Page 1

®

PRODUCT SPECIFICATIONS

Integrated Circuits Group

LH28F160BJHE-TTL90

Flash Memory

16M (1M × 16/2M × 8)

(Model No.: LHF16J04)

Spec No.: EL11X036

Issue Date: November 11, 1999

Page 2

SliARP

LHF16504

l Handle this document carefully for it contains material protected by international copyright law.

Any reproduction, full or in part, of this material is prohibited without the express written

permission of the company.

l When using the products covered herein, please observe the conditions written herein and the

precautions outlined in the following paragraphs. In no event shall the company be liable for any

damages resulting from failure to strictly adhere to these conditions and precautions.

(1) The products covered herein are designed and manufactured for the following application

areas. When using the products covered herein for the equipment listed in Paragraph (2),

even for the following application areas, be sure to observe the precautions given in

Paragraph (2). Never use the products for the equipment listed in Paragraph (3).

*Office electronics

aInstrumentation and measuring equipment

@Machine tools

*Audiovisual equipment

*Home appliance

l Com’munication equipment other than for trunk lines

(2) Those contemplating using the products covered herein for the following equipment which

demands hiuh reliabilitv, should first contact a sales representative of the company and then

accept responsibility for incorporatin,

other appropriate measures for ensuring reliability and safety of the equipment and the

overall system.

@Control and safety devices for airplanes, trains, automobiles, and other

transportation equipment

*Mainframe computers

@Traffic control systems

*Gas leak detectors and automatic cutoff devices

*Rescue and security equipment’

aOther safety devices and safety equipment, etc.

(3) Do not use the products covered herein for the following equipment which demands

extremely high oerformance in terms of functionality, reliability, or accuracy.

aAerospace equipment

*Communications equipment for trunk lines

*Control equipment for the nuclear power industry

*Medical equipment related to life support, etc.

(4) Please direct all queries and comments regardin,

Paragraphs to a sales representative of the company.

0 into the design fail-safe operation, redundancy, and

0 the interpretation of the above three

l Please direct all queries regardin,

company.

0 the products covered herein to a sales representative of the

Rev. 1.15

Page 3

SHARP

LHFl6504

CONTENTS

PAGE

INTRODUCTION.. ............................................................ 3

1.1 Features ........................................................................ 3

1.2 Product Overview..

1.3 Product Description.. ................................................... .4

1.3.1 Package Pinout ...................................................... .4

1.3.2 Block Organization.. ............................................... 4

PRINCIPLES OF OPERATION.. ...................................... 7

2.1 Data Protection.. .......................................................... .8

BUS OPERATION

3.1 Read .............................................................................. 8

3.2 Output Disable

3.3 Standby.. ....................................................................... 8

3.4 Reset ............................................................................. 8

3.5 Read Identifier Codes.. ................................................ .9

3.6 Write.. ..........................................................................

COMMAND DEFINITIONS ............................................. 9

4.1 Read Array Command.. .............................................. 12

4.2 Read

4.3 Read Status Register Command.. ............................... 12

4.4 Clear Status Register Command..

4.5 Block Erase Command..

4.6 Full Chip Erase

4.7 Word/Byte Write Command.. ..................................... 13

4.8 Block Erase Suspend Command ................................ I4

4.9 Word/Byte Write Suspend Command..

4.10 Set Block and Permanent Lock-Bit Command.. ....... I5

4.1 1 Clear Block Lock-Bits Command

4.12 Block Locking by the WP#

Identifier Codes Command ............................... 12

....................................................... 3

............................................................ 8

.............................................................. 8

.9

...............................

............................................. 13

Command ......................................... 13

......................

............................ 15

......................................

12

14

16

PAGE

5 DESIGN CONSIDERATIONS ....................................... 25

5.1 Three-Line Output Control

5.2 RY/BY# and WSM Polling .......................................

5.3 Power Supply Decoupling

5.4 Vccw Trace on Printed Circuit Boards

5.5 v,, . vccw.

5.6 Power-Up/Down

5.7 Power Dissipation

5.8 Data Protection Method

6 ELECTRICAL SPECIFICATIONS ................................

6.1 Absolute Maximum Ratings..

6.2 Operating Conditions .................................................

6.2.1 Capacitance

AC Input/Output Test Conditions.. ...................... 28

6.2.2

6.2.3 DC Characteristics ............................................... 29

6.2.4 AC Characteristics - Read-Only Operations..

6.2.5 AC Characteristics - Write Operations

6.2.6 Alternative CE#-Controlled Writes

6.2.7 Reset Operations

6.2.8 Block Erase. Full Chip Erase, Word/Byte Write and

Lock-Bit Configuration Performance ................. 39

7 PACKAGE AND PACKING SPECIFICATIONS

RP# Transitions .................................... 25

Protection.. ..................................... 26

...................................................... 26

.......................................................... 27

........................................ 25

25

......................................... 25

..................... 25

............................................. 26

27

.................................... 27

27

...... 31

................ 34

...................... 36

.................................................. 38

.......... 40

1

Rev. 1.25

Page 4

LI-IFI 6504

LH28F 160B JHE-TTL90

2

IGM-BIT ( 1Mbit x16 / 2Mbit

Boot Block Flash MEMORY

n Low Voltage Operation

- v,,=v(-cw-L.

n User-Configurable x8 or x 16 Operation

n High-Performance Read Access Time

- 90ns(Vcc=2.7V-3.6V)

n Operating Temperature

- -40°C to +85”C

I Low Power Management

-

Typ. 2uA (V,,=3,OV) Standby Current

-

Automatic Power Savings Mode Decreases ICCR in

Static Mode

- Typ. 120pA (V,,=3.OV, T,=+25”C. f=32kHz)

Read Current

n Optimized Array Blocking Architecture

-

Two 4K-word (8K-byte) Boot Blocks

-

Six 4K-word (8K-byte) Parameter Blocks

-

Thirty-one 32K-word (64K-byte) Main Blocks

- Top Boot Location

n Extended Cycling Capability

-

Minimum 100,000 Block Erase Cycles

-’ 7V-3.6V Single Voltage

x8

)

H Enhanced Automated Suspend Options

-

Word/Byte Write Suspend to Read

-

Block Erase Suspend to Word/Byte Write

-

Block Erase Suspend to Read

n Enhanced Data Protection Features

-

Absolute Protection with VCCWIVCCWLK

-

Block Erase, Full Chip Erase, Word/Byte Write and

Lock-Bit Configuration Lockout during Power

Transitions

-

Block Locking with Command and WP#

-

Permanent Locking

n

Automated Block Erase, Full Chip Erase,

Word/Byte Write and Lock-Bit Configuration

-

Command User Interface (CUB

-

Status Register (SR)

n SRAM-Compatible Write Interface

n Industry-Standard Packaging

-

G-Lead TSOP

n ETOXTkt* Nonvolatile Flash Technology

W CMOS Process (P-type silicon substrate)

w Not designed or rated as radiation hardened

iHARP’s LH28F160BJHE-TTL90 Flash memory is a high-density. low-cost. nonvolatile, read/write storage solution for a

vide range of applications.

,H28F160BJHE-TTL90 can operate at V,,=2.7V-3.6V and Vc-w--.

:apability realize battery life and suits for cellular phone application.

ts Boot, Parameter and Main-blocked architecture, low voltage and extended cycling provide for highly flexible component

uitable for portable terminals and personal computers. Its enhanced suspend capabilities provide for an ideal solution for code

- data storage applications.

:or secure code storage applications, such as networking, where code is either directly executed out of flash or downloaded to

IRAM, the LH28F160BJHE-TTL90 offers four levels of protection: absolute protection with VccwlVc-wLK, selective

lardware block locking or flexible software block locking. These alternatives Z

ecurity needs.

he LH28F160BJHE-‘ITL90 is manufactured on SHARP’s 0.25pm ETOXT”*

tandard package: the 4%lead TSOP, ideal for board constrained applications.

ETOX is a trademark of Intel Corporation.

-3 TV-3.6V or 11.7V-12.3V. Its low voltage operation

oive designers ultimate control of their code

process technology. It come in industry-

Rev. 1.25

Page 5

SHARP

LHF16504

1 INTRODUCTION

This

specifications. Section 1 provides a flash memory

overview. Sections 2. 3. 4 and 5 describe the memory

organization and functionality. Section 6 covers electrical

specifications.

datasheet

contains

LH28F160BJHE-T-IL90

1.1 Features

Key enhancements of LH28F16OBJHE-TTL90 boot block

Flash memory are:

Gingle low voltage operation

*Low power consumption

*Enhanced Suspend Capabilities

l Boot Block Architecture

Please note following:

l

VCCWLK has been lowered to l.OV to support 2.7V-

3.6V block erase. full chip erase. word/byte write and

lock-bit configuration operations. The Vccw voltage

transitions to GND is recommended for designs that

switch Vccw off during read operation.

1.2 Product Overview

The LH28F160BJHE-TTL90 is a high-performance 16Mait Boot Block Flash memory organized as lM-word of 16

aits or 2M-byte of 8 bits. The lM-word/2M-byte of data is

u-ranged in two 4K-word/SK-byte boot blocks, six 4Kword/8K-byte parameter blocks and thirty-one 32Kvord/64K-byte main blocks which are individually

:rasable, lockable and unlockable in-system. The memory

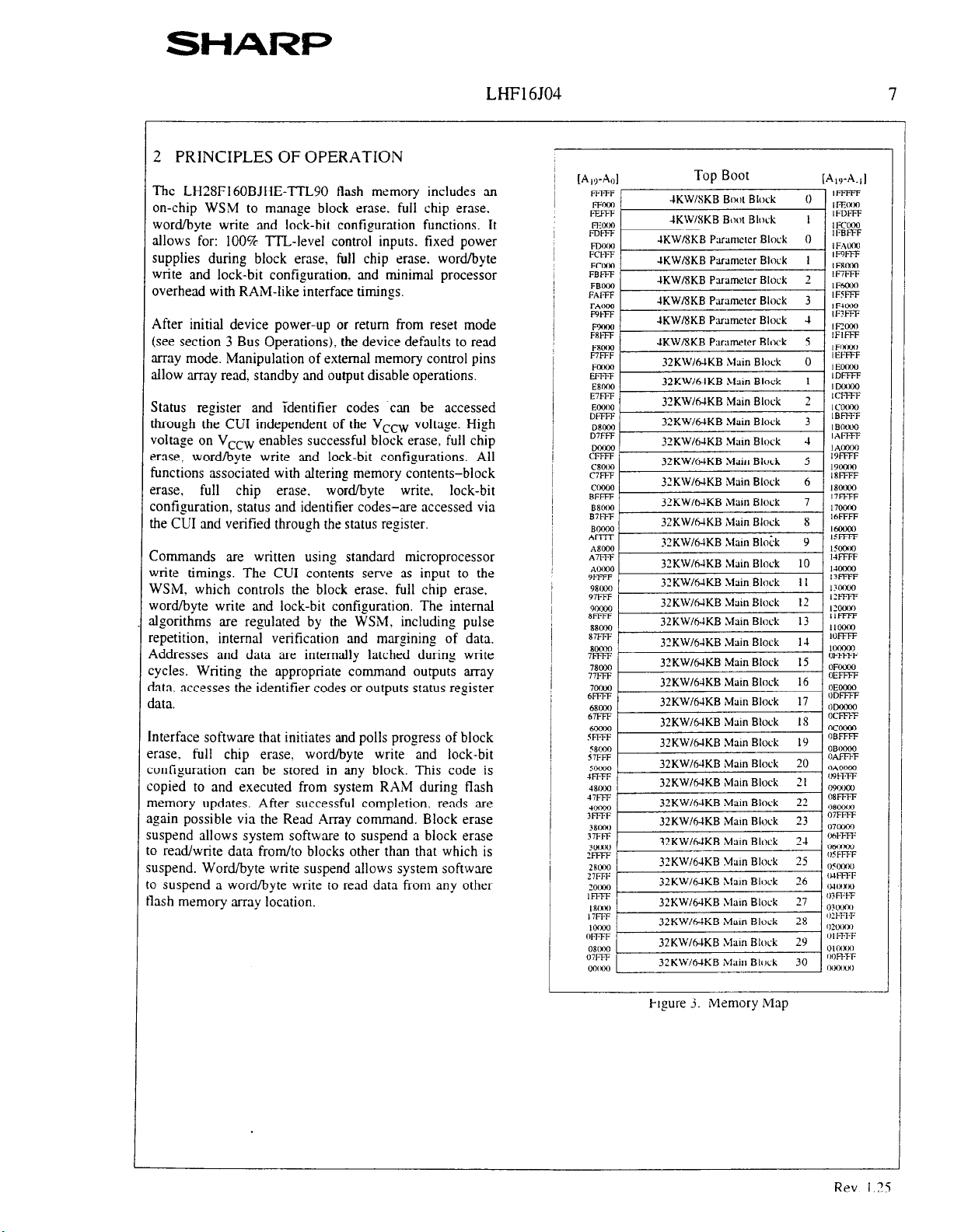

nap is shown in Figure 3.

Ihe dedicated V ccw pin gives complete data protection

vhen V

CCW’VCCWLK.

4 Command User Interface (CUD serves as the interface

jetween the system processor and internal operation of the

ievice. A valid command sequence written to the CUI

nitiates device automation. An internal Write State

vlachine (WSM) automatically executes the algorithms

md timings necessary for block erase, full chip erase.

vord/byte write and lock-bit configuration operations.

3

A block erase operation erases one of the device’s 32K-

word/6JK-byte blocks typically within 1.2s (3V Vcc. 3V

ccw). JK-word/8K-byte blocks typically within 0.6s (3V

V

V,,. 3V Vccw) independent of other blocks. Each block

can be independently erased minimum 100,000 times.

Block erase suspend mode allows system software to

suspend block erase to read or write data from any other

block.

Writing memory data is performed in word/byte

increments of the device’s 32K-word blocks typically

within 33~s (3V V,,. 3V Vccw). 6JK-byte blocks

typically within 31~s (3V V,,. 3V Vccw). 4K-word

blocks typically within 36~s (3V Vcc. 3V V,,,), 8Kbyte blocks typically within 32~s (3V Vcc. 3V Vccw).

Word/byte write suspend mode enables the system to read

data or execute code from any other flash memory array

location.

Individual block locking uses a combination of bits, thirty-

nine block lock-bits. a permanent lock-bit and WP# pin. to

lock and unlock blocks. Block lock-bits gate block erase.

full chip erase and word/byte write operations. while the

permanent lock-bit pates block lock-bit modification and

locked block alternation. Lock-bit configuration

operations (Set Block Lock-Bit, Set Permanent Lock-Bit

and Clear Block Lock-Bits commands) set and cleared

lock-bits.

The status register indicates when the WSM‘s block erase,

fuli chip erase. word/byte write or lock-bit configuration

operation is finished.

The RY/BY# output gives an additional indicator of WSM

activity by providing both a hardware signal of status

(versus software polling) and status masking (interrupt

masking for background block erase, for example). Status

polling using RY/BY# minimizes both CPU overhead and

system power consumption. When low, RY/BY# indicates

that the WSM is performing a block erase. full chip erase.

word/byte write or lock-bit configuration. RY/BY#-high Z

indicates that the WSIM is ready for a new command.

block erase is suspended (and word/byte write is

inactive), word/byte write is suspended. or the device is in

reset mode.

1

Rev. 1.25

Page 6

LHFl6504

4

The access time is 90ns (tAv v) over the operating

temperature range (-40°C to + 5°C) 8 and V,- supply

voltage range of 2.7V-3.6V.

The Automatic Power Savings (APS) feature substantially

reduces active current when the device is in static mode

(addresses not switching). In APS mode, the typicaJ ICCR

current is 2pA (CMOS) at 3.OV V,,.

When CE# and RP# pins are at V,-. the I,, CMOS

standby mode is enabled. When the RP# pin is at GND,

reset

mode is enabled which minimizes power

consumption and provides write protection. A reset time

(tpHQv) is required from RP# switching high until outputs

are valid. Likewise, the device has a wake time (tpHEL)

from RP#-high until writes to the CljI are recognized.

With RP# at GND, the WSM is reset and the status

register is cleared.

Please do not

has already been programed “0”. Overwrite operation may

generate unerasable bit. In case of reprogramming “0” to

the data which has been programed “1”.

.Prograrn “0” for the bit in which you want to change

data from ” 1” to “0”.

.Program “1” for the bit which has already been

programmed “0”.

For example, changing data from “10111101” to

‘10111100” requires “11111110” programming.

execute

reprogramming “0” for the bit which

1.3 Product Description

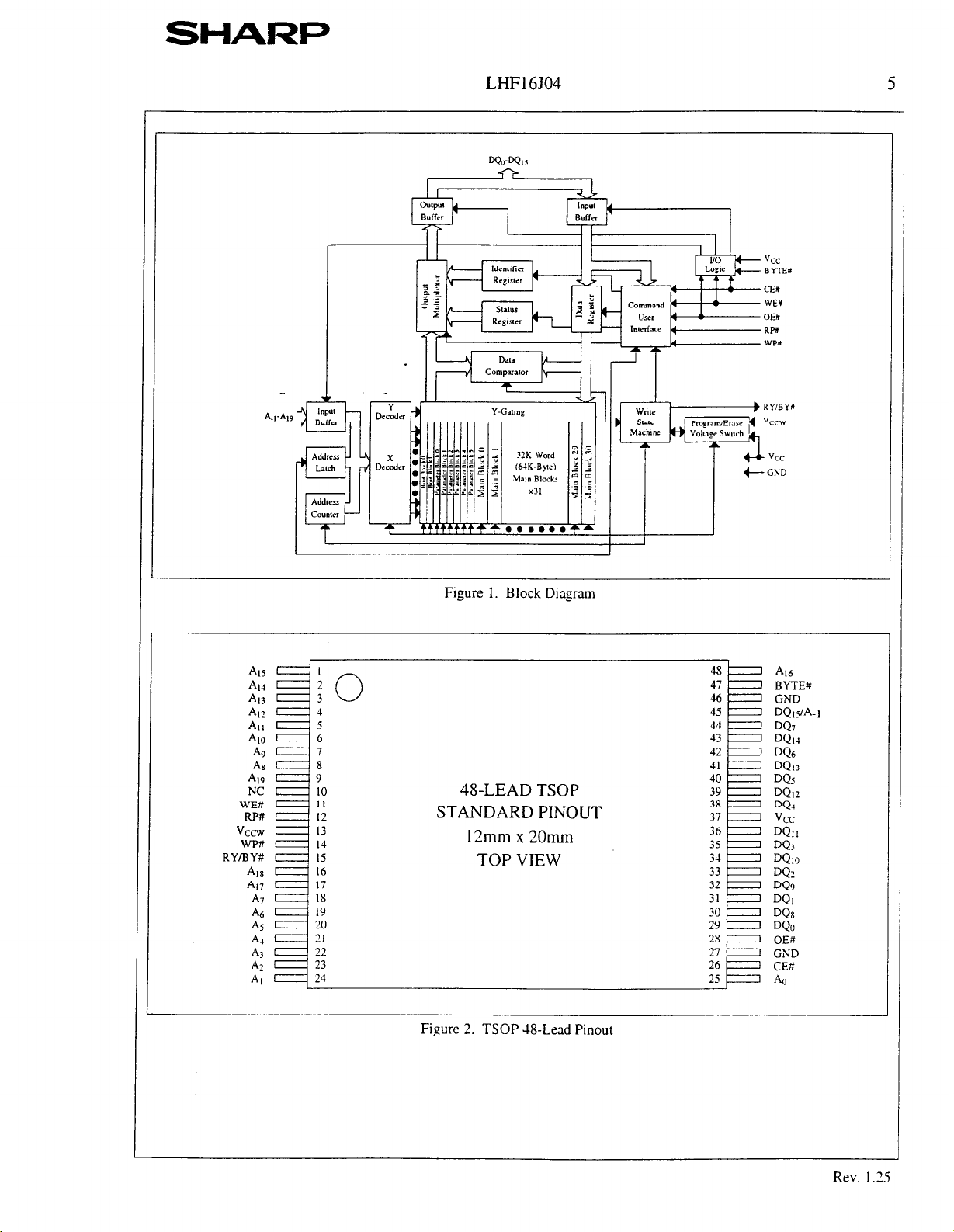

1.3.1 Package Pinout

LH28F160BJHE-TTL90 Boot Block Flash memory is

available in J8-lead TSOP package (see Figure 2).

1.32 Block Organization

This product features an asymmetrically-blocked

architecture providing system memory integration. Each

erase block can be erased independently of the others up to

100,000 times. For the address locations of the blocks. see

the memory map in Figure 3.

Boot Blocks: The boot block is intended to replace a

dedicated boot PROM in a microprocessor or

microcontroller-based system. This boot block 4K words

(4.096words) features hardware controllable write-

protection to protect the crucial microprocessor boot code

from accidental modification. The protection of the boot

block is controlled using a combination of the Vccw, RP#.

WP# pins and block lock-bit.

Parameter Blocks: The boot block architecture includes

parameter blocks to facilitate storage of frequently update

small parameters that would normally require an

EEPROM. By using software techniques. the word-rewrite

functionality of EEPROMs can be emulated. Each boot

block component contains six parameter blocks of 4K

words (4.096 words) each. The protection of the parameter

block is controlled using a combination of the Vccw. RP#

and block lock-bit.

Main Blocks: The reminder is divided into main blocks for

data

or

code storage.

one 32K words (32,768 words) blocks. The protection of

the main block is controlled using a combination of the

Vccw, RP#

and

Each 16M-bit device contains thirty-

block lock-bit.

Rev. 1.25

Page 7

SHARI=

LHF16504 5

CEY

WEX

OEX

RF?+

Buffer h /

WE#

RP#

vccw

WP#

RYlBY#

Al5

Al4

A13

A12

All

40

A9

‘48

49

NC

‘418

A17

A7

%

A5

A.,

A3

A2

Al

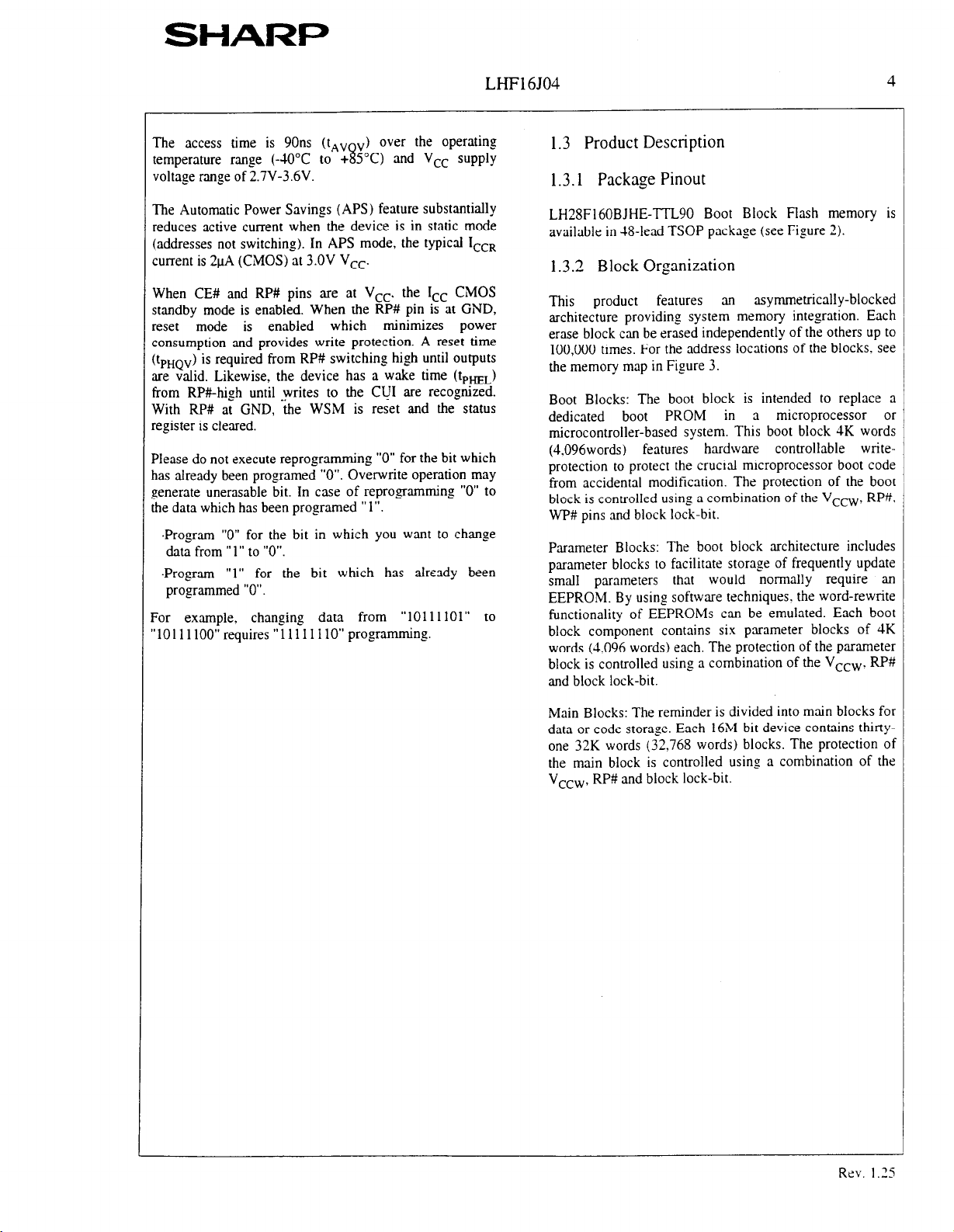

Figure 1. Block Diagram

4%LEAD TSOP

STANDARD PINOUT

12mm x 20mm

TOP VIEW

Figure 2. TSOP -%Lead Pinout

A16

BYTE?4

GND

DQJA-I

DQ7

DQu

DQ6

DQu

DQ5

DQlr

DQa

vcc

DQII

DQ3

DQIO

DQz

DQ!,

DQI

DQs

DQo

OE#

GND

CE#

A0

Rev. 1.25

Page 8

LHFl6JO4

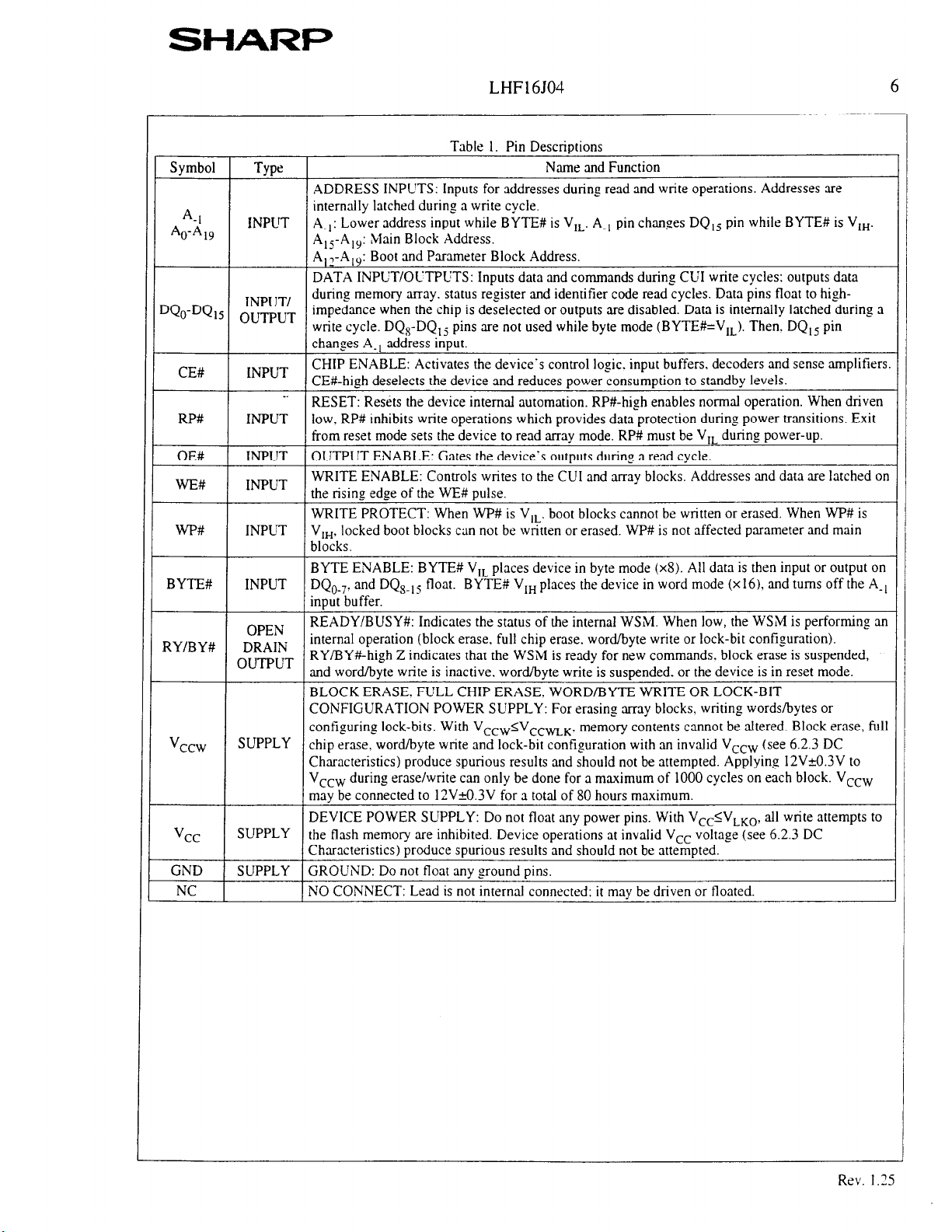

Table 1. Pin Descriptions

Symbol

A-1

A,-‘419

"Qo-DQ,,

CE#

RP#

OE#

WE#

WP#

BYTE# INPUT DQO-,. and DQ,., j float. BYTE# V,, places the device in word mode (x16), and turns off the A-,

RY/BY# DRAIN

Vccw

vcc

GND SUPPLY GROUND: Do not float any ground pins.

NC NO CONNECT: Lead is not internal connected: it may be driven or floated.

Type

ADDRESS INPUTS: Inputs for addresses during read and write operations. Addresses are

internally latched during a write cycle.

INPUT A-,: Lower address input while BYTE# is V,,. A-, pin changes DQ, j pin while BYTE# is Vt,.

A, j-A,,: Main Block Address.

A,,-A,,: Boot and Parameter Block Address.

DATA INPUT/OUTPUTS: Inputs data and commands during CUI write cycles: outputs data

INPUT/

OUTpUT

INPUT

INPUT low. RP# inhibits write operations which provides data protection during power transitions. Exit

INPUT

INPUT

INPUT V,,, locked boot blocks can not be written or erased. WP# is not affected parameter and main

OPEN

OUTPUT

SUPPLY

SUPPLY the flash memory are inhibited. Device operations at invalid V,, voltage (see 6.2.3 DC

during memory array. status register and identifier code read cycles. Data pins float to highimpedance when the chip is deselected or outputs are disabled. Data is internally latched during a

write cycle. DQs-DQ, j pins are not used while byte mode (BYTE#=V,,). Then. DQls pin

changes A-, address input.

CHIP ENABLE: Activates the device’s control logic. input buffers. decoders and sense amplifiers.

CE#-high deselects the device and reduces power consumption to standby levels.

_.

RESET: Resets the device internal automation. RP#-high enables normal operation. When driven

from reset mode sets the device to read array mode. RP# must be V,, during power-up.

OUTPUT ENABLE: Gates the device’s outputs during a read cycle.

WRITE ENABLE: Controls writes to the CUI and array blocks. Addresses and data are latched on

the rising edge of the WE# pulse.

WRITE PROTECT: When WP# is V,,. boot blocks cannot be written or erased. When WP# is

blocks.

BYTE ENABLE: BYTE# V,, places device in byte mode (x8). All data is then input or output on

input buffer.

READY/BUSY#: Indicates the status of the internal WSM. When low, the WSM is performing an

internal operation (block erase. full chip erase. word/byte write or lock-bit configuration).

RY/BY#-high Z indicates that the WSM is ready for new commands. block erase is suspended,

and word/byte write is inactive. word/byte write is suspended. or the device is in reset mode.

BLOCK ERASE. FULL CHIP ERASE. WORD/BYTE WRITE OR LOCK-BIT

CONFIGURATION POWER SUPPLY: For erasing array blocks, writing words/bytes or

configuring lock-bits. With VCCW<VCCWLK.

chip erase, word/byte write and lock-bit configuration with an invalid V,--w (see 6.2.3 DC

Characteristics) produce spurious results and should not be attempted. Applying 12Va0.3V to

Vc-w during erase/write can only be done for a maximum of 1000 cycles on each block. V,,,

may be connected to 12V@.3V for a total of 80 hours maximum.

DEVICE POWER SUPPLY: Do not float any power pins. With V&V,,,, all write attempts to

Characteristics) produce spurious results and should not be attempted.

Name and Function

memory contents cannot be altered. Block erase, full

6

Rev. 1.25

Page 9

SHARI’=

LHFI 6504 7

2 PRINCIPLES OF OPERATION

The LH?8F160BJHE-TTL90

on-chip WSM to manage block erase. full chip erase.

wordlbyte write and lock-bit configuration functions. It

allows for: 100% TILleve control inputs. fixed power

supplies during block erase, full chip erase. word/byte

write and lock-bit configuration. and minimal processor

overhead with RAIM-like interface timings.

After initial device power-up or return from reset mode

(see section 3 Bus Operations), the device defaults to read

array mode. Manipulation of external memory control pins

allow array read, standby and output disable operations.

Status register and identifier codes can be accessed

through the CUI independent of the Vccw voltage. High

voltage on Vccw enables successful block erase, full chip

erase, word/byte write and lock-bit configurations. All

functions associated with altering memory contents-block

:rase, full chip erase. word/byte write. lock-bit

:onfiguration, status and identifier codes-are accessed via

he CUI and verified through the status register.

Commands are written using standard microprocessor

vrite timings. The CUI contents serve as input to the

WSM, which controls the block erase. full chip erase,

vord/byte write and lock-bit configuration. The internal

tlgorithms are regulated by the WSM, including pulse

,epetition, internal verification and margining of data.

iddresses and data are internally latched during write

:ycles. Writing the appropriate command outputs array

lata. accesses the identifier codes or outputs status register

lata.

nterface software that initiates and polls progress of block

‘rase. full chip erase, word/byte write and lock-bit

onfiguration can be stored in any block. This code is

opied to and executed from system RAIM during flash

nemory updates.

After successful

gain possible via the Read Array command. Block erase

uspend allows system software to suspend a block erase

I read/write data from/to blocks other than that which is

uspend. Word/byte write suspend allows system software

I suspend a word/byte write to read data from any other

lash memory array location.

flash memory includes an

completion, reads are

[AII-&II

FtlTF

FFm

FE.

Flilx4

rnr7+

mow

FCtFF

FCMI

FBWF

FBCW

FAFFF

FAlKK?

F9tFF

FW”,,

FRWF

FPIIXK)

RFFF

FM*)

EFFFF

E8MO

E7FFF

Eixml

DFFFF

D8D00

D7WF

c%

C8cix)

c7m

ET?=

B8Nx)

B7tFF

BOOM)

AFFFF

A8033

Am

AcmO

9tFFF

98wxl

97FFF

9MXJ

WFFF

88mo

87FFF

8oIx)t)

7FFFF

780X

77m

7oM

6FFFF

68oMl

67FFF

5Fkz

58Mo

57FFF

5OlXKl

JFFFF

48*M

J7FFF

:I

38mi,

37FFF

3otml

FFFF

28ooo

27FFF

XOXJ

IFFFF

,R,XX,

I7FFT

IIWX

OFFFF

“8MM

“7FFF

OO~KHI

Top Boot

B

Main

Block

32KWlhAKB Mam Block 23

32KW/6-lKB Xlam Block

32KWNKB ,Mun Block 28

Figure 3. Memory ~Map

Rev. 1.35

Page 10

SHARP

LHFl6504

2.1 Data Protection

Wkn vccw~vccw,,~

altered. The GUI. with two-step block erase. full chip

erase. word/byte write or lock-bit configuration command

sequences, provides protection from unwanted operations

even when high voltage is applied to Vccw. All write

functions are disabled when Vcc is below the write

lockout voltage VLKO or when RP# is at V,,. The device’s

block locking capability provides additional protection

from inadvertent code or data alteration by gating block

erase, full chip erase and word/byte write operations.

Refer to Table 5 for write protection alternatives.

memory contents cannot be

3 BUS OPERATlON

l3e local CPU reads and writes flash memory in-system.

411

bus cycles to or from the flash memory conform to

standard microprocessor bus cycles.

3.1 Read

nformation can be read from any block. identifier codes

)r status register independent of the Vccw voltage. RP#

:an be at V,,.

i-he first task is to write the appropriate read mode

:ommand (Read Array, Read Identifier Codes or Read

itatus Register) to the GUI. Upon initial device power-up

jr after exit from reset mode, the device automatically

esets to read array mode. Six control pins dictate the data

low in and out of the component: CE#. OE#. BYTE#,

JZ#, RP# and WP#. CE# and OE# must be driven active

3 obtain data at the outputs. CE# is the device selection

ontrol. and when active enables the selected memory

evice. OE# is the data output (DQ,-DQlj) control and

{hen active drives the selected memory data onto the l/O

us. BYTE# is the device l/O interface mode control.

VE# must be at V,,, RP# must be at V,,. and BYTE#

nd WP# must be at V,,

:ad cycle.

2 Output

v’ith OE# at a logic-high level (VI,), the device outputs

re disabled. Output pins (DQ,-DQ,,) are placed in a

igh-impedance state.

Disable

or V,,. Figure 14. 15 illustrates

8

3.3 Standby

CE# a.t a logic-high level (V,,) places the device ir

standby mode which substantially reduces device powel

consumption. DQ,-DQ,, outputs are placed in a highimpedance state independent of OE#. If deselected during

block erase, full chip erase, word/byte write or lock-bil

confi,ouration, the device continues functioning, ant

consuming active power until the operation completes.

3.4 Reset

RP# at V,, initiates the reset mode.

In read modes, RP#-low deselects the memory. places

output drivers in a high-impedance state and turns off all

internal circuits. RP# must be held low for a minimum ot

IOOns. Time tpHQV

mode until initial memory access outputs are valid. After

this wake-up interval. normal operation is restored. The

GUI is reset to read array mode and status register is set to

80H.

During block erase. full chip erase, word/byte write or

lock-bit configuradon modes. RP#-low will abort the

operation. RY/E%Y# remains low until the reset operation

is complete. Memory contents being altered are no longer

valid; the data may be partially erased or written. Time

tpmvL is required after RP# goes to logic-high (VIH)

before another command can be written.

As with any automated device, it is important to assert

RP# during system reset. When the system comes out of

reset, it expects to read from the flash memory. Automated

flash memories provide status information when accessed

during block erase. full chip erase. word/byte write or

lock-bit configuration modes. If a CPU reset occurs with

no flash memory reset. proper CPU initialization may not

occur because the flash memory may be providing status

information instead of array data. SHARP’s flash

memories allow proper CPU initialization following a

system reset through the use of the RP# input. In this

application. RP# is controlled by the same RESET# signal

that resets the system CPU.

is required after return from reset

Rev. 1.25

Page 11

SHARP

I:::_::_::::::

LHFl6504

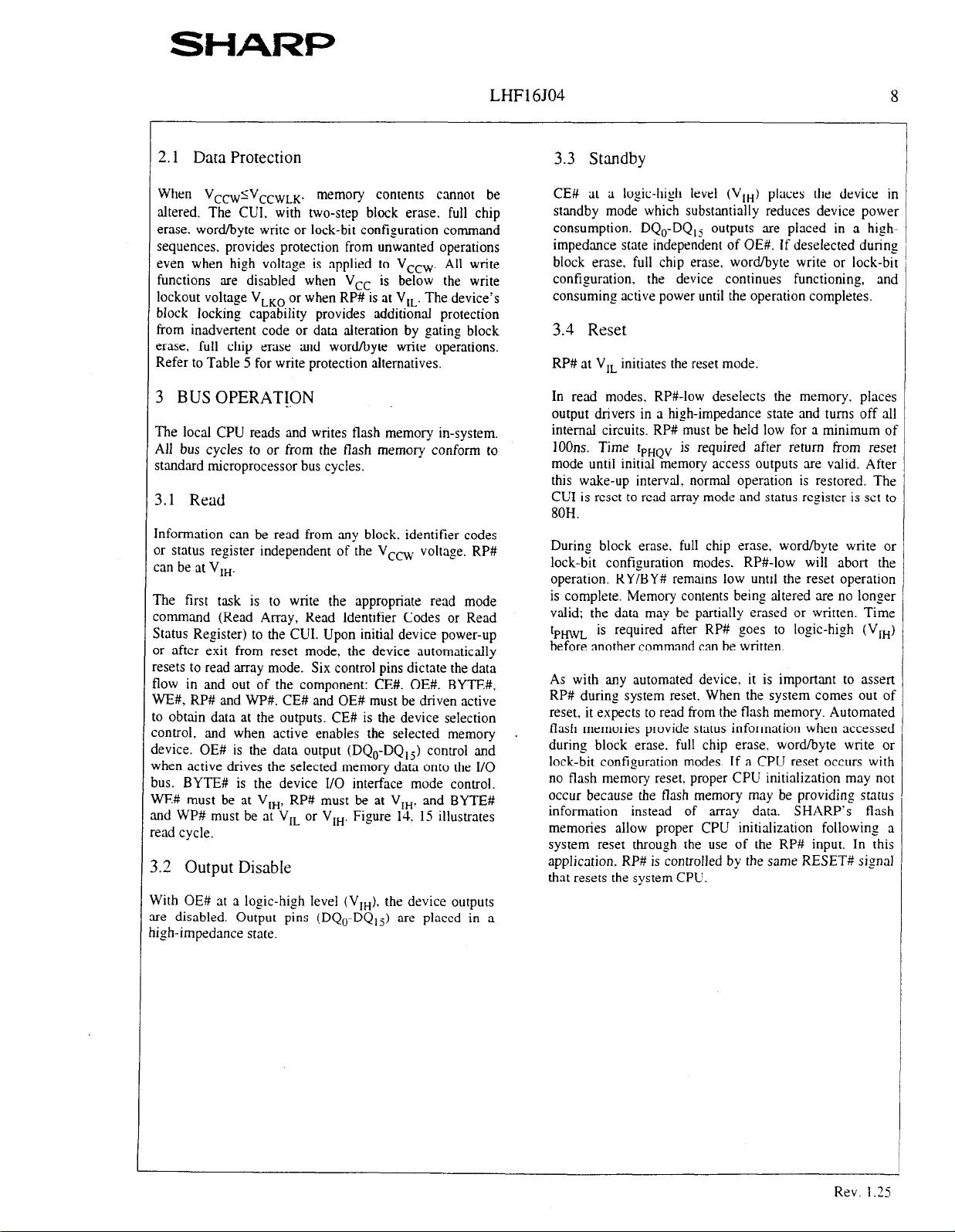

3.5 Read Identifier Codes

The read identifier codes operation outputs the

manufacturer

codes for each block and the permanent lock configuration

code (see Figure 4). Using the manufacturer and device

codes. the system CPU can automatically match the device

with its proper algorithms. The block lock and permanent

lock configuration codes identify locked and unlocked

blocks and permanent lock-bit settin:.

code.

device code. block lock configuration

3.6 Write

Writing commands to the CUI enable reading of device

data

and

identifier codes. They also control inspection and

clearing of the status register. When V&=2.7V-3.6V and

V

CCW=VCCWHIR)

erase. full chip erase, word/byte write and lock-bit

configuration.

The Block Erase command requires appropriate command

data and an address within the block to be erased. The Full

Chip Erase command requires appropriate command data

and

an address within the device. The Word/Byte Write

command requires the command and address of the

location to be written. Set Permanent and Block Lock-Bit

commands require the command and address within the

zlevice (Permanent Lock) or block within the device

iBlock Lock) to be locked. The Clear Block Lock-Bits

:ommand requires the command and address within the

levice.

lhe CUI does not occupy an addressable memory

ocation. It is written when WE# and CE# are active. The

iddress and data needed to execute a command are latched

)n the rising

‘First). Standard microprocessor write timings are used.

?gures 16 and 17 illustrate WE# and CE# controlled write

operations.

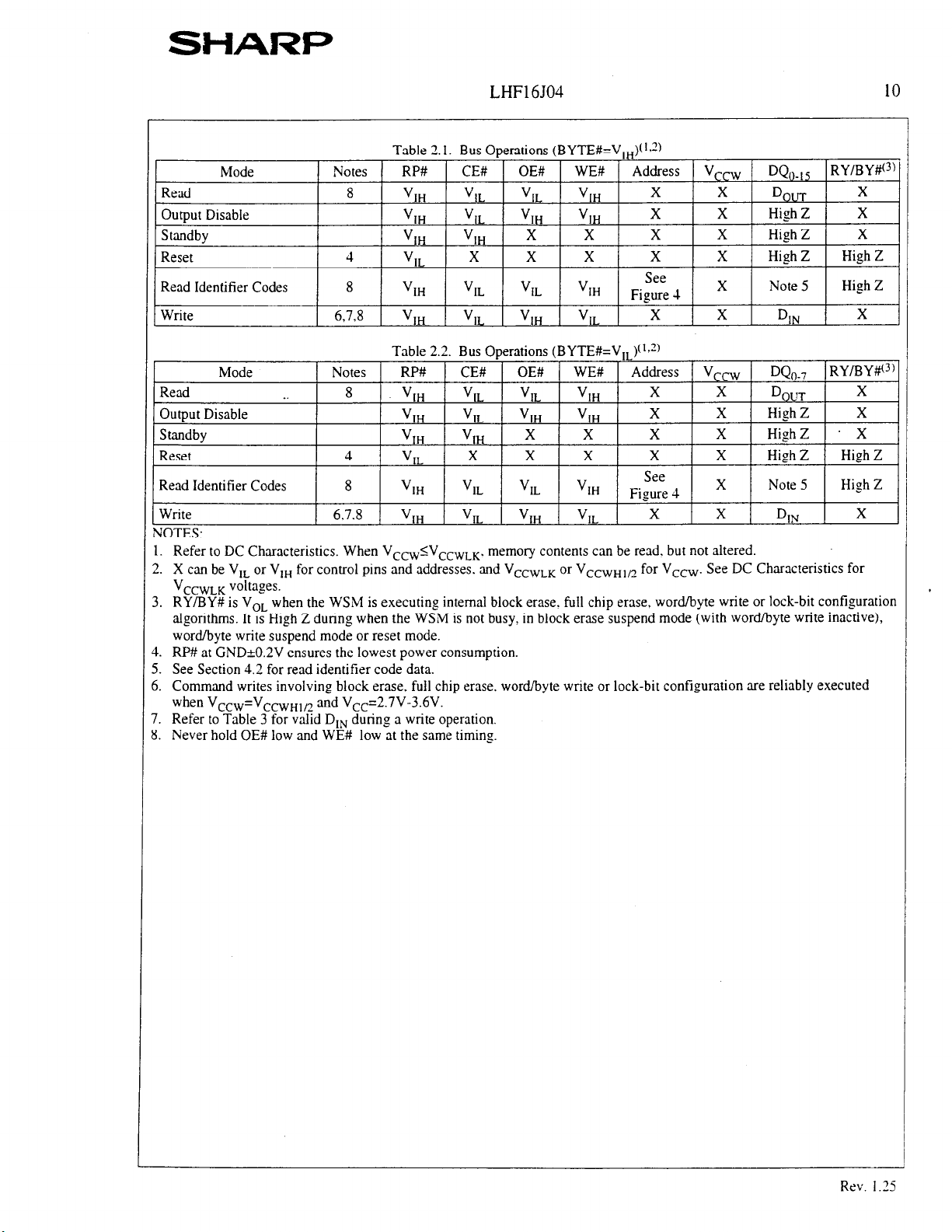

t COMMAND DEFINITIONS

Nhen the VCcw voltage IV,,,,. Read operations from

he

status

register, identifier codes. or blocks are enabled.

‘lacing VCCWH,,2 on VCCw enables successful block

:rase. full chip erase. word/byte write and lock-bit

configuration operations.

device operations are selected by writing specific

ommands into the CUI. Table 3 defines these commands.

the CUI additionally controls block

edge

of WE# or CE# (whichever goes high

FFFFFf

Reserved for Future Implementation

FFrm

I

_______________-----------------------

FFOOZ

FFOOI

FFOOO

FEFFF

FE003

FE002

FDOOl

FDmil

FCFFF ;

FW,-!il !

. ,.I--

FXOO?

F8001

F8000

F7FFF

FOO03

EFFFF:

“----

07FFF

00004

00003

OOOO?

0000 I

00000 Manufacturer Code Main Block

Figure 4. Device Identifier Code Memory .Map

Boot Block 0 Lock Conliguration Co&

_________------------~~~~~~~~~~~~~~~~~

Reserved for Future Implementation

Boot Block 0

Reserved for Future Implementation

_____________ ------- ---------- ------

Boot Block 1 Lock Conlieuration Code

__________---------------_----_-

Reserved for Future Implementation

(Parameter Blocks I through -I)

Reserved for Future Implementation

_--_-______-__-___-_------------------

Reserved for Future ImpIementation

Reserved for Future Implementation

(Main Blocks 1 through 29)

Reserved for Future Implementation

Permanent Lock Conligrration Code

Main Block 30 Lock Configuration Code

____________________------------------

*: Address A.1 don‘t care.

Device Code

Parameter Block 0

-

Parameter Block 5

9

1

I

j[J

Rev. 1.25

Page 12

SHAl?P

Read Identifier Codes

LHFl6J04

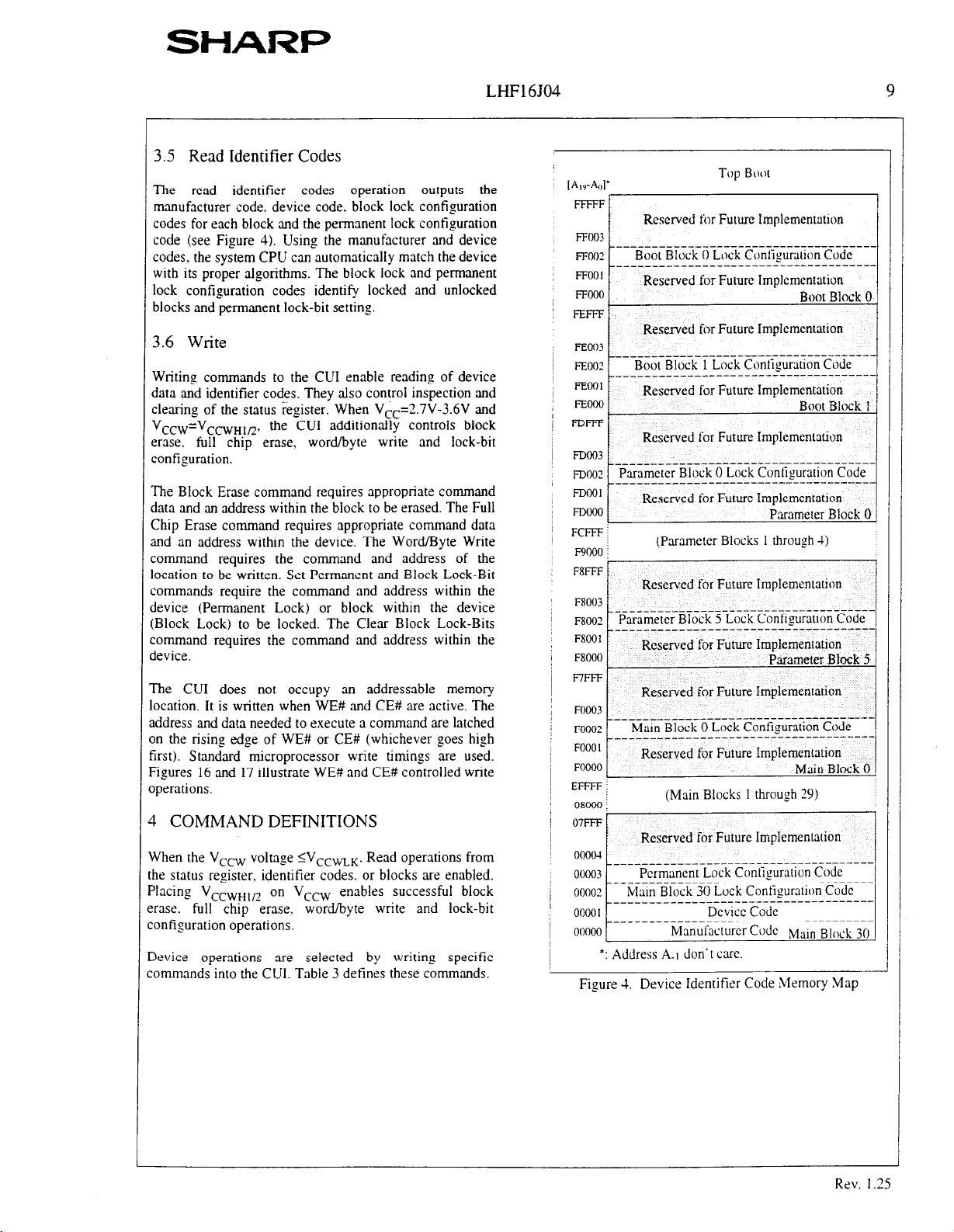

Table 2.1. Bus Onerations (BYTE#=V,U)tt+z)

Write 1 6.7.8

VOTES:

1. Refer to DC Characteristics. When V,-,wIV,,w,,. memory contents can be read. but not altered.

2. X can be V,, or V,, for control pins and addresses. and V,,,,, or V,,,,,,? for Vccw. See DC Characteristics for

VCCwLK voltages.

3. RY/BY# is V,, when the WSM is executing internal block erase. full chip erase, word/byte write or lock-bit configuration

algorithms. It is High Z during when the WSIM is not busy, in block erase suspend mode (with word/byte write inactive),

word/byte write suspend mode or reset mode.

4. RP# at GNDk0.2V ensures the lowest power consumption.

5. See Section 4.2 for read identifier code data.

6. Command writes involving block erase. full chip erase. word/byte write or lock-bit configuration are reliably executed

when VCCw=VCCWHln and V,-,=2.7V-3.6V.

7. Refer to Table 3 for valid Dt, during a write operation.

8. Never hold OE# low and WE# low at the same timing.

VI, VI, VI, VI,

X

DIN

X

Rev. 1.25

Page 13

SHARP

LHF 16504 11

Table 3. Command Definition&to)

1 Block Erase I 2 1 5 1 Write 1 X 1 20H 1 Write 1 BA 1 DOH 1

1 Full Chio Erase

Word/Byte Write

Block Erase and Word/Byte

Write Suspend -.

Block Erase and Word/Byte

Write Resume

Set Block Lock-Bit

Clear Block Lock-Bits

Set Permanent Lock-Bit

NOTES:

1. BUS operations are defined in Table 2.1 and Table 2.2.

2. X=Any valid address within the device.

IA=Identifier Code Address: see Figure 4.

BA=Address within the block being erased.

WA=Address of memory location to be written.

3. SRD=Data read from status register. See Table 6 for a description of the status register bits.

WD=Data to be written at location WA. Data is latched on the rising edge of WE# or CE# (whichever goes high first).

ID=Data read from identifier codes.

4. Following the Read Identifier Codes command, read operations access manufacturer, device, block lock configuration and

permanent lock configuration codes. See Section 4.2 for read identifier code data.

5. If WP# is V,, boot blocks are locked without block lock-bits state. If WP# is V,,, boot blocks are locked by block lockbits. The parameter and main blocks are locked by block lock-bits without WP# state.

6. Either 4OH or 10H are recognized by the WSM as the word/byte write setup.

7. The clear block lock-bits operation simultaneously clears all block lock-bits.

8. If the permanent lock-bit is set, Set Block Lock-Bit and Clear Block Lock-Bits commands can not be done.

9. Once the permanent lock-bit is set. permanent lock-bit reset is unable.

10. Commands other than those shown above are reserved by SHARP for future device implementations and should

I

2 I

2

1 5 Write X BOH

1 5 Write X DOH

2 8 Write X 60H

2 7.8 Write X 60H Write X DOH

2 9 Write X 60H

56

I

Write

Write X

I

X

l

30H I Write ( X I DOH I

40H or

10H

Write WA WD

Write BA

Write

X FlH

OIH

not be

Rev. 1.25

Page 14

LHF16504

12

4.1 Read Array Command

Upon initial device power-up and after exit from reset

mode, the device defaults to read array mode. This

aperation is also initiated by writing the Read Array

zomrnand. The device remains enabled for reads until

mother command is written. Once the internal WSM has

started a block erase. full chip erase. word/byte write or

.ock-bit configuration the device will not recognize the

Read Array command until the WSIM completes its

operation unless the WSM is suspended via an Erase

Suspend or Word/Byte Write Suspend command. The

iead Array command functions independently of the

Vccw

voltage and RP# can be Vt,.

L

1.2 Read Identifi& Codes Command

The identifier code operation is initiated by writing the

i

tead Identifier Codes command. Following the command

\

write. read cycles from addresses shown in Figure 4

r

etrieve the manufacturer. device, block lock configuration

a

tnd permanent lock configuration codes (see Table 4 for

i’

dentifier code values). To terminate the operation. write

a

another valid command. Like the Read Array command,

t

he Read Identifier Codes command functions

ndependently of the Vccw voltage and RP# can be V,,.

;

:ollowing the Read Identifier Codes command. the

f

ollowing information can be read:

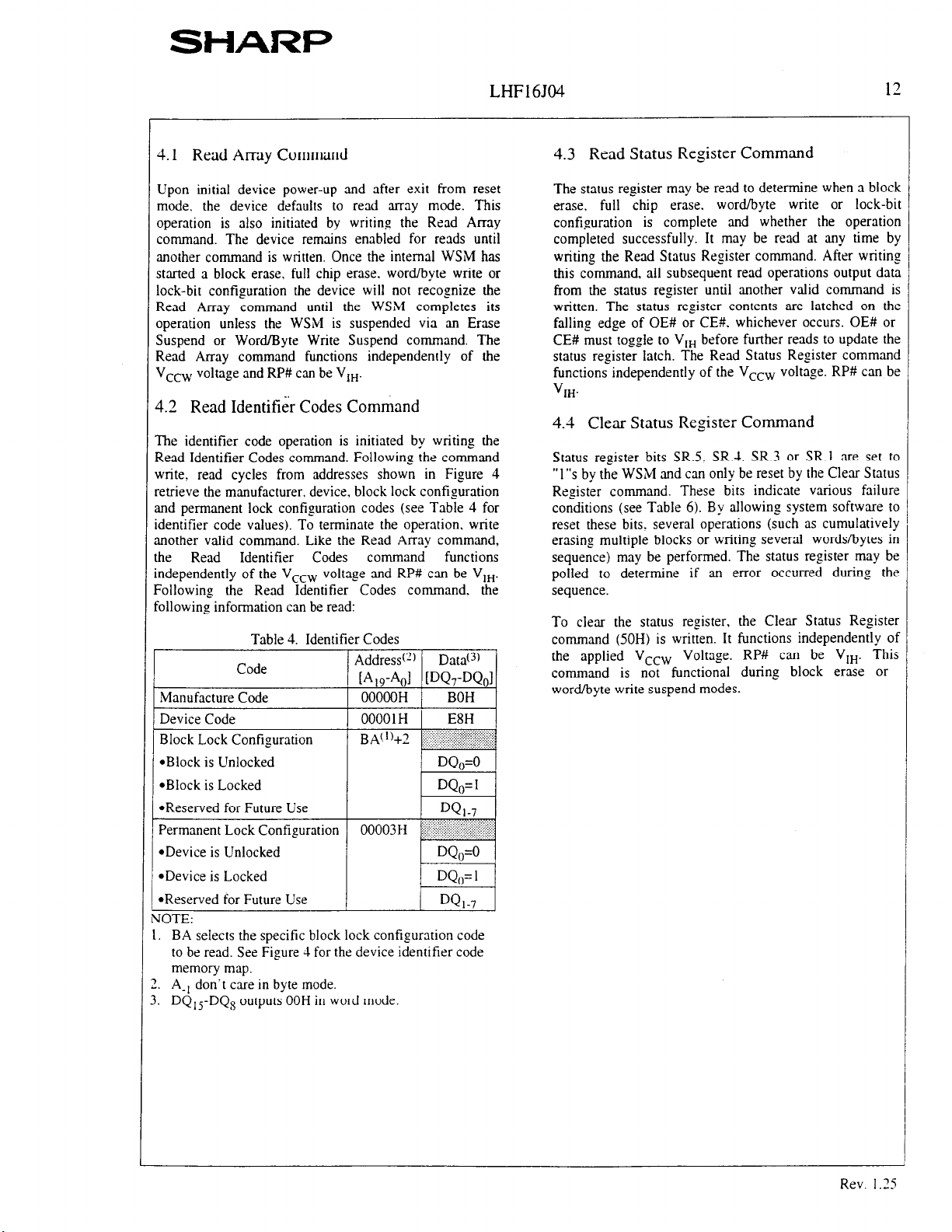

Table 4. Identifier Codes

4.3 Read Status Register Command

The status register may be read to determine when a block

erase, full chip erase. word/byte write or lock-bil

configuration is complete and whether the operation

completed successfully. It may be read at any time by

writing the Read Status Register command. After writing

this command, all subsequent read operations output data

from the status register until another valid command is

written. The status register contents are latched on the

falling edge of OE# or CE#. whichever occurs. OE# or

CE# must toggle to V,, before further reads to update the

status register latch. The Read Status Register command

functions independently of the Vccw voltage. RP# can be

VI,.

4.4 Clear Status Register Command

Status register bits SRS. SR.4 SR.3 or SR.1 are set to

“1”s by the WSM and can only be reset by the Clear Status

Register command. These bits indicate various failure

conditions (see Table 6). By allowing system software to

reset these bits. several operations (such as cumulatively

erasing multiple blocks or writing several words/bytes in

sequence) may be performed. The status register may be

polled to determine if an error occurred during the

sequence.

To clear the status register, the Clear Status Register

command (50H) is written. It functions independently of

the applied Vccw

command is not functional during block erase or

word/byte write suspend modes.

Voltage. RP# can be V,,. This

Block Lock Configuration

*Block is Unlocked

*Block is Locked

*Reserved for Future Use

Permanent Lock Configuration

*Device is Unlocked

*Device is Locked

*Reserved for Future Use

IOTE:

BA selects the specific block lock configuration code

to be read. See Figure 4 for the device identifier code

memory map.

A-, don’t care in byte mode.

DQ, ,-DQ, outputs OOH in word mode.

DQI-7

Rev. 1.25

Page 15

SHARP

LHF 16JO4

4.5 Block Erase Command

Erase is executed one block at a time and initiated by a

two-cycle command. A block erase setup is first written.

followed by an block erase confirm. This command

sequence requires appropriate sequencing and an address

within the block to be erased (erase changes all block data

to FFFFH/FFH). Block preconditioning. erase, and verify

are handled internally by the WSIM (invisible to the

system). After the two-cycle block erase sequence is

written. the device automatically outputs status register

data when read (see Figure 5). The CPU can detect block

erase completion by analyzing the output data of the

RY/BY# pin or status register bit SR.7.

When the block erase-is complete, status register bit SR.5

should be checked. If a block erase error is detected. the

status register should be cleared before system software

Ittempts corrective actions. The CUI remains in read

status register mode until a new command is issued.

I’his two-step command sequence of set-up followed by

:xecution ensures that block contents are not accidentally

:rased. An invalid Block Erase command sequence will

esult in both status register bits SR.4 and SR.5 being set

o “1”. Also, reliable block erasure can only occur when

dcc=2.7V-3.6V and VCCW=VC-wBl,,. In the absence of

his high voltage. block contents are protected against

:rasure. If block erase is attempted while VCCW<VCCWLK.

iR.3 and SR.5 will be set to “1”. Successful block erase

equires for boot blocks that WP# is V,, and the

,orresponding block lock-bit be cleared. In parameter and

nain blocks case, it must be cleared the corresponding

Ilock lock-bit. If block erase is attempted when the

xcepting above conditions. SR.1 and SR.5 will be set to

1 ‘I,

I.6 Full Chip Erase Command

his command followed by a confirm command erases all

f the unlocked blocks. A full chip erase setup (30H) is

lrst written, followed by a full chip erase confirm (DOH).

hfter a confirm command is written, device erases the all

nlocked blocks block by block. This command sequence

:quires appropriate sequencing. Block preconditioning,

rase and verify are handled internally by the WSM

nvisible to the system). After the two-cycle full chip

rase sequence is written, the device automatically outputs

atus register data when read (see Figure 6). The CPU can

etect full chip erase completion by analyzing the output

ata of the RY/BY# pin or status register bit SR.7.

ihen the full chip erase is complete. status register bit

R.5 should be checked. If erase error is detected, the

atus register should be cleared before system software

tempts corrective actions. The CUI remains in read

13

status register mode until a new command is issued. I

error is detected on a block during full chip erase

operation. WSM stops erasing. Full chip erase operatior

start from lower address block. finish the higher addres:

block. Full chip erase can not be suspended.

This two-step command sequence of set-up followed by

execution ensures that block contents are not accidentally

erased. An invalid Full Chip Erase command sequencr

will result in both status register bits SR.4 and SR.5 being

set to “1”. Also, reliable full chip erasure can only occur

when V,,=2.JV-3.6V and VCCW=VCCWHt,2. In thr

absence of this high voltage, block contents are protectec

against erasure. If full chip erase is attempted while

ccwlV,,,,, SR.3 and SR.5 will be set to “1”

V

Successful full chip erase requires for boot blocks thal

WP# is V,, and the corresponding block lock-bit be

cleared. In parameter and main blocks case, it must be

cleared the corresponding block lock-bit. If all blocks are

locked. SR.1 and SR.5 will be set to “1”.

4.7 Word/Byte Write Command

Word/Byte write is executed by a two-cycle command

sequence.

alternate 10H) is written. followed by a second write that

specifies the address and data (latched on the rising edge

of WE#). The WSiM then takes over, controlling the

word/byte write and write verify algorithms internally.

After the word/byte write sequence is written. the device

automatically outputs status register data when read (see

Figure 7). The CPU can detect the completion of the

word/byte write event by analyzing the RY/BY# pin or

status register bit SR.7.

When word/byte write is complete, status register bit SR.4

should be checked. If word/byte write error is detected. the

status register should be cleared. The internal WSM verify

only detects errors for “1”s that do not successfully write

to “0”s. The CUI remains in read status register mode until

it receives another command.

Reliable word/byte writes can only occur when

V,,=2.7V-3.6V and VCCw=VC-wHIR. In the absence of

this high voltage. memory contents are protected against

word/byte writes. If word/byte write is attempted while

V CCwIVCCLVLK. status register bits SR.3 and SR.4 will be

set to “1”. Successful word/byte write requires for boot

blocks that WP# is Vt, and the corresponding block lockbit be cleared. In parameter and main blocks case. it must

be cleared the corresponding block lock-bit. If word/byte

write is attempted when the excepting above conditions,

SR. 1 and SR.4 will be set to “1”.

Word/Byte write setup (standard 40H

OI

Rev. 1.25

Page 16

SHARP

LHFl6JO4

4.8 Block Erase Suspend Command

The Block Erase Suspend command allows block-erase

interruption to read or word/byte write data in another

block of memory. Once the block erase process starts.

writing the Block Erase Suspend command requests that

the WSM suspend the block erase sequence at a

predetermined point in the algorithm. The device outputs

status register data when read after the Block Erase

Suspend command is written. Polling status register bits

SR.7 and SR.6 can determine when the block erase

operation has been suspended (both will be set to “1”).

RY/BY# will also transition to High Z. Specification

tWHR-,,, defines the block erase suspend latency.

When Block Erase Suspend command write to the GUI. if

block erase was finished. the device places read array

mode. Therefore. after Block Erase Suspend command

write to the CUI, Read Status Register command (70H)

has to write to CUI. then status register bit SR.6 should be

checked for places the device in suspend mode.

At this point. a Read Array command can be written to

read data from blocks other than that which is suspended.

A Word/Byte Write command sequence can also be issued

during erase suspend to program data in other blocks.

Using the Word/Byte Write Suspend command (see

Section 4.9), a word/byte write operation can also be

suspended. During a word/byte write operation with block

erase suspended. status register bit SR.7 will return to “0”

and the RY/BY# output will transition to VOL. However,

SR.6 will remain “1” to indicate block erase suspend

datus.

The only other valid commands while block erase is

suspended are Read Status Register and Block Erase

Resume. After a Block Erase Resume command,is written

:o the flash memory. the WSM will continue the block

:rase process. Status register bits SR.6 and SR.7 will

automatically clear and RY/BY# will return to VOL. After

.he Erase Resume command is written. the device

automatically outputs status register data when read (see

3gure 8). Vccw must remain at VC-WHt,z (the same

Vccw level used for block erase) while block erase is

xrspended. RP# must also remain at V,,. WP# must also

.emain at V,, or V,, (the same WP# level used for block

:rase). Block erase cannot resume until word/byte write

operations initiated during block erase suspend have

:ompleted.

14

4.9

Word/Byte

The Word/Byte Write Suspend command allows

word/byte write interruption to read data in other flash

memory locations. Once the word/byte write process

starts. writing the Word/Byte Write Suspend command

requests that the WSIM suspend the Word/Byte write

sequence at a predetermined point in the algorithm. The

device continues to output status register data when read

after the Word/Byte Write Suspend command is written.

Polling status register bits SR.7 and SR.2 can determine

when the word/byte write operation has been suspended

(both will be set to “1”). RY/BY# will also transition to

High Z. Specification tWHRZl

suspend latency.

When Word/Byte Write Suspend command write to the

CUI, if word/byte write was finished. the device places

read array mode. Therefore. after Word/Byte Write

Suspend command write to the CUI. Read Status Register

command (70H) has to write to CUI. then status register

bit SR.2 should be checked for places the device in

suspend mode.

At this point. a Read Array command can be written to

read data from locations other than that which is

suspended. The only other valid commands while

word/byte write is suspended are Read Status Register and

Word/Byte Write Resume. After Word/Byte Write

Resume command is written to the flash memory. the

WSM will continue the word/byte write process. Status

register bits SR.2 and SR.7 will automatically clear and

RY/BY# will return to VOL. After the Word/Byte Write

Resume command is written. the device automatically

outputs status register data when read (see Figure 9).

Vccw must remain at VCCWHtjz (the same Vccw level

used for word/byte write) while in word/byte write

suspend mode. RP# must also remain at Vt,. WP# must

also remain at V,, or V,, (the same WP# level used for

word/byte write).

If the period of from Word/Byte Write Resume command

write to the CUI till Word/Byte Write Suspend command

write to the GUI be short and done again and again. write

time be prolonged.

Write Suspend Command

defines the word/byte write

f the period of from Block Erase Resume command write

o the GUI till Block Erase Suspend command write to the

XI be short and done again and again, erase time be

irolonged.

Rev. I.25

Page 17

LHFI 6JO4

15

4.10 Set Block and Permanent Lock-Bit

Commands

A

flexible block locking and unlocking scheme is enabled

via a combination of block lock-bits. a permanent lock-bit

and WP# pin. The block lock-bits and WP# pin gates

program and erase operations while the permanent lock-bit

gates block-lock bit modification. With the permanent

lock-bit not set, individual block lock-bits can be set using

the Set Block Lock-Bit command. The Set Permanent

Lock-Bit command. sets the permanent lock-bit. After the

permanent lock-bit is set, block lock-bits and locked block

contents cannot altered. See Table 5 for a summary of

hardware and software write protection options.

Set block lock-bit and-permanent lock-bit are executed by

1 two-cycle command sequence. The set block or

aermanent lock-bit setup along with appropriate block or

device address is written followed by either the set block

ock-bit confirm (and an address within the block to be

ocked) or the set permanent lock-bit confirm (and any

ievice address). The WSIM then controls the set lock-bit

Algorithm. After the sequence is written, the device

automatically outputs status resister data when read (see

:&tire IO). The CPU can detect the completion of the set

ock-bit event by analyzing the RY/BY# pin output or

tatus register bit SR.7.

Nhen the set lock-bit operation is complete, status register

bit SR.4 should be checked. If an error is detected, the

tatus register should be cleared. The CUI will remain in

ead status register mode until a new command is issued.

his two-step sequence of set-up followed by execution

nsures that lock-bits are not accidentally set. An invalid

‘et Block or Permanent Lock-Bit command will result in

tatus register bits SR.4 and SR.5 being set to “1”. Also,

:liable operations occur only when Vcc=2.7V-3.6V and

rCCW=vCCWHIR~

)ck-bit contents are protected against alteration.

i successful set block lock-bit operation requires that the

ermanent lock-bit be cleared. If it is attempted with the

ermanent lock-bit set. SR.1 and SR.4 will be set to “1”

?d the operation will fail.

In the absence of this high voltage,

4.1 I Clear Block Lock-Bits Command

All set block lock-bits are cleared in parallel via the Clea

Block Lock-Bits command. With the permanent lock-bi

not set. block lock-bits can be cleared using only the Clea

Block Lock-Bits command. If the permanent lock-bit i:

set, block lock-bits cannot cleared. See Table 5 for ;

summary of hardware and software write protectior

options.

Clear block lock-bits operation is executed by a two-cycle

command sequence. A clear block lock-bits setup is firs

written. After the command is written. the device

automatically outputs status register data when read (set

Figure 11). The CPU can detect completion of the cleai

block lock-bits event by analyzing the RY/BY# Pin outpu’

or status register bit SR.7.

When the operation is complete. status register bit SR.5

should be checked. If a clear block lock-bit error is

detected. the status register should be cleared. The GUI

will remain in read status register mode until another

command is issued.

This two-step sequence of set-up followed by execution

ensures that block lock-bits are not accidentally cleared.

An

invalid Clear Block Lock-Bits command sequence will

result in status register bits SR.4 and SR.5 being set to “1”.

Also, a reliable clear block lock-bits operation can only

occur when V,,=2.7V-3.6V and VCCW=VCCWHt,,. If a

clear block lock-bits operation is attempted -while

VCCWIVCCwtK, SR.3 and SR.5 will be set to “1”. In the

absence of this high voltage, the block lock-bits content

are protected against alteration. A successful clear block

lock-bits operation requires that the permanent lock-bit is

not set. If it is attempted with the permanent lock-bit set.

SR.1 and SR.5 will be set to “1” and the operation will

fail.

If a clear block lock-bits operation is aborted due to Vccw

or V,, transitioninp out of valid range or RP# active

transition, block lock-bit values are left in an

undetermined state. A repeat of clear block lock-bits is

required to initialize block lock-bit contents to known

values. Once the permanent lock-bit is set. it cannot be

cleared.

Rev. 1.25

Page 18

SHARP

LHFl6J04

. . 12 Block Locking by the WP#

his Boot Block Flash memory architecture features two

ardware-lockable boot blocks so that the kernel code for

le system can be kept secure while other blocks are

rogrammed or erased as necessary.

he lockable blocks are locked when WP#=V,: any

rogram or erase operation to a locked block will result in

Table 5. Write Protection Alternatives

16

an error. which will be reflected in the status register. FOI

top configuration. the top two boot blocks are lockable

For the bottom configuration. the bottom two boot block:

are lockable. If WP# is V,, and block lock-bit is not set

boot block can be programmed or erased normally (Unles:

Vccw is below V,,,,,). WP# is valid only two boo

blocks. other blocks are not affected.

‘1,

Set

Permanent >VcCWLK V,

Lock-Bit

‘VCCWLK ’

VI,

0 X X Clear Block Lock-Bits Enabled.

1

X X X Set Permanent Lock-Bit Disabled.

X X X Set Permanent Lock-Bit Disabled.

X X X Set Permanent Lock-Bit Enabled.

X

X Clear Block Lock-Bits Disabled.

Rev. 1.25

Page 19

SHARP

WSlMS 1 BESS

LHFl6504 17

Table 6. Status Register Definition

1 ECBLBS 1 WBWSLBS 1 VCCWS 1 WBWSS 1 DPS

R

7

SR.7 = WRITE STATE MACHINE STATUS (WSMS) Check RY/BY# or SR.7 to determine block erase. full chip

1 = Ready erase. word/byte write or lock-bit configuration completion.

0 = Busy

SR.6 = BLOCK ERASE SUSPEND STATUS (BESS)

1 = Block Erase Suspended

0 = Block Erase in Progress/Completed

SR.5 = ERASE AND CLEAR BLOCK LOCK-BITS

STATUS (ECBLBS)

1 = Error in Block Erase. Full Chip Erase or Clear Block command sequence was entered.

Lock-Bits

0 = Successful Block Erase, Full Chip Erase or Clear

Block Lock-Bits

SR.4 = WORD/BYTE WRITE

STATUS (WBWSLBS)

1 = Error in Word/Byte Write or Set Block/Permanent

Lock-Bit only after Block Erase. Full Chip Erase, Word/Byte Write or

0 = Successful Word/Byte Write or Set Block/Permanent

Lock-Bit guaranteed to reports accurate feedback only when

jR.3 = Vccw STATUS (VCCWS)

1 = Vccw Low Detect, Operation Abort

0 = Vccw OK

jR.2 = WORD/BYTE WRITE SUSPEND STATUS

(WBWSS)

1 = Word/Byte Write Suspended

0 = Word/Byte Write in Progress/Completed

iR. 1 = DEVICE PROTECT STATUS (DPS)

1 = Block Lock-Bit, Permanent Lock-Bit and/or WP#

Lock Detected. Operation Abort

0 = Unlock

6 5

AND

SET LOCK-BIT

4

3

SR.6-0 are invalid while SR.7=“0”.

If both SR.5 and SR.l are “1”s after a block erase, full chip

erase or lock-bit configuration attempt. an improper

SR.3 does not provide a continuous indication of V,--w

level. The WSM interrogates and indicates the Vccw level

Lock-Bit Configuration command sequences. SR.3 is not

VCCW'VCCWHIR.

SR. 1 does not provide a continuous indication of permanent

and block lock-bit and WP# values. The WSM interrogates

the permanent lock-bit, block lock-bit and WP# only after

Block Erase. Full Chip Erase. Word/Byte Write or Lock-Bit

Configuration command sequences. It informs the system,

depending on the attempted operation, if the block lock-bit is

set. permanent lock-bit is set and/or WP# is V,,. Reading

the block lock and permanent lock configuration codes after

writing the Read Identifier Codes command indicates

permanent and block lock-bit status.

2 1

NOTES:

0

iR.0 = RESERVED FOR FUTURE ENHANCEMENTS CR) SR.0 is reserved for future use and should be masked out

when polling the status register.

Rev. 1.25

i

Page 20

r

LHFI 6JO4

IT’LL STATUS CHECK PRCCEDCRE

(-)

Check SR.,

,=Dev,ce Praect Dew?

Figure 5. Automated Block Erase Flowchart

Rev. 1.25

Page 21

SHARI=

LHFI 6504 19

Full Swnu

Check ,f Dewed

&i&j

FL’LL STATLr.5 CHECK PROCEDCRE

(F)

Cummand Scquencc

Standby

Standby

Standby

Command

Commen1s

Clwk SR.3

,=Vccw Erra Detect

Check SR.I

I=Dcr,ce Rara Detect

(All Bids are loclud)

Cixck SR.4.3

Both I=Co-nd Scqucncc Enor

Check SR.5

I=RII Clup Eras Eira

Full Ch,p Exlse

S”ccwf”l

Figure 6. Automated Full Chip Erase Flowchart

_1

Rev. 1.25

Page 22

r

LHFl6504

FL’LL STM-L’S CHECK PROCEDCRE

Read

Standby

Stmr Regwter Data

ChcckSR.7

,=WSMRendy

o=WSM Bury

Figure 7. Automated Word/Byte Write Flowchart

Rev. 1.25

Page 23

SHARP

Write DOH

Block Erase Ramcd

Wntc FFH

R,ad hay Dm

I

Figure 8. Block Erase Suspend/Resume Flowchart

Rev. 1.25

Page 24

SHARP

Wntc BOH

LHFl6JO4

22

Figure 9. Word/Byte Write Suspend/Resume Flowchart

Rev. 1.15

Page 25

SHARf=

r

r

LHFl6504

Cheek ,f Dared

FLZL STATUS CHECK PROCEDURE

Figure 10. Set Block and Permanent Lock-Bit Flowchart

Rev. 1.15

Page 26

SHARP

Red Swu

Rsgner

LHF 16JO4 24

SR.7=

.::5:-lr

FL’LL STATL’S CHECK PROCEDURE

(F)

0

Standby

Command

l=WSM Ready

C=WSM Busy

Commen,s

check SR.3

I=Vccw Fna rktcc1

Command Sequence

C,<Y Block Lmk-B,u

Standby

Swmfby

Figure 11. Clear Block Lock-Bits Flowchart

Check SR.J.5

Both ,=Command Scqurne Error

Rev. 1.25

Page 27

LHFl6JO4 25

5 DESIGN CONSIDERATIONS

5.1 Three-Line Output Control

The device will often be used in large memory arrays.

SHARP provides three control inputs to accommodate

multiple memory connections. Three-line control provides

for:

a. Lowest possible memory power dissipation.

b. Complete assurance that data bus contention will not

occur.

To use these control inputs efficiently, an address decoder

should enable CE# while OE# should be connected to all

memory devices and ‘the system’s READ# control line.

This assures that only selected memory devices have

active outputs while deselected memory devices are in

standby mode. RP# should be connected to the system

POWERGOOD signal to prevent unintended writes during

system power transitions. POWERGOOD should also

:oggIe during system reset.

5.2 RYlBY# and WSM Polling

IY/BY# is an open drain output that should be connected

o V,, by a pull up resistor to provides a hardware method

If detecting block erase, full chip erase, word/byte write

md lock-bit configuration completion. It transitions low

tfter block erase. full chip erase. word/byte write or lock)it configuration commands and returns to VOH (while

cY/BY# is pull up) when the WSM has finished executin,o

he internal algorithm.

<Y/BY# can be connected to an interrupt input of the

ystem CPU or controller. It is active at all times. RY/BY#

s also High Z when the device is in block erase suspend

with word/byte write inactive), word/byte write suspend

)r reset modes.

5.3 Power Supply Decoupling

Flash memory power switchins characteristics require

careful device decoupling. System designers are interested

in three supply current issues: standby current levels,

active current levels and transient peaks produced by

falling and rising edges of CE# and OE#. Transient current

magitudes depend on the device outputs‘ capacitive and

inductive loading. Two-line control and proper decoupling

capacitor selection will suppress transient voltage peaks.

Each device should have a O.lpF ceramic capacitor

connected between its V,, and GND and between its

Vccw and GND. These high-frequency. low inductance

capacitors should be placed as close as possible to package

leads. Additionally. for every eight devices. a 4.7pF

electrolytic capacitor should be placed at the array’s power

supply connection between Vcc and GND. The bulk

capacitor will overcome voltape slumps caused by PC

board trace inductance.

5.4 VCCW Trace on Printed Circuit Boards

Updating flash memories that reside in the target system

requires that the printed circuit board designer pay

attention to the Vccw

supplies the memory cell current for word/byte writing

and block erasing. Use similar trace widths and layout

considerations given to the V,, power bus. Adequate

Vccw supply traces and decoupling will decrease Vccw

voltage spikes and overshoots.

Power supply trace. The Vccw pin

5.5 Vcc, Vccw, RP# Transitions

Block erase, full chip erase. word/byte write and lock-bit

configuration are not guaranteed if V,-, falls outside of a

valid VCCWHt,z range, V,, falls outside of a valid 2.7V-

3.6V range. or RP##VtH. If Vccw error is detected, status

register bit SR.3 is set to “1” along with SR.4 or SR.5,

depending on the attempted operation. If RP# transitions

to V,, during block erase. full chip erase. word/byte write

or lock-bit configuration, RY/BY# will remain low until

the reset operation is complete. Then. the operation will

abort and the device will enter reset mode. The aborted

operation may leave data partially altered. Therefore. the

command sequence must be repeated after normal

operation is restored. Device power-off or RP# transitions

to V,, clear the status register.

The CUI latches commands issued by system software and

is not altered by Vccw

actions. Its state is read array mode upon power-up. after

exit from reset mode or after Vcc transitions below V,,,.

or CE# transitions or WSIM

Rev. 1.25

Page 28

SHARP

LHFl6504 26

5.6 Power-Up/Down Protection

The device is designed to offer protection against

accidental block erase. full chip erase. word/byte write or

lock-bit configuration during power transitions. Upon

power-up. the device is indifferent as to which power

supply WCCW or VCC) P

resets the CUI to read array mode at power-up.

A system designer must guard against spurious writes for

V,, voltages above V,,, when Vccw is active. Since

both WE# and CE# must be low for a command write,

driving either to V,, will inhibit writes. The GUI’s twostep command sequence architecture provides added level

of protection against data alteration.

In-system block lock and unlock capability prevents

inadvertent data alteration. The device is disabled while

RP#=Vl, regardless of its control inputs state.

owers-up first. Internal circuitry

_.

5.7 Power Dissipation

When designing portable systems, designers must consider

battery power consumption not only during device

operation, but also for data retention during system idle

time. Flash memory’s nonvolatility increases usable

battery life because data is retained when system power is

removed.

5.8 Data Protection Method

Noises having a level exceeding the limit specified in the

specification may be generated under specific operating

conditions on some systems. Such noises, when induced

onto WE# signal or power supply. may be interpreted as

false commands, causing undesired memory updating. To

protect the data stored in the flash memory against

unwanted overwriting, systems operating with the flash

memory should have the following write protect designs.

as appropriate:

1) Protecting data in specific block

When a lock bit is set. the corresponding block (includes

the 2 boot blocks) is protected against overwriting. By

setting a WP# to low, only the 2 boot blocks can be

protected against overwriting. By using this feature. the

flash memory space can be divided into the program

section (locked section) and data section (unlocked

section). The permanent lock bit can be used to prevent

false block bit setting. For further information on

settinS/resettinp lock-bit, refer to the specification. (See

chapter-l.lOand-l.11.)

2) Data protection through Vccw

When the level of V,--w is lower than VCCWLK (lockout

voltage), write operation on the flash memory is disabled.

All blocks are locked and the data in the blocks are

completely write protected. For the lockout voltage. refer

to the specification. (See chapter 6.2.3.)

3) Data protection through RP#

When the RP# is kept low during read mode. the flash

memory will be reset mode. then write protecting all

blocks, When the RP# is kept low during power up and

power down sequence such as voltage transition, write

operation on the flash memory is disabled, write

protecting all blocks. For the details of RP# control, refer

to the specification. (See chapter 5.6 and 6.2.7.)

Rev. 1.75

Page 29

LHFl6JO4

27

6 ELECTRICAL SPECIFICATIONS

6.1 Absolute Maximum Ratings*

Operating Temperature

During Read, Block Erase.

Full Chip Erase, Word/Byte Write

and Lock-Bit Configuration ._........... -40°C to +SS’C(t)

Storage Temperature

During under Bias _..............._.............. -4Q”C to +85”C

During non Bias _................_.............. -65°C to +125”C

Voltage On Any Pin

(except V,, and vccw) . . . ..__.... -0.5V to V,,+O.5V(‘)

V,, Supply Voltage . . . . . . . . .._..................... -0.2V to +4.6V(*)

Vccw Supply Voltage . . . . . .._._.._._.......... -02V to +13.OV(*v3)

Output Short Circuit Current . . . . . . .._...__................ 1OOmA(J)

*WARNING: Stressing the device beyond the “Absolute

Maximum Ratings” may cause permanent damage. These

are stress ratings on/x Operation be?.ond the “Operating

Conditions” is not recommended and extended exposure

beyond the “Operating Conditions” ma! affect device

reliability.

NOTES:

1. Operating temperature is for extended temperature

product defined by this specification.

2. All specified voltages are with respect to GND.

Minimum DC voltage is -0.5V on input/output pins

and -0.2V on V,, and Vccw pins. During transitions.

this level may undershoot to -2.OV for periods <20ns.

Maximum DC voltage on input/output pins are

V,,+0.5V which. during transitions, may overshoot to

V,-+2.OV for periods <?Ons.

3. Maximum DC voltage on Vccw may overshoot to

+13.OV for periods <20ns. Applying 12V+O.3V to

V,,, during erase/write can only be done for a

maximum

of 1000 cycles on

each block. Vccw may be

connected to 12Va.3V for a total of 80 hours

maximum.

4. Output shorted for no more than one second. No more

than one output shorted at a time.

I

6.2 Operating Conditions

Symbol Parameter

TA

V,,

Operating Temperature

V,, Supply Voltage (2.7V-3.6V) 2.7

6.2.1 CAPACITANCE(I)

Symbol

,CIN

1 C,”

Input Capacitance

1 Output Capacitance

NO;:

1 1. Sampled, not 100% tested.

Parameter

Temperature and Vcc Operating Conditions

Min. Max. Unit Test Condition

-40 +85 “C Ambient Temperature

3.6

T,=+25”C, f=IMHz

TYP.

Max.

7 10

9 l? i

Unit

PF

PF

V

1

Condition

v,,=o.ov

v,“T=o.ov

Rev. 1.25

Page 30

LHF 16JO4 28

.2.2 AC INPUT/OUTPUT TEST CONDITIONS

I,~~z2~@T-

AC test inputs are driven at ?.7V for a Logic “1” and O.OV for a Logic “0”. Input timing be_eins. and output hung ends, ~1 1.35V.

input rise and fall limes (10% IO 9tYZ) <IO ns.

Figure 12. Transient Input/Output Reference Waveform for V,,=2.7V-3.6V

lN91-l

Test Configuration Cauacitance Loading Value

Test Configuration

V,e2.7V-3.6V

C,(pF)

50

OUT

Figure 13. Transient Equivalent Testing Load Circuit

I

Rev. 1.25

Page 31

52.3 DC CHARACTERISTICS

LHF16JO4

DC Characteristics

Conditions

-I

Rev. 1.35

I

Page 32

SHARP

LHFI 6504

DC Characteristics (Continued)

Parameter

"OH2

“CCWLK

"CCWHI

"CCWH2

"LKO

30TES:

All currents are in RMS unless otherwise noted. Typical values at nominal V,, voltage and T,=+25”C.

:: I ccws and IccEs are specified with the device de-selected. If read or word/byte written while in erase suspend mode, the

device‘s current draw is the sum of Iccws or I,,,, and ICCR or Iccw. respectively.

8. Includes RY/BY#.

. . Block erases, full chip erase, word/byte writes and lock-bit configurations are inhibited when V,,wIV,,wLK, and not

guaranteed in the range between VCCwLK(max.) and VCcwH,(min.), between VccwH,(max.) and V~cwB#nin.) and

above Vr-cwB2(max.).

The Automatic Power Savings (APS) feature is placed automatically power save mode that addresses not switching more

than 300ns while read mode.

. About all of pin except describe Test Conditions, CMOS level inputs are either V&O.2V or GND*O.?V, TIL level

inputs are either V,, or VI,.

Sampled. not 100% tested.

Applying 12VkO.3V to Vccw during erase/write can only be done for a maximum of 1000 cycles on each block. Vccw

may be connected to 12Vtio.3V for a total of 80 hours maximum.

Output High Voltage

(CMOS)

.

Vccw Lockout during Normal 4,7

Operations

Vccw during Block Erase. Full Chip

Erase, Word/Byte Write or Lock-Bit

Configuration Operations

Vccw during Block Erase. Full Chip

Erase. Word/Byte Write or Lock-Bit

Configuration Operations

Vcc Lockout Voltage

7

8

0.85

Vr--

“cc

-0.4

1.0

2.7 3.6

11.7 12.3

2.0

V

V

V

V

V

V

Test Conditions

V,,=V,c Min.

IO,=-2smA

Vcc=Vcc Min.

I,,=- lOOpA

30

Rev. 1.25

Page 33

LHF16504

62.4 AC CHARACTERISTICS - READ-ONLY OPERATIONS(‘)

,[EHOZ

tGLOX

tGHOZ

tOH

tFVOV

‘FL02

tlzr “I CE# to BYTE# High or Low 3.4 5 ns

1. See AC Input/Output Reference Waveform for maximum allowable input slew rate.

2. OE# may be delayed up to tErqv-tGLQv after the falling edge of CE# without impact on tF, &.

3. Sampled. not 100% tested.

4. If BYTE# transfer during reading cycle. exist the regulations separately.

CE# High to Output in High Z 3

OE# to Output in Low Z 3 0 ns

OE# Highto Output in High. Z

Output Hold from Address, CE# or OE# Change, Whichever

Occurs Fist

BYTE# to Output Delay 3

BYTE# Low to Output in High Z

3

3 0 ns

3

40 ns

15 ns

90

25 ns

ns

Rev. 1.25

Page 34

LHFl6504

32

VIH

rDDRESSES(A)

VIL

WE#(W)

V’H r------

hLJ

VOH

lATA(D/Q)

DQ&Qu)

VOL

Slandby

HIGH Z

Device

Address Seleclion

Address Stable

kLQV

kryx

kLQXD-+

tAVQV

tcLQV

Data Valid

l

___________

__---------

lOHb--4

I

h

Figure 14. AC Waveform for Read Operations

Rev. 1.25

Page 35

SHARP

r

VIH

ADDRESSES

VIL

Standby

Device

Address Selection Data Valid

r

Address Stable

__________.

VIH

CENE)

VU

VIH

OE#(G)

VU

VIH

BYTEWFI

VU

VOH

DATA(D/Q, HIGH Z

-.

(DQo--DQI)

VOL

VOH

)ATA(D/Q) HIGH Z

DQs-DQ1.s)

VOL

tELQV

4

,

P

tAVQV

kLFv

h

b

tGLQV

, ______-----

________..- -

kLQX

4

r

c

-:;:;:-:::(~;>j HIGH Z

4

a

tFLQ2

HIGH Z

Figure 15. BYTE# timing Waveform

Rev. I.25

Page 36

SHARP

LHFl6504

6.25 AC CHARACTERISTICS - WRITE OPERATIONS(l)

34

NOTES:

1. Read timing characteristics during block erase, full chip erase, word/byte write and lock-bit configuration operations are

the same as during read-only operations. Refer to AC Characteristics for read-only operations.

2. Sampled. not 100% tested.

3. Refer to Table 4 for valid A,, and D,, for block erase, full chip erase. word/byte write or lock-bit configuration.

4. V,-,, should be held at VCCWHt,2 until determination of block erase. full chip erase, word/byte write or lock-bit

configuration success (SR. l/3/4/5=0).

5. If BYTE# switch during reading cycle, exist the regulations separately.

Rev. 1.35

Page 37

r

LHFl6504

ADDRESSES(A)

DATACDIQ)

vCCW(~ VCCWLK

NOTES:

1. VCc power-up and standby.

2. Write each setup command.

3. Write each confirm command or valid address and data

4. Automated erase or program delay.

5. Read status register data.

6. Write Read Array command.

Figure 16. AC Waveform for WE#-Controlled Write Operations

Rev. 1.25

Page 38

LHFl6504 36

62.6 ALTERNATIVE CE#-CONTROLLED WRIT ES(‘)

V,,=?.lV-3.6V, T,=-40°C to +85”C

Sym. 1

I ~~

t AVAV

tPHEL

tWLEL WE# Setup to CE# Going Low

Write Cycle Time

RP# High Recovery to CE# Going Low

Parameter Notes Min.

I I ,T,Y

2

YU IlS

1

0 ns

-,.

1 Max Unit

I I

P

NOTES:

1. In systems where CE# defines the write pulse width (within a longer WE# timing waveform), all setup, hold. and inactive

WE# times should be measured relative to the CE# waveform.

2. Sampled, not 100% tested.

3. Refer to Table J for valid A,, and D,, for block erase, full chip erase. word/byte write or lock-bit configuration.