Page 1

In the absence of confirmation by device specification sheets, SHARP takes no responsibility for any defects that may occur in equipment using any SHARP devices shown in

catalogs, data books, etc. Contact SHARP in order to obtain the latest device specification sheets before using any SHARP device.

1

DESCRIPTION

The LH1687 is a 240-output TFT-LCD source

driver IC used in such products as TV sets. The

LH1687 samples and holds three video signals of

R, G and B by sample and hold circuits

synchronized with the CK, and simultaneously

outputs the LCD drive voltage from all output pins.

FEATURES

• Number of LCD drive outputs : 240

• Output circuit form : Push pull output

• Power save function : By setting the LCD drive

output in a high-impedance condition, the current

source of the LCD drive output circuit is cut off,

which makes low power operation possible

• Sampling timing : Normal sampling operation and

3-point simultaneous sampling operation can be

selected

• Video signal setting : Available for stripe pixel

array panels and delta pixel array panels using

mode setting circuit

• Sampling clock frequency : 25 MHz (MAX.)

• Cascade connection

• Sampling sequence :

Output shift direction can be selected

OS

1/OS240 or OS240/OS1

• Output amplitude voltage :

4.8 Vp-p (at 5.0 V supply voltage)

• Supply voltages

–V

CCL (for logic system) : +3.0 to +5.5 V

–V

CCA (for LCD drive system) : +3.0 to +5.5 V

• Operating temperature : –30 to + 85 ˚C

• Package : 264-pin TCP (Tape Carrier Package)

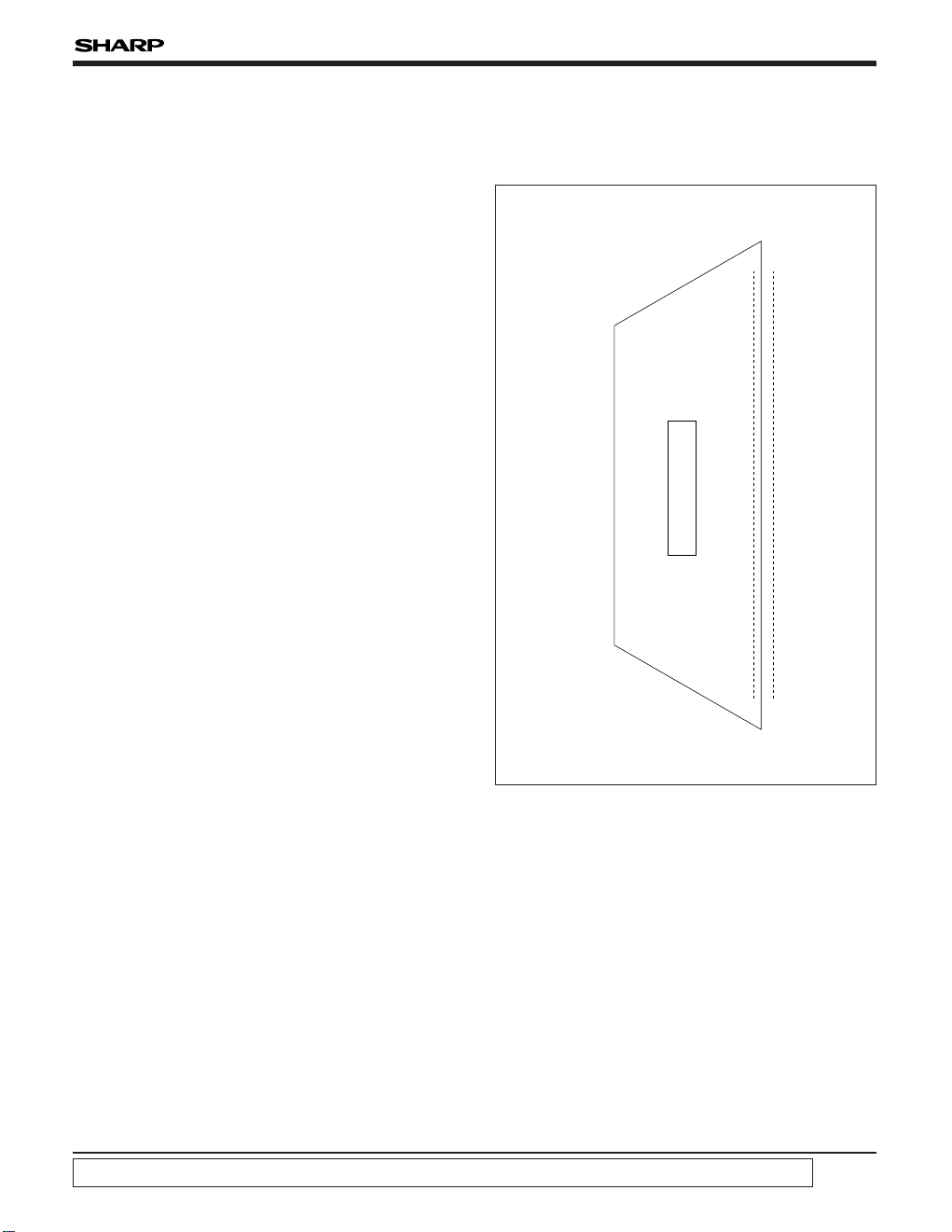

PIN CONNECTIONS

LH1687

LH1687

240-output TFT-LCD Source Driver IC

OS240240

OS

11

CHIP SURFACE

VCCA

VCCL

GNDA

GNDL

TST5

VC

VB

VA

MODE

PS

RL

SAM

CTR

CK

SPIO

SPOI

TEST4

TEST3

TEST2

TEST1

GNDL

GNDA

VCCL

VCCA

264

263

262

261

260

259

258

257

256

255

254

253

252

251

250

249

248

247

246

245

244

243

242

241

264-PIN TCP

TOP VIEW

NOTE :

Doesn't prescribe TCP outline.

Page 2

LH1687

2

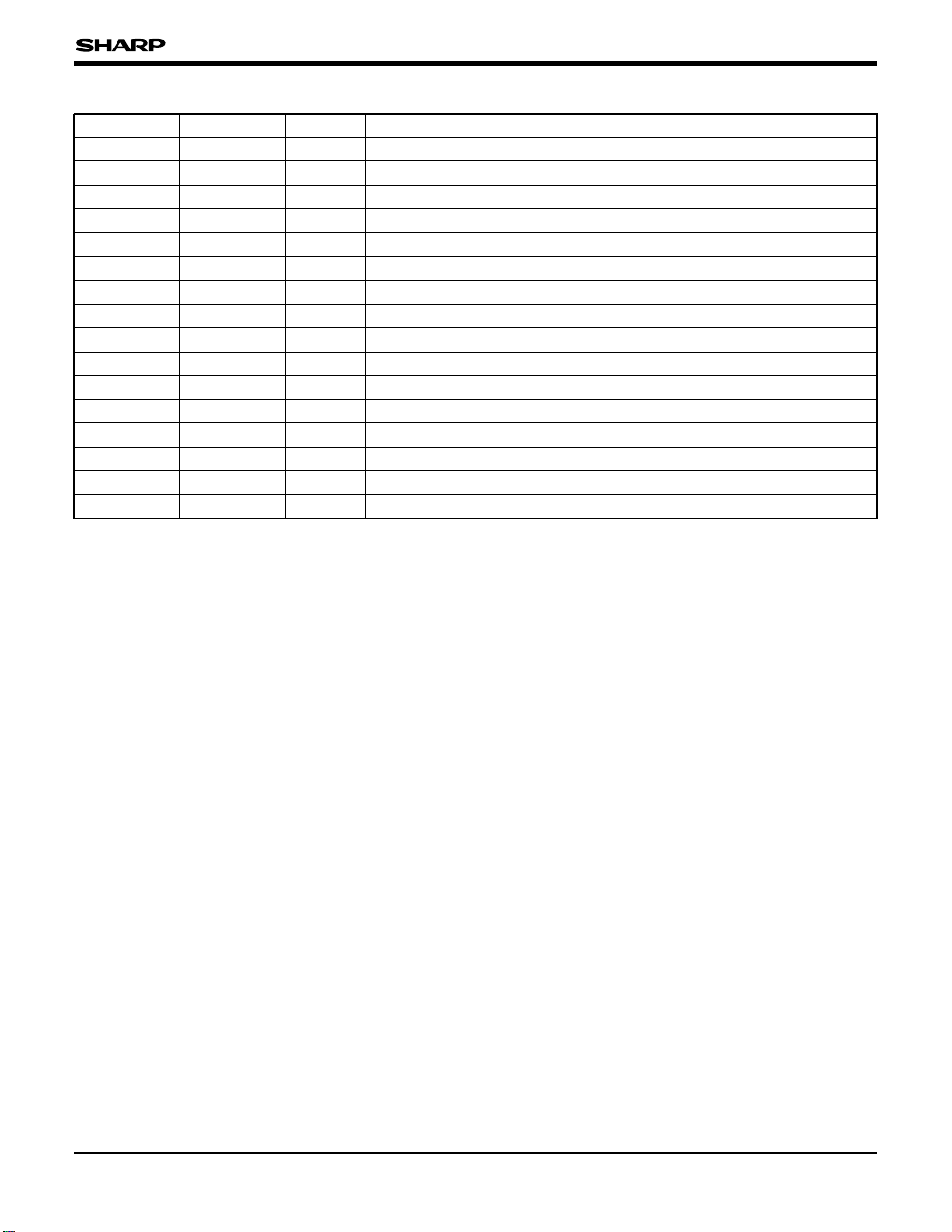

PIN NO. SYMBOL I/O DESCRIPTION

1 to 240 OS

1-OS240 O LCD drive output pins

241, 264 V

CCA – Power supply pins for LCD drive circuit

242, 263 VCCL – Power supply pins for logic circuit

243, 262 GNDA – Ground pins for LCD drive system

244, 261 GNDL – Ground pins for logic system

245 to 248 TST

1-TST4 I IC test pins

249 SPOI I/O Start pulse input/cascade output pin

250 SPIO I/O Start pulse input/cascade output pin

251 CK I Horizontal shift clock input pin

252 CTR I LCD drive circuit operation selection pin

253 SAM I Sampling mode selection pin

254 RL I Sampling sequence selection pin

255 PS I Power save mode setting pin

256 MODE I Video signals form setting pin

257 to 259 V

A, VB, VC I Video signal input pins

IC test pinITST

5260

PIN DESCRIPTION

Page 3

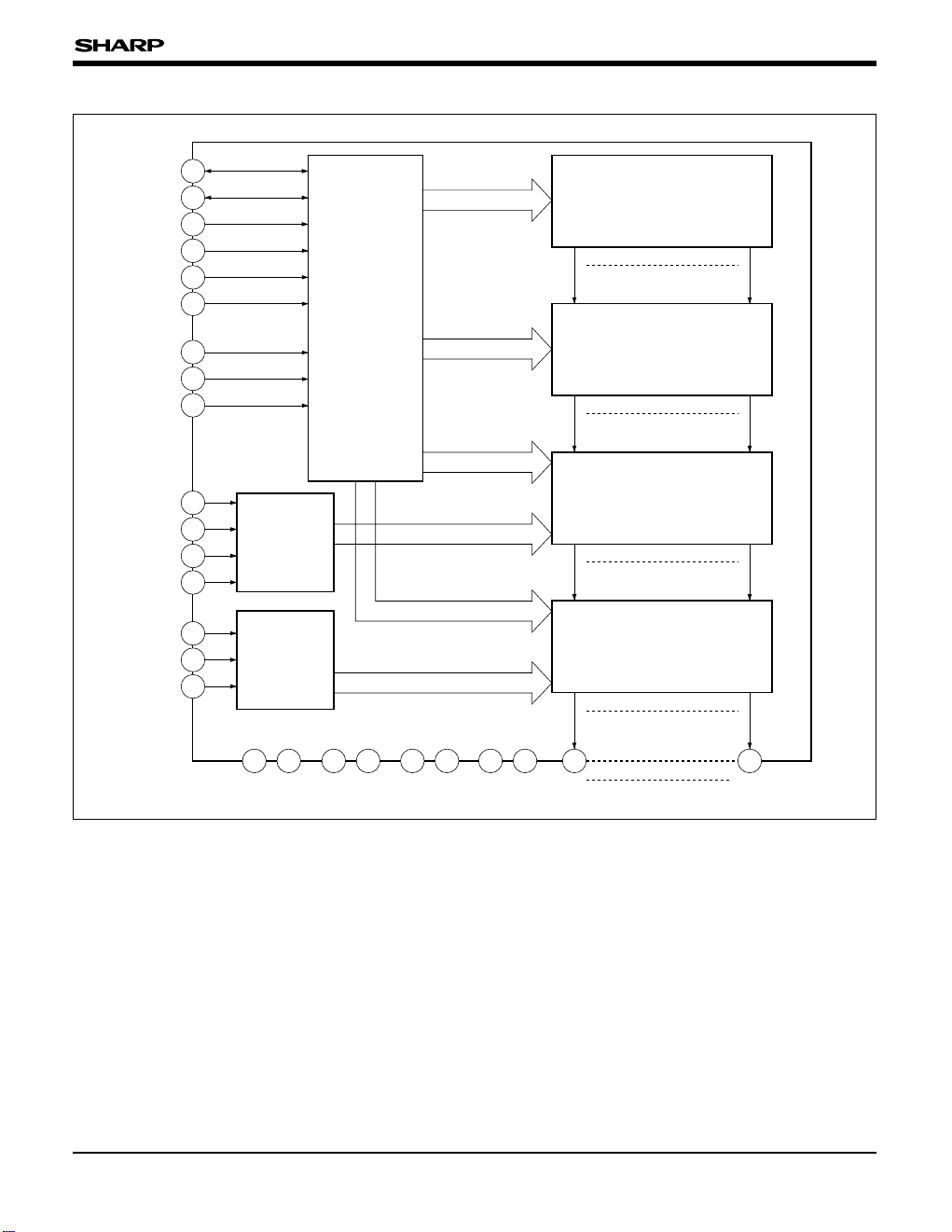

3

LH1687

TST5

VCCAVCCAVCCLVCCL GNDA GNDA GNDL GNDL OS1 OS240

241

260

TST

4 248

PS 255

V

C 259

V

B 258

V

A 257

TST

3 247

TST

2 246

TST

1 245

RL 254

SAM 253

CTR 252

CK 251

SPIO

CONTROL

LOGIC

MODE

SETTING

CIRCUIT

BIAS

GENERATION

CIRCUIT

250

SPOI 249

MODE 256

264 242 263 243 262 244 261 1 240

BI-DIRECTIONAL SHIFT

REGISTER

SAMPLING SIGNAL

CREATION CIRCUIT

SAMPLE AND HOLD CIRCUIT

OUTPUT CIRCUIT

1 240

1 240

1 240

1 240

BLOCK DIAGRAM

Page 4

LH1687

4

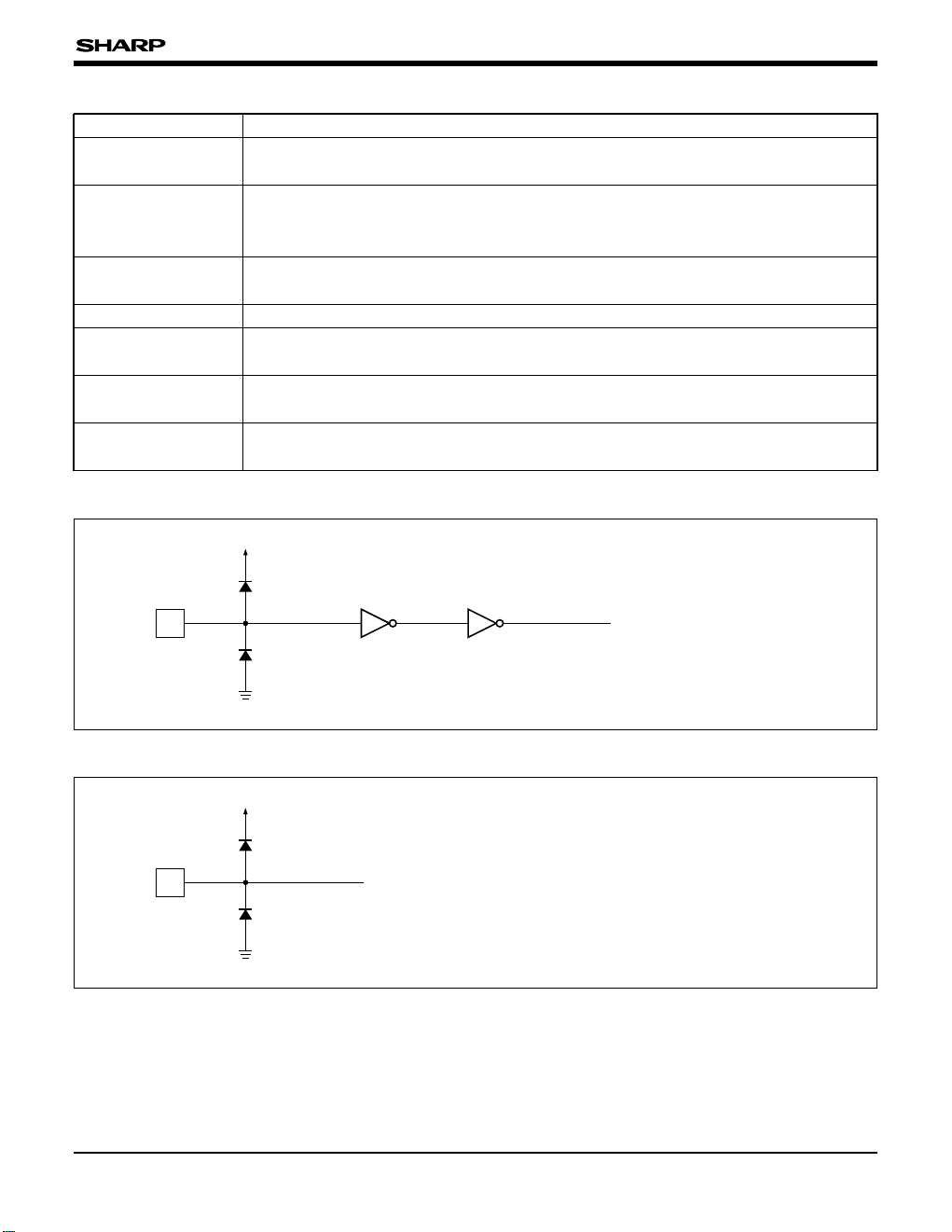

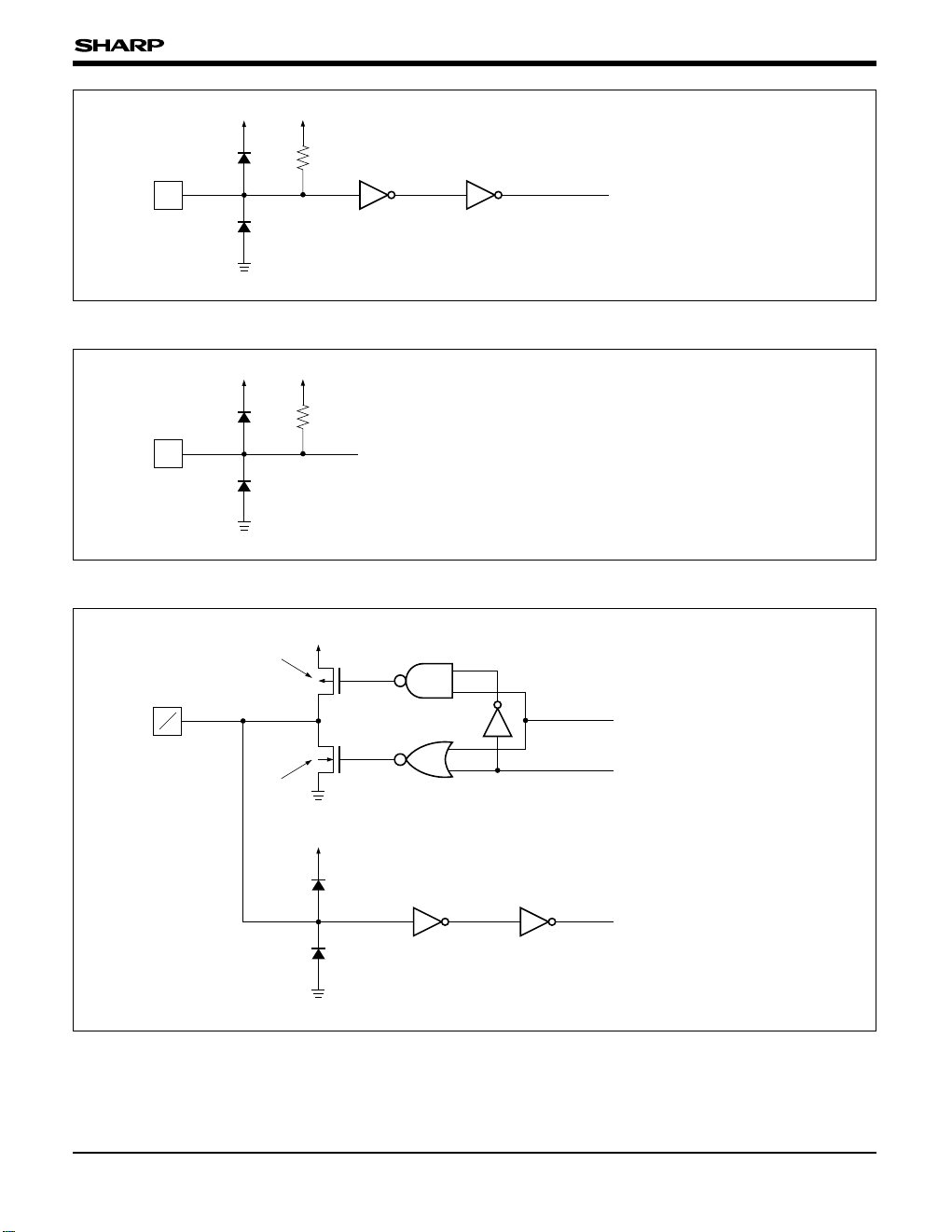

INPUT/OUTPUT CIRCUITS

I

V

CCL

GNDL

To Internal Circuit

Fig. 1 Input Circuit (1)

¿Applicable pins¡

CK, CTR, MODE

I

V

CCA

GNDA

To Internal Circuit

Fig. 2 Input Circuit (2)

¿Applicable pins¡

V

A, VB, VC

BLOCK FUNCTION

Control Logic

Used to create signals necessary for each operation mode setting and sampling signal

creation circuits, etc.

Bi-directional Shift

Register

Used as transfer circuit of video sampling start signals.

It is possible to set the direction of sampling start signal sequence OS

1/OS240 or

OS240/OS1 by setting the R/L pin.

Sampling Signal

Creation Circuit

Used to create the sampling signals corresponding to each output pin based on the

sampling start signals transferred by the bi-directional shift register.

Mode Setting Circuit Used to set the form of the video signals to be sent to the sample and hold circuits.

Sample and Hold

Circuit

Used to sample the video signals input from the mode setting circuit at the timing of the

sampling signals and hold the sampling data until the next sampling operation.

Bias Generation Circuit Used to generate bias voltage necessary for output circuits.

Output Circuit

The circuit consists of a push-pull output operational amplifier and outputs the voltage

corresponding to the data held in the sample and hold circuits.

FUNCTIONAL OPERATIONS OF EACH BLOCK

Page 5

5

LH1687

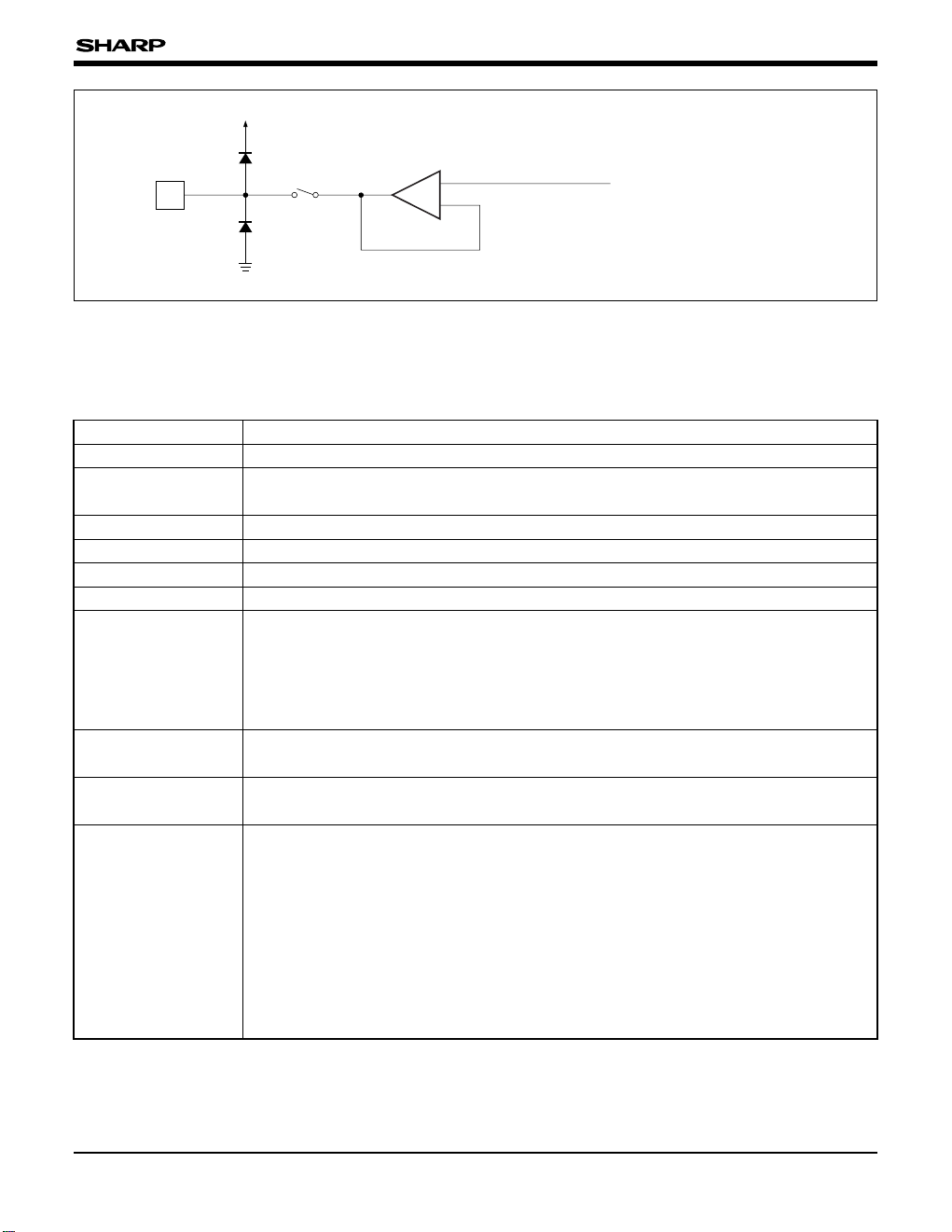

I

V

CCLVCCL

GNDL

To Internal Circuit

Fig. 3 Input Circuit (3)

¿Applicable pins¡

SAM, RL, PS,

TST

1-TST4

I

V

CCAVCCA

GNDA

To Internal Circuit

Fig. 4 Input Circuit (4)

¿Applicable pin¡

TST

5

VCCL

GNDL

Nch Tr

Output Signal

Output Control Signal

VCCL

GNDL

To Internal Circuit

I

O

Pch Tr

Fig. 5 Input/Output Circuit

¿Applicable pins¡

SPIO, SPOI

Page 6

6

LH1687

O

V

CCA

GNDA

From Internal Circuit

Operational

Amplifier

+

–

Fig. 6 Output Circuit

¿Applicable pins¡

OS

1-OS240

FUNCTIONAL DESCRIPTION

Pin Functions

SYMBOL FUNCTION

V

CCL Used as power supply pin for logic circuit, connected to +3.0 to +5.0 V.

V

CCA

Used as power supply pin for LCD drive circuit, connected to +3.0 to +5.0 V.

Must be set to V

CCL ≤ VCCA.

GNDL Used as ground pin for logic circuit, connected to 0 V.

GNDA Used as ground pin for LCD drive circuit, connected to 0 V.

TST

1-TST4 Used as input pins for IC testing, connected to VCCL (high level).

TST5 Used as input pins for IC testing, connected to VCCA (high level).

SPIO

SPOI

Used as input/output pins of cascade operation start signal.

SPIO becomes input pin of operation start signal and SPOI becomes output pin of

operation start signal of next IC when set to R/L = "H".

SPOI becomes input pin of operation start signal and SPIO becomes output pin of

operation start signal of next IC when set to R/L = "L".

CK

Used as horizontal shift clock input pin.

Video signals are sampled in order at the rising and falling edge of CK.

CTR

Used as input pin of selecting video signal sampling circuits and selecting input signal of

output operational amplifiers.

SAM

Used as input pin for setting the selecting of normal sampling operation or 3-point

simultaneous sampling operation.

For normal sampling operation, video signals are sampled into sample and hold circuits

every 1 LCD drive output.

For 3-point simultaneous sampling operation, video signals are sampled into sample and

hold circuits every 3 LCD drive outputs simultaneously.

For either operation, sampling signals are shifted at every rising and falling edge of

horizontal shift clock of CK pin (half clock), and their sampling period is equal to the period

of one clock.

Page 7

LH1687

7

SYMBOL FUNCTION

PS

Used as input pin for setting of power save mode.

LCD drive output pins output voltage corresponding to video signals held in the sample

and hold circuits when set PS to "H".

The LH1687 is set low power mode by setting high-impedance condition and cutting off

current source of LCD drive outputs when set PS to "L".

MODE

Used as input pin for setting video signals for sampling in the sample and hold circuits.

By mode setting circuit, video signals are sampled and output in order of V

B, VA, and VC

when set to "H" and in order of VC, VB, and VA when set to "L" with respect to OS1 to

OS

240 .

OS

1-OS240

Used as LCD drive output pins.

Voltage corresponding to video signals held in the sample and hold circuits is output when

set to PS = "H", and becomes high-impedance condition when set to PS = "L".

Used as input pins of video signals.

V

B, VA, VC, π VB, VA, VC or VC, VB, VA, π VC, VB, VA are input with respect to LCD drive

outputs OS1, OS2, OS3, π OS238, OS239, OS240 by MODE pin setting condition.

V

A

VB

VC

RL

Used as input pin for setting the shift direction of video signal sampling sequence and the

selecting input/output of SPIO/SPOI pins.

Video signals are sampled in order of OS

1/OS240, set SPIO to input of operation start

signal and set SPOI to output of operation start signal of next IC when set RL to "H".

Video signals are sampled in order of OS

240/OS1, set SPOI to input of operation start

signal and set SPIO to output of operation start signal of next IC when set RL to "L".

Page 8

8

LH1687

Functional Operations

(1) Examples of Cascade Sequence

When RL = "H"

SPIO SPOI

OS

1 OS240

Cascade

Sequence 1st

Start Signal

SPIO

SPOI

OS

1 OS240

Cascade

Sequence 2nd

SPIO

OS

1 OS240

Cascade

Sequence n

TFT-LCD Panel

Horizontal Scanning Direction

(n : number of LH1687 used)

When RL = "L"

SPOI SPIO

OS

240 OS1

Cascade

Sequence 1st

Start Signal

SPOI

SPIO SPIO

OS

240 OS1

Cascade

Sequence 2nd

SPOI

OS

240 OS1

Cascade

Sequence n

TFT-LCD Panel

Horizontal Scanning Direction

(n : number of LH1687 used)

Page 9

9

LH1687

(2) Video Signal Mode Setting Function

With MODE pin condition, it is possible to set the

form of video signals corresponding to each output

pin by selecting the mode setting circuit.

When MODE = "H"

When MODE = "L"

Mode Setting Circuit

Output Circuit

V

B VA VC VB VA VC VB VA VC

OS1 OS2 OS3 OS4 OS5 OS6 OS238 OS239 OS240

Mode Setting Circuit

V

C VB VA VC VB VA VC VB VA

OS1 OS2 OS3 OS4 OS5 OS6 OS238 OS239 OS240

Output Circuit

Page 10

LH1687

10

(3) Output Circuit Type

The LH1687 samples video signals by the sample

and hold circuits of 2 systems and outputs the

voltage corresponding to the sampled data by the

input switching operational amplifiers with push-pull

output buffer.

Sample and hold circuits and output circuits are as

shown in the diagram below.

When CTR = "H", the LH1687 samples the data to

system A of the sample and hold circuits and

outputs the voltage corresponding to the voltage

sampled by capacitor B of system B.

When CTR = "L", the LH1687 samples the data to

system B of the sample and hold circuits and

outputs the voltage corresponding to the voltage

sampled by capacitor A of system A.

Therefore, it is usually necessary to repeat the

sampling operation and output operation by

exchanging CTR signal ("H" to "L" or "L" to "H") for

every start signal.

While CTR signal is set to "H" or "L" several times

for start signal, the same voltage is output

continuously.

The output voltage corresponds to the data

sampled by the previous sampling operation.

Timing of operation is as follows.

Also, there is a power save function which makes

high-impedance of the output pin and a reduction in

the current of operational amplifiers possible when

set to PS = "L", but careful attention must be paid

to the displaying quality etc. when using it.

+1

+2

–

Capacitor B

GNDA

GNDA

Sampling

Signal A

Operational Amplifier

+ Output Buffer

Sampling

Signal B

Capacitor A

System B of Sample and Hold Circuits

System A of Sample and Hold Circuits

Output Pin

Video

Signal

Start signal

CTR

System A

System B Sampling 2 Output 2 Output 2 Sampling 4

Sampling 1 Output 1 Sampling 3 Sampling 3' Output 3'

Output 0

Page 11

LH1687

11

(4) Examples of LCD Panel Connection

With the video signal mode setting function of (2), it

is possible to connect LCD panel to the stripe pixel

array panel and delta pixel array panel as shown in

the following examples.

(a) Example of Stripe Pixel Array Panel Connection

VB

LH1687

V

CVA

RBGVideo Signals

1st Line

2nd Line

Sampling

Data

3rd Line

MODE = "H"

MODE = "H"

MODE = "H"

OS

1 OS2 OS3

OS238 OS239 OS240

RGBR BGRB

RGBR BGRB

RGBR BGRB

Video signal input pin

Connection of video signal input pins

VBVA VC

BGRVideo signal

Setting of video signals that are to be sampled by output circuits and MODE pin condition

2nd LINE1st LINE 3rd LINE

RRROS (3n + 1) R

AFTER 4th LINE

"H"

(n = 0, 1, 2, π, 79)

MODE pin setting "H""H" "H"

BOS (3n + 3) BBB

GOS (3n + 2) GGG

Page 12

LH1687

12

(b) Example of Delta Pixel Array Panel Connection

VB

LH1687

V

CVA

RBGVideo Signals

1st Line

2nd Line

Sampling

Data

3rd Line

MODE = "H"

MODE = "L"

MODE = "H"

OS

1 OS2 OS3

OS238 OS239 OS240

RGBR BGRB

BRGB GRBGR

RGBR BGRB

Video signal input pin

Connection of video signal input pins

VBVA VC

BGRVideo signal

Setting of video signals that are to be sampled by output circuits and MODE pin condition

2nd LINE1st LINE 3rd LINE

RRBOS (3n + 1) B and R are alternately selected.

AFTER 4th LINE

"L" and "H" are alternately selected.

(n = 0, 1, 2, π, 79)

MODE pin setting "L""H" "H"

G and B are alternately selected.OS (3n + 3) GBB

R and G are alternately selected.OS (3n + 2) RGG

NOTES :

• Set the MODE pin condition during blanking period.

• Input the horizontal shift clock signal of CK pin by shifting the phase for each line according to the shift of the pixels

connected to the same source bus line.

If the pixels connected to the same source bus line are shifted by half the pixels, change the clock phase 90 degrees.

Clock phase must be changed during blanking period.

Page 13

LH1687

13

Outline of Operation Timing

(1) Overall Operation Timing

Video signals of one horizontal scanning period are

sampled into the sample and hold circuits at the

timing of the internal sampling pulses of each

output circuit, and data corresponding to the

sampled data are output.

Horizontal

Blanking

Period

Effective

Display

Period

Video Signals

Start Pulse

(Horizontal Scanning Start Pulse)

S

1

S240

(Internal Sampling Signals)

PS

OS

1-OS240

(LCD Drive Outputs)

(Power Save Signal)

Output

High-Z

Sampling Data

(j – 1) Output

Output

High-Z

Output

High-Z

Sampling Data

(j) Output

Sampling Data

(j + 1) Output

One Horizontal

Scanning Period

(j)

One Horizontal

Scanning Period

(j + 1)

(2) Timing of Video Signal Sampling

If the normal sampling operation and cascade

sequence is 1st, the video signal sampling (internal

sampling signal Sn (n =

1, 2, π, 240)) is started at the

rising edge of first clock after falling edge of start

pulse.

CK

S1

Start Pulse

(Horizontal Scanning Start Pulse)

S2

(Normal Sampling Operation, Cascade Sequence 1st)

01 2

Video Signal Sampling Start

Page 14

LH1687

14

(2) When RL = "L"

0 1 2 120 121

CK

SPIO

S

1

S2

S239

S240

SPOI

NOTE : S1 to S240 are internal sampling signals of video signal.

NOTE : S1 to S240 are internal sampling signals of video signal.

Timing Chart for Normal Sampling Operation

(1) When RL = "H"

CK

0 1 2 120 121

SPOI

240

S

S239

S2

SPIO

S1

Page 15

LH1687

15

(2) When RL = "L"

0 1 2 40 41

CK

SPIO

S

1-S3

S4-S6

S235-S237

S238-S240

SPOI

NOTE : S1 to S240 are internal sampling signals of video signal.

NOTE : S1 to S240 are internal sampling signals of video signal.

Timing Chart for 3-point Simultaneous Sampling Operation

(1) When RL = "H"

CK

0 1 2 40 41

SPOI

238-S240

S

S235-S237

S4-S6

S1-S3

SPIO

Page 16

LH1687

16

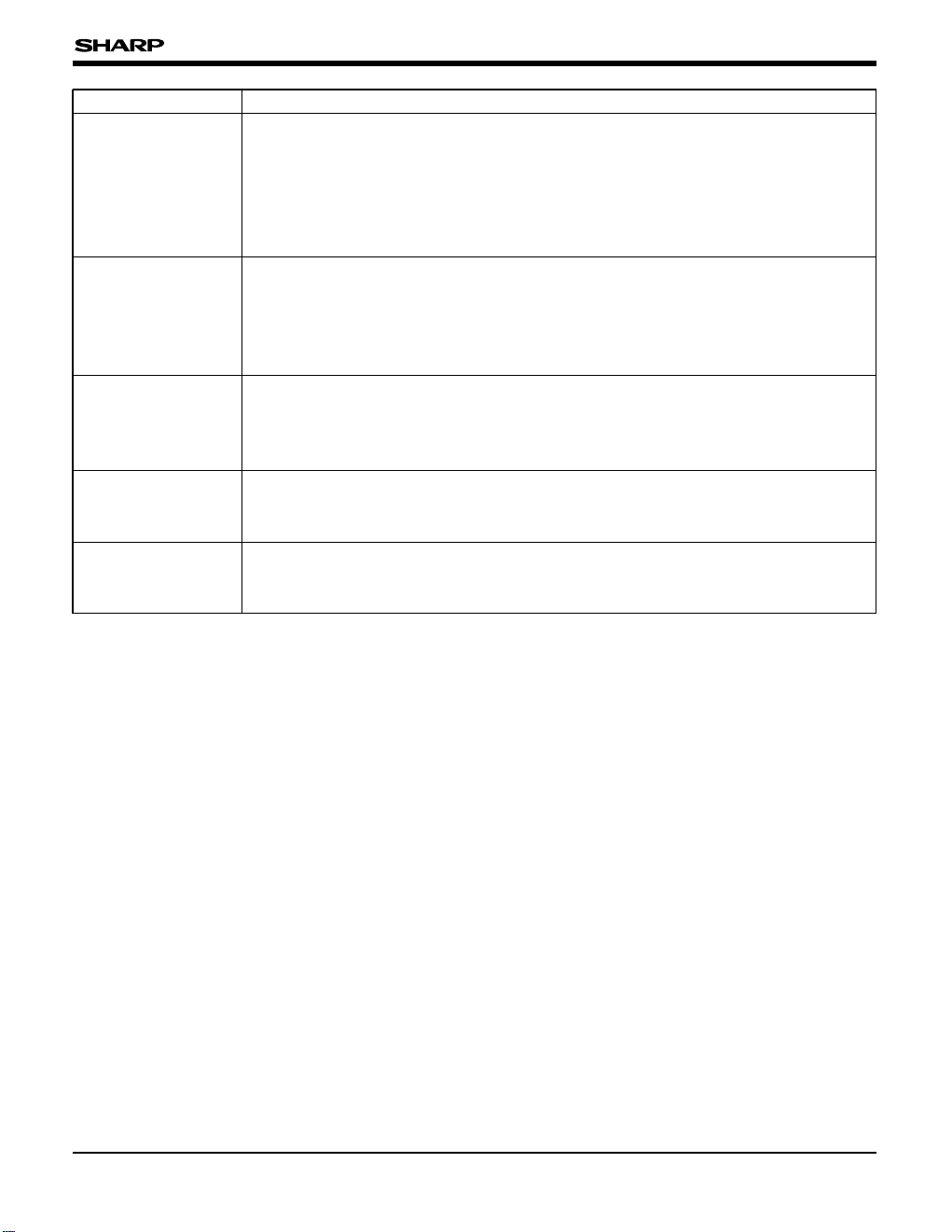

PRECAUTIONS

Precautions when connecting or disconnecting

the power supply

This IC has some power supply pins, so it may be

permanently damaged by a high current which may

flow if voltage is supplied to the LCD drive power

supply while the logic system power supply is

floating. Therefore, when connecting the power

supply, set the logic system input pins (SPIO,

SPOI, CK, CTR, MODE, SAME, RL, PS, TST

1,

TST

2, TST3, TST4) after supplying the voltage to

the logic system power supply pin (V

CCL), and next

supplying the voltage to the LCD drive system

power supply pin (V

CCA). Finally, set the LCD drive

system input pins (V

A, VB, VC, TST5).

When disconnecting the power supply, follow the

reverse sequence.

When connecting or disconnecting the power

supply follow the recommended sequence shown

here.

112

CK

PS

OS

1-OS240

Sampling Data Output Period Output Hi-impedance Period Sampling Data Output Period

Timing Chart for CTR Operation

12 12

CK

CTR

OS

1-OS240

Sampling of System A

&

Output Period System B

Sampling of System B

&

Output Period System A

Sampling of System A

&

Output Period System B

Timing Chart for PS Operation

Page 17

LH1687

17

Power Suplly of Logic System

Input of Logic System

Power Supply of LCD Drive System

Input of LCD Drive System

Connecting The Power Supply

or Input Signals

Disconnecting The Power Supply

or Input Signals

Setting of Input pins

Since 5 pins of SPIO, SPOI, CK, CTR, and MODE

of the input pins are not pulled up or pulled down in

the IC, never use these 5 pins in the "OPEN"

condition.

Since V

A, VB, and VC pins are for inputting video

signals, necessary video signals must always be

input.

Except for V

A, VB, VC, SPIO, SPOI, CK, CTR, and

MODE, all other input pins are pulled up in the IC.

However, to preventing malfunction due to noise

etc., avoid using the "OPEN" condition whenever

possible, and set to "H" level or "L" level.

Input video signals

Input video signals are target for analog signals

(continuous signals).

The input band of video signals is applicable up to

the maximum of 12.5 MHz.

Bypass capacitor

If the noise of a logic system is superposed on

analog circuits such as the sample and hold

circuits, analog characteristics (such as output

voltage deviation and dynamic range, etc.) may

deteriorate. For this reason, insert bypass

capacitors of about 1 µF between V

CCL and GNDL,

V

CCA and GNDA.

Fully evaluate and determine the value of bypass

capacitors with them actually mounted on the LCD

module.

Maximum ratings

When connecting or disconnecting the power

supply, this IC must be used within the range of the

absolute maximum ratings.

Page 18

LH1687

18

RECOMMENDED OPERATING CONDITIONS

PARAMETER SYMBOL APPLICABLE PINS RATING UNIT NOTE

Supply voltage

V

CCLVCCL –0.3 to +7.0 V

1, 2

V

CCAVCCA –0.3 to +7.0 V

Input voltage

V

INL

CK, CTR, SPIO, SPOI, MODE,

RL, SAM, PS, TST

1

-TST

4

–0.3 to VCCL + 0.3 V

Storage temperature T

STG –45 to +125 ˚C

NOTES :

1. TA = +25 ˚C

2. The maximum applicable voltage on any pin with respect to GNDL and GNDA (0 V).

NOTES :

1. The applicable voltage on any pin with respect to GNDL and GNDA (0 V).

2. Ensure that voltages are set such that V

CCL ≤ VCCA.

VINA TST5, VA, VB, VC –0.3 to VCCA + 0.3 V

PARAMETER SYMBOL APPLICABLE PINS RATING UNIT NOTE

Supply voltage

V

CCLVCCL +3.0 to +5.5 V

1, 2

V

CCAVCCA +3.0 to +5.5 V

Input voltage

V

INL

CK, CTR, SPIO, SPOI, MODE,

RL, SAM, PS, TST

1

-TST

4

0 to VCCLV

Operating temperature T

OPR –30 to +85 ˚C

V

INA TST5, VA, VB, VC 0 to VCCAV

ABSOLUTE MAXIMUM RATINGS

Page 19

LH1687

19

NOTES :

1. Start signal :

Cycle t

SP = 63.5 µs, "H" period width tWSP = 80 ns.

CTR signal :

Cycle t

CTR = 127.0 µs, "H" period width tWCTR = 63.5 µs.

Change from "H" to "L" or "L" to "H" is synchronized with

start pulse during blanking period.

CK signal :

Frequency f

CK = 12.5 MHz (duty = 50%)

V

A = VB = VC = 0.1 V to VCCA – 0.1 V

Connect all other pins to high level.

Voltage difference between the average voltage of all

OS output pins in the chip and the output voltage of

each OS output pin. T

A = 25 °C

2. Start signal :

Cycle t

SP = 63.5 µs, "H" period width tWSP = 80 ns.

CTR signal :

Cycle t

CTR = 127.0 µs, "H" period width tWCTR = 63.5 µs.

Change from "H" to "L" or "L" to "H" is synchronized with

start pulse during blanking period.

CK signal :

Frequency f

CK = 12.5 MHz (duty = 50%)

Connect V

A, VB, and VC pins to VCCA.

Connect all other pins to high level.

3. Start signal :

Cycle t

SP = 63.5 µs, "H" period width tWSP = 80 ns.

CTR signal :

Cycle t

CTR = 127.0 µs, "H" period width tWCTR = 63.5 µs.

Change from "H" to "L" or "L" to "H" is synchronized with

start pulse during blanking period.

CK signal :

Frequency f

CK = 12.5 MHz (duty = 50%)

Pin to be set to GND : PS

Connect V

A, VB, and VC pins to VCCA.

Connect all other pins to high level.

PARAMETER

SYMBOL

CONDITIONS APPLICABLE PINS MIN. TYP. MAX. UNIT. NOTE

Input "Low" voltage V

IL CK, CTR, SPIO, SPOI,

MODE, RL, SAM, PS

0

0.3VCCL

V

VIHL

0.7VCCL

VCCLV

Input "High" current

I

IHLVIN = VCCL

CK, CTR, SPIO, SPOI,

MODE, RL, SAM, PS

10 µA

Dynamic range Vp-p V

A, VB, VC 0.1

VCCA – 0.1

V

Supply current

(In power save mode)

ICCA2 100 µA 3

Supply current I

CCL1 VCCL

CK, CTR, SPIO, SPOI,

MODE, V

A, VB, VCVIN = 0 V

I

IL1

Input "Low" current

Input "High" voltage

1.5 mA 2

I

IHAVIN = VCCAVA, VB, VC 10 µA

Input voltage VV

CCA0VINAVA, VB, VC

IIL2 RL, SAM, PS

10 µA

400 µA

1mV20–20OS

1-OS240VOD

Deviations between

output voltage pins

Supply current

(In operation mode)

I

CCA1

VCCA

mA 26.0

ELECTRICAL CHARACTERISTICS

DC Characteristics

(Unless otherwise specified, GNDL = GNDA = 0 V, VCCL = +3.3 V, VCCA = +5.0 V, TOPR = –30 to +85 ˚C)

Page 20

LH1687

20

PARAMETER

SYMBOL

CONDITIONS APPLICABLE PINS MIN. TYP. MAX. UNIT

Clock frequency f

CK

SAM = "H"

CK

12.5 MHz

"H" level clock width t

WHC

SAM = "H" 30.0 ns

Input rise time t

RC

SAM = "H" 10.0 ns

Input fall time t

FC

SAM = "H" 10.0 ns

Start pulse width t

WSP SPIO, SPOI

1

-------f

CK

ns

Start pulse setup time t

SUSP 10.0 ns

Start pulse hold time tHSP 15.0 ns

Start pulse output

delay time

t

DSP CL = 15 pF 20.0 ns

PS signal setup time t

SUPS

1

--------

2f

CK

µs

CTR signal setup

time

t

SUCTR

1

-------2f

CK

µs

SPIO, SPOI, CK

ns30.0SAM = "H"

t

WLC"L" level clock width

µs5.0t

ROutput rise time

µs5.0t

DO

Output transfer delay time

PS

CTR

OS

1-OS240

Output fall time tF 5.0 µs

SPIO, SPOI, CK

1

NOTE

MHz7.0SAM = "L"

SAM = "L" 50.0 ns

SAM = "L" 50.0 ns

SAM = "L" 20.0 ns

SAM = "L" 20.0 ns

2

µs5.0t

FOPPower save fall time

Power save delay time

tDOP 3.0 µs

Power save rise time t

ROP 5.0 µs

NOTES :

1. Start signal :

Cycle t

SP = 63.5 µs, "H" period width tWSP = 80 ns.

CTR signal :

Cycle t

CTR = 127.0 µs, "H" period width tWCTR = 63.5 µs.

Change from "H" to "L" or "L" to "H" is synchronized with

start pulse during blanking period.

CK signal :

Frequency f

CK = 12.5 MHz (duty = 50%)

Connect V

A, VB, and VC pins to VCCA.

Connect all other pins to V

CCL.

Capacity of output load C

L = 150 pF

2. Add load resistor (10 k$) to NOTE 1.

Load resistor is connected to GNDA or V

CCA level as

follows.

Output Pin

10 k$ 150 pF

GNDA

Output Pin

10 k$

150 pF

GNDA

V

CCA

AC Characteristics

(Unless otherwise specified, GNDL = GNDA = 0 V, VCCL = +3.3 V, VCCA = +5.0 V, TOPR = –30 to +85 ˚C)

Page 21

LH1687

21

Timing Chart

90% 90%

90%

90%

90%

10%

90%

90%

90%

90% 90%

90%

10% 10%

10%

10%

10%

10%

90% 90%

10%

10%

90%

10%

10%

90% 90%

10%

90%

10%

10%

10%

10% 10% 10%

tWSP

tDSP

tSUPS tSUPS

tDSP

tSUSP

tHSP tRC tFC

tWLCtWHC

1

f

CK

12 3

1' 2' 3'

LAST – 1LAST – 2 LAST

tDOP

tDOP

tFOP

tROP

Sampling Data Output Output High-impedance

tSUCTR

tDO

tSUCTR

tFO

tDO

tRO

CK

(SPOI)

SPIO Input

CK

CK

PS

(SPOI)

SPIO Output

OS

1-OS240

CK

CTR

OS1-OS240

Loading...

Loading...