Page 1

DEVICES INCORPORATED

LF2301

Image Resampling Sequencer

LF2301

DEVICES INCORPORATED

FEATURES DESCRIPTION

❑❑

❑ 40 MHz Clock Rate

❑❑

❑❑

❑ High-Speed Image Manipulation

❑❑

❑❑

❑ Maximum Image Size: 4096 x 4096

❑❑

Pixels

❑❑

❑ Supports Following Interpolation

❑❑

Algorithms:

• Nearest-Neighbor

• Bilinear Interpolation

• Cubic Convolution

❑❑

❑ Applications:

❑❑

• Video Special-Effects

• Image Recognition

• High-Speed Data Encoding/

Decoding

❑❑

❑ Replaces TRW/Raytheon/Fairchild

❑❑

TMC2301

❑❑

❑ 68-pin PLCC, J-Lead

❑❑

The LF2301 is a self-sequencing

address generator designed to filter

a two-dimensional image or remap

and resample it from one set of

Cartesian coordinates (x,y) into a

new set (u,v).

The LF2301 can resample digitized

images or perform such manipulations as rotation, panning, zooming,

and warping as well as compression

in real-time.

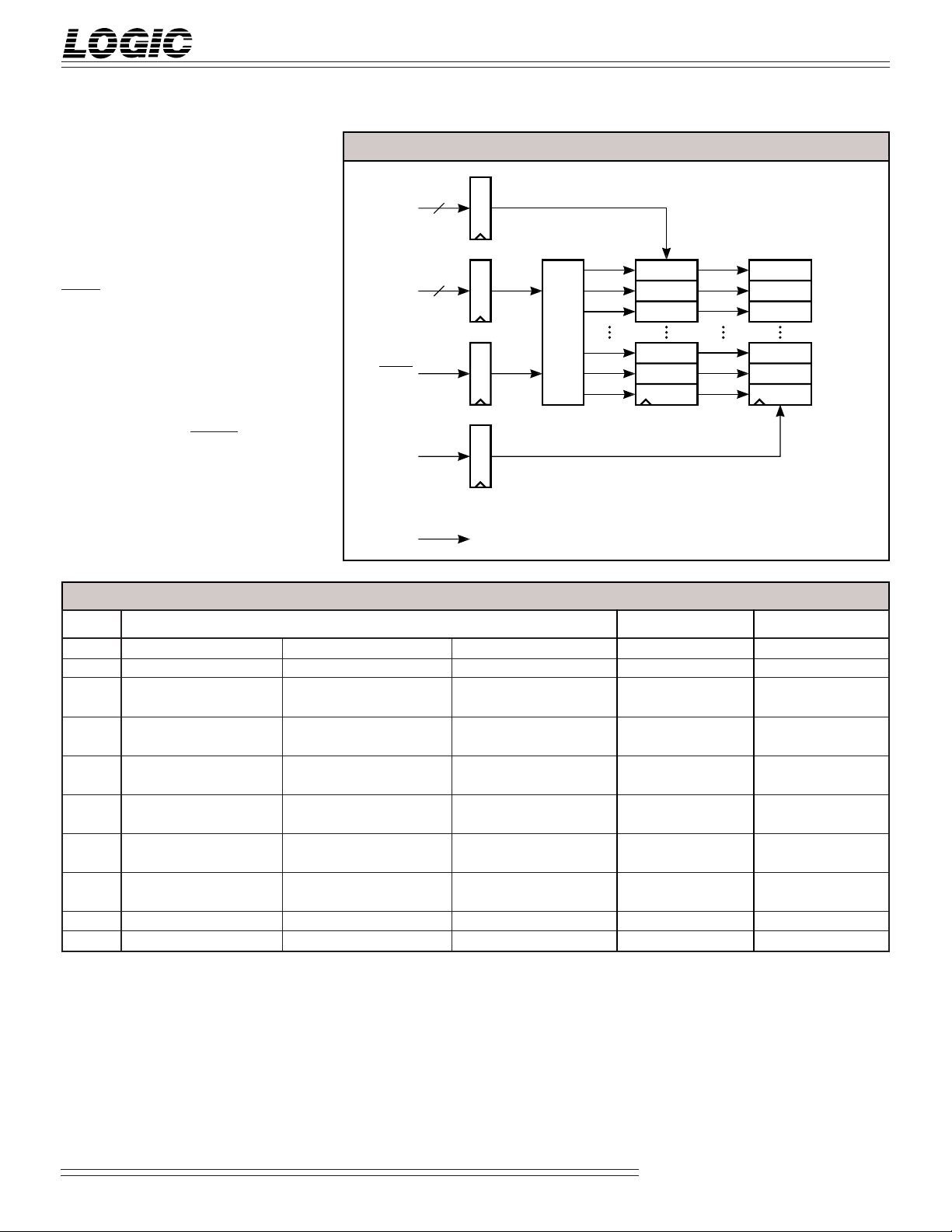

By using two LF2301s in a Image

Transformation System (ITS),

nearest-neighbor, bilinear interpolation, and cubic convolution algorithms, with kernel sizes up to 4 x 4

pixels, are all possible (see Figure 1).

This system can also implement

simple static filters with kernel sizes

up to 16 x 16 pixels.

Image Resampling Sequencer

DETAILS OF OPERATION

Most video applications use a pair

of LF2301s in tandem to construct

an ITS. One LF2301 is the row

coordinate generator (x to u) and the

other is the column generator (y to

v). External RAM is needed for

storage of the interpolation coefficient lookup table, as well as for

buffers of the source and destination

images. An external MultiplierAccumulator is required when

performing interpolation or implementing static filters.

The ITS is capable of performing the

general second-order coordinate

transformation of the form:

x(u,v) = Au2+Bu+Cuv+Dv2+Ev+F

y(u,v) = Gu2+Hu+Kuv+Lv2+Mv+N

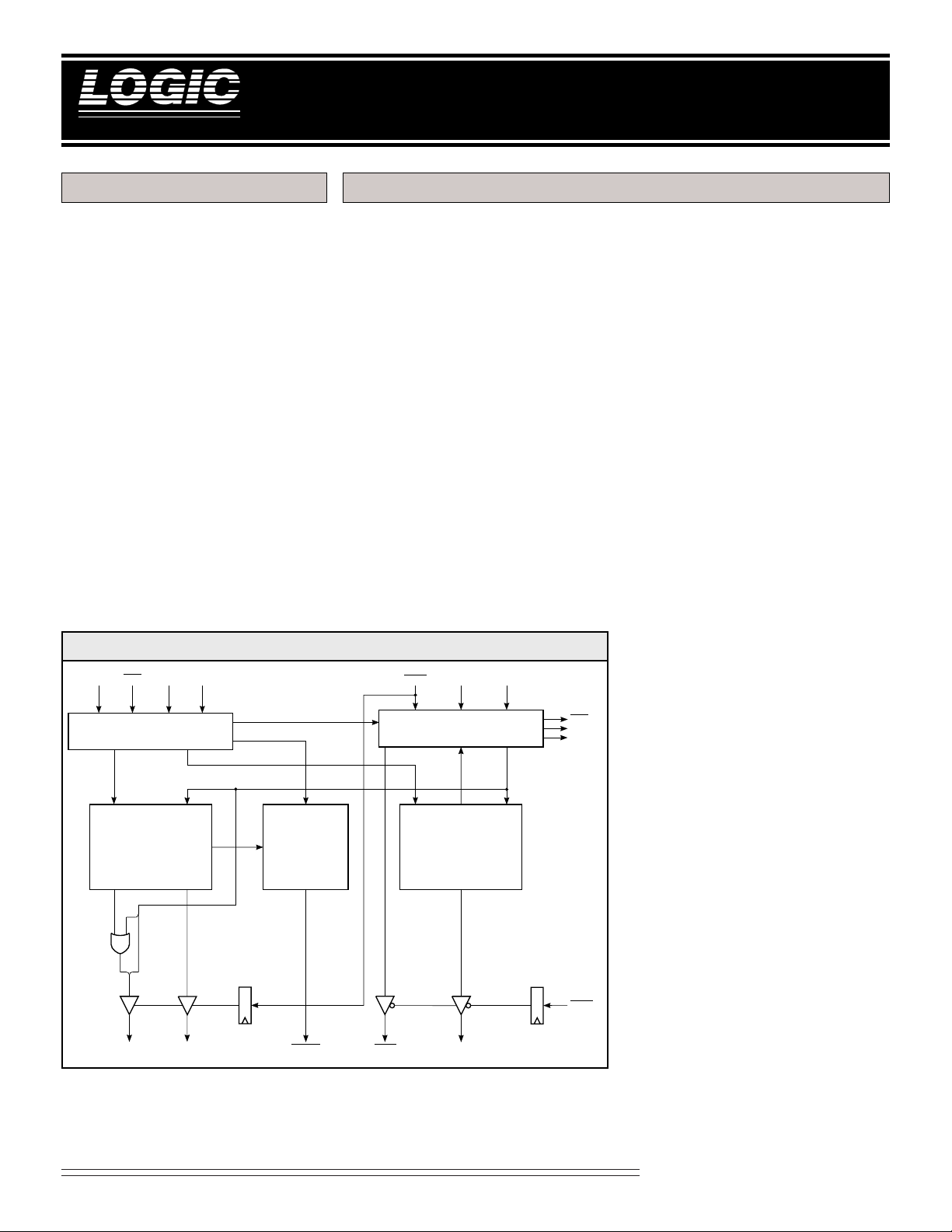

LF2301 BLOCK DIAGRAM

WENLDR B

3-0P11-0

PARAMETER

STORAGE

SOURCE

ADDRESS

GENERATOR

INTEGERFRACTION

11-0CA7-0

X

INPUT IMAGE

BOUNDARY

COMPARATOR

CZERO

UWRI

INTER INITNOOP

CONTROL

WALK COUNT

TARGET

ADDRESS

GENERATOR

U

11-0

ACC

DONE

END

OETA

where parameters A through N of

the transform are user-defined.

The system steps sequentially

through each pixel in the “target”

image lying within a user-defined

rectangle. For each “target” pixel

at (u,v), the LF2301 points to a

corresponding “source” pixel at

(x,y).

2-1

Video Imaging Products

08/16/2000–LDS.2301-H

Page 2

DEVICES INCORPORATED

LF2301

Image Resampling Sequencer

SIGNAL DEFINITIONS

Power

Vcc and GND

+5V power supply. All pins must be

connected.

Clock

CLK — Master Clock

The rising edge of CLK strobes all

enabled registers.

Inputs

P11-0 — Parameter Register Data Input

P11-0 is the 12-bit Parameter Register

Data input port. P11-0 is latched on

the rising edge of CLK.

B3-0 — Parameter Register Address Input

B3-0 is the 4-bit Parameter Register

Address input port. B3-0 is latched on

the rising edge of CLK.

Outputs

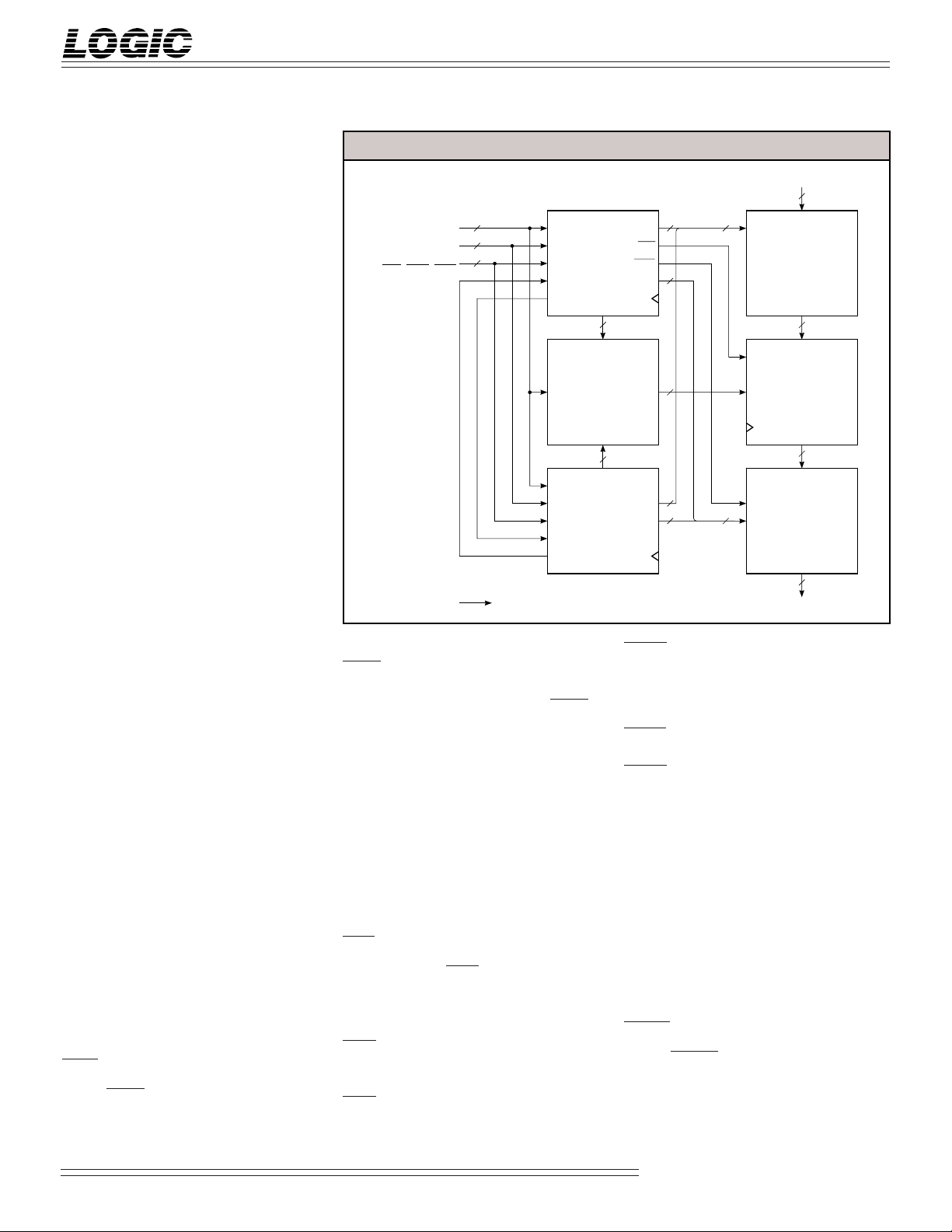

FIGURE 1. IMAGE TRANSFORMATION SYSTEM (ITS)

P

11-0

B

INIT, LDR,

WEN, NOOP, OETA

CLK

12

4

3-0

5

INTER

END

INTERPOLATION

COEFFICIENT

INTER

END

LF2301

Row

Address

Generator

(X)

7-0

CA

8

RAM

8

7-0

CA

LF2301

Column

Address

Generator

(Y)

X

ACC

UWRI

U

Y

V

11-0

11-0

11-0

11-0

12 24

12

12

12

12

IMAGE DATA IN

12

SOURCE

IMAGE

RAM

12

ACC

Y

24

X

LMA1009/2009

12 x 12 bit

Multiplier-

Accumulator

X,Y,P

D

OUT

12

DESTINATION

IMAGE

RAM

12

IMAGE DATA OUT

X11-0 — Source Address Output

X11-0 is the 12-bit registered Source

Address output port.

CA7-0 — Coefficient Address Output

CA7-0 is the 8-bit registered Coefficient Address output port.

U11-0 — Target Address Output

U11-0 is the 12-bit registered Target

Address output port.

Controls

INIT — Initialize

When INIT is HIGH for a minimum of

two clock cycles, the control logic is

cleared and initialized for the start of a

new image transformation. When

INIT goes LOW, normal operation

begins after two clock cycles. INIT is

latched on the rising edge of CLK.

WEN — Write Enable

When WEN is LOW, data latched into

the device on P11-0 is loaded into the

preload register addressed by the data

latched into the device on B3-0. When

WEN is HIGH, data cannot be loaded

into the preload registers and their

contents will not be changed. WEN is

latched on the rising edge of CLK.

LDR — Load Data Register

When LDR is HIGH, data in all

preload registers is latched into the

Transformation Parameter Registers.

When LDR is LOW, data cannot be

loaded into the Transformation

Parameter Registers and their contents

will not be changed. LDR is latched

on the rising edge of CLK.

ACC — Accumulate

The registered ACC output initializes

the accumulation register of the

external multiplier-accumulator. At

the start of each interpolation “walk,”

ACC goes LOW for one cycle effectively clearing the storage register by

loading in only the new first product.

ACC from either the row or column

LF2301 may be used.

UWRI — Target Memory Write Enable

The Target Memory Write Enable goes

LOW for one clock cycle after the end

of each interpolation “walk.” When

OETA is HIGH, this registered output

is forced to the high-impedance state.

UWRI from either the row or column

LF2301 may be used.

INTER — Interconnect

When two LF2301s are used to form

an ITS, the END flag on each device

is connected to INTER on the other

device. The END flag from the row

device indicates an “end of line” to the

column device. The END flag from the

column device indicates a “bottom of

frame” to the row device, forcing a

reset of the address counter.

NOOP — No Operation

When NOOP is LOW, the clock is

overridden holding all address

generators in their current state. X11-0

and CA7-0 are forced to the high-

2-2

Video Imaging Products

08/16/2000–LDS.2301-H

Page 3

DEVICES INCORPORATED

LF2301

Image Resampling Sequencer

impedance state. Users may then

access external memory. Normal

operation resumes on the next clock

cycle after NOOP goes HIGH. NOOP

is latched on the rising edge of CLK.

OETA — Target Memory Output Enable

When OETA is HIGH, UWRI and U11-0

are forced to the high-impedance

state. When OETA is LOW, UWRI

and U11-0 are enabled on the next

clock cycle. OETA is latched on the

rising edge of CLK.

Flags

CZERO — Coefficient Zero

If in a row device x<0,

XMIN≤x≤XMAX, or x≥4096, the

registered CZERO flag goes HIGH . If

0≤x<XMIN or XMAX<x<4096, CZERO

goes LOW. In an ITS, when the source

address falls outside a rectangle with

vertices (XMIN, YMIN), (XMAX,

YMIN), (XMIN, YMAX), and (XMAX,

YMAX), the logical AND of the

CZERO flags from the row and

column of the LF2301s will go LOW

representing an invalid address.

END — End of Row/Frame

When two LF2301s are used to form

an ITS, the END flag on each device

is connected to INTER on the other

device. The END flag from the row

device indicates an “end of line” to the

column device. The END flag from

the column device indicates a “bottom

of frame” to the row device, forcing a

reset of the address counter.

When Mode is set to “00” or “10”

END goes HIGH on the row device

for (K+1) x (K+1) clock cycles

starting[2 x (K+1) x (K+1)] + 1 clock

cycles before the last X address of a

row. END goes HIGH on the column

device for (K+1)3 x (UMAX-UMIN)

clock cycles starting at (K+1)3 x

(UMAX-UMIN) + 1 clock cycles before

the last X address of a frame.

When Mode is set to “01” or “11”

END goes HIGH on the row device

for K+1 clock cycles starting at (K+1) +

2 clock cycles before the last X address

of a row. END goes HIGH on the

column device for (K+1) x (K+1)

clock cycles starting at [(K+1) x (K+1)] +

1 clock cycles before the last X address

of a frame.

DONE — End of Transform

In a two LF2301 system, after the last

walk of the last row of an image, the

registered DONE flag goes HIGH

indicating the end of the transform.

DONE goes HIGH one clock cycle

before the last X address of a frame. If

AIN is HIGH, DONE will remain

HIGH for one clock cycle. If AIN is

LOW, DONE will remain HIGH until

a new transform begins.

Transformation Control Parameters

XMIN, XMAX, YMIN, YMAX

XMIN, XMAX, YMIN, YMAX define

the valid area in the source image

from which pixels may be read. The

CZERO flags will denote a valid

memory read whenever the LF2301s

generate an (x,y) address within this

boundary.

UMIN, UMAX, VMIN, VMAX

UMIN, UMAX, VMIN, VMAX define

the area in the destination image into

which pixels will be written.

(UMIN, VMIN) is the top left corner

and (UMAX + 1, VMAX) is the bottom

right corner. The following conditions

must be met: UMAX>UMIN and

VMAX>VMIN.

x0, y0

x0, y0 determine what the first pixel read

out of the source image will be at the

beginning of an image transformation.

x0, y0 will be the upper left corner of the

original image in non-inverting, nonreversing applications.

dx/du

dx/du is the displacement along the

x axis corresponding to a one-pixel

movement along the u axis.

2-3

dx/dv

dx/dv is the displacement along the

x axis corresponding to each one-pixel

movement along the v axis.

dy/du

dy/du is the displacement along the

y axis corresponding to each one-pixel

movement along the u axis.

dy/dv

dy/dv is the displacement along the

y axis corresponding to each one-pixel

movement along the v axis.

2

d2x/du

d2x/du2 determines the rate of change

of dx/du with each step along a line

in the output image.

2

d2x/dv

d2x/dv2 determines the rate of change

of dx/dv with each step down a

column in the output image.

2

d2y/du

d2y/du2 determines the rate of change

of dy/du with each step along a line

in the output image.

2

d2y/dv

d2y/dv2 determines the rate of change

of dy/dv with each step down a

column in the output image.

d2x/dudv

d2x/dudv determines the rate of

change of dx/du while moving

vertically through the output image.

d2x/dudv also determines the rate of

change of dx/dv while moving

horizontally through the output

image.

d2y/dudv

d2y/dudv determines the rate of

change of dy/dv while moving

horizontally through the output

image. d2y/dudv also determines the

rate of change of dy/du while

moving vertically through the output

image.

Video Imaging Products

08/16/2000–LDS.2301-H

Page 4

DEVICES INCORPORATED

LF2301

Image Resampling Sequencer

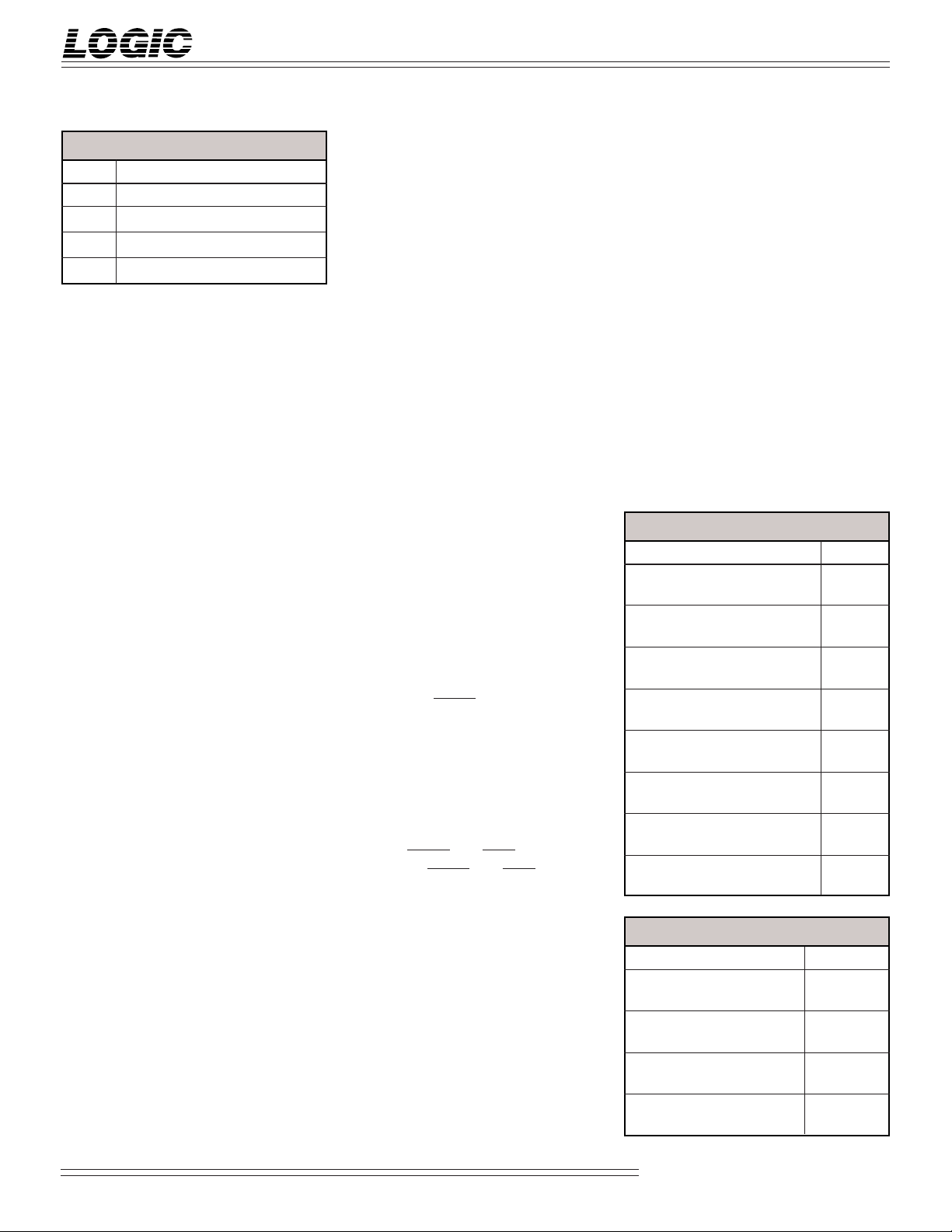

TABLE 1. MODE SELECTION

M1 M0 MODE

0 0 single-pass operation (CW)

0 1 pass 1 of two-pass operation

1 0 single-pass operation (CCW)

1 1 pass 2 of two-pass operation

R/C — Row/Column Select

When set to 0, the LF2301 functions as

a row device. When set to 1, the

LF2301 functions as a column device.

M1-0 — Mode

This 2-bit control word defines four

modes as follows (see table 1):

The 1st and 3rd modes are singlepass operations where the device

walks through a (K + 1) x (K + 1)

kernel for each output pixel. K is the

kernel size determined by K3-0 in

Parameter Register 7. In mode 00, the

spiral walk is in the clockwise direction. In mode 10, the spiral walk is in

the counter clockwise direction.

The 2nd and 4th modes are used

together to perform a two-pass

operation. The first pass (mode 01)

performs a (K+1) kernel in the

horizontal dimension. The second

pass (mode 11) performs a (K+1)

kernel in the vertical dimension.

The result of pass 1 is stored in the

destination image memory and is used

as the source image data for the second

pass. A system to switch source and

destination memory banks could be

designed, or utilization of a second

LF2301 pair in a pipelined architecture

could be used. In this case, the system

would require a third image buffer for

the final destination image.

K3-0 — Kernel

Kernel determines the length of the

spiral walk when performing image

transformations and the size of the

filter when implementing static filters

(see table 2). When performing image

transformations, the longest spiral walk

possible is 4 x 4 pixels (Kernel = 3). For

static filters, kernels of up to 16 x 16

pixels (Kernel = 15) are possible.

FOV — Field of View

FOV determines the distance between

pixels in a spiral walk. An FOV of 1

means each step in a spiral walk is one

pixel. An FOV of 2 means each step is

two pixels, and so on. FOV can be set

as high as 7 (see Table 3). It is important to note when FOV is 0, the x and

y addresses will not change during a

spiral walk. They will remain fixed at

the first pixel address of the spiral

walk.

ALR — Autoload

When set HIGH and upon INIT being

strobed, the LDR control is automatically

asserted which causes the data

currently stored in the Preload Registers

to be loaded into the Transformation

Parameter Registers.

AIN — Autoinit

A new transform automatically begins

if the AIN bit is HIGH when the end of

an image is reached. The DONE flag

will go HIGH for one clock cycle. If

AIN is LOW, UWRI and the DONE flag

remain HIGH until the user strobes the

INIT control to begin a new image

transformation.

PIPE — Pipe Control

In order to compensate for buffered

source image RAM, PIPE adjusts the

timing of UWRI and ACC. If the PIPE

bit is HIGH, UWRI and ACC will have

a one clock cycle delay added relative

to the generation of the target address.

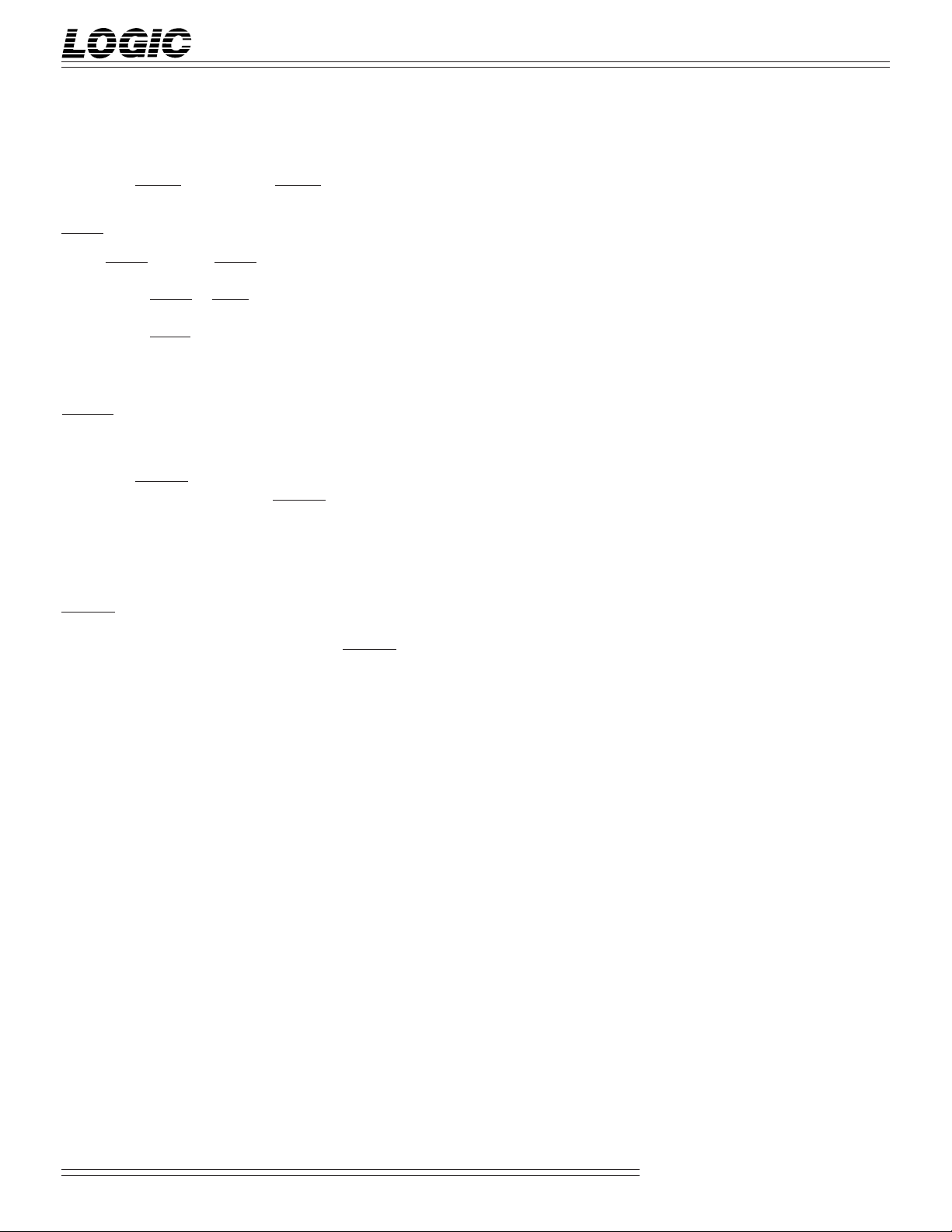

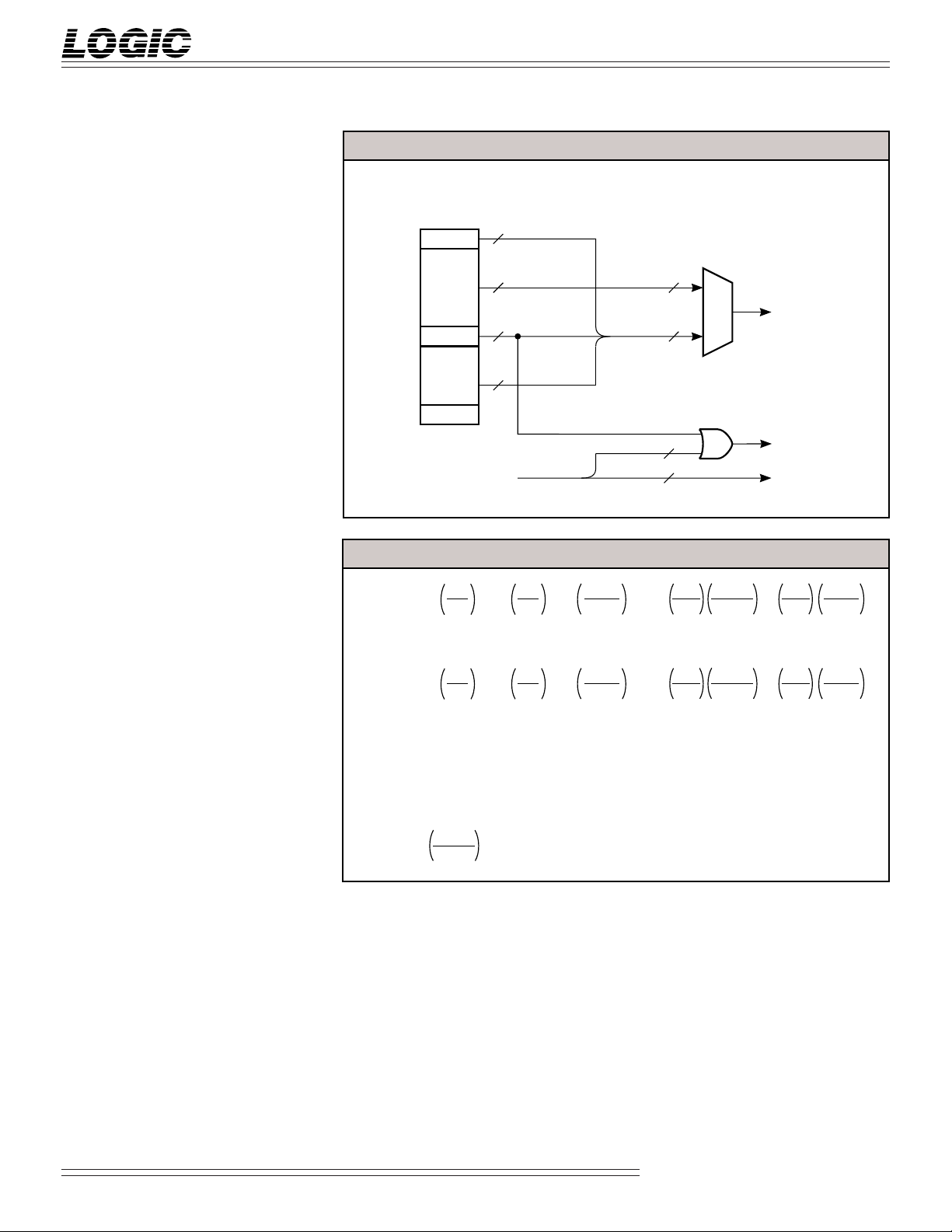

TM — Test Mode

Calculations of the source image and

coefficient addresses are made by an

internal 28-bit accumulator. TM

allows access to the sign bit and the

seven bits below the four coefficient

address bits in the accumulator. When

TM is HIGH the sign bit and 11 bits

below the source image address are fed

to X11-0 (see Figure 2). When TM is

LOW, the source image address is fed

to X11-0. Two clock cycles are required

to access both the MS and LS words of

the internal accumulator.

Functional Description

The LF2301 is an address generator

designed to be used in an image

transformation system (ITS). When

implementing an LF2301-based ITS,

second-order image transformations

can be performed like resampling,

rotation, warping, panning, and

rescaling, all at real-time video rates.

2D filtering operations, like pixel

convolutions, can also be performed.

In most applications two LF2301s are

used, one to generate the row addresses

and the other to generate the column

TABLE 2. KERNEL

K3 K2 K1 K0 Kernel

00 00 1 x 1

00 01 2 x 2

00 10 3 x 3

00 11 4 x 4

01 00 5 x 5

01 01 6 x 6

01 10 7 x 7

01 11 8 x 8

10 00 9 x 9

10 0110 x 10

10 1011 x 11

10 1112 x 12

11 0013 x 13

11 0114 x 14

11 1015 x 15

11 1116 x 16

TABLE 3. FIELD OF VIEW

F2 F1 F0 FOV

000 0

001 1

010 2

011 3

100 4

101 5

110 6

111 7

2-4

Video Imaging Products

08/16/2000–LDS.2301-H

Page 5

DEVICES INCORPORATED

LF2301

Image Resampling Sequencer

addresses. An example of an ITS

implemented with two LF2301s is

shown in Figure 1. In this system the

following components are used: two

LF2301s, a multiplier-accumulator

(MAC), interpolation coefficient RAM,

and source/target image RAM.

Maximum image size is 4096 x 4096

pixels. Data word size is determined

by the word size of the external RAM.

A typical ITS performs image transformations as follows:

a. The LF2301s generate sequential

pixel addresses (left to right, top to

bottom) which fill the rectangle in the

target image RAM defined by

(UMIN,VMIN) and (UMAX +1, VMAX).

It is important to note that the U value

of the last pixel address on each line of

the target RAM is UMAX + 1.

b. The LF2301s calculate the address

of the corresponding pixel in the

source image RAM for each target

pixel address generated.

c. If interpolation is needed, the

external MAC sums the products of

the source pixels and the interpolation coefficients. Control signals for

the MAC and address signals for the

interpolation coefficient RAM are

provided by the LF2301s.

FIGURE 2. TEST MODE DATA ROUTING

28-BIT INTERNAL

ACCUMULATOR

SIGN

WALK COUNTER

1

12

4

7

12

12

4

4

FIGURE 3. ADDRESS TRANSFORMATION EQUATIONS

+

+

+=x

0

FOV CAX(w)·

+=y

0

FOV CAY(w)·

dx

du

dy

du

m+ n+ mn+ +x

m+ n+ mn+ +y

dx

dv

+

FOV m CAX(ker)·

dy

dv

FOV m CAY(ker)·+·

·

2

d x

dudv

2

d y

dudv

2

d x

du

2

d y

du

2

2

m – m

m – m

X11-0/T11-0

CA7-4

CA3-0

2

2

2

2

2

d x

dv

2

d y

dv

2

n – n

2

2

2

n – n

2

2

d. The new pixel value is written into

the target image RAM.

The LF2301s generate source pixel

addresses according to the following

general second order equations:

x = Au2 + Bu + Cuv + Dv2 + Ev + F

y = Gu2 + Hu + Kuv + Lv2 + Mv + N

where (x,y) and (u,v) are the source

and target coordinates respectively.

A through N are user-defined parameters. The actual second order equations used are shown in Figure 3.

UMIN

VMIN

NOTE:

m=u

+

n=v

+

2

m – m

2

APPROXIMATES THEEXPONENTIAL CHARACTERISTIC OF

Video Imaging Products

2-5

2

m

.

08/16/2000–LDS.2301-H

Page 6

DEVICES INCORPORATED

LF2301

Image Resampling Sequencer

Transformation Parameter Register

Loading

The LF2301 allows Transformation

Parameters to be updated on-the-fly.

The loading of these registers is

double-buffered (see Figure 4). Any

or all of the first level registers can

be loaded using P11-0, B3-0, and

WEN without affecting the parameters currently in use.

LDR simultaneously updates all

Transformation Parameter Registers.

If Autoload (ALR) is active, these

registers will be updated automatically at the beginning of each new

image. Note that NOOP does not

affect the loading of the Transformation Parameter Registers.

FIGURE 4. LDR CONTROL FOR PARAMETER UPDATE

P11-0

3-0

B

WEN

LDR

CLK

12

4

C15

C14

C13

DECODE

C2

C1

C0

PRELOAD

REGISTERS

TRANSFORMATION

PARAMETER

REGISTERS

TABLE 4. PARAMETER REGISTER FORMATS (ROW OR COLUMN MODE)

ADDR MSB FORMAT LSB ROW COLUMN

10

9

8

7

6

5

4

3

2

1

0000 2112

0001 2112

0010 262

2

2

2

10

9

2

5

2

8

2

4

3

2

2

7

2

2

6

2

2

1

2

0011 ALR AIN PIPE R/C M1 M0 –2

–2

–3

–4

–5

0100 2–12

2

2

2

0101 TM F2 F1 F0 –2

–2

–3

0110 2–12

2

–4

2

2

0111 K 3 K2 K1 K0 –272

1000 2–92

1001 –232

1010 2–92

1011 –232

1100 2–92

1101 –232

1110 2112

1111 2112

–102–112–122–132–142–152–162–172–182–192–20

2

1

2

–102–112–122–132–142–152–162–172–182–192–20

2

2

–102–112–122–132–142–152–162–172–182–192–20

2

2

10

2

10

2

0

2

2

1

0

2

2

1

0

2

9

9

2

8

2

2

8

2

2

–6

2

7

6

2

–5

–6

2

6

–1

–2

2

–1

–2

2

–1

–2

2

7

6

2

7

6

2

2

2

2

2

5

4

2

2

0

2

2

12

2

–7

2

2

5

2

2

–7

2

2

5

2

2

–3

2

2

–3

2

2

–3

2

2

5

2

2

5

2

2

3

2

–1

–2

2

11

10

2

–8

–9

2

4

3

2

–8

–9

2

4

3

2

–4

–5

2

–4

–5

2

–4

–5

2

4

3

2

4

3

2

2

2

2

2

–3

2

2

9

2

2

–102–112–12

2

2

2

2

–102–112–12

2

2

2

2

–6

2

2

–6

2

2

–6

2

2

2

2

2

2

2

2

0

2

1

0

2

–4

–5

2

8

7

2

XMIN YMIN

XMAX YMAX

x0 (LS) y0 (LS)

Controls, x0 (MS) Controls, y0 (LS)

dx/du (LS) dy/du (LS)

1

20Controls, dx/du (MS) Controls, dy/du (MS)

dx/dv (LS) dy/dv (LS)

1

0

2

Kernel, dx/dv (MS) Kernel, dy/dv (MS)

d2x/dudv (LS) d2y/dudv (LS)

–7

–8

2

d2x/dudv (MS) d2y/dudv (MS)

d2x/du2 (LS) d2y/du2 (LS)

–7

–8

2

d2x/du2 (MS) d2y/du2 (MS)

d2x/dv2 (LS) d2y/dv2 (LS)

–7

–8

2

1

0

2

1

0

2

d2x/dv2 (MS) d2y/dv2 (MS)

UMIN VMIN

UMAX VMAX

2-6

Video Imaging Products

08/16/2000–LDS.2301-H

Page 7

DEVICES INCORPORATED

1 = 1st pixel of 1st spiral walk,

2 = 1st pixel of 2nd spiral walk, etc.

4

6789

5

6

7

8

12

5

LF2301

Image Resampling Sequencer

Static Filter

Static filtering at real-time video

rates can be performed as shown in

Figure 5. This mode is selected by

loading M1-0 with “00” for a clockwise spiral walk. A counterclockwise spiral walk could be selected

by loading M1-0 with “10.” In this

example, a static filter with a kernel

size of 3 x 3 pixels is desired. Loading K3-0 with “0010” selects a kernel

size of 3 x 3. The first pixel selected

is determined by x0 and y0. In this

example, the first pixel is (6,6). In

this case, the LF2301s should address consecutive pixels during each

spiral walk. For this to occur, FOV

must be set to 1 (F2-0 loaded with

“001”).

After the last pixel of a spiral walk

has been selected, the next pixel

address is determined by adding

dx/du to the current X address and

by adding dy/du to the current Y

address (unless the kernel just

completed was the last for that line).

At the end of the first spiral walk,

pixel (7,5) is addressed. Since the

first pixel of the next spiral walk

should be (7,6), dx/du is selected to

be 0 and dy/du is selected to be 1.

After the last pixel of the last spiral

walk on the first line has been

selected, the first pixel address of

the second line is determined by

adding dx/dv to x0 and by adding

dy/dv to y0. Since the first pixel of

the first spiral walk on the second

line should be (6,7), dx/dv is

selected to be 0 and dy/dv is selected to be 1. Second order differential terms are not used in this

filter and are therefore set to 0.

UMIN and VMIN are both selected

to be 6. UMAX and VMAX are both

selected to be 7. Table 5 shows the

values loaded into all Parameter

Registers. Table 6 shows the ITS

outputs for the 3 x 3 static filter.

FIGURE 5. 3

××

× 3 STATIC FILTER

××

TABLE 5. PARAMETER REGISTERS

ADDR Row (HEX) Column (HEX)

0000 000 000

0001 FFF FFF

0010 0C0 0C0

0011 000 100

0100 000 000

0101 100 101

0110 000 000

0111 200 201

1000 000 000

1001 000 000

1010 000 000

1011 000 000

1100 000 000

1101 000 000

1110 006 006

1111 007 007

2-7

Video Imaging Products

08/16/2000–LDS.2301-H

Page 8

DEVICES INCORPORATED

LF2301

Image Resampling Sequencer

TABLE 6. ITS OUTPUTS FOR 3

Cycle x y CAx (HEX) CAy (HEX) u v INIT ACC UWRI ENDxENDyDONE

1 66 00 00 xx101000

2 66 00 00 xx001000

3 66 00 00 xx001000

4 66 00 00 xx001000

5 76 01 01 xx010000

6 77 02 02 xx011000

7 67 03 03 xx011000

8 57 04 04 xx011000

9 56 05 05 xx011000

10 55 06 06 xx011000

11 65 07 07 xx011100

12 75 08 08 xx011100

13 76 00 00 66001100

14 86 01 01 66010100

15 87 02 02 66011100

16 77 03 03 66011100

17 67 04 04 66011100

18 66 05 05 66011100

19 65 06 06 66011100

20 75 07 07 66011000

21 85 08 08 66011000

22 86 00 00 76001000

23 96 01 01 76010000

24 97 02 02 76011000

25 87 03 03 76011000

26 77 04 04 76011000

27 76 05 05 76011000

28 75 06 06 76011000

29 85 07 07 76011010

30 95 08 08 76011010

31 67 00 00 86001010

32 77 01 01 86010010

33 78 02 02 86011010

34 68 03 03 86011010

35 58 04 04 86011010

36 57 05 05 86011010

37 56 06 06 86011010

38 66 07 07 86011110

39 76 08 08 86011110

40 77 00 00 67001110

41 87 01 01 67010110

42 88 02 02 67011110

43 78 03 03 67011110

44 68 04 04 67011110

45 67 05 05 67011110

46 66 06 06 67011110

47 76 07 07 67011010

48 86 08 08 67011010

49 87 00 00 77001010

50 97 01 01 77010010

51 98 02 02 77011010

52 88 03 03 77011010

53 78 04 04 77011010

54 77 05 05 77011010

55 76 06 06 77011010

56 86 07 07 77011001

57 96 08 08 77011001

58 66 00 00 87001001

××

× 3 STATIC FILTER

××

2-8

Video Imaging Products

08/16/2000–LDS.2301-H

Page 9

DEVICES INCORPORATED

1,2

34

5

0123

1

2

3

4

1 = 1st pixel of 1st spiral walk,

calculated pixels

0

-1

source image pixels

2 = 1st pixel of 2nd spiral walk, etc.

LF2301

Image Resampling Sequencer

Image Rotation & Bilinear Interpolation

Figure 8 shows an example of rotating

an image 30º and using bilinear

interpolation. This mode is selected by

loading M1-0 with “00” for a clockwise

spiral walk. A counterclockwise spiral

walk could be selected by loading M1-0

with “10.” Bilinear interpolation

requires a kernel size of 2 x 2 pixels.

Loading K3-0 with “0001” selects a

kernel size of 2 x 2. The first pixel

selected is determined by x0 and y0. In

this example, the first pixel is (0,0). In

this case, the LF2301s should address

consecutive pixels during each spiral

walk. For this to occur, FOV must be

set to 1 (F2-0 loaded with “001”).

After the last pixel of a spiral walk has

been selected, the next pixel address is

determined by adding dx/du to the

current X address and by adding

dy/du to the current Y address

(unless the kernel just completed was

the last for that line). At the end of the

first spiral walk, pixel (0,1) is addressed. Since the next calculated

pixel should be (0.866,0.5), dx/du is

selected to be 0.866 and dy/du is

selected to be 0.5. However, after

adding dx/du and dy/du to the X

and Y addresses respectively, the

generated address is (0.866,1.5). The Y

address is off by a value of 1. This is

due to the fact that the last pixel

address of a spiral walk is used to

calculate the first pixel address of

the next spiral walk. In order for the

LF2301s to generate the correct result,

dy/du must be modified by subtracting a 1 from it. The correct value of

dy/du is -0.5. Figure 6 shows how the

unmodified differential terms were

calculated.

After the last pixel of the last spiral

walk on the first line has been selected,

the first pixel address of the second

line is determined by adding dx/dv to

x0 and by adding dy/dv to y0. Since

the first calculated pixel of the first

spiral walk on the second line should

be (-0.5,0.866), dx/dv is selected to

be -0.5 and dy/dv is selected to be

0.866. Second order differential terms

are not used in this transform and are

therefore set to 0.

It is important to note that the integer

portion of the address generated in

the LF2301 is used as the X or Y

pixel address. The fractional portion

(sub-pixel portion) is used as the

coefficient RAM address.

UMIN and VMIN are both selected to

be 0. UMAX and VMAX are both

selected to be 2. Table 7 shows the

values loaded into all Parameter

Registers. Table 8 shows the ITS

outputs for this example.

FIGURE 6. DIFFERENTIAL TERMS

dx

= cos 30º

= 0.866

du

dy

=

sin 30º = 0.5

du

dx

=

–sin 30º = –0.5

dv

dy

cos 30º = 0.866

=

dv

FIGURE 7. 30

dy

dv

°°

° IMAGE ROTATION

°°

dx

dv

dx

du

length =1

30º

x

dy

du

u

v

source image pixels

calculated pixels

y

FIGURE 8. 30

°°

° IMAGE ROTATION

°°

TABLE 7. PARAMETER REGISTERS

ADDR Row (HEX) Column (HEX)

0000 000 000

0001 FFF FFF

0010 000 000

0011 000 100

0100 DDB 800

0101 100 1FF

0110 800 DDB

0111 1FF 100

1000 000 000

1001 000 000

1010 000 000

1011 000 000

1100 000 000

1101 000 000

1110 000 000

1111 002 002

2-9

Video Imaging Products

08/16/2000–LDS.2301-H

Page 10

DEVICES INCORPORATED

LF2301

Image Resampling Sequencer

TABLE 8. ITS OUTPUTS FOR 30

Cycle x y CAx (HEX) CA

1 00 00 00 xx101000

2 00 00 00 xx001000

3 00 00 00 xx001000

4 00 00 00 xx001000

5 10 01 01 xx010000

6 11 02 02 xx011000

7 01 03 03 xx011000

8 00 D0 80 00001000

9 10 D1 81 00010000

10 11 D2 82 00011100

11 01 D3 83 00011100

12 11 B0 00 10001100

13 21 B1 01 10010100

14 22 B2 02 10011000

15 12 B3 03 10011000

16 21 90 80 20001000

17 31 91 81 20010000

18 32 92 82 20011000

19 22 93 83 20011000

20 -10 80 D0 30001000

21 00 81 D1 30010000

22 01 82 D2 30011000

23 -11 83 D3 30011000

24 01 50 50 01001000

25 11 51 51 01010000

26 12 52 52 01011100

27 02 53 53 01011100

28 11 30 D0 11001100

29 21 31 D1 11010100

30 22 32 D2 11011000

31 12 33 D3 11011000

32 22 10 50 21001000

33 32 11 51 21010000

34 33 12 52 21011010

35 23 13 53 21011010

36 -11 00 B0 31001010

37 01 01 B1 31010010

38 02 02 B2 31011010

39 -12 03 B3 31011010

40 -12 D0 30 02001010

41 02 D1 31 02010010

42 03 D2 32 02011110

43 -13 D3 33 02011110

44 02 B0 B0 12001110

45 12 B1 B1 12010110

46 13 B2 B2 12011010

47 03 B3 B3 12011010

48 13 90 30 22001010

49 23 91 31 22010010

50 24 92 32 22011001

51 14 93 33 22011001

52 00 00 00 32001001

53 10 01 01 32010001

54 11 02 02 32011001

55 01 03 03 32011001

°°

° IMAGE ROTATION WITH BILINEAR INTERPOLATION

°°

(HEX) u v INIT ACC UWRI END

y

ENDyDONE

x

2-10

Video Imaging Products

08/16/2000–LDS.2301-H

Page 11

DEVICES INCORPORATED

LF2301

Image Resampling Sequencer

Pass 1 of Two-Pass Operation

Pass 1 of the two-pass operation

performs horizontal filtering on an

image as shown in Figure 9. This

mode is selected by loading M1-0 with

“01.” In this example, a horizontal

filter with a kernel size of 3 pixels is

desired. Loading K3-0 with “0010”

selects a kernel size of 3. The first

pixel selected is determined by x0 and

y0. In this example, the first pixel is

(0,0). In this case, the LF2301s should

address consecutive pixels during each

pixel walk. For this to occur, FOV must

be set to 1 (F2-0 loaded with “001”).

After the last pixel of a pixel walk has

been selected, the next pixel address is

determined by adding dx/du to the

current X address and by adding dy/

du to the current Y address (unless the

kernel just completed was the last for

that line). At the end of the first pixel

walk, pixel (2,0) is addressed. Since

the first pixel of the next pixel walk

should be (1,0), dx/du is selected to be

-1 and dy/du is selected to be 0. After

the last pixel of the last pixel walk on

the first line has been selected, the first

FIGURE 9. PASS 1 OF TWO-PASS

0

-1

0

1

2

3

1 = 1st pixel of 1st walk,

2 = 1st pixel of 2nd walk, etc.

pixel address of the second line is

determined by adding dx/dv to x0

and by adding dy/dv to y0. Since the

first pixel of the first pixel walk on the

second line should be (0,1), dx/dv is

selected to be 0 and dy/dv is selected

to be 1. Second order differential

terms are not used in this filter and are

therefore set to 0.

1234

123

645

7

TABLE 9. PARAMETER REGISTERS

ADDR Row (HEX) Column (HEX)

0000 000 000

0001 FFF FFF

0010 000 000

0011 040 140

0100 000 000

0101 1FF 000

0110 000 000

0111 200 201

1000 000 000

1001 000 000

1010 000 000

1011 000 000

1100 000 000

1101 000 000

1110 005 005

1111 006 006

UMIN and VMIN are both selected to

be 5. UMAX and VMAX are both

selected to be 6. Table 9 shows the

values loaded into all Parameter

Registers. Table 10 shows the ITS

outputs for the Pass 1 of a Two-Pass

operation.

TABLE 10. ITS OUTPUTS FOR PASS 1 OF TWO-PASS

Cycle x y CAx (HEX) CAy (HEX) u v INIT ACC UWRI ENDxENDyDONE

1 00 00 00 xx101000

2 00 00 00 xx001000

3 00 00 00 xx001000

4 00 00 00 xx001000

5 10 01 01 xx010100

6 20 02 02 xx011100

7 10 00 00 55001100

8 20 01 01 55010000

9 30 02 02 55011000

10 20 00 00 65001000

11 30 01 01 65010010

12 40 02 02 65011010

13 01 00 00 75001010

14 11 01 01 75010110

15 21 02 02 75011110

16 11 00 00 56001110

17 21 01 01 56010010

18 31 02 02 56011010

19 21 00 00 66001010

20 31 01 01 66010001

21 41 02 02 66011001

22 00 00 00 76001001

23 10 01 01 76010101

24 20 02 02 76011101

2-11

Video Imaging Products

08/16/2000–LDS.2301-H

Page 12

DEVICES INCORPORATED

LF2301

Image Resampling Sequencer

Pass 2 of Two-Pass Operation

Pass 2 of the two-pass operation

performs vertical filtering on an image

as shown in Figure 10. This mode is

selected by loading M1-0 with “11.” In

this example, a vertical filter with a

kernel size of 3 pixels is desired.

Loading K3-0 with “0010” selects a

kernel size of 3. The first pixel selected is determined by x0 and y0. In

this example, the first pixel is (0,0). In

this case, the LF2301s should address

consecutive pixels during each pixel

walk. For this to occur, FOV must be

set to 1 (F2-0 loaded with “001”).

After the last pixel of a pixel walk has

been selected, the next pixel address

is determined by adding dx/du to the

current X address and by adding

dy/du to the current Y address

(unless the kernel just completed was

the last for that line). At the end of

the first pixel walk, pixel (0,2) is

addressed. Since the first pixel of the

next pixel walk should be (1,0), dx/du

is selected to be 1 and dy/du is selected

to be -2. After the last pixel of the last

pixel walk on the first line has been

FIGURE 10. PASS 2 OF TWO-PASS

0

0

1

2

3

4

1 = 1st pixel of 1st walk,

2 = 1st pixel of 2nd walk, etc.

selected, the first pixel address of the

second line is determined by adding

dx/dv to x0 and by adding dy/dv to

y0. Since the first pixel of the first

pixel walk on the second line should be

(0,1), dx/dv is selected to be 0 and

dy/dv is selected to be 1. Second

order differential terms are not used

in this filter and are therefore set to 0.

123-1

123

54

TABLE 11. PARAMETER R EGISTERS

ADDR Row (HEX) Column (HEX)

0000 000 000

0001 FFF FFF

0010 000 000

0011 0C0 1C0

0100 000 000

0101 101 1FE

0110 000 000

0111 200 201

1000 000 000

1001 000 000

1010 000 000

1011 000 000

1100 000 000

1101 000 000

1110 005 005

1111 006 006

UMIN and VMIN are both selected to

be 5. UMAX and VMAX are both

selected to be 6. Table 11 shows the

values loaded into all Parameter

Registers. Table 12 shows the ITS

outputs for the Pass 2 of a Two-Pass

operation.

TABLE 12. ITS OUTPUTS FOR PASS 2 OF TWO-PASS

Cycle x y CAx (HEX) CAy (HEX) u v INIT ACC UWRI ENDxENDyDONE

1 00 00 00 xx101000

2 00 00 00 xx001000

3 00 00 00 xx001000

4 00 00 00 xx001000

5 01 01 01 xx010100

6 02 02 02 xx011100

7 10 00 00 55001100

8 11 01 01 55010000

9 12 02 02 55011000

10 20 00 00 65001000

11 21 01 01 65010010

12 22 02 02 65011010

13 01 00 00 75001010

14 02 01 01 75010110

15 03 02 02 75011110

16 11 00 00 56001110

17 12 01 01 56010010

18 13 02 02 56011010

19 21 00 00 66001010

20 22 01 01 66010001

21 23 02 02 66011001

22 00 00 00 76001001

23 01 01 01 76010101

24 02 02 02 76011101

2-12

Video Imaging Products

08/16/2000–LDS.2301-H

Page 13

DEVICES INCORPORATED

LF2301

Image Resampling Sequencer

MAXIMUM RATINGS

Storage temperature ........................................................................................................... –65°C to +150°C

Operating ambient temperature........................................................................................... –55°C to +125°C

VCC supply voltage with respect to ground............................................................................ –0.5 V to +7.0V

Input signal with respect to ground ............................................................................... –0.5 V to VCC + 0.5 V

Signal applied to high impedance output ...................................................................... –0.5 V to VCC + 0.5 V

Output current into low outputs............................................................................................................. 25 mA

Latchup current ............................................................................................................................... > 400 mA

OPERATING CONDITIONS

Active Operation, Commercial 0°C to +70°C 4.75 V ≤ VCC ≤ 5.25 V

Active Operation, Military –55°C to +125°C 4.50 V ≤ VCC ≤ 5.50 V

ELECTRICAL CHARACTERISTICS

Above which useful life may be impaired (Notes 1, 2, 3, 8)

To meet specified electrical and switching characteristics

Mode Temperature Range (Ambient) Supply Voltage

Over Operating Conditions (Note 4)

Symbol Parameter Test Condition Min Typ Max Unit

VOH Output High Voltage V CC = Min., IOH = –2.0 mA 2.4 V

VOL Output Low Voltage VCC = Min., IOL = 4.0 mA 0.4 V

VIH Input High Voltage 2.0 VCC V

VIL Input Low Voltage (Note 3) 0.0 0.8 V

IIX Input Current Ground ≤ VIN ≤ VCC (Note 12) ±10 µA

IOZ Output Leakage Current Ground ≤ VOUT ≤ VCC (Note 12) ±10 µA

ICC1 VCC Current, Dynamic (Notes 5, 6) 75 mA

ICC2 VCC Current, Quiescent (Note 7) 5mA

CIN Input Capacitance TA = 25°C, f = 1 MHz 10 pF

COUT Output Capacitance TA = 25°C, f = 1 MHz 10 pF

2-13

Video Imaging Products

08/16/2000–LDS.2301-H

Page 14

DEVICES INCORPORATED

1234567890123456789012345678901212345678901234

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

1234567890123456789012345678901212345678901234

1234567890123456

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

1234567890123456

4

4

SWITCHING CHARACTERISTICS

LF2301

Image Resampling Sequencer

COMMERCIAL OPERATING RANGE (0°C to +70°C)

Symbol Parameter Min Max Min Max Min Max

tCYC Cycle Time 66 55 25

tPW Clock Pulse Width 30 25 10

tS Input Setup Time 20 18 10

tH Input Hold Time 2 2 0

tHI Input Hold Time, INTER 10 10 5

tD Output Delay 35 27 18

tDE Output Delay, END 45 37 18

tENA Three-State Output Enable Delay (Note 11) 35 27 15

tDIS Three-State Output Disable Delay (Note 11) 20 18 15

MILITARY OPERATING RANGE (-55°C to +125°C)

Symbol Parameter Min Max Min Max Min Max

tCYC Cycle Time 66 55 30

tPW Clock Pulse Width 30 25 10

tS Input Setup Time 20 18 12

tH Input Hold Time 2 2 0

tHI Input Hold Time, INTER 10 10 6

tD Output Delay 35 27 20

tDE Output Delay, END 45 37 20

tENA Three-State Output Enable Delay (Note 11) 35 27 18

tDIS Three-State Output Disable Delay (Note 11) 20 18 18

Notes 9, 10 (ns)

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

Notes 9, 10 (ns)

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

123456789012345678901234567890121234567890123

66

66

LF2301–

*

55 25

LF2301–

*

55

*

30

*

2345678901234567890123

2345678901234567890123

*DISCONTINUED SPEED GRADE

2-14

Video Imaging Products

08/16/2000–LDS.2301-H

Page 15

DEVICES INCORPORATED

SWITCHING WAVEFORMS: DATA INPUTS (PARAMETER STORAGE)

t

CYC

t

CLK

P

11-0

B

WEN

LDR

t

S

3-0

PW

t

H

SWITCHING WAVEFORMS: DATA OUTPUTS AND CONTROL LINES

t

CYC

CLK

NOOP

OETA

tD

X11-0, CA7-0

U11-0

UWRI

tS tH

tDIS

t

PW

tPWtPW

HIGH IMPEDANCE

LF2301

Image Resampling Sequencer

tHtS

tENA

tDIS

tDIS

HIGH IMPEDANCE

HIGH IMPEDANCE

tENA

tENA

CZERO, ACC,

DONE

END

INTER

tDE

tS tHI

2-15

Video Imaging Products

08/16/2000–LDS.2301-H

Page 16

DEVICES INCORPORATED

OE

0.2 V

t

DIS

t

ENA

0.2 V

1.5 V 1.5 V

3.5V Vth

1

Z

0

Z

Z

1

Z

0

1.5 V

1.5 V

0V Vth

VOL*

V

OH

*

V

OL

*

V

OH

*

Measured V

OL

with IOH = –10mA and IOL = 10mA

Measured V

OH

with IOH = –10mA and IOL = 10mA

NOTES

LF2301

Image Resampling Sequencer

1. Maximum Ratings indicate stress

specifications only. Functional operation of these products at values beyond

those indicated in the Operating Conditions table is not implied. Exposure to

maximum rating conditions for extended periods may affect reliability.

2. The products described by this specification include internal circuitry designed to protect the chip from damaging substrate injection currents and accumulations of static charge. Nevertheless, conventional precautions should

be observed during storage, handling,

and use of these circuits in order to

avoid exposure to excessive electrical

stress values.

3. This device provides hard clamping of

transient undershoot and overshoot. Input levels below ground or above VCC

will be clamped beginning at –0.6 V and

VCC + 0.6 V. The device can withstand

indefinite operation with inputs in the

range of –0.5 V to +7.0 V. Device operation will not be adversely affected, however, input current levels will be well in

excess of 100 mA.

9. AC specifications are tested with

input transition times less than 3 ns,

output reference levels of 1.5 V (except

tDIS test), and input levels of nominally

0 to 3.0 V. Output loading may be a

resistive divider which provides for

specified IOH and IOL at an output

voltage of VOH min and VOL max

respectively. Alternatively, a diode

bridge with upper and lower current

sources of IOH and IOL respectively,

and a balancing voltage of 1.5 V may be

used. Parasitic capacitance is 30 pF

minimum, and may be distributed.

This device has high-speed outputs capable of large instantaneous current

pulses and fast turn-on/turn-off times.

As a result, care must be exercised in the

testing of this device. The following

measures are recommended:

a. A 0.1 µF ceramic capacitor should be

installed between VCC and Ground

leads as close to the Device Under Test

(DUT) as possible. Similar capacitors

should be installed between device VCC

and the tester common, and device

ground and tester common.

11. For the tENA test, the transition is

measured to the 1.5 V crossing point

with datasheet loads. For the tDIS test,

the transition is measured to the

±200mV level from the measured

steady-state output voltage with

±10mA loads. The balancing voltage, VTH, is set at 3.5 V for Z-to-0

and 0-to-Z tests, and set at 0 V for Zto-1 and 1-to-Z tests.

12. These parameters are only tested at

the high temperature extreme, which is

the worst case for leakage current.

FIGURE A. OUTPUT LOADING CIRCUIT

DUT

S1

I

OL

V

C

L

I

TH

OH

FIGURE B. THRESHOLD LEVELS

4. Actual test conditions may vary from

those designated but operation is guaranteed as specified.

5. Supply current for a given application can be accurately approximated by:

2

NCV F

where

4

N = total number of device outputs

C = capacitive load per output

V = supply voltage

F = clock frequency

b. Ground and VCC supply planes

must be brought directly to the DUT

socket or contactor fingers.

c. Input voltages should be adjusted to

compensate for inductive ground and

VCC noise to maintain required DUT in-

put levels relative to the DUT ground pin.

10. Each parameter is shown as a minimum or maximum value. Input requirements are specified from the point of

view of the external system driving the

chip. Setup time, for example, is specified

as a minimum since the external system

6. Tested with no output load at

15 MHz clock rate.

must supply at least that much time to

meet the worst-case requirements of all

parts. Responses from the internal cir-

7. Tested with all inputs within 0.1 V of

VCC or Ground, no load.

8. These parameters are guaranteed

but not 100% tested.

cuitry are specified from the point of view

of the device. Output delay, for example,

is specified as a maximum since worstcase operation of any device always provides data within that time.

2-16

Video Imaging Products

08/16/2000–LDS.2301-H

Page 17

DEVICES INCORPORATED

ORDERING INFORMATION

68-pin

LF2301

Image Resampling Sequencer

X

X

X

X

X

X

X

X

GND

X

X

X

P

P

P

P

P

O

GND

X

CA7CA6CA5CA4CA3CA2GND

896261

10

1

11

2

12

3

13

4

14

5

15

6

16

7

17

8

18

19

9

20

10

21

11

22

11

23

10

24

9

25

8

26

7

2827 42 43

P6P5P4P3P2P1P

0

VCCCA1CA0CZERO

1234567

68 67 66 65 64 63

Top

View

3635 37 38 39 413029 31 32 33 34

CC

V

CLK

GND

LDR

NOOP

ACC

40

0B1B2B3

B

UWRI

U11U

10

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

WEN

GND

U

9

U

8

U

7

U

6

U

5

U

4

U

3

GND

U

2

U

1

U

0

DONE

END

INTER

OETA

INIT

Speed

55 ns

25 ns

Plastic J-Lead Chip Carrier

(J2)

0°C to +70°C — COMMERCIAL SCREENING

LF2301JC55

LF2301JC25

2-17

Video Imaging Products

08/16/2000–LDS.2301-H

Page 18

DEVICES INCORPORATED

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Image Resampling Sequencer

ORDERING INFORMATION

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

68-pin

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

Speed

0°C to +70°C — COMMERCIAL SCREENING

–55°C to +125°C — COMMERCIAL SCREENING

–55°C to +125°C — MIL-STD-883 COMPLIANT

12345

A

WEN

B

3

B

B

INIT

2

OETA

C

INTER

END

D

DONE

0

U

E

1

U

2

U

F

GND

U

3

G

4

U

5

U

H

U

6

U

7

J

U

8

U

9

K

U

10

GND

UWRI

L

U

11

ACC

6

7 8 9 10 11

B

1

LDR

V

CC

CLK

B

0

NOOP

GND

0

P

Top View

Through Package

(i.e., Component Side Pinout)

CZERO

CA

1

CA

0

V

CC

GND

CA

CA

3

2

CA

4

Discontinued Package

Ceramic Pin Grid Array

(G1)

2-18

P

P

CA

CA

P

P

P

CA

X

5

3

4

7

0

P

P

6

7

P

9

P

8

P

11

P

10

X

10

X

11

GND

X

9

7

X

8

X

X

5

X

6

X

3

X

4

X

1

X

2

GND

Video Imaging Products

1

2

5

6

LF2301

08/16/2000–LDS.2301-H

Loading...

Loading...