Page 1

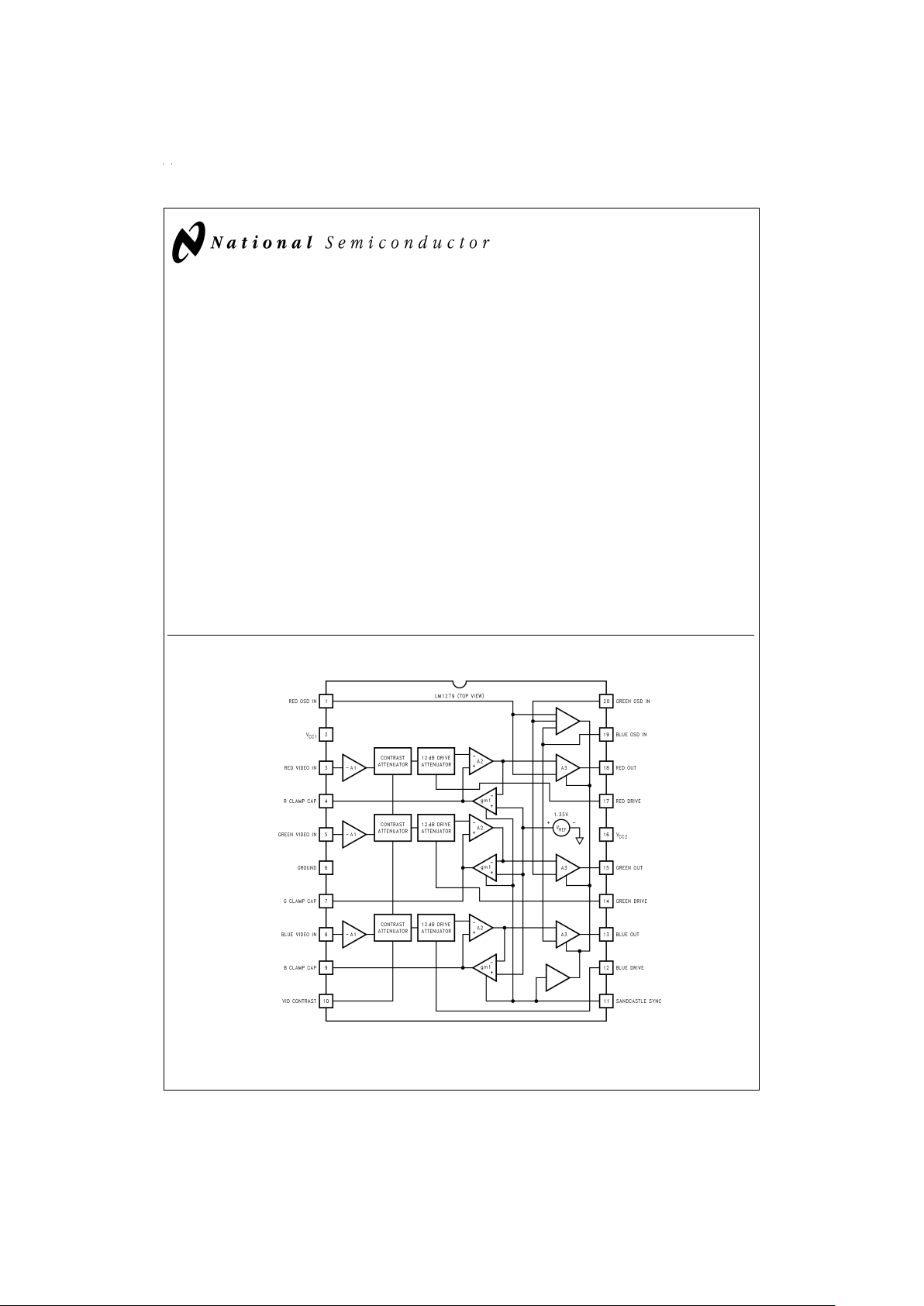

LM1279

110 MHz RGB Video Amplifier System with OSD

General Description

The LM1279 is a full featured and low cost video amplifier

with OSD (On Screen Display). 8V operation for low power

and increased reliability. Supplied in a 20-pin DIP package,

accommodating very compact designs of the video channel

requiring OSD. All video functions controlled by 0V to 4V

high impedance DC inputs. This provides easy interfacing to

5V DACs used in computer controlled systems and digital

alignment systems. Unique OSD switching, no OSD switching signalrequired.An OSDsignal at any OSD inputtypically

switches the LM1279 to the OSD mode within 5 ns. Ideal

video amplifier for the low cost OSD monitor with resolutions

up to 1280 x1024. The LM1279 provides superior protection

against ESD. Excellent alternative for the MC13282 in new

designs.

Features

n Three wideband video amplifiers 110 MHz@−3dB (4

V

PP

output)

n OSD signal to any OSD input pin automatically switches

all 3 outputs to the OSD mode

n Fast OSD switching time, typically 5 ns

n 3.5 kV ESD protection

n Fixed cutoff level typically set to 1.35V

n 0V to 4V, high impedance DC contrast control with over

40 dB range

n 0V to 4V, high impedance DC drive control (0 dB to

−12 dB range)

n Matched (

±

0.3 dB or 3.5%) attenuators for contrast

control

n Output stage directly drives CRT drivers

n Ideal combination with LM2407 CRT driver

Applications

n High resolution RGB CRT monitors

n Video AGC amplifiers

n Wideband amplifiers with contrast and drive controls

n Interface amplifiers for LCD or CCD systems

Block and Connection Diagram

DS100091-1

FIGURE 1. Order Number LM1279N

See NS Package Number N20A

September 1998

LM1279 110 MHz RGB Video Amplifier System with OSD

© 1998 National Semiconductor Corporation DS100091 www.national.com

Page 2

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage

Pins 2 and 16 (Note 3) 10V

Peak Video Output Source Current

(Any One Amp) Pins 13, 15, or 18 28 mA

Voltage at Any Input Pin (V

IN

)V

CC

≥ VIN≥ GND

Power Dissipation (P

D

)

(Above 25˚C Derate Based on θ

JA

and TJ) 2.1W

Thermal Resistance to Ambient (θ

JA

) 60˚C/W

Thermal Resistance to Case (θ

JA

) 37˚C/W

Junction Temperature (T

J

) 150˚C

ESD Susceptibility (Note 4) 3.5 kV

ESD Machine Model (Note 16) 300V

Storage Temperature −65˚C to 150˚C

Lead Temperature

(Soldering, 10 sec.) 265˚C

Operating Ratings (Note 2)

Temperature Range 0˚C to 70˚C

Supply Voltage (V

CC

)

7.5V ≤ V

CC

≤

8.5V

DC Electrical Characteristics

TA= 25˚C; V

CC1=VCC2

= 8V; V10= 4V; V

Drive

= 4V; V11= 7V; V

OSD

= 0V; RL= 390Ω unless otherwise stated.

Symbol Parameter Condition

Typical

(Note 5)

Limit

(Note 6)

Units

I

S

Supply Current I

CC1+ICC2−ILoad

(Note 7) 80 90 mA(max)

V

3, 5, 8

Video Amplifier Input Bias Voltage 2.5 V

R

IN

Video Input Resistance Any One Amplifier 20 kΩ

V

11off

Sandcastle Off Voltage 1.4 1.2 V (max)

V

11blank

Sandcastle Blank Voltage Start of Blank Region 1.4 1.7 V (min)

V

11blank

Sandcastle Blank Voltage End of Blank Region 2.8 3.2 V (max)

V

11clamp &

Blank

Sandcastle Clamp and Blank On

Voltage

Start of Clamp and Blank

Region

3.2 3.6 V (min)

V

11clamp &

Blank

Sandcastle Clamp and Blank On

Voltage

End of Clamp and Blank

Region

6.2 5.8 V (max)

V

11clamp

Sandcastle Clamp On/Blank Off

Voltage

Clamp Only Region, Max =

V

CC

6.2 6.5 V (min)

I

11off

Sandcastle Off Current V11= 0V −5.0 −8.0 µA(max)

I

11test

Sandcastle Clamp On/Blank Off

Curr

V11= 6.5V

−100 −500 nA(max)

I

clamp

Clamp Cap Charge Current Clamp Comparators On

±

750

±

500 µA(min)

I

bias

Clamp Cap Bias Discharge

Current

Clamp Comparators Off

50 200 nA (max)

V

OL

Video Black Level V

Video in

= 0V, V11= 6.5V 1.35 1.55 V (max)

∆V

OL

Video ∆Black Level Output

Voltage

Between Any Two Amplifiers

±

50

±

200 mV (max)

V

OH

Video Output High Voltage V

11

<

1.2V 5.0 4.6 V (min)

I

10, 12, 14, 17

Contrast/Drive Control Input

Current

V

Contrast=VDrive

=0Vto4V

−0.25 −1.5 µA (max)

I

1l, 19l, 20l

OSD Low Input Current (each) V

OSD in

= 0V −2.5 −10.0 µA(max)

I

1h, 19h, 20h

OSD High Input Current (each) V

OSD in

= 5V 100 130 µA(max)

V

OL

(Blank) Video Output during Blanking V11= 1.7V 0.1 0.5 V (max)

AC Electical Characteristics

TA= 25˚C; V

CC1=VCC2

= 8V. Manually adjust Video Output pins 13, 15, and 18 to 4V DC for the AC test unless otherwise

stated. (Note 15)

Symbol Parameter Conditions

Typical

(Note 5)

Limit

(Note 6)

Units

A

Vmax

Video Amplifier Gain V10= 4V, VIN= 635 mV

PP

6.8 5.9 V/V (min)

V

drive

= 4V 16.7 15.4 dB (min)

∆A

V2V

Contrast Attenuation@2V Ref: AVmax, V10=2V −6 dB

www.national.com 2

Page 3

AC Electical Characteristics (Continued)

TA= 25˚C; V

CC1=VCC2

= 8V. Manually adjust Video Output pins 13, 15, and 18 to 4V DC for the AC test unless otherwise

stated. (Note 15)

Symbol Parameter Conditions

Typical

(Note 5)

Limit

(Note 6)

Units

∆A

V 0.25V

Contrast Attenuation@0V Ref: AVmax, V10= 0V −35 dB

∆Drive Drive Control Range V

drive

=0Vto4V,V10=4V 12 dB

A

V match

Absolute Gain Match@AVmax V10= 4V, V

drive

= 4V (Note 9)

±

0.3 dB

A

V track

Gain Change Between Amplifiers V10= 4V to 2V (Notes 9, 10)

±

0.3 dB

f(−3 dB) Video Amplifier Bandwidth V

10

= 4V, V

drive

= 4V,

110 MHz

(Notes 11, 12)) V

O

= 3.5 V

P-P

tr(Video) Video Output Rise Time VO= 3.5 V

P-P

(Note 11) 3.6 ns

t

f

(Video) Video Output Fall Time VO= 3.5 V

P-P

(Note 11) 3.2 ns

V

sep

10 kHz Video Amplifier 10 kHz Isolation V10= 4V (Note 13) −70 dB

V

sep

10 MHz Video Amplifier 10 MHz Isolation V10= 4V (Notes 11, 13) −50 dB

∆V

OL

(OSD) OSD Black Level, Difference from

Video Black Level

V

OSD in

= 0.8V, OSD Mode

−0.4 −0.7 V (max)

V

OH

(OSD) OSD Output High Voltage (above

measured video black level)

V

OSD in

= 2.5V, OSD Mode

2.1 2.4 V (max)

t

r

(OSD) Going into OSD Mode OSD Mode (

Figure 2

) 5.0 ns

t

f

(OSD) Going out of OSD Mode OSD Mode (

Figure 2

) 10.0 ns

t

r-prop

(OSD) Starting OSD Propagation Delay Switching to OSD Mode (

Figure 3

) 13.0 ns

t

f-prop

(OSD) Ending OSD Propagation Delay Switching to Vid. Mode (

Figure 3

) 14.0 ns

T

pw

(Clamp) Input Clamp Pulse Width (Part of

Sandcastle Sync)

(Note 14)

200 ns (min)

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur.

Note 2: Operating Ratings indicate conditionsfor which the device is functional, butdo not guarantee specific performance limits. Forguaranteed specifications and

test conditions, see the Electrical Characteristics. The guaranteed specifications apply only for the test conditions listed. Some performance characteristics may degrade when the device is not operated under the listed test conditions.

Note 3: V

CC

supply pins 2 and 16 must be externally wired together to prevent internal damage during VCCpower on/off cycles.

Note 4: Human body model, 100 pF discharged through a 1.5 kΩ resistor.

Note 5: Typical specifications are specified at +25˚C and represent the most likely parametric norm.

Note 6: Tested limits are guaranteed to National’s AOQL (Average Outgoing Quality Level).

Note 7: The supply current specified is the current for V

CC1

and V

CC2

minus the current through RL(I

supply=ICC1+ICC2−IL

). The supply current for V

CC2

(pin 16)

does depend on the output load. With video output at 1V DC, the additional current through V

CC2

is 7.7 mA with RL= 390Ω.

Note 8: Output voltage is dependent on load resistor. Test circuit uses R

L

= 390Ω.

Note 9: Measure gain difference between any two amplifiers. V

IN

= 635 mVPP.

Note 10: ∆A

V

track is a measure of the ability of any two amplifiers to track each other and quantifies the matching of the three attenuators. It is the difference in

gain change between any two amplifiers with the contrast voltage (V

10

) at either 4V or 2V measured relative to an AVmax condition, V10= 4V. For example, at A

V

max the three amplifiers’ gains might be 17.1 dB, 16.9 dB, and 16.8 dB and change to 11.2 dB, 10.9 dB and 10.7 dB respectively for V10= 2V. This yields the measured typical

±

0.1 dB channel tracking.

Note 11: When measuring video amplifier bandwidth or pulse rise and fall times, a double sided full ground plane printed circuit board without socked is recommended. Video amplifier 10 MHz isolation test alsorequires this printed circuit board. The reason for a double sided full groundplane PCBis that large measurement

variations occur in single sided PCBs.

Note 12: Adjust input frequency from 10 MHz (A

V

max reference level) to the −3 dB corner frequency (f

−3 dB

).

Note 13: Measure output levels of the othertwo undriven amplifiers relative to the driven amplifier to determine channelseparation. Terminate the undriven amplifier

inputs to simulate generator loading. Repeat test at f

IN

= 10 MHz for V

sep

10 MHz.

Note 14: A minimum pulse width of 200 ns is guaranteed for a horizontal line of 15 kHz. This limit is guaranteed by design. If a lower line rate is used then a longer

clamp pulse may be required.

Note 15: During theAC test the 4V DC level is the center voltage of the AC output signal. For example, if the output is 4 V

PP

the signal will swing between 2V DC

and 6V DC.

Note 16: Machine Model ESD test is covered by specification EIAJ IC-121-1981. A 200 pF cap is charged to the specified voltage, then discharged directly into the

IC with no external series resistor (resistance of discharge path must be under 50Ω).

www.national.com3

Page 4

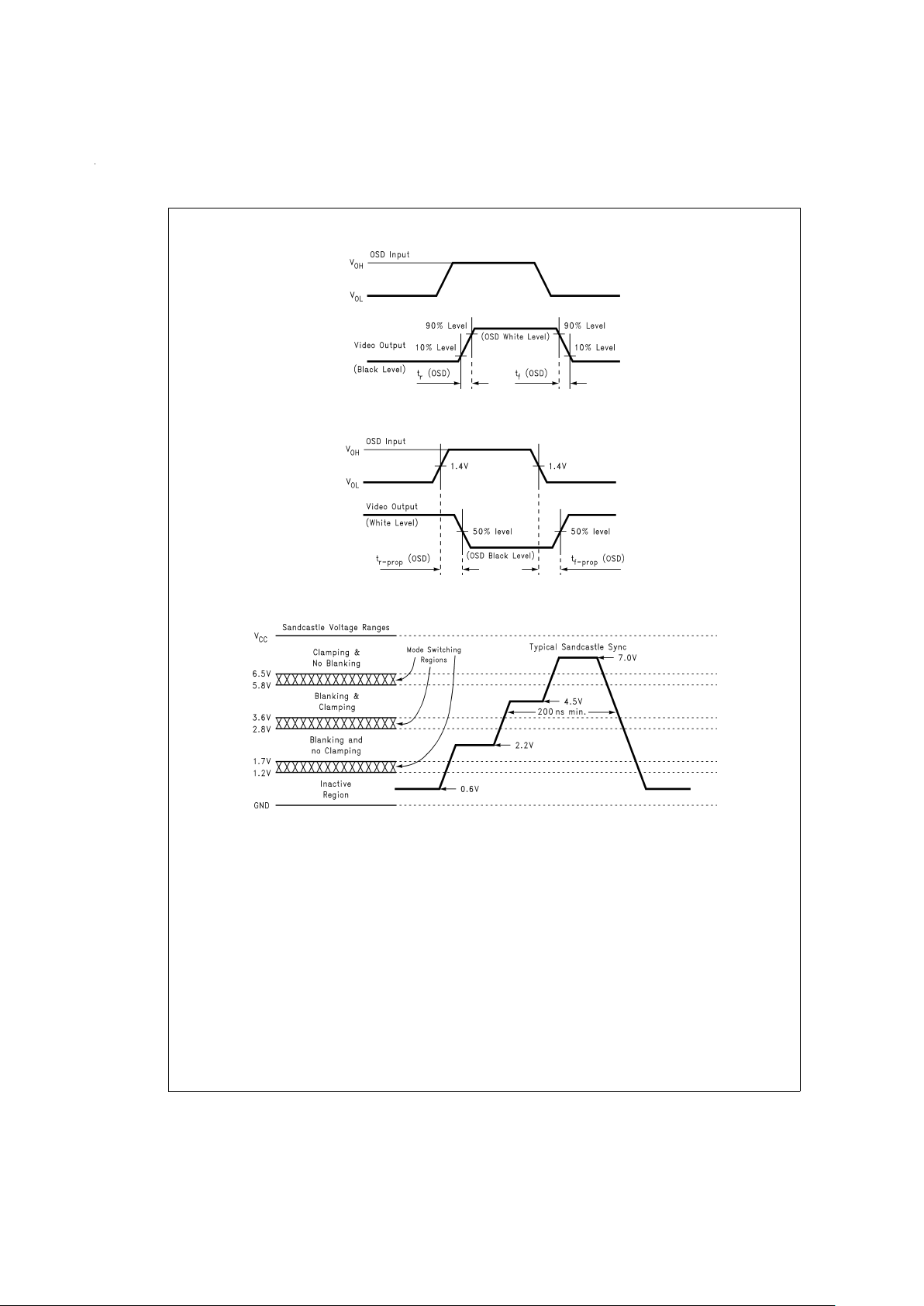

Timing Diagrams

DS100091-2

FIGURE 2. OSD Rise and Fall Times

DS100091-3

FIGURE 3. OSD Propagation Delays

DS100091-4

FIGURE 4. Sandcastle Sync Pulse

www.national.com 4

Page 5

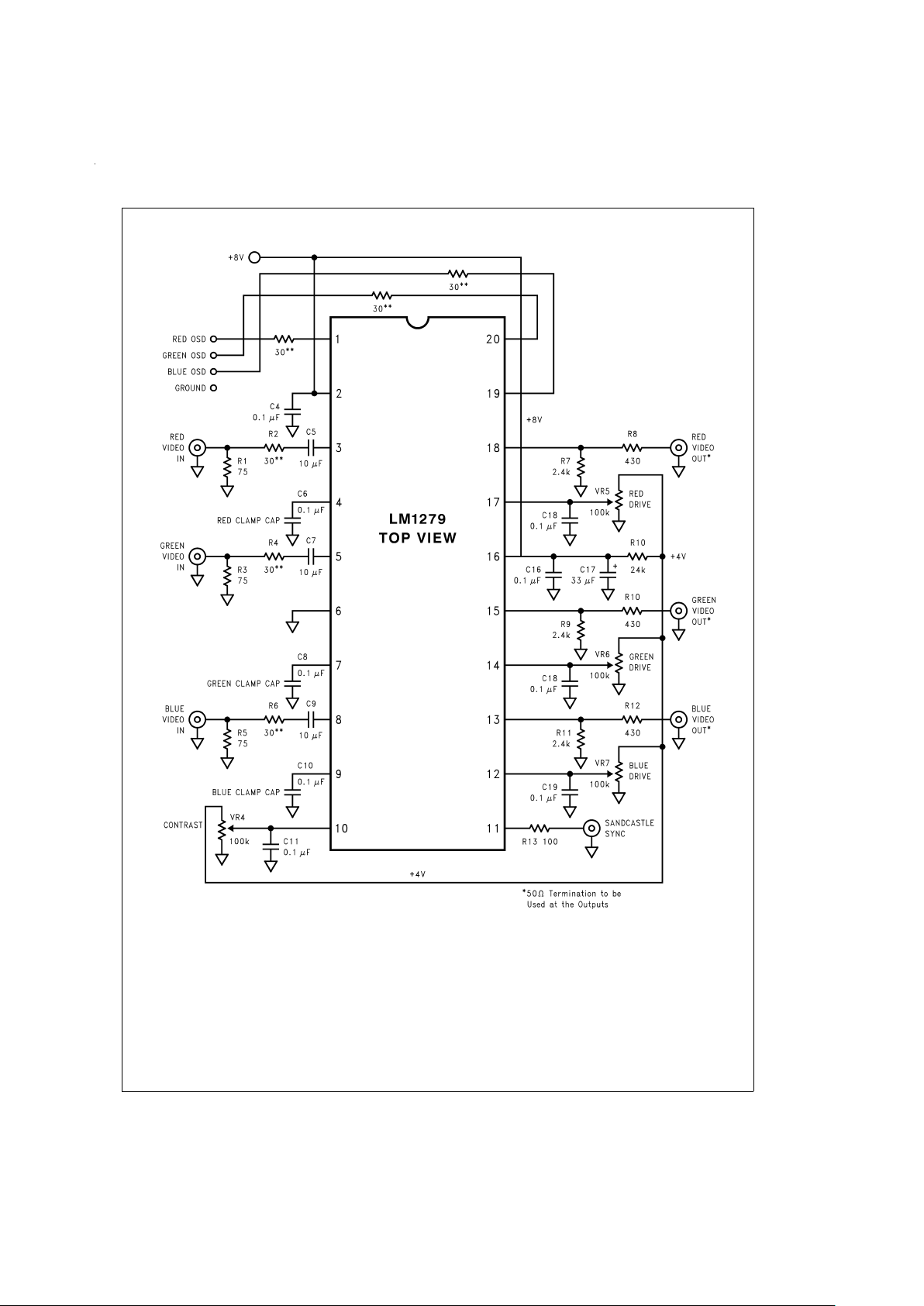

Test Circuits

DS100091-5

**Note: All video inputs

must

have a series 30Ω resistor for protection against EOS (Electrical Over Stress). If the OSD signals are external to the monitor, or

these signals are present any time when +8V is not fully powered up, then the OSD inputs also

require

a series 30Ω resistor.

FIGURE 5. LM1279 OSD Video Pre-amp Demonstration Board Schematic

www.national.com5

Page 6

Pin Descriptions

Pin

No.

Pin

Name

Schematic Description

1 Red OSD Input

These are standard TTL inputs. An OSD

signal at any of the three pins will

automatically switch the pre-amp into the

OSD mode. 7 colors, including white, are

available.

19 Blue OSD Input

20 Green OSD Input

2V

CC1

Power supply pin (excluding output stage)

3 Red Video In

Video inputs. These inputs

must

be AC

Coupled with a minimum ofa1µFcap, 10

µF is preferred. A series resistor of about

33Ω must be used for ESD protection.

5 Green Video In

8 Blue Video In

4 Red Clamp Cap

The external clamp cap is charged and

discharged to the correction voltage

needed for DC restoration. 0.1 µF is the

recommended value.

7 Green Clamp Cap

9 Blue Clamp Cap

6 Ground Ground pin.

10 Contrast

Contrast control pin:

4V - no attenuation

0V - over 40 dB attenuation

Drive control pins:

4V - no attenuation

0V - 20 dB attenuation

12 Blue Drive

14 Green Drive

17 Red Drive

11 Sandcastle Input

The sandcastle input allows for blanking

only, or blanking with DC restoration.

Blanking requires a 2V input. Clamping

with blanking requires a 4V input.

13 Blue Video Out

Video output. For proper black level the

output must drive 390Ω impedance.

15 Green Video Out

18 Red Video Out

www.national.com 6

Page 7

Pin Descriptions (Continued)

Pin

No.

Pin

Name

Schematic Description

16 V

CC2

Power supply pin for the output stage.

There are no internal connections to V

CC1

.

ESD and Arc-Over Protection

The ESD cells of the LM1279 are improved over the ESD

cells used in typical video pre-amps. The monitor designer

must still use good PC board layout techniques when designing with the LM1279. The human body model ESD susceptibility of these parts is rated at 3 kV (Note 4). However,

many monitor manufacturers are now testing their monitors

to thelevel 4 of the IEC801-2 specification. This requiresthe

inputs to the monitor to survive an 8 kV discharge. If the

monitor designer expects to survive such levels he MUST

provide external ESDprotection to the video pre-amp inputs!

PC board layout is very important with LM1279 as with other

video pre-amps. The LM1279 provides excellent protection

against ESDand arc-over, butthe LM1279 is not asubstitute

for good PCB layout.

Figure 6

shows the recommended input protection for a

video pre-amp. The two diodes at the video pre-amp input

and after the 30Ω series resistor offers the best protection

against ESD. When this protection is combined with a good

PCB layout, the video pre-amp will easily survive the IEC

801-2 level 4 (8 kV ESD) testing commonly done by monitor

manufacturers. If the protection diodes are moved to the

video input side of the 30Ω resistor, then the ESD protection

will be less effective. There is also the risk of damaging the

diodes since there is no resistor for current limiting. In such

a design a heavier duty diode, such as the FDH400, should

be used. It is strongly recommended that the protection diodes be added as shownin

Figure 6

. The 1N4148 diode has

a maximum capacitance of 4 pF.This would have little affect

on the response of the video system due to the low impedance of the input video.

Many monitor designers prefer to use a single zener diode

instead of the recommended two diodes at the video preamp input. The required location of the zener diode is shown

in

Figure 6

. It is shown as a dashed line, indicating an alternative to the two diode solution. The zener diode does give

the savings of onecomponent, but now the protection is less

effective. To minimize capacitance, the zener diode needs to

have a zener voltage of 24V or higher. This is well above the

V

CC

voltage of the LM1279. The zener diode must be located at the video input for protection against a low voltage

surge. The 30Ωresistor is needed to limit the current of such

a voltage surge, protecting the video pre-amp. Protection

against ESD by using a zener diode is about as effective as

having the two diodes at the video input (same location as

the zener diode). A higher series resistor may be necessary

for protection against the zener voltage, but the higher resistor value will impair the performance of the LM1279; resulting in a lower bandwidth and a less stable black level. For

maximum reliabilitythe monitor designer should notconsider

the zener diode solution for ESD protection of the LM1279.

The ESD cells of the LM1279 also gives good tolerance

against arc-over. Once again the monitor designer must be

careful in his PCB layout for good arc-over protection. In the

video chain only the outputs of the CRT driver are directly

exposed to the voltages that may occur during arc-over. A

good PCB layout isthe best protection for the video pre-amp

against arc-over.The pre-amp vulnerability is mainlythrough

the ground traces on the PCB. For proper operation all

ground connections associated with the video pre-amp, including the grounds to the bypass capacitors, must have

short returns to the ground pins. A significant ground plane

should be used to connect all the pre-amp grounds.

Figure

16

, the demo board layout, is an excellent example on an effective ground plane, yet using only a single sided PCB layout. Here is a check list to make sure a PC board layout has

good grounding:

•

All associated grounds with the video pre-amp are connected together through a large ground plane.

•

CRT driver ground is connected to the video pre-amp

ground at one point.

•

CRTand arc protection grounds are connecteddirectly to

chassis, or the main ground. There is no arc-over current

flow from these grounds through the pre-amp or CRT

driver grounds.

If any one of the above suggestions are not followed, then

the LM1279 may become vulnerable to arc-over. Improper

grounding is by far the most common cause of a video preamp failure during arc-over.

Functional Description

Figure 1

on the front page shows the block diagram of the

LM1279 along with the pinout of the IC. Each channel receives a video input signal at its input amplifier (-A1). The

output of the input amplifier goes to the contrast attenuator

stage. Foreasy interfacing to 5V DACsall controls inputs, including the contrast control, use a 0V to 4V range. The contrast control has no attenuation with an input of 4V, and has

full attenuation (over −40 dB) with a 0V input.All three channels will accurately track the contrast control setting at pin

10. Each channel will have the same amount of attenuation

for a given input voltage typically to within

±

0.3 dB.All channels will track because the contrast control is the first stage

of attenuation and the internal control voltage generated

from the input voltage is common to all three channels.

The output of the contrast attenuator goes to the drive attenuator.This stage has a 12 dB control range. This stage is

used for color balance, so the adjustment range has been

limited to 12 dB for a more accurate color balance. Each

DS100091-12

FIGURE 6. Recommended Video Input ESD Protection

www.national.com7

Page 8

Functional Description (Continued)

channel has its own independent control pin with the 0V to

4V control range. An input of 4V give no attenuation, and an

input of 0V gives the full 12 dB attenuation.

The output of thedrive attenuator stage goes to the inverting

input ofA2. Since this is the second inversion stage, the output of A2 will be the non-inverted video signal. Note that the

output ofgm1 goes to thenon-inverting input ofA2. Also note

that the output of A2 goes to the inverting input of gm1. This

is thefeedback for the clampcircuitry. Theoutput stage ofA2

is an exact duplicate of the video output through A3. If a

390Ω load impedance is used at the video output, then the

black level at the output stage will accuratelytrack the output

ofA2. The otherinput to gm1 isthe desired black leveloutput

of theLM1279. Since the LM1279has a fixed blacklevel output, the non-inverting inputs to gm1 in all three channels go

to a fixed 1.35V internal reference. This sets the black level

output to a nominal 1.35V. gm1 acts like a sample and hold

amplifier.Once the sandcastle syncexceeds 3.6V gm1 isactivated, driving the input ofA2 to a level where the video output will be 1.35V. For proper DC restoration it is important

that gm1 be activated only during the horizontal flyback time

when the video is at the black level. gm1 also charges the

clamp cap to the correct voltage to maintain a 1.35V black

level at the video output. When gm1 is turned off the voltage

stored on the clamp cap will maintain the correct black level

during the active video, thus restoring the DC level for a

1.35V black level.

The input ofA3 receives the outputfrom A2. The video chan-

nel of A3 is a duplication of the output stage to A2. As mentioned in the previous paragraph this is done so that the DC

restoration can be done at theA2 stage. A3also receives the

OSD input and a sandcastle input for blanking. By doing DC

restoration at the A2 stage, OSD or blanking can be activated at the output stage during the time DC restoration is

being done at A2. There is an interface circuit between the

sandcastle input and theA3 output stages. This interfacecircuit will activate the blanking if the sandcastle sync input is

between 1.7V and 6.0V. The blanking mode will force the

output down to a level of about 0.1V. This is a blacker-thanblack level and can be used for blanking at the cathodes of

the CRT.

Once the sandcastle exceeds 6.5V, then the output will no

longer be in the blanked mode, but DC restoration is still being done on the video signal.

The OSD signalgoes into a special interface circuit.The output of this circuit will drive the output of A3 to either an OSD

black level or to about 2.4V above the video black level

(OSD white level). The OSD black level is about 300 mV below the video black level. This guarantees that if the OSD

signal is notactivated for a particular channel, then itsoutput

will be slightly below the cutoff level. If an OSD input is received ina particular channel, then the video output will beat

the OSD white level. The OSD mode is automatically activated if there is only one OSD signal to any of the video

channels. This OSD control circuit will allow any color, except black, during the OSD mode. This also saves the need

for a special signal to switchinto the OSD mode. Remember

that at least one OSD input must be high to enable the OSD

mode, therefore black can’t be used in the OSD window.

Sandcastle Sync

This special sync signal is used to allow for a 20-pin OSD

video pre-amp with all the desiredcontrols. By using a sandcastle sync, both clamping and blanking can be activated

from the same pin.

Figure 4

shows the sandcastle sync signal. There are four possible modes of operation with the

Sandcastle pulse. These modes are:

1. Inactive Region

2. Blanking and no Clamping

3. Blanking and Clamping

4. Clamping and no Blanking

Figure 4

also shows the voltage levels where the LM1279

switches from one mode to the other mode. As an example

the LM1279 will switch from the inactive mode to the blanking and no clamping mode between 1.2V and 1.7V. For

proper operation the inactive input must be safely below the

1.2V level. The blanking with no clamping pulse must be

safely above 1.7V and below 2.8V. Blanking and clamping

must be between 3.6V and 5.8V. Clamping and no blanking

must be above 6.5V with the maximum voltage being limited

by V

CC

.

If the monitor designer desires to blank at the cathode, then

he would go into the blanking and no clamping mode for

most of the flyback period. During this period it is also necessary to do DC restoration. During this time the LM1279

should be operated in the blanking and clamping mode. In

this mode DC restoration is done without interfering with

blanking.

In some designs the horizontal phase shift capability of the

monitor is very large. In these designs the video can be

moved so the flyback period can be displayed during the active trace period for the video. Now the clamping could be

done during the normal video sweep time. During this period

clamping with blanking will give a black bar on the CRT

screen. This is not a normal operating mode of the monitor,

but the monitor designer still may prefer not to display this

black bar. Under this condition the clamp pulse must be

above 6.5V.

A simple two transistor sandcastle generator is covered in

separate application note. This circuit will generate all four

states for the sandcastle sync, including the clamp with no

blanking when the clamping function occurs during the period for active video. The switching timebetween the inactive

region and the clamp only region must be less than 30 ns if

complete elimination of any blanking pulse is required in an

application.

Applications of the LM1279

Two demonstration boards are available to evaluate the

LM1279. One board is the pre-amp demonstration board.

This board was used for testing and characterizing the

LM1279. The schematic for this board is shown in

Figure 5

and the printed circuit layout for this board is shown in

Figure

7

. The other board is a complete video channel neck board

that can be directly plugged into the CRT socket. The schematic for this boardis shown in

Figure 10

and the printed cir-

cuit layout is shown in

Figure 11

. The CRT driver used on

this board is the LM2407. Any of National’s monolithic CRT

drivers can be used in this board, but the LM2407 is considered the best match to the LM1279 based on cost and performance.

Some important notes on

Figure 5

. All three video inputs

have a 75Ω terminating resistor for a 75Ωvideo system. This

is the normal video impedance of the video from a computer

system. It is possible to also have a 50Ω system, then R1,

R3, and R5would be changed to 50Ω. R2, R4, and R6 are in

series with the video inputs of theLM1279. These three 30Ω

resistors are required to protect theIC from any sudden volt-

www.national.com 8

Page 9

Applications of the LM1279 (Continued)

age surges that may result during the power up and power

down modes, or when connecting the monitorto other equipment. The monitor designer must include these resistors in

his design for good monitor reliability. If additional protection

against ESD at the video inputs is necessary, then adding

clamp diodes on the IC side of the 30Ω resistors is recommended, one to V

CC1

and one to ground (see

Figure 6

).

Sometimes a designer maywant to increase the value of the

30Ω resistors at the video inputs, for additional ESD protection. Thisis not recommended with the LM1279.C5, C7, and

C9 are part of the DC restoration circuit. This circuit is depending on a total maximum circuit resistance of about

110Ω;30Ωinput series resistor plus 75Ω for the video termi-

nation resistor. Increasing the value of the 30Ω resistors will

exceed the 110Ωlimit. The excellent internal ESD protection

and the external clamp diodes (if needed) will provide excellent ESD protection.

The 30Ω resistors in series with the OSD inputs are also

necessary if the OSD signals are external to the monitor, or

if these signals are present any time when the +8V is not

fully powered up. Interfacing to the OSD inputs is quite easy

since thesignal processing necessary tomatch the OSD signals to the video levels is done internal by the LM1279.

There is also no need for an OSD window signal. Any time

there is a highTTL signal at any of the three OSD inputs, the

LM1279 will automatically switch to the OSD mode. A high

TTL OSD signal will give a high video output for that color.

The OSD level is fixed, typically 2.3V above the video black

level. This will give a fixed brightness to the OSD window,

but not at maximum video brightness which could be unpleasant to the user.

Figure 2

and

Figure 3

show the timing

diagrams of the OSD signals for the LM1279.

The recommended load impedance forthe LM1279 is 390Ω.

However, some changes in the load impedance can be

made. If the load impedance is reduced, the monitor designer mustconfirm that the part isstill operating in itsproper

die temperature range, never exceeding a die temperature

of 150˚C. When changing the load impedance, the black

level shift is shown in the chart below. The measured V

P-P

output with under 1%distortion is also listed.

Load V

P-P

Blk. Level Shift

430Ω 3.62V +15 mV

390Ω 3.62V 0 mV

330Ω 3.58V −25 mV

270Ω 3.51V −45 mV

When using a lower load impedance, the LM1279 does go

into hard clipping more quickly. This does reduce the headroom of the video output.

Board layout isalways critical in a high frequencyapplication

such as using the LM1279. Apoor layout canresult in ringing

of the video waveform after sudden transitions, or the part

could actually oscillate. A good ground plane and proper

routing of the +8V areimportant steps to a good PCB layout.

The LM1279 does require very good coupling between V

CC1

and V

CC2

(pins 2 and 16). This is clearly shown in

Figure 7

and

Figure 11

with the short and large trace between pins 2

and 16. Both demonstration boards offer the monitor designer an excellent example of good ground plane being

used withthe LM1279. These boardsare single sided, yetallow the LM1279 to operate at its peak performance. The

neck board also shows a good example of interfacing to a

CRT driver and to the CRT. The video signal path is kept as

short as possible between the LM1279 and the CRT driver,

and alsobetween the CRT driverand the CRT socket.Actual

performance of the LM1279 in the video pre-amp demonstration board is shown in

Figure 8

and

Figure 9

.

References

Ott, Henry W.

Noise Reduction Techniques in Electronic

Systems

, John Wiley & Sons, New York, 1976

Zahid Rahim, “Guide to CRT Video Design,” Application

Note 861, National Semiconductor Corp., Jan. 1993

www.national.com9

Page 10

Applications of the LM1279

DS100091-13

FIGURE 7. LM1279 OSD Video Pre-Åmp Demontration Board Layout

DS100091-16

FIGURE 8. LM1279 Rise Time

DS100091-17

FIGURE 9. LM1279 Fall Time

www.national.com 10

Page 11

Applications of the LM1279 (Continued)

DS100091-14

FIGURE 10. LM1279/LM2407 Demonstration Neck Board Schematic

www.national.com11

Page 12

Applications of the LM1279 (Continued)

DS100091-15

FIGURE 11. LM1279/LM2407 Demonstration Neck Board Layout

www.national.com 12

Page 13

13

Page 14

Physical Dimensions inches (millimeters) unless otherwise noted

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or systems which, (a) are intended for surgical implant into

the body, or(b) support or sustain life, and whosefailure to perform when properly used in accordance

with instructions for use provided in the labeling, can

be reasonably expectedtoresult in a significant injury

to the user.

2. A critical component in any component of a life support

device or system whose failure to perform can be reasonably expected to cause the failure of the life support

device or system,orto affect its safety or effectiveness.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

www.national.com

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80-532 78 32

Français Tel: +49 (0) 1 80-532 93 58

Italiano Tel: +49 (0) 1 80-534 16 80

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5620-6175

Fax: 81-3-5620-6179

Order Number LM1279N

NS Package Number N20A

LM1279 110 MHz RGB Video Amplifier System with OSD

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...