Page 1

®

PRODUCT SPECIFICATIONS

Integrated Circuits Group

LH28F800BVB-TTL90

Flash Memory

8M (1M × 8/512K × 16)

(Model No.: LHF80V07)

Spec No.: EL114067

Issue Date: August 27, 1999

Page 2

SHARP

LHFSOVO7

@Handle this document carefully for it contains material protected by international copyright law.

Any reproduction, full or in part, of this material is prohibited without the express written

permission of the company.

l When using the products covered herein, please observe the conditions written herein and the

precautions outlined in the following paragraphs. In no event shall the company be liable for any

damages resulting from failure to strictly adhere to these conditions and precautions.

(1) The products covered herein are designed and manufactured for the following application

areas. When using the products covered herein for the equipment listed in Paragraph (2),

even for the following application areas, be sure to observe the precautions given in

Paragraph (2). Never use the products for the equipment listed in Paragraph (3).

*Office electronics

*Instrumentation and measuring equipment

*Machine tools

*Audiovisual equipment

*Home appliance

*Communication equipment other than for trunk lines

(2) Those contemplating using the products covered herein for the following equipment which

demands high reliabilitv, should first contact a sales representative of the company and then

accept responsibility for incorporating into the design fail-safe operation, redundancy, and

other appropriate measures for ensuring reliability and safety of the equipment and the

overall system.

*Control and safety devices for airplanes, trains, automobiles, and other

transportation equipment

*Mainframe computers

*Traffic control systems

l Gas leak detectors and automatic cutoff devices

*Rescue and security equipment

*Other safety devices and safety equipment, etc.

(3) Do not use the products covered herein for the following equipment which demands

extremely high performance in terms of functionality, reliability, or accuracy.

*Aerospace equipment

l Communications equipment for trunk lines

*Control equipment for the nuclear power industry

l Medical equipment related to life support, etc.

(4) Please direct all queries and comments regarding the interpretation of the above three

Paragraphs to a sales representative of the company.

@Please direct all queries regarding the products covered herein to a sales representative of the

company.

Rev. 1.1

Page 3

SliARP

LHF80V07

CONTENTS

PAGE

1 INTRODUCTION.. ...........................................................

1. I Features ........................................................................

1.2 Product Overview.. ......................................................

2 PRINCIPLES

2.1 Data Protection..

3 BUS OPERATION ...........................................................

3.1 Read.. ...........................................................................

3.2 Output Disable..

3.3 Standby

3.4 Deep Power-Down..

3.5 Read Identifier Codes Operation..

3.6 Write..

4 COMMAND

4.1 Read Array Command ................................................

4.2 Read Identifier Codes Command

4.3 Read Status Register Command..

4.4 Clear Status Register Command ................................. 12

4.5 Block Erase Command..

4.6 Word/Byte Write Command..

4.7 Block Erase Suspend Command

4.8 Word/Byte Write Suspend Command..

4.9 Considerations of Suspend.. ....................................... 14

4.10 Block Locking.. ........................................................ 14

4.10.1 V,,=V,, for Complete Protection..

4.10.2 WP#=V,, for Block Locking.. ............................

4.10.3 WP#=V,, for Block Unlocking.. ........................ 14

OF OPERATION..

...........................................................

...........................................................

......................................................................... 8

..................................................... 8

.............................................

DEFINITIONS..

.....................................

...............................

. ............................

................

.............................................

.: .........................

............................... 12

............................... 12

..................................... 13

................................ 13

...................... 14

....................

.3

3

.3

.7

8

.8

.8

.8

.9

.9

9

12

12

14

14

PAGE

5 DESIGN CONSIDERATIONS

5.1 Three-Line Output Control .......................................

5.2 RY/BY# and Block Erase and Word/Byte Write

Polling.. .................................................................... 20

5.3 Power Supply Decoupling ........................................

5.4 V,, Trace on Printed Circuit Boards ........................ 20

5.5 V,, . V,,, RP# Transitions.. ..................................... 21

5.6 Power-Up/Down Protection..

5.7 Power Dissipation..

6 ELECTRICAL SPECIFICATIONS ............................... 22

6.1 Absolute Maximum Ratings ..................................... 22

6.2 Operating Conditions

6.2.1 Capacitance.. ....................................................... 22

6.2.2 AC Input/Output Test Conditions

6.2.3 DC Characteristics ..............................................

6.2.4 AC Characteristics - Read-Only Operations.. ..... 26

6.2.5 AC Characteristics - Write Operations

6.2.6 Alternative CE#-Controlled Writes..

6.2.7 Reset Operations .................................................

6.2.8 Block Erase and Word/Byte Write Performance 34

7 PACKAGE AND PACKING SPECIFICATIONS ......... 35

................................................... 21

...................................... 20

20

20

....................................

................................................

....................... 23

............... 29

...................

2 1

22

24

3 1

33

1

Rev. 1.1

Page 4

SHARIP

LH28F8OOBVB-TTL90

8M-BIT (1Mbit x 8 / 5 12Kbit x 16)

Smart3 Flash MEMORY

n Smart3 Technology

- 2.7V-3.6V Vcc

-

2.7V-3.6V or 11.4V-12.6V Vpp

n User-Configurable x8 or x 16 Operation

n High-Performance Access Time

- 90ns(2.7V-3.6V)

n Operating Temperature

- 0°C to +7O”C

n Optimized Array Blocking Architecture

-

Two 4K-word Boot Blocks

-

Six 4K-word Parameter Blocks

-

Fifteen 32K-word Main Blocks

-

Top Boot Location

n Extended Cycling Capability

-

100,000 Block Erase Cycles

n Enhanced Automated Suspend Options

-

Word/Byte Write Suspend to Read

-

Block Erase Suspend to Word/Byte Write

-

Block Erase Suspend to Read

LHF80V07

n Enhanced Data Protection Features

n Automated Word/Byte Write and Block Erase

n Low Power Management

n SRAM-Compatible Write Interface

n Chip Size Packaging

n ETOXTM* Nonvolatile Flash Technology

n CMOS Process (P-type silicon substrate)

n Not designed or rated as radiation hardened

-

Absolute Protection with Vpp=GND

-

Block Erase and Word/Byte Write Lockout

during Power Transitions

-

Boot Blocks Protection with WP#=VIL

-

Command User Interface

- Status Register

-

Deep Power-Down Mode

-

Automatic Power Savings Mode Decreases

ICC in Static Mode

- 48-Ball CSP

2

SHARP’s LH28F800BVB-TTL90 Flash memory with Smart3 technology is a high-density, low-cost, nonvolatile, read/write

storage solution for a wide range of applications. LH28F800BVB-TTL90 can operate at V,,=2.7V-3.6V and V,,=2.7V-3.6V

Its low voltage operation capability realize battery life and suits for cellular phone application.

Its Boot. Parameter and Main-blocked architecture, flexible voltage and extended cycling provide for highly flexible

:omponent suitable for portable terminals and personal computers. Its enhanced suspend capabilities provide for an ideal

solution for code + data storage applications. For secure code storage applications, such as networking, where code is either

lirectly executed out of flash or downloaded to DRAM, the LH28F8OOBVB-TTL90 offers two levels of protection: absolute

lrotection with V,, at GND, selective hardware boot block locking. These alternatives give designers ultimate control of their

:ode security needs.

Ihe LH28F800BVB-TTL90 is manufactured on SHARP’s 0.35um ETOXTM* process technology. It come in chip-size

lackage: the 48-ball CSP ideal for board constrained applications.

“ETOX is a trademark of Intel Corporation

Rev. 1.1

Page 5

SHARP

LHF8OVO7 3

1 INTRODUCTION

This datasheet contains LH28F800BVB-TI’L90

specifications. Section 1 provides a flash memory

overview. Sections 2,3,4 and 5 describe the memory

organization and functionality. Section 6 covers electrical

specifications.

1.1 Features

Key enhancements of LH28F8OOBVB-TTL90 Smart3

Flash memory are:

*Smart3 Technology

*Enhanced Suspend Capabilities

*Boot Block Architecture

Please note following important differences:

l

VPPLK has been lowered to 1.5V to support 2.7V-3.6V

block erase and word/byte write operations. The V,,

voltage transitions to GND is recommended for

designs that switch V,, off during read operation.

*To take advantage of Smart3 technology, allow V,,

and V,, connection to 2.7V-3.6V.

1.2 Product Overview

The LH28F800BVB-TTL90 is a high-performance 8M-bit

Smart3 Flash memory organized as lM-byte of 8 bits or

512K-word of 16 bits. The lM-byte/512K-word of data is

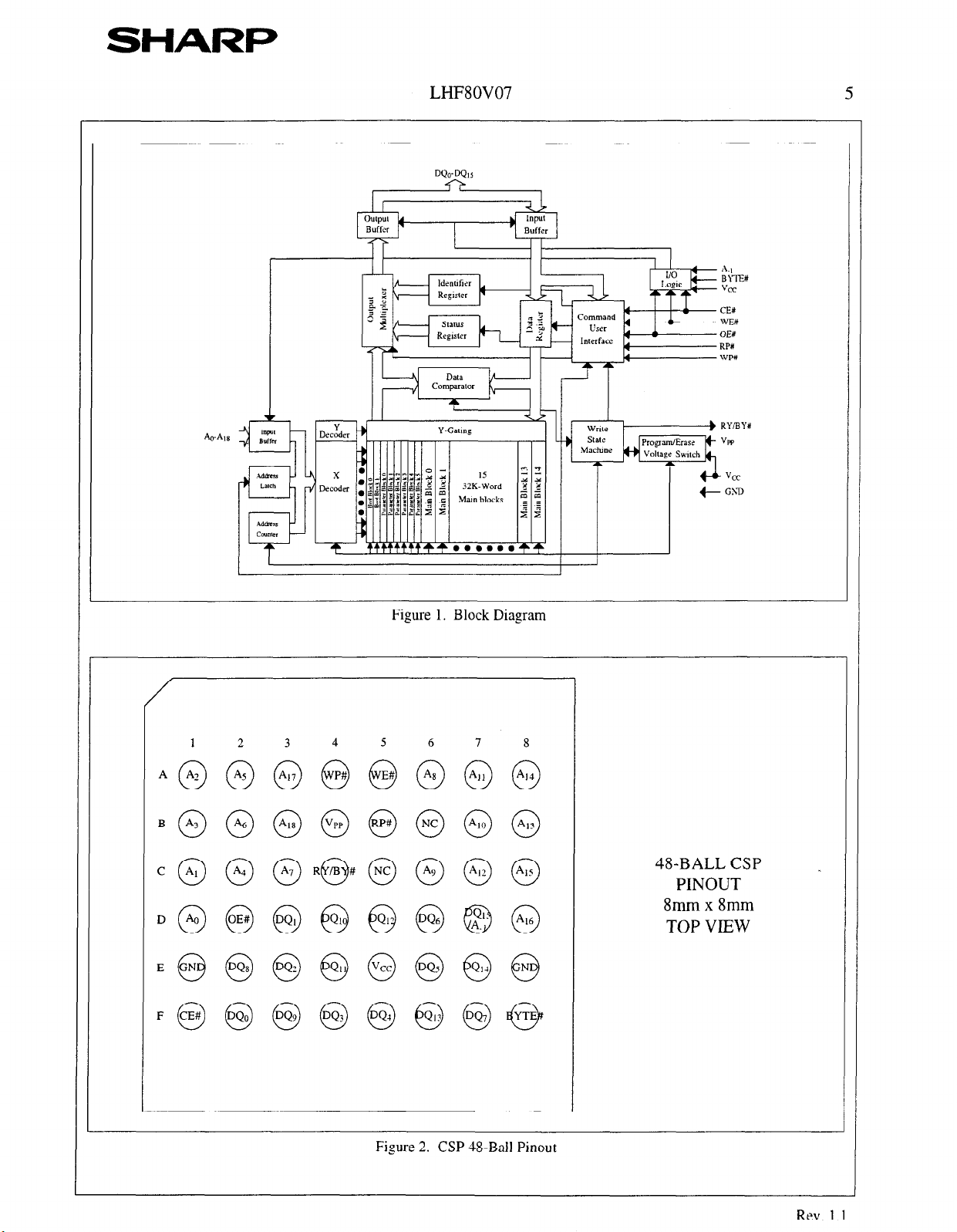

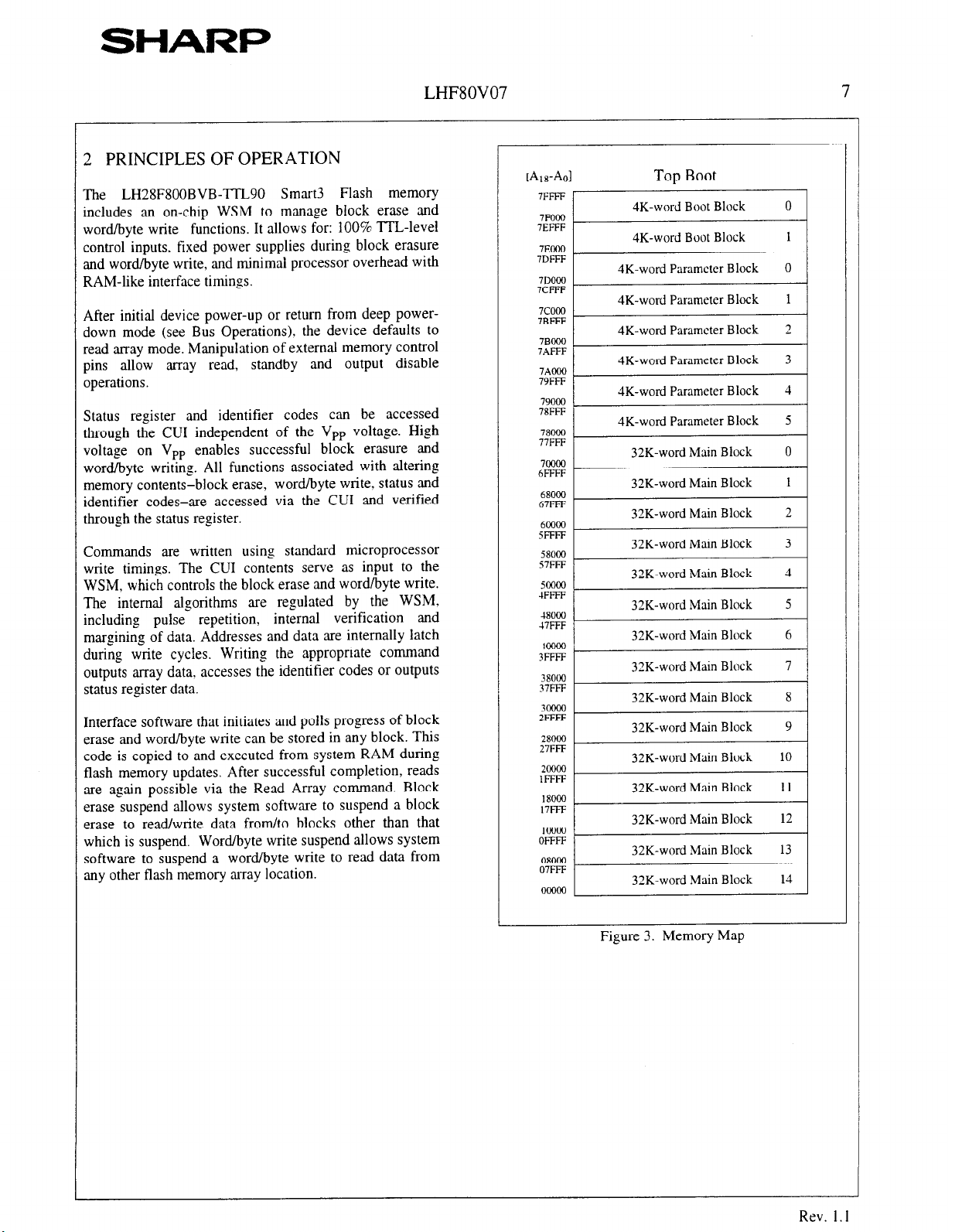

uranged in two 8K-byte/4K-word boot blocks, six SKJytel4K-word parameter blocks and fifteen 64K-byte/32Kword main blocks which are individually erasable intystem. The memory map is shown in Figure 3.

Smart3 technology provides a choice of V,, and V,,

:ombinations, as shown in Table 1, to meet system

xrformance and power expectations. V,, at 2.7V-3.6V

:liminates the need for a separate 12V converter, while

V,,=12V maximizes block erase and word/byte write

performance. In addition to flexible erase and program

voltages. the dedicated V,, pin gives complete data

protection when VPplVPPLK.

Table 1. V,, and V,, Voltage Combinations Offered by

Smart3 Technoloav

V,, Voitage

i

2.7V-3.6V 1 2.7V-3.6V, 11.4V-12.6V 1

Internal V,, and V,, detection Circuitry automatically

configures the device for optimized read and write

operations.

A Command User Interface (CUI) serves as the interface

between the system processor and internal operation of the

device. A valid command sequence written to the CUI

initiates device automation. An internal Write State

Machine (WSM) automatically executes the algorithms

and timings necessary for block erase and word/byte write

operations.

A block erase operation erases one of the device’s 32Kword blocks typically within 0.51s (2.7V-3.6V V,,,

11.4V-12.6V V,,), 4K-word blocks typically within 0.3 1s

(2.7V-3.6V V,,, 11.4V-12.6V V,,) independent of other

blocks. Each block can be independently erased 100,000

times. Block erase suspend mode allows system software

to suspend block erase to read or write data from any other

block.

Writing memory data is performed in word/byte

increments of the device’s 32K-word blocks typically

within 12.6~~ (2.7V-3.6V V,,, 11.4V-12.6V V,,), 4Kword blocks typically within 24.5~~ (2.7V-3.6V V,,,

11.4V-12.6V V,,). Word/byte write suspend mode

enables the system to read data or execute code from any

other flash memory array location.

LzJ

V,, Voltage

Rev. 1.1

Page 6

SHARP

LHF8OVO7 4

The boot blocks can be locked for the WP# pin. Block

erase or word/byte write for boot block must not be carried

out by WP# to Low and RP# to V,,.

The status register indicates when the WSM’s block erase

or word/byte write operation is finished.

The RY/BY# output gives an additional indicator of WSM

activity by providing both a hardware signal of status

(versus software polling) and status masking (interrupt

masking for background block erase, for example). Status

polling using RY/BY# minimizes both CPU overhead and

system power consumption. When low, RY/BY# indicates

that the WSM is performing a block erase or word/byte

write. RY/BY#-high Z indicates that the WSM is ready for

a new command, block erase is suspended (and word/byte

write is inactive), word/byte write is suspended, or the

device is in deep power-down mode.

The access time is 90ns (tAv

temperature range (O’C to +70 43

range of 2.7V-3.6V.

v) over the commercial

) and V,, supply voltage

The Automatic Power Savings (APS) feature substar&&

reduces active current when the device is in static modf

(addresses not switching). In APS mode, the typical I,,

current is 3 mA at 2.7V V,,.

When CE# and RP# pins are at V,-,, the I,, CM05

standby mode is enabled. When the RP# pin is at GND

deep power-down mode is enabled which minimize:

power consumption and provides write protection during

reset. A reset time (tpHQv)

high until outputs are valid. Likewise, the device has i

wake time (tpHEL ) from RP#-high until writes to the CUI

are recognized. With RP# at GND, the WSM is reset ant

the status register is cleared.

The device is available in 48-ball CSP (Chip Size

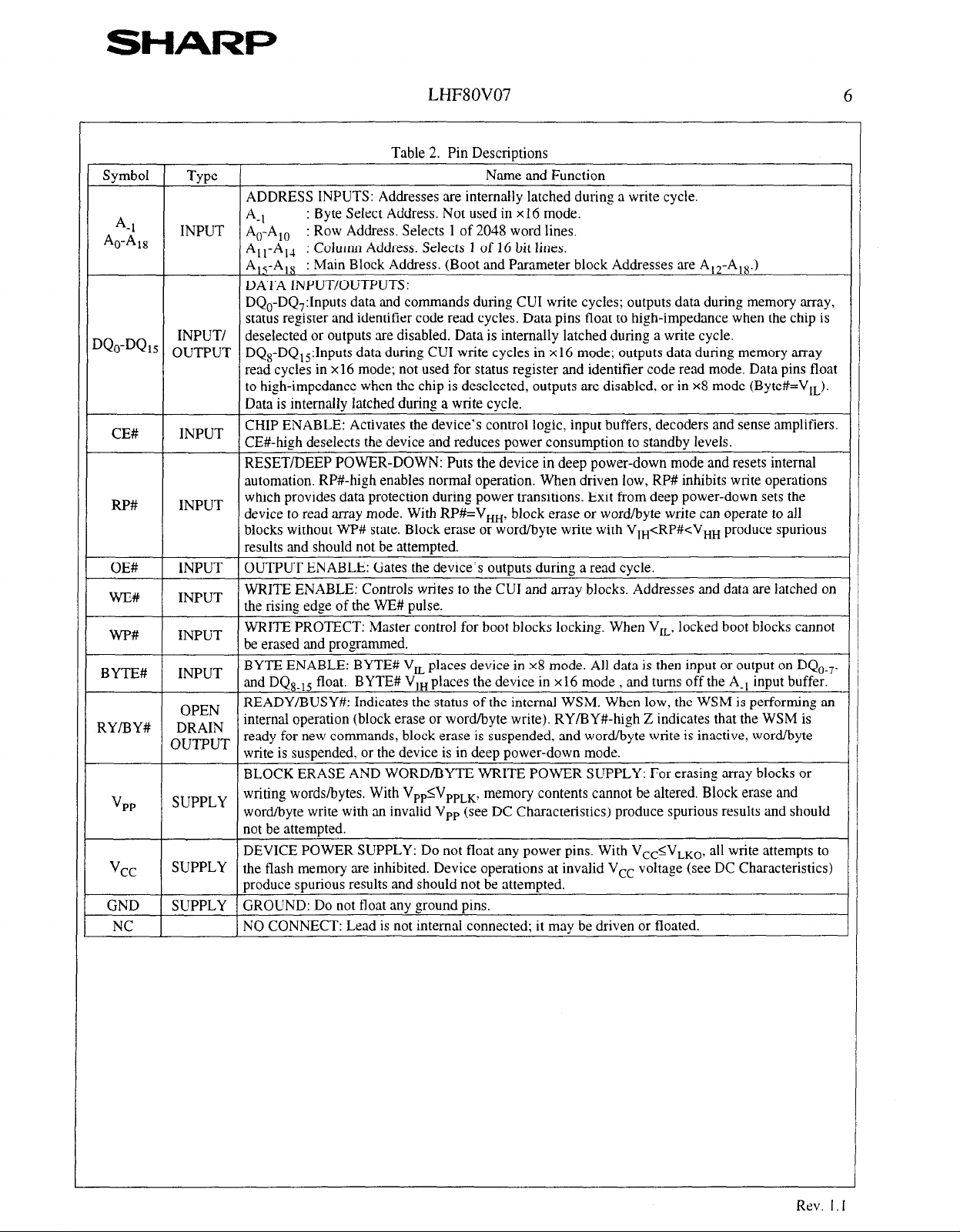

Package). Pinout is shown in Figure 2.

is required from RP# switching

Rev. 1.1

Page 7

SHARP

LHF8OVO7 5

DUO-DQls

r

1

A 0 A?

B

0

A3

C

0 Al

D 0 Ao

F 0 CE#

2

A5

0

%

0

A4

0

OE#

0

DQ8

0

DQo

0

Figure 1. Block Diagram

6

A8

0

NC

0

A9

0

DQ6

0

DQ5

0

Ql?

0

7

All

0

AIO

0

Al?

0

0

DQ7

0

QM

.%‘I

0

AI?

0

Al5

0

A16

0

8

4%BALL CSP

PINOUT

8mm x 8mm

TOP VIEW

Figure 2. CSP #-Ball Pinout

Rev. 1.1

Page 8

SHARP

r

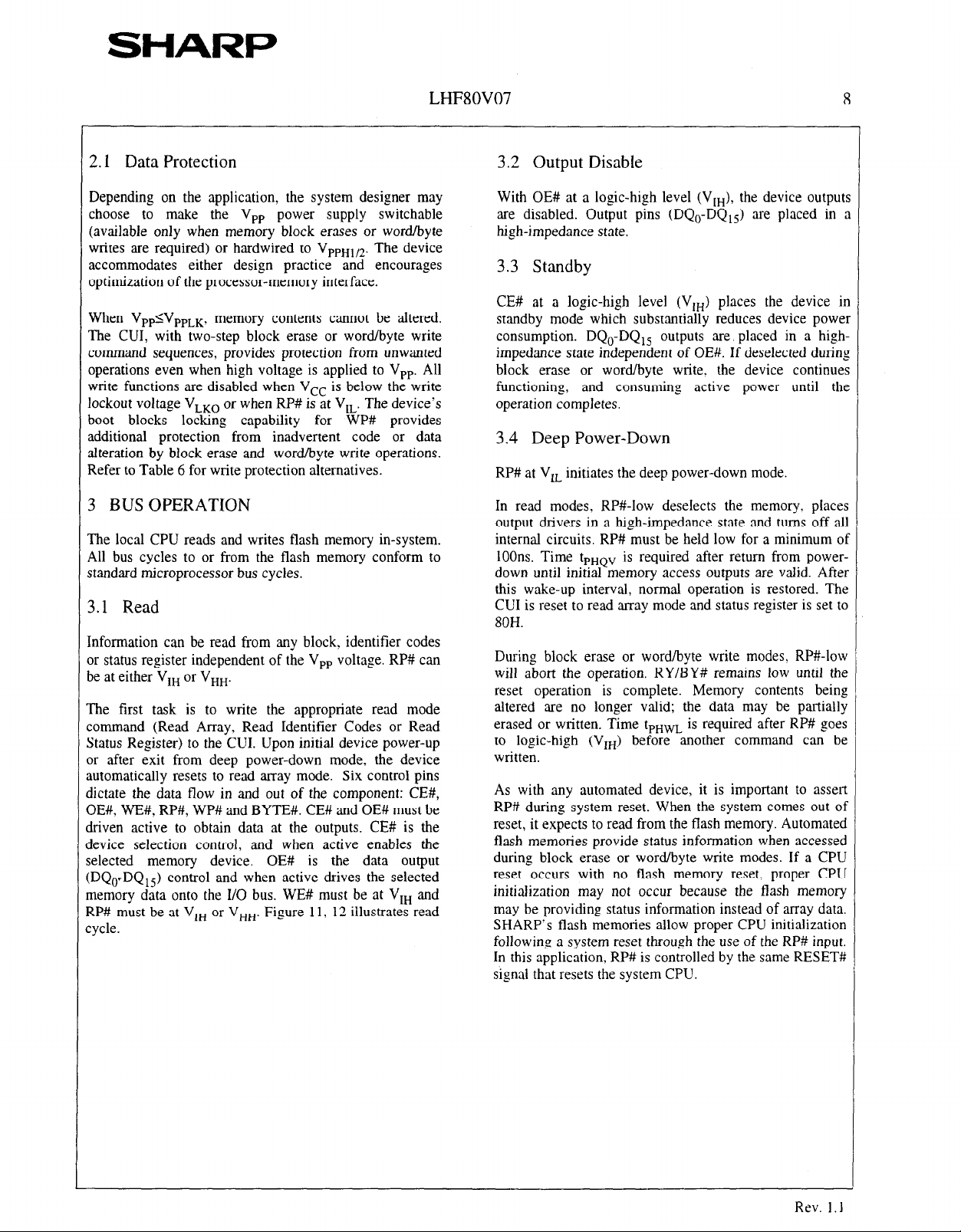

Symbol

A-,

Ao-Al8

1

DQo-DQ,,

CE#

RP#

OE#

WE# INPUT

WP# INPUT

BYTE# INPUT

RY/BY#

VCC

NC

Type

INPUT

INPUT/

OUTPUT

INPUT

INPUT

INPUT

OPEN

DRAIN

DUTPUT

SUPPLY

SUPPLY

SUPPLY GND

LHF8OVO7

Table 2. Pin Descriptions

Name and Function

ADDRESS INPUTS: Addresses are internally latched during a write cycle.

A-1

Ao-Alo

All-*,, .

<

DATA INPUT/OUTPUTS:

DQo-DQ-/:Inputs data and commands during CUI write cycles; outputs data during memory array,

status

deselected or outputs are disabled. Data is internally latched during a write cycle.

DQs-DQ, j:Inputs data during CUI write cycles in xl6 mode; outputs data during memory array

read cycles in x 16 mode; not used for status register and identifier code read mode. Data pins float

to high-impedance when the chip is deselected, outputs are disabled. or in x8 mode (Byte#=V,,J

Data is intemallv latched during a write cvcle.

CHIP ENABLE: Activates the device’s control logic. input buffers, decoders and sense amplifiers.

CE#-high deselects the device and reduces power consumption to standby levels.

RESET/DEEP POWER-DOWN: Puts the device in deep power-down mode and resets internal

automation. RP#-high enables normal operation. When driven low, RP# inhibits write operations

which provides data protection during power transitions. Exit from deep power-down sets the

device to read array mode. With RP#=V,,, block erase or word/byte write can operate to all

blocks without WP# state. Block erase or word/byte write with Vt,<RP#<V,B produce spurious

results and should not be attempted.

OUTPUT ENABLE: Gates the device’s outputs during a read cycle.

WRITE ENABLE: Controls writes to the CUI and atray blocks. Addresses and data are latched on

the rising edge of the WE# uulse.

WRITE PROTECT: Master control for boot blocks locking. When V,. locked boot blocks cannot

be erased and Droerammed.

BYTE ENABLE: BYTES V,, places device in x8 mode. All data is then input or output on DQ,,.

and DQ8-t5 float. BYTE# V,, places the device in x16 mode , and turns off the A-, input buffer.

READY/BUSY#: Indicates the status of the internal WSM. When low, the WSM is performing an

internal operation (block erase or word/byte write). RY/BY#-high Z indicates that the WSM is

ready for new commands, block erase is suspended. and word/byte write is inactive, word/byte

write is suspended, or the device is in deep power-down mode.

BLOCK ERASE AND WORD/BYTE WRITE POWER SUPPLY: For erasing array blocks or

writing words/bytes. With V,,IV,,,,. memory contents cannot be altered. Block erase and

word/byte write with an invalid V,, (see DC Characteristics) produce spurious results and should

not be attempted.

DEVICE POWER SUPPLY: Do not float any power pins. With V&V,,,, all write attempts to

the flash memory are inhibited. Device operations at invalid V,, voltage (see DC Characteristics)

oroduce sourious results and should not be attemuted.

GROUND: Do not float any ground pins.

NO CONNECT: Lead is not internal connected; it may be driven or floated.

: Byte Select Address. Not used in x16 mode.

: Row Address. Selects 1 of 2048 word lines.

. Column Address. Selects 1 of 16 bit lines.

register and identifier code read cycles. Data pins float to high-impedance when the chip is

6

Rev. I.1

i

Page 9

SHARP

LHF80V07 7

2 PRINCIPLES OF OPERATION

The LH28F800BVB-TTL90 Smart3 Flash memory

includes an on-chip WSM to manage block erase and

word/byte write functions. It allows for: 100% TTL-level

control inputs. fixed power supplies during block erasure

and word/byte write, and minimal processor overhead with

RAM-like interface timings.

After initial device power-up or return from deep powerdown mode (see Bus Operations). the device defaults to

read array mode. Manipulation of external memory control

pins allow array read, standby and output disable

operations.

Status register and identifier codes can be accessed

through the CUI independent of the V,, voltage. High

voltage on VP, enables successful block erasure and

word/byte writing. All functions associated with altering

memory contents-block erase, word/byte write, status and

identifier codes-are accessed via the CUI and verified

through the status register.

Commands are written using standard microprocessor

write timings. The CUI contents serve as input to the

WSM, which controls the block erase and word/byte write.

The internal algorithms are regulated by the WSM.

including pulse repetition, internal verification and

margining of data. Addresses and data are internally latch

during write cycles. Writing the appropriate command

outputs array data. accesses the identifier codes or outputs

status register data.

Interface software that initiates and polls progress of block

erase and word/byte write can be stored in any block. This

code is copied to and executed from system RAM during

flash memory updates. After successful completion, reads

Ire again possible via the Read Array command. Block

:rase suspend allows system software to suspend a block

erase to read/write data from/to blocks other than that

which is suspend. Word/byte write suspend allows system

;oftware to suspend a word/byte write to read data from

ury other flash memory array location.

r

tA18-&1 Top Boot

7FFFF

7FOO0

7EFFF

7EOOO

7DFFF

7DOOil

7CFFF

7coOO

7BFFF

7BOOQ

7AFFF

7.&m

79FFF

79000

78FFF

78OOa

77FFF

7oOw

6FFFF

68000

67FFF

60000

5FFFF

58000

57FFF

50000

4FFFF

48000

47FFF

-1oooo

3FFFF

38000

37FFF

3moo

ZFFFF

28000

27FFF

20000

IFFFF

18000 I

17FFF

1OQOO

OFFFF

08000

07FFF

00000

4K-word Boot Block 0

4K-word Boot Block 1

4K-word Parameter Block

4K-word Parameter Block 1

4K-word Parameter Block

4K-word Parameter Block 3

4K-word Parameter Block 4

4K-word Parameter Block

32K-word Main Block 0

32K-word Main Block

32K-word Main Block 2

32K-word Main Block 3

32K-word Main Block 4

32K-word Main Block 5

32K-word Main Block 6

32K-word Main Block

32K-word Main Block 8

32K-word Main Block 9

32K-word Main Block

32K-word Main Block 11

32K-word Main Block 12

32K-word Main Block 13

32K-word Main Block 14

1

0

2

5

1

7

10

Figure 3. Memory Map

Rev. 1.1

Page 10

SHARI=

LHF8OVO7

2.1 Data Protection

Depending on the application, the system designer may

choose to make the V,, power supply switchable

(available only when memory block erases or word/byte

writes are required) or hardwired to VPPHIR. The device

accommodates either design practice and encourages

optimization of the processor-memory interface.

When VPPIVPPLK.

The CUI, with two-step block erase or word/byte write

command sequences, provides protection from unwanted

operations even when high voltage is applied to V,,. All

write functions are disabled when V,, is below the write

lockout voltage V,,, or when RP# is at V,,. The device’s

boot blocks locking capability for WP# provides

additional protection from inadvertent code or data

alteration by block erase and word/byte write operations.

Refer to Table 6 for write protection alternatives.

memory contents cannot be altered.

3 BUS OPERATION

The local CPU reads and writes flash memory in-system.

All bus cycles to or from the flash memory conform to

standard microprocessor bus cycles.

3.1 Read

[nformation can be read from any block, identifier codes

Jr status register independent of the V,, voltage. RP# can

5e at either V,, or V,,.

The first task is to write the appropriate read mode

:ommand (Read Array, Read Identifier Codes or Read

Status Register) to the CUI. Upon initial device power-up

x after exit from deep power-down mode. the device

automatically resets to read array mode. Six control pins

dictate the data flow in and out of the component: CE#,

3E#, WE#, RP#, WP# and BYTE#. CE# and OE# must be

Iriven active to obtain data at the outputs. CE# is the

device selection control, and when active enables the

;elected memory device. OE# is the data output

DQorDQlj) control and when active drives the selected

nemory data onto the I/O bus. WE# must be at V,, and

iP# must be at V,, or V,,. L Figure 11 12 illustrates read ,

:ycle.

3.2 Output Disable

With OE# at a logic-high level (V,,), the device outputs

are disabled. Output pins (DQ,-DQ,,) are placed in a

high-impedance state.

3.3 Standby

CE# at a logic-high level (VrH) places the device in

standby mode which substantially reduces device power

consumption. DQO-DQ,, outputs are placed in a highimpedance state independent of OE#. If deselected during

block erase or word/byte write. the device continues

functioning, and consuming active power until the

operation completes.

3.4 Deep Power-Down

RP# at V, initiates the deep power-down mode.

In read modes, RP#-low deselects the memory. places

output drivers in a high-impedance state and turns off all

internal circuits. RP# must be held low for a minimum of

loons. Time tpHQV

down until initial memory access outputs are valid. After

this wake-up interval, normal operation is restored. The

CUI is reset to read array mode and status register is set to

80H.

During block erase or word/byte write modes? RP#-low

will abort the operation. RY/BY# remains low until the

reset operation is complete. Memory contents being

altered are no longer valid; the data may be partially

erased or written. Time tpHwL is required after RP# goes

to logic-high (V,,) before another command can be

written.

As with any automated device, it is important to assert

RP# during system reset. When the system comes out of

reset, it expects to read from the flash memory. Automated

flash memories provide status information when accessed

during block erase or word/byte write modes. If a CPU

reset occurs with no flash memory reset. proper CPU

initialization may not occur because the flash memory

may be providing status information instead of array data.

SHARP’s flash memories allow proper CPU initialization

following a system reset through the use of the RP# input.

In this application, RP# is controlled by the same RESET#

signal that resets the system CPU.

is required after return from power-

Rev. 1.1

Page 11

SHARP

LHF8OVO7 9

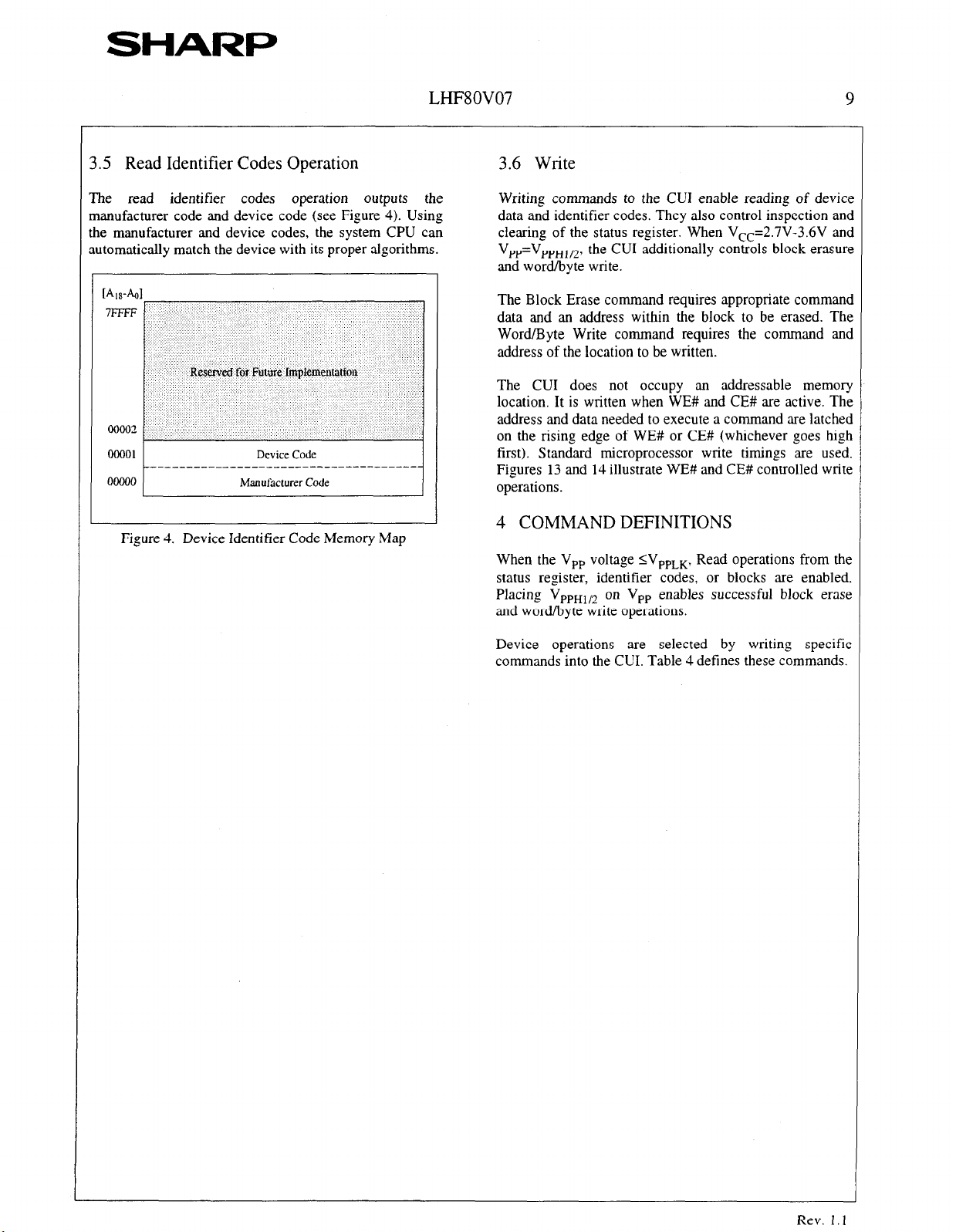

.5 Read Identifier Codes Operation 3.6 Write

he read identifier codes operation

manufacturer code and device code (see Figure 4). Using

le manufacturer and device codes, the system CPU can

ltomatically match the device with its proper algorithms.

Device Code

Manufacturer Code

Figure 4. Device Identifier Code Memory Map

outputs

the

Writing commands to the CUI enable reading of device

data and identifier codes. They also control inspection ant

clearing of the status register. When V,-=2.7V-3.6V ant

VPt,=VPPH1,2, the CUI additionally controls block erasure

and word/byte write.

The Block Erase command requires appropriate commanc

data and an address within the block to be erased. The

Word/Byte Write command requires the command and

address of the location to be written.

The CUI does not occupy an addressable memory

location. It is written when WE# and CE# are active. The

address and data needed to execute a command are latched

on the rising edge of WE# or CE# (whichever goes high

first). Standard microprocessor write timings are used.

Figures 13 and 14 illustrate WE# and CE# controlled write

operations.

4 COMMAND DEFINITIONS

When the V,, voltage IV,,,,. Read operations from the

status register, identifier codes, or blocks are enabled.

Placing VP,,,,* on V,, enables successful block erase

and word/byte write operations.

Device operations are selected by writing specific

commands into the CUI. Table 4 defines these commands.

Rev. 1.1

Page 12

SHARI=

LHF8OV07

Table 3.1. Bus Operations(BYTE#=Vu.,)(l,z)

Mode

Read

Output Disable

Standby

Deep Power-Down

Read Identifier Codes

Write

Notes RP# CE# OE# WE# Address V,,

8

10

4,lO

8

6,7,8

‘I, Or

VU,

‘1, Or

‘HH

‘1, Or

vnH

VI,

‘1, Or

vIiH

VIEI Or

‘HH

VI, VI, ‘1,

VI, VI,

‘1,

X X X

‘1,

X X

VI, VI, ‘1,

VI, vIH VI,

X

X

X X

See

Figure 4

X X

X

X High Z X

X High Z X

X High Z High Z

X

Table 3.2. Bus Operations(BYTE#=VIL)(1,2)

Mode

Read

Output Disable

Standby

Deep Power-Down

Read Identifier Codes

Write

Notes

8

10

4,lO

8.9

fj 7 8

> >

RP# CE# OE#

vIH Or

VHH

vIH Or

VHH

‘1, Or

vHH

VI,

vIH Or

‘HH

VIHor

vHH

VI, VI, ‘1,

VIL ‘1, ‘IH

‘1,

X X X X

VI, VI, ‘1,

VIL ‘1, VIL

WE# Address

X X

VW

X

X X HighZ HighZ X

X

See

Figure 4

X X

DQ,, DQ,-,, RY/BY#(3)-

X

Dour

X High Z High Z X

X High Z High Z High Z

X Note 5 High Z High Z

NOTES:

1. Refer to DC Characteristics. When V,,5V,,,,,

2. X can be VI, or VI, for control pins and addresses, and V,, or VPPHIjz

memory contents can be read, but not altered.

for V,,. See DC Characteristics for V,,, and

V,,,,,, voltages.

3. RY/BY# is V,, when the WSM is executing internal block erase or word/byte write algorithms, It is High Z during when

the WSM is not busy, in block erase suspend mode (with word/byte write inactive), word/byte write suspend mode or

deep power-down mode.

4. RP# at GNDk0.2V ensures the lowest deep power-down current.

5. See Section 4.2 for read identifier code data.

6. Command writes involving block erase or word/byte write are reliably executed when VPP=VPPH1/2 and V,,=2.7V-3.6V.

Block erase or word/byte write with Vm<RP#<VHH produce spurious results and should not be attempted.

7. Refer to Table 4 for valid DIN during a write operation.

8. Never hold OE# low and WE# low at the same timing.

9. A-, set to VI, or VI, in byte mode (BYTE#=V,,).

lo. m# set to vIL or VI,.

DQ,,,5 RY/BY#c3)

DOUT

Note 5 High Z

DIN

High Z X

DIN

X X

X

X

Rev. 1.1

Page 13

SHARP

LHF80V07 11

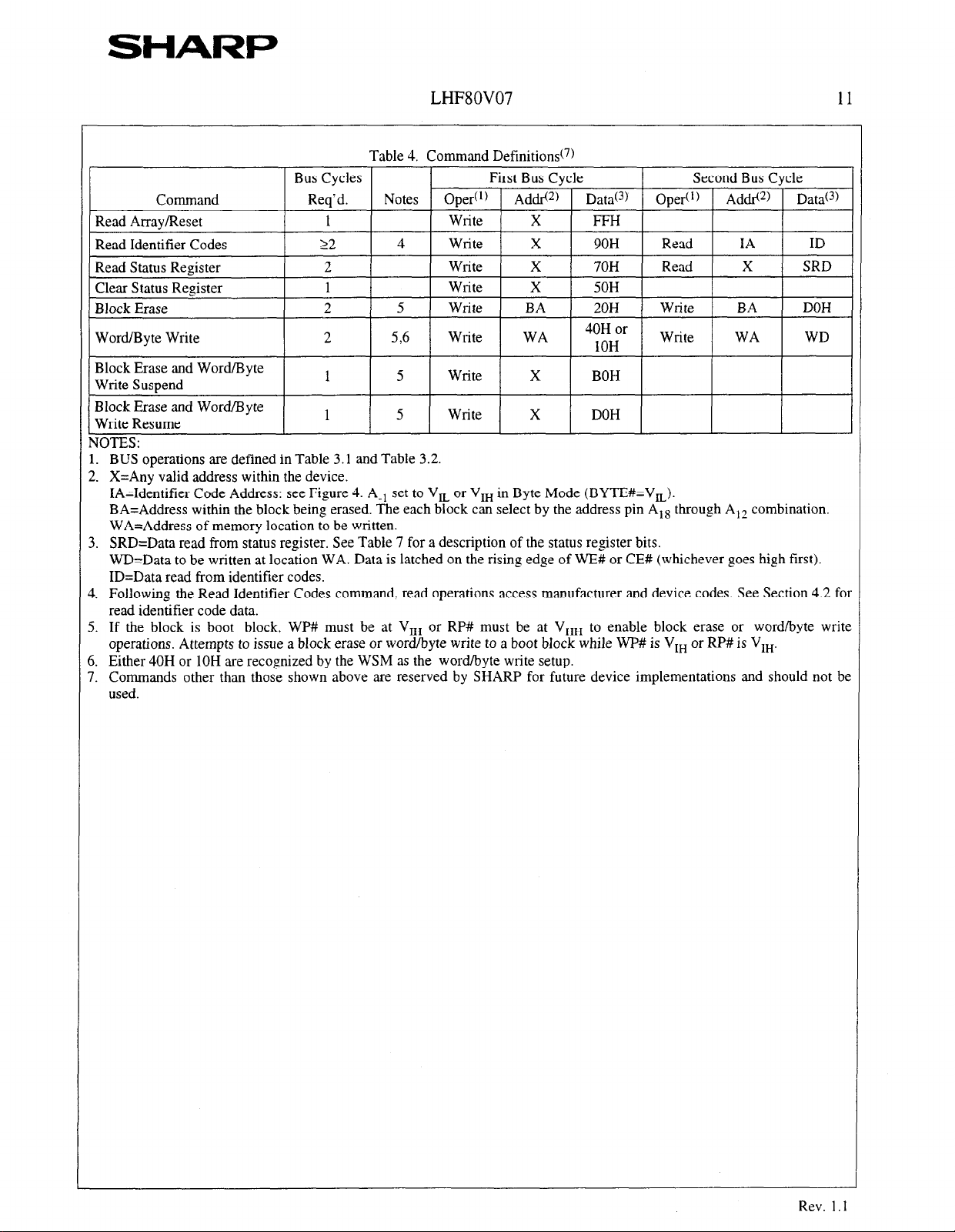

Table 4. Command Definitions(7)

NOTES:

1. BUS operations are defined in Table 3.1 and Table 3.2.

2. X=Any valid address within the device.

IA=Identifier Code Address: see Figure 4. A_, set to V,, or V,, in Byte Mode (BYTE#=V,,).

BA=Address within the block being erased. The each block can select by the address pin A,, through A,, combination.

WA=Address of memory location to be written.

3. SRD=Data read from status register. See Table 7 for a description of the status register bits.

WD=Data to be written at location WA. Data is latched on the rising edge of WE# or CE# (whichever goes high first).

ID=Data read from identifier codes.

4. Following the Read Identifier Codes command, read operations access manufacturer and device codes. See Section 4.2 foi

read identifier code data.

5. If the block is boot block, WP# must be at V, or RP# must be at V,, to enable block erase or word/byte write

operations. Attempts to issue a block erase or word/byte write to a boot block while WP# is V,, or RP# is V,,.

5. Either 40H or 1OH are recognized by the WSM as the word/byte write setup.

7. Commands other than those shown above are reserved by SHARP for future device implementations and should not be

used.

Page 14

SHARI=

LHF%OVO7

4.1 Read Array Command

Upon initial device power-up and after exit from deep

power-down mode, the device defaults to read array mode.

This operation is also initiated by writing the Read Array

command. The device remains enabled for reads until

another command is written. Once the internal WSM has

started a block erase or word/byte write. the device will

not recognize the Read Array command until the WSM

completes its operation unless the WSM is suspended via

an Erase Suspend or Word/Byte Write Suspend command.

The Read Array command functions independently of the

V,, voltage and RP# can be V,, or V,,.

4.2 Read Identifier Codes Command

The identifier code operation is initiated by writing the

Read Identifier Codes command. Following the command

write, read cycles from addresses shown in Figure 4

retrieve the manufacturer and device codes (see Table 5

for identifier code values). To terminate the operation,

write another valid command. Like the Read Array

command, the Read Identifier Codes command functions

independently of the V,, voltage and RP# can be V,, or

V,,. Following the Read Identifier Codes command, the

following information can be read:

Table 5. Identifier Codes

12

4.4 Clear Status Register Command

Status register bits SR.5, SR.4. SR.3 or SR.l are set tc

“1”s by the WSM and can only be reset by the Clear Statu:

Register command. These bits indicate various failure

conditions (see Table 7). By allowing system software tc

reset these bits, several operations (such as cumulatively

erasing multiple blocks or writing several words/bytes ir

sequence) may be performed. The status register may be

polled to determine if an error occurred during the

sequence.

To clear the status register, the Clear Status Register

command (50H) is written. It functions independently 01

the applied V,, Voltage. RP# can be V,, or V,,. This

command is not functional during block erase 01

word/byte write suspend modes.

4.5 Block Erase Command

Erase is executed one block at a time and initiated by a

two-cycle command. A block erase setup is first written.

followed by an block erase confirm. This command

sequence requires appropriate sequencing and an address

within the block to be erased (erase changes all block data

to FFFFH). Block preconditioning, erase? and verify are

handled internally by the WSM (invisible to the system).

After the two-cycle block erase sequence is written. the

device automatically outputs status register data when read

(see Figure 5). The CPU can detect block erase completion

by analyzing the output data of the RY/BY# pin or status

register bit SR.7.

4.3 Read Status Register Command

The status register may be read to determine when a block

:rase or word/byte write is complete and whether the

operation completed successfully. It may be read at any

ime by writing the Read Status Register command. After

writing this command, all subsequent read operations

output data from the status register until another valid

:ommand is written. The status register contents are

atched on the falling edge of OE# or CE#, whichever

occurs. OE# or CE# must toggle to V,, before further

.eads to update the status register latch. The Read Status

iegister command functions independently of the V,,

Joltage. RP# can be V,, or V,,.

When the block erase is complete, status register bit SR.5

should be checked. If a block erase error is detected. the

status register should be cleared before system software

attempts corrective actions. The CUI remains in read

status register mode until a new command is issued.

This two-step command sequence of set-up followed by

execution ensures that block contents are not accidentally

erased. An invalid Block Erase command sequence will

result in both status register bits SR.4 and SR.5 being set

to “1”. Also, reliable block erasure can only occur when

Vcc=2.7V-3.6V and VPP=VPPH1,2. In the absence of this

high voltage. block contents are protected against erasure.

If block erase is attempted while V,,IV,,,,, SR.3 and

SR.5 will be set to “1”. Successful block erase for boot

blocks requires that the corresponding if set, that

WP#=V,, or RP#=V,,. If block erase is attempted to

boot block when the corresponding WP#=V,, or

RP#=V,,, SR.l and SR.5 will be set to “1”. Block erase

operations with VIH<RP#<V,, produce spurious results

and should not be attempted.

Rev. 1.1

Page 15

SHARP

LHF8OVO7

4.6 Word/Byte Write Command

Word/byte write is executed by a two-cycle command

sequence.

alternate 10H) is written, followed by a second write that

specifies the address and data (latched on the rising edge

of WE#). The WSM then takes over, controlling the

word/byte write and write verify algorithms internally.

After the word/byte write sequence is written, the device

automatically outputs status register data when read (see

Figure 6). The CPU can detect the completion of the

word/byte write event by analyzing the RYlBY# pin or

status register bit SR.7.

When word/byte write is complete, status register bit SR.4

should be checked. If word/byte write error is detected, the

status register should be cleared. The internal WSM verify

only detects errors for “1”s that do not successfully write

to “0”s. The CUI remains in read status register mode until

it receives another command.

Reliable word/byte writes can only occur when

V,,=2.7V-3.6V and VPP=VPPHI,~. In the absence of this

high voltage, memory contents are protected against

word/byte writes. If word/byte write is attempted while

V,SV,,,, status register bits SR.3 and SR.4 will be set

to “1”. Successful word/byte write for boot blocks requires

that the corresponding if set, that WP#=V,, or RP#=V,,.

If word/byte write is attempted to boot block when the

corresponding WP#=V, or RP#=V,,, SR.1 and SR.4 will

be

V,<RP#<VN, p reduce spurious results and should not be

attempted.

Word/byte write setup (standard 40H or

set to ” 1”. Word/byte write operations with

13

4.7 Block Erase Suspend Command

The Block Erase Suspend command allows block-erase

interruption to read or word/byte write data in another

block of memory. Once the block-erase process starts,

writing the Block Erase Suspend command requests that

the WSM suspend the block erase sequence at a

predetermined point in the algorithm. The device outputs

status register data when read after the Block Erase

Suspend command is written. Polling status register bits

SR.7 and SR.6 can determine when the block erase

operation has been suspended (both will be set to “1”).

RY/BY# will also transition to High Z. Specification

twHRz2 defines the block erase suspend latency.

At this point, a Read Array command can be written to

read data from blocks other than that which is suspended.

A Word/Byte Write command sequence can also be issued

during erase suspend to program data in other blocks.

Using the Word/Byte Write Suspend command (see

Section 4.8), a word/byte write operation can also be

suspended. During a word/byte write operation with bIock

erase suspended, status register bit SR.7 will return to “0”

and the RY/BY# output will transition to VOL. However.

SR.6 will remain “1” to indicate block erase suspend

status.

The only other valid commands while block erase is

suspended are Read Status Register and Block Erase

Resume. After a Block Erase Resume command is written

to the flash memory, the WSM will continue the block

erase process. Status register bits SR.6 and SR.7 will

automatically clear and RY/BY# will return to VOL. After

the Erase Resume command is written, the device

automatically outputs status register data when read (see

Figure 7). V,, must remain at V,,,,,, (the same V,,

level used for block erase) while block erase is suspended.

RP# must also remain at Vr, or V,, (the same RP# level

used for block erase). WP# must also remain at V,, or V,,

(the same WP# level used for block erase). Block erase

cannot resume until wordlbyte write operations initiated

during block erase suspend have completed.

Rev. 1.1

Page 16

SHARI=

LHF8OV07 14

1

4.8 Word/Byte Write Suspend Command

The Word/Byte Write Suspend command allows

word/byte write interruption to read data in other flash

memory locations. Once the word/byte write process

starts, writing the Word/Byte Write Suspend command

requests that the WSM suspend the word/byte write

sequence at a predetermined point in the algorithm. The

device continues to

after the Word/Byte Write Suspend command is written.

Polling status register bits SR.7 and SR.2 can determine

when the word/byte write operation has been suspended

(both will be set to “1”). RY/BY# will also transition to

High Z. Specification twHRZl

suspend latency.

At this point, a Read Array command can be written to

read data from locations other than that which is

suspended. The only other valid commands while

word/byte write is suspended are Read Status Register and

Word/Byte Write Resume. After Word/Byte Write

Resume command is written to the flash memory. the

WSM will continue the word/byte write process. Status

register bits SR.2 and SR.7 will automatically clear and

RY/BY# will return to V,,. After the Word/Byte Write

Resume command is written, the device automatically

outputs

must remain at VPPH1,2 (the same V,, level used for

word/byte write) while in word/byte write suspend mode.

RP# must also remain at V,, or V,, (the same RP# level

used for word/byte write). WP# must also remain at VI, or

Vt, (the same WP# level used for word/byte write).

status

output

status register data when read

defines the word/byte write

register data when read (see Figure 8). V,,

4.10 Block Locking

This Boot Block Flash memory architecture features two

hardware-lockable boot blocks so that the kernel code for

the system can be kept secure while other blocks are

programmed or erased as necessary.

4.10.1

The V,, programming voltage can be held low for

complete write protection of all blocks in the flash device.

VPP=VIL for Complete Protection

4.102 WP#=V,, for Block Locking

The lockable blocks are locked when WP#=Vt,; any

program or erase operation to a locked block will result in

an error, which will be reflected in the status register. For

top configuration, the top two boot blocks are lockable.

For the bottom configuration. the bottom tow boot blocks

are lockable. Unlocked blocks can be programmed or

erased normally (Unless V,, is below VPPLK).

4.10.3 WP#=VIH for Block Unlocking

WP#=V,, unlocks all lockable blocks.

These blocks can now be programmed or erased.

WP# controls 2 boot blocks locking and V,, provides

protection against spurious writes. Table 6 defines the

write protection methods.

4.9 Considerations of Suspend

After the suspend command write to the CUI, read status

register command has to write to CUI, then status register

bit SR.6 or SR.2 should be checked for places the device

in suspend mode.

Table 6. Write Protection Alternatives

Operation

Block Erase

or

Word/Byte Write

VP,

VI,

‘vPPLK ‘HH

RP# WP#

x

VI,

‘1, , VI,

X All Blocks Locked.

X All Blocks Lock

X All Blocks Unlocked.

VI,

Effect

ted.

2 Boot Blocks Locked.

1 All Blocks Unlocked.

I

Rev. 1.1

Page 17

SHARI=

Table 7. Status Register Definition

WSMS 1 ESS

7 6

SR.7 = WRITE STATE MACHINE STATUS (WSMS)

1 = Ready

0 = Busy

SR.6 = ERASE SUSPEND STATUS (ESS)

1 = Block Erase Suspended

0 = Block Erase in Progress/Completed

SR.5 = ERASE STATUS (ES)

1 = Error in Block Erasure

0 = Successful Block Erase

SR.4 = WORD/BYTE WRITE STATUS (WBWS)

1 = Error in Word/Byte Write

0 = Successful Word/Byte Write

SR.3 = V, STATUS (VPPS)

1 = V,, Low Detect, Operation Abort

O=V,OK

SR.2 = WORD/BYTE WRITE SUSPEND STATUS

(WBWSS)

1 = Word/Byte Write Suspended

0 = Word/Byte Write in Progress/Completed

SR. 1 = DEVICE PROTECT STATUS (DPS)

1 = WP# or RP# Lock Detected, Operation Abort

0 = Unlock

ES 1 WBWS 1 VPPS 1 WBWSS

5 4

LIm3ovo7

Check RY/BY# or SR.7 to determine block erase or

word/byte write completion. SR.6-0 are invalid while

SR.7=“0”.

If both SR.5 and SR.4 are “1”s after a block erase attempt,

an improper command sequence was entered.

SR.3 does not provide a continuous indication of V,, level.

The WSM interrogates and indicates the V,, level only after

Block Erase or Word/Byte Write command sequences. SR.3

is not guaranteed to reports accurate feedback only when

vYY~vYY,ll2~

The WSM interrogates the WP# and RP# only after Block

Erase or Word/Byte Write command sequences. It informs

the system, depending on the attempted operation, if the

WP# is not V,,, RP# is not V,,.

3

1.5

( DPS R

2 1 0

NOTES:

SR.0 = RESERVED FOR FUTURE ENHANCEMENTS (R)

SR.0 is reserved for future use and should be masked out

when polling the status register.

Rev. 1.1

Page 18

SHARP

Block Address

Block Address

Check rf Desired

Erase Loop

LHF8OVO7

BUS

operatm

Read

Standby

Repeat for subsequent block ems”res.

Full status check can be done after each block uasc or after a sequrnce of

block crawrcs.

Command Commenls

Erase Setup

Daw=?OH

Addr=Wlthln Block to be Erased

Daa=DOH

Addr=Within Block Lo be Erased

Check SR.7

I=WSMReady

O=WSM Busy

16

R’LL STAR’S CHECK PROCEDLXE

Command

Standby

Standby

Standby

Standby

SR.5.SR.4.SR.3 and SR.1 us only cleared by tie clear Status

Register Command in cases where multiple blocks are erased

beforc full status is checked.

Check SR.3

l=Vpp Error Dctcct

Chzck SR.1

I=Devicz Protect Detect

Check SR.1.5

Both I=Command Ssquencc Error

Check SR.5

l=Block Erase Error

Commentr

Figure 5. Automated Block Erase Flowchart

Rev. 1.1

Page 19

SHARP

LHl-‘8UVU I I!

Start

Write IOH or 10H.

Address

wnrc WordAp

Data and Address

Full Status

Check If Deared

Word/Byte wms

Complete

FL-LL STATCS CHECK PROCEDL’RE

Read Status Reglstrr

Dala(See Above)

1

Suspnd Wwd/Byte

wrns Loop

BUS

Operation

Standby

Command

Setup Word/Byte Write

Word/Byte Wr,ts

Command

COlTl”X”lS

DnladOH cx 10H

Addr=Locat,on to Be Wrmen

Data=Data 10 Bc Wntwn

Addr=Loation to Be Wnttsn

Status Rep,ster Data

Check SR.7

I=WSM Ready

O=WSM Busy

.

CO”Ull?“lS

Check SR.?

,=VpP Error Dsr<cl

Standby

Sw,dby

SR.J.SR.3 and SR. I are only cleared by the Clear Status Rcg~stsr

command m cases where multiple locations are uwtten before

full S,P,U.X is checked.

Figure 6. Automated Word/Byte Write Flowchart

Check SR.1

I=Dcv,ce Praect Dstect

Check SR.?

I=Data Writs Error

Rev. 1.1

Page 20

SHARF’

LHF80V07

BUS

@erauon

Wrik

Read

Standby

Standby

Write

Command

Erase

Resume

18

Commcnls

Datn=BOH

Ad&=X

Star,,s Rzglstzr Data

Addr=X

Check SR.7

l=WSMReady

O=WSM Busy

Check SR.6

I=Block Erase Suspended

OeBlock Erase Completed

Data-WH

Addr-X

Figure 7. Block Erase Suspend/Resume Flowchart

Rev. 1.1

Page 21

SHARI=

LHF8OVO7

Writs BOW

Word/Byte write

Completed

BUS

operation

Read

Standby

Standby

Read

Command

Rad Array

Word/B)~c Write

Resume

Comments

Data=BOH

Ad&=X

Check SR.7

I=WSM Ready

C=WSM Busy

Check SR.?

I=Word/B~ze Wrltc Suspended

O=Word/B>zc Writs Completed

Data=FFH

Ad&=X

Daa=DOH

Addr=X

Word/Byte Writs

Resumed

Figure 8. Word/Byte Write Suspend/Resume Flowchart

Rev. 1.1

Page 22

SIiARl=

LHF80V07

5 DESIGN CONSIDERATIONS

5.1 Three-Line Output Control

The device will often be used in large memory arrays.

SHARP provides three control inputs to accommodate

multiple memory connections. Three-line control provides

for:

a. Lowest possible memory power dissipation.

b. Complete assurance that data bus contention will not

occur.

To use these control inputs efficiently, an address decoder

should enable CE# while OE# should be connected to all

memory devices and the system’s READ# control line.

This assures that only selected memory devices have

active outputs while deselected memory devices are in

standby mode. RP# should be connected to the system

POWERGOOD signal to prevent unintended writes during

system power transitions. POWERGOOD should aiso

toggle during system reset.

5.2 RY/BY#, Block Erase and Word/Byte

Write Polling

RYlBY# is an open drain output that should be connected

to V,, by a pull up resistor to provide a hardware method

of detecting block erase and word/byte write completion.

It transitions low after block erase or word/byte write

commands and returns to High Z when the WSM has

finished executing the internal algorithm.

5.3 Power Supply Decoupling

Flash memory power switching characteristics require

careful device decoupling. System designers are interested

in three supply current issues; standby current levels.

active current levels and transient peaks produced by

falling and rising edges of CE# and OE#. Transient currenl

magnitudes depend on the device outputs’ capacitive and

inductive loading. Two-line control and proper decoupling

capacitor selection will suppress transient voltage peaks.

Each device should have a O.lpF ceramic capacitor

connected between its V,, and GND and between its V,,

and GND. These high-frequency. low inductance

capacitors should be placed as close as possible to package

leads. Additionally, for every eight devices, a 4.7pF

electrolytic capacitor should be placed at the array’s power

supply connection between V,, and GND. The bulk

capacitor will overcome voltage slumps caused by PC

board trace inductance.

5.4 Vpp Trace on Printed Circuit Boards

Updating flash memories that reside in the target system

requires that the printed circuit board designer pay

attention to the V,,

supplies the memory cell current for word/byte writing

and block erasing. Use similar trace widths and layout

considerations given to the V,, power bus. Adequate V,,

supply traces and decoupling will decrease V,, voltage

spikes and overshoots.

Power supply trace. The V,, pin

RY/BY# can be connected to an interrupt input of the

system CPU or controller. It is active at all times. RY/BY#

IS also High Z when the device is in block erase suspend

(with word/byte write inactive), word/byte write suspend

Jr deep power-down modes.

Rev. 1.1

Page 23

SHARP

LHF8OVO7

5.5 VCC, Vpp, RP#

Block erase and word/byte write are not guaranteed if V,,

falls outside of a valid VPPHIR range, V,, falls outside of

a valid 2.7V-3.6V range. or RP##V,, or V,,. If V,, error

is detected, status register bit SR.3 is set to “1” along with

SR.4 or SR.5, depending on the attempted operation. If

RP# transitions to V,, during block erase or word/byte

write, RY/BY# will remain low until the reset operation is

complete. Then, the operation will abort and the device

will enter deep power-down. The aborted operation may

leave data partially altered. Therefore, the command

sequence must be repeated after normal operation is

restored. Device power-off or RP# transitions to V, clear

the status register.

The CUI latches commands issued by system software and

is not altered by V,, or CE# transitions or WSM actions.

Its state is read array mode upon power-up, after exit from

deep power-down or after V,, transitions below VLKO.

After block erase or word/byte write, even after V,,

transitions down to V,,,, the CUI must be placed in read

array mode via the Read Array command if subsequent

access to the memory array is desired.

Transitions

5.6 Power-Up/Down Protection

The device is designed to offer protection against

lccidental block erasure or word/byte writing during

power transitions. Upon power-up, the device is

indifferent as to which power supply (V,, or V,,)

?owers-up first. Internal circuitry resets the CUI to read

u-ray mode at power-up.

21

A system designer must guard against spurious writes for

V,, voltages above V,,, when V,, is active. Since botlWE# and CE# must be low for a command write, driving

either to V,, will inhibit writes. The GUI’s two-stey

command sequence architecture provides added level o

protection against data alteration.

WP# provide additional protection from inadvertent cod<

or data alteration. The device is disabled while RP#=V,,

regardless of its control inputs state.

5.7 Power Dissipation

When designing portable systems. designers must considel

battery power consumption not only during device

operation, but also for data retention during system idle

time. Flash memory’s nonvolatility increases usable

battery life because data is retained when system power is

removed.

In addition, deep power-down mode ensures extremely

low power consumption even when system power is

applied. For example, portable computing products and

other power sensitive applications that use an array of

devices for solid-state storage can consume negligible

power by lowering RP# to V, standby or sleep modes. If

access is again needed, the devices can be read following

the fPHQV and tPHWL

first raised to VIH. See AC Characteristics- Read Only

and Write Operations and Figures 11, 12> 13 and 14 for

more information.

wake-up cycles required after RP# is

Rev. 1.1

Page 24

SHARP

LHF8OVO7 22

6 ELECTRICAL SPECIFICATIONS

6.1 Absolute Maximum Ratings*

Operating Temperature

During Read, Block Erase and

Word/Byte Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0°C to +7O”C(r)

Temperature under Bias . . . . . . . . . . . . . . . . . . . . . . - 10°C to +SO”C

Storage Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -65°C to +125”C

Voltage On Any Pin

(except V,,, V,,, and RP#) . . . . . . . . . . . . -0.5V to +7.OV(*)

V,, Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.2V to +7.OV(*)

V,, Update Voltage during Block

Erase and Word/Byte Write . . . . . . . . . -0.2V to +l 4.0V(2,3)

RP# Voltage _....................................... -0.5V to +14.0V(*y3)

Output Short Circuit Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100mA(4)

6.2 Operating Conditions

*WARNING: Stressing the device beyond the “Absolute

Maximan Ratings” may cause permanent damage. These

are stress ratings only. Operation beyond the “Operating

Conditions” is not recommended and extended exposure

beyond the “Operating Conditions” may affect device

reliability.

NOTES:

1. Operating temperature is for commercial temperature

product defined by this specification.

2. All specified voltages are with respect to GND.

Minimum DC voltage is -0SV on input/output pins

and -0.2V on V,,

this level may undershoot to -2.OV for periods <20ns.

Maximum DC voltage on input/output pins and V,, is

V,,+OSV which, during transitions, may overshoot to

Vcc+2.0V for periods <20ns.

3. Maximum DC voltage on V,, and RP# may overshoot

to +14.OV for periods <20ns.

4. Output shorted for no more than one second. No more

than one output shorted at a time.

and V,, pins. During transitions,

Temperature

Symbol Parameter Min. Max.

TA

vcc

Operating Temperature 0 +70 “C

Vcc Supply Voltage (2.7V-3.6V)

2.7 3.6 V

5.2.1 CAPACITANCE( *)

T,=+25”C, f=lMHz

Symbol Parameter

cIN

‘OUT

VOTE:

I. Sampled, not 100% tested.

Input Capacitance 7 10

Output Capacitance

TYP.

9 12

Max. Unit Condition

Unit Test Condition

Ambient Temperature

PP

PP

v,,=o.ov

v,U,=o.ov

Rev. 1.1

Page 25

SHARP

LHF8OVO7

6.2.2 AC INPUT/OUTPUT TEST CONDITIONS

AC test inputs are driven at 2.7V for a Logic “1” and O.OV for a Logic “0.” Input timing begins, and output timing ends, at 1.35V.

Input rise and fall times (107~ to 90%) ~10 ns.

Figure 9. Transient Input/Output Reference Waveform for V,,=2.7V-3.6V

lN914

Test Confieuration Caoacitance Loading Value

Test Configuration

Vcc=2.7V-3.6V 30

C,(pF)

23

CL Includes Jig

Capacitance

Figure 10. Transient Equivalent Testing Load

Circuit

Rev. 1.1

Page 26

SHARI=

6.2.3 DC CHARACTERISTICS

Sym. Parameter Notes

IL1

IL0

kcs

‘CCD

‘CCR

ICC,

‘CC,

kcws

‘CCES

IPPS

‘PPR

‘PPD

IPPW

‘PPE

IPPWS

‘PPES

Input Load Current 1

Output Leakage Current 1

V,, Standby Current

V,, Deep Power-Down Current 1,lO

V,, Read Current

V,, Word/Byte Write Current

V,, Block Erase Current

V,, Word/Byte Write or

Block Erase Suspend Current

V, Standby or Read Current

VP, Deep Power-Down Current

VP, Word/Byte Write Current

V, Block Erase Current

VP, Word/Byte Write or 1

Block Erase Suspend Current

LHF80V07 24

DC Characteristics

V,,=27V-3.6V Test

TYP.

1,336,

10 25 50

1,3,6

0.2

5 10

1,596

15

137

5 17 mA

5 12

1,7

4

4 12 nL4

12

1

1 6 mA CE#=V,

+2 &15

10 200

1 0.1 5

1,7

177

12 40

8 25

10 200

Max.

*OS

*OS

2 mA VCC=VCCMax.

25

30 mA

17

30

20

Unit Conditions

11A

VCC=VCCMax.

V,,=V,, or GND

cul\ p=w-

OUT=VCC or GND

CMOS Inputs

ClA

Vcc=VccMax.

CE#=RP#=V,,&2V

TTL Inputs

CE#=RP#=V,,

RP#=GND*0.2V

llA

IoUT(RY/13Y#)=OmA

CMOS Inputs

mA V,,=V,,Max., CE#=GND

f=SMHz, I,,,=OmA

TlL Inputs

VCC=VCCMax., CE#=GND

f=SMHz. IoUT=OmA

V,,=2.7V-3.6V

mA V,,=11,4V-12.6V

mA V,,=2.7V-3.6V

V,,=11.4V-12.6V

PA

PA

I.rA

VPP~VCC

vPP’vcc

RP#=GND+0.2V

mA Vpp=2.7V-3.6V

mA VP,=1 1.4V- 12.6V

mA Vpp=2.7V-3.6V

mA Vpp=11.4V-12.6V

ClA

VPP=VPPHI I2

Rev. 1.1

Page 27

SHARI=

LHF8OVO7

25

DC Characteristics (Continued)

Vo=2.7V-3.6V

Sym.

V,, Low Voltage Input

VIH

VOL

‘OHI

Input High Voltage

Output Low Voltage

Output High Voltage

Cl-rL)

‘OH2

VPPLK

‘PPHl

‘PPH2

VHH

Output

(CMOS)

V, Lockout Voltage during Normal 4,7

Operations

V, Voltage during Word/Byte Write

or Block Erase Operations

VP, Voltage during Word/Byte Write

or Block Erase Operations

RP# Unlock Voltage 83

Parameter Notes Min.

7 -0.5 0.8

7

337

3.7

High Voltage

3,7

Max.

2.0

+“,c?

0.4

2.4

0.85

Vcc

2%

1.5

2.7 3.6

11.4 12.6

2.0

11.4

12.6

Unit Test Conditions

V

V

yccz;=~in.

V

V

V

V

OL

ycc~pccin~

OH- .

;CflCdMin.

OH .

Vcc=Vcc Min.

IoH’- lOOpA

V

V

V

V

V Unavailable WP#

NOTES:

1. All currents are in RMS unless otherwise noted. Typical values at nominal V,, voltage and T,=+25”C.

2. ICC,, md ‘CCES

are specified with the device de-selected. If read or wordlbyte written while in erase suspend mode, the

device’s current draw is the sum of Iccws or ICCES and ICCR or ICC,, respectively.

3. Includes RY/BY#.

4. Block erases and word/byte writes are inhibited when VppIVppLK,

and not guaranteed in the range between VppLK(max.)

and VppHl(min.), between VppHl(max.) and VppH2(min.) and above VppH2(max.).

5. Automatic Power Savings (APS) reduces typical ICC,

to 3mA at 2.7V V,, in static operation.

6. CMOS inputs are either Vcc&0.2V or GNDk0.2V. TTL inputs are either V,, or V,,.

7. Sampled, not 100% tested.

8. Boot block erases and word/byte writes are inhibited when the corresponding RP#=V,, and WP#=Vl,. Block erase and

word/byte write operations are not guaranteed with VrH<RP#<VH, and should not be attempted.

9. RP# connection to a V,,

supply is allowed for a maximum cumulative period of 80 hours.

10. BYTE# input level is Vcc&.2V in word mode or GND+-0.2V in byte mode. WP# input level is Vcck0.2V or GNDti.2V.

Rev. 1.1

Page 28

SHARP

LHF8OVO7 26

6.2.4 AC CHARACTERISTICS - READ-ONLY OPERATIONS(l)

NOTES:

1.

See AC Input/Output Reference Waveform for maximum allowable input slew rate.

2.

OE# may be delayed up to tELQV-bLQV

3. Sampled, not 100% tested.

4. If BYTE# transfer during reading cycle, exist the regulations separately.

after the falling edge of CE# without impact on tELQv.

Rev. 1.1

Page 29

SHARI=

VIH

iDDRESSES

OE#(G)

:“I--

WE#(W)

hi f-----

VOH

DATA(D/Q)

(DQo-DQd

VOL

VIL

Standby

HIGH Z

Device

Address Selection

Address Stable

4

I

tAVQV

Llw8OVO7

b

27

Data Valid

--;~j HIGH Z

“cc

VIH I

~#(P)

VIL

tPHQV

-----------7

Figure 11. AC Waveform for Read Operations

Rev. 1.1

Page 30

SHARP

II

.DDRESSES(A)

OE#(G)

BYTE#(Fj

DATA(D/Q)

(DQo-DQ7)

VIH

VIL

y---

VIH

VtL

VOH

VOL

Standby

HIGH Z

Device

Address Selection

4

Address Stable

LHF8OVO7

Data Valid

28

____-______

_______----

___________

___-_-_----

VOH

DATA(D/Q)

(DQs-DQls)

VOL

HIGH Z

Data

output

Figure

12. BYTE# timing Waveform

HIGH Z

Rev. I.1

Page 31

SHARP

LHFSOV07

6.2.5 AC CHARACTERISTICS - WRITE OPERATIONS(l)

29

NOTES:

1.

Read timing characteristics during block erase and word/byte write operations are the same as during read-only operations.

Refer to AC Characteristics for read-only operations.

2. Sampled, not 100% tested.

3. Refer to Table 4 for valid A,, and D,, for block erase or word/byte write.

4. V,, should be held at V,,,t,z (and if necessary RP# should be held at V,,) until determination of block erase or

word/byte write success (SR.1/3/4/5=0).

5. If BYTE# switch during reading cycle, exist the regulations separately.

Rev. 1.1

Page 32

SHARP

ADDRESSES(A)

CE#(E)

OE#(Gl

WE#(W)

DATA(D/Ql

BYTE#(F)

RY/BY#(R)

LHF80V07

30

WPW)

VHH

RPNP)

VIH .-

vppw

NOTES:

1. V,-c power-up and standby.

2. Write block erase or word/byte write setup.

3. Write block erase confirm or valid address and data

4. Automated erase or program delay.

5. Read status register data.

6. Write Read Array command.

Figure 13. AC Waveform for WE#-Controlled Write Operations

bHHWH ,

Rev. 1.1

Page 33

SHARP

LHF8OVO7

6.2.6 ALTERNATIVE CE#-CONTROLLED WRITES(l)

NOTES:

1.

In systems where CE# defines the write pulse width (within a longer WE# timing waveform), all setup. hold, and inactive

WE# times should be measured relative to the CE# waveform.

2. Sampled, not 100% tested.

3.

Refer to Table 4 for valid A,, and D,, for block erase or word/byte write.

4. V,, should be held at V,,,,,, (

word/byte write success (SR.1/3/4/5=0).

5. If BYTB# switch during reading cycle, exist the regulations separately.

and if necessary RP# should be held at V,,) until determination of block erase or

Rev. 1.1

Page 34

SHARI=

ADDRESSES(A)

CE#(E)

OE#(G)

WEKW)

DATA(D/Q)

BYTE#(F)

RY/BY#(R)

VIH

VIL

VIH

VIL

VIH

VIH

LHFSOV07

32

WP#(S)

RPMP)

NO-l-ES:

1. VCC power-up and standby.

2. Write block erase or word/byte write setup.

3. Write block erase confirm or valid address and data.

4. Automated erase or program delay

5. Read status register data.

6. Write Read Array command

VIH ,‘

Figure 14. AC Waveform for CE#-Controlled Write Operations

Rev. 1.1

Page 35

SHARP

RESET OPERATIONS

LHF8OVO7

RY/BY#(R)

RP#(P)

RY/BY#(R)

RP#(P)

vcc

RP#(P)

VOL

VIH

VU

High Z

VOL

VIH

VIL

2.w

VU

VIH

VIL

(A)Reset During Read Array Mode

(B)Reset During Block Erase or Word/Byte Write

L

I

- hVPH -

i

(C)RP# rising Timing

Figure 15. AC Waveform for Reset Operation

Reset AC Specifications

V,,=2.7V-3.6V

Sym. Parameter Notes Min.

RP# Pulse Low Time

‘PLPH

tPLRZ

t2VPH

(If RP# is tied to V,,. this specification is not applicable)

RP# Low to Reset during Block Erase or Word/Byte Write

12

Vcc 2.7V to RP# High 3 100

100

Max. Unit

ns

22

P

ns

VOTES:

1. If RP# is asserted while a block erase or word/byte write operation is not executing, the reset will complete within loons.

!. A reset time, tpHQVz is required from the later of RY/BY# going High Z or RP# going high until outputs are valid.

3. When the device power-up, holding RP# low minimum IOOns is required after V,,

has been in predefined range and also

has been in stable there.

Rev. 1.1

Page 36

SHARP

LHF8OVO7 34

6.2.8 BLOCK ERASE AND WORD/BYTE WRITE PERFORMANCE(3)

NOTES:

1. Typical values measured at T,=+25”C and nominal voltages. Subject to change based on device characterization.

2. Excludes system-level overhead.

3. Sampled but not 100% tested.

4. All values are in word mode (BYTE#=V,,). At byte mode (BYTE#=V,,), those values are double.

Rev. 1.1

Page 37

SHARP

__.__.______...__.__~~..~~~~~---~~~~-~~~~..-~~~.-.--~--~~~~~~..~~~~~~~~...~~~~~~~~..---~~~~~~~~--~~~~~~~-~~~~~--~~~~~~~-~~~~~.~~~....----~.--------.---------

_.__________.___________________________~~~~~~~~~~..~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~.~.~~~~~~~~~~~~~~~~~~~~~~~~~~.~~~~~~...~~~~~...~~~~

_.__________________-~.~~~~~-~~~~~--~~~...-~~...----.-~-~~~~...~~~~~~~~.--~~~~~~~~..-~~~~~~~~~~--~~~~~~~-~~~~~-~~~~~~--~~~~..-~~~~.------...-------..--------

_.._______._.__._....~~~....~~~-.~~~~~~~~~~-~~~~...-~~~~--~-~~~~-~~-~~~~~~~~~-~--~~~~~~~-~-~.~~~~~---~~~~..~~~~~~~.~~~~~~--~~~~~-~~~~..-~~~~..-----...-------

7 Package and packing specification

1. Package Outline Specification

Refer to drawing No.AA2 0 3 4

2. Markings

2 - 1. Marking contents

( 1) Product name : F800BVB-

(2) Company name : SHARP

( 3 ) Date code

(Example) Y Y Indicates the product was manufactured

(4) The marking of “JAPAN” indicates the count

2-2. Marking layout

Refer to drawing No.AA2 0 3 4

(This layout does not define the dimensions of marki

TTLSO

LHF80V07

- Denotes the production ref.code (l-3)

in the WWth week of 19YY.

Denotes the production week.

(01,02,03, . . . * . 52,53)

Denotes the production year.

(Lower

two digits of the year.)

ry of origin.

ng character and marking position.)

35

3. Packing Specification (Dry packing for surface mount packages)

Dry packing is used for the purpose of maintaining IC quality after mounting

packages on the PCB (Printed Circuit Board).

If the surface mount type package absorbs a large amount of moisture,

this moisture may suddenly vaporize into steam when the entire package is heated

during the reflow soldering process. This causes expansion and results

in separation between the resin and insert material, and sometimes cracking

of the package. This dry packing is designed to prevent the above problem

from occurring in surface mount packages.

3 - 1 . Packing Materials

Mater ial Name Material Specificaiton

Tray Conductive plastic(lOOdevices/tray) Fixing of device

___..________._.____.~~~~~~.~~~~..~~~~~-~~~~~-~~~~...-~~~~..---~~~~..-----~~~.~-.---~~~~~~~..-~~~~~~.~~~~~.~~~~~~.-~~~~~.------------------------ --------

Upper cover tray

Laminated aluminum bag Aluminum polyethylene (lbag/case)

Des iccant Silica gel Drying of device

P P band

__________-_.____.---~.~~~-~~~~~~-~~~~~..--~~..-----.---~~~....~-~~~~~~~..---~~~~~~~~~----~~~~~~~-~~-~~

Inner case Card board (lOOOdevices/case) Packaging of device

_________._______----~~~~~--~~~.--~~~~..---...-------~~~....---~~.....----~~~~....---~~~~~~..~~-~~~~~..-- ___----____----____.-~~~...----...-------.---------

Label

Outer case Card board Outer packing of tray

(Devices shall be placed into a tray in the same direction.)

Conductive plast ic (It ray/case)

Polypropylene

Paper

(5pcs/case) Fixing of tray

Purpose

Fixing of device

Drying of device

__.._____________---____________________---~~~..------

Indicates part number,quantity

and date of manufacture

Page 38

SHARP

3-2. Outline dimension of tray

Refer to attached drawing

Storage and Opening of Dry Packing

4.

LHF80V07

36

4-l. Store under conditions shown below befo

(1) Temperature range

(2) Humidity

4-2. Notes on opening the dry packing

(1) Before opening the dry packing, prepare a working table which is

grounded against ESD and use a grounding strap.

(2) The tray has been treated to be conductive or anti-static. If the

device is transferred to another tray, use a equivalent tray.

4-3. Storage after opening the dry packing

Perform the following to prevent absorption of moisture after opening.

(1) After opening the dry packing, store the ICs in an environment with

a temperature of 5--25°C and a relative humidity of 60% or less.

If doing reflow soldering once, mount ICs within 4 days after the opening.

If doing reflow soldering twice, do the first mounting within

4 days after the opening and do the second mounting within

4 days after the first mounting.

(2) To re-store the ICs for an extended period of time within 4 days after

opening the dry packing,

packing with desiccant (whoes indicater is blue), and store in an

environment with a temperature of 5-40°C and a relative humidity of

80% or less, and mount ICs within 2 weeks.

(3) Total period of storage after first opening and re-opening is within

4 days, and store the ICs in the same environment as sect ion 4-3. (I).

: 5-40°C

: 80% RH or less

use a dry box or re-seal the ICs in the dry

re opening the dry pack i

ng

First opening+ XI +re-sealing+ Y -‘re-opening- Xz

V

ICs in dry

packing

4 - 4. Baking (drying) before mounting

(1) Baking is necessary

(A) If the humidity indicator in the desiccant becomes pink

(B) If the procedure in section 4-3 could not be performed

(2) Recommended baking conditions

If the above conditions (A) and (B) are applicable, bake it before

mounting, The recommended conditions are 1-3 hours at 120 ~~““C.

Heat resistance tray is used for shipping tray.

(3) Storage after baking

After baking ICs, store the ICs in the same environment as sect ion

4-3. (1).

5-25°C 5-40°C

60%RH or less SO%RH or less 60%RH or less

5-25°C

-mount

ing

Page 39

SHARP

5. Surface Mount Conditions

Please perform the following conditions when mounting ICs not to deteriorate IC

quality.

LHF80V07

37

5-l.

,Soldering conditions

Mounting Method

Reflow soldering

5- 2. Conditions for removal of residual flux

(1) Ultrasonic washing power : 25 Watts/liter or less

(2) Washing time

( 3 > Solvent temperature

Temperature and Duration Measurement Point

Peak temperature of 240°C or less, IC package surface

duration of less than 15 seconds above

230°C. 200°C or over ,durat ion of

30-50 seconds. Preheat temperature

of 125~150°C duration of less than

180 seconds. Temperature increase

rate of l--4”C/second.

: Total 1 minute maximum

: 15-40°C

,

J

Page 40

SHARF’

LHF80V07

TOP VIEW------

I

,I NDEX

v

F8OOBVB-

TTLSO JAPAN

---_

-:’

I

I

I

0

\

\

\

\

\

\

‘.

--___-y .

1

.’

/

’ 0

A-l

\

I I\

/

\

\

J(

I

I

I

0. 4

T’TF.

a

p_

-- BOTTOM VIEW

I

I

t

I

,z- @@0.15@

%lq tB%

NAME ;

DRAWING NO. i AA2034

FBGA048-P-0808 NOTE

%iM I

UNIT ! mm

- $ 60. 30

1. 2

TYP.

cbo.45 20.03

01

@ S AB

SCD

Page 41

SHARP

-r

-

h

:

C

f

A

1

LHF80V07

a

p.3

5.8 r

!7.9

25.0~0.3*4=100.0~0.3

%vF~ fiiwi

JAME 1 LCSP80-0808TCT-RH NOTE

i+.&{Z ;

DRAWING NO. / CV812 UNIT 1 mm

I

35.8

17.4

2::

w

Page 42

SHARf=

LHE3OVO7

Flash memory LHFsOV(B)XX family Data Protection (TSOP

Noises having a level exceeding the limit specified in the specification may be

generated under specific operating conditions on some systems.

Such noises, when induced onto WE# signal or power supply, may be interpreted as false

commands, causing undesired memory updating.

To protect the data stored in the flash memory against unwanted overwriting, systems

operating with the flash memory should have the following write protect designs, as

appropriate:

1) Protecting data in specific block

By setting a WP# to low, only the boot block can be protected against overwriting.

Parameter and main blocks cannot be locked.

System program, etc.,

When a high voltage is applied to RP#, overwrite operation is enabled for all blocks.

can be locked by storing them in the boot block.

package, CSP package)

40