Page 1

LM12454/LM12458/LM12H458

12-Bit + Sign Data Acquisition System with

Self-Calibration

July 1999

LM12454/LM12458/LM12H458

12-Bit + Sign Data Acquisition System with Self-Calibration

General Description

The LM12454, LM12458, and LM12H458 are highly integrated Data Acquisition Systems. Operating on just 5V, they

combine a fully-differential self-calibrating (correcting linearity and zero errors) 13-bit (12-bit + sign) analog-to-digital

converter (ADC) and sample-and-hold (S/H) with extensive

analog functions and digital functionality. Up to 32 consecutive conversions, using two’s complement format, can be

stored in an internal 32-word (16-bit wide) FIFO data buffer.

An internal 8-word RAM can store the conversion sequence

for up to eight acquisitions through the LM12(H)458’s

eight-input multiplexer. The LM12454 has a four-channel

multiplexer,a differential multiplexer output, and a differential

S/H input. The LM12454 and LM12(H)458 can also operate

with 8-bit + sign resolution and in a supervisory “watchdog”

mode that compares an input signal against two programmable limits.

Programmable acquisition times and conversion rates are

possible through the use of internal clock-driven timers. The

reference voltage input can be externally generated for absolute or ratiometric operation or can be derived using the internal 2.5V bandgap reference.

All registers, RAM, and FIFO are directly addressable

through the high speed microprocessor interface to either an

8-bit or 16-bit databus. The LM12454 and LM12(H)458 include a direct memory access (DMA) interface for

high-speed conversion data transfer.

An evaluation/interface board is available. Order number LM12458EVAL.

Additional applications information can be found in applications notes AN-906, AN-947 and AN-949.

Key Specifications

=

(f

5 MHz; 8 MHz, H)

CLK

j

Resolution 12-bit + sign or 8-bit + sign

j

13-bit conversion time 8.8 µs, 5.5 µs (H) (max)

j

9-bit conversion time 4.2 µs, 2.6 µs (H) (max)

j

13-bit Through-put rate 88k samples/s (min),

j

Comparison time

(“watchdog” mode)

j

ILE

j

VINrange GND to V

j

Power dissipation 30 mW, 34 mW (H) (max)

j

Stand-by mode 50 µW (typ)

j

Single supply 3V to 5.5V

140k samples/s (H) (min)

2.2 µs (max),

1.4 µs (H) (max)

±

1 LSB (max)

Features

n Three operating modes: 12-bit + sign, 8-bit + sign, and

“watchdog”

n Single-ended or differential inputs

n Built-in Sample-and-Hold and 2.5V bandgap reference

n Instruction RAM and event sequencer

n 8-channel (LM12(H)458), 4-channel (LM12454)

multiplexer

n 32-word conversion FIFO

n Programmable acquisition times and conversion rates

n Self-calibration and diagnostic mode

n 8- or 16-bit wide databus dmicroprocessor or DSP

interface

+

A

Applications

n Data Logging

n Instrumentation

n Process Control

n Energy Management

n Inertial Guidance

TRI-STATE®is a registered trademark of National Semiconductor Corporation.

®

AT

is a registered trademark of International Business Machines Corporation.

© 1999 National Semiconductor Corporation DS011264 www.national.com

Page 2

Ordering Information

Guaranteed Guaranteed Order See NS

Clock Freq (min) Linearity Error (max) Part Number Package Number

8 MHz

5 MHz

±

1.0 LSB LM12H458CIV V44A

LM12H458CIVF VGZ44A

LM12H458MEL/883 EL44A

or 5962-9319502MYA

±

1.0 LSB LM12454CIV V44A

LM12458CIV V44A

LM12458CIVF VGZ44A

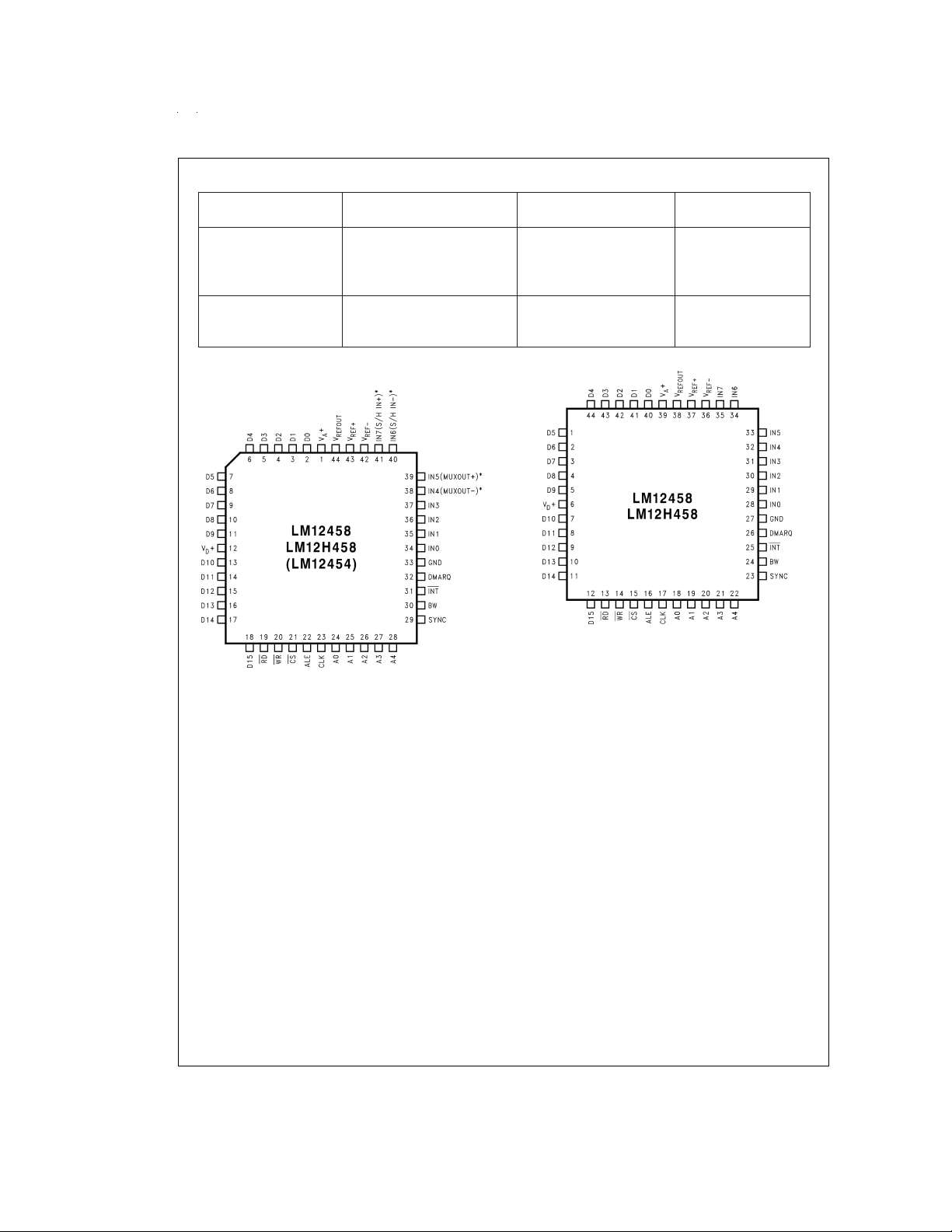

Connection Diagrams

Order Number LM12458CIVF or LM12H458CIVF

* Pin names in ( ) apply to the LM12454 and LM12H454.

DS011264-2

Order Number LM12454CIV,

LM12458CIV or LM12H458CIV

See NS Package Number V44A

Order Number LM12H458MEL/883 or 5962-9319502MYA

See NS Package Number EL44A

See NS Package Number VGZ44A

DS011264-34

www.national.com 2

Page 3

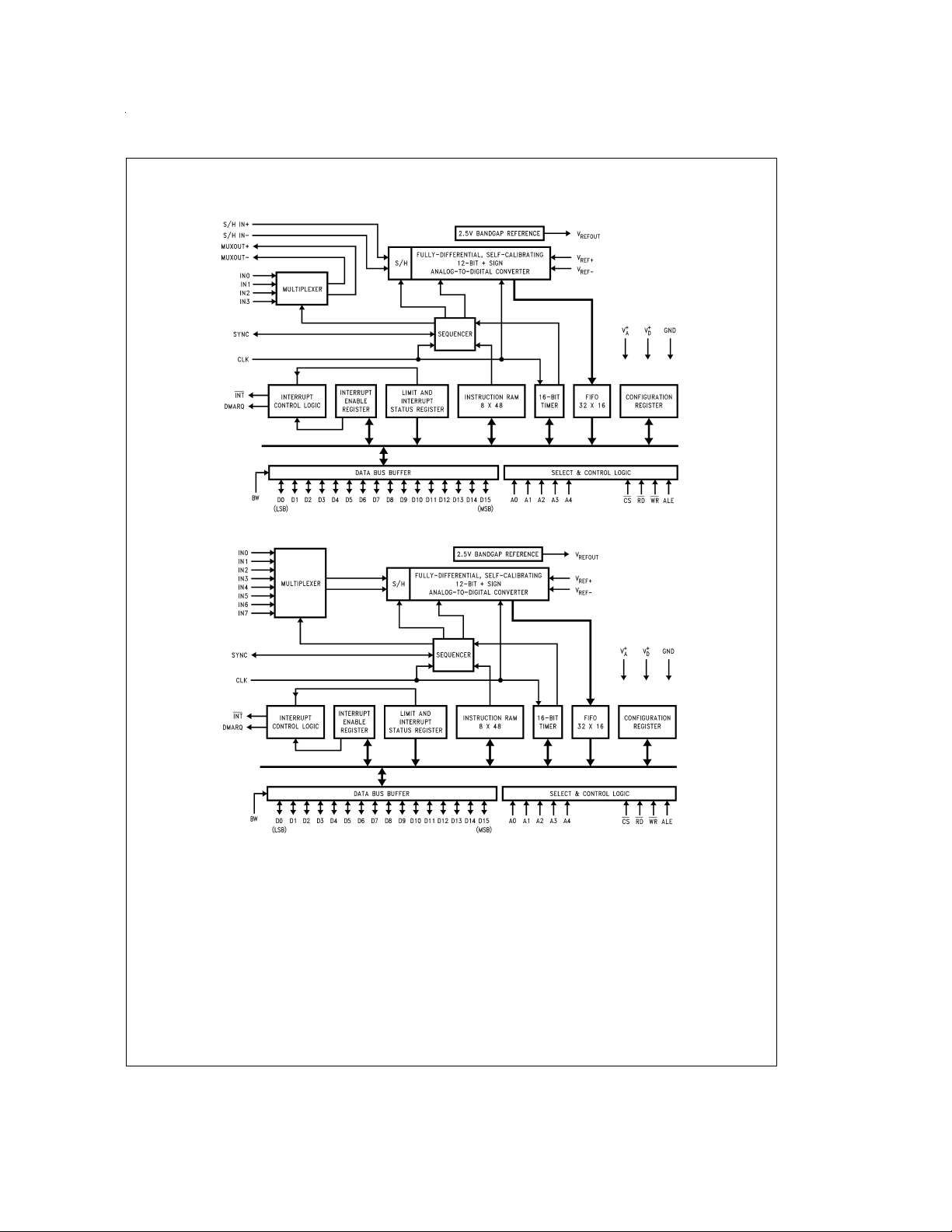

Functional Diagrams

LM12454

DS011264-1

LM12(H)458

DS011264-21

www.national.com3

Page 4

Absolute Maximum Ratings (Notes 1, 2)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage (V

Voltage at Input and Output Pins

except IN0–IN3 (LM12454) −0.3V to V

and IN0–IN7 (LM12(H)458)

Voltage at Analog Inputs IN0–IN3 (LM12454)

and IN0–IN7 (LM12(H)458) GND − 5V to V

+−VD+| 300 mV

|V

A

Input Current at Any Pin (Note 3)

Package Input Current (Note 3)

Power Dissipation (T

V Package (Note 4) 875 mW

Storage Temperature −65˚C to +150˚C

Lead Temperature

V Package, Infrared, 15 sec. +300˚C

EL and W Packages,

Solder, 10 sec. +250˚C

+ and VD+) 6.0V

A

+

+ 0.3V

+

±

5mA

±

=

25˚C)

A

20 mA

+5V

See AN-450 “Surface Mounting Methods and Their Effect on

Product Reliability” for other methods of soldering surface

mount devices.

Operating Ratings (Notes 1, 2)

Temperature Range

≤ TA≤ T

(T

min

LM12454CIV/

LM12(H)458CIV −40˚C ≤ T

LM12458MEL/883 −55˚C ≤ T

Supply Voltage

+, VD+ 3.0V to 5.5V

V

A

+−VD+| ≤100 mV

|V

A

Input Range GND ≤ V

V

IN+

Input Range GND ≤ V

V

IN−

Input Voltage 1V ≤ V

V

REF+

Input Voltage 0V ≤ V

V

REF−

V

REF+−VREF−

Common Mode

V

REF

Range (Note 16) 0.1 V

max

)

A

IN+

IN−

REF+

≤ V

REF−

REF+

1V ≤ V

REF

+

≤ V

A

REFCM

≤ 0.6 V

ESD Susceptibility (Note 5) 1.5 kV

LM12458MEL/883 2.0 kV

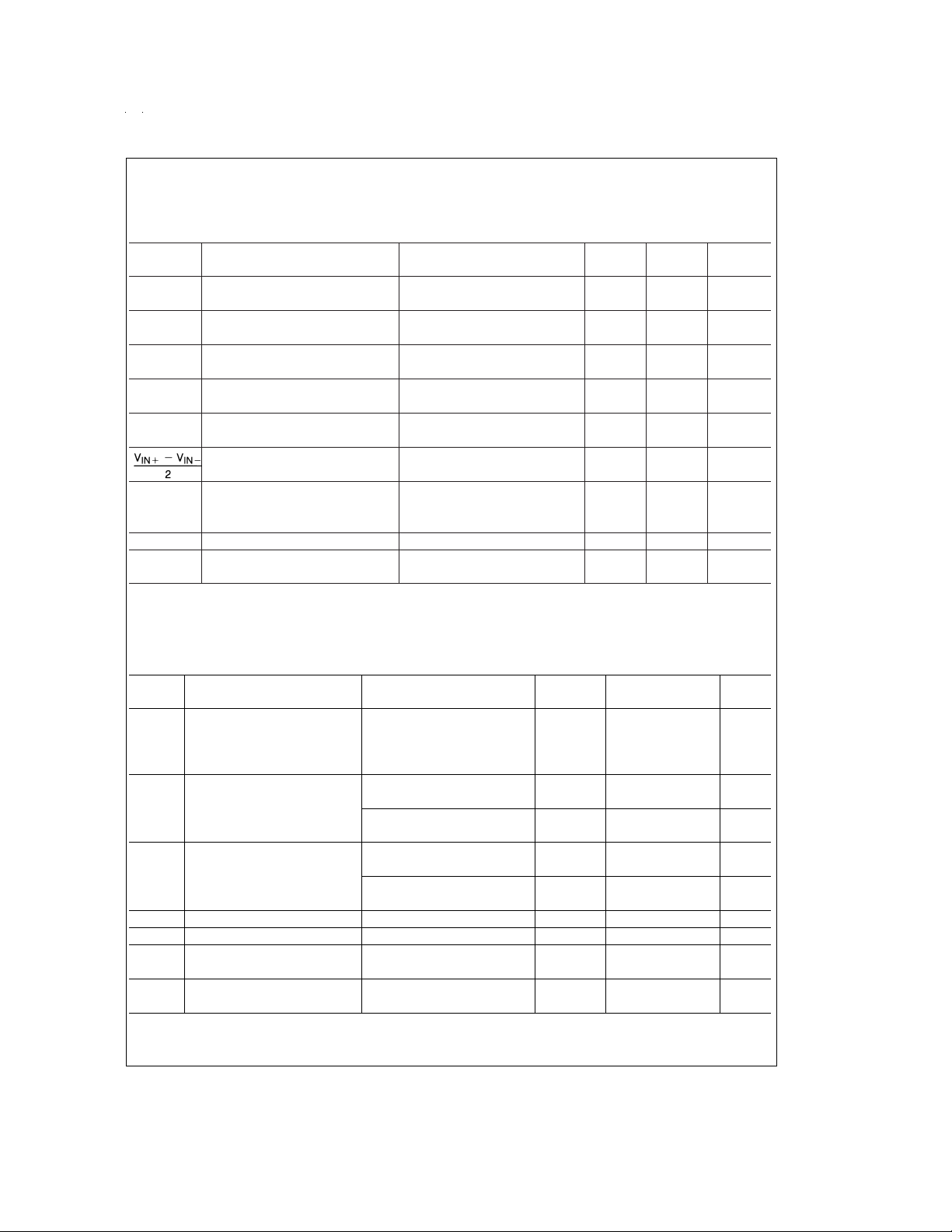

Converter Characteristics (Notes 6, 7, 8, 9, 19)

The following specifications apply to the LM12454, LM12458, and LM12H458 for VA+=VD+=5V, V

12-bit + sign conversion mode, f

and V

V

REF+

otherwise specified. Boldface limits apply for T

≤ 25Ω, fully-differential input with fixed 2.5V common-mode voltage, and minimum acquisition time unless

REF−

=

8.0 MHz (LM12H458) or f

CLK

A

=

5.0 MHz (LM12454/8), R

CLK

=

=

to T

T

T

J

MIN

; all other limits T

MAX

S

=

=

T

A

J

Symbol Parameter Conditions Typical Limits Unit

(Note 10) (Note 11) (Limit)

ILE Positive and Negative Integral After Auto-Cal (Notes 12, 17)

±

Linearity Error

TUE Total Unadjusted Error After Auto-Cal (Note 12)

±

Resolution with No Missing Codes After Auto-Cal (Note 12) 13 Bits (max)

DNL Differential Non-Linearity After Auto-Cal

Zero Error After Auto-Cal (Notes 13, 17)

LM12H458

Positive Full-Scale Error After Auto-Cal (Notes 12, 17)

±

±

LM12(H)458MEL

Negative Full-Scale Error After Auto-Cal (Notes 12, 17)

±

LM12(H)458MEL

DC Common Mode Error (Note 14)

±

ILE 8-Bit + Sign and “Watchdog” (Note 12)

Mode Positive and Negative

Integral Linearity Error

TUE 8-Bit + Sign and “Watchdog” Mode After Auto-Zero

±

Total Unadjusted Error

8-Bit + Sign and “Watchdog” Mode 9 Bits (max)

Resolution with No Missing Codes

DNL 8-Bit + Sign and “Watchdog” Mode

Differential Non-Linearity

8-Bit + Sign and “Watchdog” Mode After Auto-Zero

Zero Error

8-Bit + Sign and “Watchdog” Positive

and Negative Full-Scale Error

=

5V, V

REF+

=

25Ω, source impedance for

REF−

25˚C.

1/2

±

1 LSB (max)

1 LSB

3

±

⁄

4

LSB (max)

±

1

1/2

1/2

1/2

2

1/2

±

1.5 LSB (max)

±

2 LSB (max)

±

2.5

±

2 LSB (max)

±

2.5

±

3.5 LSB (max)

±

1/2 LSB (max)

±

3/4 LSB (max)

±

3/4 LSB (max)

±

1/2 LSB (max)

±

1/2 LSB (max)

≤ 85˚C

A

≤ 125˚C

≤ VA+

≤ VA+

≤ VA+

−1V

≤ VA+

=

0V,

+

A

www.national.com 4

Page 5

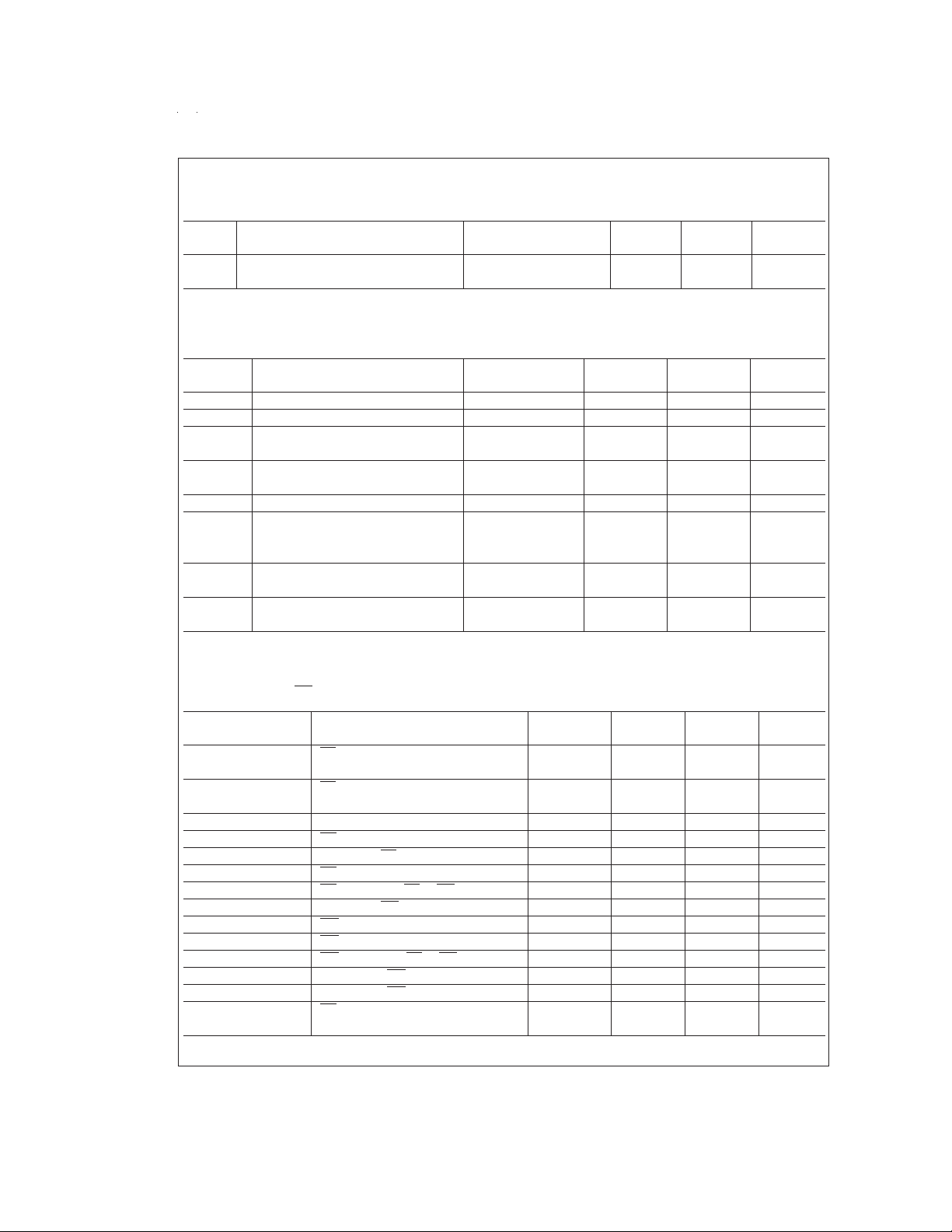

Converter Characteristics (Notes 6, 7, 8, 9, 19) (Continued)

The following specifications apply to the LM12454, LM12458, and LM12H458 for VA+=VD+=5V, V

12-bit + sign conversion mode, f

and V

V

REF+

otherwise specified. Boldface limits apply for T

≤ 25Ω, fully-differential input with fixed 2.5V common-mode voltage, and minimum acquisition time unless

REF−

=

8.0 MHz (LM12H458) or f

CLK

A

=

5.0 MHz (LM12454/8), R

CLK

=

=

to T

T

T

J

MIN

; all other limits T

MAX

S

=

=

T

A

J

Symbol Parameter Conditions Typical Limits Unit

(Note 10) (Note 11) (Limit)

8-Bit + Sign and “Watchdog” Mode

±

DC Common Mode Error

Multiplexer Channel-to-Channel

±

0.05 LSB

Matching

V

IN+

V

IN−

V

IN+−VIN−

Non-Inverting Input Range GND V (min)

Inverting Input Range GND V (min)

Differential Input Voltage Range −V

Common Mode Input Voltage Range GND V (min)

PSS Power Supply Zero Error V

Sensitivity Full-Scale Error V

(Note 15) Linearity Error

C

REF

C

IN

V

REF+/VREF−

Input Capacitance 85 pF

Selected Multiplexer Channel Input 75 pF

+=VD+=5V±10

A

=

4.5V, V

REF+

REF−

%

=

GND

±

±

±

Capacitance

=

5V, V

REF+

=

25Ω, source impedance for

REF−

25˚C.

1/8 LSB

V

+ V (max)

A

V

+ V (max)

A

+

A

V

+ V (max)

A

V

+ V (max)

A

0.2

0.4

±

1.75 LSB (max)

±

2 LSB (max)

0.2 LSB

=

0V,

V (min)

Converter AC Characteristics (Notes 6, 7, 8, 9, 19)

The following specifications apply to the LM12454, LM12458, and LM12H458 for VA+=VD+=5V, V

12-bit + sign conversion mode, f

and V

V

REF+

otherwise specified. Boldface limits apply for T

≤ 25Ω, fully-differential input with fixed 2.5V common-mode voltage, and minimum acquisition time unless

REF−

=

8.0 MHz (LM12H458) or f

CLK

A

=

5.0 MHz (LM12454/8), R

CLK

=

=

to T

T

T

J

MIN

; all other limits T

MAX

S

=

=

T

A

J

=

5V, V

REF+

=

25Ω, source impedance for

25˚C.

Symbol Parameter Conditions Typical Limits Unit

(Note 10) (Note 11) (Limit)

Clock Duty Cycle 50

40

60

t

C

Conversion Time 13-Bit Resolution, 44 (t

Sequencer State S5 (

Figure 15

)

9-Bit Resolution, 21 (t

Sequencer State S5 (

t

A

Acquisition Time Sequencer State S7 (

Figure 15

Figure 15

)

)9(t

) 44 (t

CLK

) 21 (t

CLK

) 9(t

CLK

)+50ns (max)

CLK

)+50ns (max)

CLK

)+50ns (max)

CLK

Built-in minimum for 13-Bits

Built-in minimum for 9-Bits and 2 (t

) 2(t

CLK

)+50ns (max)

CLK

“Watchdog” mode

t

Z

t

CAL

Auto-Zero Time Sequencer State S2 (

Full Calibration Time Sequencer State S2 (

Figure 15

Figure 15

)76(t

) 4944 (t

CLK

CLK

) 76 (t

) 4944 (t

)+50ns (max)

CLK

)+50ns (max)

CLK

Throughput Rate 89 88 kHz

(Note 18) LM12H458 142 140 (min)

t

WD

“Watchdog” Mode Comparison Sequencer States S6, S4, 11 (t

Time and S5 (

Figure 15

)

) 11 (t

CLK

)+50ns (max)

CLK

REF−

=

0V,

%

(max)

%

(min)

%

www.national.com5

Page 6

Converter AC Characteristics (Notes 6, 7, 8, 9, 19) (Continued)

The following specifications apply to the LM12454, LM12458, and LM12H458 for VA+=VD+=5V, V

12-bit + sign conversion mode, f

and V

V

REF+

otherwise specified. Boldface limits apply for T

≤ 25Ω, fully-differential input with fixed 2.5V common-mode voltage, and minimum acquisition time unless

REF−

=

8.0 MHz (LM12H458) or f

CLK

A

=

5.0 MHz (LM12454/8), R

CLK

=

=

to T

T

T

J

MIN

; all other limits T

MAX

S

=

=

T

A

J

=

5V, V

REF+

=

25Ω, source impedance for

25˚C.

Symbol Parameter Conditions Typical Limits Unit

(Note 10) (Note 11) (Limit)

=

±

DSNR Differential Signal-to-Noise Ratio V

SESNR Single-Ended Signal-to-Noise V

Ratio f

DSINAD Differential Signal-to-Noise + V

Distortion Ratio f

SESINAD Single-Ended Signal-to-Noise + V

Distortion Ratio f

DTHD Differential Total Harmonic V

Distortion f

SETHD Single-Ended Total Harmonic V

Distortion f

DENOB Differential Effective Number V

of Bits f

SEENOB Single-Ended Effective Number V

of Bits f

DSFDR Differential Spurious Free V

Dynamic Range f

Multiplexer Channel-to-Channel V

Crosstalk f

5V

IN

=

f

1 kHz 77.5 dB

IN

=

f

20 kHz 75.2 dB

IN

=

f

40 kHz 74.7 dB

IN

=

5V

IN

p-p

=

1 kHz 69.8 dB

IN

=

f

20 kHz 69.2 dB

IN

=

f

40 kHz 66.6 dB

IN

=

±

5V

IN

=

1 kHz 76.9 dB

IN

=

f

20 kHz 73.9 dB

IN

=

f

40 kHz 70.7 dB

IN

=

5V

IN

p-p

=

1 kHz 69.4 dB

IN

=

f

20 kHz 68.3 dB

IN

=

f

40 kHz 65.7 dB

IN

=

±

5V

IN

=

1 kHz −85.8 dB

IN

=

f

20 kHz −79.9 dB

IN

=

f

40 kHz −72.9 dB

IN

=

5V

IN

p-p

=

1 kHz −80.3 dB

IN

=

f

20 kHz −75.6 dB

IN

=

f

40 kHz −72.8 dB

IN

=

±

5V

IN

=

1 kHz 12.6 Bits

IN

=

f

20 kHz 12.2 Bits

IN

=

f

40 kHz 12.1 Bits

IN

=

5V

IN

p-p

=

1 kHz 11.3 Bits

IN

=

f

20 kHz 11.2 Bits

IN

=

f

40 kHz 10.8 Bits

IN

=

±

5V

IN

=

1 kHz 87.2 dB

IN

=

f

20 kHz 78.9 dB

IN

=

f

40 kHz 72.8 dB

IN

=

5V

IN

PP

=

40 kHz

IN

LM12454 MUXOUT Only −76 dB

LM12(H)458 MUX −78 dB

plus Converter

t

PU

t

WU

Power-Up Time 10 ms

Wake-Up Time 10 ms

REF−

=

0V,

www.national.com 6

Page 7

DC Characteristics (Notes 6, 7, 8, 19)

The following specifications apply to the LM12454, LM12458, and LM12H458 for VA+=VD+=5V, V

=

f

8.0 MHz (LM12H454/8) or f

CLK

face limits apply for T

=

T

A

J

=

5.0 MHz (LM12458), and minimum acquisition time unless otherwise specified. Bold-

CLK

=

to T

T

MIN

; all other limits T

MAX

=

=

T

25˚C.

A

J

REF+

=

5V, V

Symbol Parameter Conditions Typical Limits Unit

(Note 10) (Note 11) (Limit)

+VD+ Supply Current CS=“1”

I

D

LM12454/8 0.55 1.0 mA (max)

LM12H458 0.55 1.2

I

+V

A

+ Supply Current CS=“1”

A

LM12454/8 3.1 5.0 mA (max)

LM12H458 3.1 5.5

I

ST

Stand-By Supply Current (ID++IA+) Power-Down Mode Selected

Clock Stopped 10 µA (max)

8 MHz Clock 40 µA (max)

Multiplexer ON-Channel Leakage Current V

+=5.5V

A

ON-Channel=5.5V 0.3

OFF-Channel=0V 0.1 µA (max)

LM12(H)458MEL 0.5

ON-Channel=0V 0.3

OFF-Channel=5.5V 0.1 µA (max)

LM12(H)458MEL 0.5

Multiplexer OFF-Channel Leakage Current V

+=5.5V

A

ON-Channel=5.5V 0.3

OFF-Channel=0V 0.1 µA (max)

LM12(H)458MEL 0.5

ON-Channel=0V 0.3

OFF-Channel=5.5V 0.1 µA (max)

LM12(H)458MEL 0.5

R

Multiplexer ON-Resistance LM12454

ON

=

V

5V 800 1500 Ω(max)

IN

=

V

2.5V 850 1500 Ω(max)

IN

=

V

0V 760 1500 Ω(max)

IN

Multiplexer Channel-to-Channel LM12454

R

matching V

ON

=

5V

IN

=

V

2.5V

IN

=

V

0V

IN

±

1.0

±

1.0

±

1.0

±

%

%

%

%

3.0

±

%

3.0

±

%

3.0

REF−

=

0V,

(max)

(max)

(max)

Internal Reference Characteristics (Notes 6, 7, 19)

The following specifications apply to the LM12454, LM12458, and LM12H458 for VA+=VD+=5V unless otherwise specified.

Boldface limits apply for T

Symbol Parameter Conditions Typical Limits Unit

V

REFOUT

∆V

Internal Reference Output Voltage 2.5 2.5±4

/∆T Internal Reference Temperature 40 ppm/˚C

REF

Coefficient

∆

/∆ILInternal Reference Load Regulation Sourcing (0<IL≤ +4 mA) 0.2

REF

∆V

I

∆V

SC

Line Regulation 4.5V ≤ VA+ ≤ 5.5V 3 20 mV (max)

REF

Internal Reference Short Circuit Current V

/∆t Long Term Stability 200 ppm/kHr

REF

=

=

to T

T

A

T

J

MIN

; all other limits T

MAX

=

=

T

A

25˚C.

J

(Note 10) (Note 11) (Limit)

%

V (max)

±

LM12(H)458MEL 2.5

Sinking (−1 ≤ I

REFOUT

<

0 mA) 1.2

IL

=

0V 13 25 mA (max)

%

6

%

/mA (max)

%

/mA (max)

www.national.com7

Page 8

Internal Reference Characteristics (Notes 6, 7, 19) (Continued)

The following specifications apply to the LM12454, LM12458, and LM12H458 for VA+=VD+=5V unless otherwise specified.

Boldface limits apply for T

Symbol Parameter Conditions Typical Limits Unit

t

SU

Internal Reference Start-Up Time VA+=VD+=0V→5V 10 ms

=

=

to T

T

A

T

J

MIN

; all other limits T

MAX

=

=

T

25˚C.

A

J

(Note 10) (Note 11) (Limit)

=

C

100 µF

L

Digital Characteristics (Notes 6, 7, 8, 19)

The following specifications apply to the LM12454, LM12458, and LM12H458 for VA+=VD+=5V, unless otherwise specified. Boldface limits apply for T

Symbol Parameter Conditions Typical Limits Unit

V

V

I

IN(1)

I

IN(0)

C

V

V

I

OUT

IN(1)

IN(0)

IN

OUT(1)

OUT(0)

Logical “1” Input Voltage VA+=VD+=5.5V 2.0 V (min)

Logical “0” Input Voltage VA+=VD+=4.5V 0.8 V (max)

Logical “1” Input Current V

Logical “0” Input Current V

D0–D15 Input Capacitance 6 pF

Logical “1” Output Voltage VA+=VD+=4.5V

Logical “0” Output Voltage VA+=VD+=4.5V 0.4 V (max)

TRI-STATE®Output Leakage Current V

=

=

to T

T

T

A

J

MIN

; all other limits T

MAX

=

=

T

25˚C.

A

J

(Note 10) (Note 11) (Limit)

=

5V 0.005 1.0 µA (max)

IN

LM12(H)458MEL 2.0

=

0V −0.005 −1.0 µA (max)

IN

LM12(H)458MEL −2.0

=

I

−360 µA 2.4 V (min)

OUT

=

I

−10 µA 4.25 V (min)

OUT

=

I

1.6 mA

OUT

=

0V −0.01 −3.0 µA (max)

OUT

=

V

5V 0.01 3.0 µA (max)

OUT

Digital Timing Characteristics (Notes 6, 7, 8, 19)

The following specifications apply to the LM12454, LM12458, and LM12H458 for VA+=VD+=5V, t

100 pF on data I/O, INT and DMARQ lines unless otherwise specified. Boldface limits apply for T

other limits T

Figures 8, 9, 10

(See

www.national.com 8

=

=

T

25˚C.

A

J

Symbol Parameter Conditions Typical Limits Unit

) (Note 10) (Note 11) (Limit)

1, 3 CS or Address Valid to ALE Low

Set-Up Time

2, 4 CS or Address Valid to ALE Low

Hold Time

5 ALE Pulse Width 45 ns (min)

6 RD High to Next ALE High

7 ALE Low to RD Low

8 RD Pulse Width

9 RD High to Next RD or WR Low

10 ALE Low to WR Low

11 WR Pulse Width

12 WR High to Next ALE High

13 WR High to Next RD or WR Low

14 Data Valid to WR High Set-Up Time

15 Data Valid to WR High Hold Time

16 RD Low to Data Bus Out of TRI-STATE

=

r

A

t

f

=

T

=

3 ns, and C

=

T

J

MIN

to T

MAX

=

L

; all

40 ns (min)

20 ns (min)

35 ns (min)

20 ns (min)

100 ns (min)

100 ns (min)

20 ns (min)

60 ns (min)

75 ns (min)

140 ns (min)

40 ns (min)

30 ns (min)

40 10 ns (min)

70 ns (max)

Page 9

Digital Timing Characteristics (Notes 6, 7, 8, 19) (Continued)

=

The following specifications apply to the LM12454, LM12458, and LM12H458 for VA+=VD+=5V, t

100 pF on data I/O, INT and DMARQ lines unless otherwise specified. Boldface limits apply for T

other limits T

=

=

T

25˚C.

A

J

r

A

t

f

=

T

=

3 ns, and C

=

T

J

MIN

Symbol Parameter Conditions Typical Limits Unit

Figures 8, 9, 10

(See

17 RD High to TRI-STATE

) (Note 10) (Note 11) (Limit)

=

R

1kΩ 30 10 ns (min)

L

110 ns (max)

18 RD Low to Data Valid (Access Time)

30 10 ns (min)

80 ns (max)

20 Address Valid or CS Low to RD Low

21 Address Valid or CS Low to WR Low

20 ns (min)

20 ns (min)

19 Address Invalid 10 ns (min)

from RD or WR High

22 INT High from RD Low 30 10 ns (min)

60 ns (max)

23 DMARQ Low from RD Low

30 10 ns (min)

60 ns (max)

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur.Operating Ratings indicate conditions for which the device is func-

tional, but do not guarantee specific performance limits. For guaranteed specifications and test conditions, see the Electrical Characteristics. The guaranteed specifications apply only for the test conditions listed. Some performance characteristics may degrade when the device is not operated under the listed test conditions.

Note 2: All voltages are measured with respect to GND, unless otherwise specified.

Note 3: When the input voltage (V

The 20 mA maximum package input current rating allows the voltage at any four pins, with an input current of 5 mA, to simultaneously exceed the power supply voltages.

Note 4: The maximum power dissipation must be derated at elevated temperatures and is dictated by T

to ambient thermal resistance), and T

ber given in the Absolute Maximum Ratings, whichever is lower. For this device, T

LM12(H)458 in the V package, when board mounted, is 47˚C/W, in the W package, when board mounted, is 50˚C/W (θJ

board mounted, is 70˚C/W (θJ

Note 5: Human body model, 100 pF discharged through a 1.5 kΩ resistor.

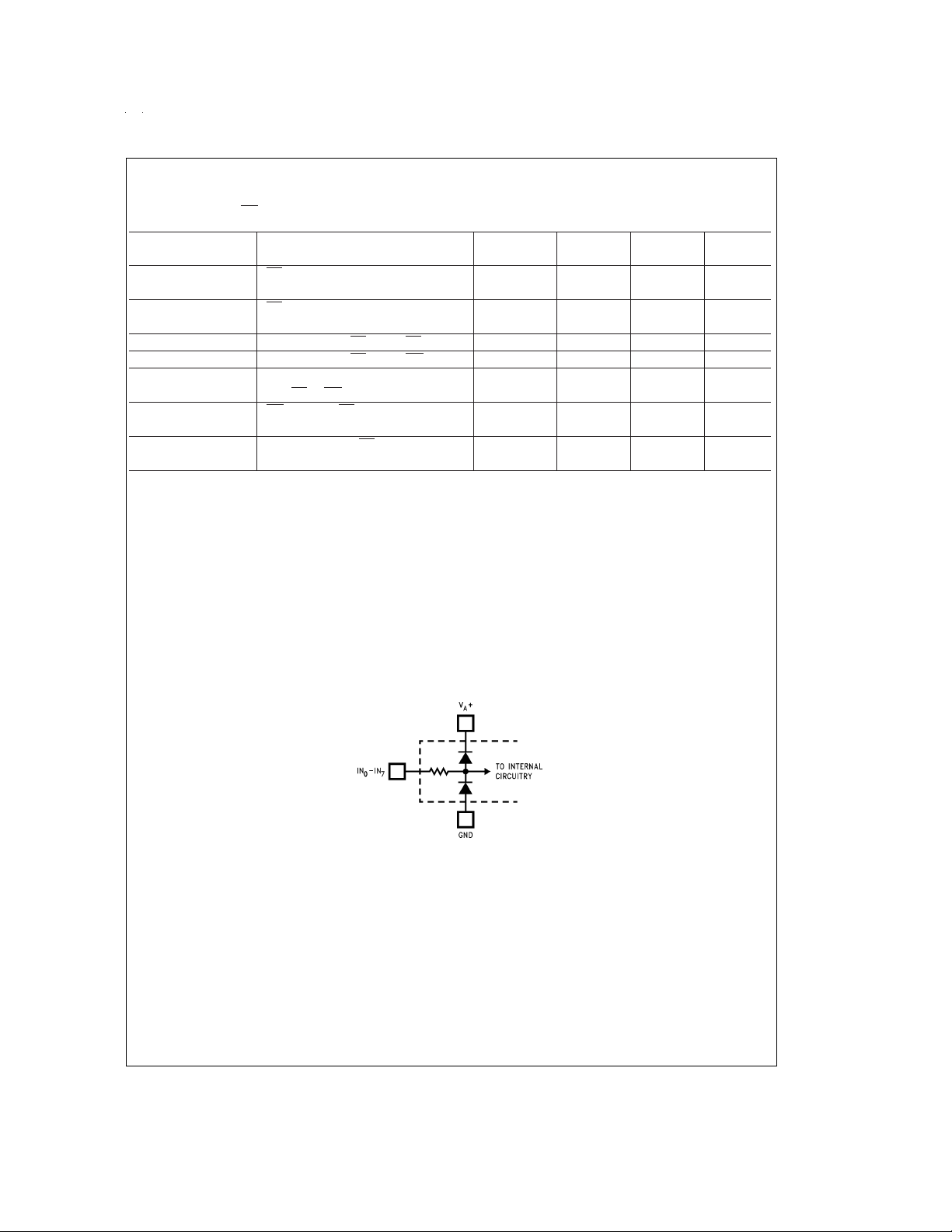

Note 6: Two on-chip diodes are tied to each analog input through a series resistor, as shown below. Input voltage magnitude up to 5V above V

will not damage the LM12454 or the LM12(H)458. However, errors in the A/D conversion can occur if these diodes are forward biased by more than 100 mV.As an

example, if V

+ is 4.5 VDC, full-scale input voltage must be ≤4.6 VDCto ensure accurate conversions.

A

) at any pin exceeds the power supply rails (V

IN

(ambient temperature). The maximum allowable power dissipation at any temperature is PD

A

=

3.5˚C/W).

C

<

IN

Jmax

>

GND or V

(VA+orVD+)), the current at that pin should be limited to 5 mA.

IN

(maximum junction temperature), θJA(package junction

Jmax

=

150˚C, and the typical thermal resistance (θ

=

(T

max

Jmax−TA

) of the LM12454 and

=

5.8˚C/W), and in the EL package, when

C

JA

+ or 5V below GND

A

=

L

to T

MAX

)/θJAor the num-

; all

DS011264-3

+ and VD+ must be connected together to the same power supply voltage and bypassed with separate capacitors at each V+pin to assure conversion/

Note 7: V

A

comparison accuracy.

Note 8: Accuracy is guaranteed when operating at f

Note 9: With the test condition for V

Note 10: Typicals are at T

Note 11: Limits are guaranteed to National’s AOQL (Average Output Quality Level).

Note 12: Positive integral linearity error is defined as the deviation of the analog value, expressed in LSBs, from the straight line that passes through positive

full-scale and zero. For negative integral linearity error the straight line passes through negative full-scale and zero. (See

Note 13: Zero error is a measure of the deviation from the mid-scale voltage (a code of zero), expressed in LSB. It is the worst-case value of the code transitions

between −1 to 0 and 0 to +1 (see

Note 14: The DC common-mode error is measured with both inputs shorted together and driven from 0V to 5V.The measured value is referred to the resulting out-

put value when the inputs are driven with a 2.5V signal.

Note 15: Power Supply Sensitivity is measured after Auto-Zero and/or Auto-Calibration cycle has been completed with V

Note 16: V

(Reference Voltage Common Mode Range) is defined as (V

REFCM

REF(VREF+−VREF−

=

25˚C and represent most likely parametric norm.

A

Figure 8

).

=

5 MHz for the LM12454/8 and f

CLK

) given as +5V, the 12-bit LSB is 1.22 mV and the 8-bit/“Watchdog” LSB is 19.53 mV.

REF++VREF−

=

8 MHz for the LM12H458.

CLK

)/2.

Figure 6 Figure 7

+ and VD+ at the specified extremes.

A

).

www.national.com9

Page 10

Digital Timing Characteristics (Notes 6, 7, 8, 19) (Continued)

Note 17: The LM12(H)454/8’s self-calibration technique ensures linearity and offset errors as specified, but noise inherent in the self-calibration process will result

in a repeatability uncertainty of

Note 18: The Throughput Rate is for a single instruction repeated continuously. Sequencer states 0 (1 clock cycle), 1 (1 clock cycle), 7 (9 clock cycles) and 5 (44

clock cycles) are used (see

version. The Throughput Rate is f

Note 19: A military RETS specification is available upon request.

±

0.10 LSB.

Figure 15

). One additional clock cycle is used to read the conversion result stored in the FIFO, for a total of 56 clock cycles per con-

(MHz)/N, where N is the number of clock cycles/conversion.

CLK

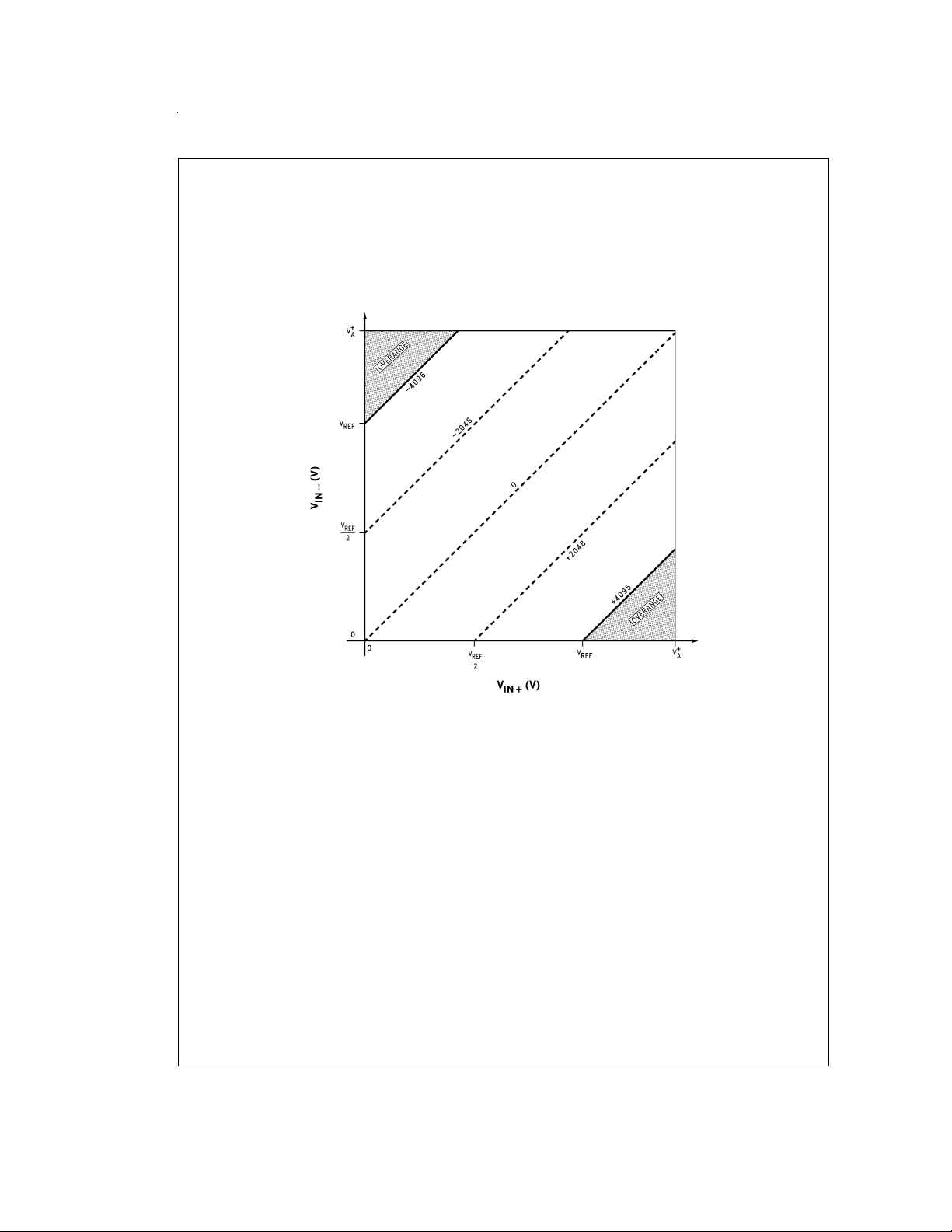

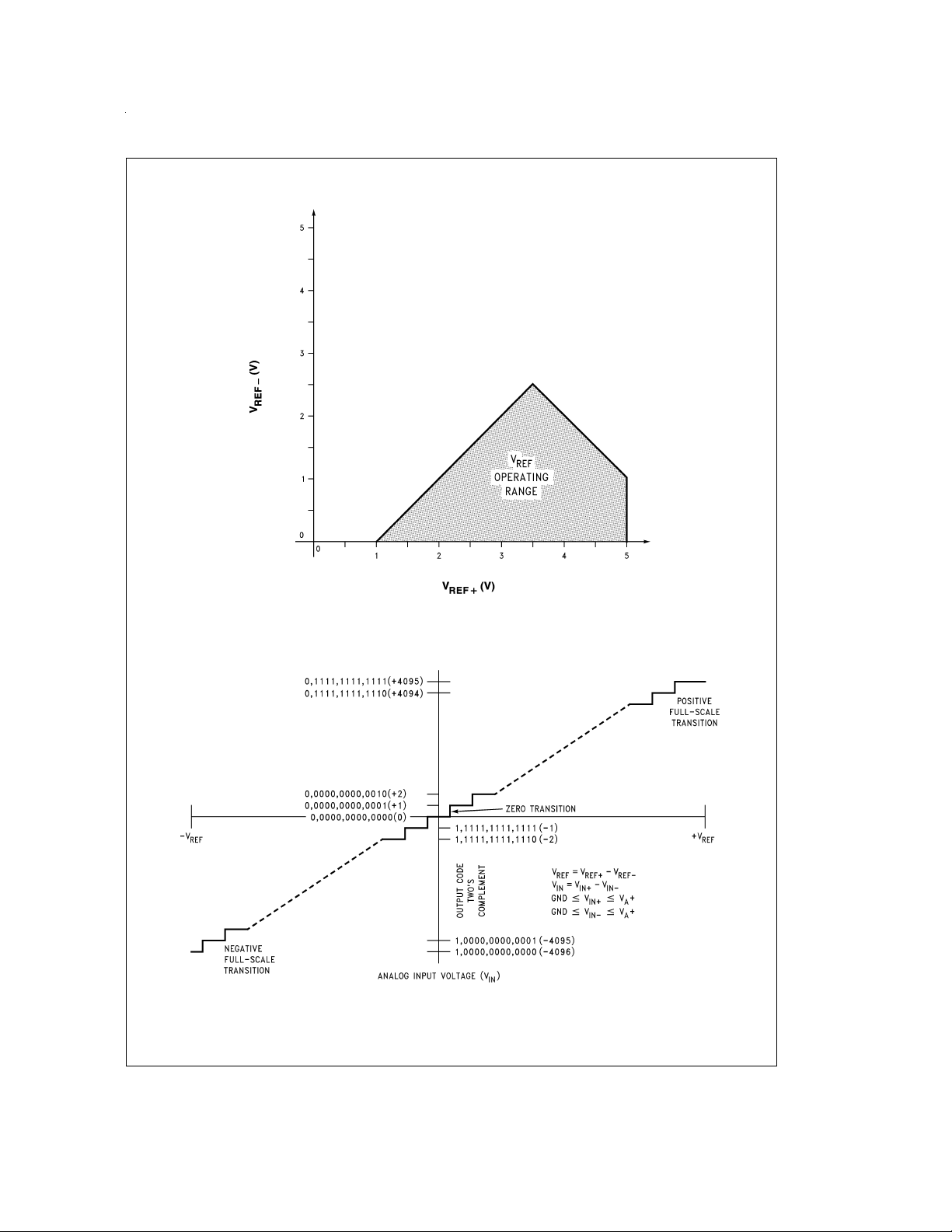

Electrical Characteristics

=

V

V

REF

REF+−VREF−

=

V

V

IN

IN+−VIN−

GND ≤ V

GND ≤ V

IN+≤VA

IN−≤VA

+

+

FIGURE 1. The General Case of Output Digital Code vs the Operating Input Voltage Range

www.national.com 10

DS011264-22

Page 11

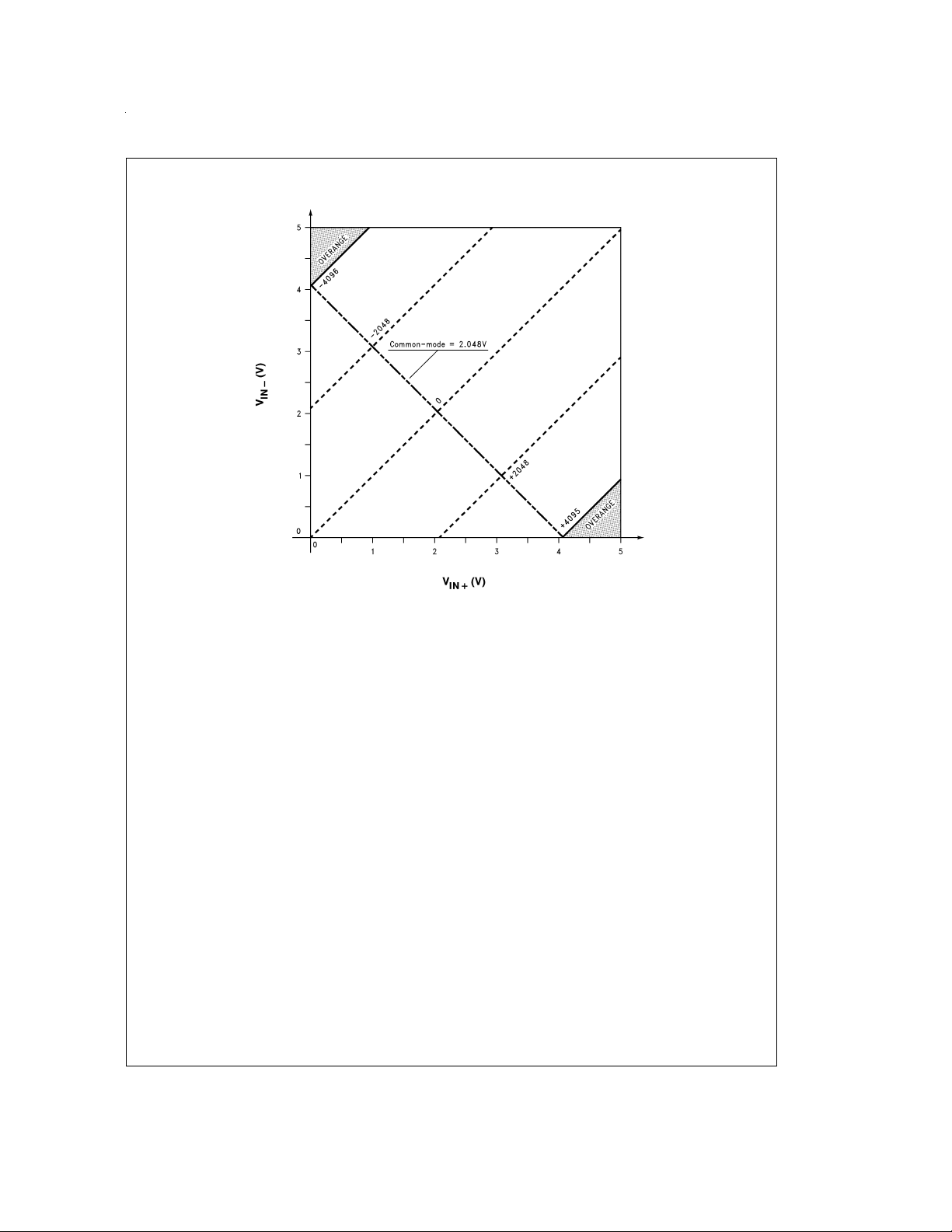

Electrical Characteristics (Continued)

=

V

IN+−VIN−

IN+≤VA

IN−≤VA

=

+

+

4.096V

V

REF+−VREF−

V

IN

GND ≤ V

GND ≤ V

FIGURE 2. Specific Case of Output Digital Code vs the Operating Input Voltage Range for V

DS011264-23

REF

=

4.096V

www.national.com11

Page 12

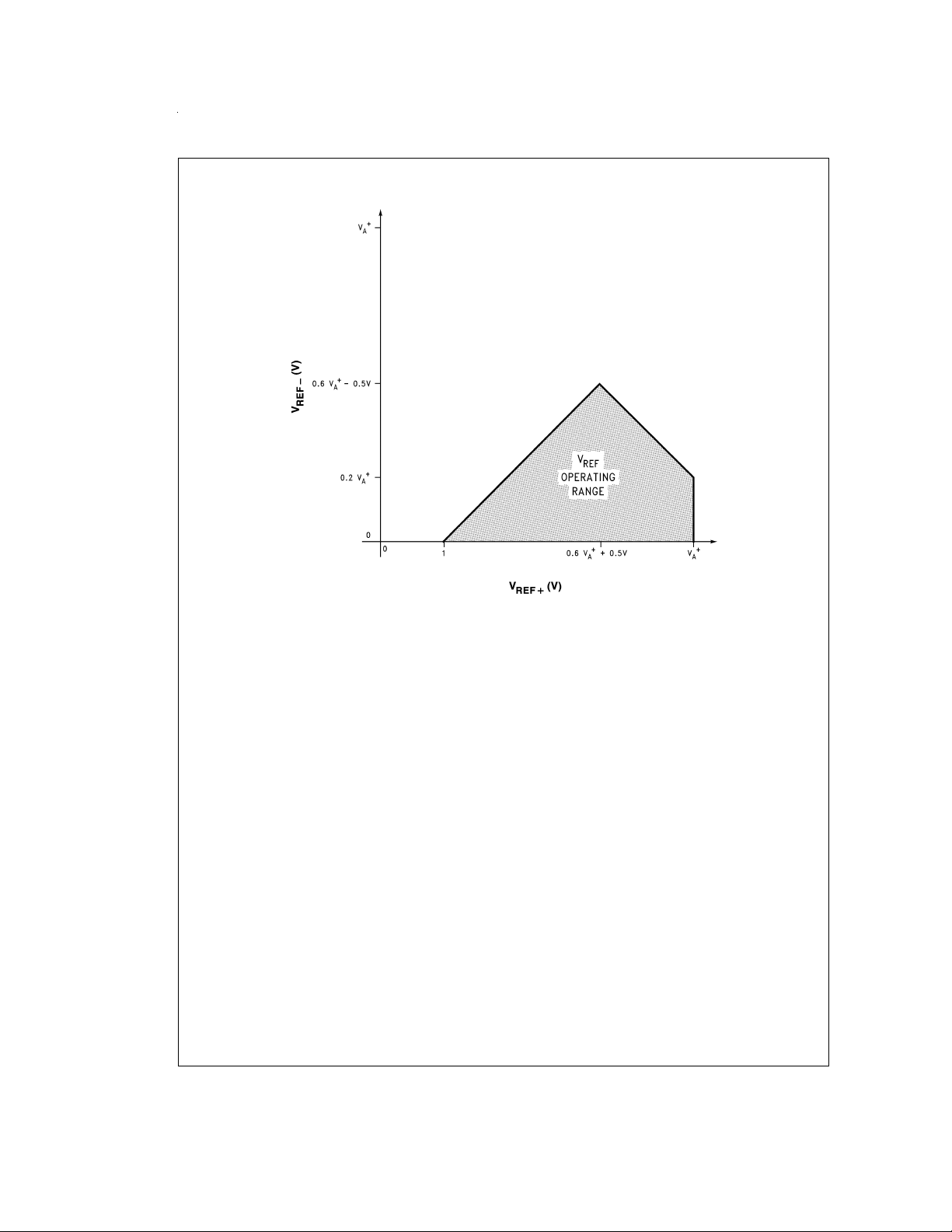

Electrical Characteristics (Continued)

V

REF

=

V

REF+−VREF−

FIGURE 3. The General Case of the V

Operating Range

REF

DS011264-24

www.national.com 12

Page 13

Electrical Characteristics (Continued)

=

V

REF

VA+=5V

V

REF+−VREF−

FIGURE 4. The Specific Case of the V

FIGURE 5. Transfer Characteristic

Operating Range for VA+=5V

REF

DS011264-25

DS011264-4

www.national.com13

Page 14

Electrical Characteristics (Continued)

FIGURE 6. Simplified Error Curve vs Output Code without Auto-Calibration or Auto-Zero Cycles

DS011264-5

FIGURE 7. Simplified Error Curve vs Output Code after Auto-Calibration Cycle

FIGURE 8. Offset or Zero Error Voltage

www.national.com 14

DS011264-6

DS011264-7

Page 15

Typical Performance Characteristics (Note 9) The following curves apply for 12-bit + sign mode after

auto-calibration unless otherwise specified. The performance for 8-bit + sign and “watchdog” modes is equal to or better than

shown.

Linearity Error Change

vs Clock Frequency

Linearity Error Change

vs Supply Voltage

Full-Scale Error Change

vs Reference Voltage

DS011264-37

DS011264-40

Linearity Error Change

vs Temperature

Full-Scale Error Change

vs Clock Frequency

Full-Scale Error

vs Supply Voltage

DS011264-38

DS011264-41

Linearity Error Change

vs Reference Voltage

DS011264-39

Full-Scale Error Change

vs Temperature

DS011264-42

Zero Error Change

vs Clock Frequency

DS011264-43

DS011264-44

DS011264-45

www.national.com15

Page 16

Typical Performance Characteristics (Note 9) The following curves apply for 12-bit + sign mode after

auto-calibration unless otherwise specified. The performance for 8-bit + sign and “watchdog” modes is equal to or better than

shown. (Continued)

Zero Error Change

vs Temperature

Analog Supply Current

vs Temperature

V

Load Regulation

REFOUT

DS011264-46

DS011264-49

Zero Error Change

vs Reference Voltage

Digital Supply Current

vs Clock Frequency

V

REFOUT

DS011264-47

DS011264-50

Line Regulation

Zero Error Change

vs Supply Voltage

DS011264-48

Digital Supply Current

vs Temperature

DS011264-51

DS011264-52

www.national.com 16

DS011264-53

Page 17

Typical Dynamic Performance Characteristics The following curves apply for 12-bit + sign

mode after auto-calibration unless otherwise specified.

Bipolar Signal-to-Noise Ratio

vs Input Frequency

DS011264-54

Bipolar Spectral Response

with 1.028 kHz Sine Wave Input

DS011264-57

Bipolar Signal-to-Noise

+ Distortion Ratio

vs Input Frequency

Bipolar Spectral Response

with 10 kHz Sine Wave Input

DS011264-58

DS011264-55

Bipolar Signal-to-Noise

+ Distortion Ratio

vs Input Signal Level

DS011264-56

Bipolar Spectral Response

with 20 kHz Sine Wave Input

DS011264-59

Bipolar Spectral Response

with 40 kHz Sine Wave Input

DS011264-60

Bipolar Spurious Free

Dynamic Range

DS011264-61

Unipolar Signal-to-Noise Ratio

vs Input Frequency

DS011264-62

www.national.com17

Page 18

Typical Dynamic Performance Characteristics The following curves apply for 12-bit + sign

mode after auto-calibration unless otherwise specified. (Continued)

Unipolar Signal-to-Noise

+ Distortion Ratio

vs Input Frequency

DS011264-63

Unipolar Spectral Response

with 10 kHz Sine Wave Input

DS011264-66

Unipolar Signal-to-Noise

+ Distortion Ratio

vs Input Signal Level

Unipolar Spectral Response

with 20 kHz Sine Wave Input

Test Circuits and Waveforms

DS011264-64

DS011264-67

Unipolar Spectral Response

with 1.028 kHz Sine Wave Input

DS011264-65

Unipolar Spectral Response

with 40 kHz Sine Wave Input

DS011264-68

DS011264-12

DS011264-14

FIGURE 9. TRI-STATE Test Circuits and Waveforms

www.national.com 18

DS011264-13

DS011264-15

Page 19

Timing Diagrams V

+=VD+=+5V, t

A

FIGURE 10. Multiplexed Data Bus

1, 3: CS or Address valid to ALE low set-up time.

2, 4: CS or Address valid to ALE low hold time.

5: ALE pulse width

6: RD high to next ALE high

7: ALE low to RD low

8: RD pulse width

9: RD high to next RD or WR low

10: ALE low to WR low

=

=

t

R

F

3 ns, C

=

100 pF for the INT, DMARQ, D0–D15 outputs.

L

DS011264-16

11: WR pulse width

12: WR high to next ALE high

13: WR high to next WR or RD low

14: Data valid to WR high set-up time

15: Data valid to WR high hold time

16: RD low to data bus out of TRI-STATE

17: RD high to TRI-STATE

18: RD low to data valid (access time)

www.national.com19

Page 20

Timing Diagrams V

outputs. (Continued)

+=VD+=+5V, t

A

=

=

t

R

F

3 ns, C

=

100 pF for the INT, DMARQ, D0–D15

L

FIGURE 11. Non-Multiplexed Data Bus (ALE=1)

8: RD pulse width

9: RD high to next RD or WR low

11: WR pulse width

13: WR high to next WR or RD low

14: Data valid to WR high set-up time

15: Data valid to WR high hold time

VA+=VD+=+5V, t

=

t

R

F

3 ns, C

=

100 pF for the INT, DMARQ, D0–D15 outputs.

L

=

FIGURE 12. Interrupt and DMARQ

22: INT high from RD low

23: DMARQ low from RD low

www.national.com 20

DS011264-17

16: RD low to data bus out of TRI-STATE

17: RD high to TRI-STATE

18: RD low to data valid (access time)

19: Address invalid from RD or WR high (hold time)

20: CS low or address valid to RD low

21: CS low or address valid to WR low

DS011264-18

Page 21

Pin Description

VA+VD+ Analog and digital supply voltage pins. The

D0–D15 The internal data input/output TRI-STATE buffers

RD

WR

CS

ALE Address Latch Enable input. It is used in systems

CLK External clock input pin. The LM12(H)454/8 oper-

A0–A4 The LM12(H)454/8’s address lines. They are

SYNC Synchronization input/output. When used as an

LM12(H)454/8’s supply voltage operating range

is +3.0V to +5.5V.Accuracy is guaranteed only if

V

+ and VD+ are connected to the same power

A

supply.Each pin should have a parallel combination of 10 µF (electrolytic or tantalum) and 0.1 µF

(ceramic) bypass capacitors connected between

it and ground.

are connected to these pins. These buffers are

designed to drive capacitive loads of 100 pF or

less. External buffers are necessary for driving

higher load capacitances. These pins allows the

user a means of instruction input and data output. With a logic high applied to the BW pin, data

lines D8–D15 are placed in a high impedance

state and data lines D0–D7 are used for instruction input and data output when the

LM12(H)454/8 is connected to an 8-bit wide data

bus. A logic low on the BW pin allows the

LM12(H)454/8 to exchange information over a

16-bit wide data bus.

Input for the active low READ bus control signal.

The data input/output TRI-STATE buffers, as selected by the logic signal applied to the BW pin,

are enabled when RD and CS are both low. This

allows the LM12(H)454/8 to transmit information

onto the databus.

Input for the active low WRITE bus control signal.

The data input/output TRI-STATE buffers, as selected by the logic signal applied to the BW pin,

are enabled when WR and CS are both low. This

allows the LM12(H)454/8 to receive information

from the databus.

Input for the active low Chip Select control signal.

A logic low should be applied to this pin only during a READ or WRITE access to the

LM12(H)454/8. The internal clocking is halted

and conversion stops while Chip Select is low.

Conversion resumes when the Chip Select input

signal returns high.

containing a multiplexed databus. When ALE is

asserted high, the LM12(H)454/8 accepts information on the databus as a valid address. A

high-to-low transition will latch the address data

on A0–A4 while the CS is low. Any changes on

A0–A4 and CS while ALE is low will not affect the

LM12(H)454/8. See

Figure 10

. When a

non-multiplexed bus is used, ALE is continuously

asserted high. See

Figure 11

.

ates with an input clock frequency in the range of

0.05 MHz to 10.0 MHz.

used to access all internal registers, Conversion

FIFO, and Instruction RAM.

output, it is designed to drive capacitive loads of

100 pF or less. External buffers are necessary for

driving higher load capacitances. SYNC is an in-

put if the Configuration register’s “I/O Select” bit

is low. A rising edge on this pin causes the inter-

nal S/H to hold the input signal. The next rising

clock edge either starts a conversion or makes a

comparison to a programmable limit depending

on which function is requested by a programming

instruction. This pin will be an output if “I/O Select” is set high. The SYNC output goes high

when a conversion or a comparison is started

and low when completed. (See Section 2.2). An

internal reset after power is first applied to the

LM12(H)454/8 automatically sets this pin as an

input.

BW Bus Width input pin. This input allows the

LM12(H)454/8 to interface directly with either an

8- or 16-bit databus.A logic high sets the width to

8 bits and places D8–D15 in a high impedance

state. A logic low sets the width to 16 bits.

INT

Active low interrupt output. This output is designed to drive capacitive loads of 100 pF or less.

External buffers are necessary for driving higher

load capacitances. An interrupt signal is generated any time a non-masked interrupt condition

takes place. There are eight different conditions

that can cause an interrupt. Any interrupt is reset

by reading the Interrupt Status register. (See

Section 2.3.)

DMARQ Active high Direct Memory Access Request out-

put. This output is designed to drive capacitive

loads of 100 pF or less. External buffers are necessary for driving higher load capacitances. It

goes high whenever the number of conversion

results in the conversion FIFO equals a programmable value stored in the Interrupt Enable register. It returns to a logic low when the FIFO is

empty.

GND LM12(H)454/8 ground connection. It should be

connected to a low resistance and inductance

analog ground return that connects directly to the

system power supply ground.

IN0–IN7

(IN0–IN3

LM12H454

LM12454)

The eight (LM12(H)458) or four (LM12454)

analog inputs. A given channel is selected

through the instruction RAM. Any of the channels can be configured as an independent

single-ended input. Any pair of channels,

whether adjacent or non-adjacent, can operate

as a fully differential pair.

S/H IN+

S/H IN−

MUXOUT+

MUXOUT−

V

REF−

The LM12454’s non-inverting and inverting inputs to the internal S/H.

The LM12454’s non-inverting and inverting outputs from the internal multiplexer.

The negative reference input. The

LM12(H)454/8 operate with 0V ≤ V

V

. This pin should be bypassed to ground

REF+

with a parallel combination of 10 µF and 0.1 µF

REF−

(ceramic) capacitors.

V

REF+

The positive reference input. The

LM12(H)454/8 operate with 0V ≤ V

This pin should be bypassed to ground with a

REF+

≤ VA+.

parallel combination of 10 µF and 0.1 µF (ceramic) capacitors.

V

REFOUT

The internal 2.5V bandgap’s output pin. This

pin should be bypassed to ground with a 100

µF capacitor.

≤

www.national.com21

Page 22

Application Information

1.0 Functional Description

The LM12454 and LM12(H)458 are multi-functional Data Acquisition Systems that include a fully differential

12-bit-plus-sign self-calibrating analog-to-digital converter

(ADC) with a two’s-complement output format, an 8-channel

(LM12(H)458) or a 4-channel (LM12454) analog multiplexer,

an internal 2.5V reference, a first-in-first-out (FIFO) register

that can store 32 conversion results, and an Instruction RAM

that can store as many as eight instructions to be sequentially executed. The LM12454 also has a differential multiplexer output and a differential S/H input. All of this circuitry

operates on only a single +5V power supply.

The LM12(H)454/8 have three modes of operation:

12-bit + sign with correction

8-bit + sign without correction

8-bit + sign comparison mode (“watchdog” mode)

The fully differential 12-bit-plus-sign ADC uses a charge redistribution topology that includes calibration capabilities.

Charge re-distribution ADCs use a capacitor ladder in place

of a resistor ladder to form an internal DAC. The DAC is used

by a successive approximation register to generate intermediate voltages between the voltages applied to V

V

. These intermediate voltages are compared against

REF+

the sampled analog input voltage as each bit is generated.

The number of intermediate voltages and comparisons

equals the ADC’s resolution. The correction of each bit’s accuracy is accomplished by calibrating the capacitor ladder

used in the ADC.

Two different calibration modes are available; one compensates for offset voltage, or zero error,while the other corrects

both offset error and the ADC’s linearity error.

When correcting offset only, the offset error is measured

once and a correction coefficient is created. During the full

calibration, the offset error is measured eight times, averaged, and a correction coefficient is created. After completion of either calibration mode, the offset correction coefficient is stored in an internal offset correction register.

The LM12(H)454/8’s overall linearity correction is achieved

by correcting the internal DAC’s capacitor mismatch. Each

capacitor is compared eight times against all remaining

smaller value capacitors and any errors are averaged. Acorrection coefficient is then created and stored in one of the

thirteen internal linearity correction registers. An internal

state machine, using patterns stored in an internal 16 x 8-bit

ROM, executes each calibration algorithm.

Once calibrated, an internal arithmetic logic unit (ALU) uses

the offset correction coefficient and the 13 linearity correction

coefficients to reduce the conversion’s offset error and linearity error, in the background, during the 12-bit + sign conversion. The 8-bit + sign conversion and comparison modes

use only the offset coefficient. The 8-bit + sign mode performs a conversion in less than half the time used by the

12-bit + sign conversion mode.

The LM12(H)454/8’s “watchdog” mode is used to monitor a

single-ended or differential signal’s amplitude. Each

sampled signal has two limits.An interrupt can be generated

if the input signal is above or below either of the two limits.

This allows interrupts to be generated when analog voltage

inputs are “inside the window” or, alternatively, “outside the

window”. After a “watchdog” mode interrupt, the processor

can then request a conversion on the input signal and read

the signal’s magnitude.

REF−

and

The analog input multiplexer can be configured for any combination of single-ended or fully differential operation. Each

input is referenced to ground when a multiplexer channel operates in the single-ended mode. Fully differential analog input channels are formed by pairing any two channels together.

The LM12454’s multiplexer outputs and S/H inputs (MUXOUT+, MUXOUT− and S/H IN+, S/H IN−) provide the option

for additional analog signal processing. Fixed-gain amplifiers, programmable-gain amplifiers, filters, and other processing circuits can operate on the signal applied to the selected multiplexer channel(s). If external processing is not

used, connect MUXOUT+ to S/H IN+ and MUXOUT− to

S/H IN−.

The LM12(H)454/8’s internal S/H is designed to operate at

its minimum acquisition time (1.13 µs, 12 bits) when the

source impedance, R

<

RS≤ 4.17 kΩ, the internal S/H’s acquisition time can be increased to a maximum of 4.88 µs (12 bits, f

See Section 2.1 (Instruction RAM “00”) Bits 12–15 for more

,is≤60Ω (f

S

≤ 8 MHz). When 60Ω

CLK

CLK

=

8 MHz).

information.

An internal 2.5V bandgap reference output is available at pin

44. This voltage can be used as the ADC reference for ratiometric conversion or as a virtual ground for front-end analog

conditioning circuits. The V

to ground with a 100 µF capacitor.

pin should be bypassed

REFOUT

Microprocessor overhead is reduced through the use of the

internal conversion FIFO. Thirty-two consecutive conversions can be completed and stored in the FIFO without any

microprocessor intervention. The microprocessor can, at any

time, interrogate the FIFO and retrieve its contents. It can

also wait for the LM12(H)454/8 to issue an interrupt when

the FIFO is full or after any number (≤32) of conversions

have been stored.

Conversion sequencing, internal timer interval, multiplexer

configuration, and many other operations are programmed

and set in the Instruction RAM.

A diagnostic mode is available that allows verification of the

LM12(H)458’s operation. The diagnostic mode is disabled in

the LM12454. This mode internally connects the voltages

present at the V

internal V

setting the Diagnostic bit (Bit 11) in the Configuration register

REFOUT,VREF+,VREF−

and V

IN+

IN−

S/H inputs. This mode is activated by

, and GND pins to the

to a “1”. More information concerning this mode of operation

can be found in Section 2.2.

2.0 Internal User-Programmable

Registers

INSTRUCTION RAM

The instruction RAM holds up to eight sequentially executable instructions. Each 48-bit long instruction is divided into

three 16-bit sections. READ and WRITE operations can be

issued to each 16-bit section using the instruction’s address

and the 2-bit “RAM pointer” in the Configuration register. The

eight instructions are located at addresses 0000 through

0111 (A4–A1, BW=0) when using a 16-bit wide data bus or

at addresses 00000 through 01111 (A4– A0, BW=1) when

using an 8-bit wide data bus. They can be accessed and programmed in random order.

www.national.com 22

Page 23

2.0 Internal User-Programmable

Registers

Any Instruction RAM READ or WRITE can affect the sequencer’s operation:

The Sequencer should be stopped by setting the RESET

bit to a “1” or by resetting the STARTbit in the Configuration Register and waiting for the current instruction to finish execution before any Instruction RAM READ or

WRITE is initiated.

A soft RESET should be issued by writing a “1” to the

Configuration Register’s RESET bit after any READ or

WRITE to the Instruction RAM.

The three sections in the Instruction RAM are selected by

the Configuration Register’s 2-bit “RAM Pointer”, bits D8 and

D9. The first 16-bit Instruction RAM section is selected with

the RAM Pointer equal to “00”. This section provides multiplexer channel selection, as well as resolution, acquisition

time, etc. The second 16-bit section holds “watchdog” limit

#

1, its sign, and an indicator that shows that an interrupt can

be generated if the input signal is greater or less than the

programmed limit. The third 16-bit section holds “watchdog”

#

limit

2, its sign, and an indicator that shows that an interrupt

can be generated if the input signal is greater or less than the

programmed limit.

Instruction RAM “00”

Bit 0 is the LOOP bit. It indicates the last instruction to be ex-

ecuted in any instruction sequence when it is set to a “1”.

The next instruction to be executed will be instruction 0.

Bit 1 is the PAUSEbit. This controls the Sequencer’s operation. When the PAUSEbit is set (“1”), the Sequencer will stop

after reading the current instruction and before executing it,

and the start bit in the Configuration register is automatically

reset to a “0”. Setting the PAUSEalso causes an interrupt to

be issued. The Sequencer is restarted by placing a “1” in the

Configuration register’s Bit 0 (Start bit).

After the Instruction RAM has been programmed and the

RESET bit is set to “1”, the Sequencer retrieves Instruction

000, decodes it, and waits for a “1” to be placed in the Configuration’s START bit. The START bit value of “0” “overrides” the action of Instruction 000’s PAUSE bit when the Sequencer is started. Once started, the Sequencer executes

Instruction 000 and retrieves, decodes, and executes each

of the remaining instructions. No PAUSE Interrupt (INT 5) is

generated the first time the Sequencer executes Instruction

000 having a PAUSE bit set to “1”. When the Sequencer encounters a LOOP bit or completes all eight instructions, Instruction 000 is retrieved and decoded. A set PAUSE bit in

Instruction 000 now halts the Sequencer before the instruction is executed.

Bits 2–4 select which of the eight input channels (“000” to

“111” for IN0–IN7) will be configured as non-inverting inputs

to the LM12(H)458’s ADC. (See Page 27,

lect which of the four input channels (“000” to “011” for

IN0–IN4) will be configured as non-inverting inputs to the

LM12454’s ADC. (See Page 27,

Bits 5–7 select which of the seven input channels (“001” to

“111” for IN1 to IN7) will be configured as inverting inputs to

the LM12(H)458’s ADC. (See Page 27,

which of the three input channels (“001” to “011” for IN1–IN4)

will be configured as inverting inputs to the LM12454’s ADC.

(See Page 27,

by selecting two multiplexer channels, one operating in the

(Continued)

Table1

Table 2

.)

Table1

Table2

.) Fully differential operation is created

.) They se-

.) They select

non-inverting mode and the other operating in the inverting

mode. A code of “000” selects ground as the inverting input

for single ended operation.

Bit 8 is the SYNC bit. Setting Bit 8 to “1” causes the Sequencer to suspend operation at the end of the internal S/H’s

acquisition cycle and to wait until a rising edge appears at

the SYNC pin. When a rising edge appears, the S/H acquires the input signal magnitude and the ADC performs a

conversion on the clock’s next rising edge. When the SYNC

pin is used as an input, the Configuration register’s “I/O Select” bit (Bit 7) must be set to a “0”. With SYNC configured as

an input, it is possible to synchronize the start of a conversion to an external event. This is useful in applications such

as digital signal processing (DSP) where the exact timing of

conversions is important.

When the LM12(H)454/8 are used in the “watchdog” mode

with external synchronization, two rising edges on the SYNC

input are required to initiate two comparisons. The first rising

edge initiates the comparison of the selected analog input

signal with Limit

second rising edge initiates the comparison of the same analog input signal with Limit

Bit 9 is the TIMER bit. When Bit 9 is set to “1”, the Sequencer will halt until the internal 16-bit Timer counts down

to zero. During this time interval, no “watchdog” comparisons

or analog-to-digital conversions will be performed.

Bit 10 selects the ADC conversion resolution. Setting Bit 10

to “1” selects 8-bit + sign and when reset to “0” selects 12-bit

+ sign.

Bit 11 is the “watchdog” comparison mode enable bit. When

operating in the “watchdog” comparison mode, the selected

analog input signal is compared with the programmable values stored in Limit

and Instruction RAM “10”). Setting Bit 11 to “1” causes two

comparisons of the selected analog input signal with the two

stored limits. When Bit 11 is reset to “0”, an 8-bit + sign or

12-bit + sign (depending on the state of Bit 10 of Instruction

RAM “00”) conversion of the input signal can take place.

#

1 (found in Instruction RAM “01”) and the

#

2 (found in Instruction RAM “10”).

#

1 and Limit#2 (see Instruction RAM “01”

www.national.com23

Page 24

2.0 Internal User-Programmable Registers (Continued)

Don’t Care)

=

IN+

V

IN−

00) Time dog 8/12 Timer Sync (MUXOUT−) (MUXOUT+) Pause Loop

=

1

#

Sign Limit

<

/

>

01) Don’t Care

=

2

#

Sign Limit

<

/

>

10) Don’t Care

=

Mask by CAL Zero

ec

0 Pointer Sel Zero

=

Register (Note 21)

Interrupt Enable R/W Number of Conversions Sequencer INT7 INT6 INT5 INT4 INT3 INT2 INT1 INT0

to Generate INT2 Generate INT1

Address

R Actual Number of of INST7 INST6 INST5 INST4 INST3 INST2 INST1 INST0

being

Register in Conversion FIFO Instruction

Executed

Register

FIFO or Sign Data: MSBs

1: Status

#

2: Status Limit

#

).

Table 2

Register

“0” and A0

=

“0”, Test Bit

=

FIGURE 13. LM12(H)454/8 Memory Map for 16-Bit Wide Databus (BW

0 0 0 Instruction RAM R/W Acquisition Watch- V

111 (Note 20) (Note 20)

0 0 0 Instruction RAM R/W

111

0 0 0 Instruction RAM R/W

0 to (RAM Pointer

A4 A3A2A1 Purpose Type D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

www.national.com 24

0 to (RAM Pointer

111

0 to (RAM Pointer

1 0 0 0 Configuration R/W Don’t Care DIAG Test RAM I/O Auto Chan Stand- Full Auto- Reset Start

1 0 0 1 Register in Conversion FIFO Address to

1 0 1 0 Interrupt Status Conversion Results Sequencer

1 0 1 1 Timer R/W Timer Preset High Byte Timer Preset Low Byte

1 1 0 0 Conversion R Address Sign Conversion Conversion Data: LSBs

1 1 0 1 Limit Status R Limit

Note 20: LM12454 (Refer to

Note 21: LM12(H)458 only. Must be set to “0” for the LM12454.

Page 25

2.0 Internal User-Programmable Registers (Continued)

A4 A3 A2 A1 A0 Purpose Type D7 D6 D5 D4 D3 D2 D1 D0

000

0to0 Pause Loop

111

0 0 0 R/W Watch-

0 to 1 Acquisition Time dog 8/12 Timer Sync

111

000

0 to 0 Comparison Limit

111

000 R/W

0 to 1 Don’t Care

111

000

0 to 0 Comparison Limit

111

000 R/W

0 to 1 Don’t Care

111

10000

10001 R/W

10010

10011 R/W Number of Conversions in Conversion Sequencer Address to

10100

10101 R Actual Number of Conversions Results Address of Sequencer

10110

10111 R/W Timer Preset: High Byte

11000

11001 R Address or Sign Sign Conversion Data: MSBs

11010

11011 R Limit

Instruction

RAM

(RAM

Pointer

00)

Instruction

RAM

(RAM

Pointer

01)

Instruction

RAM

(RAM

Pointer

10)

Configuration

Register

Interrupt

Enable

Register

Interrupt

Status

Register

Timer

Register

Conversion

FIFO

Limit Status

Register

R/W V

=

R/W

=

R/W

=

R/W I/O Auto Chan Stand- Full Auto- Reset Start

Sel Zero

R/W INT7 INT6 INT5 INT4 INT3 INT2 INT1 INT0

R INST7 INST6 INST5 INST4 INST3 INST2 INST1 INST0

R/W Timer Preset: Low Byte

R Conversion Data: LSBs

R Limit

IN−

(MUXOUT−) (Note 22)

ec

Don’t Care

FIFO to Generate INT2 Generate INT1

in Conversion FIFO Instruction

Mask by Cal Zero

V

IN+

(MUXOUT+) (Note 22)

#

1

#

2

DIAG

Test

(Note

23)

#

1 Status

#

2 Status

>/<

>/<

=

0

being Executed

RAM Pointer

FIGURE 14. LM12(H)454/8 Memory Map for 8-Bit Wide Databus (BW=“1” and Test Bit=“0”)

Note 22: LM12454 (Refer to

Note 23: LM12(H)458 only. Must be set to “0” for the LM12454.

Table 2

).

Sign

Sign

www.national.com25

Page 26

2.0 Internal User-Programmable

Registers

Bits 12–15 are used to store the user-programmable acqui-

sition time. The Sequencer keeps the internal S/H in the acquisition mode for a fixed number of clock cycles (nine clock

cycles, for 12-bit + sign conversions and two clock cycles for

8-bit + sign conversions or “watchdog” comparisons) plus a

variable number of clock cycles equal to twice the value

stored in Bits 12–15. Thus, the S/H’s acquisition time is (9 +

2D) clock cycles for 12-bit + sign conversions and (2 + 2D)

clock cycles for 8-bit + sign conversions or “watchdog” comparisons, where D is the value stored in Bits 12–15. The

minimum acquisition time compensates for the typical internal multiplexer series resistance of 2 kΩ, and any additional

delay created by Bits 12–15 compensates for source resistances greater than 60Ω (100Ω). (For this acquisition time

discussion, numbers in ( ) are shown for the LM12(H)454/8

operating at 5 MHz.) The necessary acquisition time is determined by the source impedance at the multiplexer input. If

the source resistance (R

quency is 8 MHz, the value stored in bits 12–15 (D) can be

0000. If R

the value that should be stored in bits 12–15.

for 12-bits + sign

for 8-bits + sign and “watchdog”

is in kΩ and f

R

S

higher integer value. If D is greater than 15, it is advisable to

lower the source impedance by using an analog buffer between the signal source and the LM12(H)458’s multiplexer

inputs. The value of D can also be used to compensate for

the settling or response time of external processing circuits

connected between the LM12454’s MUXOUT and S/H IN

pins.

Instruction RAM “01”

The second Instruction RAM section is selected by placing a

“01” in Bits 8 and 9 of the Configuration register.

Bits 0–7hold “watchdog” limit

RAM “00” is set to a “1”, the LM12(H)454/8 performs a

“watchdog” comparison of the sampled analog input signal

with the limit

same sampled analog input signal with the value found in

#

limit

2 (Instruction RAM “10”).

Bit 8 holds limit

Bit 9’s state determines the limit condition that generates a

“watchdog” interrupt. A “1” causes a voltage greater than

#

limit

1 to generate an interrupt, while a “0” causes a voltage

less than limit

Bits 10–15 are not used.

Instruction RAM “10”

The third Instruction RAM section is selected by placing a

“10” in Bits 8 and 9 of the Configuration register.

Bits 0–7hold “watchdog” limit

RAM “00” is set to a “1”, the LM12(H)454/8 performs a

“watchdog” comparison of the sampled analog input signal

with the limit

by a comparison of the same sampled analog input signal

with the value found in limit

Bit 8 holds limit

(Continued)

)<60Ω (100Ω) and the clock fre-

S

>

60Ω (100Ω), the following equations determine

S

D=0.45 x R

D=0.36 x R

is in MHz. Round the result to the next

CLK

#

1 value first, followed by a comparison of the

#

1’s sign.

#

1 to generate an interrupt.

#

1 value first (Instruction RAM “01”), followed

#

2’s sign.

SxfCLK

SxfCLK

#

1. When Bit 11of Instruction

#

2. When Bit 11of Instruction

#

2.

Bit 9 ’s state determines the limit condition that generates a

“watchdog” interrupt. A “1” causes a voltage greater than

#

limit

2 to generate an interrupt, while a “0” causes a voltage

less than limit

#

2 to generate an interrupt.

Bits 10–15 are not used.

2.2 CONFIGURATION REGISTER

The Configuration register, 1000 (A4–A1, BW=0) or 1000x

(A4–A0, BW=1) is a 16-bit control register with read/write

capability.It acts as the LM12454’s and LM12(H)458’s “control panel” holding global information as well as start/stop, reset, self-calibration, and stand-by commands.

Bit 0 is the START/STOP bit. Reading Bit 0 returns an indication of the Sequencer’s status. A “0” indicates that the Sequencer is stopped and waiting to execute the next instruction. A “1” shows that the Sequencer is running. Writing a “0”

halts the Sequencer when the current instruction has finished execution. The next instruction to be executed is

pointed to by the instruction pointer found in the status register. A “1” restarts the Sequencer with the instruction currently pointed to by the instruction pointer. (See Bits 8–10 in

the Interrupt Status register.)

Bit 1 is the LM12(H)454/8’s system RESET bit. Writing a “1”

to Bit 1 stops the Sequencer (resetting the Configuration register’s START/STOP bit), resets the Instruction pointer to

“000” (found in the Interrupt Status register), clears the Conversion FIFO, and resets all interrupt flags. The RESET bit

will return to “0” after two clock cycles unless it is forced high

by writing a “1” into the Configuration register’s Standby bit.

A reset signal is internally generated when power is first applied to the part. No operation should be started until the RESET bit is “0”.

Writing a “1” to Bit 2 initiates an auto-zero offset voltage calibration. Unlike the eight-sample auto-zero calibration performed during the full calibration procedure, Bit 2 initiates a

“short” auto-zero by sampling the offset once and creating a

correction coefficient (full calibration averages eight samples

of the converter offset voltage when creating a correction coefficient). If the Sequencer is running when Bit 2 is set to “1”,

an auto-zero starts immediately after the conclusion of the

currently running instruction. Bit 2 is reset automatically to a

“0” and an interrupt flag (Bit 3, in the Interrupt Status register)

is set at the end of the auto-zero (76 clock cycles). After

completion of an auto-zero calibration, the Sequencer

fetches the next instruction as pointed to by the Instruction

RAM’s pointer and resumes execution. If the Sequencer is

stopped, an auto-zero is performed immediately at the time

requested.

Writing a “1” to Bit 3 initiates a complete calibration process

that includes a “long” auto-zero offset voltage correction (this

calibration averages eight samples of the comparator offset

voltage when creating a correction coefficient) followed by

an ADC linearity calibration. This complete calibration is

started after the currently running instruction is completed if

the Sequencer is running when Bit 3 is set to “1”. Bit 3 is reset automatically to a “0” and an interrupt flag (Bit 4, in the Interrupt Status register) will be generated at the end of the

calibration procedure (4944 clock cycles). After completion

of a full auto-zero and linearity calibration, the Sequencer

fetches the next instruction as pointed to by the Instruction

RAM’s pointer and resumes execution. If the Sequencer is

stopped, a full calibration is performed immediately at the

time requested.

Bit 4 is the Standby bit. Writing a “1” to Bit 4 immediately

places the LM12(H)454/8 in Standby mode. Normal operation returns when Bit 4 is reset to a “0”. The Standby com-

www.national.com 26

Page 27

2.0 Internal User-Programmable

Registers

mand (“1”) disconnects the external clock from the internal

circuitry, decreases the LM12(H)454/8’s internal analog circuitry power supply current, and preserves all internal RAM

contents. After writing a “0” to the Standby bit, the

LM12(H)454/8 returns to an operating state identical to that

caused by exercising the RESET bit. A Standby completion

interrupt is issued after a power-up completion delay that allows the analog circuitry to settle. The Sequencer should be

restarted only after the Standby completion is issued. The Instruction RAM can still be accessed through read and write

operations while the LM12(H)454/8 are in Standby Mode.

Bit 5 is the Channel Address Mask. If Bit 5 is set to a “1”, Bits

13–15 in the conversion FIFO will be equal to the sign bit (Bit

12) of the conversion data. Resetting Bit 5 to a “0” causes

conversion data Bits 13 through 15 to hold the instruction

pointer value of the instruction to which the conversion data

belongs.

Bit 6 is used to select a “short” auto-zero correction for every

conversion. The Sequencer automatically inserts an

auto-zero before every conversion or “watchdog” comparison if Bit 6 is set to “1”. No automatic correction will be performed if Bit 6 is reset to “0”.

The LM12(H)454/8’s offset voltage, after calibration, has a

typical drift of 0.1 LSB over a temperature range of −40˚C to

+85˚C. This small drift is less than the variability of the

change in offset that can occur when using the auto-zero

correction with each conversion. This variability is the result

of using only one sample of the offset voltage to create a correction value. This variability decreases when using the full

calibration mode because eight samples of the offset voltage

are taken, averaged, and used to create a correction value.

Bit 7 is used to program the SYNC pin (29) to operate as either an input or an output. The SYNC pin becomes an output

when Bit 7 is a “1” and an input when Bit 7 is a “0”. With

SYNC programmed as an input, the rising edge of any logic

signal applied to pin 29 will start a conversion or “watchdog”

comparison. Programmed as an output, the logic level at pin

29 will go high at the start of a conversion or “watchdog”

comparison and remain high until either have finished. See

Instruction RAM “00”, Bit 8.

Bits 8 and 9 form the RAM Pointer that is used to select

each of a 48-bit instruction’s three 16-bit sections during

read or write actions. A “00” selects Instruction RAM section

one, “01” selects section two, and “10” selects section three.

Bit 10 activates the Test mode that is used only during production testing. Leave this bit reset to “0”.

Bit 11 is the Diagnostic bit and is available only in the

LM12(H)458. It can be activated by setting it to a “1” (theTest

bit must be reset to a “0”). The Diagnostic mode, along with

a correctly chosen instruction, allows verification that the

LM12(H)458’s ADC is performing correctly. When activated,

the inverting and non-inverting inputs are connected as

shown in Table I.As an example, an instruction with “001” for

both V

IN+

results in a full-scale output.

2.3 INTERRUPTS

The LM12454 and LM12(H)458 have eight possible interrupts, all with the same priority. Any of these interrupts will

cause a hardware interrupt to appear on the INT pin (31) if

(Continued)

and V

while using the Diagnostic mode typically

IN−

they are not masked (by the Interrupt Enable register). The

Interrupt Status register is then read to determine which of

the eight interrupts has been issued.

TABLE 1. LM12(H)458 Input Multiplexer

Channel Configuration Showing Normal

Mode and Diagnostic Mode

Channel

Selection

Data

000 IN0 GND V

001 IN1 IN1 V

Normal Diagnostic

Mode Mode

V

V

IN+

IN−

V

IN+

REFOUT

REF+

V

GND

V

REF−

IN−

010 IN2 IN2 IN2 IN2

011 IN3 IN3 IN3 IN3

100 IN4 IN4 IN4 IN4

101 IN5 IN5 IN5 IN5

110 IN6 IN6 IN6 IN6

111 IN7 IN7 IN7 IN7

TABLE 2. LM12454 Input Multiplexer

Channel Configuration

Channel

Selection MUX+ MUX−

Data

000 IN0 GND

001 IN1 IN1

010 IN2 IN2

011 IN3 IN3

1XX OPEN OPEN

The Interrupt Status register, 1010 (A4–A1, BW=0) or

1010x (A4–A0, BW=1) must be cleared by reading it after

writing to the Interrupt Enable register. This removes any

spurious interrupts on the INT pin generated during an Interrupt Enable register access.

Interrupt 0 is generated whenever the analog input voltage

on a selected multiplexer channel crosses a limit while the

LM12(H)454/8 are operating in the “watchdog” comparison

mode. Two sequential comparisons are made when the

LM12(H)454/8 are executing a “watchdog” instruction. Depending on the logic state of Bit 9 in the Instruction RAM’s

second and third sections, an interrupt will be generated either when the input signal’s magnitude is greater than or less

than the programmable limits. (See the Instruction RAM, Bit

9 description.) The Limit Status register will indicate which

preprogrammed limit,

#

1or#2 and which instruction was ex-

ecuting when the limit was crossed.

Interrupt 1 is generated when the Sequencer reaches the

instruction counter value specified in the Interrupt Enable

register’s bits 8–10. This flag appears before the instruction’s execution.

Interrupt 2 is activated when the Conversion FIFO holds a

number of conversions equal to the programmable value

stored in the Interrupt Enable register’s Bits 11–15. This

value ranges from 0001 to 1111, representing 1 to 31 conversions stored in the FIFO. A user-programmed value of 0000

has no meaning. See Section 3.0 for more FIFO information.

The completion of the short, single-sampled auto-zero calibration generates Interrupt 3.

www.national.com27

Page 28

2.0 Internal User-Programmable

Registers

The completion of a full auto-zero and linearity

self-calibration generates Interrupt 4.

Interrupt 5 is generated when the Sequencer encounters an

instruction that has its Pause bit (Bit 1 in Instruction RAM

“00”) set to “1”.

The LM12(H)454/8 issues Interrupt 6 whenever it senses

that its power supply voltage is dropping below 4V (typ). This

interrupt indicates the potential corruption of data returned

by the LM12(H)454/8.

Interrupt 7 is issued after a short delay (10 ms typ) while the

LM12(H)454/8 returns from Standby mode to active operation using the Configuration register’s Bit 4. This short delay

allows the internal analog circuitry to settle sufficiently, ensuring accurate conversion results.

2.4 INTERRUPT ENABLE REGISTER

The Interrupt Enable register at address location 1001

(A4–A1, BW=0) or 1001x (A4–A0, BW=1) has READ/

WRITE capability. An individual interrupt’s ability to produce

an external interrupt at pin 31 (INT) is accomplished by placing a “1” in the appropriate bit location. Any of the internal

interrupt-producing operations will set their corresponding

bits to “1” in the Interrupt Status register regardless of the

state of the associated bit in the Interrupt Enable register.

See Section 2.3 for more information about each of the eight

internal interrupts.

Bit 0 enables an external interrupt when an internal “watchdog” comparison limit interrupt has taken place.

Bit 1 enables an external interrupt when the Sequencer has

reached the address stored in Bits 8–10 of the Interrupt Enable register.

Bit 2 enables an external interrupt when the Conversion

FIFO’s limit, stored in Bits 11–15 of the Interrupt Enable register, has been reached.

Bit 3 enables an external interrupt when the single-sampled

auto-zero calibration has been completed.

Bit 4 enables an external interrupt when a full auto-zero and

linearity self-calibration has been completed.

Bit 5 enables an external interrupt when an internal Pause

interrupt has been generated.

Bit 6 enables an external interrupt when a low power supply

condition (V

Bit 7 enables an external interrupt when the LM12(H)454/8

return from power-down to active mode.

Bits 8–10 form the storage location of the

user-programmable value against which the Sequencer’s

address is compared. When the Sequencer reaches an address that is equal to the value stored in Bits 8–10, an internal interrupt is generated and appears in Bit 1 of the Interrupt

Status register. If Bit 1 of the Interrupt Enable register is set

to “1”, an external interrupt will appear at pin 31 (INT).

The value stored in bits 8–10 ranges from 000 to 111, representing 0 to 7 instructions stored in the Instruction RAM. After the Instruction RAM has been programmed and the RESET bit is set to “1”, the Sequencer is started by placing a “1”

in the Configuration register’s START bit. Setting the INT 1

trigger value to 000 does not generate an INT 1 the first

time the Sequencer retrieves and decodes Instruction 000.

The Sequencer generates INT 1 (by placing a “1” in the Interrupt Status register’s Bit 1) the second time and after the

Sequencer encounters Instruction 000. It is important to re-

www.national.com 28

(Continued)

+<4V) has generated an internal interrupt.

A

member that the Sequencer continues to operate even if an

Instruction interrupt (INT 1) is internally or externally generated. The only mechanisms that stop the Sequencer are an

instruction with the PAUSEbit set to “1” (halts before instruction execution), placing a “0” in the Configuration register’s

STARTbit,or placing a “1” in the Configuration register’s RESET bit.

Bits 11–15 hold the number of conversions that must be

stored in the Conversion FIFO in order to generate an internal interrupt. This internal interrupt appears in Bit 2 of the Interrupt Status register. If Bit 2 of the Interrupt Enable register

is set to “1”, an external interrupt will appear at pin 31 (INT).

2.5 INTERRUPT STATUS REGISTER

This read-only register is located at address 1010 (A4–A1,

BW=0) or 1010x (A4–A0,BW=1). The corresponding flag

in the Interrupt Status register goes high (“1”) any time that

an interrupt condition takes place, whether an interrupt is enabled or disabled in the Interrupt Enable register. Any of the

active (“1”) Interrupt Status register flags are reset to “0”

whenever this register is read or a device reset is issued

(see Bit 1 in the Configuration Register).