Page 1

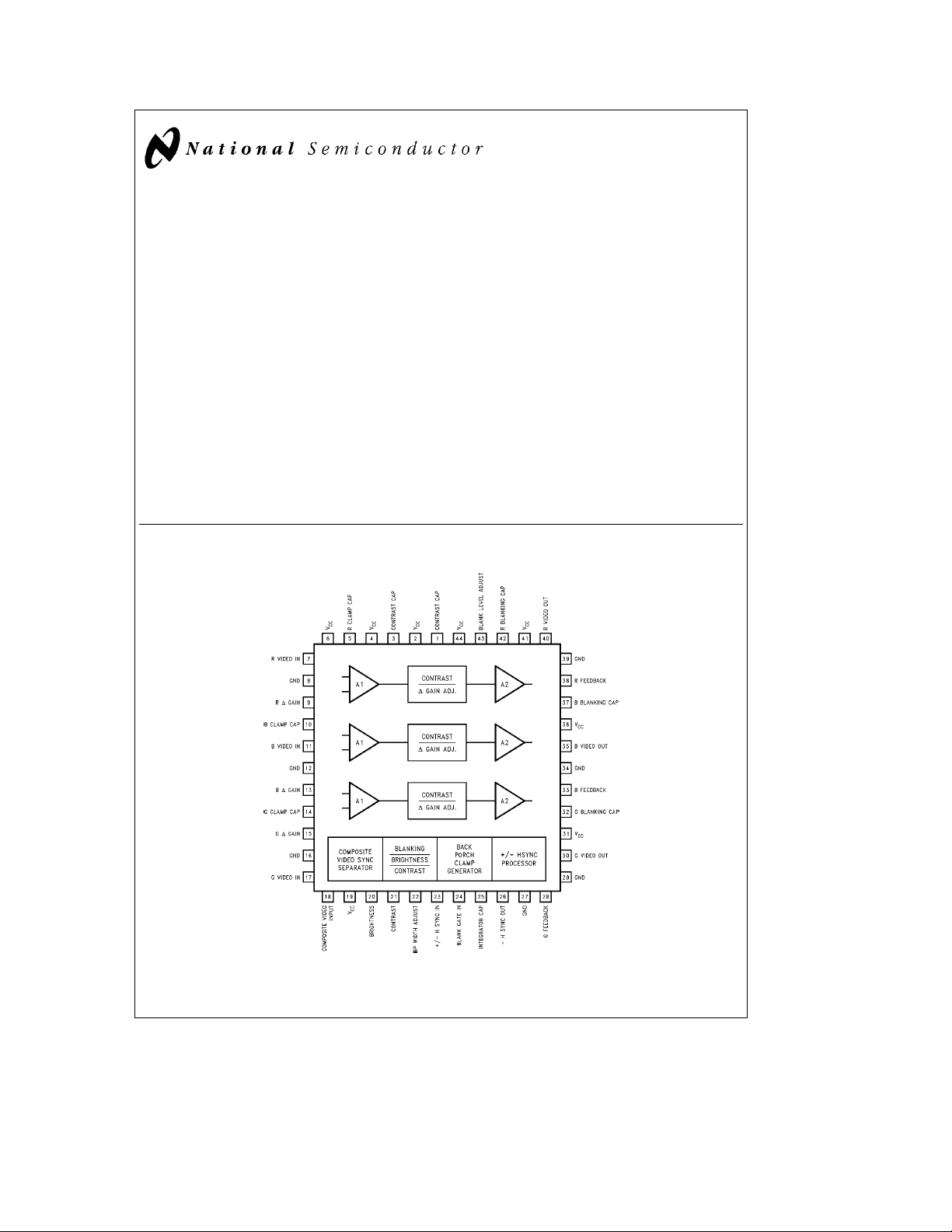

LM1204 150 MHz RGB Video Amplifier System

General Description

The LM1204 is a triple 150 MHz video amplifier system

designed specifically for high resolution RGB video display

applications. In addition to three matched video amplifiers,

the LM1204 contains a DC operated contrast control, a DC

operated drive control for each amplifier, and a dual clamping system for both brightness control and video blanking.

The LM1204 also contains a back porch clamp pulse generator which is activated by an externally supplied

g

H/HV

sync signal or by an external composite video signal. The

g

H/HV sync input will have priority over the composite vid-

eo input. A single

b

H/HV sync output is provided for the

automatically selected sync input signal. The back porch

clamp pulse width is user adjustable from 0.3 msto4ms.

The LM1204 video output stage will directly drive most

Hybrid or discrete CRT amplfier input stages without the

need for an external buffer transistor. The device has been

designed to operate from a 12V supply with all DC controls

operating over a 0V to 4V range providing for an easy interface to serial digital buss controlled monitors.

Block Diagram and Connection Diagram

Features

Y

Built-in video blanking function

Y

Built-in sync separator for composite video input

Y

Includes DC restoration of video signals

Y

Back porch clamp pulse width user adjustable

Y

DC control of brightness, contrast, blanking level, drive

and cutoff

Y

DC controls are 0V to 4V for easy interfacing to a

digitally controlled system

Key Specifications

Y

150 MHz large signal bandwidth (typ)

Y

2.3 ns rise/fall times (typ)

Y

0.1 dB contrast tracking (typ)

Y

g

3 dB drive (D gain) adjustments on R, G, B channels

(typ)

Applications

Y

High resolution CRT monitors

Y

Video AGC amplifier

Y

Wideband amplifier with gain and DC offset control

Top View

LM1204 150 MHz RGB Video Amplifier System

December 1994

Ordering Information

TL/H/11238– 1

Order Number LM1204V

See NS Package Number V44A

C

1995 National Semiconductor Corporation RRD-B30M115/Printed in U. S. A.

TL/H/11238

Page 2

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales

Office/Distributors for availability and specifications.

Supply Voltage, V

Pins 2, 4, 6, 19, 31, 41, 44 (Note 3) 13.5V

Peak Video Output Source Current

(Any One Amplifier) Pins 30, 35 or 39 30 mA

Voltage at Any Input Pin, V

MaximumgH Sync Input Voltage 5.5 V

Power Dissipation, PD (Above 25§C

Derate Based on iJAand TJ) 2.4W

CC

IN

GNDsV

s

V

IN

CC

Thermal Resistance, i

Junction Temperature, T

JA

J

52§C/W

150§C

ESD Susceptibility (Note 4) 2.5 kV

Storage Temperature

b

65§Cto150§C

Lead Temperature

Vapor Phase (60 seconds) 215

Infrared (15 seconds) 220

PP

Operating Ratings (Note 2)

C

§

C

§

Temperature Range 0§Cto70§C

Supply Voltage, V

CC

10.8VsV

CC

s

13.2V

DC Electrical Characteristics (Video Amplifier Section)

The following specifications apply for VCC(pins 2, 4, 6, 19, 31, 36, 41 and 44)e12V and T

e

S1

B, S2eB, S3, 4, 5 closed, V9, 13, 15e2V, V20, 21, 22, 24, 43e0.5V unless otherwise specified; see test circuit,

Figure 1

.

Symbol Parameter Conditions

I

I

Blank

I

Blank

I

Clamp

I

Clamp

V

V

V

H

V

L

V

CM43

I

I

24h

I

24l

I

FB

I

BB

I

CB

24h

B

24l

Supply Current No Video or Sync Input

S

Signals, S1

e

A (Max)

Input Bias Current S1eA

(Pin 9, 13, 15, 20, 21 or 22) (Max)

Blank Gate Input High Current V24e4V

Blank Gate Input Low Current V24e0V

Feedback Input Current

(Pin 28, 33 or 38)

Blank Cap Charge Current V

a

Blank Cap Discharge Current V

b

32,37,42

32,37,42

e

0V 185 75 mA (Min)

e

5V

Blank Cap Bias Current (Pins 32, 37, 42) 20 nA

Clamp Cap Charge Current V

a

Blank Cap Discharge Current V

b

5,10,14

5,10,14

e

0V 185 75 mA (Min)

e

5V

Clamp Cap Bias Current (Pins 5, 10, 14) 20 nA

Blank Gate High Input Voltage Input Signal is Not Blanked 2 V (Min)

Blank Gate Low Input Voltage Input Signal is Blanked 0.8 V (Max)

Blank Comparator Offset Voltage Voltage between V43 and

Any One Video Output (Max)

Video Output High Voltage R

(Pins 30, 35, 40) V28, 33, 38

Video Output Low Voltage R

(Pins 30, 35, 40) V28, 33, 38

e

350X

L

L

e

350X

e

0V

e

4V

Common Mode Range of Blank 0.5 V(Min)

Comparator (Pins 43, 28, 33, 38)

e

25§C unless otherwise specified.

A

Typical Limit

(Note 5) (Note 6)

100 125

0.3 2

0.01 2

25

150 nA

b

185

b

185

b

75 mA (Min)

b

75 mA (Min)

250

8.7 7 V(Min)

0.1 0.5 V(Max)

4 V(Max)

Units

mA

mA

mA

(Max)

mA

(Max)

mV

2

Page 3

DC Electrical Characteristics (Sync Separator/Processor Section)

The following specifications apply for VCC(Pins 2, 4, 6, 19, 31, 36, 41 and 44)e12V and T

specified. S1

Circuit

Symbol Parameter Conditions

b

HV

b

HV

V

23

Figure 1

OH

OL

e

B, S2eB, S3, 4, 5 closed, V9, 13, 15e2V, V20, 21, 22, 24, 43e0.5V, unless otherwise specified; see Test

.

Typical Limit

(Note 5) (Note 6)

b

H Sync Output Logic High (Pin 26) 4.2 2.4 V(Min)

b

H Sync Output Logic Low (Pin 26) 0.1 0.4 V(Max)

Quiescent DC Voltage atgH

Sync Input

3V

e

25§C, unless otherwise

A

Units

AC Electrical Characteristics (Video Amplifier Section)

The following specifications apply for VCC(Pins 2, 4, 6, 19, 31, 36, 41 and 44)e12V and T

specified. S1

Figure 1

Symbol Parameter Conditions

R

IN

A

Vmax

DA

Vtrack

DA

V2V

DA

V0.5V

DGain D Gain Range (Pins 9, 13, 15) V9, 13, 15e0V to 4V

DV

O

f

b

3dB

THD Video Amplifier Distortion V

t

R

t

F

V

ISO (1 MHz)

V

ISO (130 MHz)

e

B, S2eB, S3, 4, 5 closed, V9, 13, 15, 21, 24, 43e4V, V20e2V, unless otherwise specified; see Test Circuit

.

Video Amplifier Input Resistance 20 kX

Maximum Video Amplifier Gain f

e

12 kHz 10 5.5 V/V(Min)

IN

Amplifier Gain (Contrast)

Tracking (Note 7)

Attenuation at 2V Ref: A

Attenuation at 0.5V Ref: A

V21e2V 6 dB

V

max

V21e0.5V 28 20 dB(Min)

V

max

Max Brightness Tracking Error (Note 8) 100 mV

Video Amplifier Bandwidth (Note 9) V

e

3.5 V

OUT

OUT

PP

e

1VPP,fe12 kHz 0.3 %

Video Output Rise Time (Note 9) Square Wave Input

V

OUT

e

3.5 VPP,R

e

350X

L

Video Output Fall Time (Note 9) Square Wave Input

V

OUT

e

3.5 VPP,R

e

350X

L

Video Amplifier 1 MHz

Isolation (Notes 9, 10)

Video Amplifier 130 MHz

Isolation (Notes 9, 10)

e

25§C, unless otherwise

A

Typical Limit

(Note 5) (Note 6)

Units

0.1 dB

g

3dB

150 MHz

2.0 ns

2.3 ns

b

50 dB

b

10 dB

3

Page 4

AC Electrical Characteristics (Sync Separator/Processor Section)

The following specifications apply for VCC(Pins 2, 4, 6, 19, 31, 36, 41 and 44)e12V and T

specified. S1

e

A, S2eB, S3, 4, 5 closed, V9, 13, 15, 20, 21, 43e2V, unless otherwise specified; see Test Circuit

e

25§C, unless otherwise

A

Figure 1

and Timing Diagram for input waveform.

Symbol Parameter Conditions

V

18(Min)

V

18(Max)

V

23

Composite Video Input Voltage S2eA, Inpute10% Duty

(Pin 18) Cycle, Test for Loss of BP (Min)

Composite Video Input Voltage Pulse at Pin 26

(Pin 18) (Max)

g

H Sync Input Voltage (Pin 23) Inpute10% Duty Cycle

Back Porch Clamp Pulse Width S2eA, Pin 26eBP Output

e

at V

1V (Max)

24

Back Porch Clamp Pulse Width

e

at V

4V (Max)

24

Typical Limit

(Note 5) (Note 6)

0.15

2

1.6

1 1.4

300 600

Units

V

V

V

(Min)

ms

ns

MaximumgH Sync Input Frequency 600 KHz

D

HI

D

LO

t

pdl1

t

pdh1

t

pd1

t

pdl2

t

pdh2

t

pd2

t

pdl2–tpdl1

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur.

Note 2: Operating Ratings indicate conditions for which the device is functional, but do not guarantee specific performance limits. For guaranteed specifications

and test conditions, see the Electrical Characteristics. The guaranteed specifications apply only for the test conditions listed. Some performance characteristics

may degrade when the device is not operated under the listed test conditions.

Note 3: V

Note 4: Human body model, 100 pF discharged through a 1.5 kX resistor.

Note 5: Typical specifications are specified at

Note 6: Tested limits are guaranteed to National’s AOQL (Average Outgoing Quality Level).

Note 7: DA

gain change between any two amplifiers with the contrast voltage, V21, at either 4V or 2V measured relative to an A

max, the three amplifier gains might be 17.4 dB, 16.9 dB and 16.4 dB and change to 7.3 dB, 6.9 dB and 6.5 dB respectively for V21e2V. This yields the measured

typical

Note 8: Brightness tracking error is measured with all three video channels set for equal gain. The measured value is limited by the resolution of the measurement

equipment.

Note 9: When measuring video amplifier bandwidth or pulse rise and fall times, a double sided full ground plane printed circuit board is recommended. Video

amplifier isolation tests also require this printed circuit board. The measured rise and fall times are effective rise and fall times, taking into account the rise and fall

times of the generator.

Note 10: Measure output levels of either undriven amplifier relative to the driven amplifier to determine channel isolation. Terminate the undriven amplifier inputs.

Max Duty Cycle of Active High Test for Loss of Sync

H Sync (Pin 23) at Pin 26

Max Duty Cycle of Active Low

H Sync (Pin 23)

g

H Sync Input tobH Sync Inpute10% Duty Cycle

Output Low Delay

g

H Sync Input tobH Sync Inpute10% Duty Cycle

Output High Delay

g

H Sync Input Trailing Edge to Inpute10% Duty Cycle,

Back Porch Clamp Output Delay S2

e

A

Composite Video Input tobH Inpute10% Duty Cycle

Sync Output Low Delay

Composite Video Input tobH Inpute10% Duty Cycle

Sync Output High Delay

Composite Video Input Trailing Inpute10% Duty Cycle

Edge to Back Porch Clamp Output Delay S2

e

A

Composite Video andgH Sync Input Inpute10% Duty Cycle

b

to

H Sync Output Delta Delay

supply pins 2, 4, 6, 19, 31, 36, 41 and 44 must be externally wired together to prevent internal damage during VCCpower on/off cycle.

CC

a

25§C and represent the most likely parametric norm.

tracking is a measure of the ability of any two amplifiers to track each other and quantifies the matching of the three attenuators. It is the difference in

V

g

0.1 dB channel tracking.

22 %

22 %

100 ns

65 ns

70 ns

106 ns

68 ns

78 ns

6ns

max condition V21e4V. For example, at A

V

PP

PP

PP

V

4

Page 5

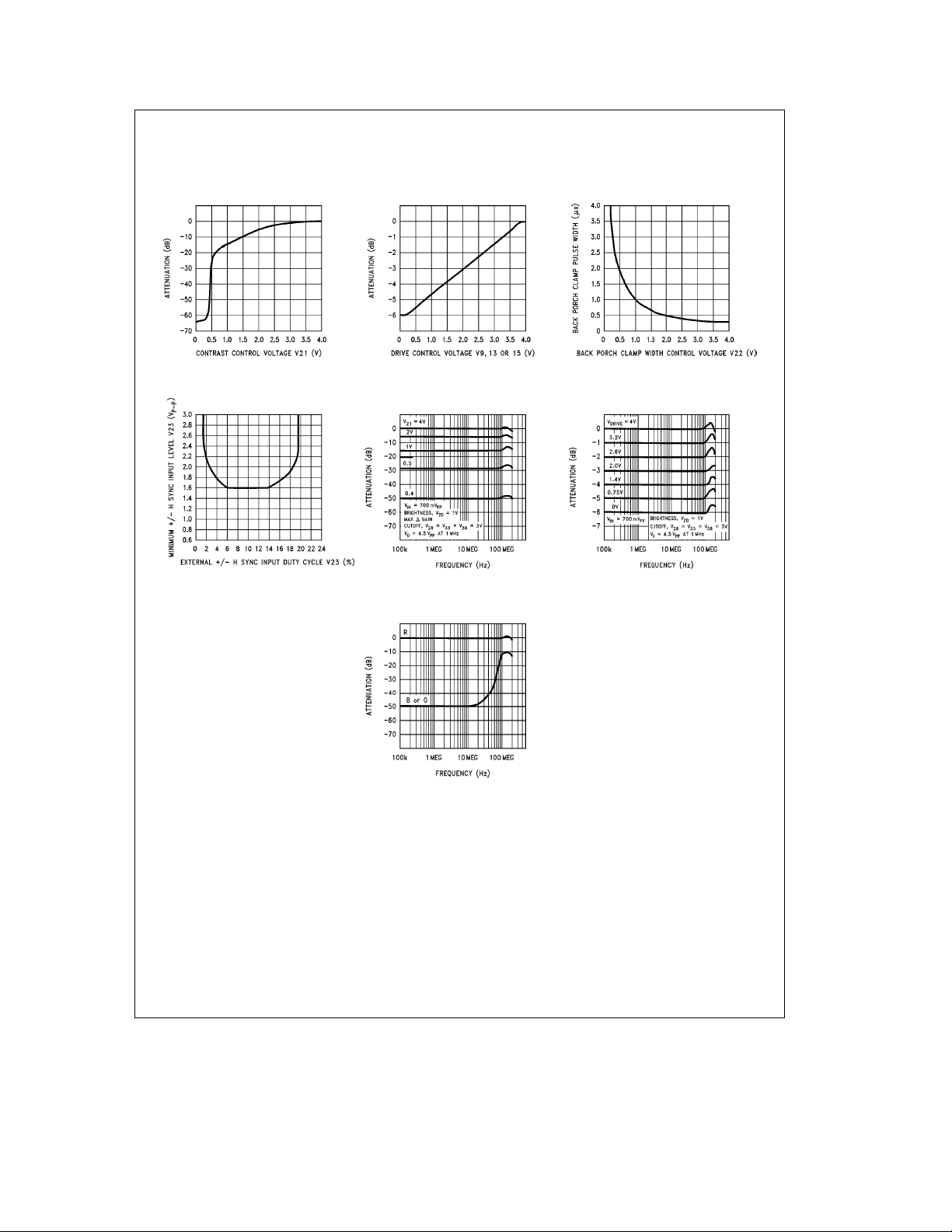

Typical Performance Characteristics V

CC

e

12V, T

e

25§C unless otherwise specified

A

Attenuation vs Contrast

Control Voltage (

Minimum External

Sync Input Level (V

vs Input Duty Cycle (%)

f

e

g

H

PP

12 kHz)

Attenuation vs Drive

Control Voltage (

f

e

12 kHz)

Back Porch Clamp Pulse

Width vs Pin 22 Voltage

)

Contrast vs Frequency Drive Control vs Frequency

Crosstalk vs Frequency

TL/H/11238– 2

5

Page 6

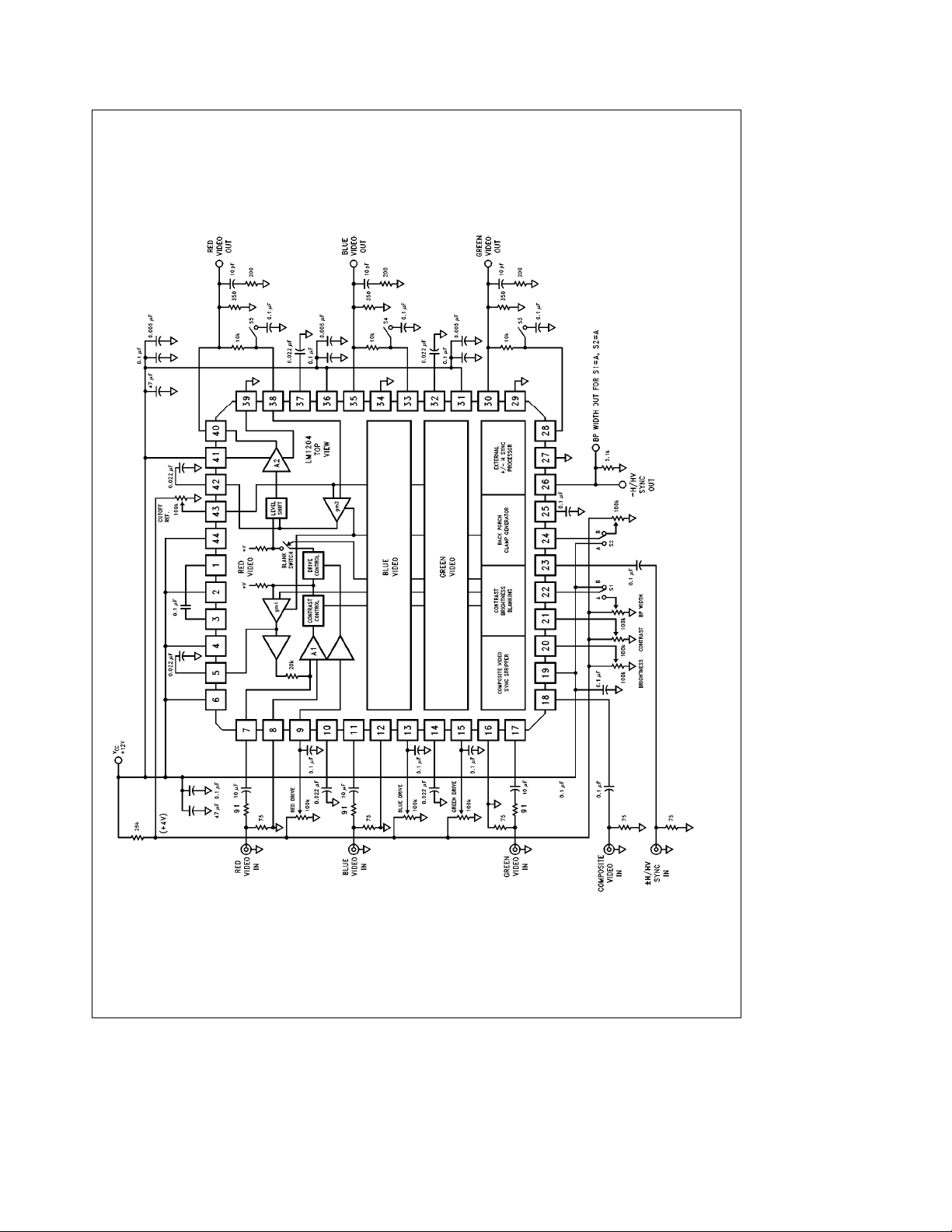

TL/H/11238– 3

FIGURE 1. LM1204 Test Circuit

6

Page 7

Timing Diagram

Input/Output Stages

b

H Sync Output Stage

TL/H/11238– 4

Composite Video Input

TL/H/11238– 6

TL/H/11238– 5

Video Output Stage

TL/H/11238– 21

7

Page 8

Input/Output Stages (Continued)

g

H/HV Sync Input

TL/H/11238– 7

Video Input Stage

TL/H/11238– 8

Pin Descriptions

VCC(Pins 2, 4, 6, 19, All VCCpins must be externally wired together. For stable operation, each supply pin should be

31, 36, 41, 44) bypassed with a 0.01 mF and a 0.1 mF capacitor connected as close to the pin as is possible.

Contrast Cap (Pins 1, 3) An external decoupling capacitor of value 0.1 mF should be connected between pins 1 and 3 for

R Clamp Cap (Pin 5) A 0.022 mFto0.1mF capacitor should be connected from this pin to ground. This capacitor allows

B Clamp Cap (Pin 10) A 0.022 mFto0.1mF capacitor should be connected from this pin to ground. This capacitor allows

G Clamp Cap (Pin 14) A 0.022 mFto0.1mF capacitor should be connected from this pin to ground. This capacitor allows

R Video In (Pin 7) This is the input for the red channel video signal, the signal should be AC coupled to the input through

B Video In (Pin 11) This is the input for the blue channel video signal, the signal should be AC coupled to the input

G Video In (Pin 17) This is the input for the green channel video signal, the signal should be AC coupled to the input

R D Gain (Pin 9) This is the gain adjustment pin for the red video channel. A 0V to 4V

B D Gain (Pin 13) This is the gain adjustment pin for the blue video channel. A 0V to 4 V

G D Gain (Pin 15) This is the gain adjustment pin for the green video channel. A 0V to 4 V

Compose Video Input This is the sync separator input pin. For Sync on Green systems, the green channel video signal

(Pin 18) should be AC coupled to pin 18 through a 0.1 mF capacitor.

Brightness Control If the LM1204 is used without blanking then this pin should be biased at 2.0 V

(Pin 20) for all three video channels is now controlled by pin 43 (blank level adjust pin). See

Contrast Control This pin simultaneously controls the gain of all three video channels. A 0V to 4 VDCinput voltage is

(Pin 21) applied to this pin, with 0V corresponding to minimum gain (i.e., maximum attenuation of video signal)

contrast control.

clamping of the red channel video signal to the reference black level.

clamping of the blue channel video signal to the reference black level.

clamping of the green channel video signal to the reference black level.

a10mF capacitor.

through a 10 mF capacitor.

through a 10 mF capacitor.

voltage is applied to this pin to

vary the gain of the red channel. Usually, the red channel is set for maximum gain and the gains of the

DC

blue and green channels are reduced relative to the red channel until white balance is achieved on

the CRT screen.

voltage is applied to this pin

to vary the gain of the blue channel.

to vary the gain of the green channel.

DC

voltage is applied to this pin

DC

. Brightness control

DC

Figure 4

.Ifthe

LM1204 is used with blanking then this pin allows the user to simultaneously DC offset the video

portion of the output signals of all three channels thus allowing brightness control (See

Figure 5

).

and 4V corresponding to maximum gain (i.e., minimum attenuation of the video signal).

8

Page 9

Pin Descriptions (Continued)

Back Porch Clamp Width The LM1204 provides DC restoration or clamping during the back porch interval of the video signal.

Adjust (Pin 22) The width of LM1204’s internally generated back porch clamp signal can be varied by applying a 0V

g

H Sync In (Pin 23) This is the external sync input pin, it accepts a negative or positive polarity signal, either horizontal

Blank Gate In (Pin 24) This is the blank gate input pin. The LM1204 allows video blanking at the preamplifier. If blanking is

Integrator Cap (Pin 25) A 0.1 mF capacitor should be connected from this pin to ground. This capacitor allows the LM1204 to

b

H Sync Out (Pin 26) This output pin provides a negative polarity horizontal sync signal for other system uses. There is

G Feedback (Pin 28) This is the cutoff adjustment input for the green video channel. The green video output signal from

B Feedback (Pin 33) This is the cutoff adjustment input for the blue video channel. The blue video output signal from pin

R Feedback (Pin 38) This is the cutoff adjustment input for the red video channel. The red video output signal from pin 40

G Video Output This is the green channel video output.

(Pin 30)

B Video Output This is the blue channel video output.

(Pin 35)

R Video Output This is the red channel video output.

(Pin 40)

G Blank Clamp Cap A 0.022 mFto0.1mF capacitor should be connected from this pin to ground. This capacitor allows

(Pin 32) blanking for the green video channel.

B Blank Clamp Cap A 0.022 mFto0.1mF capacitor should be connected from this pin to ground. This capacitor allows

(Pin 37) blanking for the blue video channel.

R Blank Clamp Cap A 0.022 mFto0.1mF capacitor should be connected from this pin to ground. This capacitor allows

(Pin 42) blanking for the red video channel.

Blank Level Adjust This pin serves two functions depending on whether the LM1204 is used with blanking or without

(Pin 43) blanking. If blanking is not selected then pin 20 should be biased at 2.0 V

GND (Pins 8, 12 16, 27, Ground. All ground pins must be connected to the ground plane.

29, 34, 39)

to4V

voltage to this pin. The back porch clamp signal width can be varied from approximately

DC

0.3 msto4.0ms by applying 4V to 0.5V respectively. By connecting the blank gate input pin (pin 24)

to V

, the back porch clamp pulse can be monitored on thebH Sync output pin (pin 26). See

CC

Figures 4

and5. By connecting pin 22 to VCC, the LM1204 functions as a non-gated amplifier

requiring no clamping. See Section 4 under application hints for further information.

sync or a composite sync (1.2 V

polarity (TTL compatible) horizontal sync or composite sync output on pin 26. If the composite video

minimum amplitude). The LM1204 also provides a negative

PP

input (pin 18) is not used then an H Sync signal should be AC coupled to this pin through a 0.1 mF

capacitor. The

g

H Sync input has priority over the composite video input if both signals are present.

desired then a TTL compatible, negative polarity blanking signal should be applied to this pin. During

the blanking interval, all three video outputs are level shifted to the blank level set by the voltage at

pin 43. If blanking is not required then, pin 24 should be biased at 4V.

Connecting pin 24 to V

signal. The user can observe the change in back porch width as the potential at pin 22 is varied (see

Figures 4

integrate the

and5).

g

H Sync input signal and genreate the proper polarity switch forbH Sync output.

approximately 100 ns delay between the

will cause pin 26 to output the internally generated back porch clamp

CC

g

H Sync input signal at pin 23 and thebH Sync output

signal at pin 26.

Connecting pin 24 to V

signal. The user can observe the change in back porch clamp pulse width as the potential at pin 22 is

varied (See

Figures 4

will cause pin 26 to output the internally generated back porch clamp

CC

and5).

pin 30 is fed back to this input through a potentiometer thus allowing the user to individually adjust

the cutoff (black reference) level for each gun. The signal level at this pin should be between 0.5V

and 4V.

35 is fed back to this input through a potentiometer thus allowing the user to individually adjust the

cutoff (black reference) level for each gun. The signal level at this pin should be between 0.5V and

4V.

is fed back to this input through a potentiometer thus allowing the user to individualy adjust the cutoff

(black reference) level for each gun. The signal level at this pin should be between 0.5V and 4V.

and pin 43 assumes the

role of brightness control. Varying the potential at pin 43 will simultaneously DC offset the video

output signals of all three channels (See

Figure 4

). If the LM1204 is used with blanking then during

DC

the blanking interval, all three video output signals will be level shifted to the blank level. The desired

blank level can be set by adjusting the potential at pin 43. Brightness control is now made possible

by varying the potential at pin 20. Adjusting the brightness control DC offsets the video portion of the

signal relative to the fixed blank level (all channels are affected simultaneously). See

Figure 5

.

9

Page 10

Applications Hints

The LM1204 is a wideband video amplifier system designed

specifically for high resolution RGB CRT monitors. The device includes circuitry for DC restoration of video signals

and also allows contrast and brightness control. DC restoration is done during the back porch interval of the video signal. An internal sync separator generates a back porch

clamp signal either from a ‘‘Sync on Green’’ signal applied

to the composite video input (pin 18) or from an externally

g

supplied

g

is not present then the device syncs off the composite video

input. The internally generated back porch clamp pulse

width is user adjustable.

A blanking function is also included. This allows the user to

cutoff the beam current in the CRT’s guns during the blanking interval thereby preventing horizontal retrace lines from

being visible. Normally blanking is done by applying a high

voltage pulse at the grid. However, blanking at the cathode

using the LM1204 leads to ease of design and lowered cost.

Figure 2

nel and the control logic. The two modes of operation, with

and without blanking, are described below in detail.

H Sync signal . The LM1204 first looks at the

H Sync input (pin 23), if an external horizontal sync signal

shows the block diagram of the green video chan-

1.0 Operation without Blanking

For operation without blanking, the blank gate input (pin 24)

should be connected to

parator to connect switch S2 to position Y (See

Furthermore, the brightness control input pin (pin 20) should

be biased at a potential between 1V (Min) and 3.8V (Max), it

is best to bias this pin at 2V. The video signal is AC coupled

to the input of the LM1204 as shown for the green channel

in

Figure 2

nal (See

clamping pulse goes low, causing switches S1A and S1B to

be closed. The closure of S1A causes g

itor C2 to a potential determined by the DC voltage at pin

20. This allows g

coupled video signal at the input of A1. When the back

porch clamping pulse is high, S1A and S1B are opened.

With S1A open, g

now holds the DC bias voltage. The transconductance

stage g

and holds the input of A1 at the desired DC bias.

The LM1204 uses black level clamping at the back porch of

the video signal to accomplish DC restoration. The transconductance stage g

clamp period to provide a sample and hold function. During

the back porch clamp period, DC feedback from LM1204’s

video output is compared with the voltage set by potentiometer R9. Depending on A2’s output voltage, C6 is either

charged or discharged so that the feedback loop consisting

of g

black level. All this occurs during the back porch clamp period. During the video portion of the signal, g

and C6 holds the fixed black level reference voltage. The

beginning of each new line on the raster always starts from

a fixed reference black level thus restoring the DC component of each line.

A2 is a summing amplifier that adds a DC offset component

from g

R9 will DC offset the output signals of all three channels

thus providing brightness control. Individual cutoff adjust-

. During the back porch interval of the video sig-

Figure 3

1 therefore functions as a sample and hold device

m

2 and A2 is stabilized and the output is clamped to the

m

2 to the video signal from the multiplier. Adjusting

m

a

4V. This causes the blank com-

Figure 2

), the internally generated back porch

1 to charge capac-

m

1 to set up an average DC bias for the AC

m

1 is effectively disconnected from C2, C2

m

2 is enabled during the back porch

m

2 is disabled

m

ment for each channel is done by varying the feedback voltage at each of the R, G and B feedback inputs (Pins 38, 28

and 33). For example, cutoff adjustment for the green channel is done by potentiometer R8 shown in

Adjusting the contrast control (potentiometer R3 in

2

) varies the peak to peak amplitude (includes sync tip if

present) of all three video output signals relative to their

black reference level. The D Gain adjust (pins 9, 15 and 13

for R, G, and B channels respectively) allows the user to

individually adjust the AC gain of each channel. For example

the AC gain of the green channel is adjusted using potentiometer R5 as shown in

is set for maximum gain and the gains of the blue and green

channels are reduced until white balance is achieved on the

CRT monitor’s screen.

operation without blanking.

Figure 2

Figure 4

. Normally the red channel

shows the adjustments for

2.0 Operation with Blanking

Much of what was discussed in Section 1.0 also applies

when the LM1204 is used with the blanking function. However, there are notable differences as described herein. For

operation with blanking, a TTL compatible blanking signal

must be applied to the blank gate input (pin 24).

During the blanking period, the blanking comparator connects switch S2 to position X (See

the LM1204 to level shift the video output signal to the blank

level. Adjusting R9 will adjust the blank level of all three

channels. Individual blank level adjustment for each chan-

).

nel is done by varying the feedback voltage at each of the

R, G and B feedback inputs (pin 38, 28 and 33). In

this is done by adjusting potentiometer R8 for the green

channel.

During the video portion of the video signal, S2 is connected

to position Y. Brightness control is now accomplished by

varying the potential at the brightness control pin (pin 20).

Adjusting R6 offsets the video portion of all three output

signals relative to the fixed blank level, restoring the DC

level of the video signal.

operation with blanking.

Figure 5

Figure 2

shows the adjustments for

3.0 Stability Considerations

For optimum performance and stable operation, a double

sided PC board with adequate ground plane is essential.

Moreover, soldering the LM1204 on to the PC board will

yield best results. Each supply pin (pins 2, 4, 6, 19, 31, 36,

41 and 44) should be bypassed with a 0.01 mF and a 0.1 mF

capacitor connected as close to the supply pin as is possible.

When driving the LM1204 from a 75X video source, the

cable is terminated with 75X to minimize reflections caused

by transmission line effects. However, the input impedance

of LM1204 is capacitive and is also affected by the stray

capacitance of the PC board. Thus the input impedance is a

function of frequency. This changes the impedance of the

cable termination. This can introduce overshoot and ringing

in LM1204’s pulse response. A 100X resistor in series with

the blocking capacitor at the video input will minimize overshoot and ringing (see

empirically determined. 100X is a good starting value.

Since the LM1204 is a wide bandwidth amplifier with high

gain at high frequencies, the device may oscillate when driving a large capacitive/inductive load. To prevent oscillation,

the amplifier’s gain is rolled off at high frequencies. This is

accomplished by an RC network comprised of a resistor in

Figure 8

). The value of the resistor is

Figure 2

.

). This causes

Figure 2

Figure

10

Page 11

3.0 Stability Considerations (Continued)

series with a capacitor connected from the video output pin

to ground (see Test Circuit,

resistor in series with 10 pF is quite adequate for most applications. However, if oscillations don’t cease then the value

of the resistor should be decreased or the value of the capacitor should be increased or a combination of the two.

Figure 1

). A 110X to 200X

LM1204

Non-Gated High

Frequency Application

By connecting the back porch width adjust pin (pin 22) to

V

, the LM1204 functions as a non-gated amplifier requir-

CC

ing no sync or blanking signals.

frequency amplifier with variable gain and DC offset control.

In this mode of operation, filtered DC feedback must be

provided to pins 28, 33 and 38 as shown in

Figure 9

shows a triple high

Figure 9

.

FIGURE 2. Block Diagram Showing Timing Circuitry and Green Video Channel

FIGURE 3. Composite Video and Timing Signals

11

TL/H/11238– 9

TL/H/11238– 10

Page 12

TL/H/11238– 11

TL/H/11238– 12

FIGURE 4. LM1204 Adjustments without Blanking

12

TL/H/11238– 13

TL/H/11238– 14

Page 13

FIGURE 5. LM1204 Adjustments with Blanking

13

TL/H/11238– 15

Page 14

Typical Applications Circuits

Figure 4

TL/H/11238– 16

pin should be bypassed with a 0.01 mF and a 0.1 mF capacitor connected as close to the pin as is possible.

CC

for explanation of adjustments). Each V

FIGURE 6. The LM1204 driving cascode CRT video amplifiers and operating without blanking. Brightness control is accomplished by potentiometer R12 (See

14

Page 15

Typical Applications Circuits (Continued)

TL/H/11238– 17

Figure 5

pin should be bypassed with a 0.01 mF and a 0.1 mF capacitor connected as close to the pin as is possible.

CC

for explanation of adjustments. Each V

FIGURE 7. The LM1204 driving cascode CRT video amplifiers and operating with blanking. The video signal is level shifted to the user adjustable blank level

during the blanking period. Brightness control DC offsets the video signal relative to the fixed blank level and is accomplished by potentiometer R7. See

15

Page 16

Typical Applications Circuits (Continued)

FIGURE 8. Complete circuitry for an RGB CRT video board using the LM1204 and LH2426AS.

The video output signals from LH2426AS are AC coupled and diode clamped to greater than 80V.

16

TL/H/11238– 18

Page 17

Typical Applications Circuits (Continued)

FIGURE 8. (Continued)

17

TL/H/11238– 20

Page 18

Typical Applications Circuits (Continued)

TL/H/11238– 19

pin should be

CC

bypassed with a 0.01 mF and a 0.1 mF capacitor connected as close to the pin as is possible.

FIGURE 9. Three channel high frequency amplifier with gain and DC offset control (non-video application). Each V

18

Page 19

19

Page 20

Physical Dimensions inches (millimeters)

LM1204 150 MHz RGB Video Amplifier System

Order Number LM1204V

NS Package Number V44A

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL

SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or 2. A critical component is any component of a life

systems which, (a) are intended for surgical implant support device or system whose failure to perform can

into the body, or (b) support or sustain life, and whose be reasonably expected to cause the failure of the life

failure to perform, when properly used in accordance support device or system, or to affect its safety or

with instructions for use provided in the labeling, can effectiveness.

be reasonably expected to result in a significant injury

to the user.

National Semiconductor National Semiconductor National Semiconductor National Semiconductor

Corporation Europe Hong Kong Ltd. Japan Ltd.

1111 West Bardin Road Fax: (

Arlington, TX 76017 Email: cnjwge@tevm2.nsc.com Ocean Centre, 5 Canton Rd. Fax: 81-043-299-2408

Tel: 1(800) 272-9959 Deutsch Tel: (

Fax: 1(800) 737-7018 English Tel: (

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Fran3ais Tel: (

Italiano Tel: (

a

49) 0-180-530 85 86 13th Floor, Straight Block, Tel: 81-043-299-2309

a

49) 0-180-530 85 85 Tsimshatsui, Kowloon

a

49) 0-180-532 78 32 Hong Kong

a

49) 0-180-532 93 58 Tel: (852) 2737-1600

a

49) 0-180-534 16 80 Fax: (852) 2736-9960

Loading...

Loading...