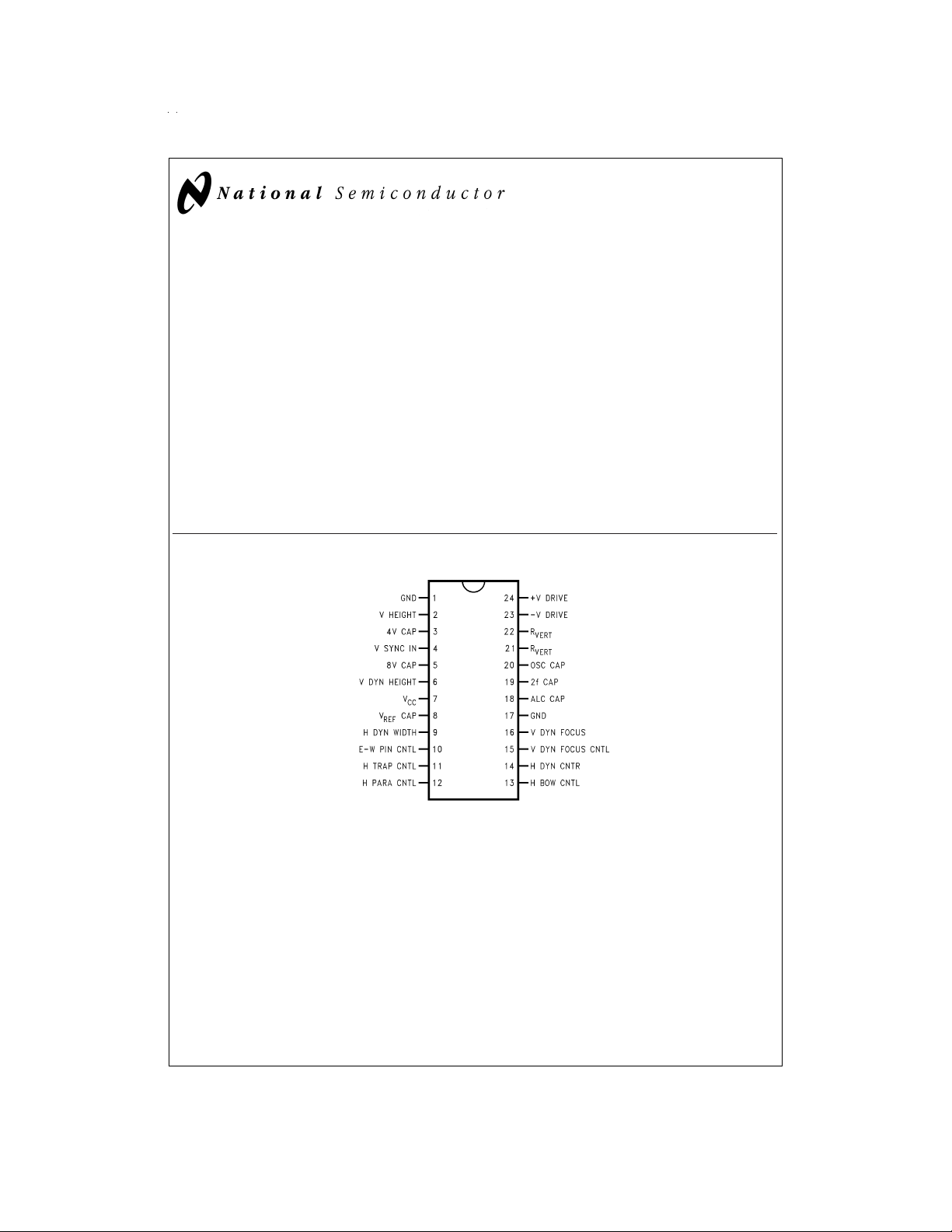

LM1295

DC Controlled Geometry Correction System for

Continuous Sync Monitors

LM1295 DC Controlled Geometry Correction System for Continuous Sync Monitors

April 1999

General Description

The LM1295 is specifically designed for use in a continuous

sync monitor. The injection-locked vertical oscillator operates from 50 Hz to 170 Hz, covering all known video monitors. A differential output current is provided in order to prevent ground interaction.

The IC provides two outputs composed of the summation of

DC controlled 1st and 2nd order output terms. The first output corrects for EW pincushion and trapezoid. The second

corrects for parallelogram and bow.

A DCcontrolled output is provided for vertical dynamic focus

correction.

The IC is packaged in a 24-pin narrow DIP package and operates on a single 12V power supply.

Connection Diagram

Features

n Vertical scanning frequency 50 Hz–170 Hz

n DC controlled correction term amplitudes

n Up to 125 kHz bandwidth for dynamic input signals

n Minimum external parts count

n Multiple IC connection for convergence applications

flexibility

n Stable vertical amplitude over temperature

n Compatible with the LM1291 Horizontal PLL in a H/V

system

n Dynamic vertical deflection correction for second anode

high voltage drop

n Both positive and negative going correction signals

DS012324-1

FIGURE 1. Order Number LM1295N

See NS Package Number N24C

© 1999 National Semiconductor Corporation DS012324 www.national.com

Page 2

Absolute Maximum Ratings (Notes 1, 3)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage 15V

Input Voltage

(DC, pins 2, 4, 6, 10, 11, 12, 13, 15) 5V

Input Voltage (AC, Pin 4) 5 V

Power Dissipation (Note 4)

(Above 25˚C Derate Based on

and TJ) 1.8W

θ

JA

Thermal Resistance (θ

Junction Temperature (T

) 70˚C/W

JA

) 150˚C

J

ESD Susceptibility (Note 5) 1.8 kV

Storage Temperature −65˚C to +150˚C

Lead Temperature (Soldering, 10 sec.) 265˚C

Operating Ratings (Note 2)

Operating Temperature Range −20˚C to +80˚C

PP

Supply Voltage (V

Input Voltage

(DC, pins 2, 4, 6, 10, 11, 12,

13, 15) 4V

Input Voltage

(AC, pin 4) 4 V

) 10.8V ≤ VCC≤ 13.2V

CC

PP

Electrical Characteristics

See Test Circuit (

Figure 2

); T

A

=

25˚C; V

Symbol Parameter Conditions

I

CC

V

R

F

FR

F

max

Supply Current All Control Inputs=3V

Internal Ref Voltage at Pin 8 8.2 V

REF

Input Resistance Pins 6, 10–13, 15

IN

Free-Run Frequency 45 Hz

Maximum Frequency 170 Hz

Cntlbw Control Inputs Bandwidth Pins 6, 10–13, 15 125 kHz

V

V

V

V

V

V

V

V

V

CR

CR

CP

Vertical Height Temperature

HTS

Stability

Vertical Differential Output Current V Height=4V, V Dyn Height=4V,

DIFF

V Sync High Input Voltage 2.4 V(min)

SYNH

V Sync Low Input Voltage

SYNL

Vertical Output CMRR V

CMRR

Vertical Output PSSR V

PSRR

Vertical Peak Output Voltage R

OP-P

Vertical Ramp Distortion (Note 8) V Height=4V,

RERR

Vertical Parabola Distortion (Note 9) V Height=2.2V, F=100 Hz,

SOERR

First Order (Ramp) Correction,

FO

H Dyn Cntr (Pin 14)

First Order (Ramp) Correction,

FO

H Dyn Width (Pin 19)

Parabola Correction Range,

SO

H Dyn Cntr (Pin 14),

H Dyn Width (Pin 9),

V Dyn Focus (Pin 16)

=

12V.

CC

V Height=4V, V Dyn Height=3V,

=

F=100 Hz, T

0˚C to 70˚C (Note 9)

A

Pin 24 Minus Pin 23

=

1V to 4V, V Height=2V,

O

V Dyn Height=3V

=

10.8V to 13.2V, V Height=2V,

CC

V Dyn Height=3V

=

10k

L

V Dyn Height=3V

V Dyn Height=3V

Pin 12=0V

Pin 12=4V

V Dyn Height=3V, V Height=4V,

Parabola Nulled

Pin 11=0V

Pin 11=4V

V Dyn Height=3V, V Height=4V,

Parabola Nulled

Pins 10, 13, 15=0V

Pins 10, 13, 15=4V

V Dyn Height=3V, V Height=4V,

Ramp Nulled for H Dyn Cntr and H Dyn

Width

Typical

(Note 6)

Limit

(Note 7)

25 35

50 30

1

1 mA(min)

0.8

30 dB

30 dB

65

1

8

2.50

2.25

0.85

0.75

1.2

1.0

Units

mA

(max)

kΩ

(min)

%

V

(max)

V

(min)

%

%

V

V

V

PP

PP

PP

PP

www.national.com 2

Page 3

Electrical Characteristics (Continued)

See Test Circuit (

Figure 2

); T

A

=

25˚C; V

Symbol Parameter Conditions

V

I

O

Output DC Bias Pins 9, 14 and 16; All Control

ODC

Output Current Pins 9, 14 and 16 5.0 mA

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur.

Note 2: Operating Ratings indicate conditions for which the device is functional, but do not guarantee specific performance limits. For guaranteed specifications and

test conditions, see the Electrical Characteristics. The guaranteed specifications apply only for the test conditions listed. Some performance characteristics may degrade when the device is not operated under the listed test conditions.

Note 3: All voltages are measured wIth respect to GND, unless otherwise specified.

Note 4: The maximum power dissipation must be derated at elevated temperatures and is dictated by T

allowable power dissipation at any temperature is P

=

T

150˚C. The typical thermal resistance (θ

Jmax

Note 5: Human body model, 100 pF capacitor discharged through a 1.5 kΩ resistor.

Note 6: Typicals are at T

Note 7: Tested limits are guaranteed to National’s AOQL (Average Outgoing Quality Level).

Note 8: The deviation from a straight line drawn through measured points at 5%and 95%of the ramp is used to calculate distortion.

Distortion=100 (deviation, volts)/(95%value − 5%value, volts). Deviations are measured at

Note 9: The deviation from a theoretical parabola drawn through the apex of the actual parabola is used to calculate distortion.

Distortion=100 (deviation, volts)/(theoretical parabola, volts) at measuring point. Nine points are measured.

Note 10: The amplitude stability versus temperature is typically 1%or less at 100 Hz when a standard 10k 5

21 and 22 and located close to the package. The negative temperature coefficient of the resistor corrects for the negative temperature coefficient of the LM1295. The

typical amplitude stability of the LM1295 by itself is 2%.

=

=

T

25˚C and represent most likely parametric norm.

A

J

=

12V.

CC

Inputs at 2.2V

=

D

) of these parts when board mounted follow: LM1295N 70˚C/W.

JA

)/θJAor the number given in the Absolute Maximum Ratings, whichever is lower. For this device,

(T

Jmax−TA

Jmax

1

⁄3and2⁄3of the ramp time period.

Typical

(Note 6)

Limit

(Note 7)

4.0 V

, θJAand the ambient temperature, TA. The maximum

1

%

⁄4W carbon film resistor is connected between pins

Units

DC

www.national.com3

Page 4

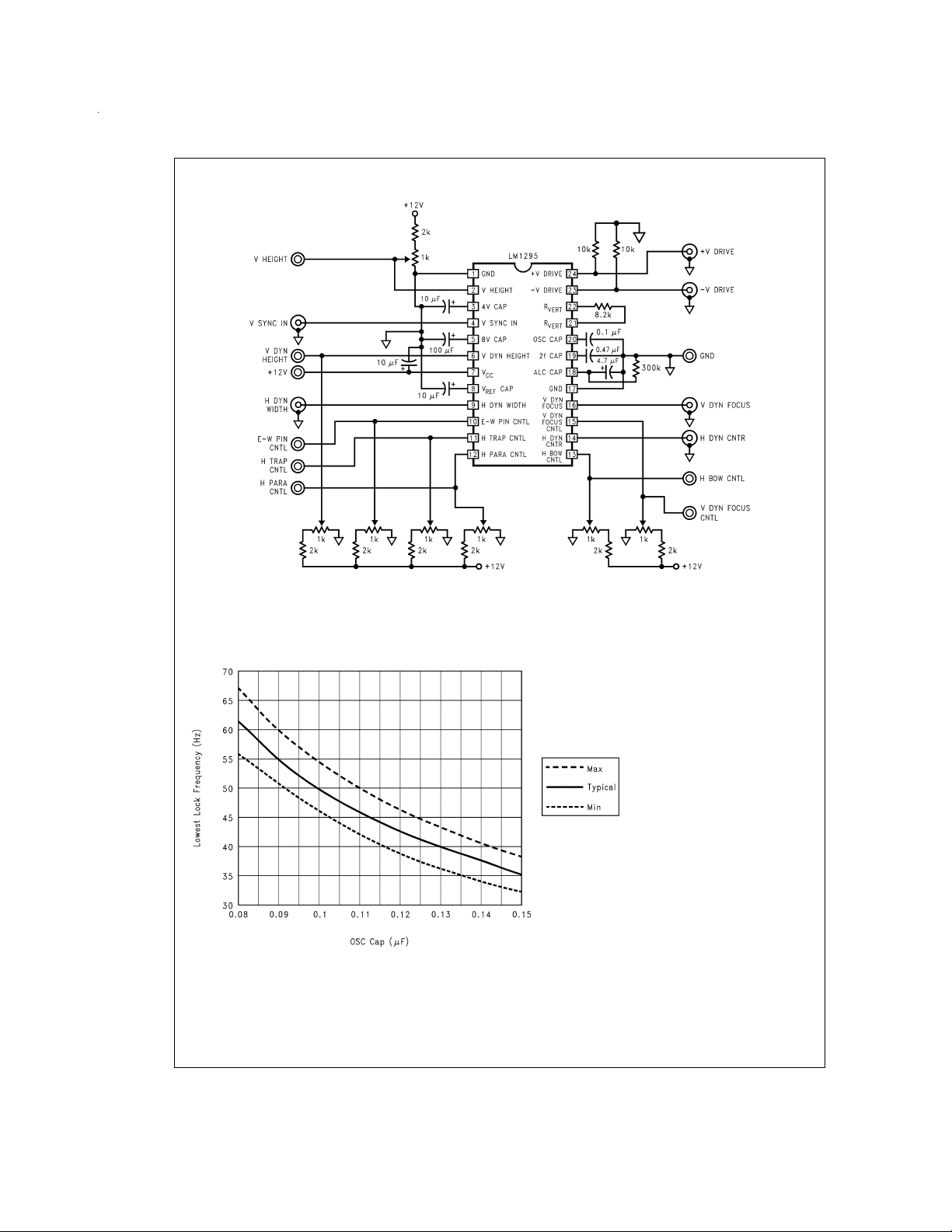

Test Circuit

FIGURE 2.

Typical Performance Characteristics

DS012324-2

=

T

25˚C, V

A

Height

=

0V to 4V, V

Dyn Height

=

3V

Lowest Lock Frequency vs OSC Cap

Graph 1

www.national.com 4

DS012324-12

Page 5

Typical Performance Characteristics T

Circuit—

Figure 2

=

25˚C, F=100 Hz, V

A

Height

=

4V, V

Dyn Height

=

3V, Test

H Dyn Width Output (Pin 9)

H Dyn Width Output (Pin 9)

DS012324-10

DS012324-13

H Dyn Width Output (Pin 9)

DS012324-11

H Dyn Width Output (Pin 9)

DS012324-14

H Dyn Ctr Output (Pin 14)

DS012324-15

H Dyn Ctr Output (Pin 14)

DS012324-16

www.national.com5

Page 6

Typical Performance Characteristics T

Figure 2

Circuit—

(Continued)

=

25˚C, F=100 Hz, V

A

Height

=

4V, V

Dyn Height

=

3V, Test

H Dyn Cntr Output (Pin 14)

V Dyn Focus Output (Pin 16)

DS012324-17

H Dyn Cntr Output (Pin 14)

DS012324-18

V Dyn Focus Output (Pin 16)

DS012324-19

−V Drive Output (Pin 23)

DS012324-21

Circuit Description

(See

Figure 3

, Block Diagram)

The LM1295 has outputs which provide signals for correcting the following CRT distortions: Vertical de-focusing,

East-West pincushion, horizontal trapezoid, horizontal paral-

www.national.com 6

DS012324-20

+V Drive Output (Pin 24)

DS012324-22

lelogram and horizontal bow. The amount and polarity of the

corrections are controlled by voltages between 0V and 4V.

The corrections track the vertical output amplitude.

The LM1295 has five major sections: the vertical oscillator/

amplifier, the parabolic function generator and three

voltage-controlled channels with the correction term outputs.

Page 7

Circuit Description (Continued)

VERTICAL OSCILLATOR

The vertical oscillator is an injection-locked ramp generator

with automatic level control. The automatic level control

maintains the oscillator output ramp height with changes in

input frequency. The oscillator requires negative-going TTL

level vertical sync pulses, wider than 200 ns, to lock. In the

absence of vertical sync, the oscillator runs at free-run frequency.The vertical output amplitude is controlled by a voltage between 0V and 4V on the V Height input with a range

of about 1.8 to 1, and by a voltage between 3V and 4V on the

Vertical Dynamic Height input with a range of about 1.3 to 1.

The control bandwidth of the V Height input is low due to the

automatic level control, but that of the Vertical Dynamic

Height is greater than 125 kHz. The oscillator has a circuit,

requiring an external capacitor, 2f Cap, that prevents the oscillator from locking at twice the vertical sync frequency.The

oscillator ramp voltage is converted into differential currents

superimposed on DC currents of about 315 µA for each output. The voltage to current conversion gain is inversely proportional to the value of the resistor connected between the

Rvert pins (21 and 22). Differential current outputs are provided instead of voltage to avoid ground noise. The ramp

voltage goes to the parabolic function generator and to two

multipliers used as voltage controlled amplifiers, one for horizontal trapezoid correction and the other for horizontal parallelogram correction.

PARABOLIC FUNCTION GENERATOR

The parabolic function generator makes a parabolic waveform from the vertical ramp. Its output goes to three multipliers used as voltage controlled amplifiers, one each for V Dyn

Focus, E-W Pin, and H Bow.

VOLTAGE CONTROLLED AMPLIFIERS

The V Dyn Focus voltage controlled amplifier is controlled by

the V Dyn Focus Cntl input. Its output goes to an op amp

whose output is V Dyn Focus. The voltage controlled amplifier has zero gain at approx. 2V input, maximum positive

gain at 4V, and maximum negative gain at 0V. The E-W Pin,

H Bow, H Trap and H Para voltage controlled amplifiers are

identical to the V Dyn Focus stage, each adjusted by its corresponding Cntl input. The bandwidth of the Cntl inputs is

greater than 125 kHz. The E-W Pin and H Bow amplifiers

have the parabolic waveform as their input, and the H Trap

and H Para amplifiers have the vertical ramp as their input.

The parabolic waveform and the ramp amplitudes track the

vertical output amplitude so the correction amplitudes follow

accordingly.The outputs of the E-W Pin amplifier (parabola)

and the H Trap amplifier (ramp) are summed together in an

op amp summing circuit, with H Trap weight

Pin. The output of the summing amplifier is H Dyn Width,

used for correcting E-W pincushion and horizontal trapezoid

distortion. The outputs of the H Bow amplifier (parabola) and

the H Para amplifier (ramp) are summed together similarly,

with H Bow and H Para equally weighted. The output of the

summing amplifier is H Dyn Cntr, used for correcting horizontal bow and horizontal parallelogram distortion. All three

op amp outputs are identical structures and are typical low

output impedance type op amp outputs, capable of sinking

or sourcing 5 mA minimum.

1

⁄3that of E-W

Block Diagram

DS012324-3

FIGURE 3.

www.national.com7

Page 8

Pin Descriptions

See

Figure 4

through

Figure 8

ics.

GND (Pin 1): This pin should be connected to the power

ground at pin 17.

V Height (Pin 2): Vertical Height. A voltage between 0V and

4V on this pin controls the amplitude of the +V and −V Drive

currents, with increasing voltage giving increasing current.

The control range is approximately 1.8 to 1. The response

time is slow,being limited by the automatic level control loop.

4 V Cap (Pin 3): 4 Volt Cap Capacitor. A 10 µF capacitor,

aluminum electrolytic or tantalum, should be connected between pin 3 (positive side) and GND (pin 17) to bypass the

internal 4V reference.

V Sync In (Pin 4): Vertical Sync Input. The vertical sync input takes a negative-going TTL level pulse which injection

locks the vertical oscillator to the vertical sync frequency if it

is above the LM1295 minimum frequency. The input threshold level is approximately 2V, so pulses other than TTL level

are satisfactory as long as they cross the 2V threshold with

at least a 400 mV margin either side. The minimum pulse

width is approximately 200 ns. For free-running detection (no

V Sync in), this input should be at logic high.

8 V Cap (Pin 5): 8 Volt Capacitor. A 100 µF capacitor, aluminum electrolytic or tantalum, should be connected between

pin 5 (positive side) and GND (pin 17) to bypass the internal

8V reference.

V Dyn Height (Pin 6): Vertical Dynamic Height. A voltage

between 3V and 4V on this pin controls the amplitude of the

+V and −V Drive currents with increasing voltage giving increasing current. The control range is approximately

1.3 to 1. The bandwidth of this input is DC to greater than

125 kHz in contrast to the slow Vertical Height input.

V

(Pin 7): Power, 12V nominal. VCCshould be bypassed

CC

to GND (pin 17) with a 10 µF aluminum electrolytic or tantalum capacitor.

VrefCap (Pin 8): VoltageReference Cap. A 10 µF capacitor,

aluminum electrolytic or tantalum, should be connected between pin 8 (positive side) and GND (pin 17).

H Dyn Width (Pin 9): Horizontal Dynamic Width. This output

consists of the sum of the vertical ramp and the parabola derived from the ramp. The amplitude and polarity of the ramp

signal is DC controlled by H Trap Cntl (pin 11) and of the parabola by E-W Pin Cntl (pin 10). The weighting of the ramp is

1

⁄3the parabola; i.e., with the H Trap and E-W Pin Cntls at

4V,theoutput is 3 parts parabola and 1 part ramp. Horizontal

Dynamic Width is used to correct for trapezoid and east-west

pincushion distortion. The output stage is similar to a standard op-amp output. The bandwidth from either of the 2 control pins to the output is DC to greater than 125 kHz.

E-W Pin Cntl (Pin 10): East-West Pincushion Control. A

voltage of 0V to 4V adjusts the polarity and the amount of

parabola in the Horizontal Dynamic Width (pin 9) output. At

approximately 2V, the amount is zero. From 2V to 4V, the

amplitude increases and the parabola is positive-going.

From 2V to 0V, the amplitude increases and the parabola is

negative-going.

H Trap Cntl (Pin 11): Horizontal Trapezoid Control. A voltage of 0V to 4V adjusts the polarity and the amount of vertical ramp in the Horizontal Dynamic Width (pin 9) output. At

approximately 2V, the amount is zero. From 2V to 4V, the

amplitude increases and the ramp is positive-going. From 2V

to 0V, the amplitude increases and the ramp is

negative-going.

for Input and Output schemat-

H Para Cntl (Pin 12): Horizontal Parallelogram Control. A

voltage of 0V to 4V adjusts the polarity and the amount of

vertical ramp in the Horizontal Dynamic Center (pin 14) output.At approximately 2V, the amount is zero. From 2V to 4V,

the amplitude increases and the ramp is positive-going.

From 2V to 0V, the amplitude increases and the ramp is

negative-going.

H Bow Cntl (Pin 13): Horizontal Bow Control. A voltage of

0V to 4V adjusts the polarity and the amount of parabola in

the Horizontal Dynamic Center (pin 14) output. At approximately 2V, the amount is zero. From 2V to 4V, the amplitude

increases and the parabola is positive-going. From 2V to 0V,

the amplitude increases and the parabola is negative-going.

H Dyn Cntr (Pin 14): Horizontal Dynamic Center. This output consists of the sum of the vertical ramp and the parabola

derived from the ramp. The amplitude and polarity of the

ramp signal is DC controlled by H Para Cntl (pin 12) and of

the parabola by H Bow Cntl (pin 13). The difference between

this output and the Horizontal Dynamic Width output is in the

weighting of the ramp, which is equal to the parabola; i.e.,

with the H Para and H Bow Cntls at 4V, the output is 1 part

parabola and 1 part ramp. Horizontal Dynamic Center is

used to correct for parallelogram and bow distortion. The

output stage is similar to a standard op-amp output. The

bandwidth from either of the 2 control pins to the output is

DC to greater than 125 kHz.

V Dyn Focus Cntl (Pin 15): Vertical Dynamic Focus Control.Avoltage of 0V to 4V adjusts the polarity and the amount

of parabola in the Vertical Dynamic Focus (pin 16) output. At

approximately 2V, the amount is zero. From 2V to 4V, the

amplitude increases and the parabola is positivegoing. From

2V to 0V, the amplitude increases and the parabola is

negative-going.

V Dyn Focus (Pin 16): Vertical Dynamic Focus. This output

consists of the parabola derived from the vertical ramp. The

amplitude and polarity are controlled by V Dyn Focus Cntl.

The output stage is similar to a standard op-amp output. The

bandwidth from the control pin to the output is DC to greater

than 125 kHz.

GND (Pin 17): Ground. This is the power supply ground for

the 12V supply and the point to which the bypass capacitors

are returned.

ALC Cap (Pin 18): Automatic Level Control Capacitor. This

capacitor is part of the level control circuit that maintains

constant vertical height in spite of vertical sync frequency

changes. The recommended value is 4.7 µF, aluminum electrolytic or tantalum capacitor. If the VCO capacitor value is

changed, this capacitor value should change in the same ratio. A 300k resistor should be connected from this pin to

ground.

2f Cap (Pin 19): Double frequency Capacitor. This capacitor

prevents the vertical oscillator from locking at twice the vertical sync frequency. The recommended value is 0.47 µF. If

the VCO capacitor value is changed, this capacitor value

should change in the same ratio.

Osc Cap (Pin 20): A timing capacitor is connected from this

pin to ground for the internal oscillator. The capacitance determines the lowest lock frequency. See Graph 1.

Rvert (Pin 21): Vertical Resistor.One end of the Vertical Resistor connects to this pin. This resistor determines the gain

of the vertical ramp current generator. The gain is inversely

proportional to the resistance. It is recommended that this be

a standard 5

1

%

⁄4W carbon film resistor whose negative tem-

www.national.com 8

Page 9

Pin Descriptions (Continued)

perature coefficient corrects for the negative temperature coefficient of the LM1295. The resistor should be located near

the LM1295. The recommended value is 10 kΩ.

Rvert (Pin 22): Vertical Resistor. The other end of the Vertical Resistor connects to this pin.

− V Drive (Pin 23): − Vertical Drive. This is the

negative-going vertical ramp output current of the differential

pair.The ramp current waveform is superimposed on a direct

Input/Output Schematics

current of approximately 315 µA. The waveform amplitude is

determined by the Vertical Height (pin 2) control voltage and

the Vertical Dynamic Height (pin 6) control voltage. The current can be converted into voltage by a resistor (typically 10

kΩ) to ground or by a differential amplifier using the differential currents as inputs. The voltage compliance of the output

is typically 6V.

+ V Drive (Pin 24): + Vertical Drive. This is the same as − V

Drive except it is the positive-going output current of the differential pair.

FIGURE 4.

FIGURE 5.

DS012324-4

DS012324-5

DS012324-6

FIGURE 6.

DS012324-7

FIGURE 7.

FIGURE 8.

DS012324-8

www.national.com9

Page 10

Typical Application

Note: LM1295 is designed to drive a differential input vertical deflection amplifier. The LM1295, however, can also drive a single-ended input vertical deflection

amplifier by just using either the +V drive or −V drive pins.

DS012324-9

FIGURE 9.

www.national.com 10

Page 11

Physical Dimensions inches (millimeters) unless otherwise noted

LM1295 DC Controlled Geometry Correction System for Continuous Sync Monitors

24-Lead (0.300" Wide) Molded Dual-In-Line Package

Order Number LM1295N

NS Package Number N24C

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

www.national.com

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80-532 78 32

Français Tel: +49 (0) 1 80-532 93 58

Italiano Tel: +49 (0) 1 80-534 16 80

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...