Page 1

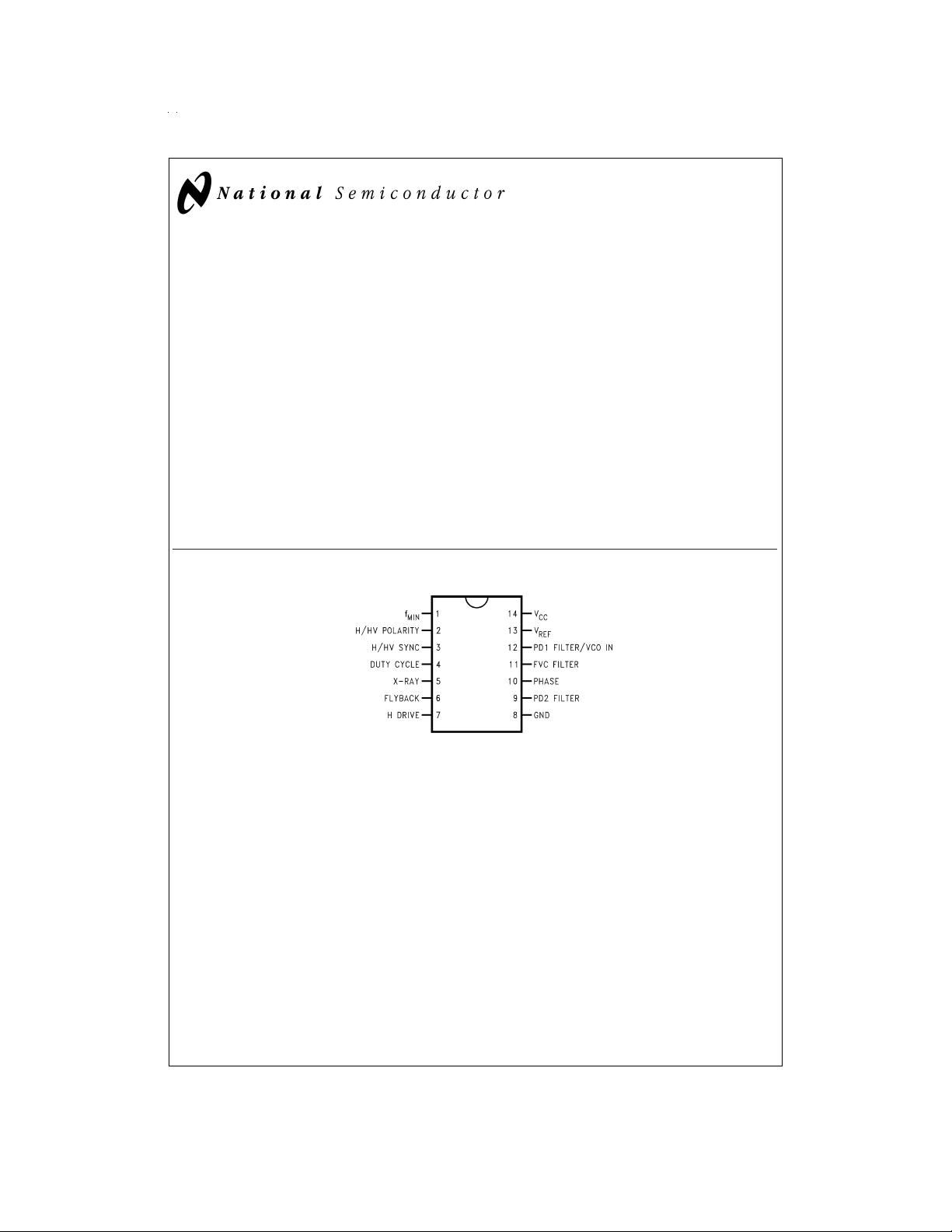

LM1290

Autosync Horizontal Deflection Processor

LM1290 Autosync Horizontal Deflection Processor

January 1997

General Description

The LM1290 is a high-performance, low-cost deflection solution for autosync monitors.

The LM1290 provides full autosync capability, DC controls

and complete freedom from manufacturing trims. Its continuous capture range is from 22 kHz to 110 kHz (1:5). Mode

change frequency ramping, for protection of the horizontal

deflection output transistor, is programmable by using an external capacitor.

Together with the National Semiconductor LM1296 Raster

Geometry Correction System for Multi-Frequency Displays,

excellent performance is offered. The two-chip solution provides the advantage of good jitter performance, simplified

board layout, and lower system cost.

The LM1290 is packaged in a 14-pin plastic DIP package.

Connection Diagram

FIGURE 1.

Order Number LM1290N

See NS Package Number N14A

Features

n Full autosync—22 kHz to 110 kHz with no component

switching or external adjustments

n No manufacturing trims needed—internal VCO

capacitor trimmed on chip

n Sample-and-hold circuit for fast top-of-screen phase

recovery, even when using composite sync

n DC-controlled H phase and duty cycle

n Resistor-programmable minimum VCO frequency

n Excellent jitter performance

n X-ray input disables H drive until V

n Low V

n H output transistor protected against accidental turn on

during flyback

n Capacitor-programmable frequency ramping, d

protects H output transistor during scanning mode

changes

disables H drive (V

CC

DS012917-1

CC

powered down

CC

<

8.5V)

f

VCO

/dt

,

© 1999 National Semiconductor Corporation DS012917 www.national.com

Page 2

Absolute Maximum Ratings (Notes 1, 3)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage (V

Input Voltage (V

Pin 1 8V

Pins 3, 4, 5, 6 V

Pin 10 1.0V<V

Pin 12 10V

Output Sink Current, Pin 7 130 mA

Power Dissipation (P

(Above 25˚C, derate based on θ

and TJ) 1.65W

) 15V

CC

)

DC

)

D

JA

CC

<

7.5V

DC

Thermal Resistance (θ

Junction Temperature (T

) 75˚C/W

JA

) 150˚C

J

ESD Susceptibility (Note 5) 3.5 kV

Storage Temperature −65˚C to +150˚C

Lead Temperature

(Soldering 10 seconds) 265˚C

Operating Ratings (Note 2)

Operating Temperature Range −20˚C to +80˚C

Supply Voltage 10.8V ≤ V

CC

≤ 13.2V

Electrical Characteristics

See Test Circuit (

Figure 2

);T

A

=

25˚C; V

Parameter Condition Typical Limit Units

Supply Current (Pin 14) Pin 3 and Pin 7 Open Circuit, 30 40 mA (max)

Minimum Capture Frequency H Sync Duty Cycle=10%; 10 22 kHz (max)

Maximum Capture Frequency Pin 1 (f

H/HV SYNC Input (Pin 3) High Level 2.2 V (min)

Threshold Voltage Low Level 0.8 V (max)

H/HV SYNC Input (Pin 3) 26 24

Maximum Sync Tip Duty Cycle

H/HV SYNC Input (Pin 3) f

Minimum Sync Tip Duty Cycle

H/HV POLARITY (Pin 2) C

Low Level Output Voltage, V

OL

H/HV POLARITY (Pin 2) C

High Level Output Voltage, V

OH

FVC Gain 22 kHz ≤ fH≤ 110 kHz 0.055 V/kHz

VCO Gain 22 kHz ≤ f

Phase Detector 1 Gain H Sync Duty Cycle=10%:

Phase Detector 1 Output Impedance 20 kΩ

(Pin 12)

Phase Detector 1 Leakage Current + H/HV SYNC Input Grounded 0.3 2 µA

VCO Bias Current (Pin 12)

Jitter f

Free Run Frequency Variation I

H Drive Phase Control Gain V

=

CC

12V; V

=

0V unless otherwise stated.

5

(Note 6) (Note 7)

Pin 1=−100 µA

) Open 115 110 kHz (min)

MIN

=

22 kHz 5

H

=

0.1 µF; I

POL

=

0.1 µF; I

POL

=

f

110 kHz 120

H

=

f

60 kHz 80

H

=

f

22 kHz 30

H

=

110 kHz (Note 8) 0.9

H

=

90 kHz 1.1

f

H

=

f

60 kHz 1.6

H

=

f

31 kHz 3.6

H

=

f

22 kHz 5.8

H

=

−225 µA 32 34 kHz (max)

1

=

+1 µA 0.05 0.4 V (max)

OL

=

−1 µA 4.5 4 V (min)

OL

≤ 110 kHz 18.2 kHz/V

VCO

26 25 kHz (min)

=

2V to 6V (Note 11) 8.89

10

(32) (˚/V)

%

%

µA/radian

ns p-p

%

/V

T

H

www.national.com 2

Page 3

Electrical Characteristics (Continued)

See Test Circuit (

Figure 2

);T

A

=

25˚C; V

Parameter Condition Typical Limit Units

H Drive Phase Control Range V

H Drive Duty Cycle Control Gain V

H Drive Duty Cycle Maximum (Pin 7) V

H Drive Duty Cycle Minimum (Pin 7) V

H Drive Low Level Output Voltage (Pin 7) I

Flyback Input Threshold Voltage (Pin 6) Positive-Going Flyback Pulse 2.2 V

Maximum Allowable Storage Delay of From H Drive Rising Edge to

Horizontal Deflection Output Transistor Center of Flyback Pulse 30

Plus Half of Flyback Pulse Width

V

Lockout Threshold Voltage VCCBelow Threshold: 8.5 V (max)

CC

(Pin 14) H Drive Output Disabled

X-Ray Shutdown Threshold Voltage Above Threshold: 1.85 2 V (min)

(Pin 5) H Drive Output Disabled

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur.

Note 2: Operating Ratings indicate conditions for which the device is functional, but do not guarantee specific performance limits. For guaranteed specifications and

test conditions, see the Electrical Characteristics. The guaranteed specifications apply only for the test conditions listed. Some performance characteristics may degrade when the device is not operated under the listed test conditions.

Note 3: All voltages are measured with respect to GND, unless otherwise specified.

Note 4: The maximum power dissipation must be derated at elevated temperatures and is dictated by T

allowable power dissipation at any elevated temperature is P

this device, T

Note 5: Human Body model, 100 pF capacitor discharged through a 1.5 kΩ resistor.

Note 6: Typical specifications are at T

Note 7: Tested limits are guaranteed to National’s AOQL (Average Outgoing Quality Level).

Note 8: The standard deviation, σ, of the flyback pulse period is measured with a HP 53310A Modulation Domain Analyzer.Peak-to-peak jitter of the flyback pulse

is defined by 6σ.

Note 9: A positive phase value represents a phase lead of the flyback pulse peak with reference to the center of H sync.

Note 10: The duty cycle is measured under the conditions of free run with I

and the turn off delay of the H deflection output transistor respectively.

Note 11: T

=

150˚C. The typical thermal resistance (θ

JMAX

=

25˚C and represent most likely parametric norm.

A

is defined as the total time of one horizontal line.

H

=

CC

12V; V

=

0V unless otherwise stated.

5

(Note 6) (Note 7)

=

3.6V to 7V (Notes 9, 11)

10

±

14

(See Application Hint#3)

=

0V to 4V (Note 10) 10.8

4

=

0V (Note 10) 68 63

4

=

4V (Note 10) 25 35

4

=

100 mA 0.7 V

OL

V

Above Threshold: 10.5 V (min)

CC

H Drive Output Enabled

, θJAand the ambient temperature, TA. The maximum

=

3 µs and T

JMAX

=

d

3.5 µs where T

and Tdare the flyback pulse width

FBP

=

(T

D

) of the LM1290N is 75˚C/W.

JA

)/θJAor the number given in the Absolute Maximum Ratings, whichever is lower. For

JMAX−TA

=

−100 µA,T

1

FBP

%

%

%

T

%

/V

(min)

(max)

%

T

H

H

www.national.com3

Page 4

Test Circuit

System Block Diagram

DS012917-2

FIGURE 2.

FIGURE 3.

www.national.com 4

DS012917-3

Page 5

Pin Descriptions

See

Figure 4

through

Figure 10

for input and output sche-

matics.

Pin 1 —f

run frequency of the LM1290. The freerun frequency should

: A resistor from this pin to ground sets the free

MIN

be set typically as:

=

f

0.85(f

MIN

where f

the application. The resistance required to set this frequency

is the minimum lock frequency required for

MINLOCK

MINLOCK

)−2kHz

is approximately:

For example, to find R

31.469 kHz,

=

f

0.85(31.469 kHz)−2kHz=24749

MIN

Rounding to the closest standard 1%resistor gives R

21.5 kΩ.

for VGA which has f

MIN

MINLOCK

MIN

Pin 2—H/HV POLARITY: A 0.1 µF capacitor is connected

from this pin togroundfor detecting the polarity of H/HV sync

at pin 3. A low logic level at pin 2 indicates active-high H/HV

sync to pin 3, a high level indicates active-low. See

Figure 4

for the output schematic.

Pin 3— H/HV SYNC: This input pin accepts DC-coupled H

or composite sync of either polarity. For best noise immunity,

a resistor of 2 kΩ or less should be connected from this pin

to pin 8 (GND) via a short path. See

Figure 5

for the input

schematic.

Pin 4— DUTY CYCLE: A DC voltage applied to this pin sets

the duty cycle of the H DRIVE output (pin 7), with a range of

approximately 30%to 70%. 2V sets the duty cycle to approximately 50%. See

Figure 6

for the input schematic.

Pin 5— X-RAY: This pin is for monitoring CRT anode voltage. If the input voltage exceeds an internal threshold, H

Input/Output Schematics

DRIVE output (pin 7) is latched high. V

to below approximately 2V to clear thelatched condition, i.e.,

power must be turned off. See

CC

Figure 7

matic.

Pin 6 —FLYBACK: Input pin for phase detector 2. For best

operation, the flyback peak should be at least 5V but not

greater than V

ceptable. See

. Any pulse width greater than 1.5 µs is ac-

CC

Figure 8

for the input schematic.

Pin 7 — H DRIVE: This is an open-collector output which

provides the drive pulse for the high power deflection circuit.

The pulse duty cycle is controlled by pin 4. Polarity convention: Horizontal deflection output transistor is on when H

DRIVE OUT is low. See

Figure 9

for the output schematic.

Pin 8— GND: System ground. For best jitter performance,

all bypass capacitors should be connected to this pin via

=

short paths.

Pin 9— PD2 FILTER: The low-pass filter cap of between

0.01 µF to 1 µF for the output of phase detector 2 is connected from this pin to pin 8 (GND) via a short path. A

smaller value increases the response.

Pin 10— PHASE: A DC control voltage applied to this pin

=

sets the phase of the flyback pulse with respect to thecenter

of H sync. See

Figure 10

for the input schematic.

Pin 11— FVC FILTER: A 1 µF capacitor is connected from

this pin to pin 8 (GND) via a short path.

Pin 12 — PD1 OUT/VCO IN: Phase detector 1 has a gated

charge pump output which requires an external low-pass filter. For best jitter performance, the filter should be grounded

to pin 8 (GND) via a short path. Ifa voltagesource is applied

to this pin, the phase detector is disabled and the VCO can

be controlled directly.

Pin 13— V

8.2V reference. It should be decoupled to pin 8 (GND) via a

: This is the decoupling pin for the internal

REF

short path with a cap of at least 470 µF. Do not load this pin.

Pin 14 —V

should be decoupled to pin 8 (GND) via a short path with a

: 12V nominal power supply pin. This pin

CC

cap of at least 47 µF.

has to be reduced

for the input sche-

FIGURE 4.

DS012917-4

DS012917-5

FIGURE 5.

www.national.com5

Page 6

Input/Output Schematics (Continued)

DS012917-7

FIGURE 7.

DS012917-6

FIGURE 6.

DS012917-9

FIGURE 9.

DS012917-8

FIGURE 8.

www.national.com 6

DS012917-10

FIGURE 10.

Page 7

Application Hints

1. Phase Control for Geometry Correction: Pin 10

(PHASE) is designed to control static phase (picture

horizontal position) as well as dynamic phase for geometry correction. Complete control of static and dynamic

phase can be achieved by superposing a correction

waveform (Sawtooth and/or parabola) onthe DC control

voltage at pin 10 (see

2. Programmable Frequency Ramping: H frequency

transitions from high to low present aspecial problem for

deflection output stages without current limiting. If, during such a transition, the output transistor on-time increases excessively before the B+ voltage has decreased to its final level, then the deflection inductor

current ramps too high and the induced flyback pulse

can exceed the breakdownvoltage, BV

transistor.To prevent this, the rate of change of the VCO

frequency must be limited.

Figure 12

).

, of the output

CEX

Recommended Phase Voltage for 640 x 480

Consider a scanning mode transitionat t=0 from f

The VCO frequency as a function of time, f

scribed by the equation,

f

(t)≅f

+(

f

−

f

VCO

1

where τ=40x10

) (1 – exp (−t/τ)),

2

1

3

xC

FVC

.

VCO

to f2.

1

(t), is de-

The above equation can be used to predict VCO behavior during frequency transitions, but in practice the value

of C

is most easily determined empirically. In general,

FVC

large values minimize the chance of exceeding BV

but generate long PLL capture times.

CEX

3. Phase Voltage Range vs Delay Time: The recommended phase voltage range to use on pin 10 (PHASE)

depends on the delay time of the deflection output stage.

Delay time is defined as the time from the rising edge of

H Drive to the center of flyback. For best performance

the phase voltage range should be inthe unshadedarea

of

Figure 11

.

@

60 Hz

,

FIGURE 11.

DS012917-11

www.national.com7

Page 8

Typical Application

*Actual value depends on the application and the ambient noise level inside the monitor.

FIGURE 12.

DS012917-12

www.national.com 8

Page 9

Physical Dimensions inches (millimeters) unless otherwise noted

Order Number LM1290N

NS Package Number N14A

LM1290 Autosync Horizontal Deflection Processor

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80-532 78 32

Français Tel: +49 (0) 1 80-532 93 58

Italiano Tel: +49 (0) 1 80-534 16 80

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

Loading...

Loading...